Simplified model of pre-composited rod's normal penetration into steel target

-

摘要: 针对均质长杆体侵彻能力提高陷入瓶颈的问题,设计了由高密度钨合金和高硬度碳化钨组合的新型前置组合杆体。通过试验和数值模拟验证,前置组合杆体能利用材料的不同性能,在稳定侵彻阶段形成更尖锐头部形状,从而提高侵彻能力。根据试验和数值模拟结果,描述了前置组合杆体垂直侵彻钢靶的物理图像,将前置组合杆体侵彻划分为开坑段、组杆段和单杆段三部分,分别建立其各自侵彻阶段的理论模型,最终得到前置组合杆体总侵彻深度计算模型。通过与试验和数值模拟结果对比,验证了该模型的合理性。Abstract: In this study, to improve the penetration capability of the homogeneous long rod, a problem whose solution has hit a bottleneck, we designed a new pre-composited rod fabricated with high density tungsten alloy and high hardness tungsten carbide. It was validated through experiment and numerical simulation that our newly-designed rod can form a sharp nose shape in the steady penetration stage by cashing in on the different properties of different materials to improve the penetration capability of the long rod. Based on the experimental and simulated results, we presented a full description of the physical image of the pre-composited rod's normal penetration into a steel target, which can be divided into three sections, those of the cratering, the composited rod, and the homogeneous rod, with their theoretical models established respectively, thus obtaining the calculation model of the total pre-composited rod's penetration depth. The rationality of the model was verified by comparing it with the experiment and simulation results. The conclusions from our study are helpful for the kinetic design of weapons using the new long rod.

-

爆轰是复杂的流体力学与剧烈的化学动力学耦合的一种物理现象。固体炸药的爆轰能够提供强大的能量来驱动和压缩材料,在国防科技和国民经济中获得广泛应用,因此,固体炸药爆轰与惰性介质相互作用问题是工程应用中十分重要的问题。固体炸药爆轰与惰性介质相互作用问题本质上是一种可压缩多物质流动问题,除了可压缩单物质流动中出现的激波、稀疏波、接触间断外,一种新的间断,即物质界面出现了,它隔开热力学性质或状态方程不一样的两种物质,这种物质界面实质上也是一种接触间断,它满足物质界面压力相等与速度相等的条件。对可压缩多物质流动,传统的数值模拟方法多是拉格朗日方法[1-3],它不能有效地处理物质大变形运动,为了较好地处理物质大变形运动,欧拉方法成为一个很好的选择[3-4]。根据对处理物质界面的不同方式,欧拉方法大致可以分为4类:阵面追踪(front tracking)法[5-6]、流体体积(volume of fluid)法[7-8]、水平集合(level set)法[9-10]以及扩散界面(diffuse interface)法[11-17]等,其中,扩散界面法由于具有逻辑结构简单、物理量守恒性良好、对界面形状没有几何拓扑限制、对多物理问题适应性较强的特点,近年来获得了越来越多的关注。

扩散界面法将离散网格视为包含有多种组分物质的混合网格,物质界面被认为是具有一定厚度的虚拟混合区,即把无厚度的物质界面当作有一定厚度的扩散界面,扩散界面内部采用“虚拟状态方程”或混合规则来描述。根据对多物质混合状态的不同处理方式,扩散界面模型可以分为两种[18]:基于单物质流动欧拉方程组的扩展欧拉模型(augmented Euler model)以及基于多相流动Baer-Nunziato方程组的多相流模型(multiphase flow model)。

在扩展欧拉模型中,混合规则通常采用基于力学平衡和热学平衡的假设。事实上,热学平衡仅适用于均匀混合状况,而包含有物质界面的混合网格内各组分物质通常不是均匀混合的,由此将热学平衡的假设用于计算包含界面接触间断的混合物质的热力学性质时,往往使得物质界面附近的压力和速度等物理量出现非物理振荡现象[19]。为了消除物质界面附近的非物理振荡现象,不得不采取另外的技术方案进行修正处理,如附加状态方程参数演化方程[20]、总能量调整[21]、守恒与原始变量转换[22]等。

不同于扩展欧拉模型,多相流模型[23]中的混合物质被认为由处于热学、力学、化学非平衡的多种组分物质组成,每种组分物质具有各自的物理状态并按照各自的动力学规律分别进行演化,演化方程含有用于表达由组分物质非平衡引起的质量、动量和能量相互转化的各种源项,同时采用组分物质体积分数方程来描述物质界面的运动过程。由于考虑了每种组分物质各自的变化规律,能够保证混合物质的热力学性质自动满足一致性,从物理建模上消除了物质界面附近的非物理振荡,对诸如爆轰这种带有化学非平衡的可压缩流动,消除物质界面附近的非物理压力振荡非常重要,因为爆轰化学反应的激发与压力等量密切相关,如果压力出现非物理振荡会激发虚假的化学反应,进一步会引起错误的爆轰特性。针对具体物理过程,热学、力学、化学非平衡这些状态可以全部满足也可以部分满足,在全部满足非平衡条件下即为著名的Baer-Nunziato模型,在部分满足非平衡条件下形成各种简化多相流模型,如在力学平衡、热学非平衡条件下有Kapila模型[24]、Allaire模型[25]、Massoni模型[26]、Murrone模型[27]、Grove模型[28]等多种典型模型,这些不同模型的差异主要在于以不同方式处理组分物质混合状态,使得组分物质体积分数方程有不同的表达形式。多相流模型由于考虑了更精确的物理机制,更加符合物理意义,近年来在可压缩多物质流动数值模拟领域获得了极大的重视,本文的工作正是基于多相流模型。

在固体炸药爆轰与惰性介质的相互作用过程中,爆轰化学反应过程通常简化为固相反应物转化成气相生成物,这样组分混合物质通常包括固相反应物、气相生成物、惰性介质这3种成分,由于这3种组分物质的材料物态性质和热力学性质差异极大,因此它们之间的相互作用过程被认为满足力学平衡和热学非平衡状态[13,24,29],即在流场控制体中每种组分物质拥有相同的压力和速度、以及不同的温度和内能。基于多相流思想,固体炸药爆轰与惰性介质相互作用过程首先由各种组分物质的质量守恒方程、混合物质的动量与总能量守恒方程描述,组分物质的质量守恒方程还需考虑由化学反应引起的质量转化的影响,然后需要补充每种组分物质的体积分数的控制方程。由混合物质能量守恒方程可以分解获得每种组分物质的内能变化方程,再利用每种组分物质压力相等的条件并结合组分物质的质量守恒方程,可以推导出每种组分物质的体积分数控制方程。由于涉及到热学非平衡状态,组分物质之间存在热量交换,分解获得的组分物质内能变化方程还需考虑热量交换的影响。这样,推导出的组分物质体积分数控制方程同时包含了化学反应和热学非平衡的影响。并且,混合物质的压力演化方程也被纳入到模型方程组中,这样压力通过直接离散求解演化方程获得而不是由流动守恒变量计算获得,这种方案可以增强消除物质界面非物理振荡的效果,也可以避免由状态方程非线性形式引起的压力迭代求解[28]或者由组分体积方程非守恒型引起的压力松弛求解[13],还可以避免计算压力对守恒变量的导数而简化高阶精度格式的运算过程。最终,获得的扩散界面模型方程组包括组分物质的质量守恒方程、混合物质的动量及总能量守恒方程、组分物质的体积分数演化方程以及混合物质的压力演化方程。获得的扩散界面模型的最主要特点是考虑了化学反应以及热学非平衡的影响,因此具有良好的热力学一致性,同时,该扩散界面模型能够适用于任意表达形式的状态方程以及任意数目的多种惰性介质。

对所获得的扩散界面模型方程组采用一个具有波传播性质的时空二阶精度的有限体积法进行数值求解,典型算例结果显示,数值模拟图像与物理规律符合,物质界面附近不会出现物理量的非物理振荡现象。

1. 扩散界面模型的推导

首先给出物理量的定义。考虑一个控制体包含有炸药固相反应物、炸药气相生成物以及惰性物质,固相反应物的物理量用下标s表示、气相生成物的物理量用下标g表示,惰性物质设有K种物质,每种物质的物理量用下标k表示;其中

ρ 表示密度,e 表示内能,p 表示压力,u 表示速度矢量,α 表示体积分数,v 表示比容,Q 表示单位质量的固体炸药由固相反应物转化为气相生成物时所释放的热量。在力学平衡条件下,混合物质物理量与组分物质物理量的关系式为:ρ=ρsαs+ρgαg+K∑k=1ρkαk (1) e=ρsαsρes+ρgαgρeg−ρgαgρQ+K∑k=1ρkαkρek (2) v=αsρ+αgρ+K∑k=1αkρ (3) p=ps=pg=pkk=1,2,⋯,K (4) u=us=ug=ukk=1,2,⋯,K (5) αs+αg+K∑k=1αk=1 (6) 不考虑各种耗散因素及外力做功情况,则在力学平衡状态条件下固体炸药爆轰与惰性介质的可压缩流动方程组可以表达为:

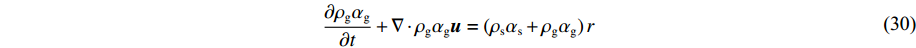

∂ρsαs∂t+∇⋅(ρsαsu)=−(ρsαs+ρgαg)r (7) ∂ρgαg∂t+∇⋅(ρgαgu)=(ρsαs+ρgαg)r (8) ∂ρkαk∂t+∇⋅(ρkαku)=0k=1,2,⋯,K (9) ∂ρu∂t+∇⋅(ρuu+pI)=0 (10) ∂ρE∂t+∇⋅(ρE+p)u=0 (11) 式中:

E=e+12u2 为总能量,r 为固体炸药的化学反应率,I 为单位张量。式(7)为固体炸药固相反应物的质量守恒方程,式(8)为固体炸药气相生成物的质量守恒方程,式(9)为惰性介质的质量守恒方程,式(10)为混合物质的动量守恒方程,式(11)为混合物质的总能量守恒方程。

在给定每种组分物质的状态方程条件下,并确定了每种组分物质的体积分数的控制方程之后,上述流动方程组成为封闭系统进而可以获得定解。组分物质体积分数的控制方程可由混合物质的能量守恒方程并结合混合网格内每种组分物质压力相等的条件导出,混合物质的能量守恒方程可以分解为每种组分物质的内能变化方程。

上述流动方程组式(7)~(11)可以经过变换得到混合物质的内能守恒方程:

dedt+pdvdt=0 (12) 将式(1)~(3)代入式(12),有:

ddt(ρsαsρes+ρgαgρeg−ρgαgρQ+K∑k=1ρkαkρek)+pddt(αsρ+αgρ+K∑k=1αkρ)=0 (13) 式(13)也可化为:

(ddtρsαsρes+pddtαsρ)+(ddtρgαgρeg−ddtρgαgρQ+pddtαgρ)+K∑k=1(ddtρkαkρek+pddtαkρ)=0 (14) 式(14)中3个括号中分别表示炸药固相反应物、炸药气相生成物、惰性介质的内能变化,再考虑到这多种物质由于处于热学非平衡状态而存在温度差异,物质之间会产生热量交换,则可以将式(14)分裂为各种组分物质的内能变化方程:

ddtρsαsρes+pddtαsρ=qs (15) ddtρgαgρeg−Qddtρgαgρ+pddtαgρ=qg (16) ddtρkαkρek+pddtαkρ=qkk=1,2,⋯,K (17) 式中:

qs 、qg 、qk (k=1,2,⋯,K )表示单位质量的物质由于温度差产生的热流率,并有约束条件qs+qg+K∑k=1qk=0 。针对炸药固相反应物流动过程,式(15)借助混合物质质量守恒方程可以化成如下形式:

dρsesαsdt+ρsesαs∇⋅u+αsp∇⋅u+pdαsdt=ρqs (18) 由式(7)、(18)可得固相反应物的内能变化方程:

desdt=(ρsαs+ρgαg)esr+ρqsρsαs−pρs∇⋅u−pρsαsdαsdt (19) 为简化推导过程可不失一般性地认为,每种物质具有

pi(ρi,ei) (i=s,g,1,2,⋯,K )表达形式的状态方程,则在混合网格内各种组分物质压力相等:p=ps(ρs,es)=pg(ρg,eg)=pk(ρk,ek) (k=1,2,⋯,K )的条件下,可以得到固相反应物的压力控制方程:dpdt=∂ps(ρs,es)∂ρsdρsdt+∂ps(ρs,es)∂esdesdt (20) 为求出固相反应物的密度变化,由式(7)可得:

dρsdt=−ρsαs+ρgαgαsr−ρs∇⋅u−ρsαsdαsdt (21) 将式(19)、(21)代入式(20)中,可得:

dpdt=−∂ps(ρs,es)∂ρs((ρsαs+ρgαg)rαs+ρs∇⋅u+ρsαsdαsdt)+∂ps(ρs,es)∂es((ρsαs+ρgαg)esr+ρqsρsαs−pρs∇⋅u−pρsαsdαsdt) (22) 式(22)也可以转化成如下固相反应物的体积分数变化方程:

dαsdt=−(ρsαs+ρgαg)r∂ps∂ρs+(ρsαs+ρgαg)esr+ρqsρs∂ps∂esρs∂ps∂ρs+pρs∂ps∂es−αs∇⋅u−αsρs∂ps∂ρs+pρs∂ps∂esdpdt (23) 同理可得到气相生成物、惰性物质的体积分数变化方程,这样各组分物质的体积分数变化方程有:

dαsdt=−∂ps∂ρs(ρsαs+ρgαg)rρsc2s+∂ps∂es(ρsαs+ρgαg)esr+ρqsρ2sc2s−αs∇⋅u−αsρsc2sdpdt (24) dαgdt=∂pg∂ρg(ρsαs+ρgαg)rρgc2g+∂pg∂eg(ρsαs+ρgαg)(Q−eg)r+ρqgρ2gc2g−αg∇⋅u−αgρgc2gdpdt (25) dαkdt=∂pk∂ρkρqkρ2kc2k−αk∇⋅u−αkρkc2kdpdtk=1,⋯,K, (26) 式中:

c2s=∂ps∂ρs+pρ2s∂ps∂es ,c2g=∂pg∂ρg+pρ2g∂pg∂eg ,c2k=∂pk∂ρk+pρ2k∂pk∂ek 。在固相反应物、气相生成物、惰性物质满足体积分数的总和为一的条件下,即有恒等式

αs+αg+K∑k=1αk=1 ,则由式(24)~(26)可以获得混合物质的压力演化方程:dpdt+1αsρsc2s+αgρgc2g+K∑k=1αkρkc2k∇⋅u=−(∂ps∂ρs−esρs∂ps∂esρsc2s−∂pg∂ρg−eg−Qρg∂pg∂egρgc2g)ρsαs+ρgαgαsρsc2s+αgρgc2g+K∑k=1αkρkc2kr+ρqsρ2sc2s∂ps∂es+ρqgρ2gc2g∂pg∂eg+K∑k=1ρqkρ2kc2k∂pk∂ekαsρsc2s+αgρgc2g+K∑k=1αkρkc2k (27) 将式(27)代入式(24),可以获得固相反应物的体积分数演化方程:

dαsdt+αs(1−1ρsc2s1αsρsc2s+αgρgc2g+K∑k=1αkρkc2k)∇⋅u=αsρsc2s(∂ps∂ρs−esρs∂ps∂esρsc2s−∂pg∂ρg−eg−Qρg∂pg∂egρgc2g)ρsαs+ρgαgαsρsc2s+αgρgc2g+K∑k=1αkρkc2kr−∂ps∂ρs−esρs∂ps∂esρsc2s(ρsαs+ρgαg)r−αsρsc2sρqsρ2sc2s∂ps∂es+ρqgρ2gc2g∂pg∂eg+K∑k=1ρqkρ2kc2k∂pk∂ekαsρsc2s+αgρgc2g+K∑k=1αkρkc2k+ρqsρ2sc2s∂ps∂es (28) 同理可以得到气相生成物与惰性介质的体积分数控制方程,这样各组分物质的体积分数控制方程均可获得,同时,混合物质的压力演化方程也成为一个流动控制方程,这样固体炸药爆轰与惰性介质相互作用的扩散界面模型被推导出:

∂ρsαs∂t+∇⋅ρsαsu=−(ρsαs+ρgαg)r (29) ∂ρgαg∂t+∇⋅ρgαgu=(ρsαs+ρgαg)r (30) ∂ρkαk∂t+∇⋅ρkαku=0k=1,2,⋯,K (31) ∂ρu∂t+∇⋅(ρuu+pI)=0 (32) ∂ρE∂t+∇⋅(ρE+p)u=0 (33) ∂αs∂t+u⋅∇αs+αs(1−1ρsc2s1αsρsc2s+αgρgc2g+K∑k=1αkρkc2k)∇⋅u=αsρsc2s(∂ps∂ρs−esρs∂ps∂esρsc2s−∂pg∂ρg−eg−Qρg∂pg∂egρgc2g)×ρsαs+ρgαgαsρsc2s+αgρgc2g+K∑k=1αkρkc2kr−∂ps∂ρs−esρs∂ps∂esρsc2s(ρsαs+ρgαg)r−αsρsc2sρqsρ2sc2s∂ps∂es+ρqgρ2gc2g∂pg∂eg+K∑k=1ρqkρ2kc2k∂pk∂ekαsρsc2s+αgρgc2g+K∑k=1αkρkc2k+ρqsρ2sc2s∂ps∂es (34) ∂αk∂t+u⋅∇αk+αk(1−1ρkc2k1αsρsc2s+αgρgc2g+K∑k=1αkρkc2k)∇⋅u=αkρkc2k(∂ps∂ρs−esρs∂ps∂esρsc2s−∂pg∂ρg−eg−Qρg∂pg∂egρgc2g)×ρsαs+ρgαgαsρsc2s+αgρgc2g+K∑k=1αkρkc2kr−αkρkc2kρqsρ2sc2s∂ps∂es+ρqgρ2gc2g∂pg∂eg+K∑k=1ρqkρ2kc2k∂pk∂ekαsρsc2s+αgρgc2g+K∑k=1αkρkc2k+ρqkρ2kc2k∂pk∂ekk=1,2,⋯,K (35) ∂p∂t+u⋅∇p+1αsρsc2s+αgρgc2g+K∑k=1αkρkc2k∇⋅u=−(∂ps∂ρs−esρs∂ps∂esρsc2s−∂pg∂ρg−eg−Qρg∂pg∂egρgc2g)ρsαs+ρgαgαsρsc2s+αgρgc2g+K∑k=1αkρkc2kr+ρqsρ2sc2s∂ps∂es+ρqgρ2gc2g∂pg∂eg+K∑k=1ρqkρ2kc2k∂pk∂ekαsρsc2s+αgρgc2g+K∑k=1αkρkc2k (36) 2. 数值方法

为了便于数值求解,获得的界面扩散模型方程组(29)~(36)在二维直角坐标系下可以写成如下矢量-矩阵形式的偏微分方程组:

∂q∂t+A(q)∂q∂x+B(q)∂q∂y=s(q) (37) 这里状态变量

q=[ρsαs,ρgαg,ρkαk,ρu,ρv,ρE,αs,αk,p]T (不失一般性,惰性介质只写一种物质),矩阵A(q) 与矩阵B(q) 是具有类似表达形式的Jacobi矩阵,其中A(q)=[(1−ρsαsρ)u−ρsαsρu−ρsαsρuρsαsρ00000−ρgαgρu(1−ρgαgρ)u−ρgαgρuρgαgρ00000−ρkαkρu−ρkαkρu(1−ρkαkρ)uρkαkρ00000−u2−u2−u22u00001−uv−uv−uvvu0000−Hu−Hu−HuH0u00u−αsρ(1−ρc2ρsc2s)u−αsρ(1−ρc2ρsc2s)u−αsρ(1−ρc2ρsc2s)uαsρ(1−ρc2ρsc2s)00u00−αkρ(1−ρc2ρkc2k)u−αkρ(1−ρc2ρkc2k)u−αkρ(1−ρc2ρkc2k)uαkρ(1−ρc2ρkc2k)000u0−c2u−c2u−c2uc20000u], 源项

s(q)=[−(ρsαs+ρgαg)r,(ρsαs+ρgαg)r,0,0,0,0,Φ,Ψ,Π]T, 式中:u、v为速度分量,c为声速,

H=E+pρ, 1ρc2=αsρsc2s+αgρgc2g+K∑k=1αkρkc2k, Φ=ρc2αsρsc2s(∂ps∂ρs−esρs∂ps∂esρsc2s−∂pg∂ρg−eg−Qρg∂pg∂egρgc2g)(ρsαs+ρgαg)r−∂ps∂ρs−esρs∂ps∂esρsc2s(ρsαs+ρgαg)r− ρc2αsρsc2s(ρqsρ2sc2s∂ps∂es+ρqgρ2gc2g∂pg∂eg+K∑k=1ρqkρ2kc2k∂pk∂ek)+ρqsρ2sc2s∂ps∂es ,Ψ=ρc2αkρkc2k(∂ps∂ρs−esρs∂ps∂esρsc2s−∂pg∂ρg−eg−Qρg∂pg∂egρgc2g)(ρsαs+ρgαg)r− ρc2αkρkc2k(ρqsρ2sc2s∂ps∂es+ρqgρ2gc2g∂pg∂eg+K∑k=1ρqkρ2kc2k∂pk∂ek)+ρqkρ2kc2k∂pk∂ek, Π=−ρc2(∂ps∂ρs−esρs∂ps∂esρsc2s−∂pg∂ρg−eg−Qρg∂pg∂egρgc2g)(ρsαs+ρgαg)r+ρc2(ρqsρ2sc2s∂ps∂es+ρqgρ2gc2g∂pg∂eg+K∑k=1ρqkρ2kc2k∂pk∂ek) 。非齐次非守恒型双曲律方程组(30)可用Strang分裂方法[30]来求解,求解过程依次为双曲律方程组求解步与常微分方程组求解步。在双曲律方程组求解步中,一个具有波传播特征的二阶精度Godunov型格式[31]被采用,该格式能够很好地处理双曲律方程组中的非守恒型对流项。在常微分方程组求解步中,首先根据固体炸药爆轰通常具有快反应过程和慢反应过程的特点[29],将爆轰化学反应率分解成快反应率和慢反应率两部分,然后一个具有显-隐离散特性的二阶精度Runge-Kutta格式[32]被采用,显式离散用于处理慢反应率源项、隐式离散用于处理快反应率源项。

3. 典型算例

3.1 一维爆轰增长问题

考察固体炸药的起爆及爆轰增长过程[33],固相反应物和气相生成物均采用刚性气体状态方程

p=(γ−1)ρe−λQ 形式,爆轰化学反应率采用r=H√1−λ 形式,这里λ 为固相反应物的质量分数,且γ=3 ,Q=3.68GPa ,H=2.0 μs−1。计算获得爆轰增长过程中压力变化如图1所示,爆轰波头压力单调增加,同时获得定常状态下爆压和爆速的计算值分别约为44.8 GPa、8 460 m/s,与爆压和爆速的理论值45.0 GPa、8 500 m/s相比,计算值与理论值一致。3.2 滑移爆轰约束效应问题

考察一平面爆轰在金属铜的约束下向前传播情况,计算域如图2所示,固体炸药固相反应物和气相生成物均采用Jones-Wilkins-Lee形式状态方程[34];爆轰化学反应率采用Ignition-Growth模型[34];铜采用Mie-Grüneisen形式状态方程[18]。起爆区域设置有压力为36.5 GPa的高压静止气相生成物,其余区域均设置为标准状态;计算域入口设置为定值,其余边界设置为无反射边界条件。

计算获得爆轰波达到定常状态时的密度及压力的分布,如图3所示,可以看出,炸药与铜界面附近的爆轰波阵面呈弯曲状态,爆轰波向铜介质折射一激波。数值计算获得定常爆轰状态下炸药与铜界面附近的爆轰波阵面的形态,如图4所示,爆轰定常传播速度计算值为7 670 m/s(理论值为7655 m/s);爆轰波阵面边缘角

α 的计算值为81.3°(理论值为78.8°),偏转角θ 的计算值为4.86°(理论值为4.75°),计算结果与理论结果吻合较好。同时也可以看出,爆轰波向金属进行的折射为正规折射,界面处没有出现反射波。3.3 平面爆轰波绕射问题

定常的平面爆轰波绕一个由金属铜构成的90°扩张通道进行传播,计算域如图5所示。固体炸药固相反应物和气相生成物均采用Jones-Wilkins-Lee形式状态方程[34];爆轰化学反应率采用Ignition-Growth模型[34];铜采用Mie-Grüneisen形式状态方程[18]。起爆区域设置有压力为36.5 GPa的高压静止气相生成物,其余均为标准状态;计算域入口设置为定值,上边界设置为固壁条件,其余边界设置为无反射边界条件。

计算获得爆轰波在t = 4.25,5.00,5.75,6.50 μs这4个时刻的密度和压力分布,如图6所示。

从密度图看,爆轰波在铜介质中产生正规折射激波,该折射激波跨过台阶时会预压炸药;从压力图看,铜介质中折射激波在向炸药折射过程中产生稀疏波引起铜介质出现一个低压区。

4. 结 论

本文中提出一种具有热力学一致性的数值模拟固体炸药爆轰与惰性介质相互作用的扩散界面模型,该模型基于混合网格内各组分物质处于力学平衡与热学非平衡假设,推导获得的模型流动控制系统包括组分物质的质量守恒方程、混合物质的动量及总能量守恒方程,以及组分物质的体积分数演化方程和混合物质的压力演化方程。典型算例表明,数值计算结果与物理规律符合,并且在物质界面附近不会出现物理量的非物理振荡现象、适用于任意表达形式的物质状态方程以及任意数目的惰性介质。

-

表 1 不同配置的前置组合杆体

Table 1. Different configurations of pre-composited rods

杆结构 小杆体直径d2/mm 小杆体长度H1/mm 均质杆 0 0 前置组合杆体1 1.5 25 前置组合杆体2 2.5 30 前置组合杆体3 5.5 30 表 2 不同配置的前置组合杆体

Table 2. Different configurations of pre-composited rods

材料 ρ/(g·cm-3) G/GPa σy/MPa γ 93钨 17.6 136 1 506 1.54 碳化钨 14.7 254 5 100 1.50 45钢 7.85 77 700 2.17 表 3 两组杆体头部形状图

Table 3. Nose shape of two rods

杆结构 v/(m·s-1) h/mm ε/% 试验 数值模拟 均质杆 1 356 84.0 81.5 2.98 前置组合杆体1 1 310 83.0 77.7 6.39 前置组合杆体2 1 320 84.0 80.9 3.70 前置组合杆体3 1 200 78.0 76.2 2.31 表 4 侵彻过程中各阶段的速度变化和侵彻深度

Table 4. Velocity variation and penetration depth in different stages of penetration process

杆结构 开坑段 前置组杆段 单杆段 v0/(m·s-1) v1/(m·s-1) x1/mm v1/(m·s-1) v2/(m·s-1) x2/mm v2/(m·s-1) v3/(m·s-1) x3/mm 均质杆 1 356 1 342.0 11.0 1 342.0 0 71.2 前置组合杆体1 1 310 1 295.5 10.9 1 295.5 1 257.9 22.0 1 257.9 0 50.0 前置组合杆体2 1 320 1 305.7 10.9 1 305.7 1 251.3 29.8 1 251.3 0 46.1 前置组合杆体3 1 200 1 184.2 10.6 1 184.2 1 096.4 27.3 1 096.4 0 42.6 表 5 不同初速度下侵彻深度理论和试验对比

Table 5. Comparison of penetration depth between theory and test at different initial velocities

杆结构 v0/(m·s-1) 侵彻深度 ε/% 理论计算(x1+x2+x3)/mm 试验h/mm 均质杆 1 356 82.2 84 2.14 前置组合杆体1 1 310 82.9 83 0.12 前置组合杆体2 1 320 86.8 84 3.33 前置组合杆体3 1 200 80.5 78 3.21 表 6 不同杆结构侵彻深度数值模拟和理论对比

Table 6. Comparison of penetration depth between simulation and theory with different rod structures

H1/mm 侵彻深度 ε/% 数值模拟h/mm 理论计算(x1+x2+x3)/mm 0 74.5 77.7 4.23 30 78.0 83.4 6.92 50 80.5 85.4 6.09 70 84.0 88.5 5.36 90 85.0 90.0 5.88 -

[1] FORRESTAL M J, LUK V K. Dynamic spherical cavity-expansion in a compressible elastic-plastic solid[J]. Journal of Applied Mechanics, 1988, 55(2):275-279. DOI: 10.1115/1.3173672. [2] ROSENBERG Z, DEKEL E. On the role of nose profile in long-rod penetration[J]. International Journal of Impact Engineering, 1999, 22(5):551-557. DOI: 10.1016/S0734-743X(98)00054-2. [3] JONES S E, RULE W K. On the optimal nose geometry for a rigid penetrator, including the effects of pressure-dependent friction[J]. International Journal of Impact Engineering, 2000, 24(4):403-415. DOI: 10.1016/S0734-743X(99)00157-8. [4] JONES S E, RULE W K, JEROME D M, et al. On the optimal nose geometry for a rigid penetrator[J]. Computational Mechanics, 1998, 22(5):413-417. DOI: 10.1007/s004660050373. [5] CHEN X W, LI Q M. Deep penetration of a non-deformable projectile with different geometrical characteristics[J]. International Journal of Impact Engineering, 2002, 27(6):619-637. DOI: 10.1016/S0734-743X(02)00005-2. [6] LI Q M, CHEN X W. Dimensionless formulae for penetration depth of concrete target impacted by a non-deformable projectile[J]. International Journal of Impact Engineering, 2003, 28(1):93-116.DOI: 10.1016/S0734-743X(02)00037-4. [7] CHIAN S C, TAN B C V, SARMA A. Projectile penetration into sand:Relative density of sand and projectile nose shape and mass[J]. International Journal of Impact Engineering, 2017, 103:29-37.DOI: 10.1016/j.ijimpeng.2017.01.002. [8] 程兴旺, 王富耻, 李树奎, 等.不同头部形状长杆弹侵彻过程的数值模拟[J].兵工学报, 2007, 28(8):930-933. DOI: 10.3321/j.issn:1000-1093.2007.08.007.CHENG Xingwang, WANG Fuchi, LI Shukui, et al. Numerical simulation on the penetrations of long-rod projectiles with different nose shapes[J]. Acta Armamentarii, 2007, 28(8):930-933. DOI: 10.3321/j.issn:1000-1093.2007.08.007. [9] 高光发, 李永池, 黄瑞源, 等.杆弹头部形状对侵彻行为的影响及其机制[J].弹箭与制导学报, 2012, 32(6):51-54. DOI: 10.3969/j.issn.1673-9728.2012.06.015.GAO Guangfa, LI Yongchi, HUANG Ruiyuan, et al. Effect of nose shape on penetration performance of long-rod penetrator and its mechanism[J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2012, 32(6):51-54. DOI: 10.3969/j.issn.1673-9728.2012.06.015. [10] 孙庚辰, 吴锦云, 赵国志, 等.长杆弹垂直侵彻半无限厚靶板的简化模型[J].兵工学报, 1981(4):1-8. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000005146030SUN Gengchen, WU Jinyun, ZHAO Guozhi, et al. A simplified model of the penetration of the long-rod penetrator against the plated with semi-infinite thickness at normal angle[J]. Acta Armamentarii, 1981(4):1-8. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=QK000005146030 [11] 吴群彪, 沈培辉, 刘荣忠, 等.长杆体稳定侵彻阶段头部形状的侵彻效率分析[J].兵器材料科学与工程, 2014, 37(3):80-83.DOI: 10.3969/j.issn.1004-244X.2014.03.023.WU Qunbiao, SHEN Peihui, LIU Rongzhong, et al. Long rod penetration efficiency analysis of nose shape at quasi-steady penetration stage[J]. Ordnance Material Science and Engineering, 2014, 37(3):80-83. DOI: 10.3969/j.issn.1004-244X.2014.03.023. 期刊类型引用(1)

1. 吴宗铎,满庆洋,严谨,庞建华,孙一方. 三介质Mie-Grüneisen混合模型在水下爆炸防护层问题中的应用. 计算物理. 2023(05): 556-569 .  百度学术

百度学术其他类型引用(0)

-

下载:

下载:

下载:

下载:

百度学术

百度学术