Simulation test technique for impact disturbance of deep surrounding rock

-

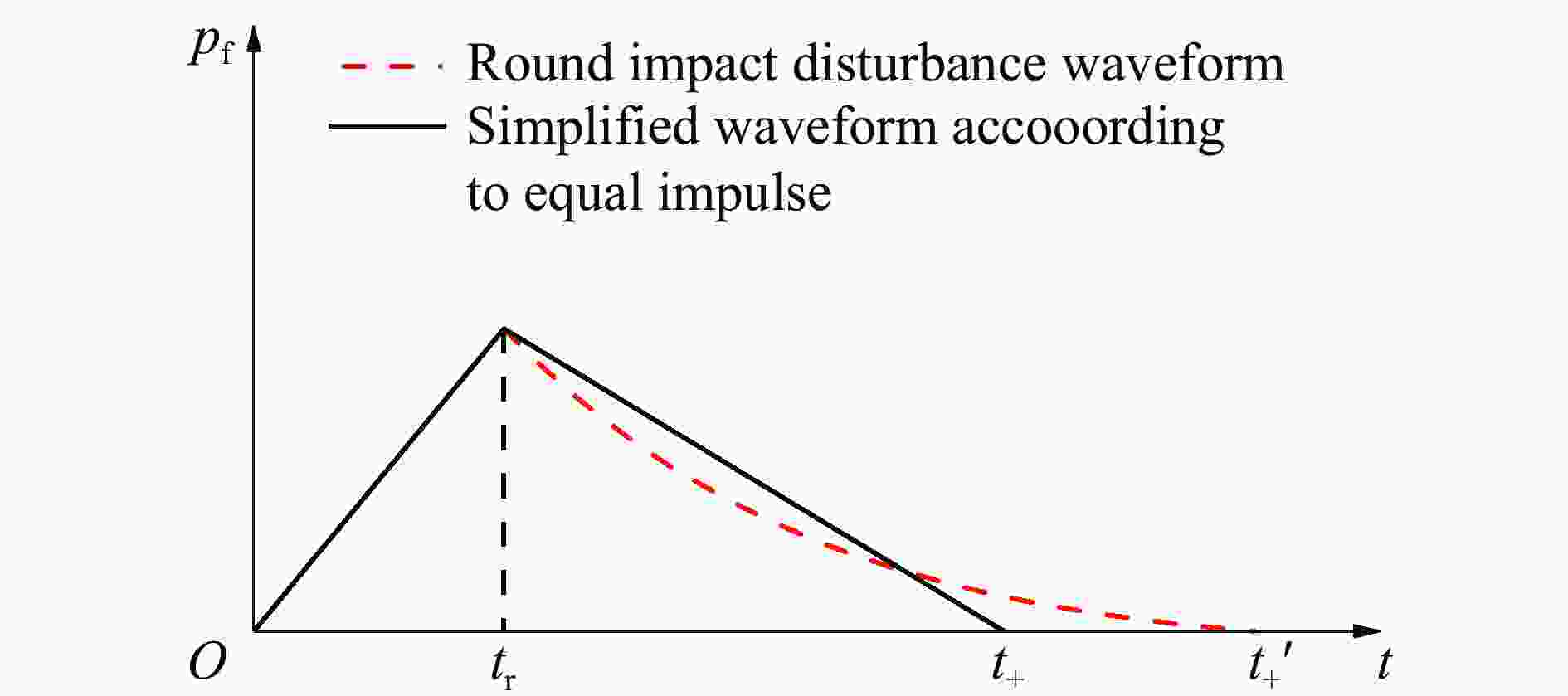

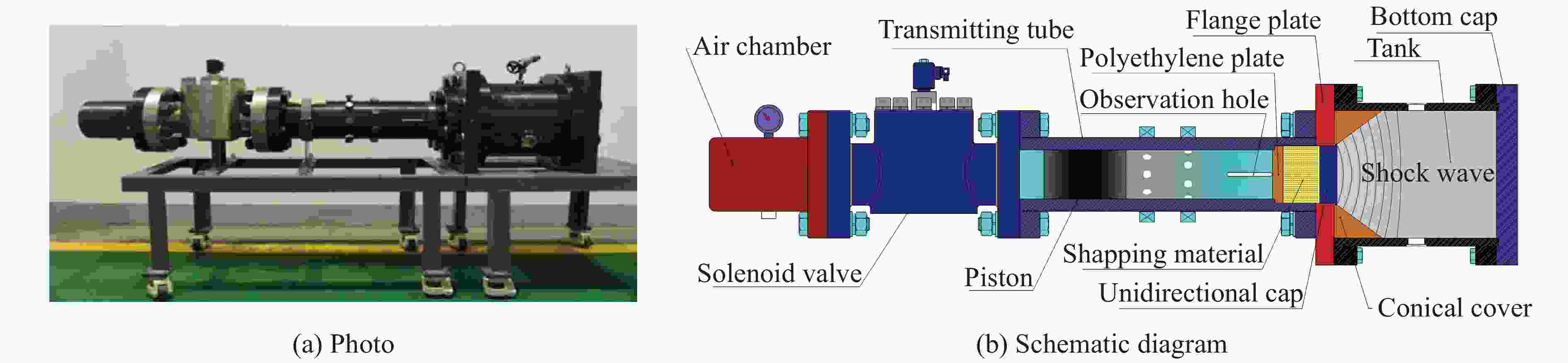

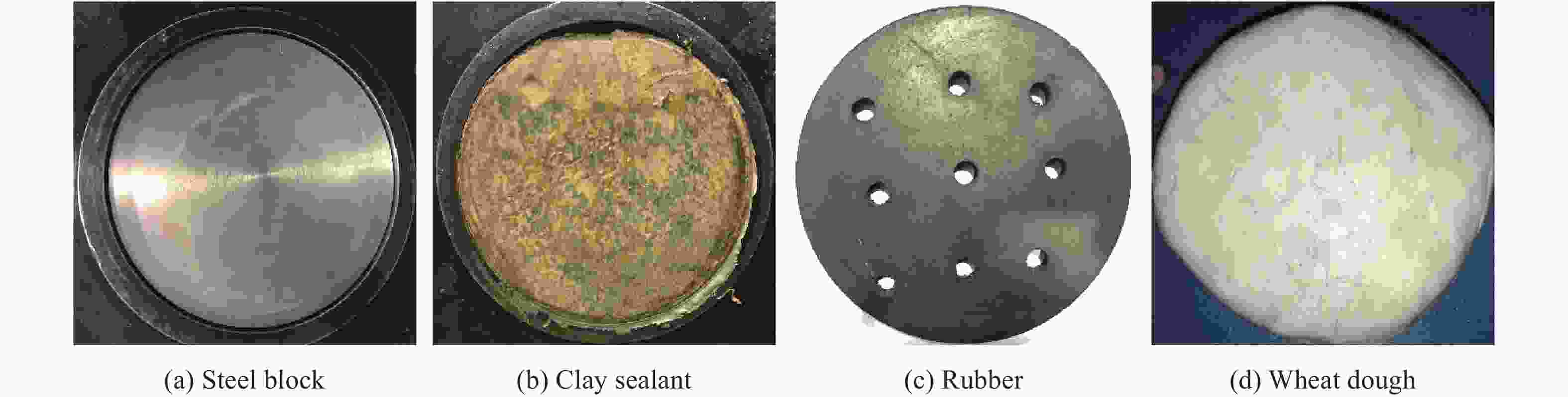

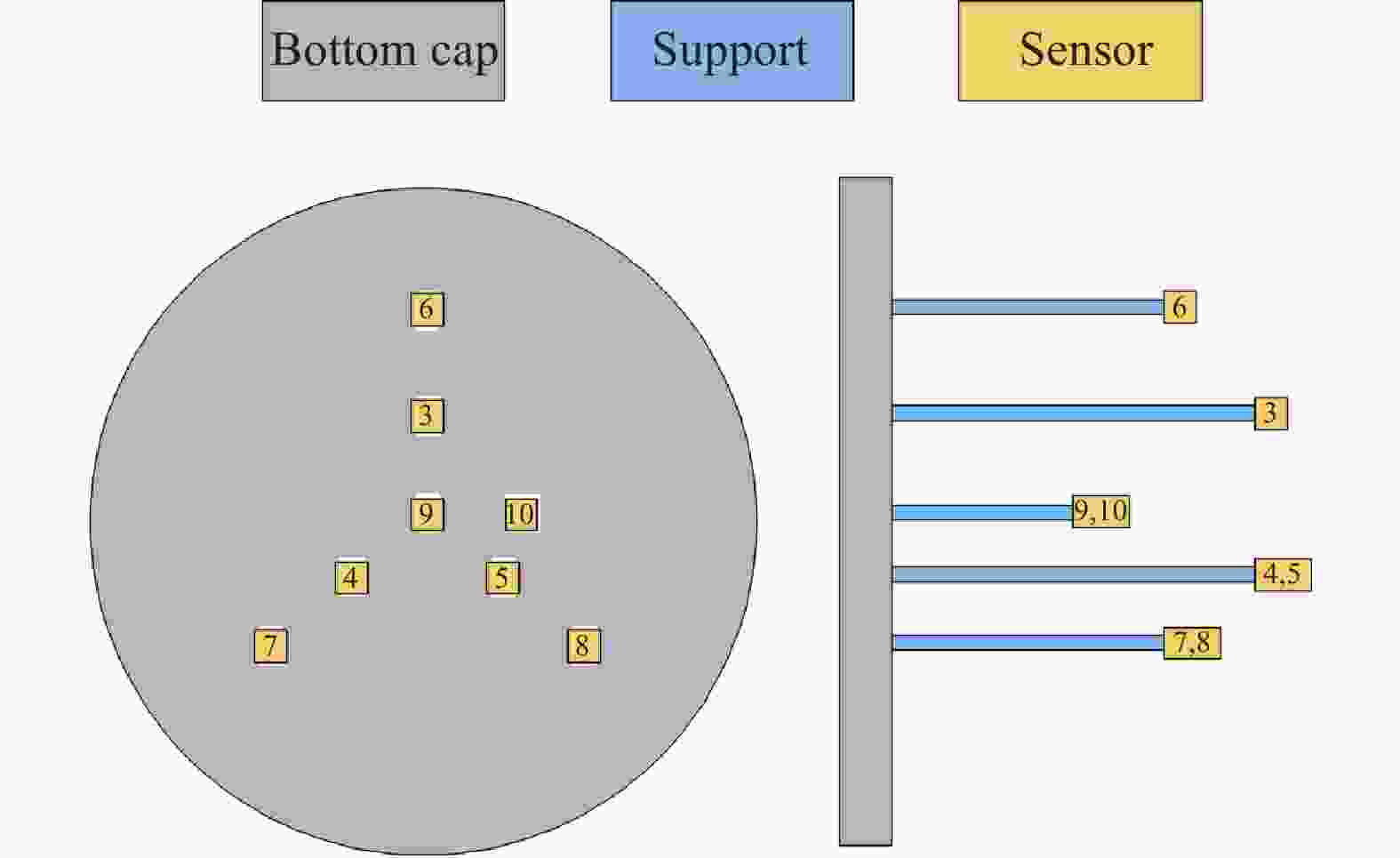

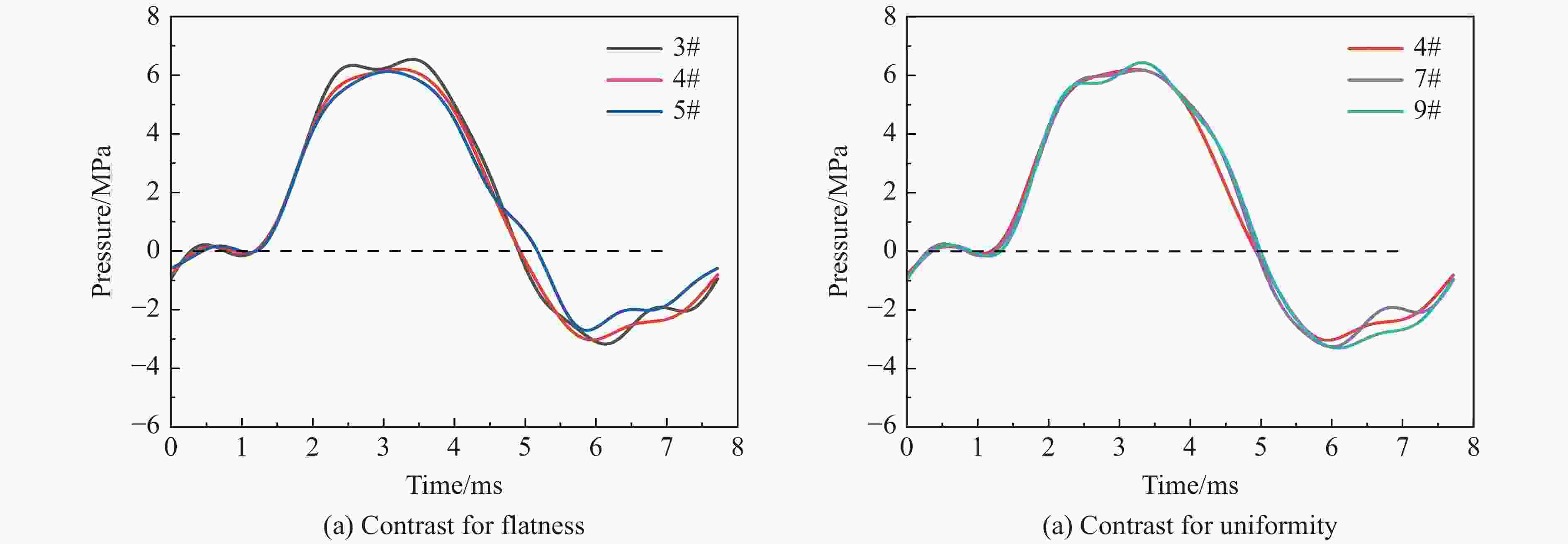

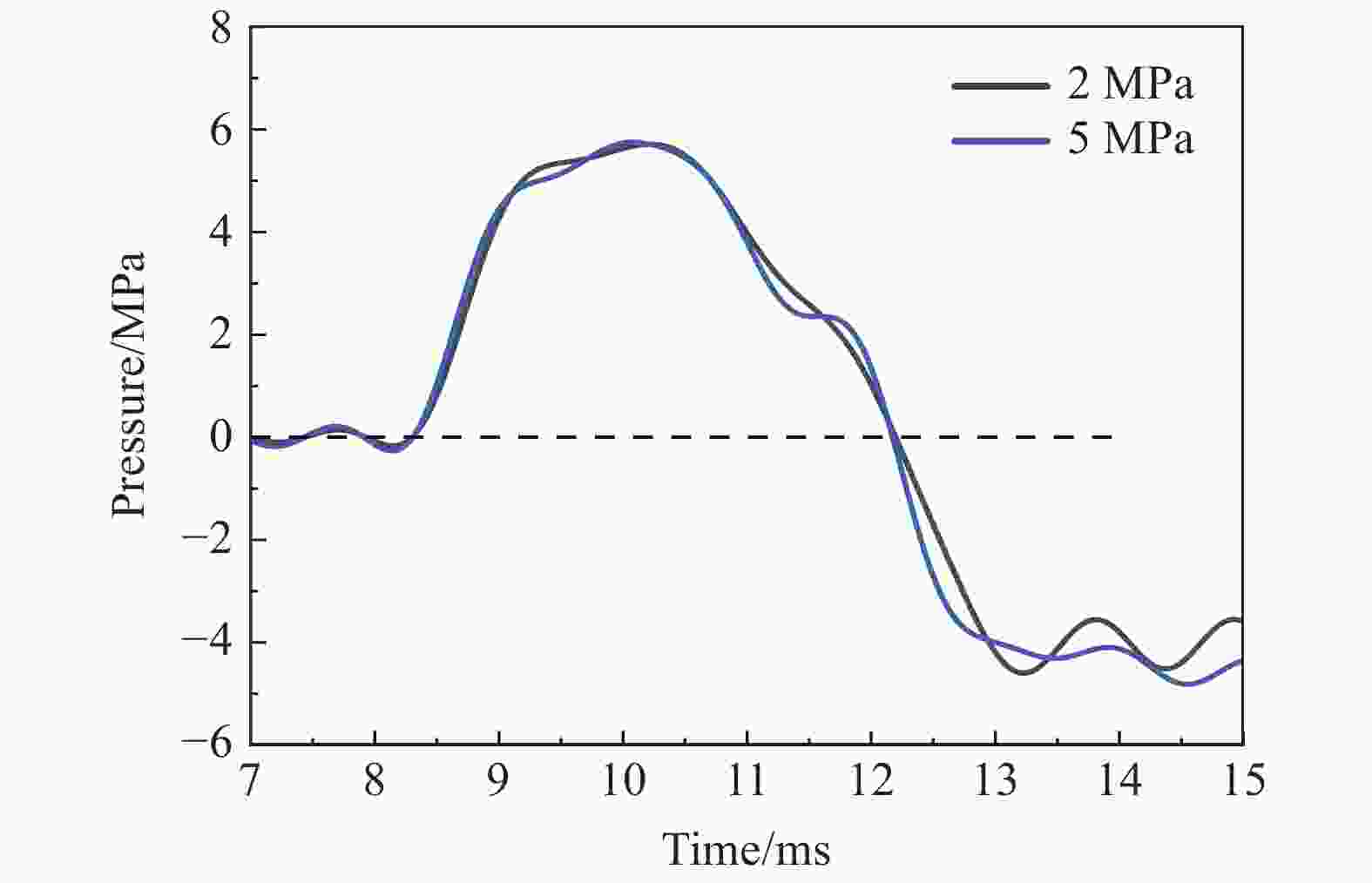

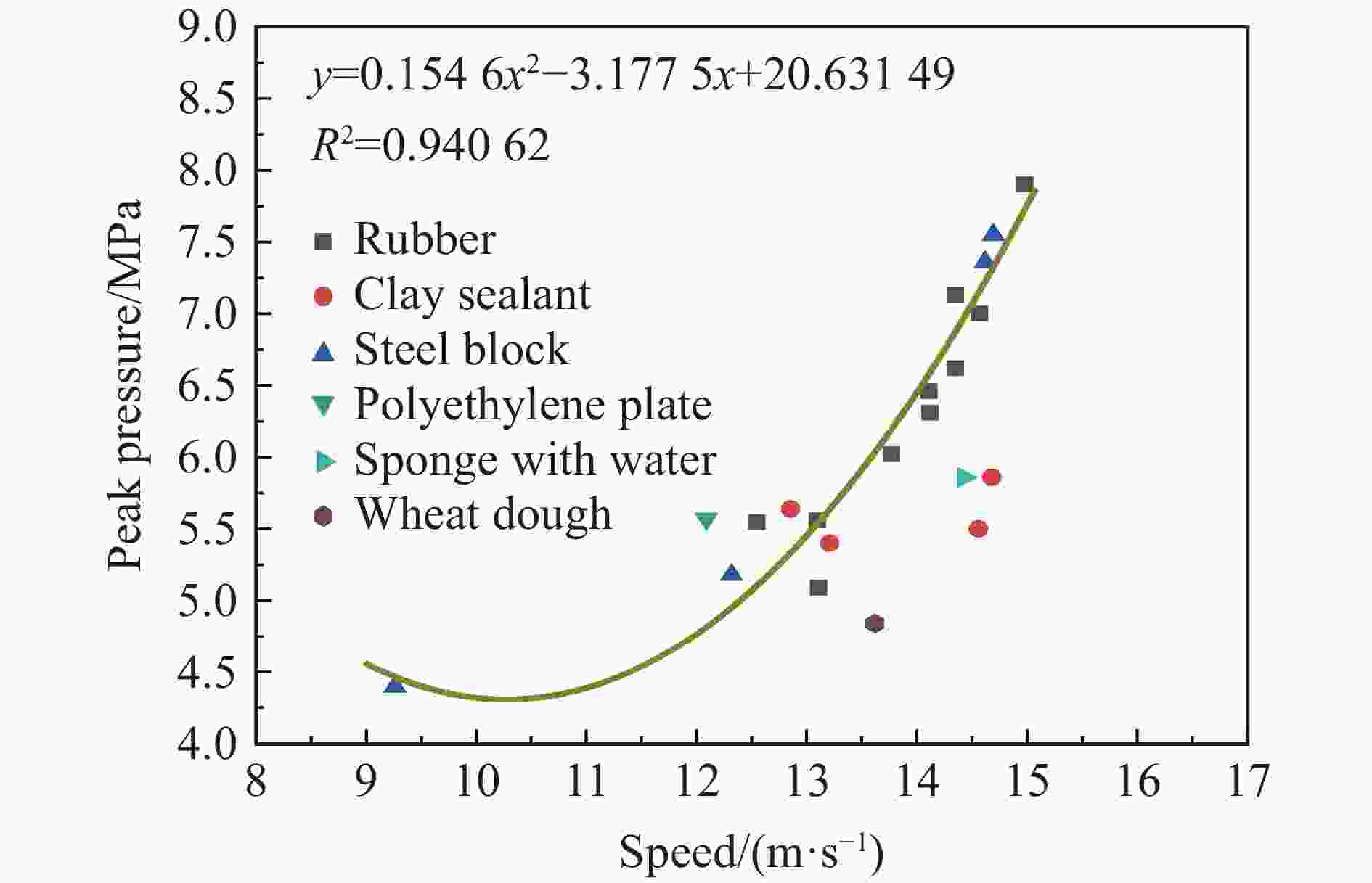

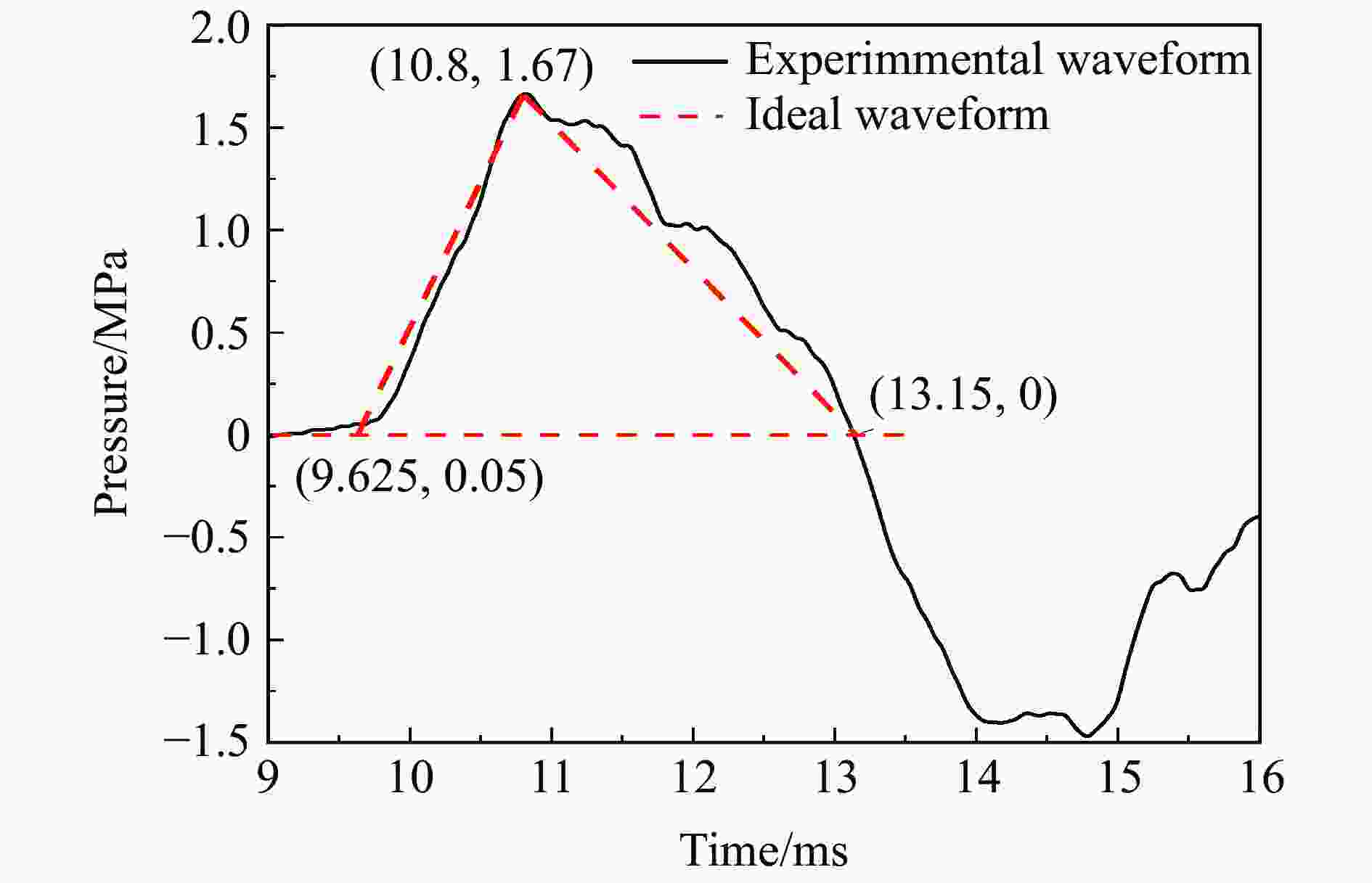

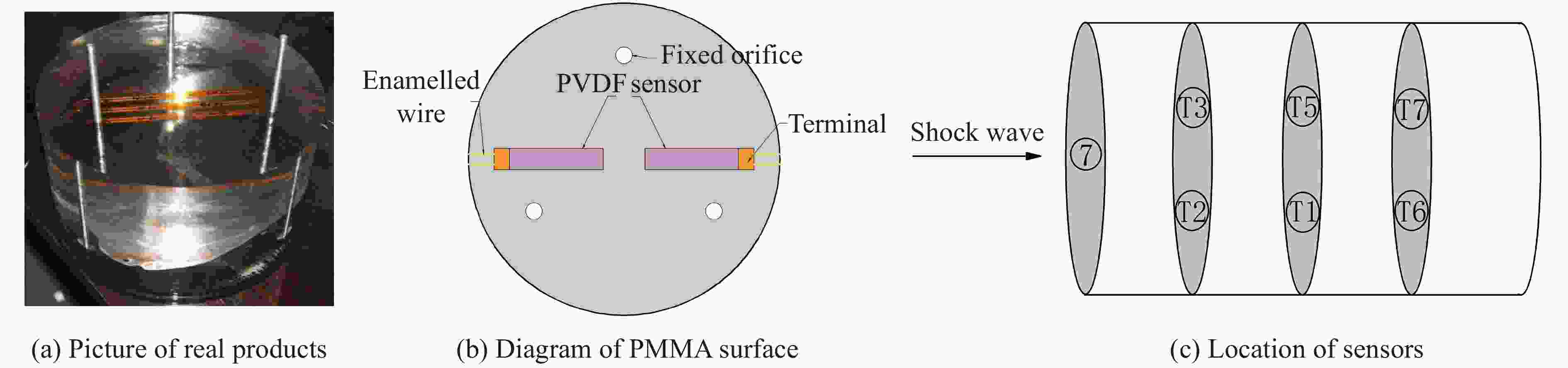

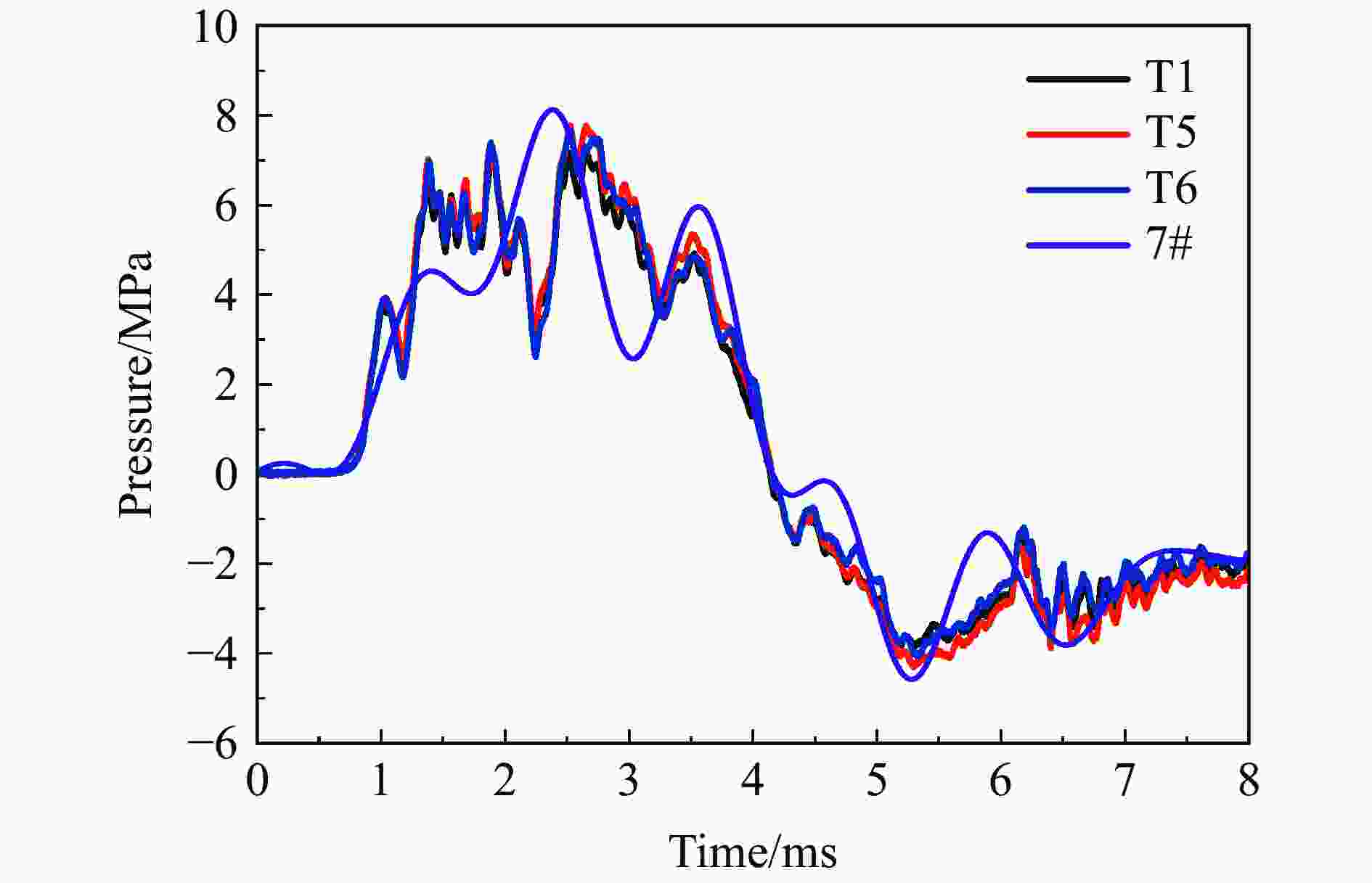

摘要: 为模拟深部高围压硐室结构在爆炸地冲击扰动作用下的长持时加载过程,开展了模拟装置的调试和试验工作。分析了爆炸作用下,远场扰动应力波的主参量,并采用量纲分析获得了满足相似定律的仪器参数指标。利用模拟试验装置,分析探讨了气室压力、电磁阀开启时间、活塞速度、水压以及整形材料等因素对冲击波形、正压时间、升压时间和峰值的影响规律。结果表明,整形材料的刚度越低,应力波形的正压时间及升压时间越长,峰值相对越低;活塞撞击速度越高,应力峰值越高,但是正压时间及波形无明显变化。通过控制电磁阀开闭时间和气室气体压力值,可以控制活塞撞击的速度。通过改变整形材料和活塞撞击速度,实现了正压时间在3.5~5.0 ms之间的调整、升压时间在0.9~2.5 ms之间的调整,峰值在4~8 MPa之间的调整,调整后输出的压力波形可有效模拟深部围岩中远区爆炸应力波。采用有机玻璃复合结构作为试件,验证了装置在模拟深部围岩地冲击扰动作用的可行性及可靠性。上述研究证明了装置可为室内试验提供参数可控的爆炸地冲击扰动,丰富了深部地质力学试验系统模拟爆炸扰动的研究。Abstract: Aiming to simulate the long-term continuous loading process of high confining pressure deep underground spaces under the explosion and impact disturbance, alignment and related tests on the simulation test apparatus were carried out. An air pressure driven piston was used to impact the shaping material and produce an impact disturbance. After passing through the conical cover, the wave front expanded, resulting in a uniform stress wave acting on the cabin body. Main parameters of the far-field disturbed stress wave under explosion were analyzed, and the instrument parameters satisfying the similarity law were obtained by dimensional analysis. The effects of gas pressure, solenoid valve opening time, piston speed, water pressure and shaping material on the shape, positive pressure time, rising pressure time and peak value of the stress wave were discussed by using the developed instrument. The results illustrate that the lower the stiffness of shaping materials, the longer the positive pressure time and rising pressure time of the stress wave, and the lower the peak value of stress. Although an increase in the piston impact velocity will bring an increase in the peak of the stress wave, it will not significantly affect the positive pressure time and waveform. The piston speed can be determined by controlling the opening time of the solenoid valve and the gas pressure in the air chamber. By changing the shaping material and impact speed of the piston, the positive pressure time can be adjusted between 3.5 ms and 5.0 ms, pressure rising time between 0.9 ms and 2.5 ms, and peak value between 4 MPa and 8 MPa. The adjusted pressure waveform output can effectively simulate the far-field explosion stress wave in the deep surrounding rock. The polymethyl methacrylate (PMMA) composite structure was used as the specimen to verify the feasibility and reliability of the apparatus in simulating the impact disturbance in the deep surrounding rock. The above tests prove that this apparatus can provide explosive ground shock disturbances with controllable parameters for laboratory tests. This apparatus enriches the research of simulating explosion disturbances in deep geomechanical test systems.

-

材料 A n 盐岩 (0.8~1)×104 1.6 花岗岩 (1~1.3)×104 1.6 密凝灰岩 (0.3~0.5)×104 1.6 表 2 不同工况下参量的取值

Table 2. Parameters under different working conditions

爆炸当量/

kt爆心距/

m原型正压时间 /

ms模型正压时间/

ms原型应力峰值/

MPa模型应力峰值/

MPa原型地应力/

MPa模型地应力/

MPa30 1000 15.30 1.76 16.40 0.22 27.0 0.36 30 1500 38.76 4.48 8.60 0.11 40.5 0.54 30 2000 75.12 8.70 5.40 0.07 54.0 0.72 50 2000 38.70 4.46 7.12 0.10 54.0 0.72 表 3 材料刚度参数

Table 3. Stiffness parameters of different shaping materials

整形材料 刚度 / (N·m−1) 所处阶段 油(充满) 假定不可压缩 弹性阶段 水(不充满) — 直接塑性 钢块 3.68×1010 弹性阶段 压板 4.18×108 弹性阶段 橡胶 1.07×105 弹性阶段 吸水海绵 2.05×103 弹性阶段 密封胶泥 — 直接塑性 面 — 直接塑性 -

[1] 胡威. 岩爆机理: 世界性科学难题[N]. 光明日报, 2011–07–25. [2] 刘垠. 世界性难题牵绊大工程进展: 钱七虎院士: 岩爆机理尚待摸底[N]. 大众科技报, 2011–7–15. [3] 钱七虎. 岩爆、冲击地压的定义、机制、分类及其定量预测模型 [J]. 岩土力学, 2014, 35(1): 1–6.QIAN Q H. Definition, mechanism, classification and quantitative forecast model for rockburst and pressure bump [J]. Rock and Soil Mechanics, 2014, 35(1): 1–6. [4] 陈宗基. 岩爆的工程实录、理论与控制 [J]. 岩石力学与工程学报, 1987, 6(1): 1–18.CHEN Z J. Engineering record, theory and control of rock burst [J]. Chinese Journal of Rock Mechanics and Engineering, 1987, 6(1): 1–18. [5] 袁亮, 顾金才, 薛俊华, 等. 深部围岩分区破裂化模型试验研究 [J]. 煤炭学报, 2014, 39(6): 987–993. DOI: 10.13225/j.cnki.jccs.2014.0085.YUAN L, GU J C, XUE J H, et al. Model test research on the zonal disintegration in deep rock [J]. Journal of China Coal Society, 2014, 39(6): 987–993. DOI: 10.13225/j.cnki.jccs.2014.0085. [6] TAN T K. Rockbursts, case records, theory and control [J]. Chinese Journal Rock Mechanics and Engineering, 1987, 6(1): 1–18. DOI: 10.1353/saa.2013.0018. [7] 佘诗刚, 林鹏. 中国岩石工程若干进展与挑战 [J]. 岩石力学与工程学报, 2014, 33(3): 433–457. DOI: 10.3969/j.issn.1000-6915.2014.03.001.SHE S G, LIN P. Some developments and challenging issues in rock engineering field in China [J]. Chinese Journal Rock Mechanics and Engineering, 2014, 33(3): 433–457. DOI: 10.3969/j.issn.1000-6915.2014.03.001. [8] 范鹏贤, 王明洋, 冯淑芳, 等. 爆炸地震波作用下深埋圆形隧道的动力响应分析 [J]. 岩石力学与工程学报, 2013, 32(4): 671–680. DOI: 10.3969/j.issn.1000-6915.2013.04.004.FAN P X, WANG M Y, FENG S F, et al. Analysis of dynamic response of deep-buried circular tunnel to explosion seismic wave [J]. Chinese Journal Rock Mechanics and Engineering, 2013, 32(4): 671–680. DOI: 10.3969/j.issn.1000-6915.2013.04.004. [9] 陈昊祥, 王明洋, 李杰. 深部岩体变形破坏的特征能量因子与应用 [J]. 爆炸与冲击, 2019, 39(8): 081103. DOI: 10.11883/bzycj-2019-0191.CHEN H X, WANG M Y, LI J. A characteristic energy factor for deformation and failure of deep rock masses and its application [J]. Explosion and Shock Waves, 2019, 39(8): 081103. DOI: 10.11883/bzycj-2019-0191. [10] 李利萍, 李卫军, 潘一山. 冲击扰动对超低摩擦型冲击地压影响分析 [J]. 岩石力学与工程学报, 2019, 38(1): 111–120. DOI: 10.13722/j.cnki.jrme.2018.0922.LI L P, LI W J, PAN Y S. Influence of impact disturbance on anomalously low friction rock bursts [J]. Chinese Journal Rock Mechanics and Engineering, 2019, 38(1): 111–120. DOI: 10.13722/j.cnki.jrme.2018.0922. [11] 李杰, 蒋海明, 王明洋, 等. 爆炸与冲击中的非线性岩石力学问题 (Ⅱ): 冲击扰动诱发岩块滑移的物理模型试验 [J]. 岩石力学与工程学报, 2018, 37(2): 291–301. DOI: 10.13722/j.cnki.jrme.2017.0684.LI J, JIANG H M, WANG M Y, et al. Nonlinear mechanical problems in rock explosion and shock: Part Ⅱ: physical model test on sliding of rock blocks triggered by external disturbance [J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(2): 291–301. DOI: 10.13722/j.cnki.jrme.2017.0684. [12] 张晓春, 卢爱红, 王军强. 动力扰动导致巷道围岩层裂结构及冲击矿压的数值模拟 [J]. 岩石力学与工程学报, 2006, 25(S1): 3110–3114. DOI: 10.3321/j.issn:1000-6915.2006.z1.080.ZHANG X C, LU A H, WANG J Q. Numerical simulation of layer-crack structure of surrounding rock and rock burst in roadway under dynamic disturbance [J]. Chinese Journal of Rock Mechanics and Engineering, 2006, 25(S1): 3110–3114. DOI: 10.3321/j.issn:1000-6915.2006.z1.080. [13] SUAZO G, VILLAVICENCIO G. Numerical simulation of the blast response of cemented paste backfilled stopes [J]. Computers and Geotechnics, 2018, 100(8): 1–14. DOI: 10.1016/j.compgeo.2018.04.007. [14] 王明洋, 李杰, 李凯锐. 深部岩体非线性力学能量作用原理与应用 [J]. 岩石力学与工程学报, 2015, 34(4): 659–667. DOI: 10.13722/j.cnki.jrme.2015.04.002.WANG M Y, LI J, LI K R. A nonlinear mechanical energy theory in deep rock mass engineering and its application [J]. Chinese Journal of Rock Mechanics and Engineering, 2015, 34(4): 659–667. DOI: 10.13722/j.cnki.jrme.2015.04.002. [15] 钱七虎. 战略防护工程面临的核钻地弹威胁及连续介质力学模的不适用性[C]// 第五届全国工程结构安全防护学术会议论文集. 南京, 2005: 1–8.QIAN Q H. Study on threat of strategic protective engineering from nuclear weapons and inapplicability of continuative mechanic model[C]// Proceedings of the Fifth Conference on Nationwide Structure Engineering Security. Nanjing, 2005: 1–8. [16] 李夕兵, 宫凤强, 王少锋, 等. 深部硬岩矿山岩爆的动静组合加载力学机制与动力判据 [J]. 岩石力学与工程学报, 2019, 38(4): 708–723. DOI: 10.13722/j.cnki.jrme.2018.1496.LI X B, GONG F Q, WANG S F, et al. Coupled static-dynamic loading mechanical mechanism and dynamic criterion of rockburst in deep hard rock mines [J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(4): 708–723. DOI: 10.13722/j.cnki.jrme.2018.1496. [17] 袁璞. 爆炸荷载作用下深部岩体分区破裂模型试验研究[D]. 淮南: 安徽理工大学, 2016. [18] 宫凤强, 张乐, 李夕兵, 等. 不同预静载硬岩在动力扰动下断裂特性的试验研究 [J]. 岩石力学与工程学报, 2017, 36(8): 1841–1854. DOI: 10.13722/j.cnki.jrme.2016.1439.GONG F Q, ZHANG L, LI X B, et al. Experimental study on fracture behaviors of hard rock under dynamic disturbance with different pre-static loads [J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(8): 1841–1854. DOI: 10.13722/j.cnki.jrme.2016.1439. [19] 胡李华. 低应变率动力扰动下触发型岩爆过程研究[D]. 南宁: 广西大学, 2017. [20] 唐礼忠, 程露萍, 王春, 等. 高静载条件下受频繁动力扰动时蛇纹岩动力学特性研究 [J]. 岩土力学, 2016, 37(10): 1–10. DOI: 10.16285/j.rsm.2016.10.001.TANG L Z, CHENG L P, WANG C, et al. Dynamic characteristics of serpentine under the condition of high static load and frequent dynamic disturbance [J]. Rock and Soil Mechanics, 2016, 37(10): 1–10. DOI: 10.16285/j.rsm.2016.10.001. [21] 何满潮, 刘冬桥, 宫伟力, 等. 冲击岩爆试验系统研发及试验 [J]. 岩石力学与工程学报, 2014, 33(9): 1729–1739. DOI: 10.13722/j.cnki.jrme.2014.09.001.HE M C, LIU D Q, GONG W L, et al. Development of a testing system for impact rockbursts [J]. Chinese Journal of Rock Mechanics and Engineering, 2014, 33(9): 1729–1739. DOI: 10.13722/j.cnki.jrme.2014.09.001. [22] 郝保田. 地下核爆炸及其应用[M]. 北京: 国防工业出版社, 2002: 48−60. [23] 钱七虎, 王明洋. 岩土中的冲击爆炸效应[M]. 北京: 国防工业出版社, 2010: 80−85. [24] 李杰, 陈伟, 施存程, 等. 基于块系构造的大规模地下爆炸不可逆位移计算方法 [J]. 爆炸与冲击, 2018, 38(6): 1271–1277. DOI: 10.11883/bzycj-2017-0201.LI J, CHEN W, SHI C C, et al. Calculation method of irreversible displacement region radius based on block hierarchical structure under large-scale underground explosion [J]. Explosion and Shock Waves, 2018, 38(6): 1271–1277. DOI: 10.11883/bzycj-2017-0201. [25] RADIONOV V N, ADUSHKIN V V, ROMASHEV. Mechanical effect of an underground explosion[M]. Moscow: Nedra, 1971. [26] 谈庆明. 量纲分析[M]. 合肥: 中国科学技术大学出版社, 2005: 100−110. [27] BROWN E T, HOEK E. Technical note trends in relationships between measured in-situ stress and depth [J]. International Journal of Rock Mechanics and Mining Science, 1978, 15(4): 211–215. DOI: 10.1016/0148-9062(78)91227-5. [28] 李浪. 深部围岩模型试验技术及相应研究[D]. 南京: 解放军理工大学, 2016. [29] 王明洋, 徐子章, 岳松林, 等. PVDF压力计在相似材料动态力学参数测试中的应用 [J]. 北京理工大学学报, 2017, 37(10): 991–997. DOI: 10.15918/j.tbit1001-0645.−2017.10.001.WANG M Y, XU Z Z, YUE S L, et al. Calibration of PVDF pressure gauge and its application in dynamic parameters tests of similar materials [J]. Transactions of Beijing Institute of Technology, 2017, 37(10): 991–997. DOI: 10.15918/j.tbit1001-0645.−2017.10.001. -

下载:

下载: