Feasibility of deep-hole blasting technology for outburst prevention and permeability enhancement in high-gas-content coal seams with low-permeability subjected to high geo-stresses

-

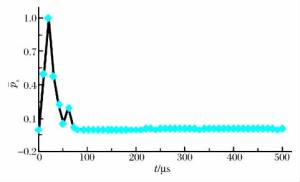

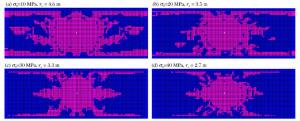

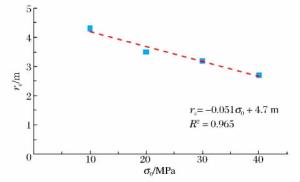

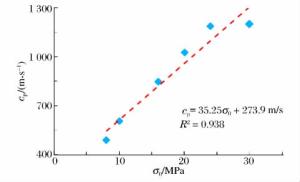

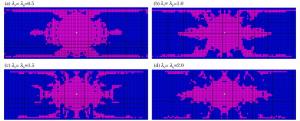

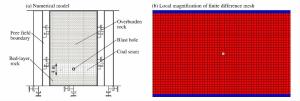

摘要: 同时考虑爆炸波、爆生气体、煤层原始瓦斯压力和煤层地应力的作用,对不同地应力条件下的高瓦斯低透气性煤层深孔爆破进行了有限差分动力数值模拟,并与室内相似模型实验和相关现场实践进行了对比。结果表明:地应力对煤层深孔爆破效果的影响显著,尤其对于高地应力煤层,地应力严重抑制着煤层爆生裂隙的扩展,煤层爆生裂隙半径随地应力的增大而近线性地减小,但深孔爆破技术对于高应力低透气性煤层仍可取得良好的增透效果;煤层地应力的主应力方向在一定程度上影响着爆生裂隙的扩展方向,实际工程需结合煤层地应力状况来布置爆破孔的空间位置。Abstract: By considering the action of blasting wave, explosion-induced gas and initial gas pressure as well as geo-stress endured by coal seam simultaneously, the deep-hole blasting in low-permeability high-gas-content coal seams under different geo-stresses were numerically simulated by using the FLAC3Dcode.And the simulated results were compared with the laboratory model test and other related field studies on the permeability improvement of the low-permeability coal seams.The comparable analysis indicates that the geo-stress can dramatically inhibit the extension of the blast-induced cracks in the coal seams, especially for the deeply-buried coal seams.Though the radius of the blasting crack zones linearly decreases with the increasing of geo-stress, the blasting technique can also be adapted to enhance the permeability of the deeply-buried low-permeability coal seams.And the direction of the maximum geo-stress can affect the extension direction of the blast-induced cracks in some degree.Therefore, in a practical blasting engineering, the spatial location of the blast holes should be determined according to the state of the geo-stress endured by the coal seam.

-

表 1 煤体HB和MC模型参数

Table 1. Coal parameters for HB and MC models

模型 S σci /MPa mi s a mb Ei /GPa HB本构模型 50 45 7 0.004 0.51 1.17 35 模型 σct/MPa σcc /MPa ccm /MPa φ /(°) Ei /GPa Ecm/GPa MC本构模型 0.15 2.71 1.73 45 35 1.08 -

[1] 李润求, 施式亮, 念其锋, 等.近10年我国煤矿瓦斯灾害事故规律研究[J].中国安全科学学报, 2011, 21(9): 143-151. doi: 10.3969/j.issn.1003-3033.2011.09.024Li Run-qiu, Shi Shi-liang, Nian Qi-feng, et al. Research on coalmine gas accident rules in China in recent decade[J]. China Safety Science Journal, 2011, 21(9): 143-151. doi: 10.3969/j.issn.1003-3033.2011.09.024 [2] 袁亮, 薛俊华.中国煤矿瓦斯治理理论与技术[C]//2010中国煤矿瓦斯治理国际研讨会论文集.合肥: 中国矿业大学出版社, 2010: 3-16. [3] 胡社荣, 彭纪超, 黄灿, 等.千米以上深矿井开采研究现状与进展[J].中国矿业, 2011, 20(7): 105-110. doi: 10.3969/j.issn.1004-4051.2011.07.027Hu She-rong, Peng Ji-chao, Huang Can, et al. An overview of current status and progress in coal mining of deep over a kilometer[J]. China Mining Magazine, 2011, 20(7): 105-110. doi: 10.3969/j.issn.1004-4051.2011.07.027 [4] 林柏泉, 李子文, 翟成, 等.高压脉动水力压裂卸压增透技术及应用[J].采矿与安全工程学报, 2011, 28(3): 452-455. doi: 10.3969/j.issn.1673-3363.2011.03.022Lin Bo-quan, Li Zi-wen, Zhai Cheng, et al. Pressure relief and permeability increasing technology based on high pressure pulsating hydraulic fracturing and its application[J]. Journal of Mining & Safety Engineering, 2011, 28(3): 452-455. doi: 10.3969/j.issn.1673-3363.2011.03.022 [5] 邢昭芳, 阎永利, 李会良.深孔控制卸压爆破防突机理和效果考察[J].煤炭学报, 1991, 16(2): 1-9.Xing Zhao-fang, Yan Yong-li, Li Hui-liang. Mechanism and results of prevention of rockburst by controlled pressure relief deep holes[J]. Journal of China Coal Society, 1991, 16(2): 1-9. [6] 赵东, 冯增朝, 赵阳升.高压注水对煤体瓦斯解吸特性影响的试验研究[J].岩石力学与工程学报, 2011, 30(3): 547-555. http://www.cnki.com.cn/Article/CJFDTotal-YSLX201103014.htmZhao Dong, Feng Zeng-chao, Zhao Yang-sheng. Experimental study of effects of high pressure water injection on desorption characteristic of coal-bed methane(CBM)[J]. Chinese Journal of Rock Mechanics and Engineering, 2011, 30(3): 547-555. http://www.cnki.com.cn/Article/CJFDTotal-YSLX201103014.htm [7] 王海东.深部开采低渗透煤层预裂控制爆破增透机理研究[D].哈尔滨: 中国地震局工程力学研究所, 2012: 47-56. [8] 龚敏, 王华, 文斌.岩石深孔爆破对邻近煤层的动应力作用[J].爆炸与冲击, 2012, 32(2): 196-202. doi: 10.3969/j.issn.1001-1455.2012.02.014Gong Min, Wang Hua, Wen Bin. Dynamic stress in adjacent coal seams induced by deep-hole blasting in rock[J]. Explosion and Shock Waves, 2012, 32(2): 196-202. doi: 10.3969/j.issn.1001-1455.2012.02.014 [9] Hoek E. Pratical rock engineering[M/OL]. [2011-03-01]. http://www.rocscience.com/hoek/corner/Practical_Rock_Engineering.pdf.Chapter11:1-28. [10] 杨圣奇, 温森.不同直径煤样强度参数确定方法的探讨[J].岩土工程学报, 2010, 32(6): 881-891. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ytgcxb201006011Yang Sheng-qi, Wen Sen. Method for strength parameters of coal samples with different diameters[J]. Chinese Journal of Geotechnical Engineering, 2010, 32(6): 881-891. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=ytgcxb201006011 [11] 郭进平, 聂兴信.新编爆破工程实用技术大全[M].北京: 光明日报出版社, 2002: 18-22. [12] 吴亮, 卢文波, 宗琦.岩石中柱状装药爆炸能量分布[J].岩土力学, 2006, 27(5): 735-739. doi: 10.3969/j.issn.1000-7598.2006.05.010Wu Liang, Lu Wen-bo, Zong Qi. Distribution of explosive energy consumed by column charge in rock[J]. Rock and Soil Mechanics, 2006, 27(5): 735-739. doi: 10.3969/j.issn.1000-7598.2006.05.010 [13] 赵铮, 陶钢, 杜长星.爆轰产物JWL状态方程应用研究[J].高压物理学报, 2009, 23(4): 277-284. doi: 10.3969/j.issn.1000-5773.2009.04.007Zhao Zheng, Tao Gang, Du Chang-xing. Application research on JWL equation of state of detonation products[J]. Chinese Journal of High Pressure Physics, 2009, 23(4): 277-284. doi: 10.3969/j.issn.1000-5773.2009.04.007 [14] ABAQUS Inc. ABAQUS theory manual[M/OL]. [2011-03-11]. http://abaqusdoc.ucalgary.ca/v6.9/books/stm/default.htm. [15] Liu Li-qing, Katsabanis P D. A numerical study of the effects of accurate timing on rock fragmentation[J]. International Journal of Rock Mechanics and Mining Sciences, 1997, 34(5): 817-835. doi: 10.1016/S1365-1609(96)00067-8 [16] Chen S G, Zhao J. A study of UDEC modeling for blast wave propagation in jointed rock masses[J]. International Journal of Rock Mechanics and Mining Sciences, 1998, 35(1): 93-99. doi: 10.1016/S0148-9062(97)00322-7 [17] Wei X Y, Zhao Z Y, Gu J. Numerical simulations of rock mass damage induced by underground explosion[J]. International Journal of Rock Mechanics and Mining Sciences, 2009, 46(7): 1206-1213. doi: 10.1016/j.ijrmms.2009.02.007 [18] Nilson R H. An integral method for predicting hydraulic fracture propagation driven by gasses or liquids[J]. International Journal for Numerical and Analytical Methods in Geomechanics, 1986, 10(2): 191-211. doi: 10.1002/nag.1610100207 [19] 卢文波, 陶振宇.预裂爆破中炮孔压力变化历程的理论分析[J].爆炸与冲击, 1994, 14(2): 140-147.Lu Wen-bo, Tao Zhen-yu. Theoretical analysis of the pressure variation in borehole for pre-splitting explosion[J], Explosion and Shock Waves, 1994, 14(2): 140-147. [20] 李宁, 陈莉静, 张平.爆生气体驱动岩石裂纹动态扩展分析[J].岩土工程学报, 2006, 28(4): 460-463. doi: 10.3321/j.issn:1000-4548.2006.04.007Li Ning, Chen Li-jing, Zhang Ping. Dynamic analysis for fracturing progress by detonation gas[J]. Chinese Journal of Geotechnical Engineering, 2006, 28(4): 460-463. doi: 10.3321/j.issn:1000-4548.2006.04.007 [21] 张奇.岩石爆破的粉碎区及其空腔膨胀[J].爆炸与冲击, 1990, 10(1): 68-95. http://www.bzycj.cn/article/id/10822Zhang Qi. Smash districts and expanding of cavities in rock blasting[J]. Explosion and Shock Waves, 1990, 10(1): 68-95. http://www.bzycj.cn/article/id/10822 [22] 宗琦.岩石爆破的扩腔作用及能量消耗[J].煤炭学报, 1997, 22(4): 392-396. doi: 10.3321/j.issn:0253-9993.1997.04.012Zong Qi. Function of cavity expansion and energy consumption in rock blasting[J]. Journal of China Coal Society, 1997, 22(4): 392-396. doi: 10.3321/j.issn:0253-9993.1997.04.012 [23] 李鸿宽, 吴继园, 刘思远.深孔预裂爆破强化抽放低透气性特厚煤层瓦斯的实践[J].煤矿安全, 2003, 34(2): 12-14. doi: 10.3969/j.issn.1003-496X.2003.02.006Li Hong-kuan, Wu Ji-yuan, Liu Si-yuan. Practice of using deep-hole presplitting blasting technology to drainage methane from extremely thick coal seam with low permeability[J]. Safety in Coal Mines, 2003, 34(2): 12-14. doi: 10.3969/j.issn.1003-496X.2003.02.006 [24] 张兴华.利用深孔控制预裂爆破强化瓦斯抽放消除回采工作面突出危险性[J].煤矿安全, 2006, 37(2): 22-24. doi: 10.3969/j.issn.1003-496X.2006.02.008Zhang Xing-hua. Strengthening methane drainage using deep-hole controlled pre-split blasting for eliminating risk of working face outburst[J]. Safety in Coal Mines, 2006, 37(2): 22-24. doi: 10.3969/j.issn.1003-496X.2006.02.008 [25] 谢友友, 张连军, 林柏泉, 等.穿层深孔控制爆破有效影响半径的确定[J].煤矿安全, 2008, 39(11): 11-14.Xie You-you, Zhang Lian-jun, Lin Bo-quan, et al. Determination of effective influence radius for strata penetration controlled blasting[J]. Safety in Coal Mines, 2008, 39(11): 11-14. -

下载:

下载: