Perforation modes of double-layered plates with air space struckby a blunt rigid projectile

-

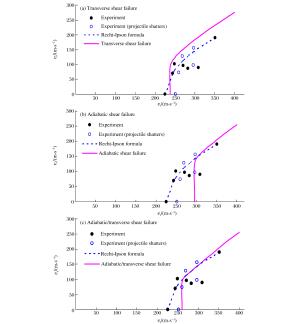

摘要: 平头弹贯穿单层金属靶,随着靶厚的增加和弹速的增高,穿甲模式均可能由剪切冲塞向绝热剪切冲塞转换。因此,对于双层或多层靶的穿甲,其不同层的靶板失效模式可能是不同的。本文中对相关的平头弹穿甲Weldox 700E单层及双层间隙式钢靶的实验数据进行分析,讨论其穿甲模式。弹速较高时,贯穿第1层靶发生绝热剪切失效,弹速降低,贯穿第2层靶板发生绝热剪切失效或剪切冲塞失效, 最终失效模式为绝热剪切和剪切冲塞混杂。Abstract: In the cases of the perforation of a single-layered metal plate struck by a blunt rigid projectile, along with the increase of the plate thickness and that of the projectile velocity, the failure mode of the metal plate may transform from shear plugging to adiabatic shear plugging. Therefore, regarding the perforation of double-layered or multi-layered plates, the failure modes of various plates can be quite different. In this work we investigated these different perforation modes by conducting experimental analyses on the perforations of single- and double-layered Weldox E steel plates with air space. Our results indicate that, in the case of a higher initial striking velocity, the failure mode of the first layer plate is adiabatic shear plugging, while that of the second layer plate is adiabatic shear plugging or shear plugging as the striking velocity of the projectile slows down. We conclude that the final failure mode of the double-layered plates is the mixture of both shear plugging and adiabatic shear plugging.

-

表 1 实验结果和数值模拟结果

Table 1. Experimental results and numerical simulation results

vi/(m·s-1) vr/(m·s-1) 实验[1] 剪切冲塞模型 绝热剪切冲塞模型 绝热/剪切冲塞混杂模型 第1层 第2层 第1层 第2层 第1层 第2层 400.0 - 317.5 275.8 309.5 254.9 309.5 254.9 380.0 - 300.1 258.3 291.6 235.3 291.6 235.3 360.0 - 282.7 240.5 273.6 214.8 273.6 214.8 351.1 189.9 274.9 232.5 265.4 205.3 265.4 205.3 330.0 - 256.3 213.0 245.9 180.9 245.9 180.9 309.4 89.8 238.0 193.1 226.5 157.2 226.5 157.2 297.0 155.6 226.8 180.7 214.5 143.8 214.5 143.8 296.7 97.7 226.6 180.4 214.2 142.3 214.2 142.3 296.0 - 225.9 179.6 213.5 141.1 213.5 141.1 295.5 - 225.5 179.1 213.0 0 213.0 140.4 282.6 86.4 213.7 165.5 200.2 0 200.2 127.2 270.8 96.6 202.9 152.1 188.1 0 188.1 113.4 269.3 128.4 201.5 150.4 186.6 0 186.6 111.5 261.0 - 193.7 140.1 177.8 0 177.8 96.3 260.3 - 193.1 139.2 177.0 0 177.0 0 259.7 73.3 192.5 138.4 176.3 0 176.3 0 255.0 - 188.1 132.1 171.2 0 171.2 0 251.7 0 184.9 127.3 167.5 0 167.5 0 249.1 101.7 182.4 123.3 164.5 0 164.5 0 244.0 69.6 177.5 114.4 158.6 0 158.6 0 238.0 - 171.7 98.2 151.2 0 151.2 0 237.5 - 171.2 0 150.6 0 150.6 0 225.2 0 159.0 0 133.7 0 133.7 0 -

[1] Dey S, Bϕrvik T, Teng X, et al. On the ballistic resistance of double-layered steel plates: An experimental and numerical investigation[J]. International Journal of Solids and Structures, 2007, 44(20):6701-6723. doi: 10.1016/j.ijsolstr.2007.03.005 [2] 张伟, 肖新科, 郭子涛, 等.双层A3钢靶对平头杆弹的抗侵彻性能研究[J].高压物理学报, 2012, 26(2):163-170. http://www.cnki.com.cn/Article/CJFDTotal-GYWL201202008.htmZhang Wei, Xiao Xinke, Guo Zitao, et al. Investigation on the ballistic resistance of double-layered A3 steel targets against blunt projectile impact[J]. Chinese Journal of High Pressure Physics, 2012, 26(2):163-170. http://www.cnki.com.cn/Article/CJFDTotal-GYWL201202008.htm [3] Teng X, Dey S, Bϕrvik T, et al. Protection performance of double-layered metal shields against projectile impact[J]. Journal of Mechanics of Materials and Structures, 2007, 2(7):1309-1330. doi: 10.2140/jomms [4] Woodward R L, Cimpoeru S J. A study of the perforation of aluminium laminate targets[J]. International Journal of Impact Engineering, 1998, 21(3):117-131. doi: 10.1016/S0734-743X(97)00034-1 [5] 邓云飞, 张伟, 曹宗胜.间隙对A3钢薄板抗卵形头弹侵彻性能影响的实验研究[J].振动与冲击, 2013, 32(12):95-99. doi: 10.3969/j.issn.1000-3835.2013.12.018Deng Yunfei, Zhang Wei, Cao Zongsheng. Effect of gap on the ballistic performance of double-layered A3 steel shields against ogival rigid projectiles[J]. Journal of Vibration and Shock, 2013, 32(12):95-99. doi: 10.3969/j.issn.1000-3835.2013.12.018 [6] Liang C C, Yang M F, Wu P W, et al. Resistant performance of perforation of multi-layered targets using an estimation procedure with marine application[J]. Ocean Engineering, 2005, 32(3):441-468. http://cn.bing.com/academic/profile?id=c75169062d5b4f71d71d96545f7b3a42&encoded=0&v=paper_preview&mkt=zh-cn [7] Recht R F, Ipson T W. Ballistic perforation dynamics[J]. Journal of Applied Mechanics, 1963, 30(3):384-390. doi: 10.1115/1.3636566 [8] Almohandes A A, Abdel-Kader M S, Eleiche A M. Experimental investigation of the ballistic resistance of steel-fiberglass reinforced polyester laminated plates[J]. Composites Part B: Engineering, 1996, 27(5):447-458. doi: 10.1016/1359-8368(96)00011-X [9] Chen X W, Li Q M. Shear plugging and perforation of ductile circular plates struck by a blunt projectile[J]. International Journal of Impact Engineering, 2003, 28 (5):513-536. doi: 10.1016/S0734-743X(02)00077-5 [10] Chen X W, Li Q M, Fan S C. Initiation of adiabatic shear failure in a clamped circular plate struck by a blunt projectile[J]. International Journal of Impact Engineering, 2005, 31(7): 877-893. doi: 10.1016/j.ijimpeng.2004.04.011 [11] 陈小伟, 梁冠军, 姚勇, 等.平头弹穿透金属靶板的模式分析[J].力学学报, 2009, 41(1):84-90. doi: 10.3321/j.issn:0459-1879.2009.01.012Chen Xiaowei, Liang Guanjun, Yao Yong, et al. Perforation modes of metal plates struck by a blunt rigid projectile[J]. Chinese Journal of Theoretical and Applied mechanics, 2009, 41(1):84-90. doi: 10.3321/j.issn:0459-1879.2009.01.012 [12] Chen X W, Liang G J. Perforation modes of metal plates struck by a blunt rigid projectile[J]. Engineering Transactions, 2012, 60(1):15-29. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=lxxb200901012 [13] Bϕrvik T, Hopperstad O S, Langseth M, et al. Effect of target thickness in blunt projectile penetration of Weldox 460E steel plates[J]. International Journal of Impact Engineering, 2003, 28(4):413-464. doi: 10.1016/S0734-743X(02)00072-6 [14] Dey S, Bϕrvik T, Hopperstad O S, et al. The effect of target strength on the perforation of steel plates using three different projectile nose shapes[J]. International Journal of Impact Engineering, 2004, 30(8):1005-1038. http://cn.bing.com/academic/profile?id=63c9cdab5fc4517c3691043fa16af0e8&encoded=0&v=paper_preview&mkt=zh-cn [15] 潘建华, 文鹤鸣.平头弹丸正撞击下延性金属靶板的破坏模式[J].高压物理学报, 2007, 21(2):157-164. doi: 10.3969/j.issn.1000-5773.2007.02.007Pan Jianhua, Wen Heming. Failure modes of ductile metal plates under normal impact by flat-ended projectiles[J]. Chinese Journal of High Pressure Physics, 2007, 21(2):157-164. doi: 10.3969/j.issn.1000-5773.2007.02.007 -

下载:

下载: