Protection ability of liquid-filled structure subjected to penetration by high-velocity long-rod projectile

-

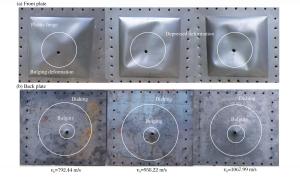

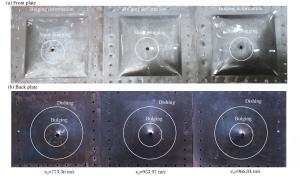

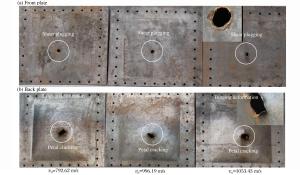

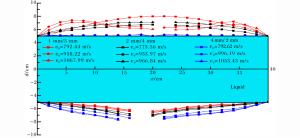

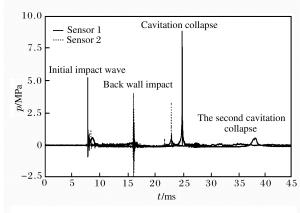

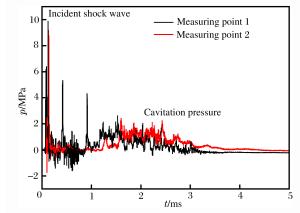

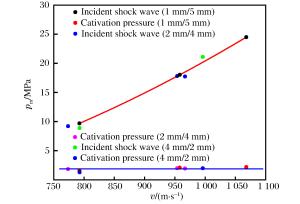

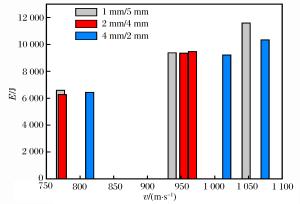

摘要: 为提高蓄液结构的防护能力,开展蓄液结构弹道侵彻实验,通过改变其前、后面板厚度配比,研究前、后面板不同厚度匹配对蓄液结构破坏模式、压力载荷特性及防护能力的影响。结果表明:弹丸初速是影响入射波压力峰值大小的主要因素。固定前、后面板总厚度不变时,随着前、后面板厚度比的增大,前面板破坏模式由剪切冲塞-薄膜鼓胀-凹陷变形转变为剪切冲塞-薄膜鼓胀直至剪切冲塞破坏,后面板破坏模式由隆起-碟形破坏转变为薄膜鼓胀-花瓣开裂破坏。前、后面板破坏模式是相互影响的,前、后面板厚度匹配关系决定了其相应破坏模式的发生。前面板薄后面板厚的蓄液结构吸收冲击动能更多,抗侵彻能力也更强。Abstract: In this work we carried out ballistic impact tests on the liquid-filled structure to improve its protection capability. By adjusting the thickness match ratio to the structure's front panel to its rear ones, we studied how this ratio's influence on the structure's failure modes, pressure loading characteristics and protection capabilities. The results show that the projectile velocity is the main factor that affects the magnitude of the incident pressure peaks. With the increase of the ratio of the back panel thickness to the rear panel thickness, the front panel's failure mode changes from the shear plugging-film bulging-depressed deformation to the shear plugging-film bulging until the shear plugging is damaged, whereas the back panel's failure mode changes from the bulging-dishing damage to the film bulging-petal cracking damage. The front and back panels' failure modes affect each other, the matching relationship of the front and back panels' thicknesses determines the occurrence of the corresponding failure modes. The total thickness of the front and back panels being the same, the larger the thickness ratio, the more the impact energy is absorbed and the stronger the structure's penetration capability.

-

表 1 材料参数

Table 1. Material parameters

材料 E/GPa ρ/(kg·m-3) ν σy/MPa σb/MPa δ/% 45钢 205 7 800 0.3 335 598 16 Q235钢 210 7 850 0.3 235 400~490 22 表 2 弹道实验结果

Table 2. Result of ballistic experiment

工况 h1/mm h2/mm v0/(m·s-1) vr/(m·s-1) ΔE/J pm/MPa pc/MPa 1 1 5 792.44 300.60 6 585.61 9.70 1.61 2 1 5 958.22 390.62 9 378.62 18.04 2.14 3 1 5 1 067.99 440.90 11 591.07 24.50 2.20 4 2 4 773.56 294.30 6 269.34 9.22 1.85 5 2 4 953.97 383.20 9 349.40 17.82 2.06 6 2 4 966.84 402.70 9 464.50 17.74 1.95 7 4 2 792.62 321.73 6 428.02 8.90 1.31 8 4 2 996.19 490.10 9 214.41 21.10 2.01 9 4 2 1 053.43 531.00 10 128.89 -

[1] NICOLAS L, AURÉLIA D, FRÉDÉRIC H, et al. Ballistic impact on an industrial tank: Study and modeling of consequences[J]. Journal of Hazardous Materials, 2009, 172(2/3):587-594. https://www.researchgate.net/publication/257919582_Ballistic_impact_on_an_industrial_tank_Study_and_modeling_of_consequences [2] 矶部孝. 水下弹道的研究[M]. 周佩芬, 译. 北京: 国防工业出版社, 1983: 56-128. [3] DELETOMBE E, FABIS J, DUPAS J, et al. Experimental analysis of 7.62 mm hydrodynamic ram in containers[J]. Journal of Fluids and Structures, 2013, 37(11):1-21.DOI: 10.1016/j.jfluidstructs.2012.11.003. [4] PETER J, DISIMILE L A, SWANSON N T. The hydrodynamic ram pressure generated by spherical projectiles[J]. International Journal of Impact Engineering, 2009, 36(6):821-829. doi: 10.1016/j.ijimpeng.2008.12.009 [5] TOWNSEND D, PARK N, DEVALL P M. Failure of fluid filled structures due to high velocity fragment impact[J]. International Journal of Impact Engineering, 2003, 29(1):723-733.DOI: 10.1016/j.ijimpeng.2003.10.019. [6] 李典, 朱锡, 侯海量, 等.高速杆式弹体侵彻下蓄液结构载荷特性的有限元分析[J].爆炸与冲击, 2016, 36(1):1-8. doi: 10.11883/1001-1455(2016)01-0001-08LI Dian, ZHU Xi, HOU Hailiang, et al. Finite element analysis of load characteristic of liquid-filled structure subjected to high velocity long-rod projectile penetration[J]. Explosion and Shock Waves, 2016, 36(1):1-8. doi: 10.11883/1001-1455(2016)01-0001-08 [7] VARAS D, ZAERA R, LÓPEZ P. Experimental study of CFRP fluid-filled tubes subjected to high-velocity impact[J]. Composite Structures, 2011, 93(10):2598-2609.DOI: 10.1016/j.compstruct.2011.04.025. [8] NISHIDA M, TANAKA K. Experimental study of perforation and cracking of water-filled aluminum tubes impacted by steel spheres[J]. International Journal of Impact Engineering, 2006, 32(12):2-16. https://www.sciencedirect.com/science/article/pii/S0734743X05000916 [9] SHI H H, ITOH M, TAKAMi T. Optical observation of the supercavitation Induced by high-speed water entry[J]. Journal of Fluids Engineering, 2000, 122(4):806-810. doi: 10.1115/1.1310575 [10] KNAPP R T, DAILY J W, HAMMIT F G. Cavitation[M]. New York: McGraw Hill, 1979. [11] 曹伟, 王聪, 魏英杰, 等.自然超空泡形态特性的射弹试验研究[J].工程力学, 2006, 23(12):175-187. doi: 10.3969/j.issn.1000-4750.2006.12.031CAO Wei, WANG Cong, WEI Yingjie, et al. High-speed projectile experimental investigation on the characteristics of natural supercaviation[J]. Engineering Mechanics, 2006, 23(12):175-187. doi: 10.3969/j.issn.1000-4750.2006.12.031 [12] 沈晓乐, 朱锡, 侯海量, 等.高速破片侵彻防护液舱试验研究[J].中国舰船研究, 2011, 6(3):12-15. http://www.cqvip.com/QK/93256A/201103/38474331.htmlSHEN Xiaole, ZHU Xi, HOU Hailiang, et al. Experimental study on penetration properties of high velocity fragment into safety liquid cabin[J]. Chinese Journal of Ship Research, 2011, 6(3):12-15. http://www.cqvip.com/QK/93256A/201103/38474331.html [13] 李营, 吴卫国, 郑元洲, 等.舰船防护液舱吸收爆炸破片的机理[J].中国造船, 2015, 56(2):38-44. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=D617120LI Ying, WU Weiguo, ZHENG Yuanzhou, et al. Study on mechanism of explosive fragments absorbed by vessel protective tank[J]. Ship Buliding of China, 2015, 56(2):38-44. http://www.wanfangdata.com.cn/details/detail.do?_type=degree&id=D617120 [14] 孔祥韶, 吴卫国, 刘芳, 等.舰船舷侧防护液舱对爆炸破片的防御作用研究[J].船舶力学, 2014, 18(8):996-1004. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=cblx201408015KONG Xiangshao, WU Weiguo, LIU fang, et al. Research on protective effect of guarding fluid cabin under attacking by explosion fragments[J]. Journal of Ship Mechanics, 2014, 18(8):996-1004. http://www.wanfangdata.com.cn/details/detail.do?_type=perio&id=cblx201408015 [15] 沈晓乐, 朱锡, 侯海量, 等.高速破片入水镦粗变形及侵彻特性有限元分析[J].舰船科学技术, 2012, 34(7):25-29. doi: 10.3404/j.issn.1672-7649.2012.07.005SHEN Xiaole, ZHU Xi, HOU Hailiang, et al. Finite element analysis of underwater high velocity fragment mushrooming and penetration properties[J]. Ship Science and Technology, 2012, 34(7):25-29. doi: 10.3404/j.issn.1672-7649.2012.07.005 [16] NICOLAS L, AURÉLIA D. Experimental study of hydraulic ram effects on a liquid storage tank: Analysis of overpressure and cavitation induced by a high-speed projectile[J]. Journal of Hazardous Materials, 2010, 178(1/2/3):635-643.DOI: 10.1016/j.jhazmat.2010.01.132. [17] DISIMILEA P J, SWANSONB L A, NORMAN T, et al. The hydrodynamic ram pressure generated by spherical projectiles[J]. International Journal of Impact Engineering, 2009, 36(6):821-829.DOI: 10.1016/j.ijimpeng.2008.12.009. -

下载:

下载: