Performance of retrofitted autoclaved aerated concrete masonry walls subjected to gas explosions

-

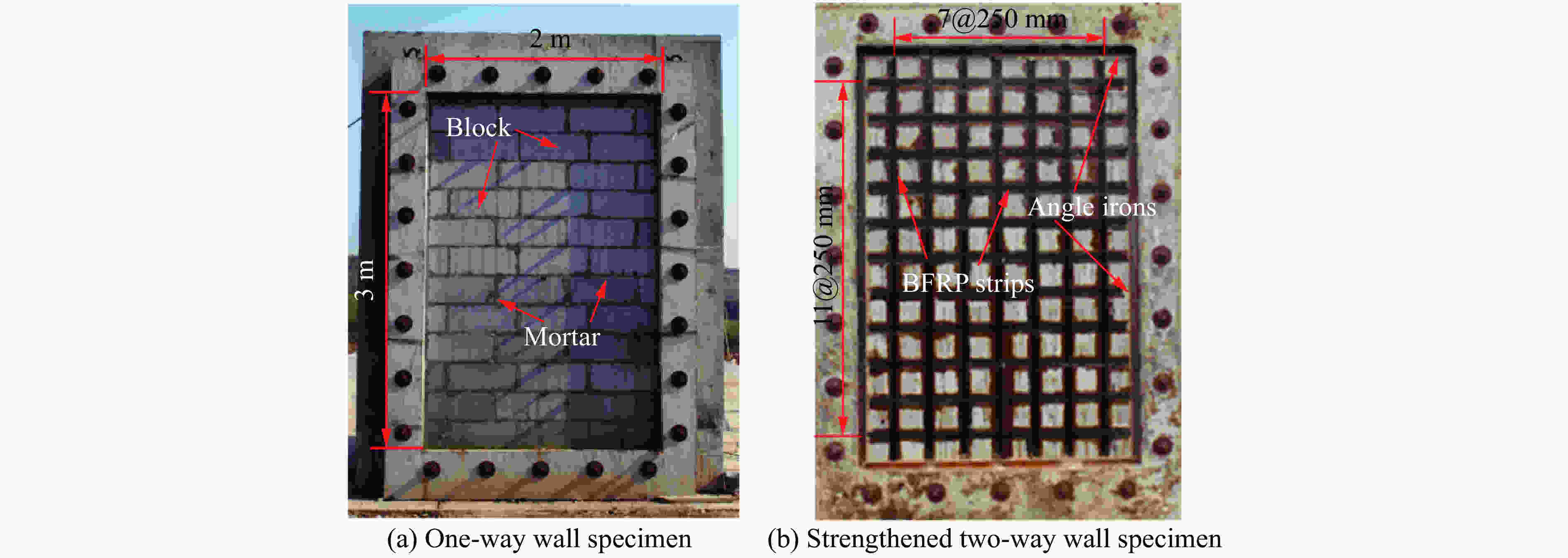

摘要: 为研究燃气爆炸作用下蒸压加气混凝土砌体墙的加固性能,基于有限元软件LS-DYNA,建立了砌体墙简化数值模型,分析了GB 50779-2012 石油化工控制室抗爆设计规范中建议的荷载作用下砌体墙高度和厚度的影响,对比了玄武岩纤维(basalt fiber reinforced plastic, BFRP)布与喷涂式聚脲对蒸压加气混凝土单向砌体墙的加固效果,并以防止砌体墙倒塌为设计目标,给出了加固建议。研究表明,本文中建立的简化数值模型能较好地模拟燃气爆炸作用下蒸压加气混凝土砌体墙的变形和破坏模式,计算结果与试验吻合良好;《规范》建议荷载作用下,未加固砌体墙以弯曲破坏为主,随着墙体高度增加,破坏模式由弯曲破坏向剪切破坏转变;BFRP布条加固可以有效提高墙体抗弯刚度和压拱效应,而聚脲涂层加固对抗弯刚度提高有限但墙体拉拱效应明显,二者均能显著提高墙体抗爆性能;加固墙体均发生弯曲破坏,BFRP布条材料的断裂一般发生在墙体位移最大处,而聚脲涂层材料的断裂发生在跨端边界处。Abstract: Numerical studies were conducted by using the finite element software LS-DYNA to investigate the performances of the retrofitted autoclaved aerated concrete masonry (AAC) walls subjected to gas explosions. A simplified numerical model for the masonry walls was developed and calibrated with the test data. Under the blast loads specified by the design codes, the influences of wall height and thickness on the structural response of the unstrengthened one-way AAC masonry walls were discussed. In addition, the performances of the BFRP strip and spray-on polyurea strengthened one-way AAC masonry walls were compared and the retrofitting suggestions for engineering practice were proposed. It is found that the numerical predications of the mid-span displacements and failure modes are in agreement with the test data. Under the specified blast loads, the unstrengthened masonry walls mainly fail for bending of the structures, and with the increase of wall height, the failure mode changes from flexure failure to shear failure. Using the BFRP strips can improve the stiffness and arching effect of the walls significantly while the spray-on polyurea can enhance the tensile membrane effect of walls effectively. The failure mode of the strengthened masonry walls is a typical flexure failure. The fracture of the BFRP strips generally occurs at the mid-span area of the one-way masonry walls, while the fracture of spray-on polyurea occurs at the boundary of the masonry walls.

-

Key words:

- gas explosion /

- autoclaved aerated concrete /

- masonry wall /

- BFRPstrip /

- spray-on polyurea

-

表 1 试验方案

Table 1. Testing scheme

表 2 AAC砌块的材料参数

Table 2. Material parameters of AAC blocks

材料 密度/(kg·m−3) 杨氏模量/MPa 泊松比μ 拉伸极限/MPa 剪切极限/MPa 抗压强度/MPa 断裂韧度/(N·m−1) 剪力滞留系数 砌块 625 530 0.20 0.70 1 3 80 0.03 材料 密度/(kg·m−3) 杨氏模量/GPa 泊松比μ 抗拉强度/MPa 极限应变/% BFRP 2 500 77.90 0.17 1 642 2.1 材料 密度/(kg·m−3) 杨氏模量/MPa 泊松比μ 屈服应力/MPa 单元失效应变 切线模量/MPa 聚脲涂层 1 150 80 0.17 8 1.20 6.45 表 5 不同高度、厚度条件下蒸压加气混凝土单向墙损伤情况

Table 5. Damage of one-way AAC masonry walls with different heights and thicknesses

墙体高度/m 不同厚度墙体损伤结果 120 mm 240 mm 360 mm 3 倒塌 不可修复 可修复 4 倒塌 倒塌 不可修复 5 倒塌 倒塌 不可修复 表 6 不同墙体的加固方案

Table 6. Retrofitting suggestions for masonry walls

加固材料 高度/m 不同厚度墙体的加固方案 120 mm 240 mm 360 mm BFRP 3 0.48 mm(4层) 无需加固 无需加固 4 0.36 mm(3层) 0.12 mm(1层) 无需加固 5 0.36 mm(3层) 0.24 mm(2层) 无需加固 聚脲涂层 3 0.40 mm 无需加固 无需加固 4 0.40 mm 0.10 mm 无需加固 5 0.30 mm 0.10 mm 无需加固 -

[1] 彭军芝. 蒸压加气混凝土孔结构及其对性能的影响研究进展 [J]. 材料导报, 2013, 27(15): 103–107;118. DOI: 10.3969/j.issn.1005-023X.2013.15.022.PENG J Z. A review on pore structure and properties of autoclaved aerated concrete [J]. Materials Review, 2013, 27(15): 103–107;118. DOI: 10.3969/j.issn.1005-023X.2013.15.022. [2] 马力, 曾力, 张艳花. 加气混凝土节能应用发展现状综述 [J]. 混凝土, 2012(5): 50–52. DOI: 10.3969/j.issn.1002-3550.2012.05.016.MA L, ZENG L, ZHANG Y H. Overview of the development of the energy saving application of aerated concrete [J]. Concrete, 2012(5): 50–52. DOI: 10.3969/j.issn.1002-3550.2012.05.016. [3] 吴会阁, 赵彦. 蒸压加气混凝土砌块砌体承重墙抗震性能研究综述 [J]. 防灾科技学院学报, 2012, 14(2): 38–42. DOI: 10.3969/j.issn.1673-8047.2012.02.007.WU H G, ZHAO Y. Review of studies on the seismic behavior of autoclaved aerated block bearing walls [J]. Journal of Institute of Disaster-Prevention Science and Technology, 2012, 14(2): 38–42. DOI: 10.3969/j.issn.1673-8047.2012.02.007. [4] 许三罗. 爆炸荷载作用下砌体结构响应的有限元分析 [J]. 防灾减灾工程学报, 2007, 27(3): 357–362. DOI: 10.3969/j.issn.1672-2132.2007.03.019.XU S L. Finite element analysis of response of masonry wall under blast loading [J]. Journal of Disaster Prevention and Mitigation Engineering, 2007, 27(3): 357–362. DOI: 10.3969/j.issn.1672-2132.2007.03.019. [5] 范俊余, 方秦, 陈力, 等. 砌体填充墙的抗爆性能 [J]. 爆炸与冲击, 2014, 34(1): 59–66. DOI: 10.11883/1001-1455(2014)01-0059-08.FAN J Y, FANG Q, CHEN L, et al. Anti-blast properties of masonry infill walls [J]. Explosion and Shock Waves, 2014, 34(1): 59–66. DOI: 10.11883/1001-1455(2014)01-0059-08. [6] DAVIDSON J S, FISHER J W, HAMMONS M I, et al. Failure mechanisms of polymer-reinforced concrete masonry walls subjected to blast [J]. Journal of Structural Engineering, 2005, 131(8): 1194–1205. DOI: 10.1061/(ASCE)0733-9445(2005)131:8(1194). [7] CHEN L, FANG Q, FAN J Y, et al. Responses of masonry infill walls retrofitted with CFRP, steel wire mesh and laminated bars to blast loadings [J]. Advances in Structural Engineering, 2014, 17(6): 817–836. DOI: 10.1260/1369-4332.17.6.817. [8] COOPER M G, FAIRWEATHER M, TITE J P. On the mechanisms of pressure generation in vented explosions [J]. Combustion and Flame, 1986, 65(1): 1–14. DOI: 10.1016/0010-2180(86)90067-2. [9] MERCX W P M, VAN WINGERDEN C J M, PASMAN H J. Venting of gaseous explosions [J]. Process Safety Progress, 1993, 12(1): 40–46. DOI: 10.1002/prs.680120106. [10] BAO Q, FANG Q, ZHANG Y D, et al. Effects of gas concentration and venting pressure on overpressure transients during vented explosion of methane-air mixtures [J]. Fuel, 2016, 175: 40–48. DOI: 10.1016/j.fuel.2016.01.084. [11] LI Z, CHEN L, FANG Q, et al. Experimental and numerical study of unreinforced clay brick masonry walls subjected to vented gas explosions [J]. International Journal of Impact Engineering, 2017, 104: 107–126. DOI: 10.1016/j.ijimpeng.2017.02.002. [12] 韩永利, 陈洋, 陈龙珠. 基于LS-DYNA的墙体抗燃气爆炸能力数值分析 [J]. 防灾减灾工程学报, 2010, 30(3): 298–302. DOI: 10.3969/j.issn.1672-2132.2010.03.012.HAN Y L, CHEN Y, CHEN L Z. Simulation on anti-blast ability of masonry wall under gas explosion load based on LS-DYNA [J]. Journal of Disaster Prevention and Mitigation Engineering, 2010, 30(3): 298–302. DOI: 10.3969/j.issn.1672-2132.2010.03.012. [13] 韩永利, 陈龙珠, 陈洋. 民用住宅墙体抗燃气爆炸能力的数值模拟研究 [J]. 建筑科学, 2010, 26(9): 49–53. DOI: 10.3969/j.issn.1002-8528.2010.09.012.HAN Y L, CHEN L Z, CHEN Y. Numerical analysis of civil house wall under gas explosion load [J]. Building Science, 2010, 26(9): 49–53. DOI: 10.3969/j.issn.1002-8528.2010.09.012. [14] 韩笑. 燃气爆炸荷载下砖砌墙体的动力响应研究[D]. 西安: 长安大学, 2012: 32-40.HAN X. The dynamic response of brick masonry wall subjected to gas explosion load [D]. Xi’an: Chang’an University, 2012: 32−40. [15] 中国石油化工集团公司. 石油化工控制室抗爆设计规范: GB 50779-2012[S]. 北京: 中国计划出版社, 2012: 9−13. [16] LI Z, CHEN L, FANG Q, et al. Study of autoclaved aerated concrete masonry walls under vented gas explosions [J]. Engineering Structures, 2017, 141: 444–460. DOI: 10.1016/j.engstruct.2017.03.033. [17] LI Z, CHEN L, FANG Q, et al. Experimental and numerical study of basalt fiber reinforced polymer strip strengthened autoclaved aerated concrete masonry walls under vented gas explosions [J]. Engineering Structures, 2017, 152: 901–919. DOI: 10.1016/j.engstruct.2017.09.055. [18] HALQUIST J. LS-DYNA keyword user’s manual: Version 971 [M]. Livermore, CA: Livermore Software Technology Corporation, 2007: 350−352. [19] GOVINDJEE S, KAY G J, SIMO J C. Anisotropic modelling and numerical simulation of brittle damage in concrete [J]. International Journal for Numerical Methods in Engineering, 1995, 38(21): 3611–3633. DOI: 10.1002/nme.1620382105. [20] 国家建筑材料工业局. 加气混凝土力学性能试验方法: GB/T11971-1997[S]. 北京: 中国标准出版社1998: 10−14. [21] 陕西省建筑科学研究院. 建筑砂浆基本性能试验方法标准: JGJ/T70-2009[S]. 北京: 中国建筑工业出版社, 2009: 1−22. [22] U.S. Department of Defense. Standard test method for tensile properties of polymer matrix composite materials: ASTM D 3039-14 [S]. 2014. [23] American Society of Testing Materials. Standard test method for determining tensile properties of fiber reinforced polymer matrix composites used for strengthening of civil structures: ASTM D 7565-10 [S]. 2010. [24] IRSHIDAT M, AL-OSTAZ A, CHENG A, et al. Nanoparticle reinforced polymer for blast protection of unreinforced masonry wall: laboratory blast load simulation and design models [J]. Journal of Structural Engineering, 2011, 137(10): 1193–1204. DOI: 10.1061/(ASCE)ST.1943-541X.0000361. [25] 许三罗, 方秦. 弹性聚合物和碳纤维布加固的砌体墙抗爆性能的数值分析 [J]. 解放军理工大学学报(自然科学版), 2010, 11(3): 306–311. DOI: 10.3969/j.issn.1009-3443.2010.03.013.XU S L, FANG Q. Numerical analysis on blast-resistant capacity of masonry walls retrofitted with elastomeric polymer and CFRP [J]. Journal of PLA University of Science and Technology (Natural Science Edition), 2010, 11(3): 306–311. DOI: 10.3969/j.issn.1009-3443.2010.03.013. [26] 黄华, 吕卫东, 刘伯权. 爆炸荷载作用下粘贴Polymer Sheet膜材砌体墙防护性能研究 [J]. 振动与冲击, 2013, 32(19): 131–138. DOI: 10.3969/j.issn.1000-3835.2013.19.023.HUANG H, LYU W D, LIU B Q. Protective performance of masonry walls strengthened with polymer sheet under explosive loading [J]. Journal of Vibration and Shock, 2013, 32(19): 131–138. DOI: 10.3969/j.issn.1000-3835.2013.19.023. [27] EAMON C D. Reliability of concrete masonry unit walls subjected to explosive loads [J]. Journal of Structural Engineering, 2007, 133(7): 935–944. DOI: 10.1061/(ASCE)0733-9445(2007)133:7(935). [28] EAMON C D, BAYLOT J T, O’DANIEL J L. Modeling concrete masonry walls subjected to explosive loads [J]. Journal of Engineering Mechanics, 2004, 130(9): 1098–1106. DOI: 10.1061/(ASCE)0733-9399(2004)130:9(1098). [29] DENNIS S T, BAYLOT J T, WOODSON S C. Response of 1/4-scale concrete masonry unit (CMU) walls to blast [J]. Journal of Engineering Mechanics, 2002, 128(2): 134–142. DOI: 10.1061/(ASCE)0733-9399(2002)128:2(134). [30] U.S. Department of Defense. Structures to resist the effects of accidental explosions: UFC 3-340-02 [S]. 2008: 1635−1649. -

下载:

下载: