Shear characteristics and failure mechanism of laser metal deposition GH4169 at different strain rates

-

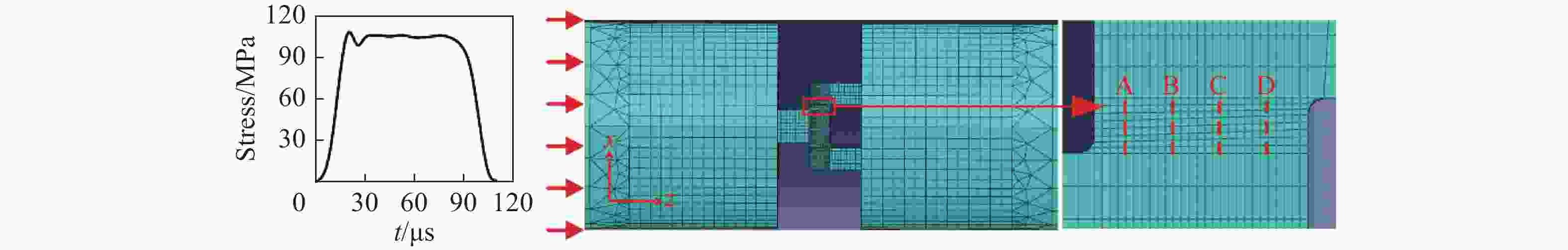

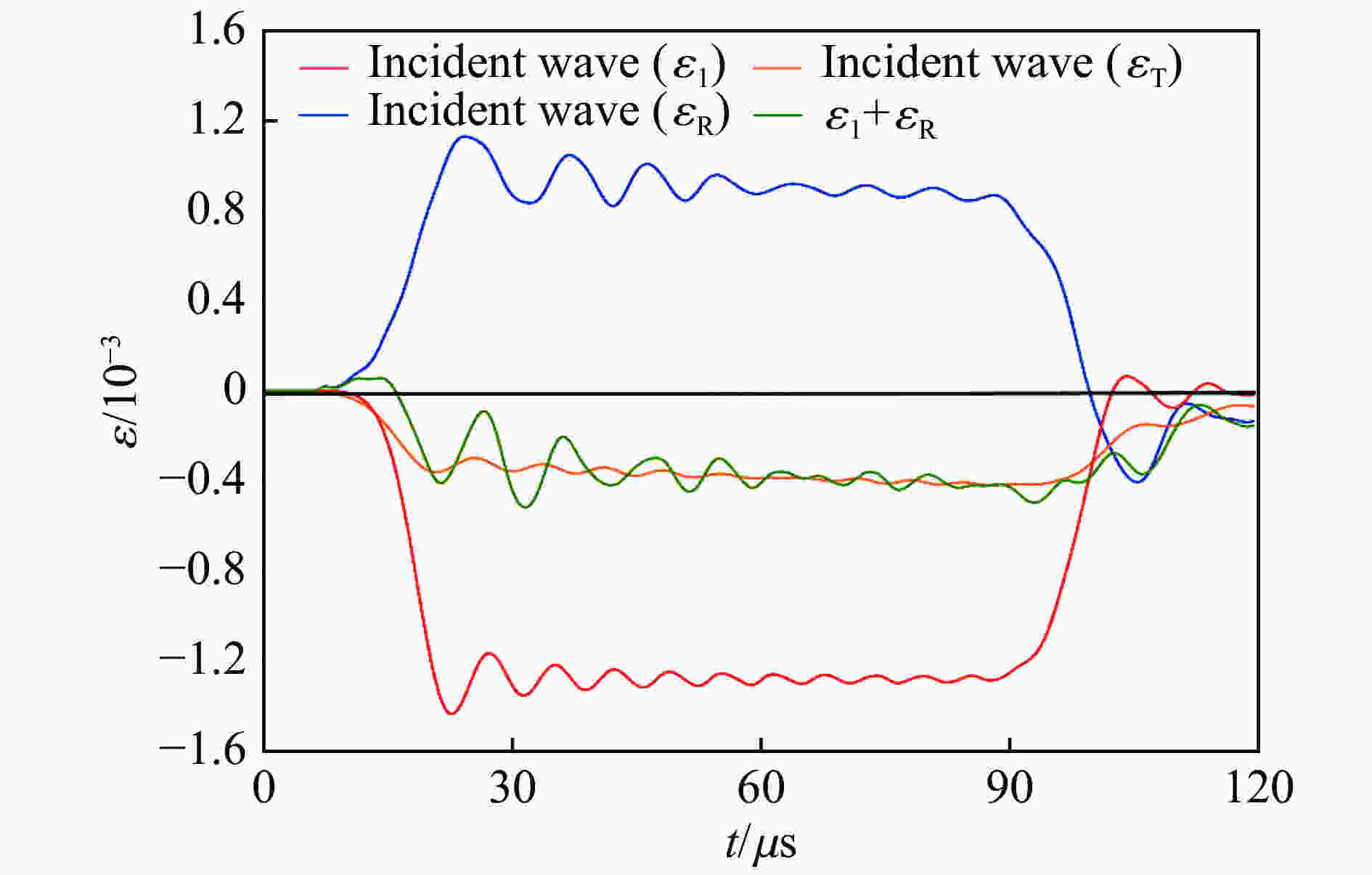

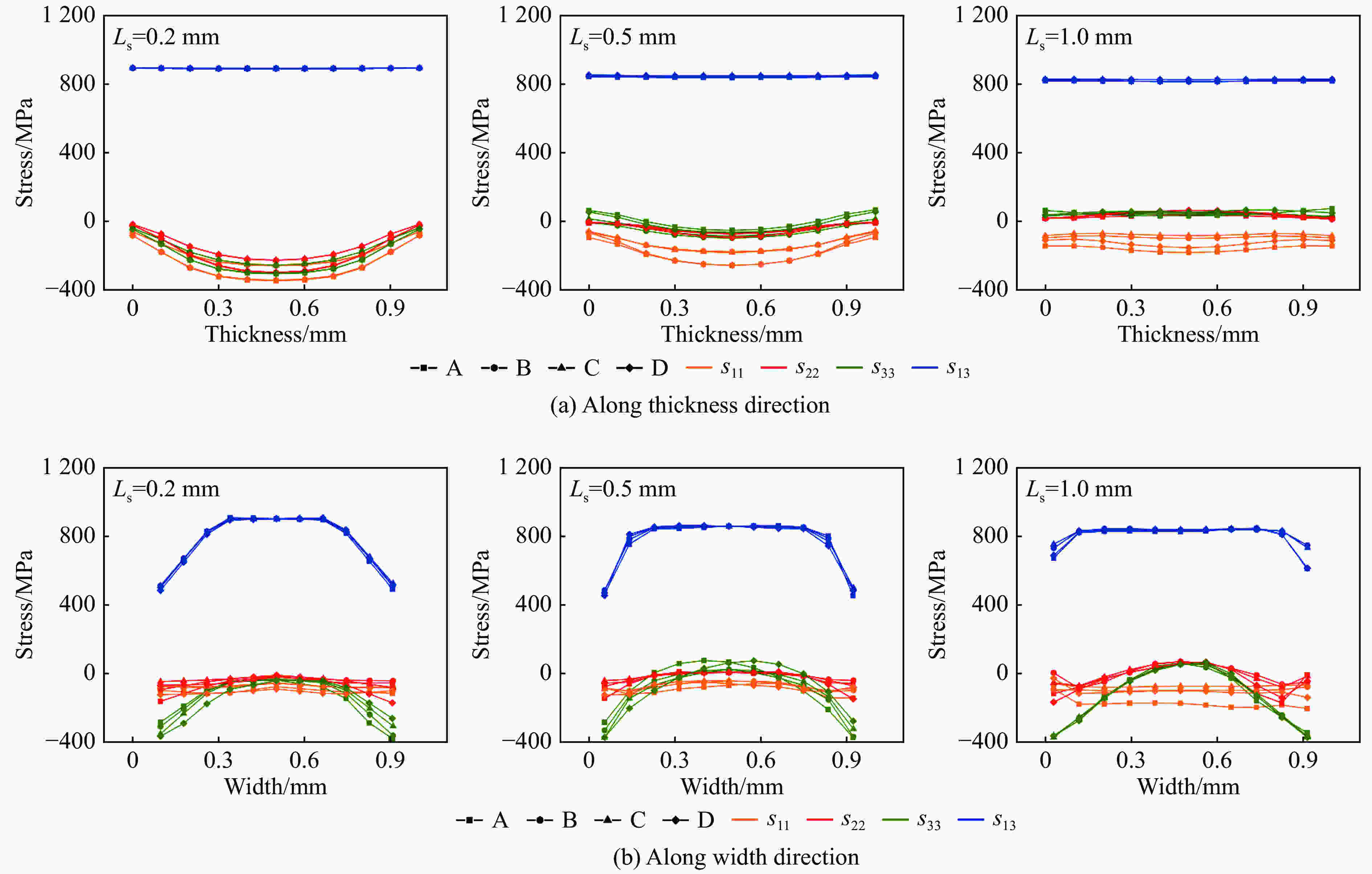

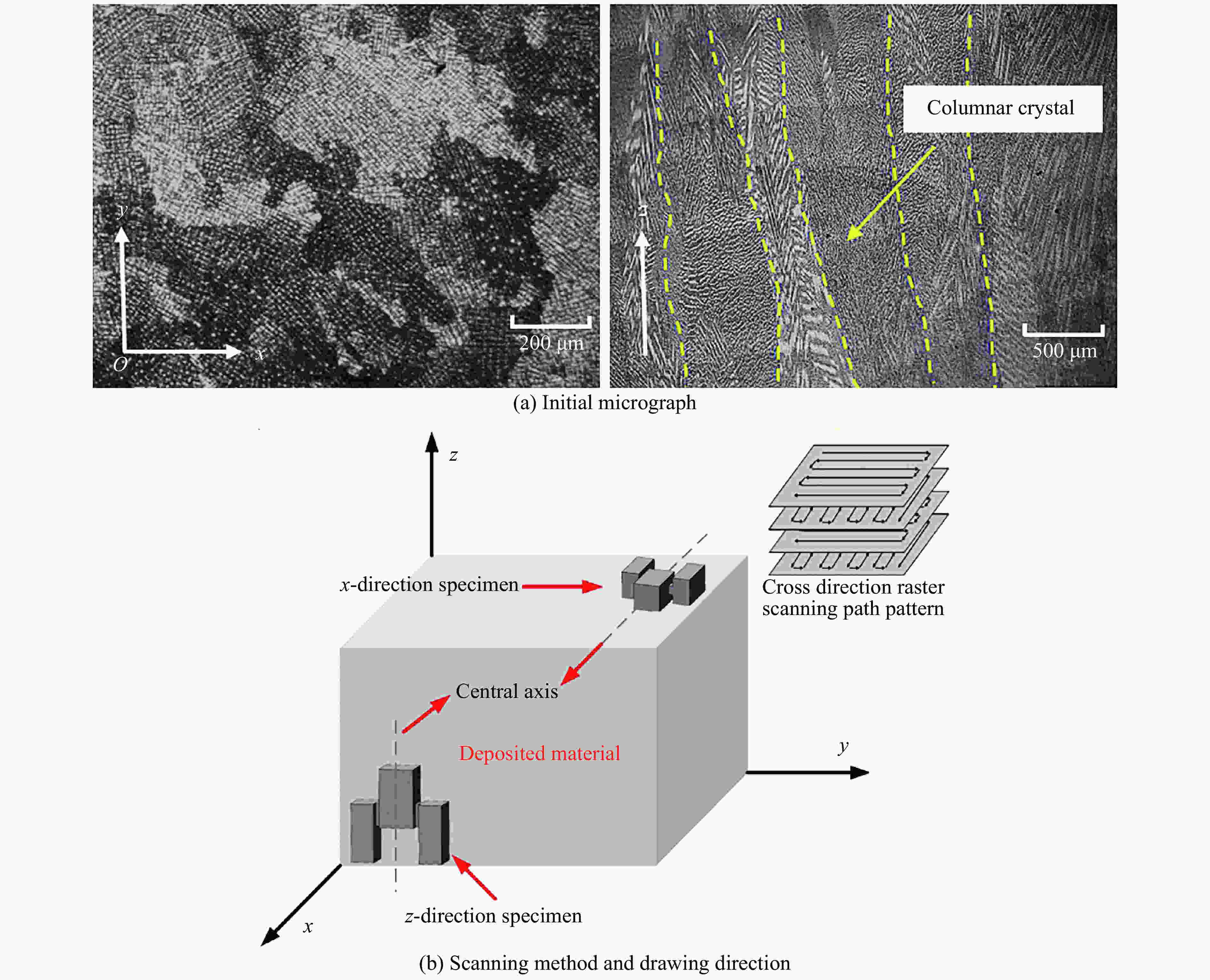

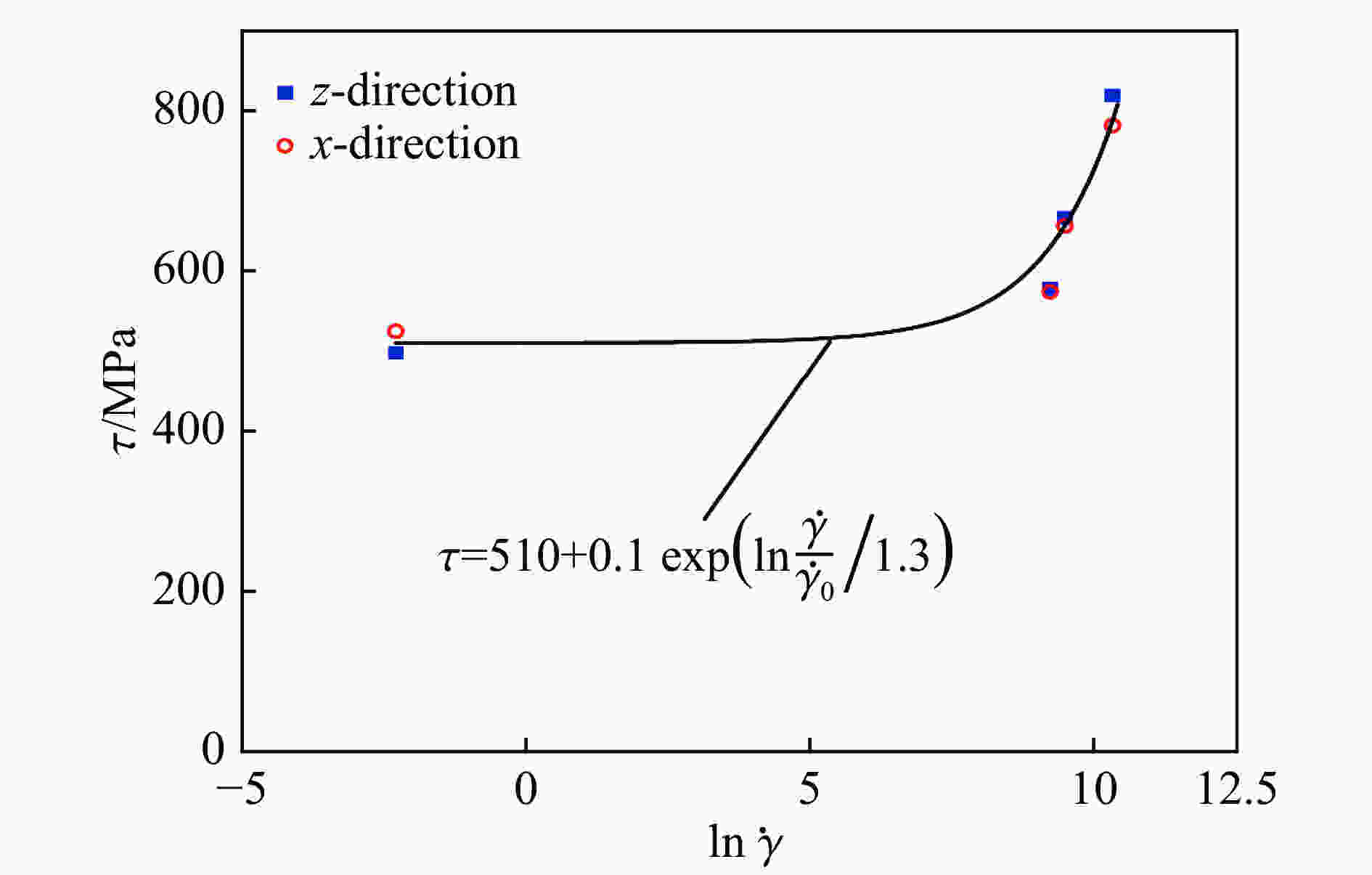

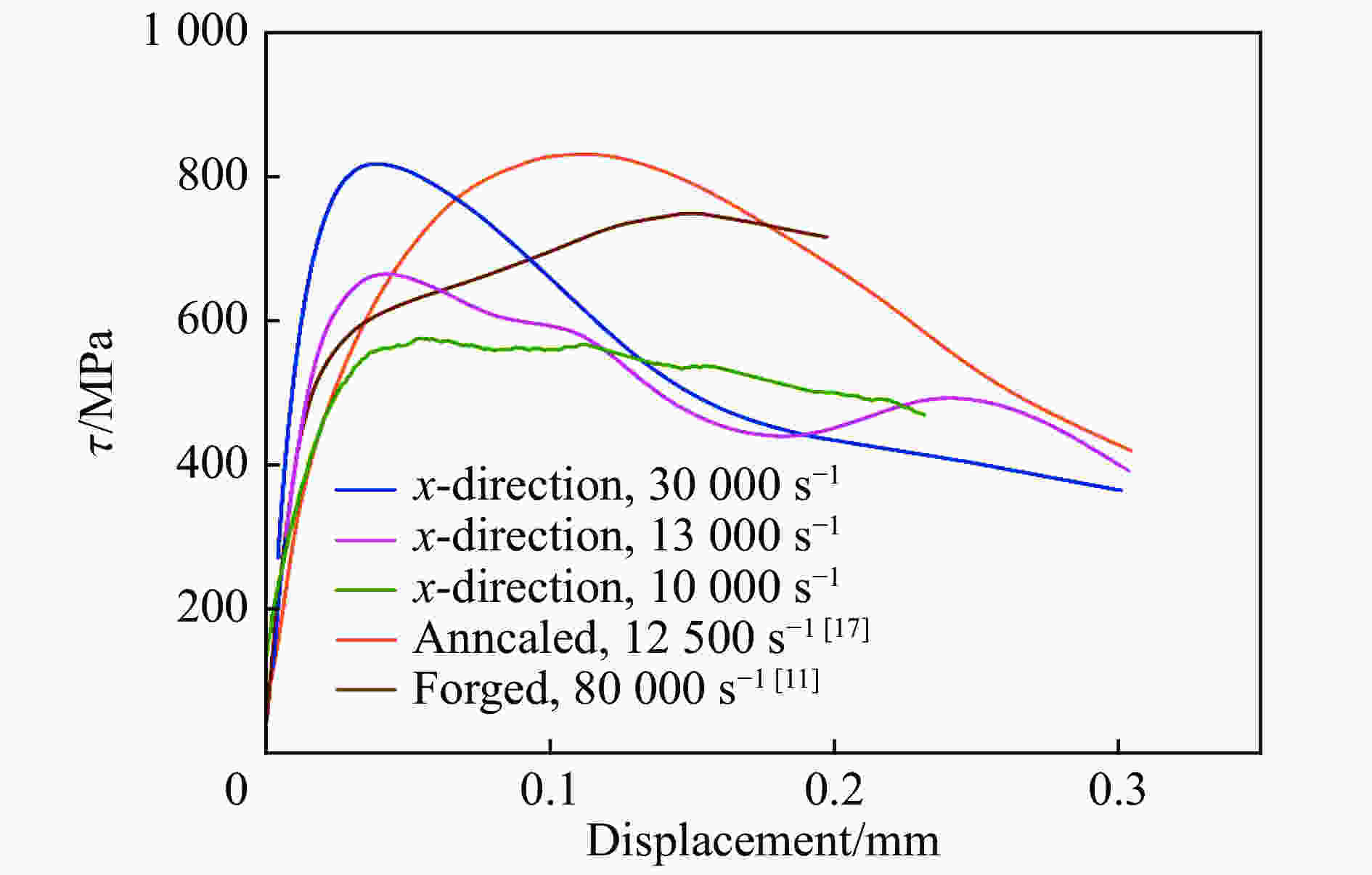

摘要: 为了能在传统的分离式Hopkinson压杆上准确可靠地测试激光金属沉积GH4169的动态剪切特性,基于数值模拟方法对比分析了三种不同动态剪切试样形式及尺寸对剪切区应力分布的影响,结果表明:经过尺寸优化后的双剪切试样的剪切区剪应力占主导地位,可实现近似纯剪切的动态剪切实验。利用此试样形式,系统测试了不同取向(扫描方向、沉积方向)的LMD GH4169试样在不同应变率下的剪切应力应变曲线,并对破坏后试样进行了SEM分析观察。结果表明:(1) 本文中选用的试样形式剪切纯度高,应力沿剪切区宽度厚度分布均匀,可以更好地得到材料的动态剪切特性;(2) 对实验所得剪应力-剪应变曲线进行分析,发现本材料在扫描路径方向和沉积方向并没有表现出明显的各向异性,但随着应变率的增加,具有明显的应变率强化效应;将单轴压缩和动态剪切应力应变曲线同时转换为等效应力应变曲线,对比证实了试样形式能很好反应材料的剪切特性;(3) 通过对LMD GH4169剪切变形破坏试样的微观分析发现,随着应变率升高,断口韧窝尺寸和深度减小,韧性降低,在更小的变形量下容易剪切失效。初始微观缺陷容易导致材料的动态剪切破坏。

-

关键词:

- 激光金属沉积 /

- 高温合金GH4169 /

- 应变率 /

- 动态剪切 /

- 破坏机理

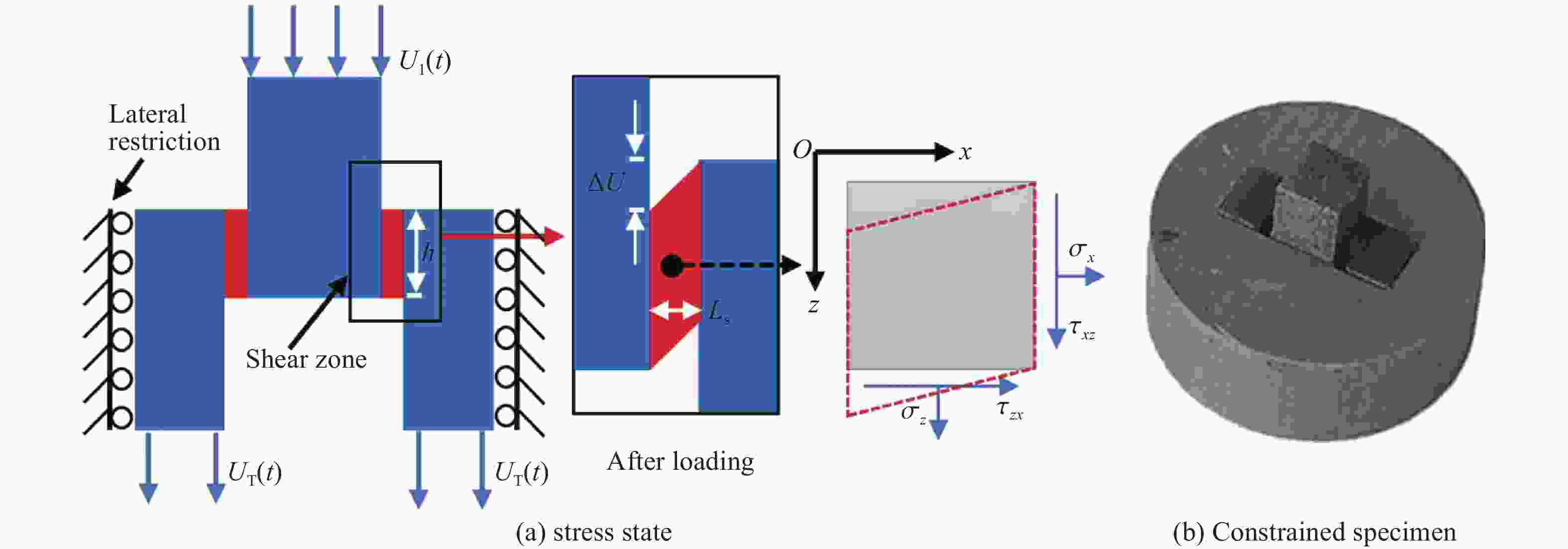

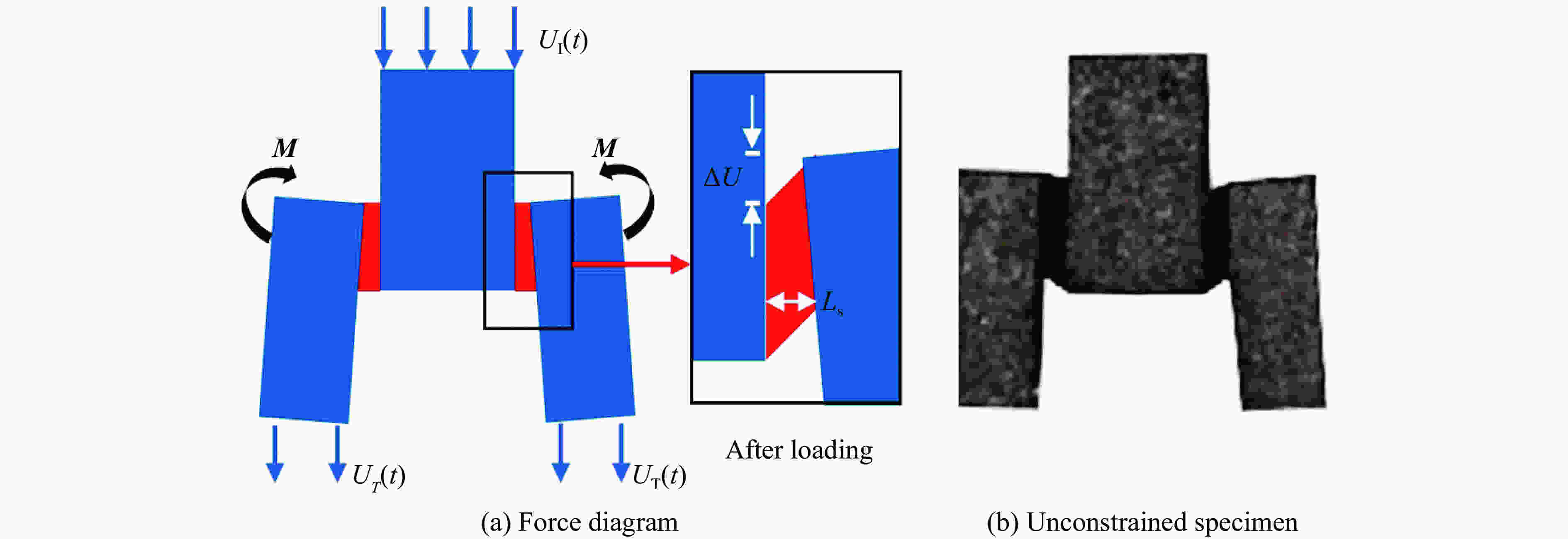

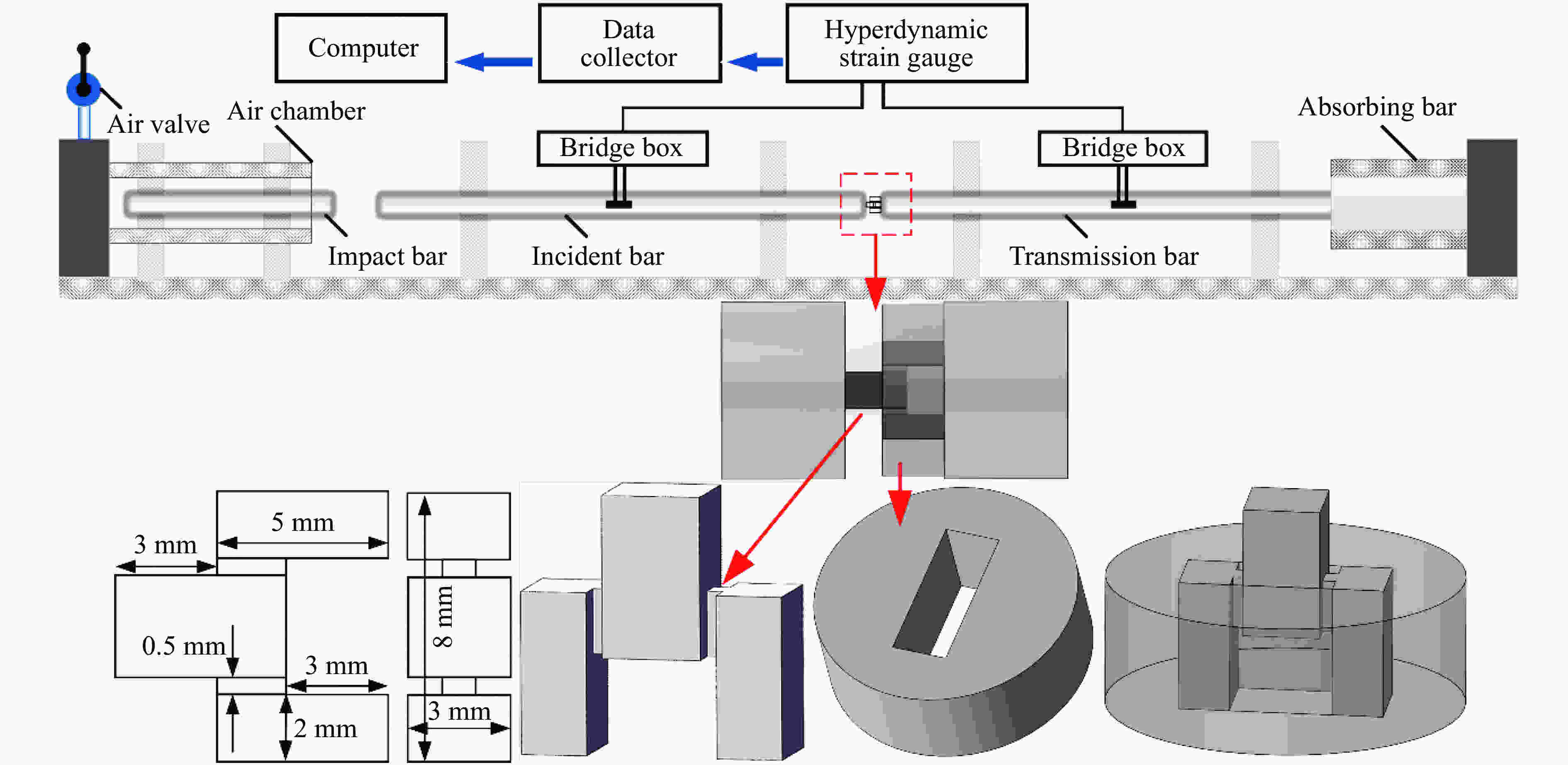

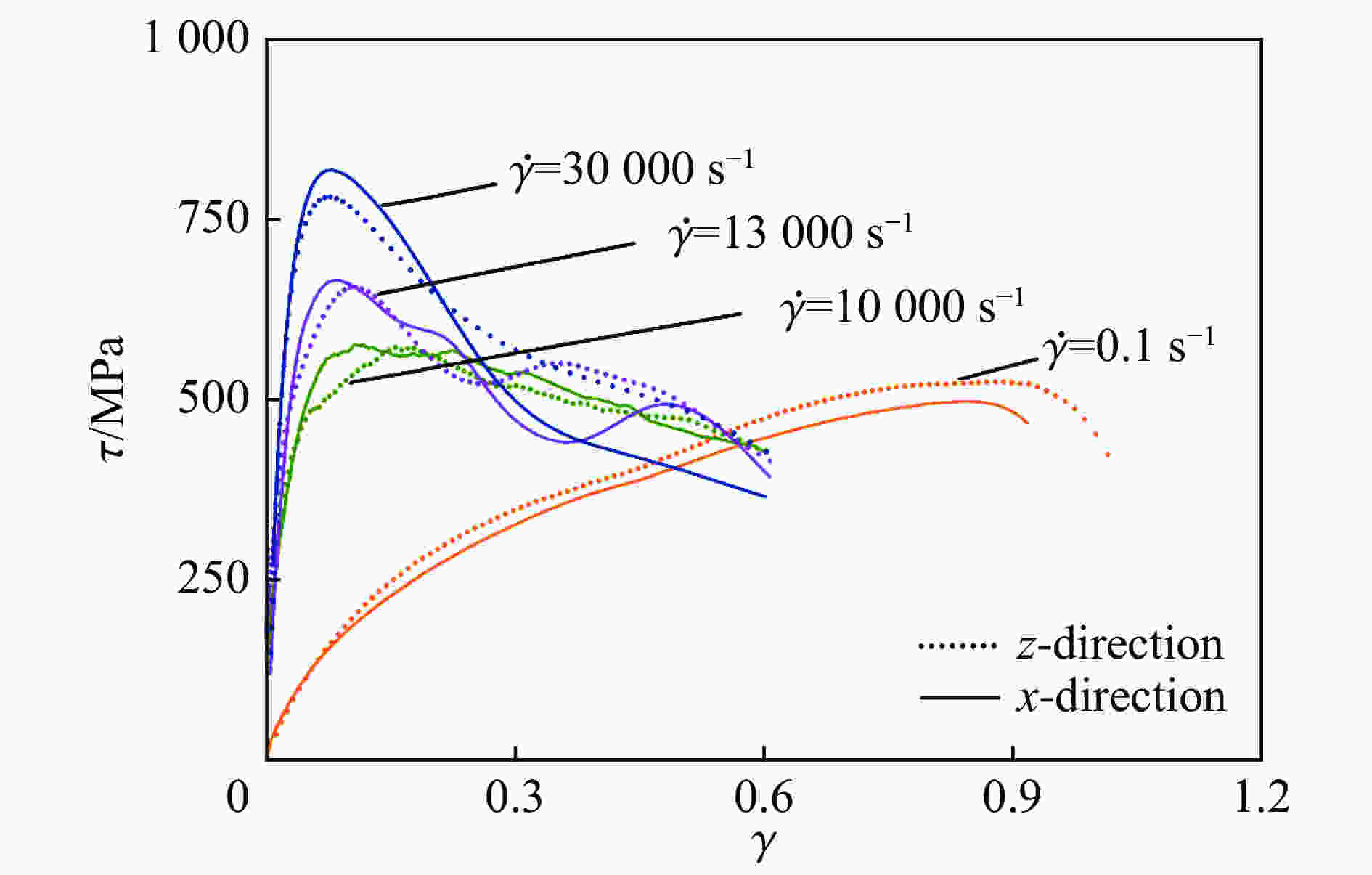

Abstract: In order to accurately and reliably test the dynamic shear characteristics of laser metal deposition GH4169 on a traditional split Hopkinson pressure bar, this study compared the three different dynamic shear sample forms and dimensions to the shear zone stress based on numerical simulation. The influence of the distribution shows that the shear stress of the shear zone of the double shear specimen after optimization is dominant, and the dynamic shear test of approximate pure shear can be realized. Using this specimen form, the shear stress-strain curves of LMD GH4169 specimens with different orientations (scanning direction, deposition direction) at different strain rates were systematically tested, and the specimens were analyzed by SEM. The results show that: (1) the specimen used in this paper has high shear purity and uniform thickness distribution along the shear zone width, which can better obtain the dynamic shear properties of the material; (2) the shear stress-shear strain curves obtained from the experiment were analyzed. It is found that the material shows unobvious anisotropy in the scanning path direction and deposition direction. With the increase of strain rate, it has obvious strain rate strengthening effect; the uniaxial compression and dynamic shear stress-strain curves were simultaneously converted into equivalent stress-strain curves; the comparison confirms that the specimen form in this manuscript can exactly reflect the shear properties of the material; (3) through the microscopic analysis of the shear deformation of LMD GH4169, the size and depth of the fracture dimple decrease as the strain rate increases, and the toughness decreases. The shear failure is easy under a smaller deformation. Initial microscopic defects are likely to cause dynamic shear failure of the material.-

Key words:

- laser metal eeposition /

- GH4169 /

- strain rate /

- dynamic shear /

- fracture mechanism

-

表 1 三种试样尺寸

Table 1. Sizes of three specimens

表 2 材料弹性参数

Table 2. Material elasticity parameters

材料 E/GPa ρ/(kg·m−3) μ 18Ni钢 190 7800 0.3 GH4169 210 8240 0.3 注:E为弹性模量,ρ为密度,μ为泊松比。 A/MPa B/MPa n C m 1241 622 0.6522 0.0134 1.3 表 4 LMD GH4169工艺参数

Table 4. LMD GH4169 process parameters

激光功率/W 扫描速度/(mm·s−1) 送粉速度/(g·min−1) 载粉气流/(L·min−1) 光斑直径/mm 搭接率/% 抬升高度/mm 2200 10 9 7 3 50 0.3 -

[1] BAI Y L, DODD B. Adiabatic shear localization: occurrence, theories, and applications[J]. Oxford University Press, 1992 [2] WANG Z, GUAN K, GAO M, et al. The microstructure and mechanical properties of deposited-IN718 by selective laser melting [J]. Journal of Alloys and Compounds, 2012, 513: 0–523. [3] ZHANG D, FENG Z, WANG C, et al. Comparison of microstructures and mechanical properties of GH4169 alloy pro-cessed by selective laser melting and casting [J]. Materials Science and Engineering: A, 2018, 724(18): 357–367. [4] TROSCH T, JOHANNES S, RAINER V, et al. Microstructure and mechanical properties of selective laser melted GH4169 compared to forging and casting [J]. Materials Letters, 2016, 164: 428–431. [5] QI H, AZER M, RITTER A. Studies of standard heat treatment effects on microstructure and mechanical properties of laser net shape manufactured GH4169 [J]. Metallurgical & Materials Transactions Part A, 2009, 40(10): 2410–2422. [6] YUAN K, GUO W, LI P, et al. Influence of process parameters and heat treatments on the microstructures and dynamic mechanical behaviors of GH4169 superalloy manufactured by laser metal deposition [J]. Materials Science & Engineering A, 2018, 721: 215. [7] LEE W S, LIN C F, CHEN T H, et al. Dynamic shear properties of alloy 718 over wide temperature range [J]. Materials Transactions, 2012, 53(10): 1758–1764. [8] JOHANSSON J, PERSSON C, LAI H, et al. Microstructural examination of shear localisation during high strain rate deformation of alloy 718 [J]. Materials Science and Engineering A, 2016, 662: 363–372. DOI: 10.1016/j.msea.2016.03.080. [9] MURR L E, STAUFHAMMER K P, MEYERS M A, et al. Metallurgical applications of shock-wave and high-strain-rate phenomena [J]. Metallography, 1987, 20(2): 249–250. DOI: 10.1016/0026-0800(87)90034-6. [10] PEIRS J, VERLEYSEN P, DEGRIECK J, et al. The use of hat-shaped specimens to study the high strain rate shear be-haviour of Ti-6Al-4V [J]. International Journal of Impact Engineering, 2010, 37(6): 703–714. DOI: 10.1016/j.ijimpeng.2009.08.002. [11] SONG W D, HU M L, ZHANG H S, et al. Effects of different heat treatments on the dynamic shear response and shear localization in GH4169 alloy [J]. Materials Science and Engineering: A, 2018, 725: 76–87. DOI: 10.1016/j.msea.2018.04.010. [12] 许泽建, 丁晓燕, 张炜琪, 等. 一种用于材料高应变率剪切性能测试的新型加载技术 [J]. 力学学报, 2016, 48(03): 143–148.XU Z J, DING X Y, ZHANG W Q, et al. A new loading technique for measuring shearing properties of materials under high strain rates [J]. Chinese Journal of Theoretical and Applied Mechanics, 2016, 48(03): 143–148. [13] AHMED N, MITROFANOV A V, BABITSKY V I, et al. Analysis of material response to ultrasonic vibration loading in turning GH4169 [J]. Materials Science and Engineering: A, 2006, 424(1−2): 318–325. DOI: 10.1016/j.msea.2006.03.025. [14] 朱龙权, 朱志武, 张光瀚, 等. 霍普金森试验技术及6005A铝合金冲击动态试验 [J]. 成都大学学报(自然科学版), 2018, 37(03): 10–15.ZHU L Q, ZHU Z W, ZHANG G H, et al. Hopkinson experimental technique and 6005A aluminum alloy impact dynamic experimental study [J]. Journal of Chengdu University(Natural Science Edition), 2018, 37(03): 10–15. [15] ZHOU T, WU J, CHE J, et al. Dynamic shear characteristics of titanium alloy Ti-6Al-4V at large strain rates by the split Hopkinson pressure bar test [J]. International Journal of Impact Engineering, 2017, 109: 167–177. DOI: 10.1016/j.ijimpeng.2017.06.007. [16] CULVER R S. Thermal instability strain in dynamic plastic deformation [M] // Metallurgical Effects at High Strain Rates. Boston, MA: Springer, 1973: 519-530. DOI: 10.1007/978-1-4615-8696-8_29 [17] DEMANGE J J, PRAKASH V, PEREIRA J M. Effects of material microstructure on blunt projectile penetration of a nickel-based super alloy [J]. International Journal of Impact Engineering, 2009, 36(8): 1027–1043. DOI: 10.1016/j.ijimpeng.2009.01.007. -

下载:

下载: