Penetration characteristics of jacketed rods into semi-infinite steel targets

-

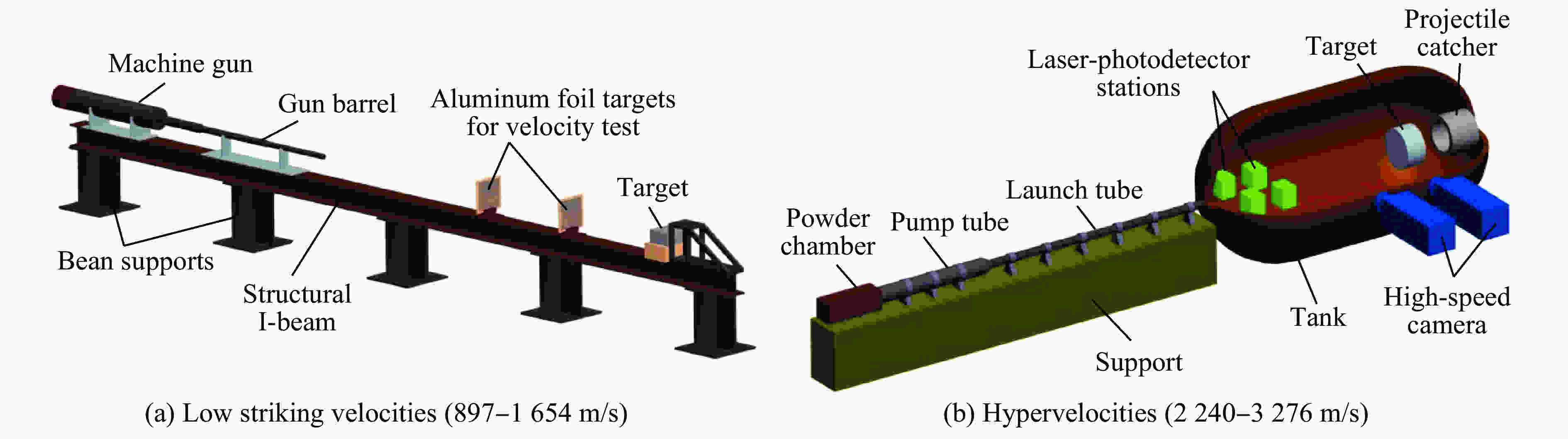

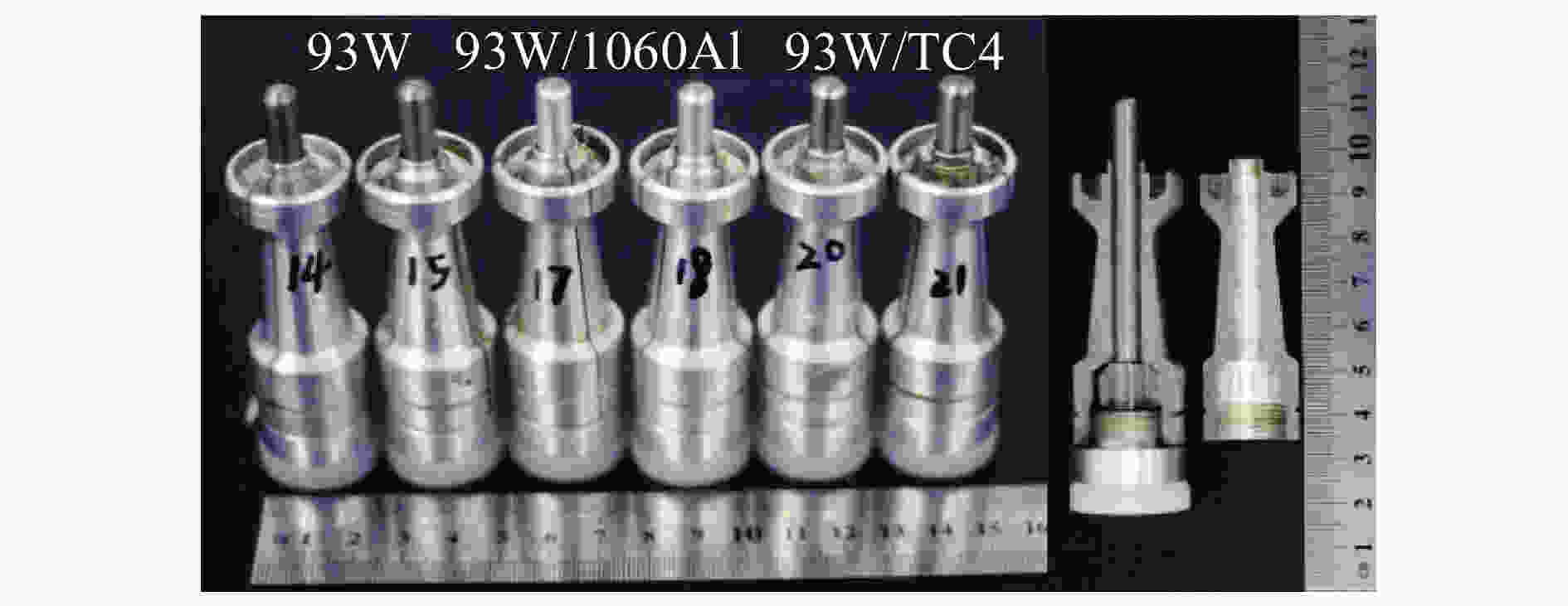

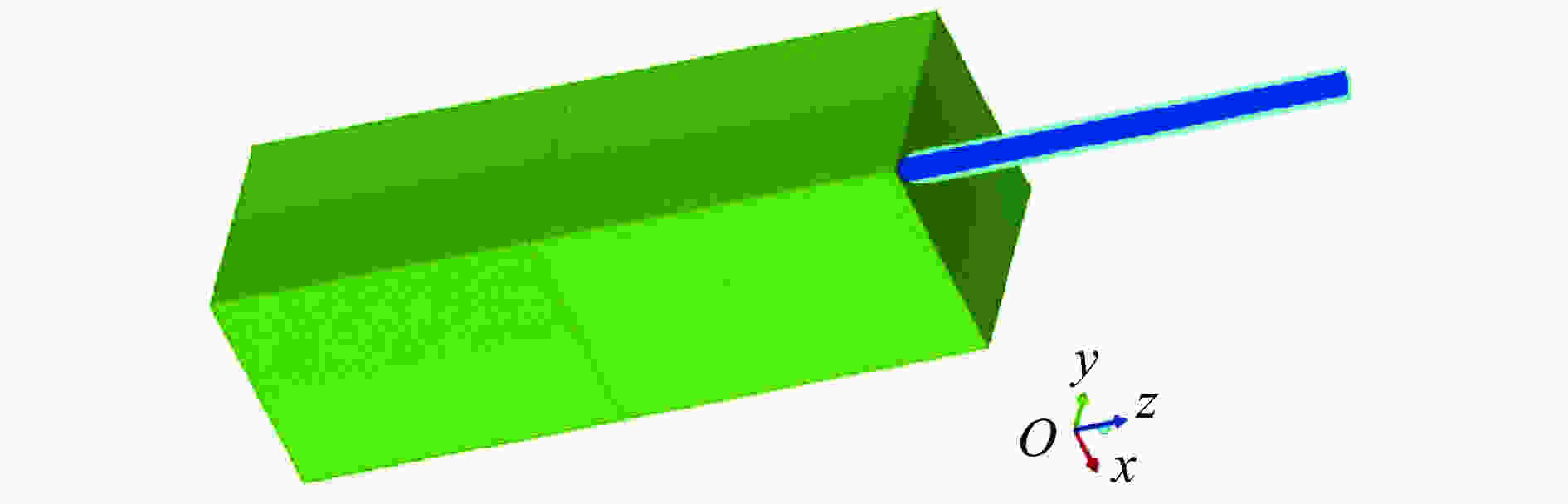

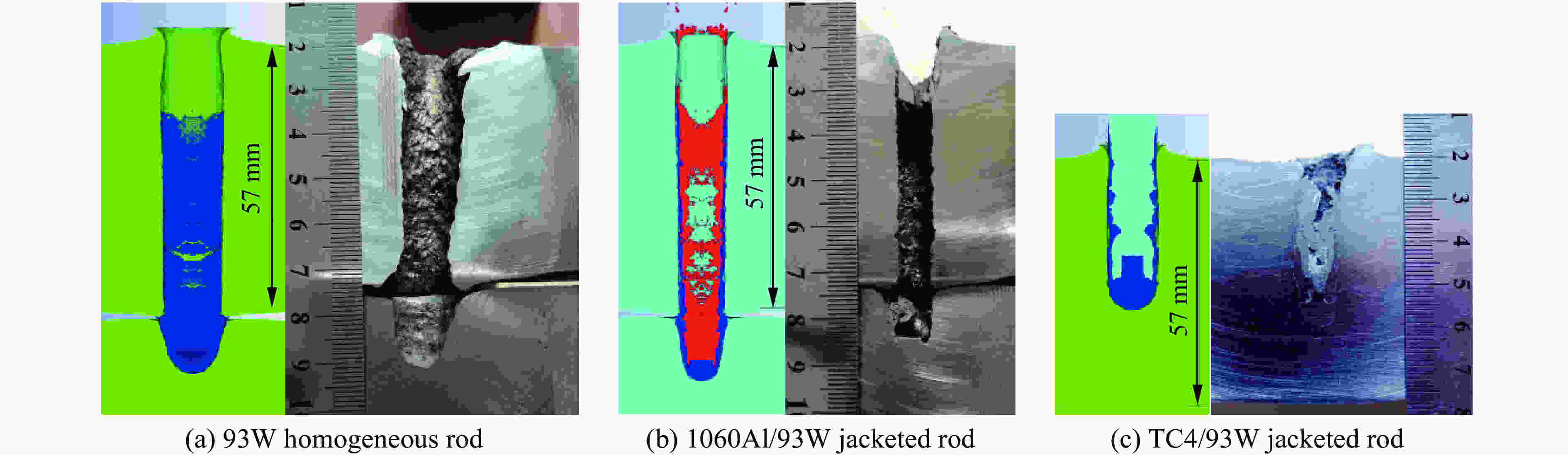

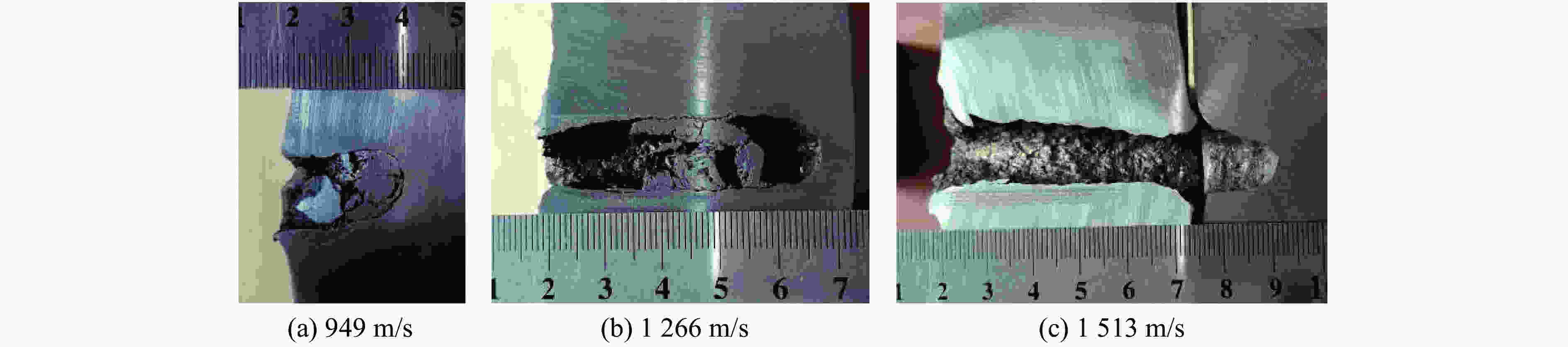

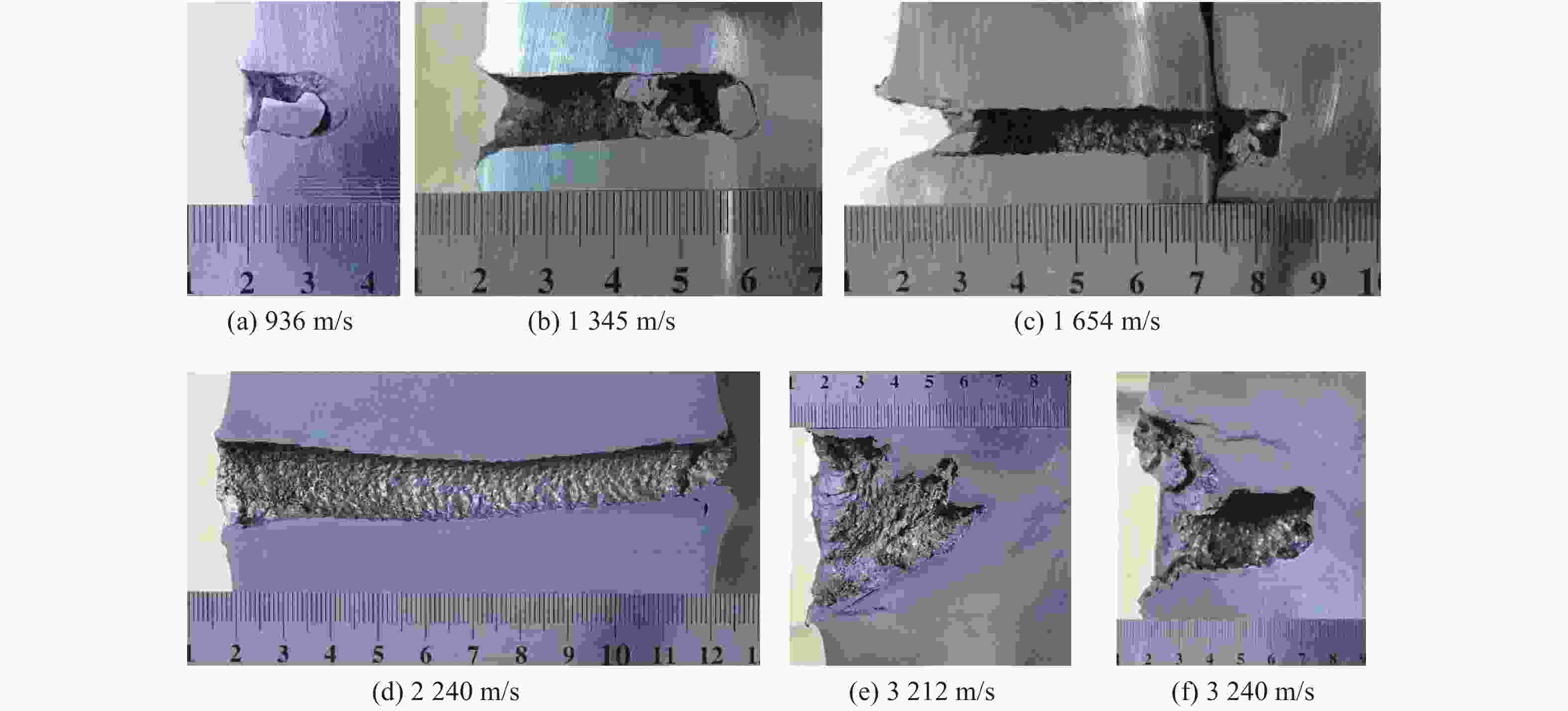

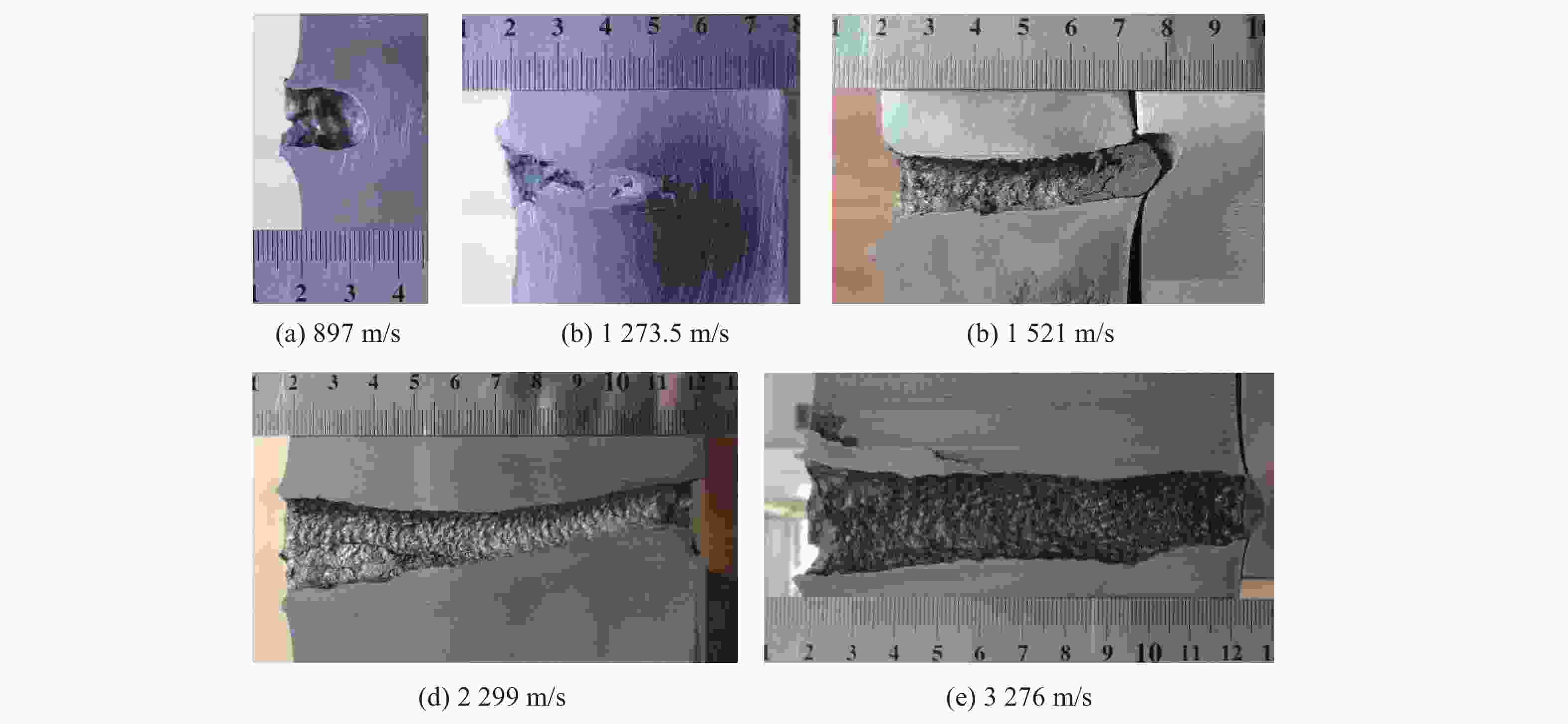

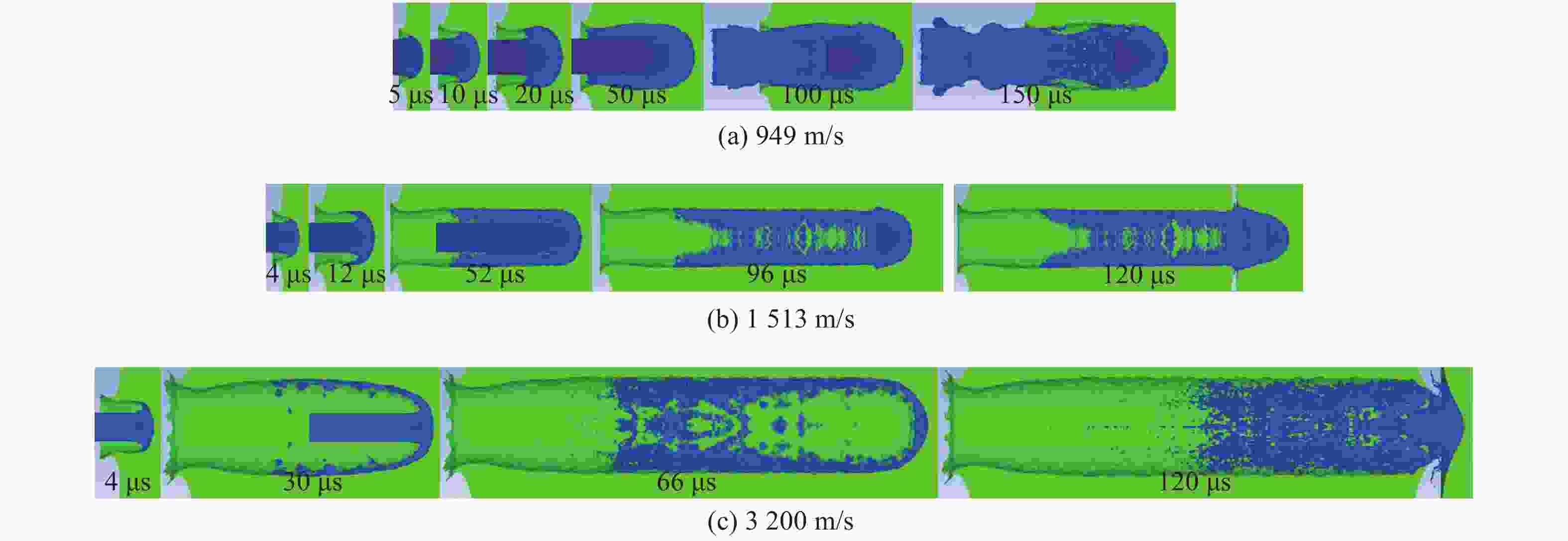

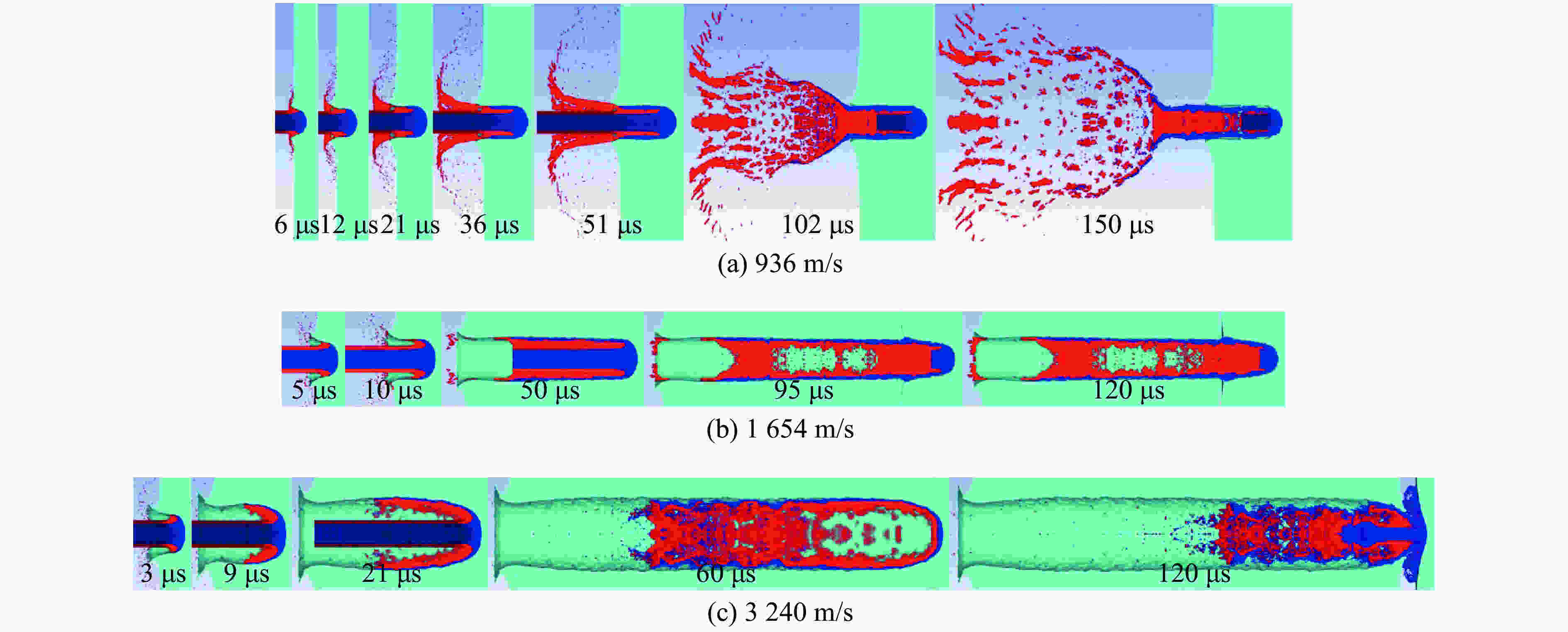

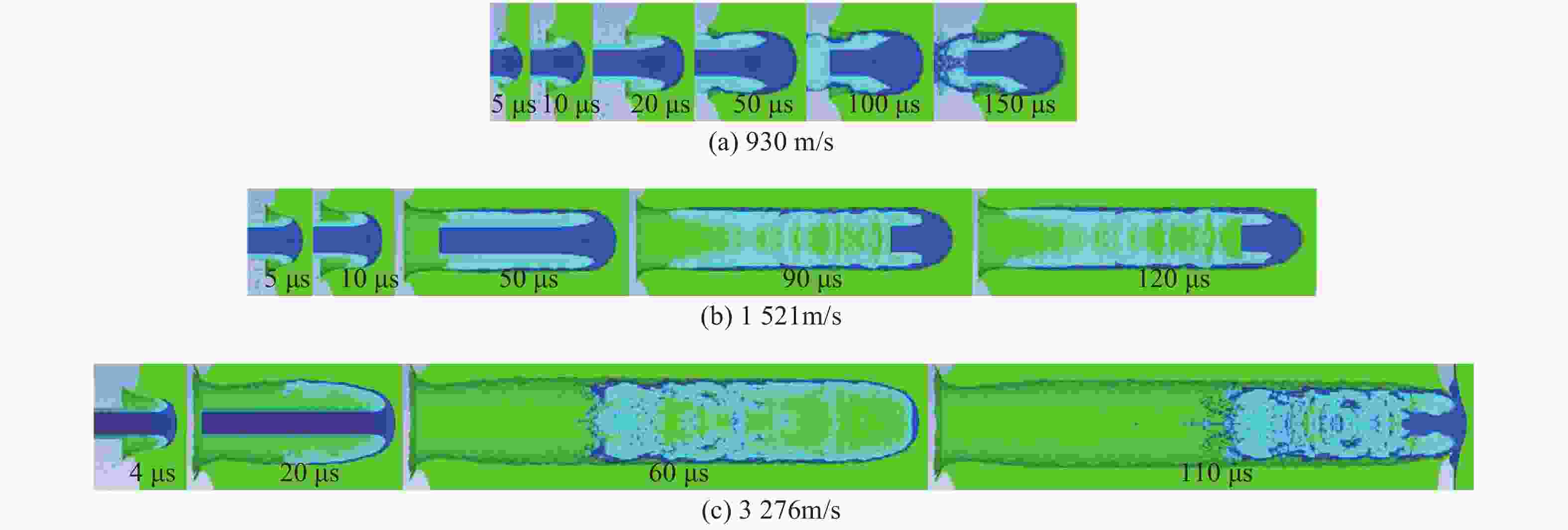

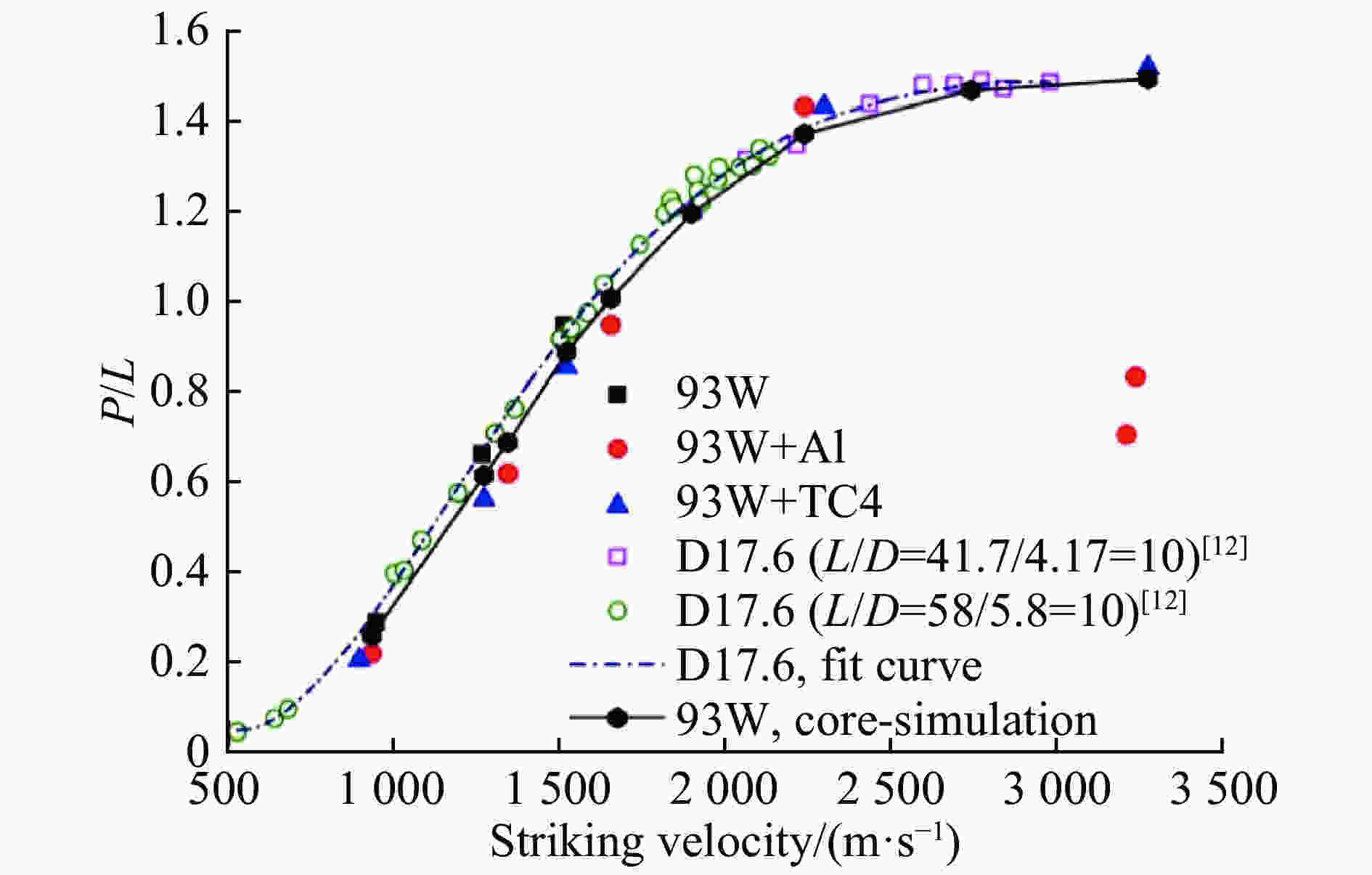

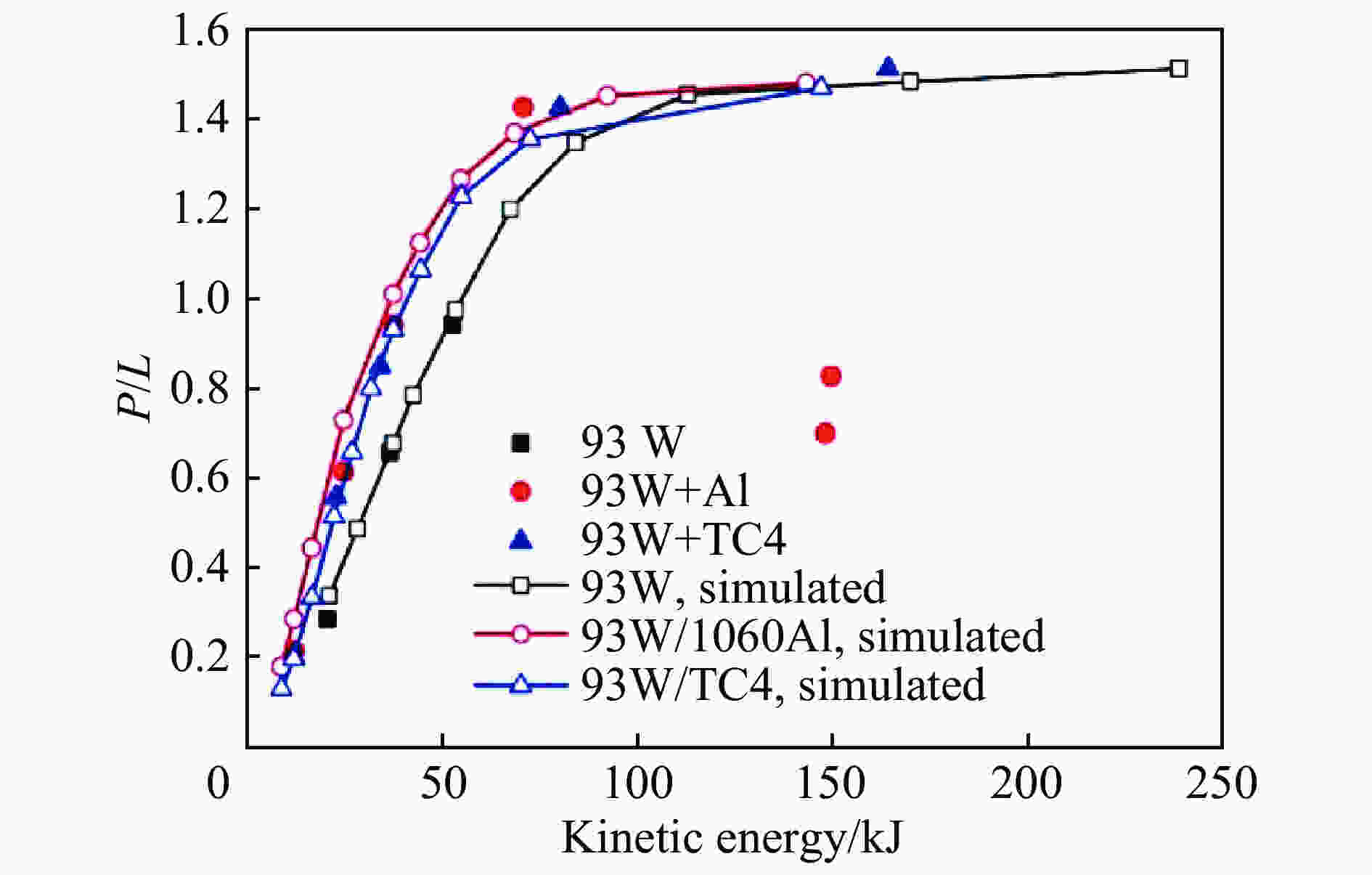

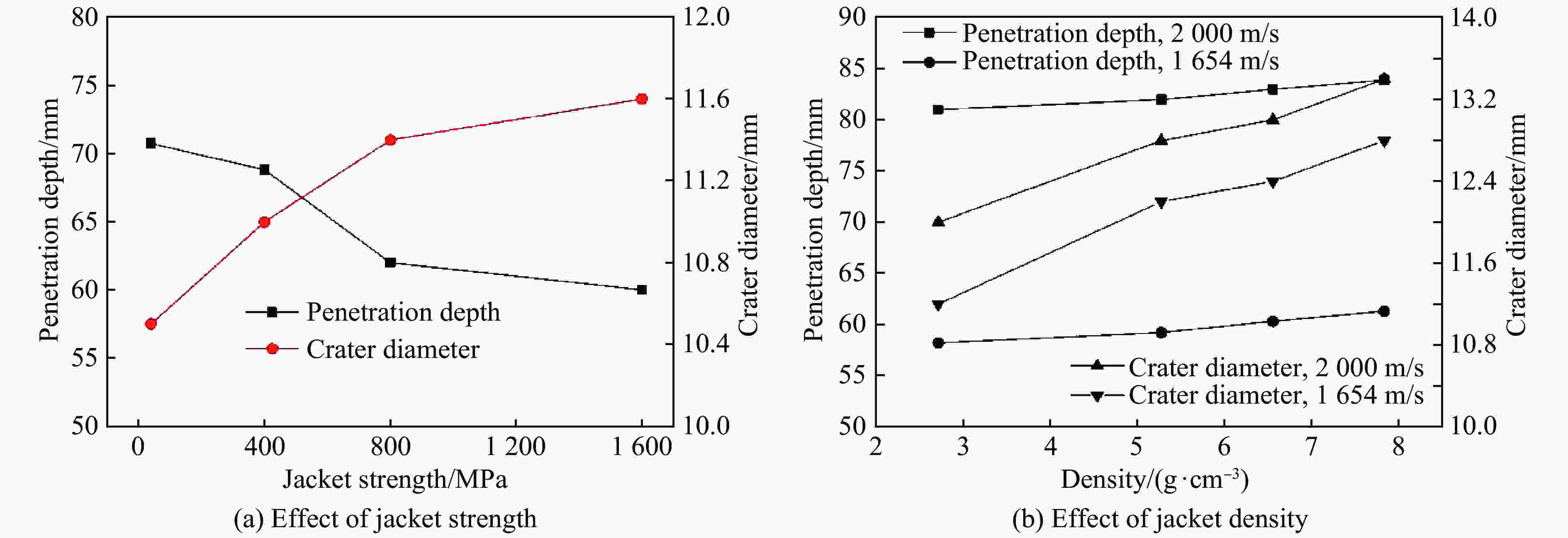

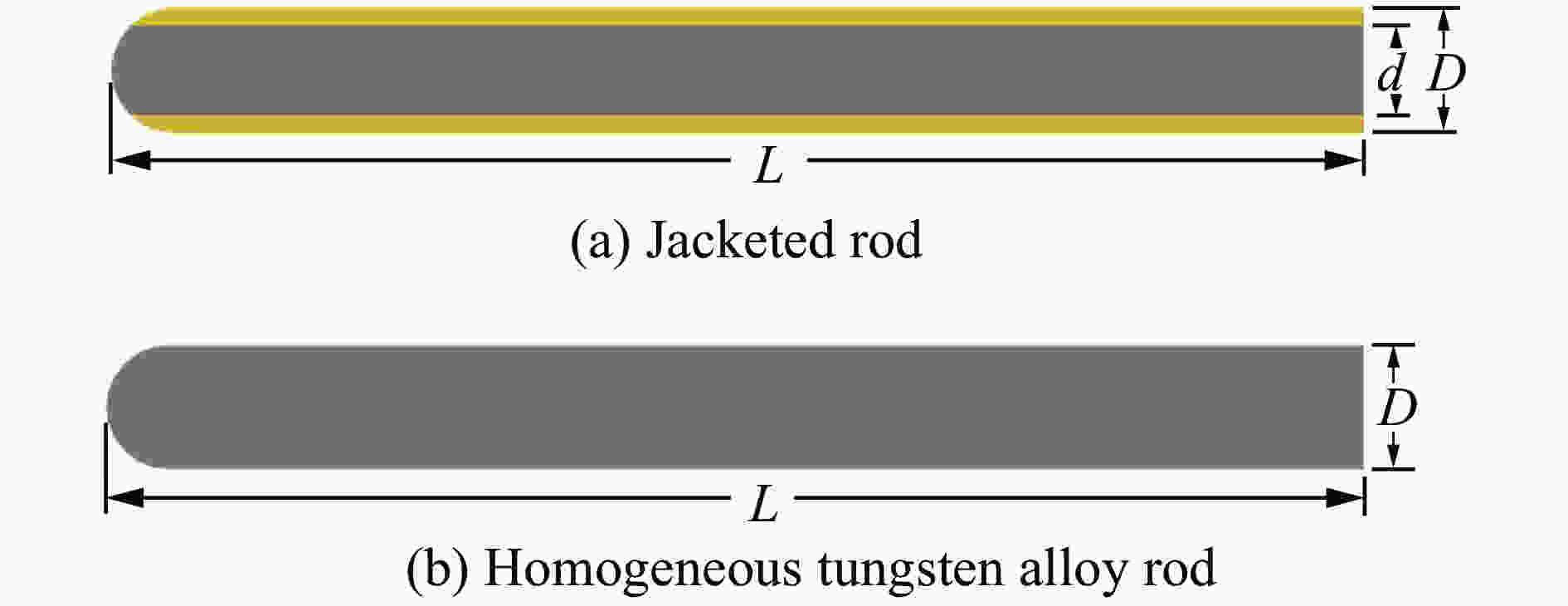

摘要: 为研究夹心长杆弹在较大速度范围内的失效机理、侵彻性能及影响因素,在较大着靶速度(0.9~3.3 km/s)下开展了两种夹心弹侵彻半无限厚4340钢靶的弹道实验,并结合数值模拟方法进行了深入分析。实验和数值模拟结果表明:超高速(>2.0 km/s)条件下,均质钨合金弹和夹心弹均呈现出显著的流体动力学侵彻特性;中低速度(0.9~1.8 km/s)条件下,均质钨合金弹始终呈现出典型的“蘑菇头”失效,而夹心弹始终呈现出“co-erosion”失效;特别地,初速为936 m/s时,1060铝外套夹心弹的失效模式由初始的“bi-erosion”在后期转变为“co-erosion”。在实验速度范围内,中低速度下,夹心弹的侵彻性能低于均质钨合金弹;而在超高速条件下,两者的侵彻性能基本一致。然而,初始入射动能相同时,夹心弹的侵彻性能显著优于均质钨合金弹;与外套材料的密度相比,其强度对夹心弹侵彻性能的影响更显著,且外套材料强度越小,弹体的侵彻性能越好。综合分析可知,进行夹心弹设计时,应优先选取密度小、强度适中的材料作为外套材料。Abstract: To found out the damage mechanism, penetration performance, and the effect factors on the penetration performance of the jacketed rod, two kinds of jacketed rods are penetrated into the semi-infinite 4340 steel targets with striking velocities in the range of 0.9−3.3 km/s experimentally and numerically. Based on the experimental and numerical results, it was found that both homogeneous tungsten alloy rod and jacketed rods presents typical hydrodynamic penetration characteristics under hypervelocity (>2.0 km/s) penetration. While the homogeneous tungsten alloy rod formed a “mushroom head” and the jacketed rods presented typical “co-erosion” damage mode during penetration process under low and medium striking velocity (0.9−1.8 km/s) conditions. Specially, the failure mode of the 1060Al/93W jacketed rod changed from the initial “bi-erosion” to the later “co-erosion”, while the striking velocity equals to 936 m/s. In the experimental speed range, the penetration performance of the jacketed rod is lower than that of the homogeneous tungsten alloy rod at low and medium striking velocities, and the penetration performance of the two is basically the same under hypervelocity conditions. However, the penetration performance of the jacketed rod is significantly better than that of the homogeneous tungsten alloy rod when the initial striking kinetic energy is the same. Compared to density, strength of the jacket has a more significant effect on the penetration performance of the jacketed rod, and the smaller the strength of the jacket material, the better the penetration performance is. According to the above analysis, it can be concluded that for a fixed ratio of the jacket radius to the core radius, it is preferred to use a jacket material with a lower density and a moderate strength.

-

Key words:

- jacketed rod /

- semi-infinite target /

- damage mechanism /

- penetration performance

-

表 1 弹靶材料模型和状态方程

Table 1. Constitutive model and equation of state for projectile and target materials

表 2 钨合金和4340钢材料参数

Table 2. Material parameters for 93W and 4340 steel

材料 ρ/

(g·cm−3)G0/

GPaA/

GPaB/

MPan C m Tm0/

Kc1 /

(m·s−1)S1 γ0 Tr /

KK /

GPac /

(J·(kg·K)−1)93W 17.6 160.0 1.51 177 0.12 0.016 1.00 1 723 4 029 1.237 1.54 300 − 134 4340钢 7.83 81.8 0.835 510 0.26 0.014 1.03 1 793 − − − 300 159 477 表 3 外套材料参数

Table 3. Material parameters for jacket materials

材料 ρ /

(g·cm−3)G0 /

GPaσ0 /

GPaTm0 /

Kc1 /

(m·s−1)S1 dG/dP (dG/dT)/

(GPa·K−1)dY/dP β n γ0 σm/

GPaTC4 4.42 41.9 1.33 2 110 5 130 1.028 0.481 9 −2.698×10−2 0.015 3 12.0 0.1 1.23 2.12 1060铝 2.70 27.1 0.04 1 220 5 386 1.339 1.767 −1.669×10−2 0.002 6 400 0.27 1.97 0.048 -

[1] ERNST H J, LANZ W, WOLF T. Penetration comparison of L/D=20 and 30 mono-block penetrators with L/D=40 jacketed penetrators in different target materials [C] // ROSE I, MARTI F. Proceedings of 19th International Symposium of Ballistics. Interlaken, Switzerland: Casino Kursaal Congress Center, 2001: 1151−1158. [2] LEHR H F, WOLLMAN E, KOERBER G. Experiments with jacketed rods of high fineness ratio [J]. International Journal of Impact Engineering, 1995, 17: 517–526. DOI: 10.1016/0734-743X(95)99876-S. [3] PEDERSEN B A, BLESS S J, CAZAMIAS J U. Hypervelocity jacketed penetrators [J]. International Journal of Impact Engineering, 2001, 26(1−10): 603–611. DOI: 10.1016/S0734-743X(01)00121-X. [4] ANDERSSON O, OTTOSSON J. High velocity jacketed long rod projectiles hitting oblique steel plates [C] // ROSE I, MARTI F. Proceedings of the 19th International Symposium on Ballistics. Interlaken, Switzerland: Casino Kursaal Congress Center, 2001: 1241−1247. [5] PESKES G J J M, LANZ W. Evaluation of replica scale jacketed penetrators for tank ammunition [C] // ROSE I, MARTI F. Proceedings of the 19th International Symposium on Ballistics. nterlaken, Switzerland: Casino Kursaal Congress Center, 2001: 1223−1229. [6] CULLIS I G, LYNCH N J. Hydrocode and experimental analysis of scale size jacketed KE projectiles [C] // ROSE I, MARTI F. Proceedings of the 19th International Symposium on Ballistics. Casino Kursaal Congress Center, 1993: 271−280. [7] JOHNSON G R, COOK W H. A constitutive model and data for metals subjected to large strains, high strain rates and high temperature [C] // PASMAN H. Proceedings of the 7th International Symposium on Ballistics. The Hague, Netherlands, 1983: 541−547. [8] STEINBERG D J, COCHRAN S G, GUINAN M W. A constitutive model for metals applicable at high strain rate [J]. Journal of Applied Physics, 1980, 51: 1498–1504. DOI: 10.1063/1.327799. [9] AUTODYN, Theory manual revision 4.3 [Z]. Concord, Mass, USA: Century Dynamics, 2005. [10] LEE M. Analysis of jacketed rod penetration [J]. International Journal of Impact Engineering, 2000, 24(9): 891–905. DOI: 10.1016/S0734-743X(00)00020-8. [11] 荣光, 黄德武. 钨纤维复合材料穿甲弹芯侵彻时的自锐现象 [J]. 爆炸与冲击, 2009, 29(4): 351–355. DOI: 10.11883/1001-1455(2009)04-0345-06.RONG G, HUANG D W. Self-sharpening phenomena of tungsten fiber composite material penetrators during penetration [J]. Explosion and Shock Waves, 2009, 29(4): 351–355. DOI: 10.11883/1001-1455(2009)04-0345-06. [12] HOHLER V, STILP A J. Hypervelocity impact of rod projectiles with L/D from 1 to 32 [J]. International Journal of Impact Engineering, 1987, 5(1−4): 323–331. DOI: 10.1016/0734-743X(87)90049-2. -

下载:

下载: