Ballistic behavior of tungsten fiber/metallic glass matrix composite segmented rods

-

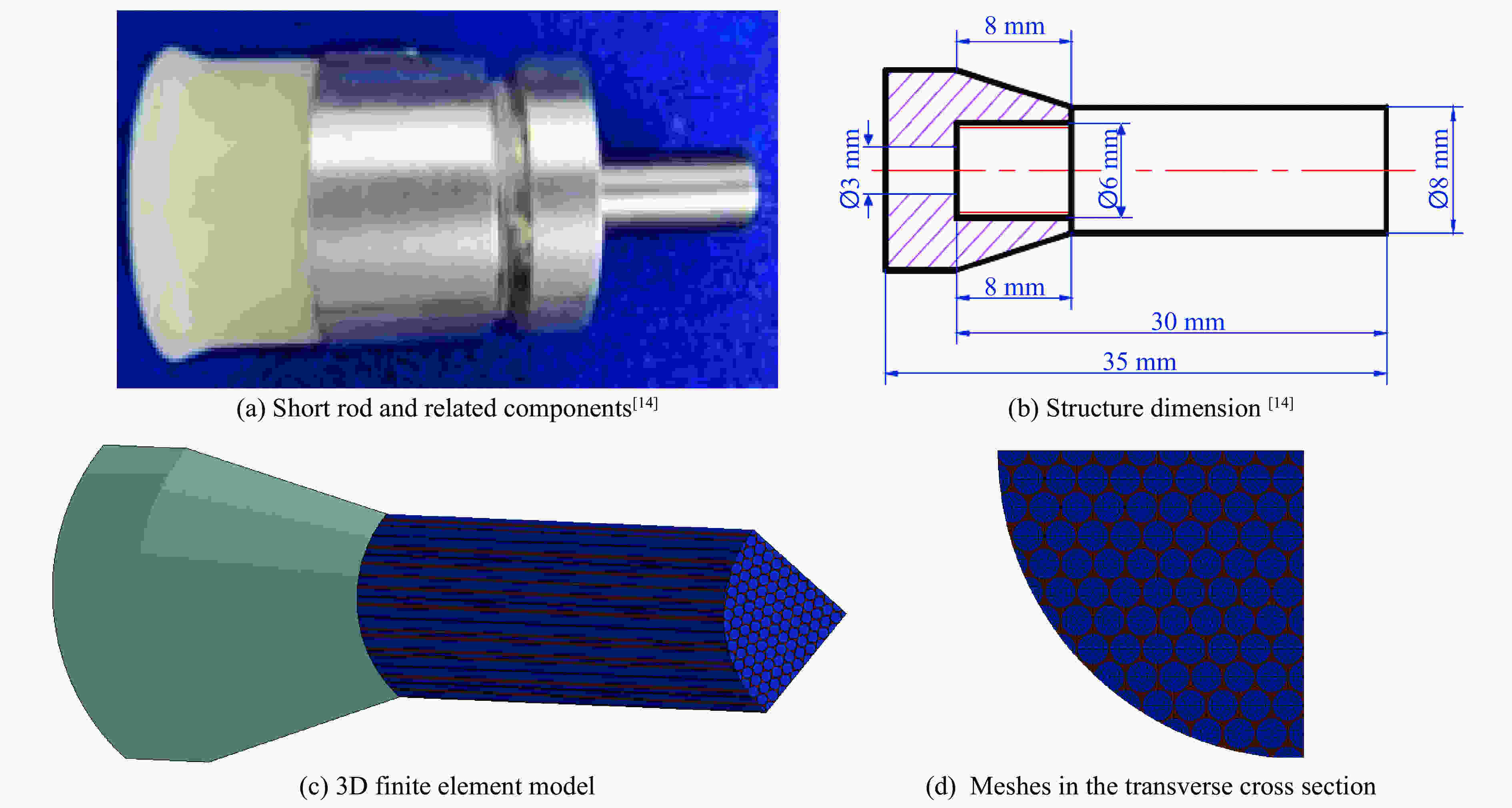

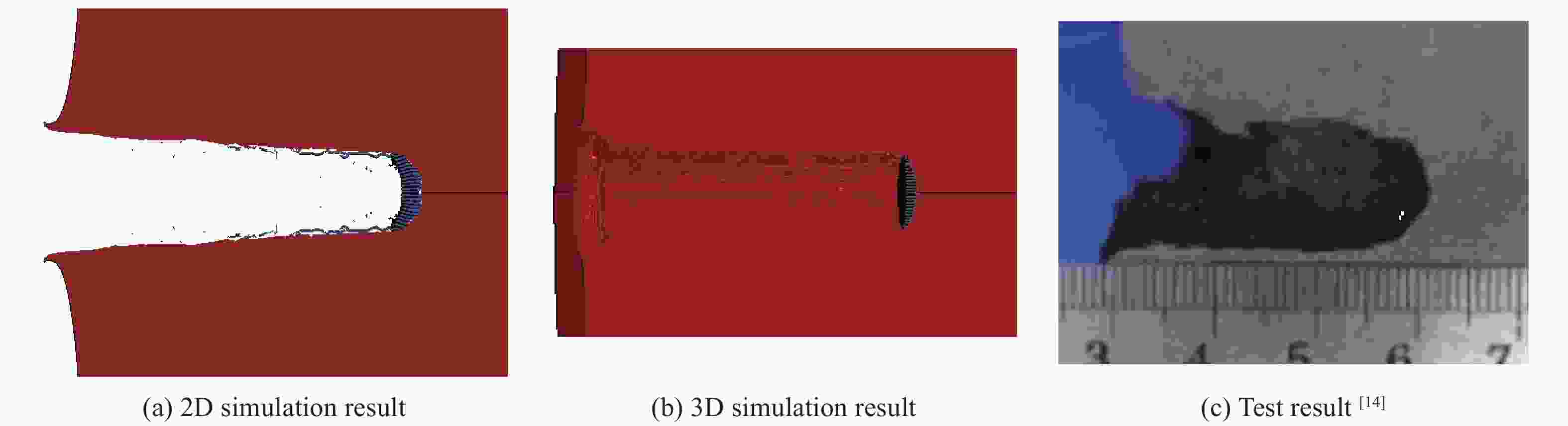

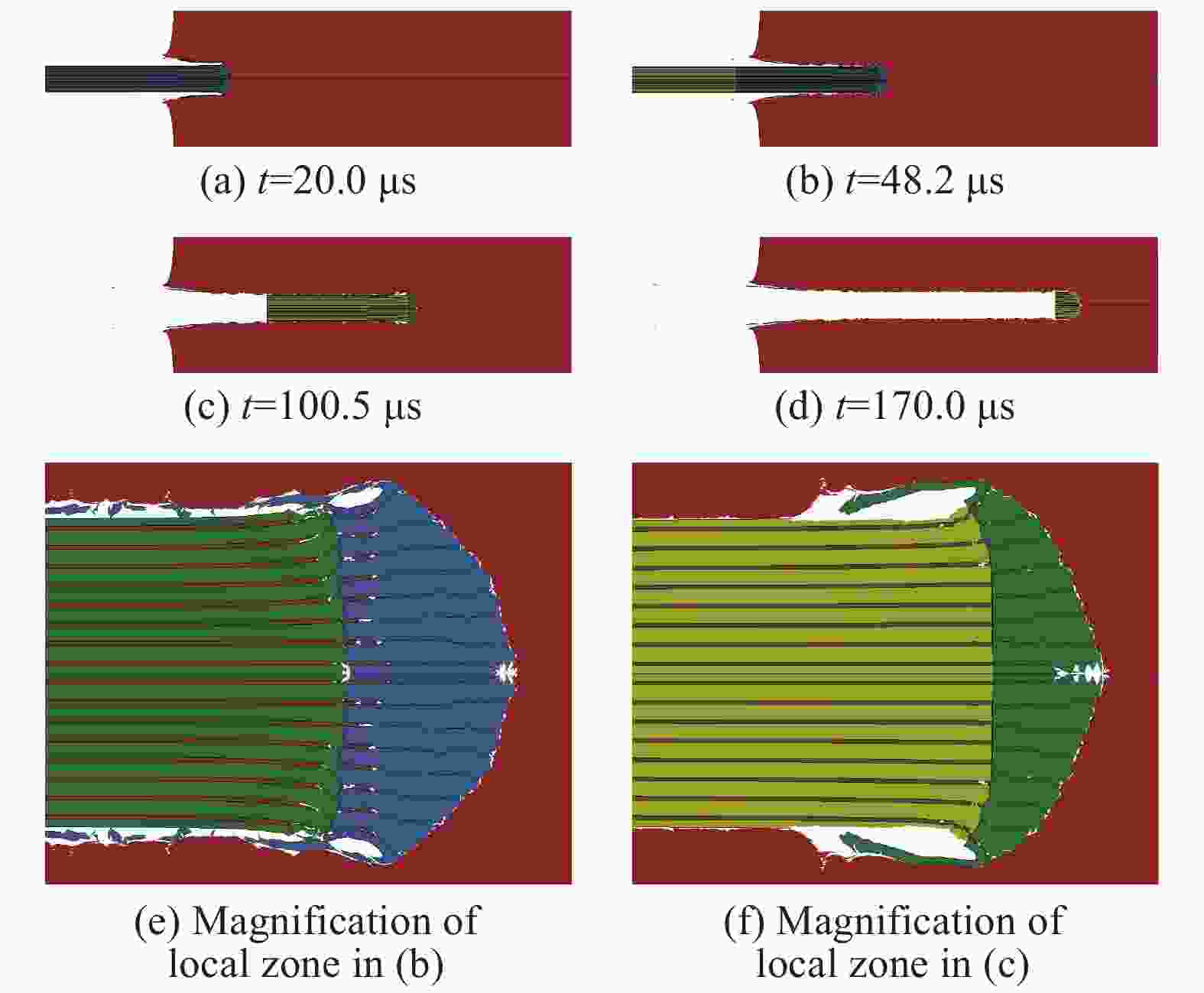

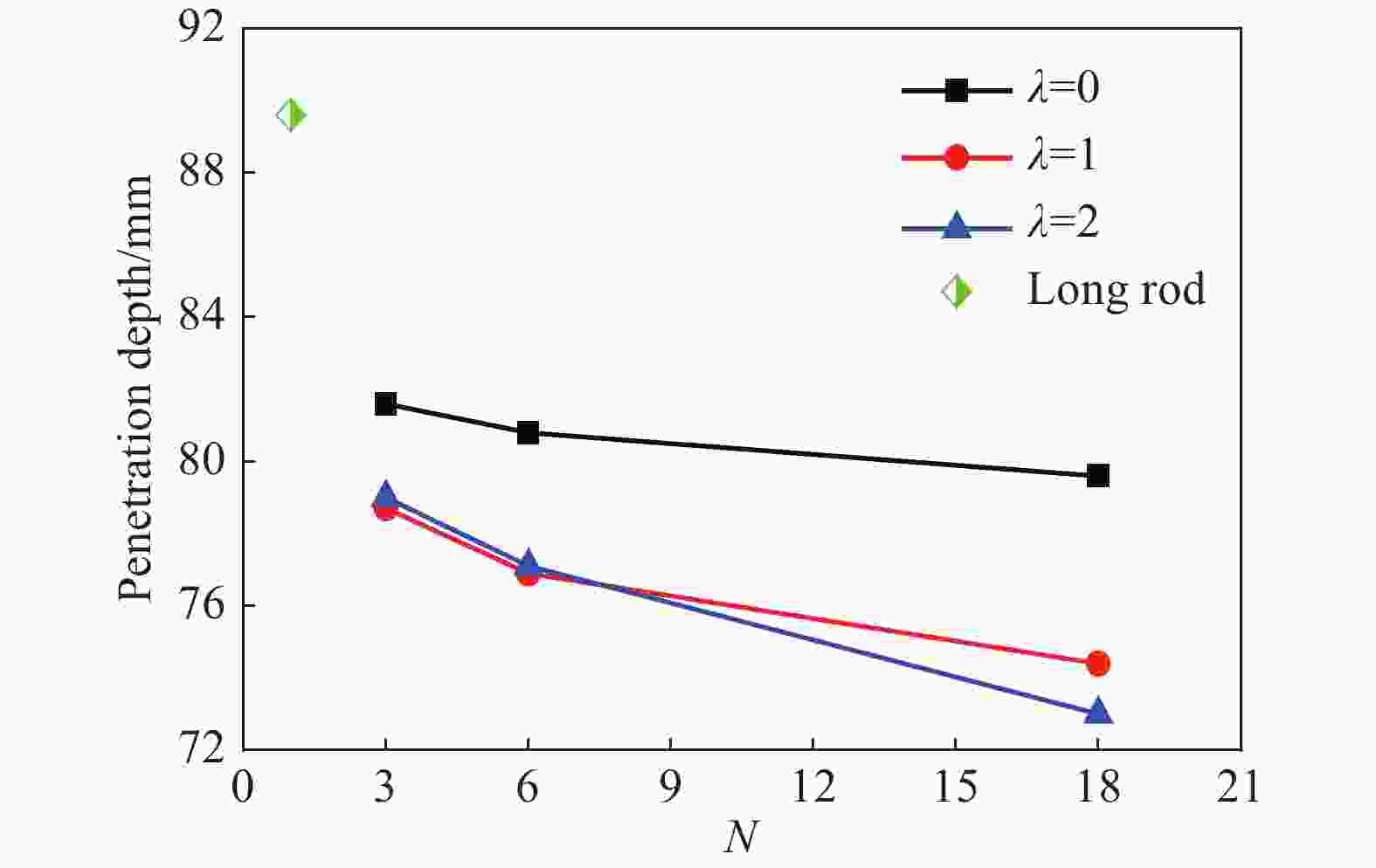

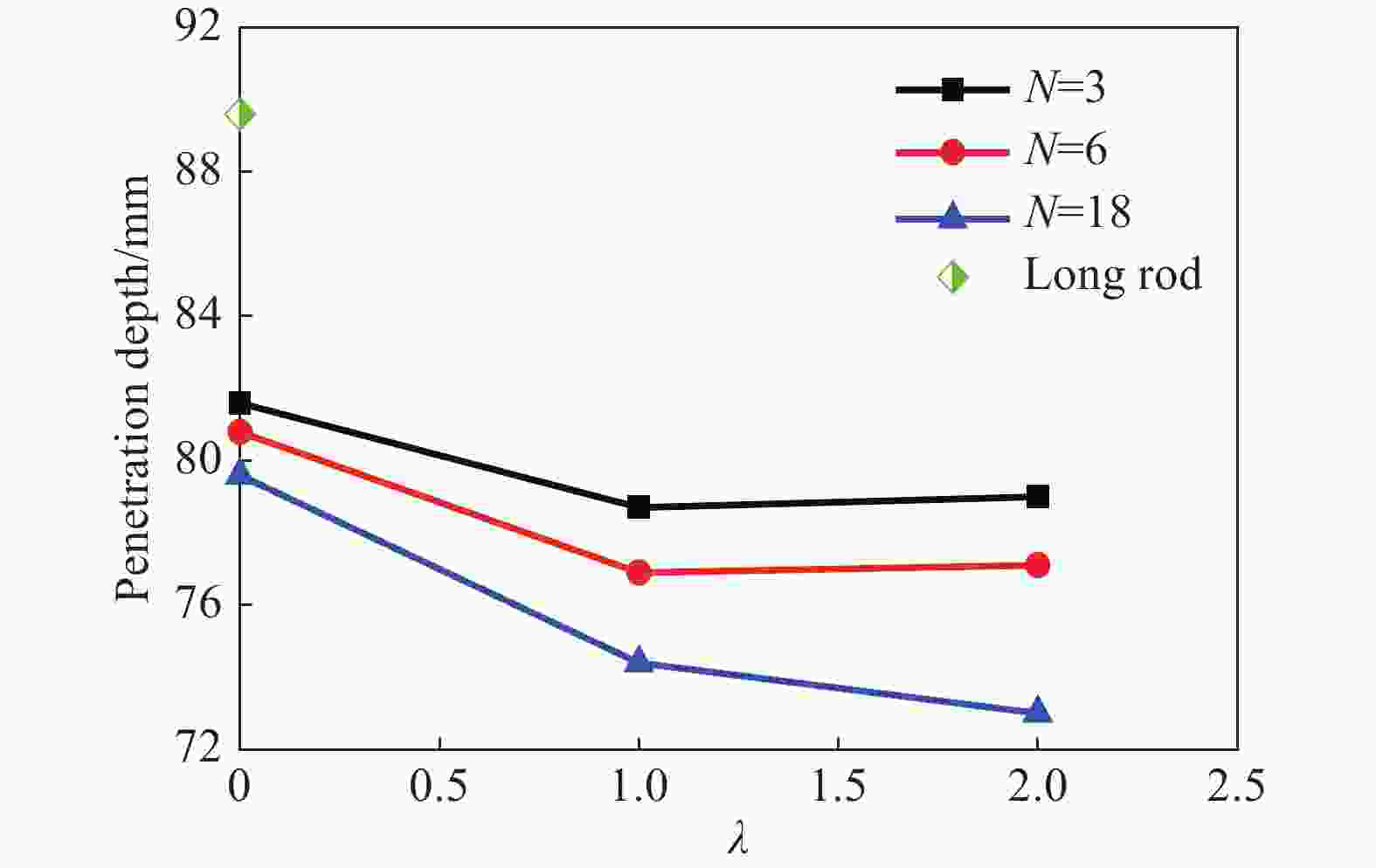

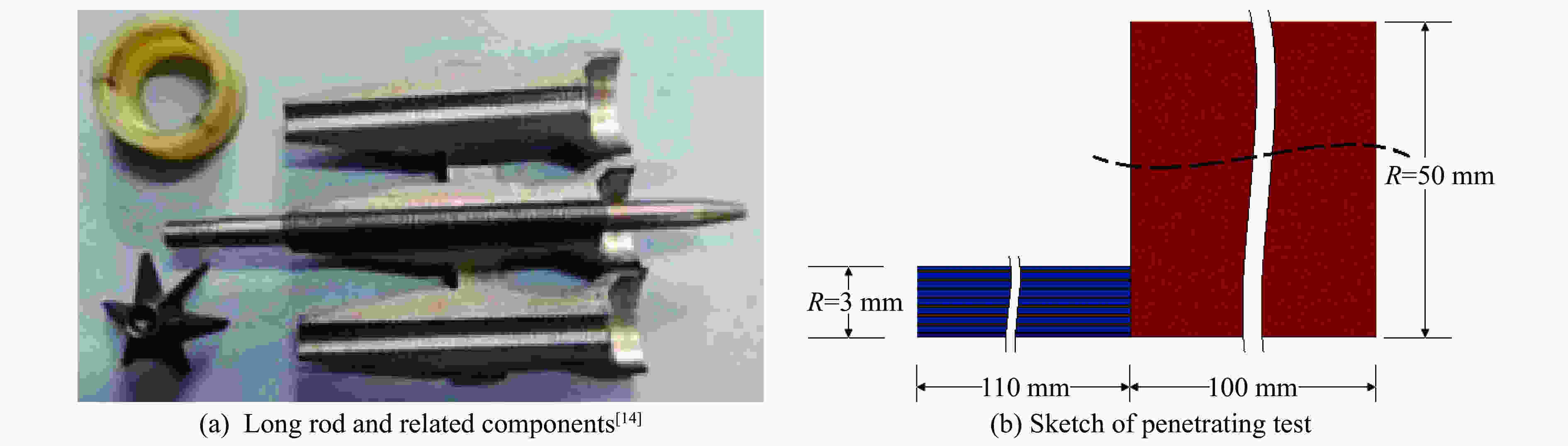

摘要: 结合穿甲实验,基于复合材料细观有限元模拟,系统开展针对钨纤维增强金属玻璃复合材料分段弹体侵彻性能的研究,并与复合材料长杆弹进行对比分析。结果表明,相对于复合材料长杆弹显著的穿甲“自锐”行为和优异的侵彻性能,复合材料分段弹体在侵彻过程中的“自锐”特性有所减弱,且弹体结构容易发生分散,进而导致弹体侵彻能力明显降低。另外,分段数目和分段间隔等因素对复合材料分段弹体的侵彻性能具有一定影响,但总体而言,不同构型分段弹体的侵彻能力均弱于复合材料长杆弹。Abstract: Integrated with the relevant penetrating tests, the ballistic behavior of the tungsten fiber/metallic glass matrix (WF/MG) composite segmented rod is systematically investigated based on the meso-scale finite element method (FEM), and the comparative analysis on the penetrating performance is conducted between the composite segmented rod and the composite long rod. Related analysis shows that the composite long rod has the remarkable “self-sharpening” behavior as well as good penetrating performance, the “self-sharpening” in the composite segmented rod is less significant, and particularly, dispersal of the reinforced fibers is easily to occur in the structure. Correspondingly, the penetrating capability in the composite segmented rod is remarkably weakened compared with that in the long rod. In addition, the segmental number and the segmental interval have considerable effects on the ballistic behavior; however, the penetrating performance of the composite segmented rods with various structures is always lower than that of the composite long rod.

-

表 1 钨纤维增强金属玻璃复合材料分段弹体结构特征

Table 1. Geometries of the tungsten fiber / metallic glass matrix composite segmented rods

工况 N L/mm S/mm λ lA/mm lB/mm lC/mm C1 3 36.7 0 0 36.7 73.4 110.0 C2 6 18.3 0 0 36.7 73.4 110.0 C3 18 6.1 0 0 36.7 73.4 110.0 C4 3 36.7 36.7 1 36.7 110.0 183.4 C5 6 18.3 18.3 1 55.0 128.3 201.6 C6 18 6.1 6.1 1 67.2 140.6 213.9 C7 3 36.7 73.4 2 36.7 146.7 256.7 C8 6 18.3 36.7 2 73.4 183.3 293.3 C9 18 6.1 12.2 2 97.8 207.8 317.8 Table 2. Mechanical properties of the Zr-based metallic glass and parameters in the modified coupled thermo-mechanical constitutive model[17- 18]

ρ/(kg·m−3) E/GPa ν T0/K Tg/K Tm/K f/s−1 Ω/m3 6 125 96 0.36 300 625 993 1×1013 2.5×10−29 V*/m3 cV/(J·kg−1·K−1) ξ0 ξc α nD ΛC ΛT 2×10−29 400 0.05 0.065 0.05 3 0.05 0.35 表 3 金属材料的Johnson-Cook模型参数

Table 3. Johnson-Cook model parameters of metallic materials

材料 ρ/(kg·m−3) E/GPa ν Tr/K Tm/K A/MPa B/MPa n C m ${\dot \varepsilon _0}$/s−1 95W钨合金 17 900 410 0.28 300 1 752 1 650 450 0.12 0.016 1.00 1 30CrMnMo钢 7 850 200 0.29 300 1 793 1 200 310 0.26 0.014 1.03 1 LY-9铝合金 2 700 68.9 0.33 300 925 270 154 0.22 0.130 1.34 1 材料 cV/(J·kg−1·K−1) D1 D2 D3 D4 D5 c0/(m·s−1) S1 γ0 α 95W钨合金 134 3.0 0 0 0 0 3 850 1.44 1.58 0 30CrMnMo钢 477 3.2 0 0 0 0 4 578 1.38 1.67 0.47 LY-9铝合金 910 2.5 0 0 0 0 5 200 1.40 1.97 0.48 表 4 侵彻实验数据以及相应数值模拟结果

Table 4. Penetrating test data and the corresponding simulation results

弾型 撞击速度v0/

(m·s−1)实验侵彻深度/

mm模拟侵彻深度/mm 二维 三维 长杆弹 1 406.8 92 89.6 88.9 1 565.5 贯穿 贯穿 贯穿 短杆弹 1 886.0 32 34.5 34.7 -

李继承, 陈小伟. 块体玻璃及其复合材料的压缩剪切特性以及侵彻穿甲“自锐”行为 [J]. 力学进展, 2011, 41(5): 480–518. DOI: 10.6052/1000-0992-2011-5-lxjzJ2011-056.LI J C, CHEN X W. Compressive-shear behavior and self-sharpening of bulk metallic glasses and their composite materials [J]. Advances in Mechanics, 2011, 41(5): 480–518. DOI: 10.6052/1000-0992-2011-5-lxjzJ2011-056. 荣光, 黄德武. 钨纤维复合材料穿甲弹芯侵彻时的自锐现象 [J]. 爆炸与冲击, 2009, 29(4): 351–355. DOI: 10.11883/1001-1455(2009)04-0351-05.RONG G, HUANG D W. Self-sharpening phenomena of tungsten fiber composite material penetrators during penetration [J]. Explosion and Shock Waves, 2009, 29(4): 351–355. DOI: 10.11883/1001-1455(2009)04-0351-05. 陈小伟, 李继承, 张方举, 等. 钨纤维增强金属玻璃复合材料弹穿甲钢靶的实验研究 [J]. 爆炸与冲击, 2012, 32(4): 346–354. DOI: 10.11883/1001-1455(2012)04-0346-09.CHEN X W, LI J C, ZHANG F J, et al. Experimental research on the penetration of tungsten-fiber /metallic glass-matrix composite material penetrator into steel target [J]. Explosion and Shock Waves, 2012, 32(4): 346–354. DOI: 10.11883/1001-1455(2012)04-0346-09. CHEN X W, WEI L M, LI J C. Experimental research on long rod penetration of tungsten fiber / Zr-based metallic glass matrix composite into Q235 steel target [J]. International Journal of Impact Engineering, 2015, 79: 102–116. DOI: 10.1016/j.ijimpeng.2014.11.007. LI J C, CHEN X W, HUANG F L. FEM analysis on the “self-sharpening” behavior of tungsten fiber / metallic glass matrix composite long rod [J]. International Journal of Impact Engineering, 2015, 86: 67–83. DOI: 10.1016/j.ijimpeng.2015.07.006. ORPHAL D L, FRANZEN R R. Penetration mechanics and performance of segmented rods against metal targets [J]. International Journal of Impact Engineering, 1990, 10: 427–438. DOI: 10.1016/0734-743X(90)90077-9. ORPHAL D L, MILLER C W. Penetration performance of non-ideal segmented rods [J]. International Journal of Impact Engineering, 1991, 11(4): 457–461. DOI: 10.1016/0734-743X(91)90013-6. WANG X M, ZHAO G Z, SHEN P H. High velocity impact of segmented rods with an aluminum carrier tube [J]. International Journal of Impact Engineering, 1995, 17(8): 915–923. DOI: 10.1016/0734-743X(95)99910-J. TATE A. Engineering modelling of some aspects of segmented rod penetration [J]. International Journal of Impact Engineering, 1990, 9: 327–341. DOI: 10.1016/0734-743X(90)90006-H. ALY S Y, LI Q M. Numerical investigation of penetration performance of non-ideal segmented rod projectiles [J]. Transactions of Tianjin University, 2008, 14(6): 391–395. DOI: 10.1007/s12209-008-0067-x. 邓云飞, 张伟, 曹宗胜, 等. 分段弹侵彻效率的数值模拟研究 [J]. 高压物理学报, 2011, 25(3): 251–260. DOI: 10.11858/gywlxb.2011.03.010.DENG Y F, ZHANG W, CAO Z S, et al. Numerical investigation of penetration performance of segmented rods penetration into steel target [J]. Chinese Journal of High Pressure Physics, 2011, 25(3): 251–260. DOI: 10.11858/gywlxb.2011.03.010. 郎林, 陈小伟, 雷劲松. 长杆和分段杆侵彻的数值模拟 [J]. 爆炸与冲击, 2011, 31(2): 127–134. DOI: 10.11883/1001-1455(2011)02-0127-08.LANG L, CHEN X W, LEI J S. Numerical simulations on long rod and segmented rods penetrating into steel targets [J]. Explosion and Shock Waves, 2011, 31(2): 127–134. DOI: 10.11883/1001-1455(2011)02-0127-08. 陈小伟, 郎林. 长径比和分段间隔对理想分段杆侵彻钢靶的影响 [J]. 爆炸与冲击, 2013, 33(S): 1–7.CHEN X W, LANG L. Effects of segment length and gap spacing on segmented rods penetrating into steel target [J]. Explosion and Shock Waves, 2013, 33(S): 1–7. 夏龙祥. 钨纤维增强块体金属非晶复合材料侵彻行为研究[D]. 南京: 南京理工大学, 2013. DOI: 10.7666/d.Y2520745.XIA L X. Penetration behaviors of tungsten fiber / bulk metallic glass composite rods [D]. Nanjing: Nanjing University of Science and Technology, 2013. DOI: 10.7666/d.Y2520745. LI J C, CHEN X W, HUANG F L. FEM analysis on the deformation and failure of fiber reinforced metallic glass matrix composite [J]. Materials Science and Engineering: A, 2016, 652: 145–166. DOI: 10.1016/j.msea.2015.11.051. ZHANG H F, LI H, WANG A M, et al. Synthesis and characteristics of 80 vol.% tungsten (W) fibre-Zr based metallic glass composite [J]. Intermetallics, 2009, 17: 1070–1077. DOI: 10.1016/j.intermet.2009.05.011. LI J C, WEI Q, CHEN X W, et al. On the mechanism of deformation and failure in bulk metallic glasses [J]. Materials Science and Engineering: A, 2014, 610: 91–105. DOI: 10.1016/j.msea.2014.04.106. LI J C, CHEN X W, HUANG F L. Inhomogeneous deformation in bulk metallic glasses: FEM analysis [J]. Materials Science and Engineering: A, 2015, 620: 333–351. DOI: 10.1016/j.msea.2014.10.013. -

下载:

下载: