An FEM-SPH coupled model for simulating penetration of armor-piercing bullets into ceramic composite armors and glass composite armors

-

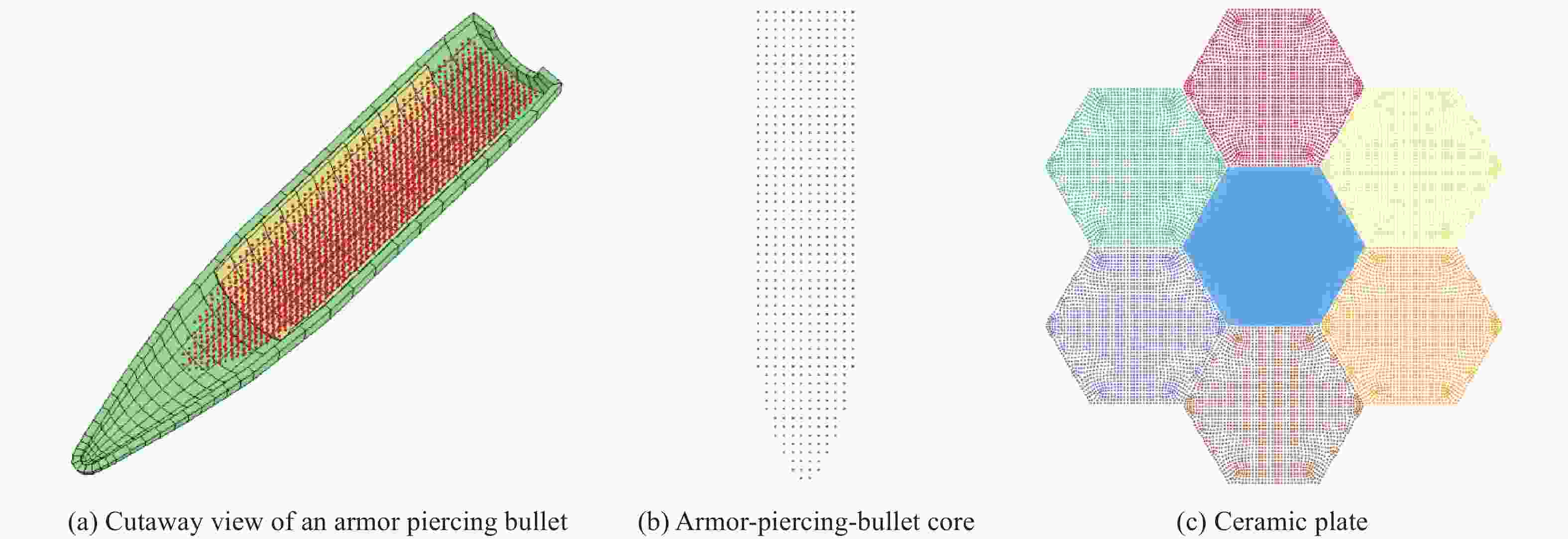

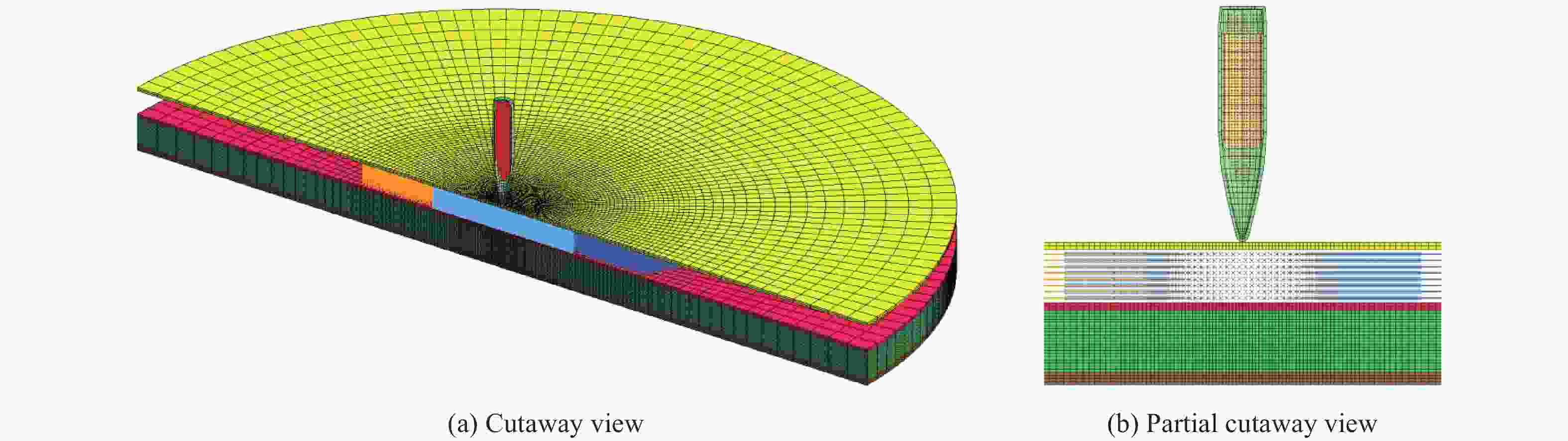

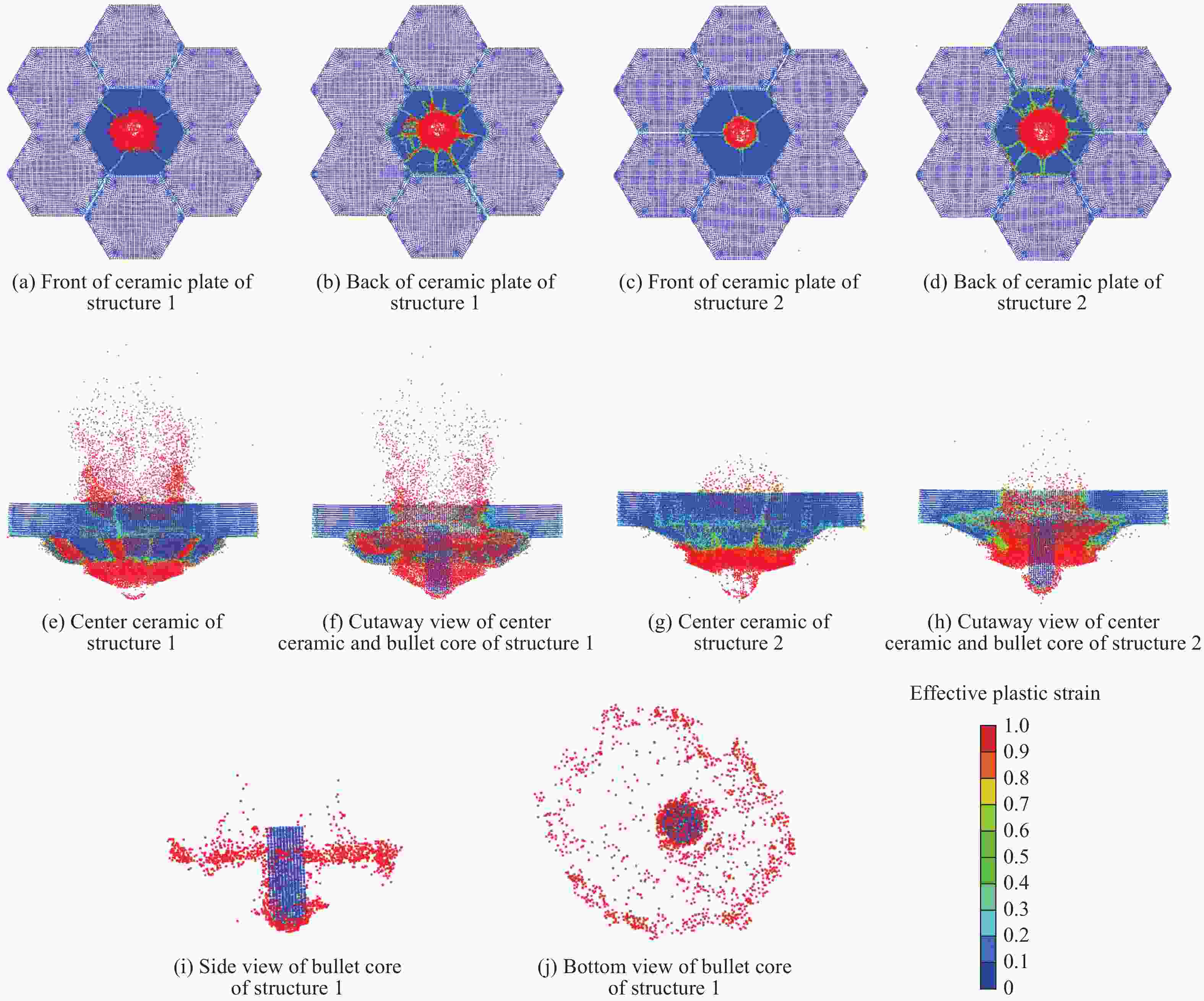

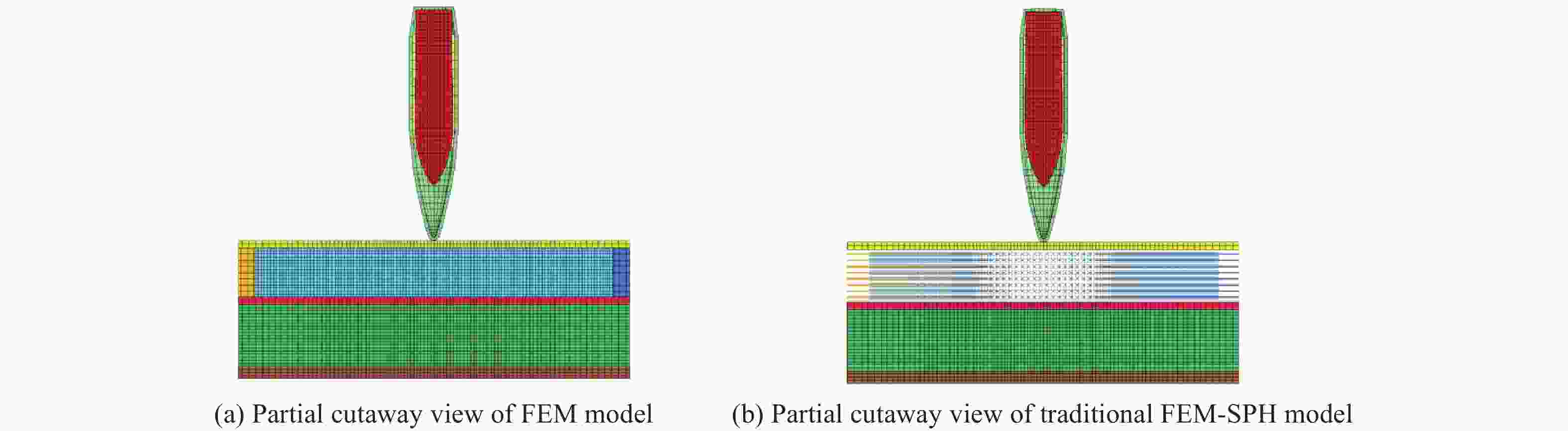

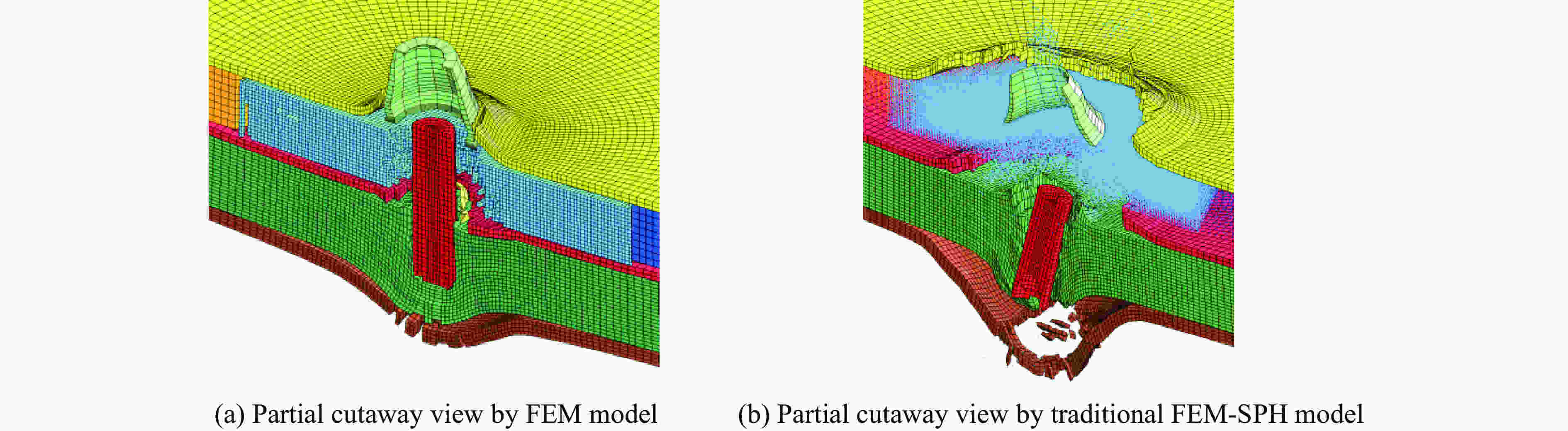

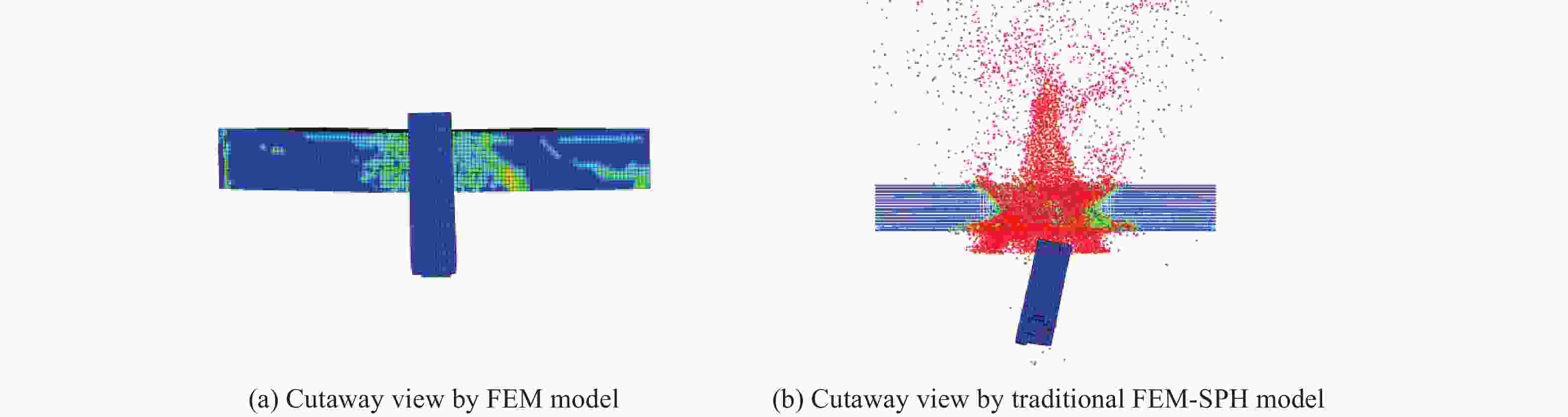

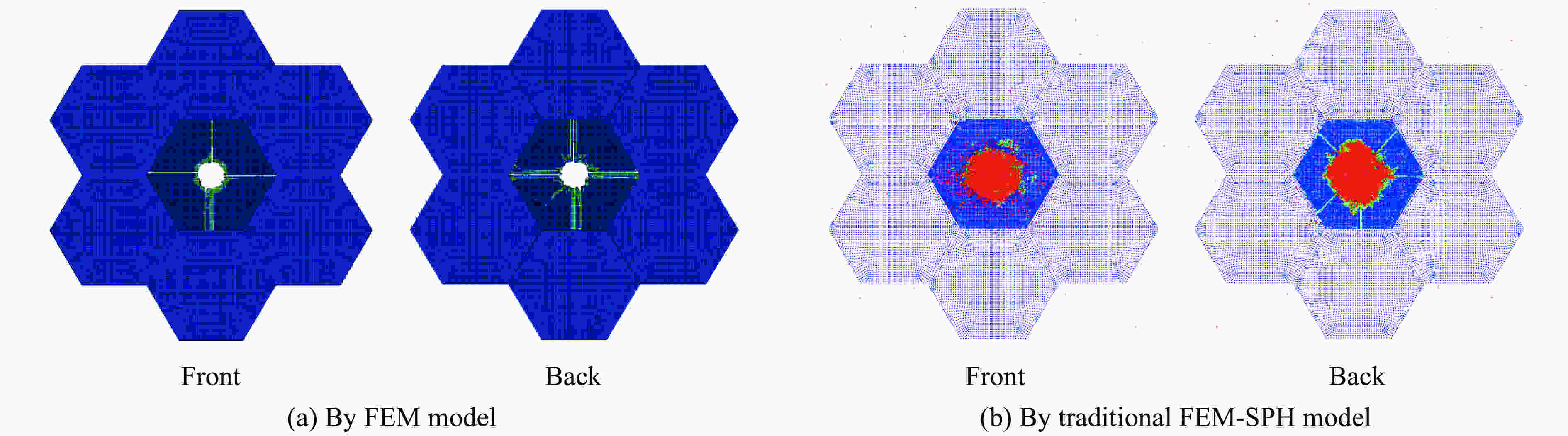

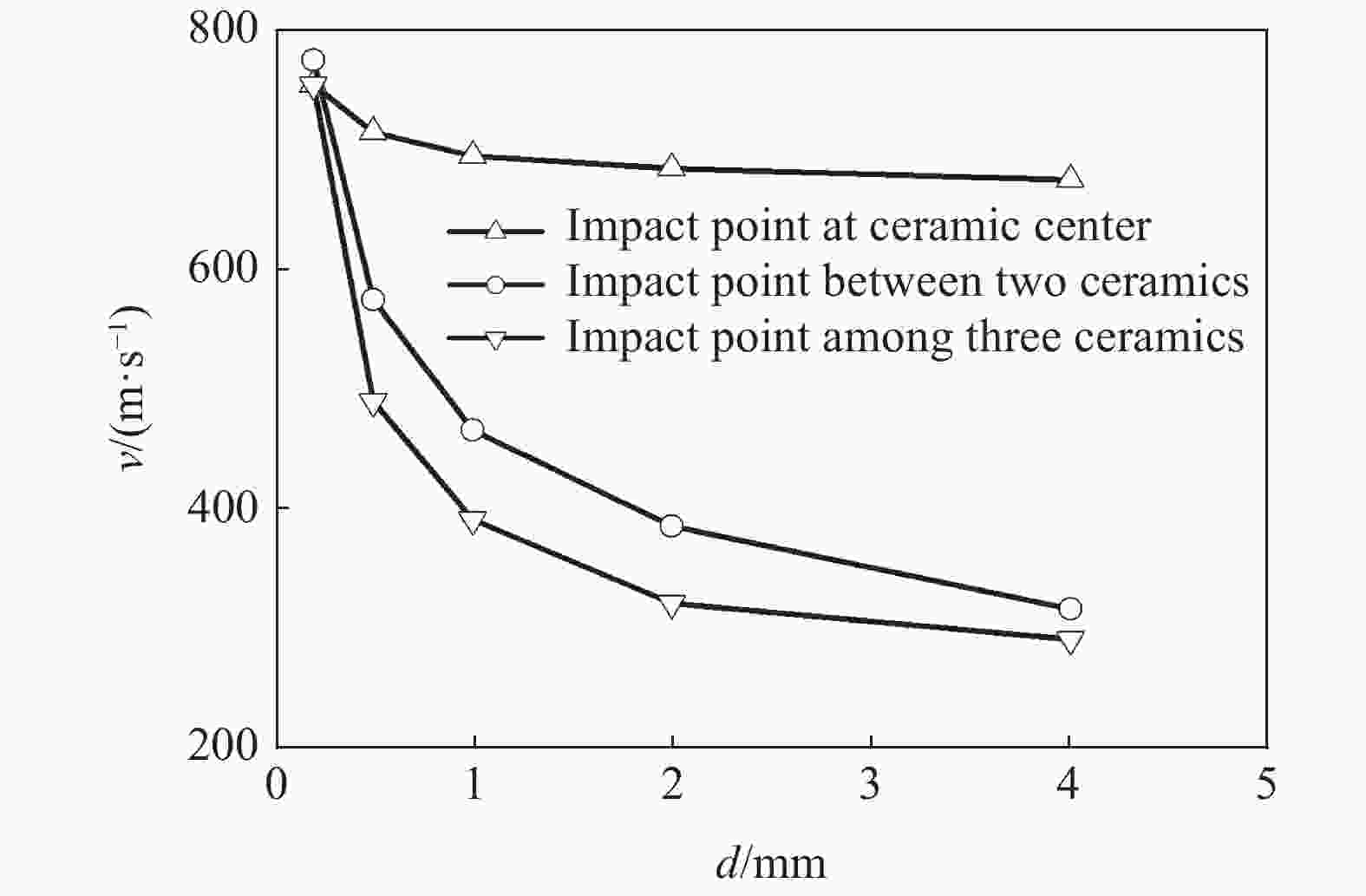

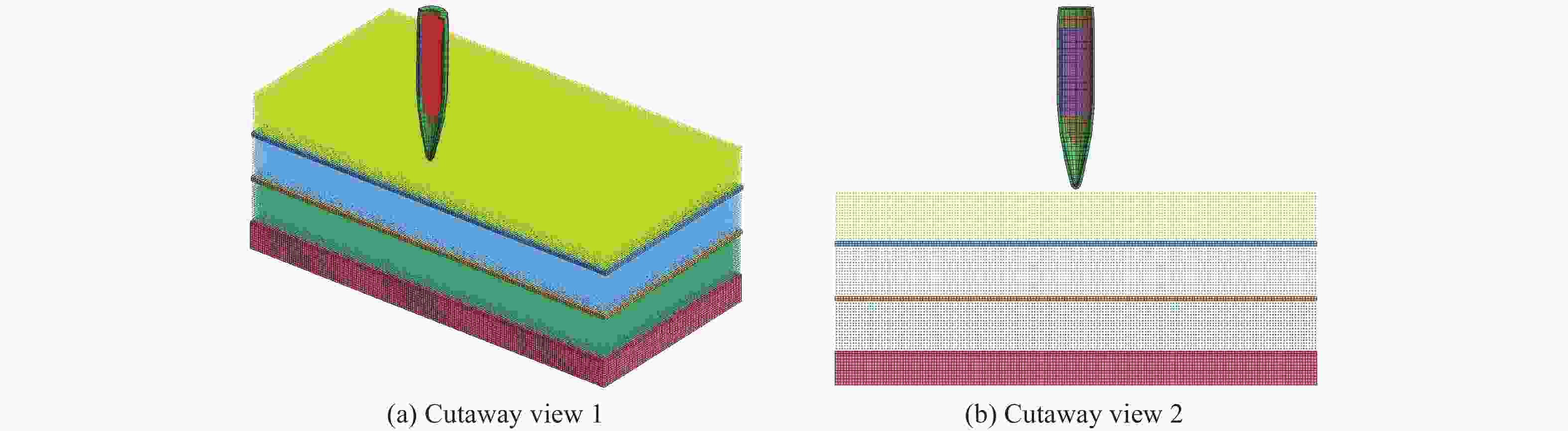

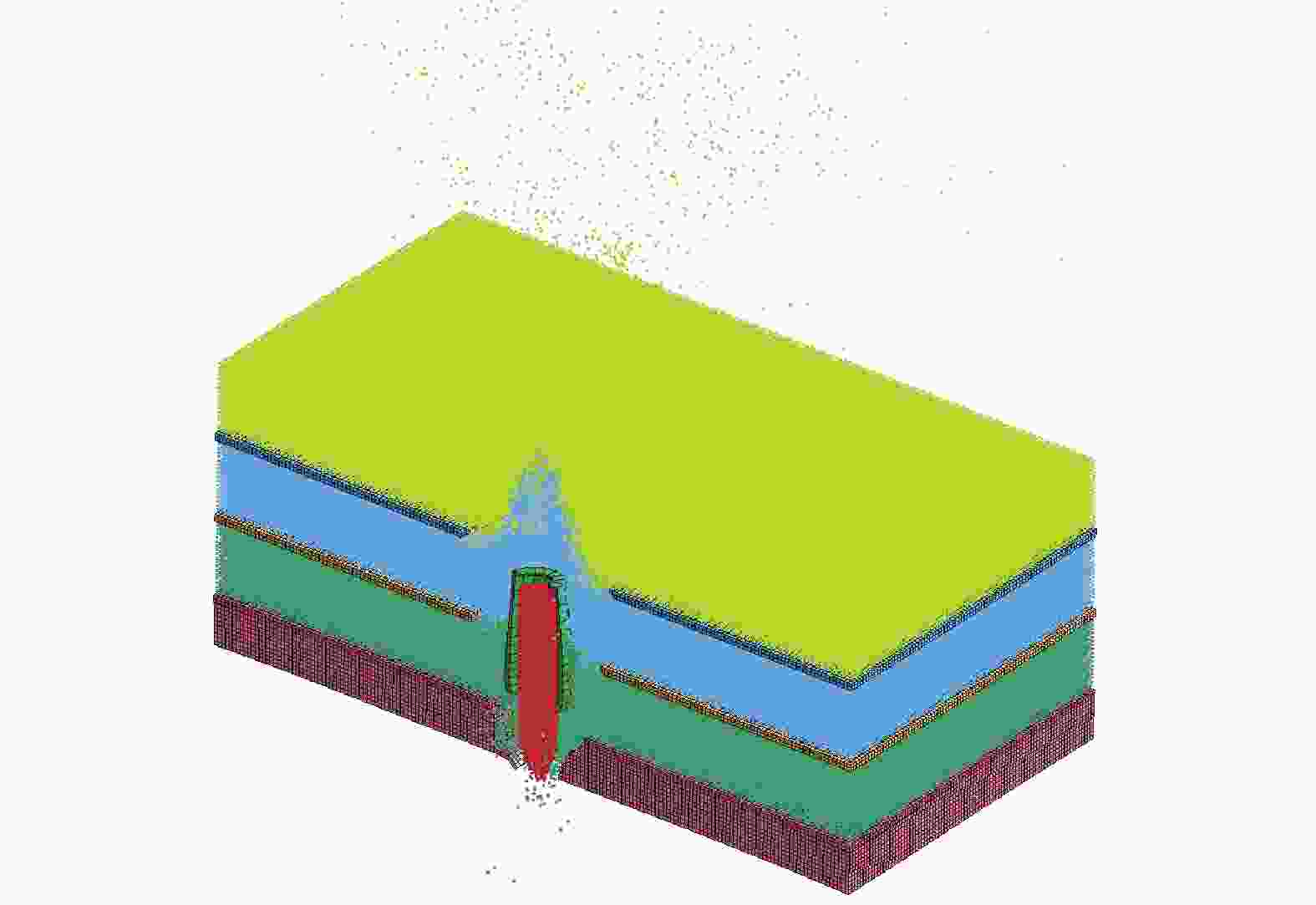

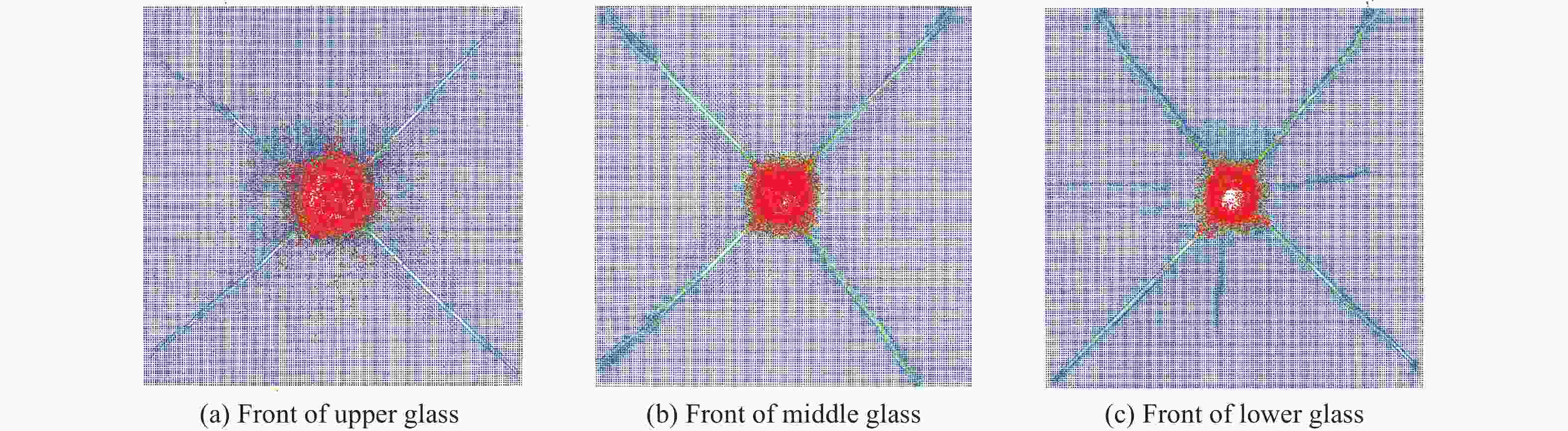

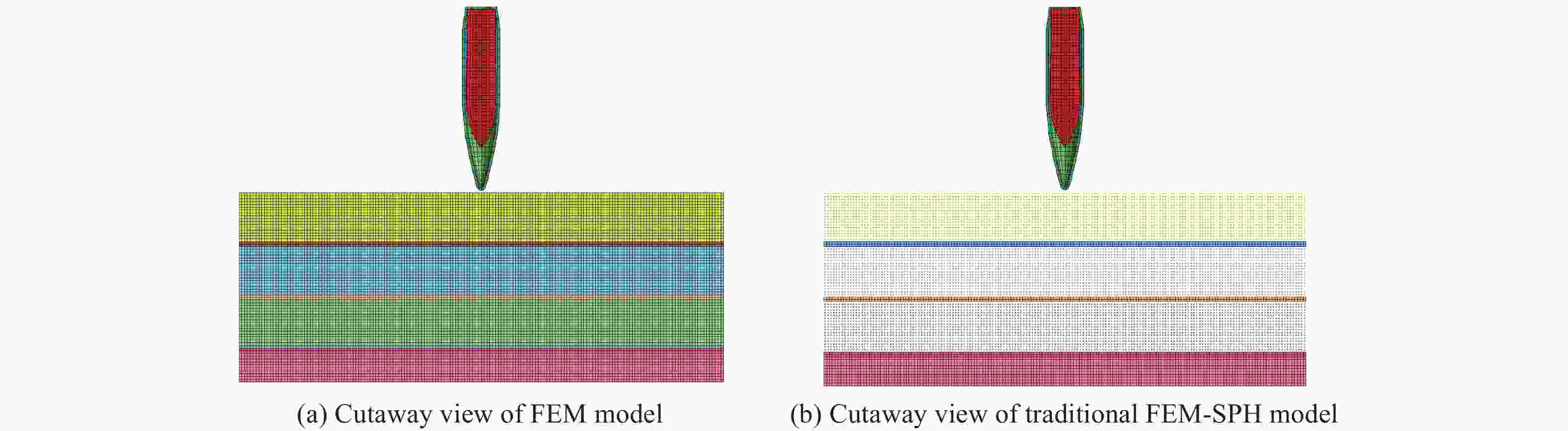

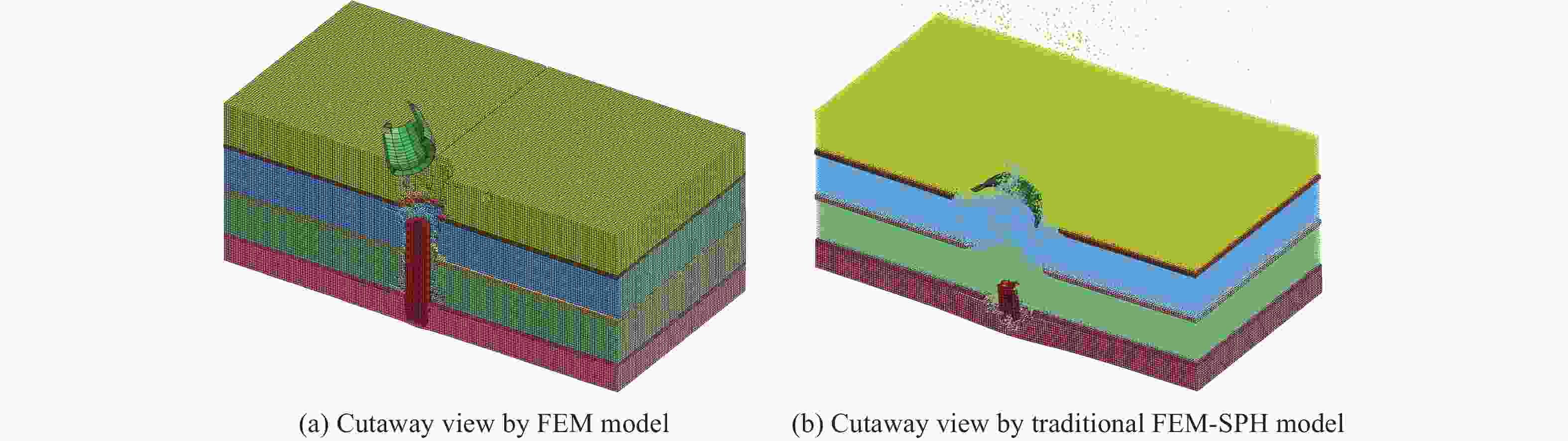

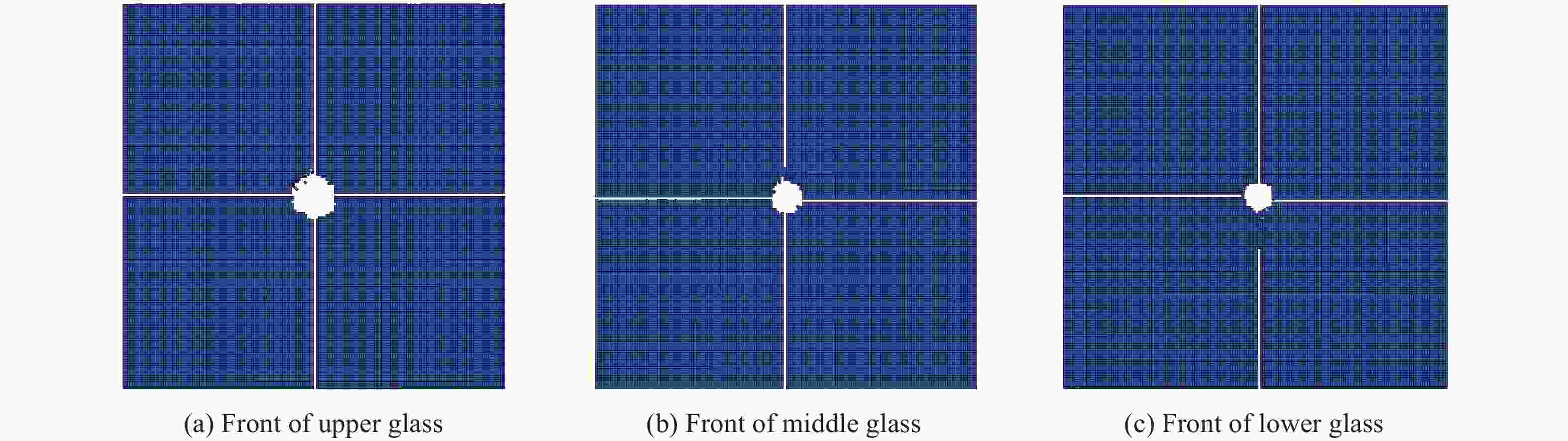

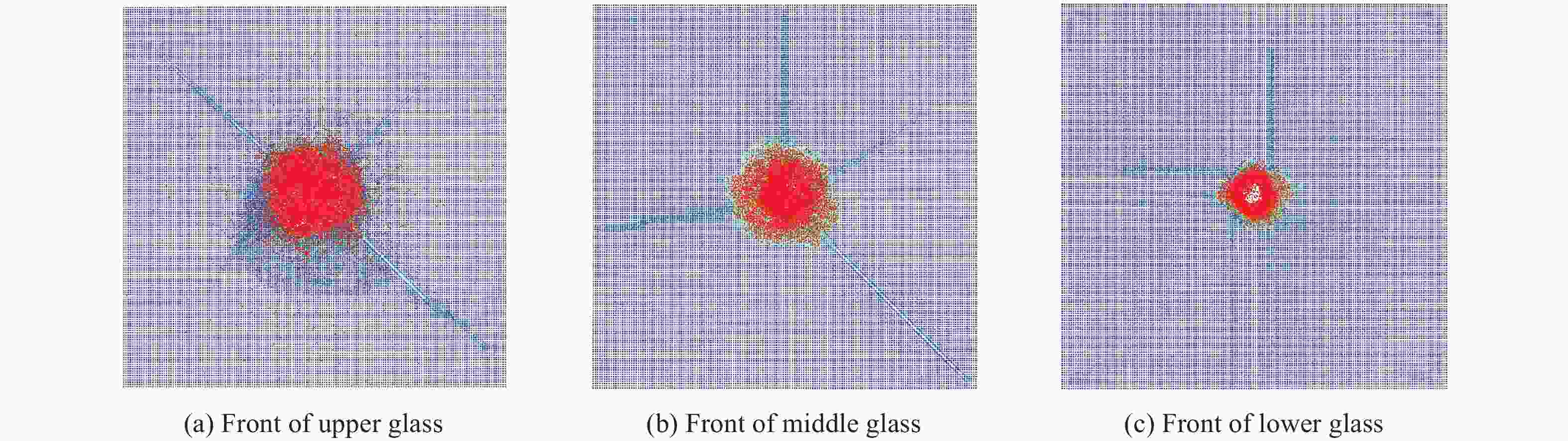

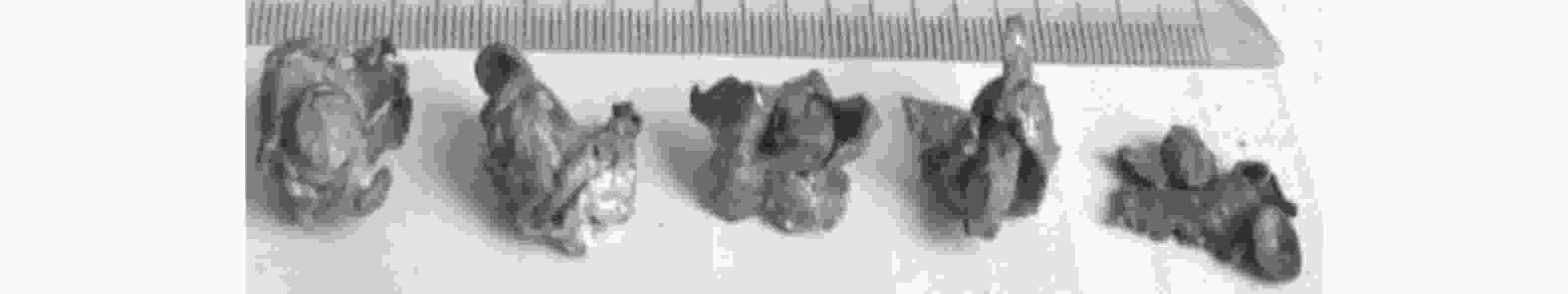

摘要: 为了提高小口径穿甲燃烧弹侵彻陶瓷复合装甲和玻璃复合装甲(透明装甲)的仿真分析精度,本文将传统的FEM(finite element method)-SPH(smooth particle hydrodynamics)耦合计算模型中穿甲燃烧弹弹芯的有限元模型和JC(Johnson-Cook)材料模型分别替换为SPH模型和JH2(Johnson-Holmquist-ceramics)材料模型,提出了新型FEM-SPH耦合计算模型。研究表明,新型FEM-SPH耦合计算模型可以有效模拟弹芯碎裂现象,减少SPH粒子和有限元耦合计算量,进而显著提高仿真模型的计算精度和计算效率,并给出了新型FEM-SPH耦合计算模型的有限元/粒子尺度和建模尺寸的优选结果。Abstract: To improve the ballistic simulation accuracy of ceramic composite armors and glass composite armors (transparent armors) against small-caliber armor piercing bullets, the new FEM (finite element method) -SPH (smooth particle hydrodynamics) coupled model was proposed, which replaced the FEM model and JC (Johnson-Cook) material model of the armor-piercing-bullet core of traditional FEM-SPH coupled model with the SPH model and JH2 (Johnson-Holmquist-ceramics) material model. The results show that the new FEM-SPH coupled model can effectively simulate bullet core fragmentation and reduce FEM-SPH coupled calculation amount. So it can improve the computation accuracy and efficiency. And the FEM element/SPH particle size and armor modeling size of the new FEM-SPH coupled model are optimized.

-

表 1 陶瓷复合装甲组成

Table 1. Composition of ceramic composite armors

装甲方案 组分(面板到背板) 各组分厚度/mm 1 G/A陶瓷/G/K/G 1.2/X/1.2/10/2 2 G/B陶瓷/G/K/G 1.2/X/1.2/10/2 表 2 陶瓷复合装甲的新型FEM-SPH耦合计算模型的建模方式和材料模型

Table 2. Modeling methods and material models for the new FEM-SPH model of ceramic composite armors

部件 建模方式 平均尺度/mm 材料模型 弹芯 SPH 0.5 JH2 (Johnson-Holmquist-ceramics)模型 陶瓷 0.5~1.0 铅套 FEM 0.2~2.0 JC (Johnson-Cook)模型 被甲 玻纤板 0.5~8.0 正交各向异性连续损伤本构模型 Kevlar纤维板 表 3 穿甲燃烧弹弹芯的JH2材料模型主要参数

Table 3. Material constants for the JH2 model of an armor-piercing-bullet core

A B C M N D1 D2 $T{\rm{/GPa}}$ ${P_{{\rm{Hel}}}}{\rm{/GPa}}$ ${\sigma _{{\rm{Hel}}}}{\rm{/GPa}}$ 0.2 0.014 0.005 0 0 0.15 30 20 20 14.0 表 4 方案1采用不同计算模型得到的弹道极限速度以及计算所用的时间

Table 4. Ballistic limit velocities of structure 1 by different computational models and the corresponding time used for computation

计算模型 FEM OFS NFS NFSA NFSB NFSC NFSD 弹道极限速度计算值 0.598 0.636 0.970 0.546 0.996 0.855 1.003 计算时间 0.224 5.582 1.000 0.522 2.284 0.493 1.746 表 5 透明装甲组成

Table 5. Composition of the transparent armor

组分(面板到背板) G PU G PU G PU PC 厚度/mm 10 1 10 1 10 1 6 表 6 透明装甲的新型FEM-SPH耦合计算模型的建模方式和材料模型

Table 6. Modeling methods and material models for the new FEM-SPH model of the transparent armor

部件 建模方式 平均尺度/mm 材料模型 弹芯 SPH 0.5 JH2 (Johnson-Holmquist-ceramics)模型 无机玻璃 0.6 铅套 FEM 0.2~2.0 JC (Johnson-Cook)模型 被甲 聚氨酯 0.6 弹塑性材料模型 聚碳酸酯 表 7 透明装甲采用不同计算模型得到的弹道极限速度以及计算所用的时间

Table 7. Ballistic limit velocities of the transparent armor by different computational models and the corresponding time used for computation

计算模型 FEM OFS NFS NFSA NFSB NFSC NFSD 弹道极限速度计算值 0.711 0.865 0.950 0.899 0.916 0.813 0.967 计算时间 0.171 5.384 1.000 0.253 8.637 0.233 3.178 -

[1] 胡德安, 韩旭, 肖毅华, 等. 光滑粒子法及其与有限元耦合算法的研究进展 [J]. 力学学报, 2013, 45(5): 639–652. DOI: 10.6052/0459-1879-13-092.HU D A, HAN X, XIAO Y H, et al. Research developments of smoothed particle hydrodynamics method and its coupling with finite element method [J]. Chinese Journal of Theoretical and Applied Mechanics, 2013, 45(5): 639–652. DOI: 10.6052/0459-1879-13-092. [2] 陈斌, 罗夕容, 曾首义. 穿甲子弹侵彻陶瓷/钢靶板的数值模拟研究 [J]. 弹道学报, 2009, 21(1): 14–18.CHEN B, LUO X R, ZENG S Y. Simulation study on ceramic/mild steel targets penetrated by APP [J]. Journal of Ballistics, 2009, 21(1): 14–18. [3] 卿尚波, 晏麓晖, 曾首义. 陶瓷靶的多片组合效应分析 [J]. 弹箭与制导学报, 2010, 30(3): 72–74. DOI: 10.15892/j.cnki.djzdxb.2010.03.019.QING S B, YAN L H, ZENG S Y. Studies on combinational effect of multi-ceramics [J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2010, 30(3): 72–74. DOI: 10.15892/j.cnki.djzdxb.2010.03.019. [4] 孙素杰, 赵宝荣, 王军, 等. 不同背板对陶瓷复合装甲抗弹性能影响的研究 [J]. 兵器材料科学与工程, 2006, 29(2): 70–72. DOI: 10.3969/j.issn.1004-244X.2006.02.019.SUN S J, ZHAO B R, WANG J, et al. Study on the penetration performance of ceramic armors with different backing plate [J]. Ordnance Material Science and Engineering, 2006, 29(2): 70–72. DOI: 10.3969/j.issn.1004-244X.2006.02.019. [5] 蒋志刚, 申志强, 曾首义, 等. 穿甲子弹侵彻陶瓷/钢复合靶板试验研究 [J]. 弹道学报, 2007, 19(4): 38–42. DOI: 10.3969/j.issn.1004-499X.2007.04.011.JIANG Z G, SHEN Z Q, ZENG S Y, et al. An experimental study on ceramic/mild steel targets against APP [J]. Journal of Ballistics, 2007, 19(4): 38–42. DOI: 10.3969/j.issn.1004-499X.2007.04.011. [6] JOHNSON G R, HOLMQUIST T J. Response of boron carbide subjected to large strains, high strain rates, and high pressures [J]. Journal of Applied Physics, 1999, 85(12): 8060–8073. DOI: 10.1063/1.370643. [7] BØRVIK T, DEY S, CLAUSEN A H. Perforation resistance of five different high-strength steel plates subjected to small-arms projectiles [J]. International Journal of Impact Engineering, 2009, 36(7): 948–964. DOI: 10.1016/j.ijimpeng.2008.12.003. [8] CRONIN D S, BUI K, KAUFMANN C, et al. Implementation and validation of the Johnson-Holmquist ceramic material model in LS-DYNA [C] // Proceedings of the 4th European LS-DYNA User Conference. Stuttgart, Germany: DY-NAmore GmbH, 2003: 47−60. [9] 谢恒, 吕振华. 破片侵彻纤维复合材料板的有限元数值模拟 [J]. 清华大学学报(自然科学版), 2012, 52(1): 96–101. DOI: 10.16511/j.cnki.qhdxxb.2012.01.005.XIE H, LÜ Z H. Finite element simulation of FRP plates impacted by fragments [J]. Journal of Tsinghua University (Science and Technology), 2012, 52(1): 96–101. DOI: 10.16511/j.cnki.qhdxxb.2012.01.005. [10] XIAO J R, GAMA B A, GILLESPIE Jr J W. Progressive damage and delamination in plain weave S-2 glass/SC-15 composites under quasi-static punch-shear loading [J]. Composite Structures, 2007, 78(2): 182–196. DOI: 10.1016/j.compstruct.2005.09.001. [11] 王元博. 纤维增强层合材料的抗弹性能和破坏机理研究[D]. 合肥: 中国科学技术大学, 2006: 87−89. DOI: 10.7666/d.y918786. [12] 陈宇宏, 厉蕾. 轻型防弹玻璃的结构研究 [J]. 材料工程, 2002(6): 7–9; 36. DOI: 10.3969/j.issn.1001-4381.2002.06.002.CHEN Y H, LI L. Study on the structure of lightweight bulletproof glass [J]. Journal of Materials Engineering, 2002(6): 7–9; 36. DOI: 10.3969/j.issn.1001-4381.2002.06.002. [13] HOLMQUIST T J, JOHNSON G R, GRADY D E, et al. High strain rate properties and constitutive modeling of glass [C] // Proceedings of the 15th International Symposium on Ballistics. Jerusalem, Israel, 1995: 237−244.DOI: 10.2172/41367. [14] LI Z H, LAMBROS J. Strain rate effects on the thermomechanical behavior of polymers [J]. International Journal of Solids and Structures, 2001, 38(20): 3549–3562. DOI: 10.1016/s0020-7683(00)00223-7. [15] TI Y, CHEN D J. Mechanical and dynamic mechanical properties of polyurethane/Fe-octacarboxyl acid phthalocyanine blends [J]. Progress in Organic Coatings, 2013, 76(1): 119–124. DOI: 10.1016/j.porgcoat.2012.08.019. [16] 曹侃, 汪洋, 王宇. 低温下聚碳酸酯冲击拉伸性能的实验研究 [J]. 兵工学报, 2010, 31(S1): 195–198.CAO K, WANG Y, WANG Y. Experimental study on impact tensile properties of polycarbonate at low temperature [J]. Acta Armamentarii, 2010, 31(S1): 195–198. [17] 张龙辉, 张晓晴, 姚小虎, 等. 高应变率下航空透明聚氨酯的动态本构模型 [J]. 爆炸与冲击, 2015, 35(1): 51–56. DOI: 10.11883/1001-1455(2015)01-0051-06.ZHANG L H, ZHANG X Q, YAO X H, et al. Constitutive model of transparent aviation polyurethane at high strain rates [J]. Explosion and Shock Waves, 2015, 35(1): 51–56. DOI: 10.11883/1001-1455(2015)01-0051-06. [18] 姚小虎, 张龙辉, 张晓晴, 等. 航空透明聚氨酯胶片动态力学性能实验研究 [J]. 航空学报, 2015, 36(7): 2236–2243. DOI: 10.7527/S1000-6893.2014.0281.YAO X H, ZHANG L H, ZHANG X Q, et al. Experimental study on dynamic mechanical behavior of aerospace- transparent polyurethane interlayer [J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(7): 2236–2243. DOI: 10.7527/S1000-6893.2014.0281. [19] 胡文军, 张方举, 田常津, 等. 聚碳酸酯的动态应力应变响应和屈服行为 [J]. 材料研究学报, 2007, 21(4): 439–443. DOI: 10.3321/j.issn: 1005-3093.2007.04.019.HU W J, ZHANG F J, TIAN C J, et al. Dynamic stress-strain response and yield behavior of polycarbonate [J]. Chinese Journal of Materials Research, 2007, 21(4): 439–443. DOI: 10.3321/j.issn: 1005-3093.2007.04.019. -

下载:

下载: