On slamming load and structural response of a flexible wedge via analytical methods and numerical simulations

-

摘要: 针对弹性楔形体砰击载荷及结构响应问题,采用理论解析计算方法以及任意拉格朗日-欧拉(arbitrary Lagrangian-Eulerian, ALE)流固耦合数值计算方法开展研究。分别分析不同边界条件、入水速度、板厚以及斜升角对弹性结构所受砰击力及结构响应的影响及变化规律,并探讨砰击载荷时间历程和物面分布特性。结果表明,通过增大斜升角可有效降低弹性楔形体砰击载荷和结构响应,斜升角自10°增大至30°,无量纲砰击力峰值减小至6.9%,结构变形极值减小至6.5%。可通过水弹性因数

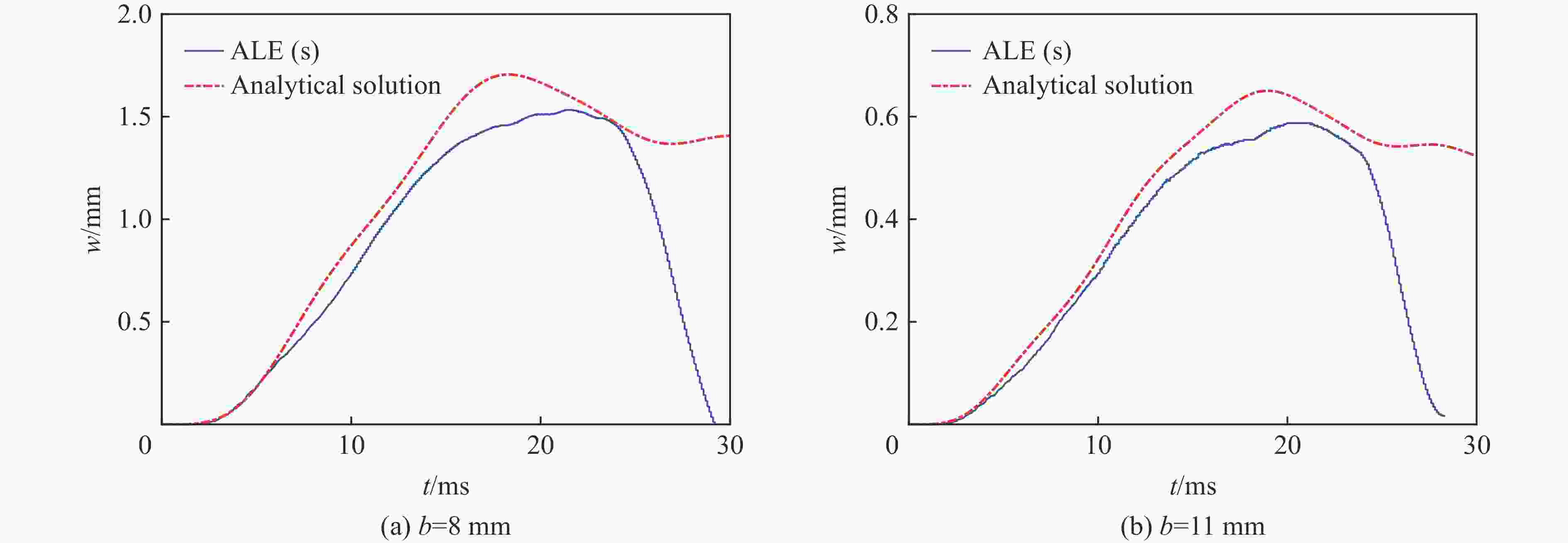

${ {R_{\text{F}}} = {C_{\text{B}}}\tan \beta \sqrt {EI/(\rho {L^3})} /v }$ 评估板厚、入水速度、斜升角以及边界条件对砰击载荷作用下结构水弹性效应的影响,在水弹性因数RF>1.71时,可采用理论解析方法高效高精度预报砰击载荷作用下弹性楔形体结构变形响应。Abstract: The slamming load and structural response of flexible wedges were investigated by both analytical methods and numerical simulations based on the ALE (arbitrary Lagrangian-Eulerian) coupled method. The cases with various boundary conditions, impact velocities, thicknesses and deadrise angles were simulated and the corresponding slamming loads and the structural responses were discussed as well. The slamming load and the structural response are susceptible to the variation of the deadrise angle. To increase the deadrise angles is an effective way to ensure the structural strength concerning about the impact load. With the increase of the deadrise angle from 10º to 30º, the dimensionless slamming load decreased to 6.9% and the structural response decreased to 6.5%. The hydroelastic effects of the response of the flexible structure under slamming load can be evaluated by the factor${ {R_{\text{F}}} = {C_{\text{B}}}\tan \beta \sqrt {EI/(\rho {L^3})} /v }$ which combining with boundary condition, deadrise angle and rigidity of the structure. If the RF>1.71, the hydroelastic analytical method is an efficient and effective way to evaluate the response of the flexible structure under slamming load.-

Key words:

- hydroelastic effect /

- flexible wedge /

- water impact /

- fluid-structure interaction

-

表 1 空气域及水域状态方程参数

Table 1. Parameters for equations of state of air and water

材料 ρ0/(kg·m−3) c/(m·s−1) C4 C5 S1 S2 空气 1.2 340 0.4 0.4 水 1 000 1 480 1.92 −0.096 表 2 不同网格尺寸模型信息

Table 2. Three models with different mesh sizes

网格尺寸/mm 结构单元数量 流体单元数量 计算时长/min 4 100 24 000 57 2 200 55 800 440 1 400 223 500 5 142 表 3 两端简支的不同板厚的弹性楔形体

$x' = 0.5L $ 处的结构变形峰值Table 3. The maximum structural responses at

$x' = 0.5L $ of the supported wedges with different plate thickessesb/mm wmax/mm 理论解析解 ALE BEM[5] β=10° β=30° β=45° β=10° β=30° β=45° β=30° β=45° 5 6.970 0.420 0.200 4.320 0.410 0.210 0.380 0.150 8 1.710 0.100 0.049 1.530 0.100 0.051 0.095 0.035 11 0.660 0.039 0.019 0.590 0.400 0.020 0.036 0.015 表 4

$\ \beta=30^\circ $ 的不同板厚的弹性楔形体$x'=0.5L$ 处的结构变形峰值Table 4. The maximum structural responses at

$x'=0.5L$ of the wedges with$\ \beta=30^\circ $ and different plate thicknessesb/mm wmax/μm 理论解析 ALE 两端简支 两端固支 两端简支 两端固支 5 420 84.0 410 96.0 8 100 21.0 100 24.0 11 39 7.9 400 9.1 表 5 不同板厚的楔形体在不同入水速度下的水弹性因数

Table 5. The hydroelastic factors of the wedges with different plate thicknesses at different water-enter velocities

速度/(m·s-1) RF b=5 mm b=8 mm b=11 mm 1 3.38 6.83 11.01 2 1.69 3.42 5.51 4 0.84 1.71 2.75 6 0.56 1.14 1.84 8 0.42 0.85 1.38 -

[1] KVALSVOLD J, FALTINSEN O M. Hydroelastic modeling of wet deck slamming on multihull vessels [J]. Journal of Ship Research, 1995, 39(3): 225–239. DOI: 10.5957/jsr.1995.39.3.225. [2] FALTINSEN O M, KVÅLSVOLD J, AARSNES J V. Wave impact on a horizontal elastic plate [J]. Journal of Marine Science and Technology, 1997, 2(2): 87–100. DOI: 10.1007/BF02491523. [3] KHABAKHPASHEVA T I, KOROBKIN A A. Elastic wedge impact onto a liquid surface: Wagner’s solution and approximate models [J]. Journal of Fluids and Structures, 2013, 36: 32–49. DOI: 10.1016/j.jfluidstructs.2012.08.004. [4] SHAMS A, PORFIRI M. Treatment of hydroelastic impact of flexible wedges [J]. Journal of Fluids and Structures, 2015, 57: 229–246. DOI: 10.1016/j.jfluidstructs.2015.06.017. [5] LU C H, HE Y S, WU G X. Coupled analysis of nonlinear interaction between fluid and structure during impact [J]. Journal of Fluids and Structures, 2000, 14(1): 127–146. DOI: 10.1006/jfls.1999.0257. [6] STENIUS I, ROSÉN A, KUTTENKEULER J. Hydroelastic interaction in panel-water impacts of high-speed craft [J]. Ocean Engineering, 2011, 38(2−3): 371–381. DOI: 10.1016/j.oceaneng.2010.11.010. [7] PANCIROLI R, ABRATE S, MINAK G, et al. Hydroelasticity in water-entry problems: comparison between experimental and SPH results [J]. Composite Structures, 2012, 94(2): 532–539. DOI: 10.1016/j.compstruct.2011.08.016. [8] PANCIROLI R. Water entry of flexible wedges: some issues on the FSI phenomena [J]. Applied Ocean Research, 2013, 39: 72–74. DOI: 10.1016/j.apor.2012.10.010. [9] HASSOON O H, TARFAOUI M, ALAOUI A E M, et al. Experimental and numerical investigation on the dynamic response of sandwich composite panels under hydrodynamic slamming loads [J]. Composite Structures, 2017, 178: 297–307. DOI: 10.1016/j.compstruct.2017.07.014. [10] HASSOON O H, TARFAOUI M, ALAOUI A E M, et al. Mechanical behavior of composite structures subjected to constant slamming impact velocity: an experimental and numerical investigation [J]. International Journal of Mechanical Sciences, 2018, 144: 618–627. DOI: 10.1016/j.ijmecsci.2018.05.035. [11] HASSOON O H, TARFAOUI M, ALAOUI A E M, et al. Mechanical performance evaluation of sandwich panels exposed to slamming impact: comparison between experimental and SPH results [J]. Composite Structures, 2019, 220: 776–783. DOI: 10.1016/j.compstruct.2019.04.051. [12] KOROBKIN A. Analytical models of water impact [J]. European Journal of Applied Mathematics, 2004, 15(6): 821–838. DOI: 10.1017/S0956792504005765. -

下载:

下载: