Impact resistence mechanism and deflection prediction of steel-concrete composite wall under fire exposure

-

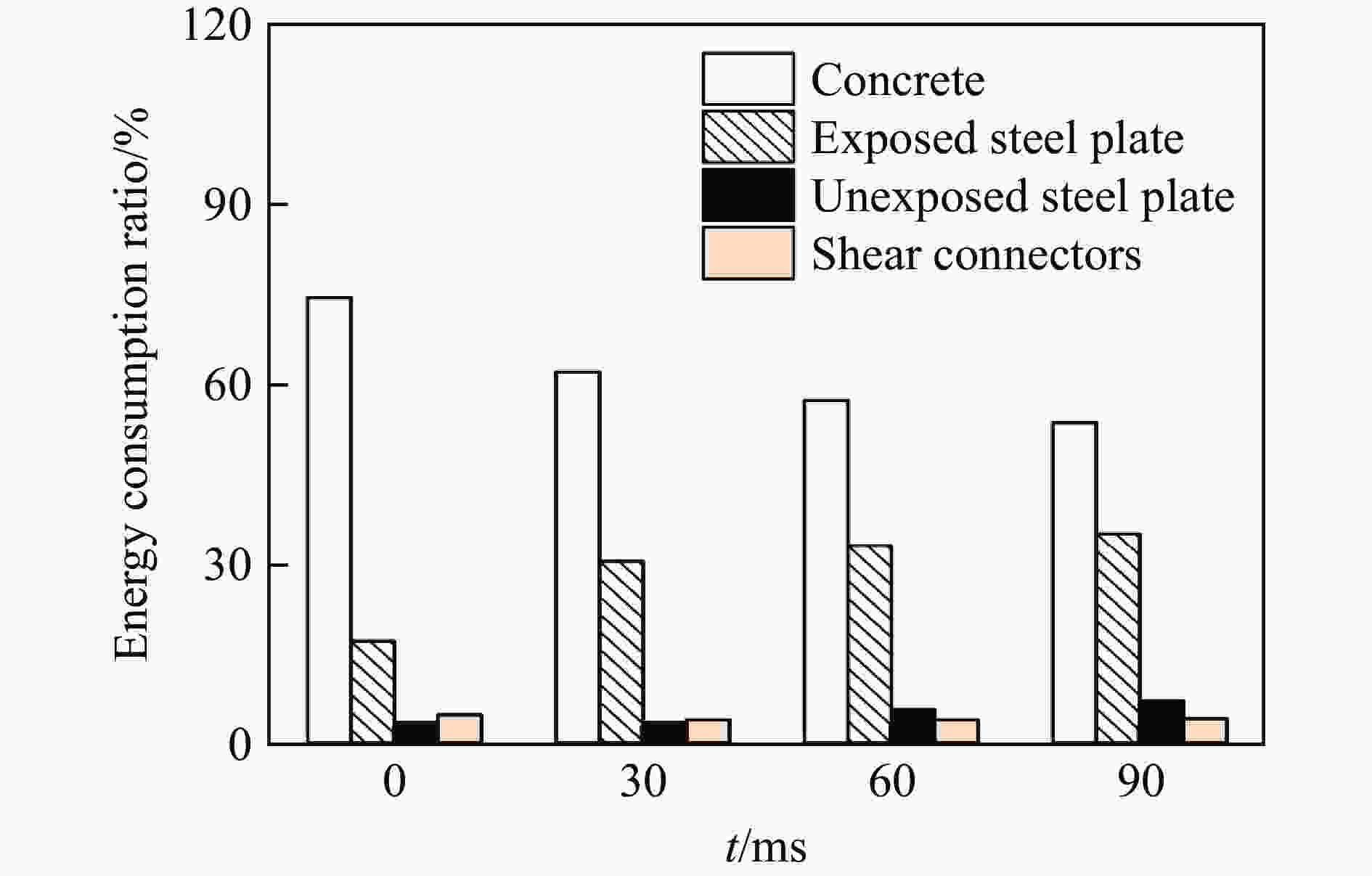

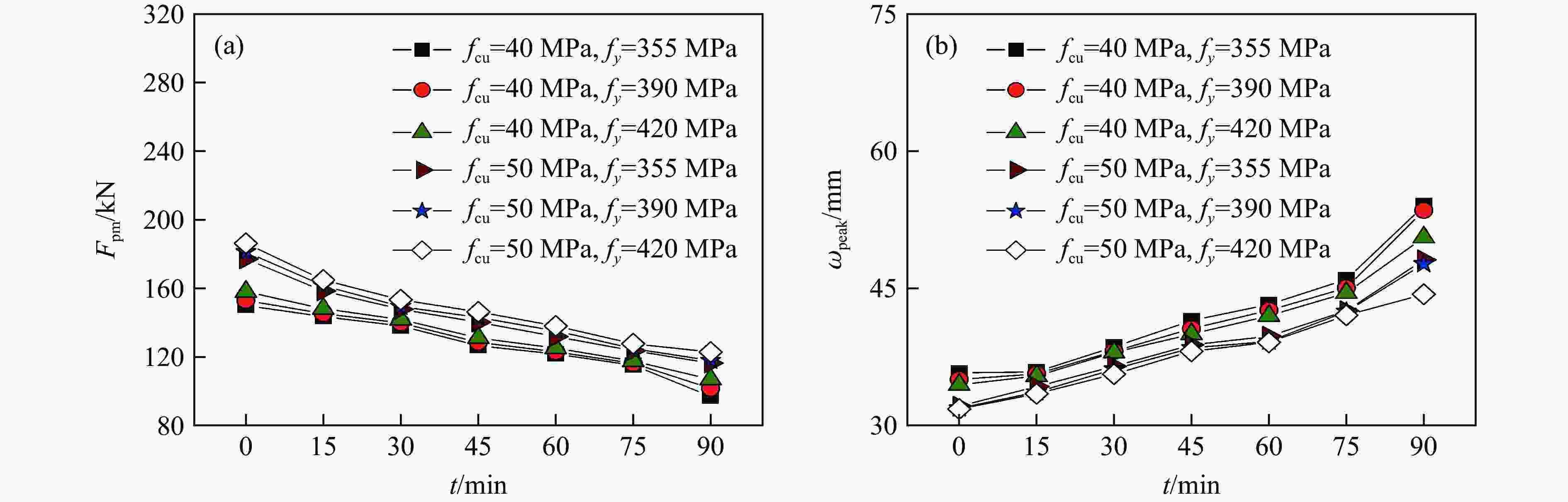

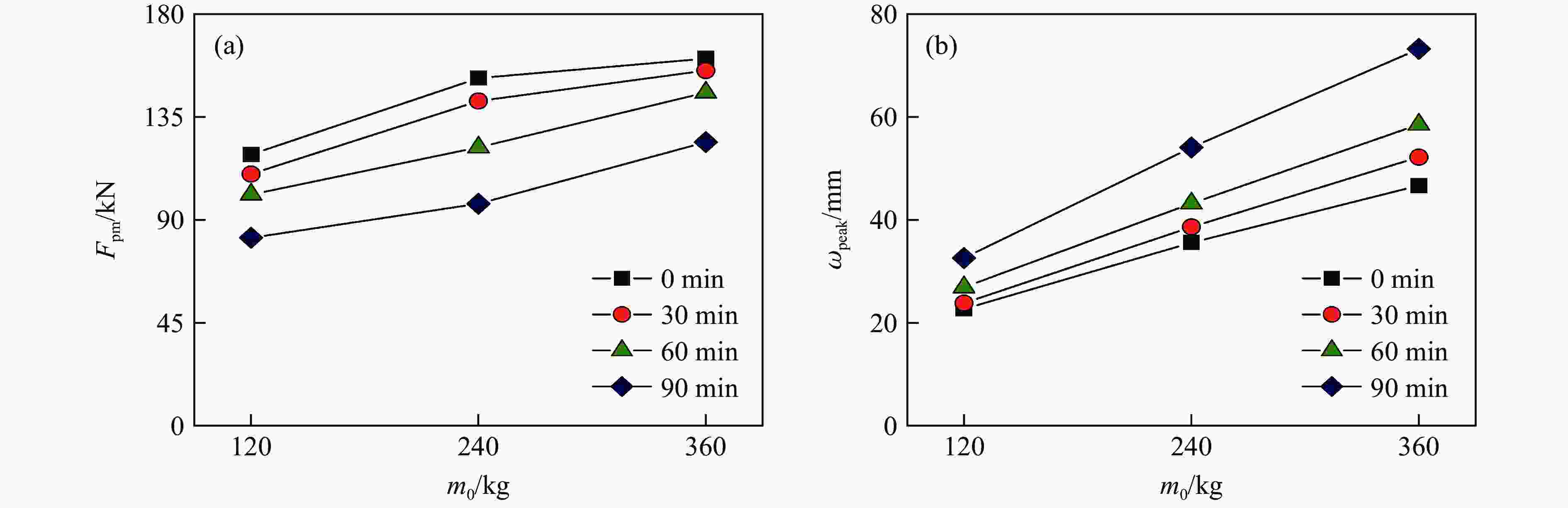

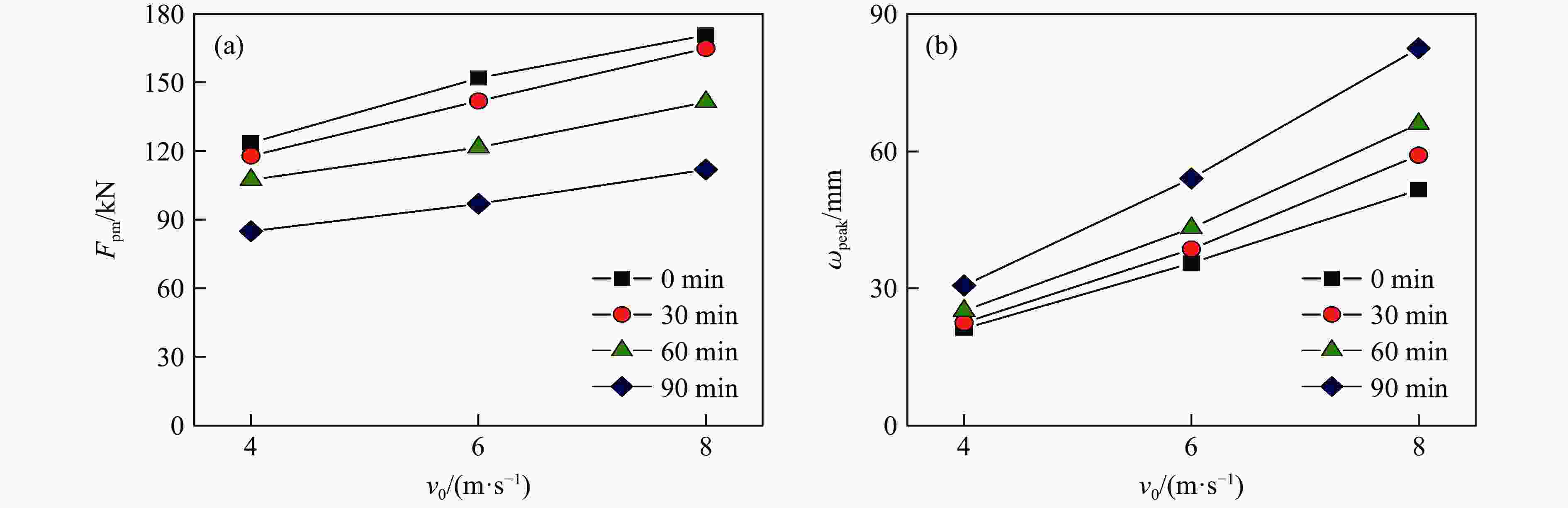

摘要: 双钢板-混凝土组合墙(steel-concrete composite wall, SC wall)常用于核电站、超高层等重要结构的承重构件,其在偶然荷载作用下的力学性能也是其推广应用的关键指标。为此,针对火灾下SC墙的抗冲击性能进行研究并给出相关设计建议。首先建立了SC墙在火灾与冲击耦合作用下的有限元模型,在验证模型可靠性基础上,开展了火灾下SC墙抗冲击机理的分析;然后研究了轴力、受火时间、材料强度、冲击能量与抗剪连接件形式等参数对SC墙在火灾下抗冲击性能的影响规律;最后给出了该类构件在耦合工况下跨中峰值挠度的预测公式。结果表明:随着受火时间的增加,SC墙受冲击变形模式由局部冲切逐渐转变为整体弯曲破坏;火灾下,混凝土为SC墙受冲击的主要耗能部件;混凝土强度、轴力与抗剪连接件形式对SC墙在高温下的抗冲击性能影响显著,钢板强度的影响则较小;建议的公式可较合理地预测火灾下SC墙受冲击后的跨中峰值挠度。

-

关键词:

- 双钢板-混凝土组合墙 /

- 火灾 /

- 抗冲击性能 /

- 破坏模式 /

- 挠度预测

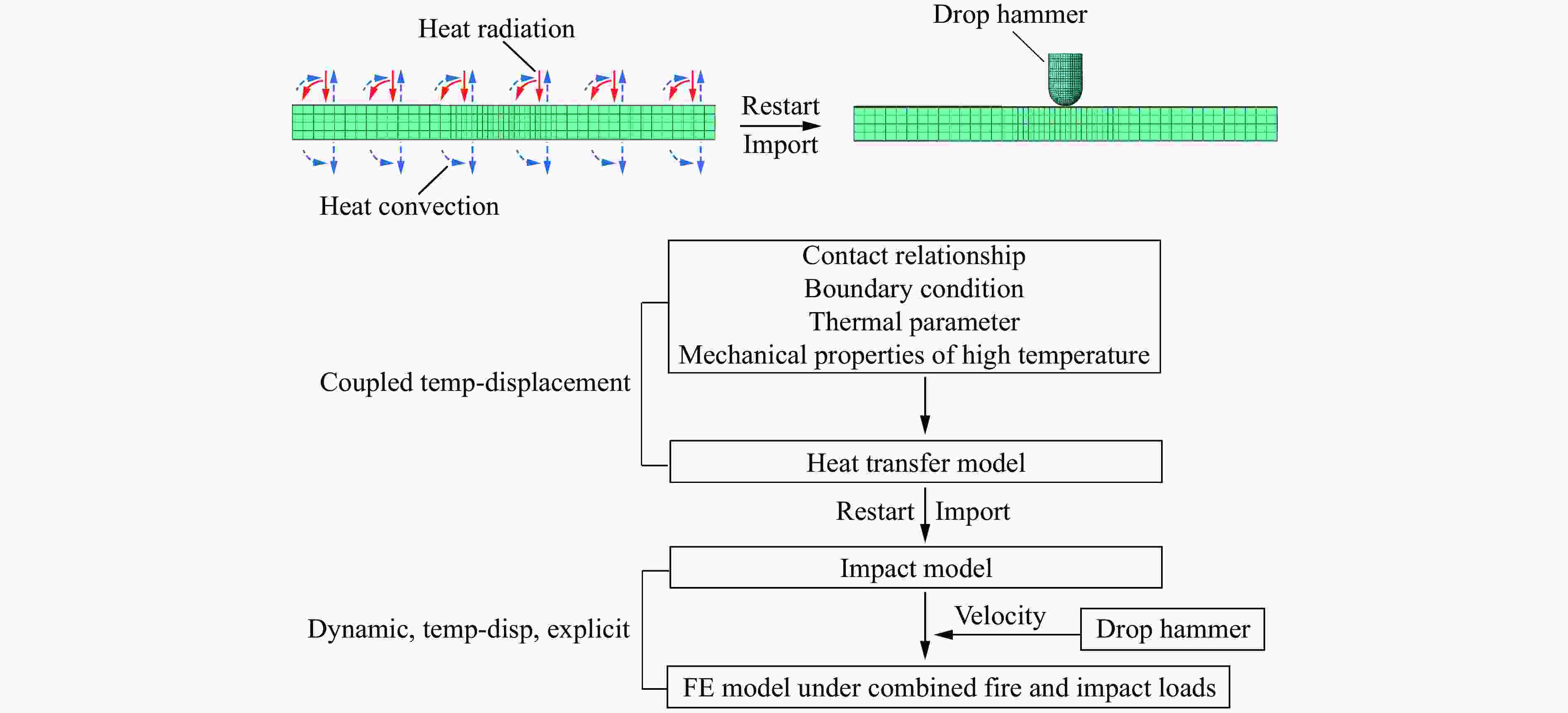

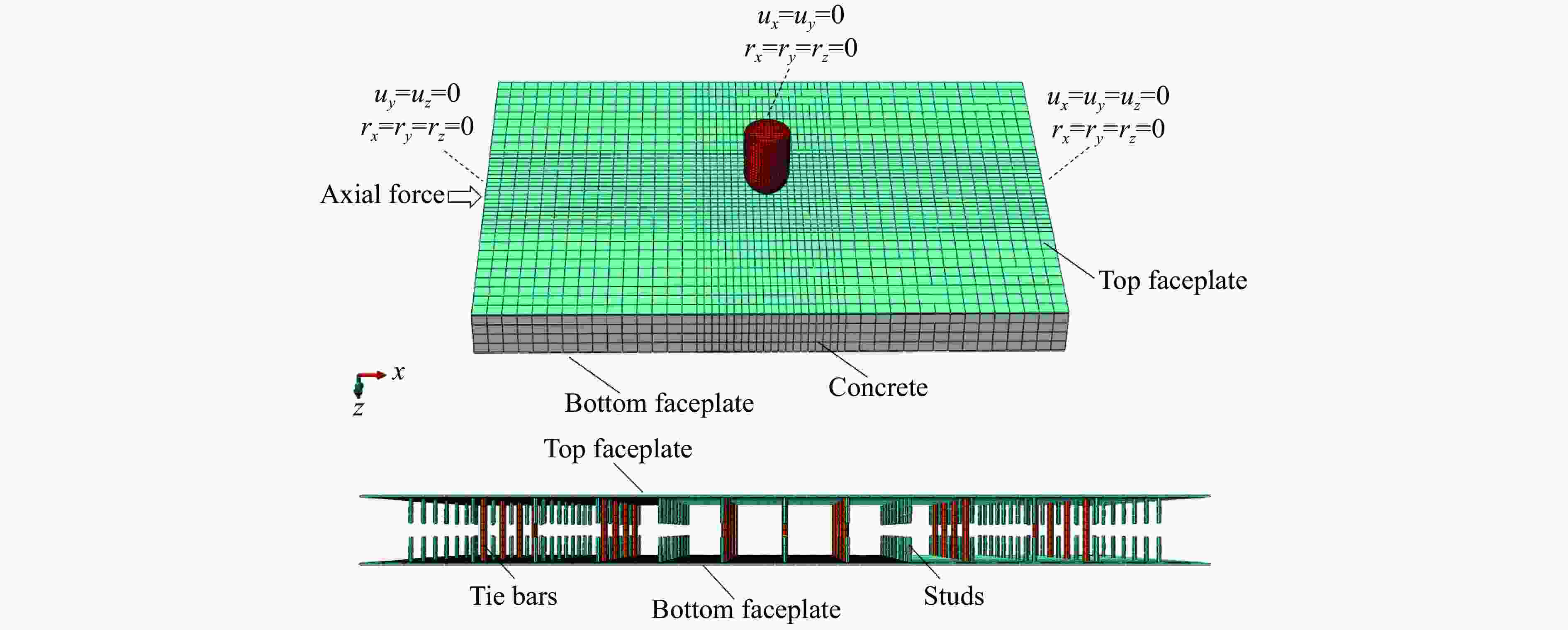

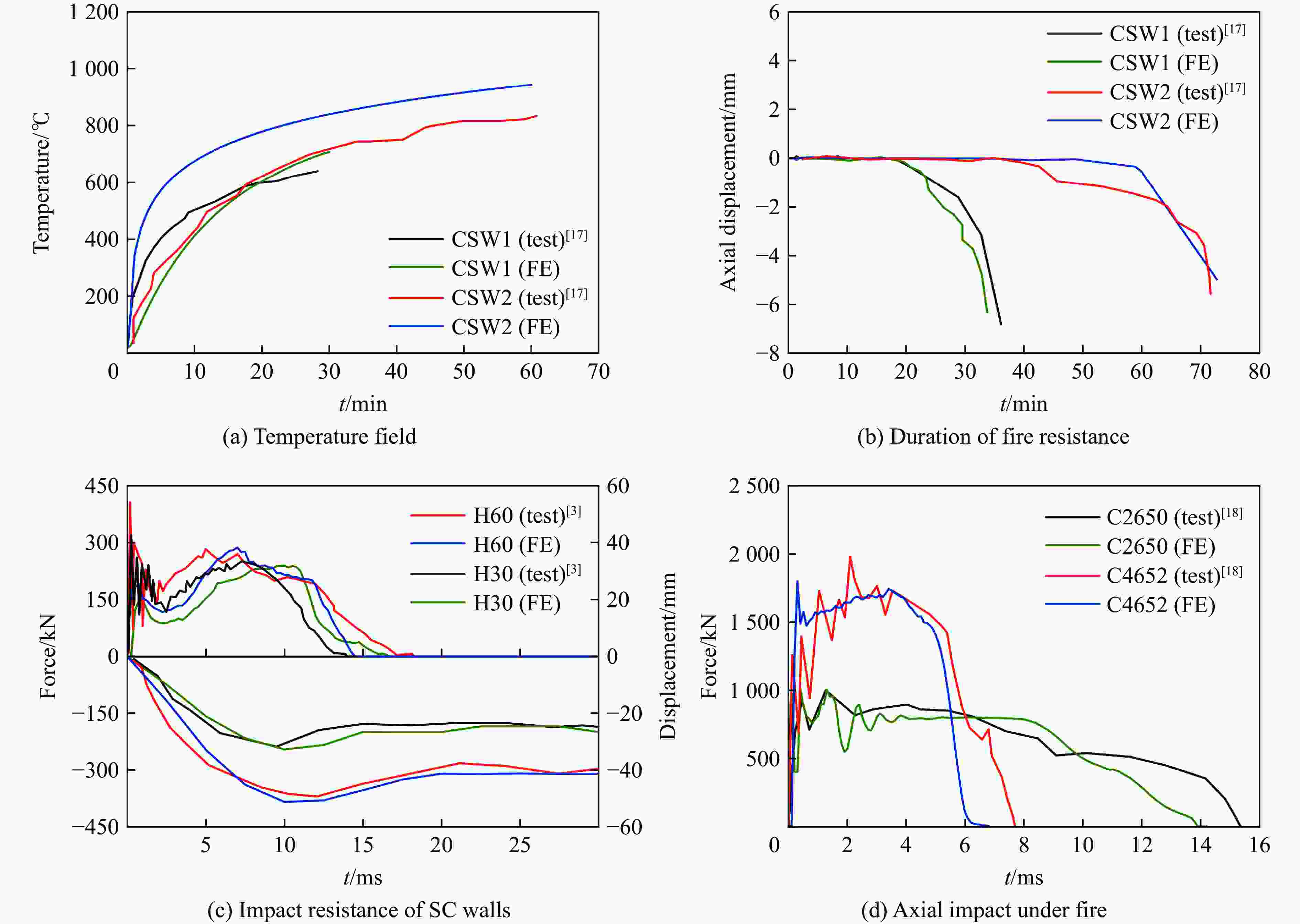

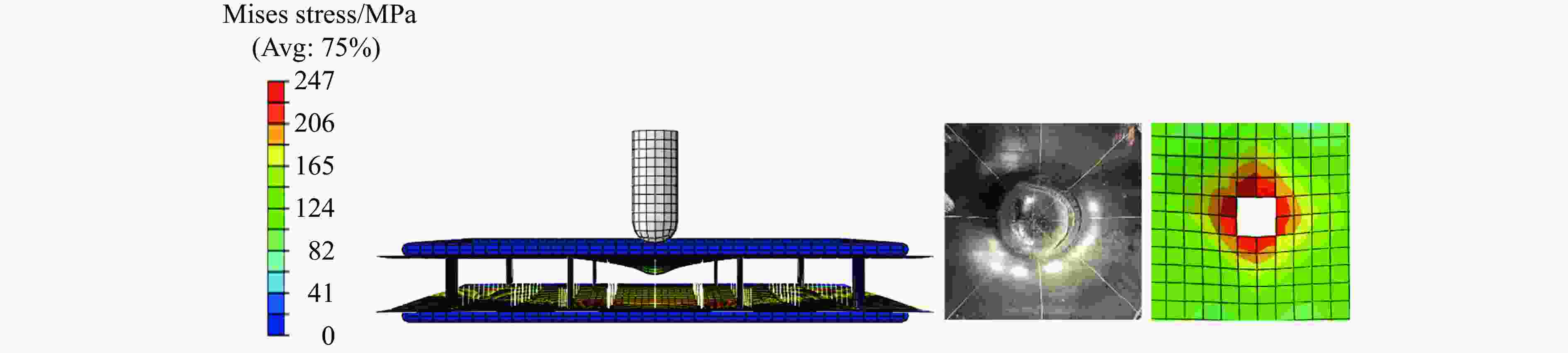

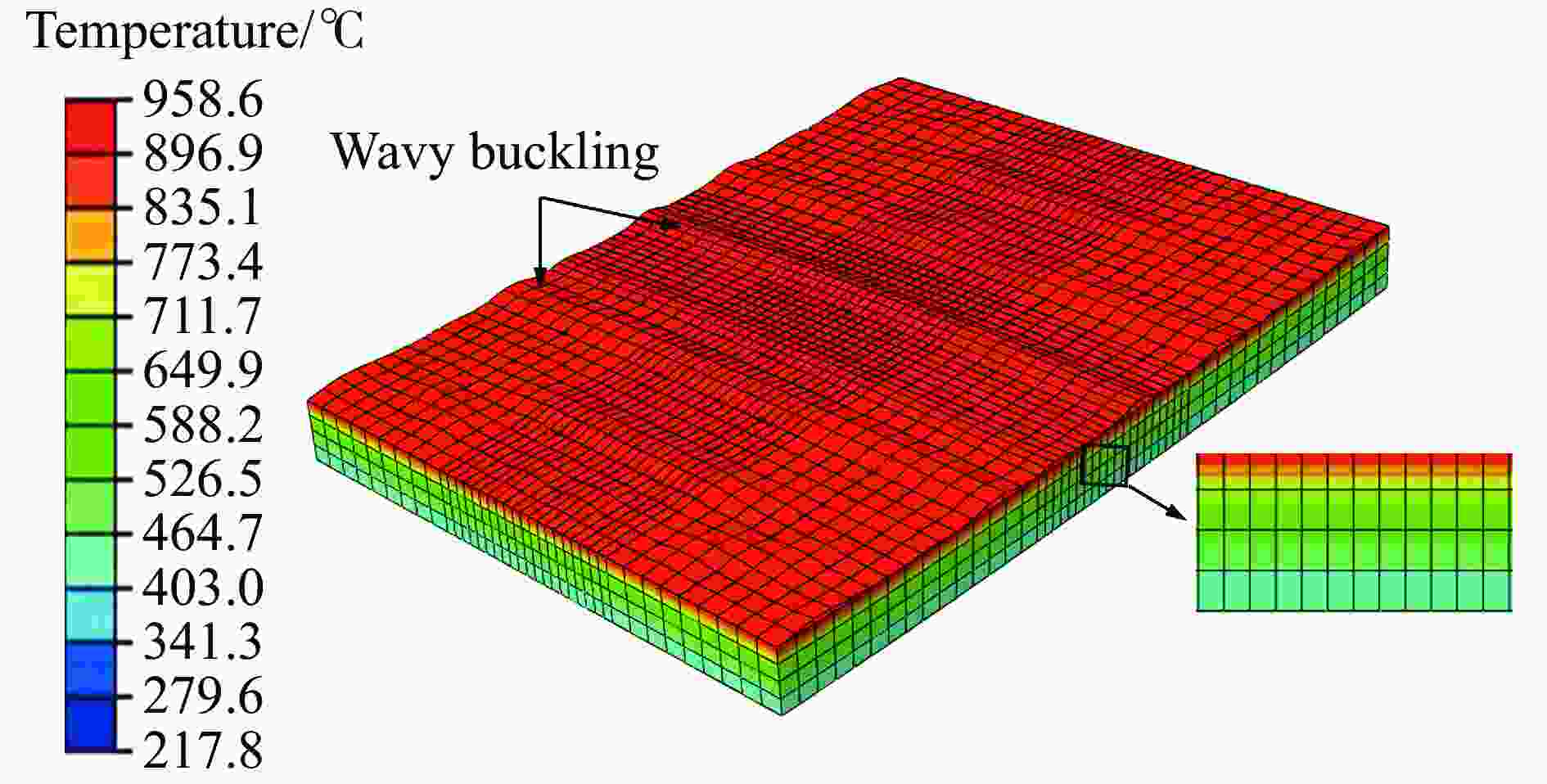

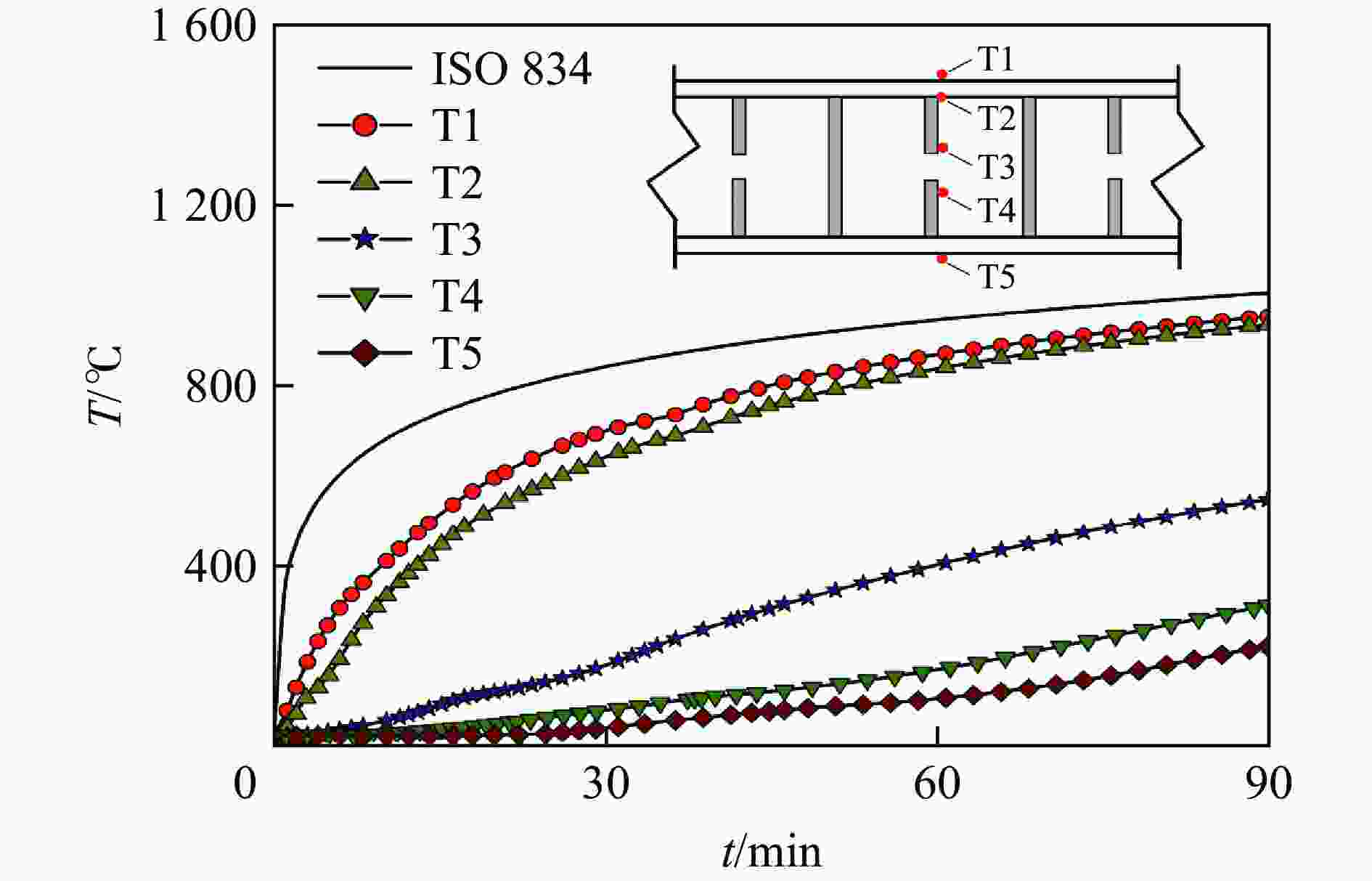

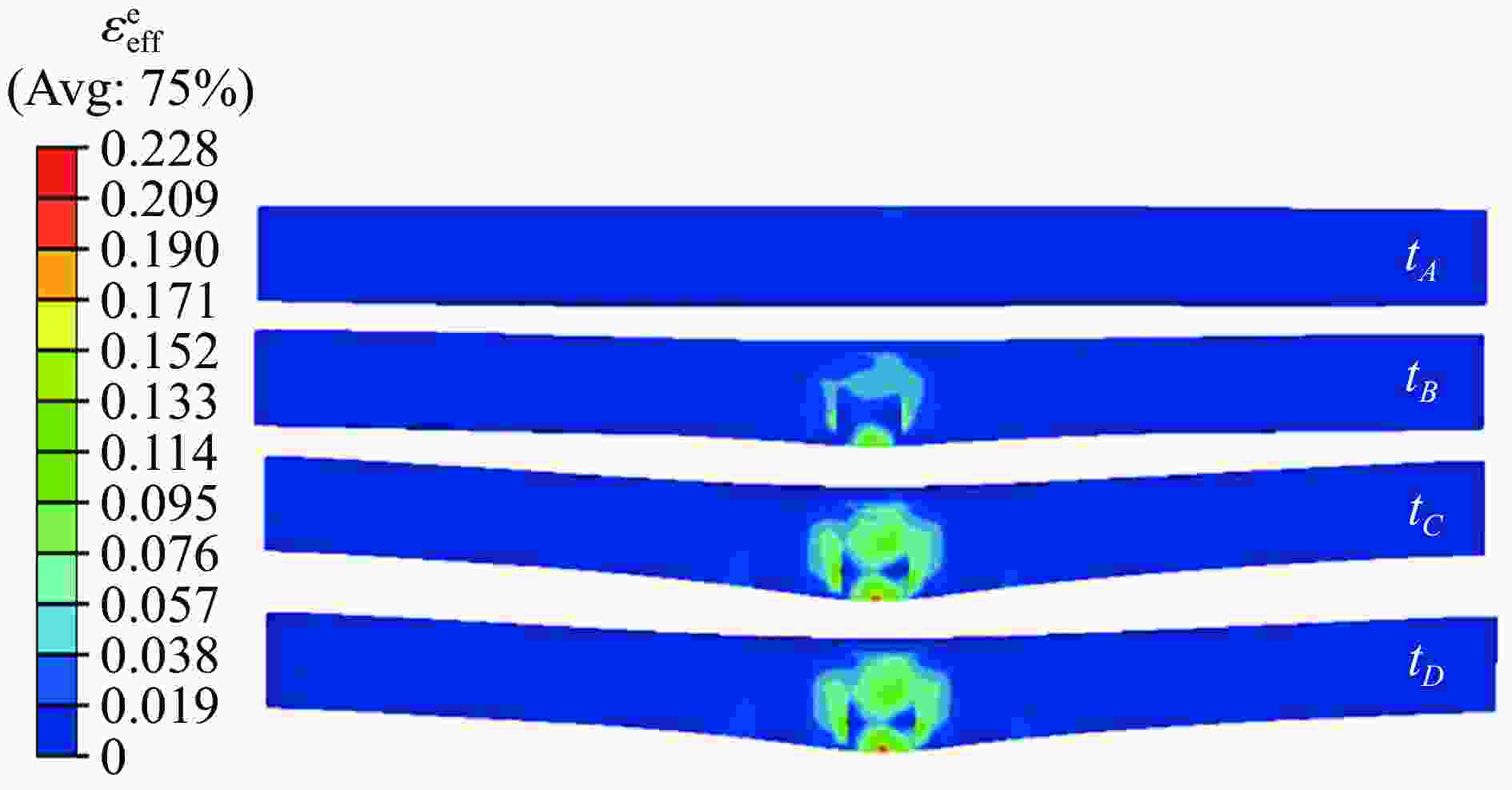

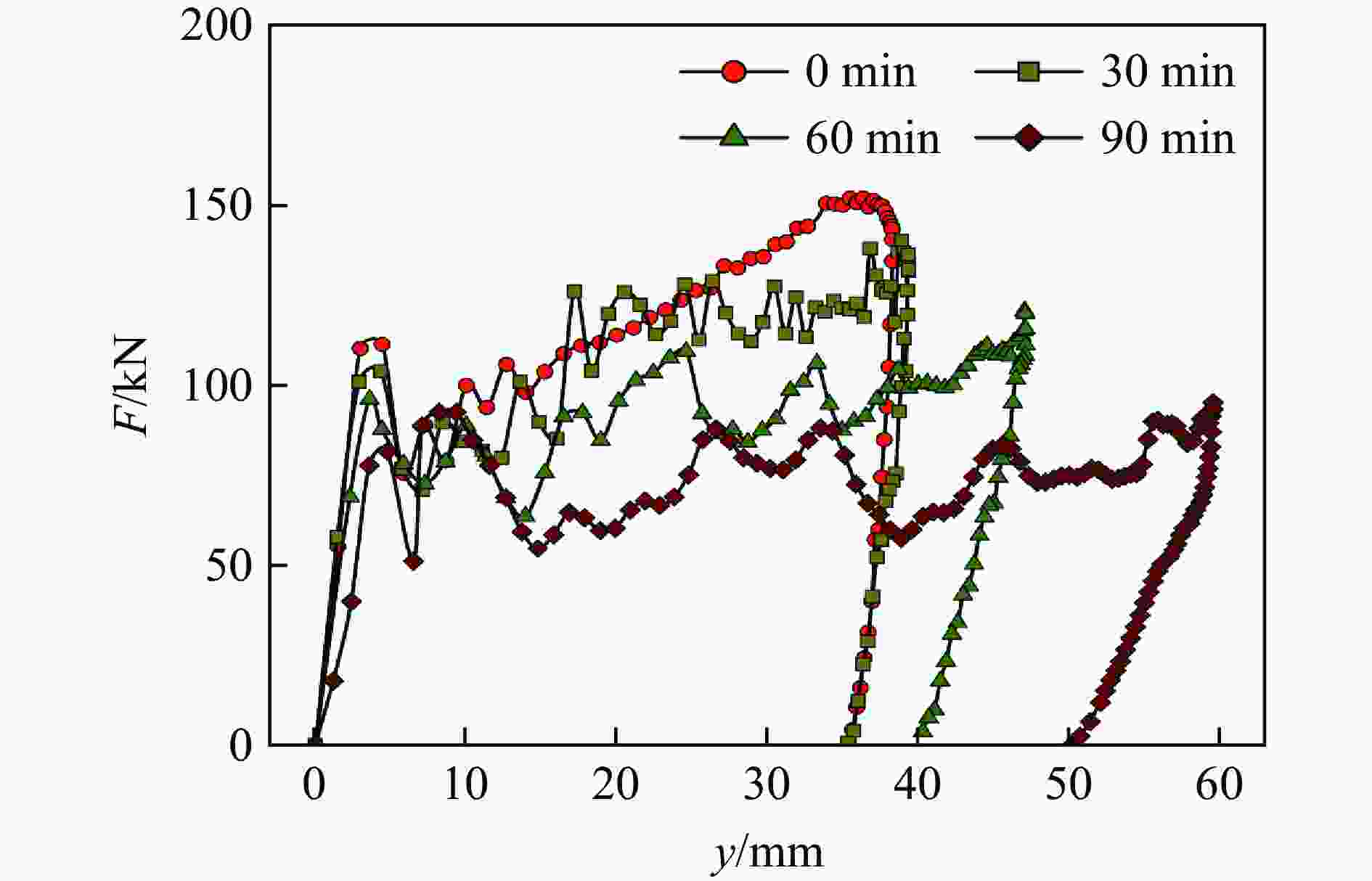

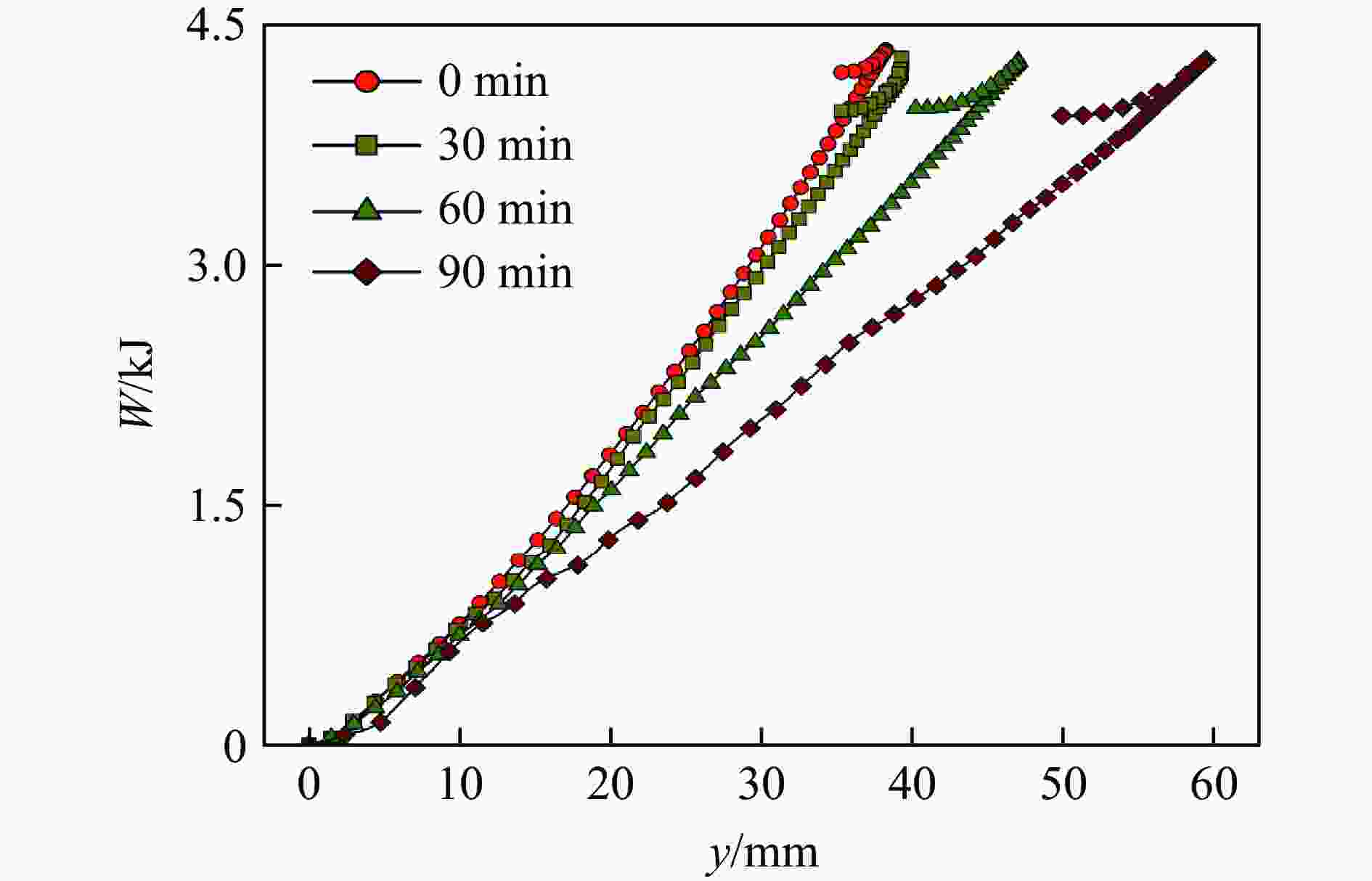

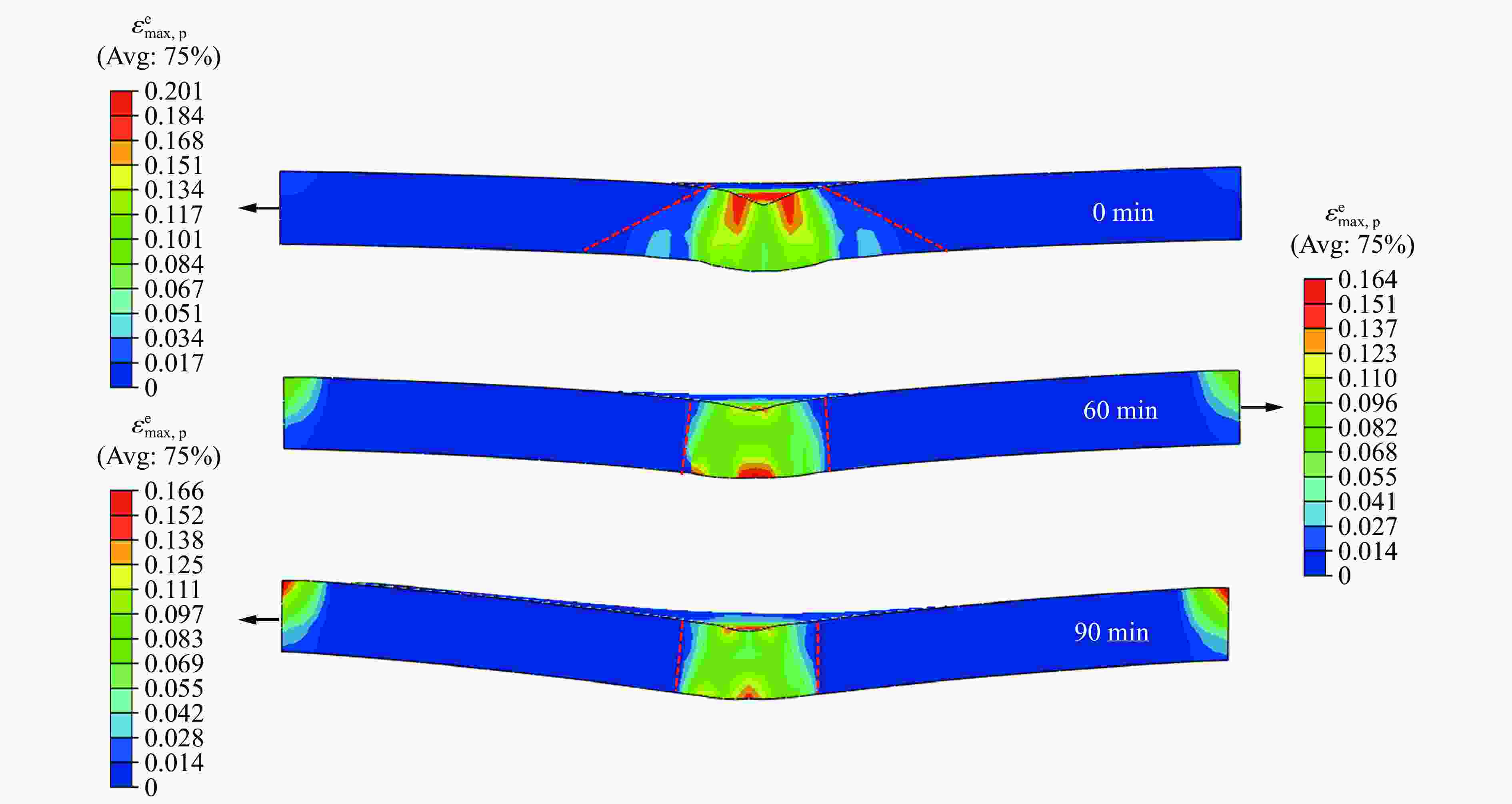

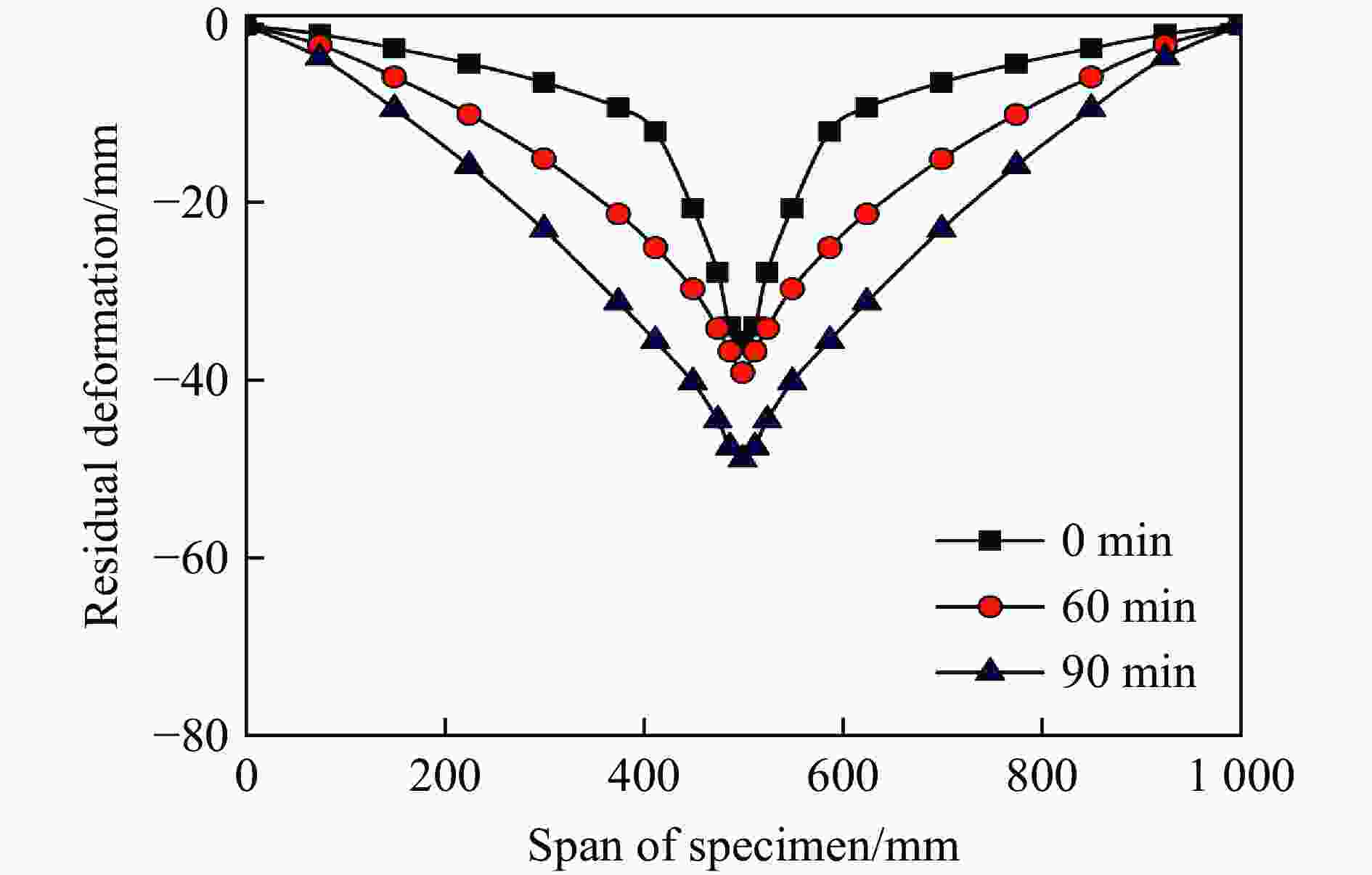

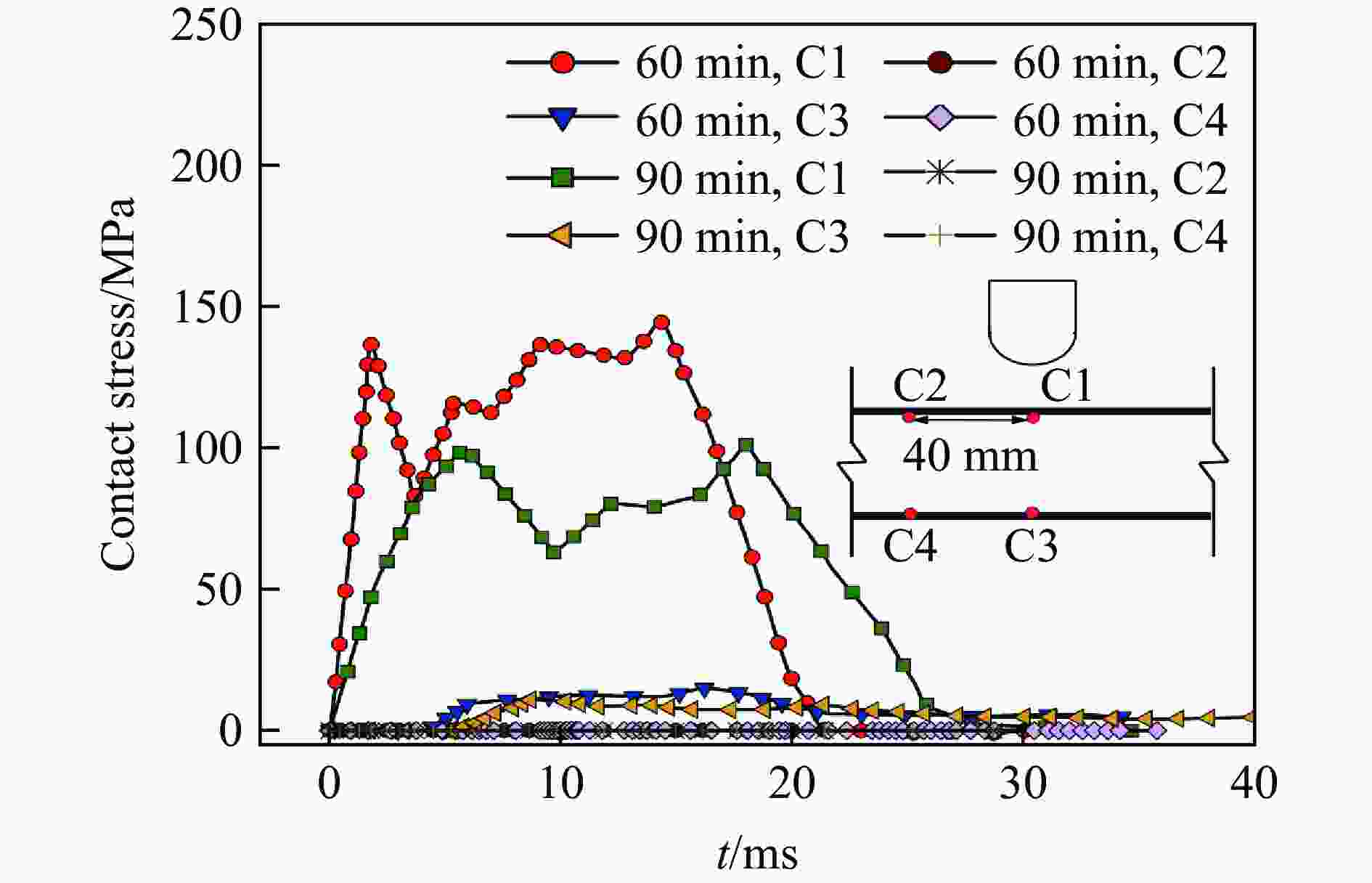

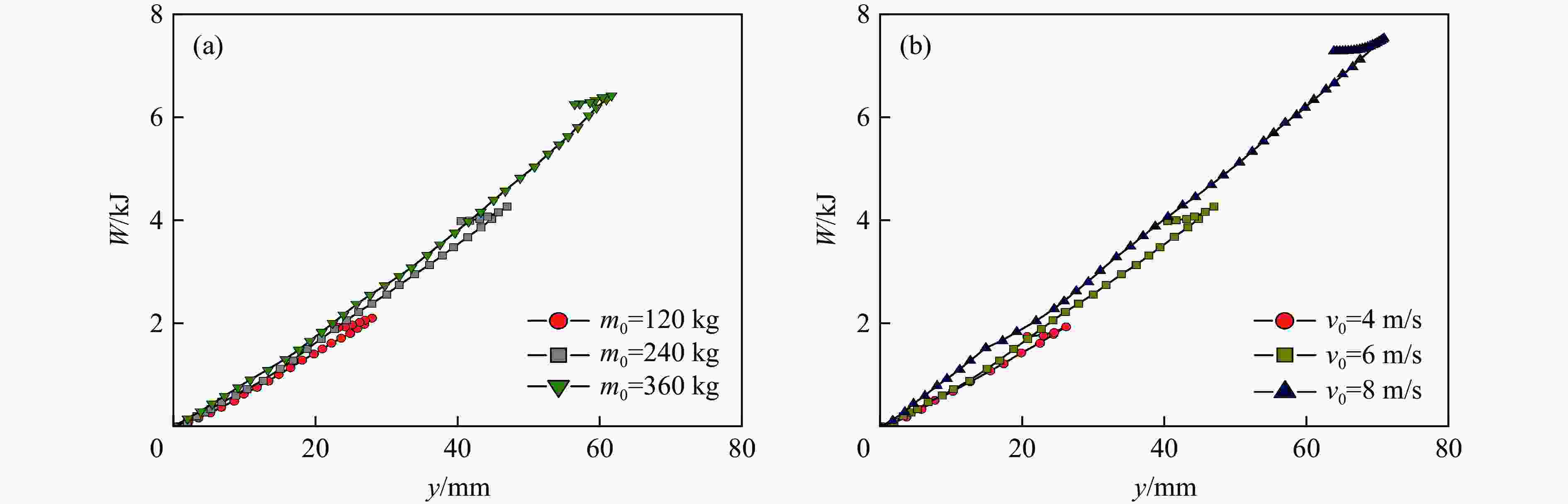

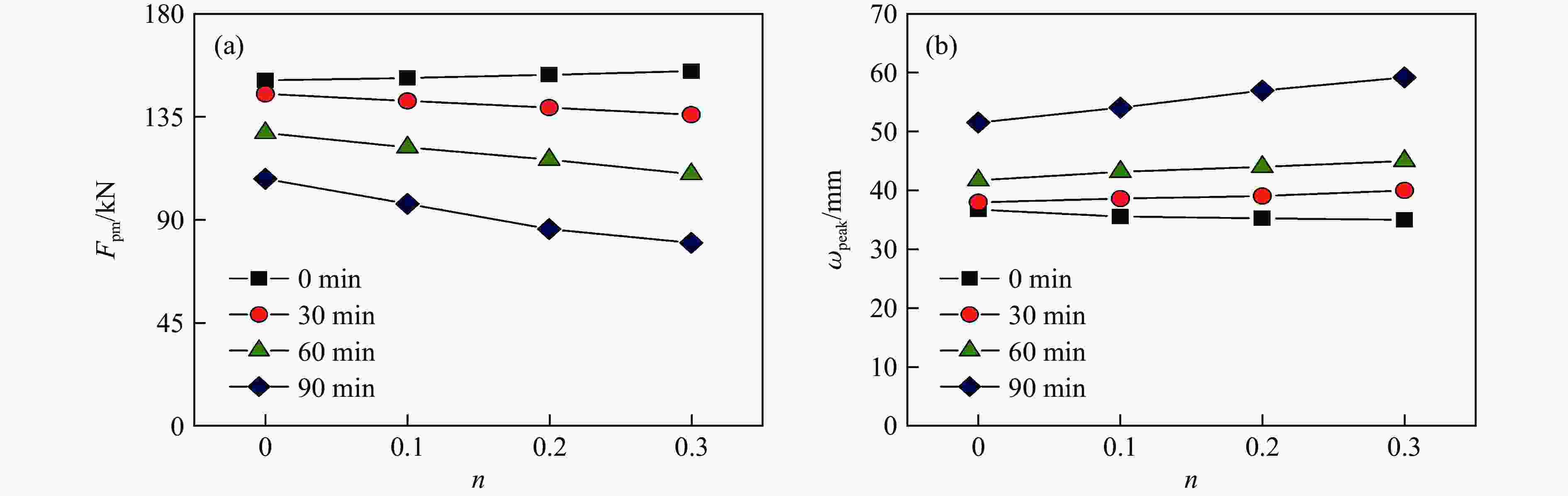

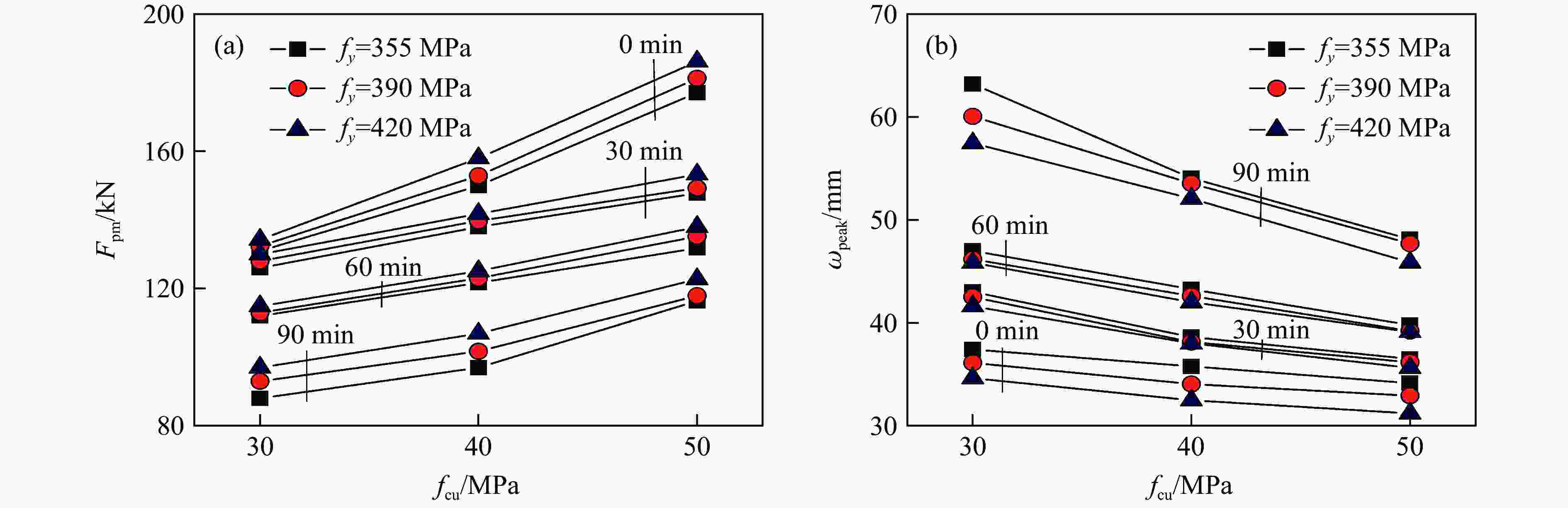

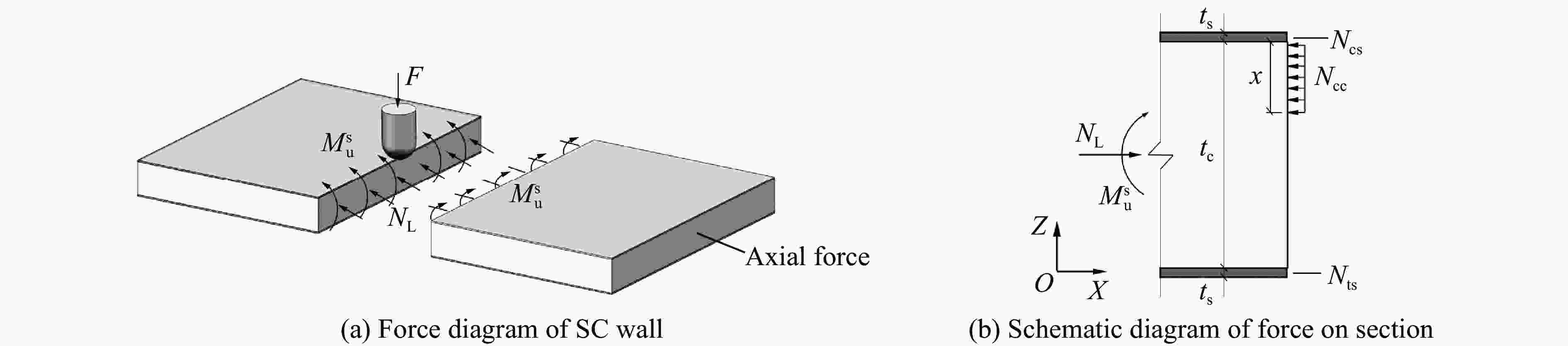

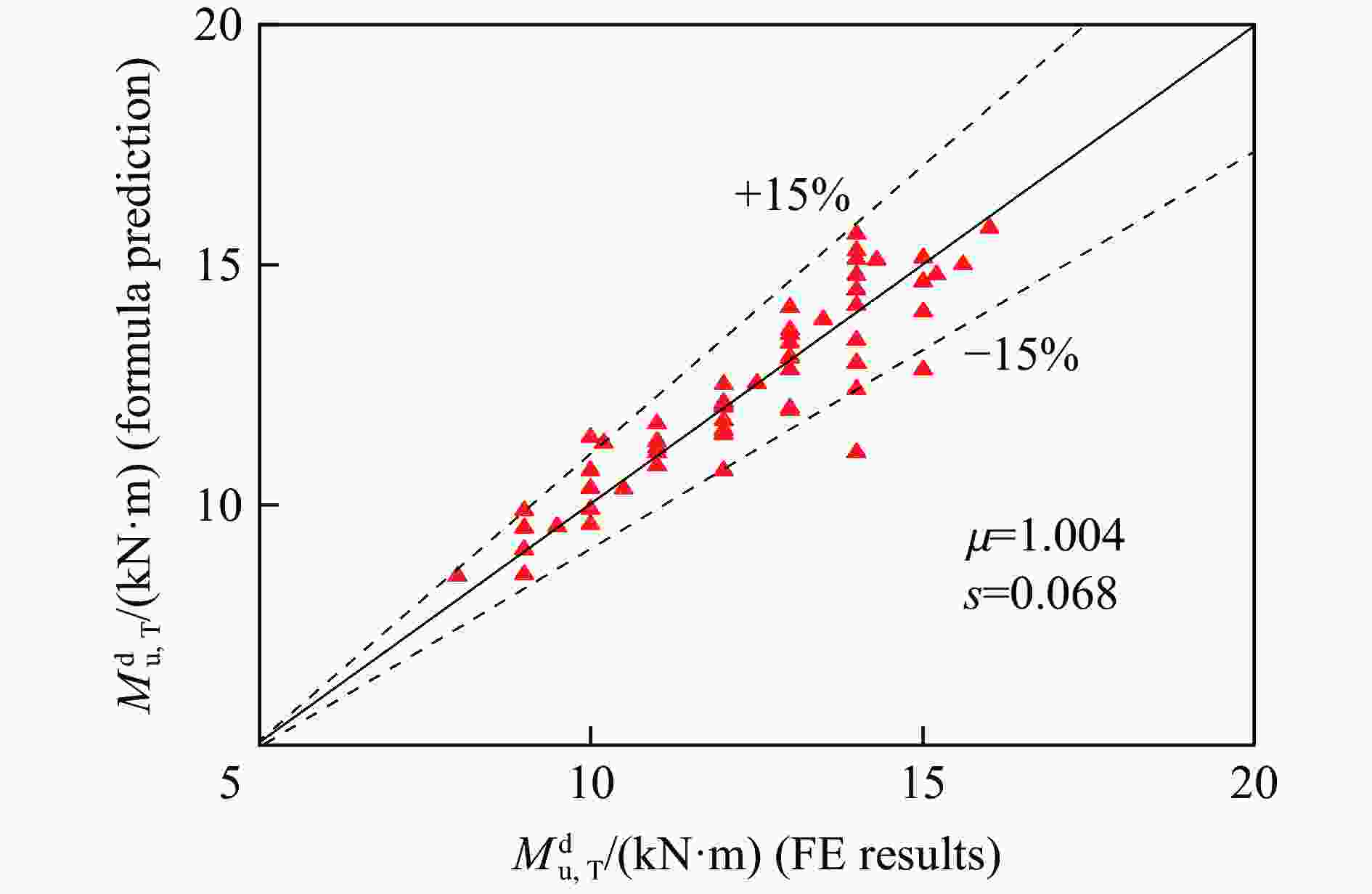

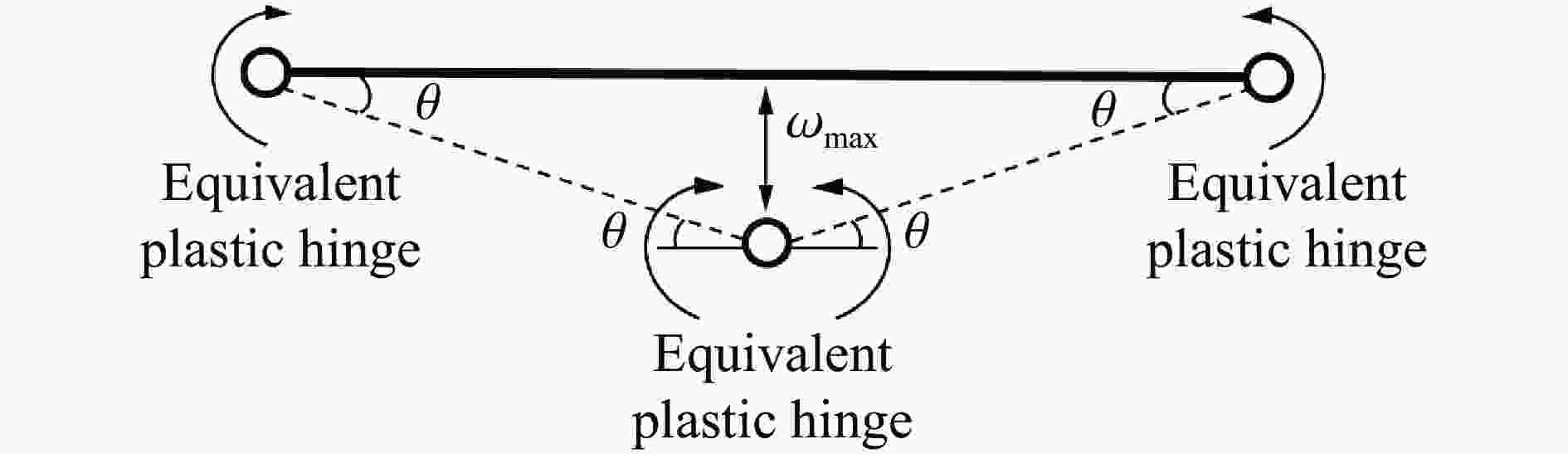

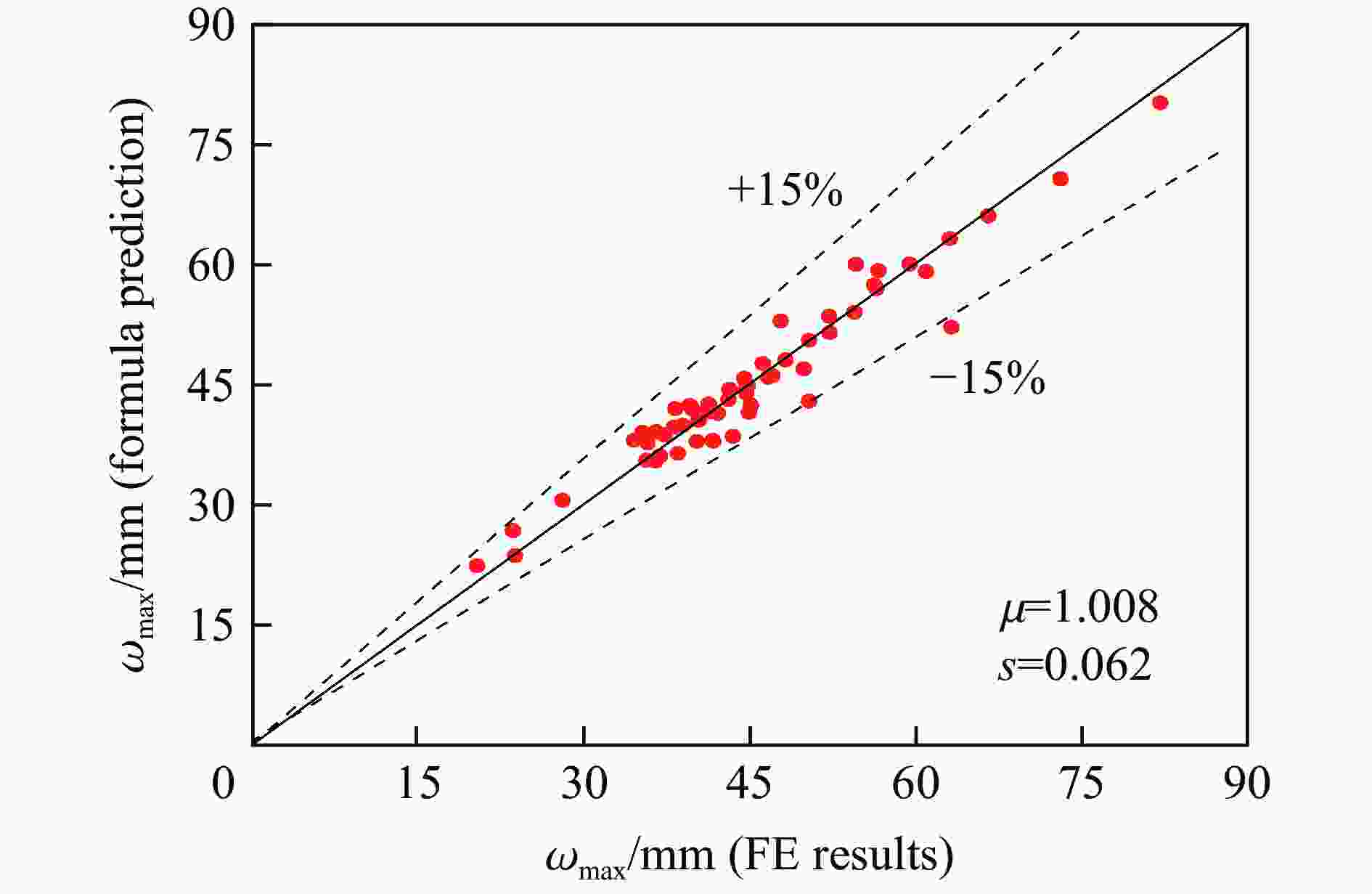

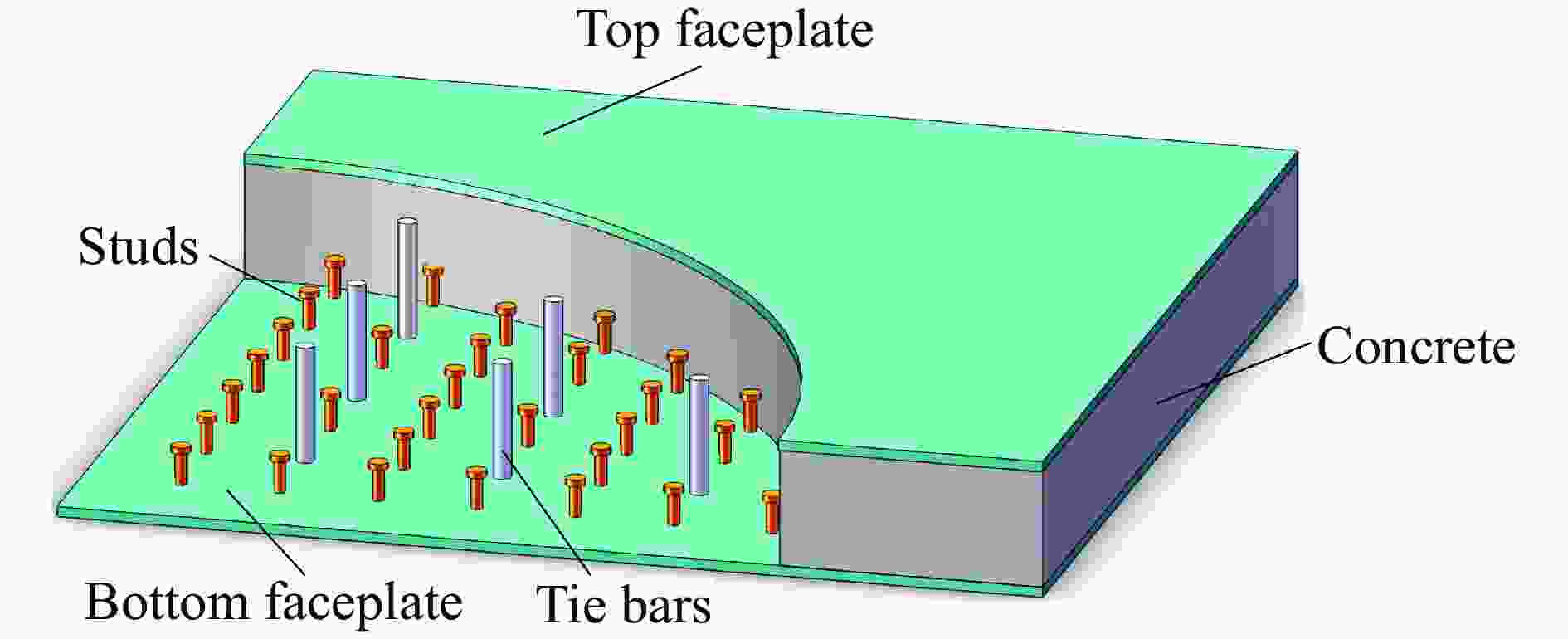

Abstract: Steel-concrete composite wall (SC wall) has been widely employed as the main structural components in nuclear power plants and high-rise buildings. Its performance under accidental loads is a key index for its utilization. In this paper, the mechanical behaviors of SC walls under coupled fire and impact loads are investigated and corresponding design recommendations are given. Firstly, a finite element (FE) model of SC walls under combined fire and impact loads is developed. After validating the FE model, the response mechanism of SC walls under combined fire and impact loads is analyzed. Afterwards, effects of axial force, fire duration, material strength, impact energy and type of shear connectors on the impact resistance performance of components under fire condition are studied. Finally, simplified formula for predicting the maximum mid-span deflection under coupled fire and impact loadings is proposed. In view of the failure pattern, the outer steel plate on the surface exposed to fire presents wavy buckling. With the increase of fire duration, the deformation mode of SC walls changes from local punching deformation to overall flexural deformation. Under combined fire and impact loads, concrete is observed to be the main energy consumption component within the SC walls. The peak membrane force and the maximum mid-span deflection are employed to analyze the impact resistance of the SC walls. Test results show that the fire duration has a significant effect on the impact resistance. The peak membrane force of the SC walls reduces by approximately 36% under 90 min fire duration, while the maximum mid-span deflection increases by 50%. The concrete strength, axial force and type of shear connectors also obviously affect the impact resistance of the SC walls, while the influence of the yield strength of steel plate is moderate. The proposed formula can reasonably predict the maximum deflection of the SC walls under combined fire and impact loads.-

Key words:

- steel-concrete composite wall /

- fire /

- impact resistance /

- failure pattern /

- deflection prediction

-

表 1 SC墙的详细参数

Table 1. Detailed parameters of SC walls

研究内容 剪力件形式 t/min n m0/kg v0/(m·s−1) fcu/MPa fy/MPa 机理分析 栓钉+对拉钢筋 0/30/60/90 0.1 240 6 40 355 受火时间 栓钉+对拉钢筋 0/15/30/45/60/75/90 0.1 240 6 40/50 355/390/420 轴压比 栓钉+对拉钢筋 0/30/60/90 0/0.1/0.2/0.3 240 6 40 355 材料强度 栓钉+对拉钢筋 0/30/60/90 0.1 240 6 30/40/50 355/390/420 剪力件形式 栓钉+对拉钢筋/对拉钢筋 0/30/60/90 0.1 240 6 40 355 冲击能量 栓钉+对拉钢筋 0/30/60/90 0.1 180/240/360 8/6/4 40 355 表 2 试验与模拟结果比值

Table 2. Ratio of test to numerical results

构件编号 冲击力/kN 试验值/模拟值 峰值挠度/mm 试验值/模拟值 试验 模拟 试验 模拟 H30 250 240 1.04 32.0 32.5 0.98 H60 296 298 0.99 47.6 51.0 0.93 C2650 896 943 0.95 − − − C4652 998 898 1.11 − − − 平均值 1.02 0.96 标准差 0.06 0.03 -

[1] 李小军, 李晓虎. 核电工程双钢板混凝土组合剪力墙面内受弯性能研究 [J]. 工程力学, 2017, 34(9): 43–53. DOI: 10.6052/j.issn.1000-4750.2016.08.0665.LI X J, LI X H. Study on in-plane flexural behavior of double steel plates and concrete infill composite shear walls for nuclear engineering [J]. Engineering Mechanics, 2017, 34(9): 43–53. DOI: 10.6052/j.issn.1000-4750.2016.08.0665. [2] 赵唯以, 王琳, 郭全全, 等. 双钢板混凝土组合结构抗冲击性能的研究进展 [J]. 钢结构(中英文), 2020, 35(3): 26–36. DOI: 10.13206/j.gjgS19121501.ZHAO W Y, WANG L, GUO Q Q, et al. Research advances of impact resistance of steel-concrete composite structures [J]. Steel Construction (Chinese & English), 2020, 35(3): 26–36. DOI: 10.13206/j.gjgS19121501. [3] 赵唯以, 郭全全. 低速冲击下双钢板混凝土组合墙的力学性能研究 [J]. 土木工程学报, 2018, 51(11): 88–94. DOI: 10.15951/j.tmgcxb.2018.11.007.ZHAO W Y, GUO Q Q. Study on behavior of double-skin steel-concrete composite walls subjected to low-velocity impact [J]. China Civil Engineering Journal, 2018, 51(11): 88–94. DOI: 10.15951/j.tmgcxb.2018.11.007. [4] 严加宝, 刘青峰, 张令心, 等. 设槽钢连接件的钢-混凝土-钢组合剪力墙抗冲击性能研究 [J]. 建筑结构学报, 2020, 41(S2): 270–279. DOI: 10.14006/j.jzjgxb.2020.S2.0030.YAN J B, LIU Q F, ZHANG L X, et al. Study on impact behavior of steel-concrete-steel sandwich shear wall with channel connectors [J]. Journal of Building Structures, 2020, 41(S2): 270–279. DOI: 10.14006/j.jzjgxb.2020.S2.0030. [5] 朱立猛, 高晓飞, 张春巍. 无焊缝全螺栓连接双钢板混凝土组合剪力墙平面外抗冲击性能有限元分析 [J]. 振动与冲击, 2021, 40(9): 166–174. DOI: 10.13465/j.cnki.jvs.2021.09.022.ZHU L M, GAO X F, ZHANG C W. Finite element analysis for out of plane anti-impact performance of unwelded steel plate-concrete-steel plate composite shear wall with all bolted joints [J]. Journal of Vibration and Shock, 2021, 40(9): 166–174. DOI: 10.13465/j.cnki.jvs.2021.09.022. [6] WEI F, FANG C, WU B. Fire resistance of concrete-filled steel plate composite (CFSPC) walls [J]. Fire Safety Journal, 2017, 88: 26–39. DOI: 10.1016/j.firesaf.2016.12.008. [7] 钱凯, 谭鑫宇, 李治, 等. 高温下钢筋混凝土板抗冲击性能及其影响因素 [J]. 工程力学, 2023, 40(1): 132–143, 154. DOI: 10.6052/j.issn.1000-4750.2021.08.0594.QIAN K, TAN X Y, LI Z, et al. Impact performance and the influence factors of reinforced concrete slabs under high temperatures [J]. Engineering Mechanics, 2023, 40(1): 132–143, 154. DOI: 10.6052/j.issn.1000-4750.2021.08.0594. [8] JIN L, BAI J J, ZHANG R B, et al. Effect of elevated temperature on the low-velocity impact performances of reinforced concrete slabs [J]. International Journal of Impact Engineering, 2021, 149: 103797. DOI: 10.1016/j.ijimpeng.2020.103797. [9] LIE T T, KODUR V K R. Fire resistance of steel columns filled with bar-reinforced concrete [J]. Journal of Structural Engineering, 1996, 122(1): 30–36. DOI: 10.1061/(ASCE)0733-9445(1996)122:1(30). [10] NARAYANAN R S. EN 1993-1-2: 2005 design of steel structures-part 1-2: general rules-structural fire design [S]. Britain: British Standard Institution, 2005. [11] CHEN L, FANG Q, JIANG X Q, et al. Combined effects of high temperature and high strain rate on normal weight concrete [J]. International Journal of Impact Engineering, 2015, 86: 40–56. DOI: 10.1016/j.ijimpeng.2015.07.002. [12] AL-THAIRY H, WANG Y C. A numerical study of the behaviour and failure modes of axially compressed steel columns subjected to transverse impact [J]. International Journal of Impact Engineering, 2011, 38(8/9): 732–744. DOI: 10.1016/j.ijimpeng.2011.03.005. [13] 李国强, 陈凯, 蒋首超, 等. 高温下Q345钢的材料性能试验研究 [J]. 建筑结构, 2001, 31(1): 53–55. DOI: 10.19701/j.jzjg.2001.01.019.LI G Q, CHEN K, JIANG S C, et al. Experimental studies on the high-temperature material properties of Q345 steel [J]. Building Structure, 2001, 31(1): 53–55. DOI: 10.19701/j.jzjg.2001.01.019. [14] CHEN H, LIEW J Y. Explosion and fire analysis of steel frames using mixed element approach [J]. Journal of Engineering Mechanics, 2005, 131(6): 606–616. DOI: 10.1061/(ASCE)0733-9399(2005)131:6(606). [15] 李国强. 钢结构及钢-混凝土组合结构抗火设计 [M]. 北京: 中国建筑工业出版社, 2006.LI G Q. Fire resistance design of steel structure and steel-concrete composite structure [M]. Beijing: China Architecture & Building Press, 2006. [16] 王泽芳. 双钢板-超高性能混凝土组合板冲切性能研究[D]. 哈尔滨: 哈尔滨工业大学, 2019.WANG Z F. Punching shear performance of steel-ultra-high performance concrete-steel sandwich slabs [D]. Harbin: Harbin Institute of Technology, 2019. [17] 韦芳芳, 杜金娥, 胡雪峰, 等. 单面受火双钢板-混凝土组合剪力墙的耐火性能试验研究 [J]. 东南大学学报(自然科学版), 2016, 46(3): 518–522. DOI: 10.3969/j.issn.1001-0505.2016.03.011.WEI F F, DU J E, HU X F, et al. Experimental research on fire performance of concrete filled double-steel-plate composite wall exposed to one-side fire [J]. Journal of Southeast University (Natural Science Edition), 2016, 46(3): 518–522. DOI: 10.3969/j.issn.1001-0505.2016.03.011. [18] 霍静思, 任晓虎, 肖岩. 标准火灾作用下钢管混凝土短柱落锤动态冲击试验研究 [J]. 土木工程学报, 2012, 45(4): 9–20. DOI: 10.15951/j.tmgcxb.2012.04.009.HUO J S, REN X H, XIAO Y. Impact behavior of concrete-filled steel tubular stub columns under ISO-834 standard fire [J]. China Civil Engineering Journal, 2012, 45(4): 9–20. DOI: 10.15951/j.tmgcxb.2012.04.009. [19] 瞿海雁, 李国强, 孙建运, 等. 侧向冲击作用下钢管混凝土构件的简化分析模型 [J]. 同济大学学报(自然科学版), 2011, 39(1): 35–41. DOI: 10.3969/j.issn.0253-374x.2011.01.007.QU H Y, LI G Q, SUN J Y, et al. Simplified analysis model of circular concrete-filled steel tube specimen under lateral impact [J]. Journal of Tongji University (Natural Science), 2011, 39(1): 35–41. DOI: 10.3969/j.issn.0253-374x.2011.01.007. [20] JI S H, WANG W D, XIAN W. Lateral impact behaviour of square CFST columns under fire condition [J]. Journal of Constructional Steel Research, 2022, 196: 107367. DOI: 10.1016/j.jcsr.2022.107367. [21] 赵唯以, 高泽鹏, 王琳, 等. 集中荷载作用下四边简支双钢板混凝土组合板的力学性能研究 [J]. 工程力学, 2022, 39(3): 158–170, 192. DOI: 10.6052/j.issn.1000-4750.2021.01.0077.ZHAO W Y, GAO Z P, WANG L, et al. Mechanical performance of two-way simply supported steel-plate composite slabs under concentrated load [J]. Engineering Mechanics, 2022, 39(3): 158–170, 192. DOI: 10.6052/j.issn.1000-4750.2021.01.0077. -

下载:

下载: