Critical condition for tensile tearing failure of unidirectional stiffened plate under strong impact load

-

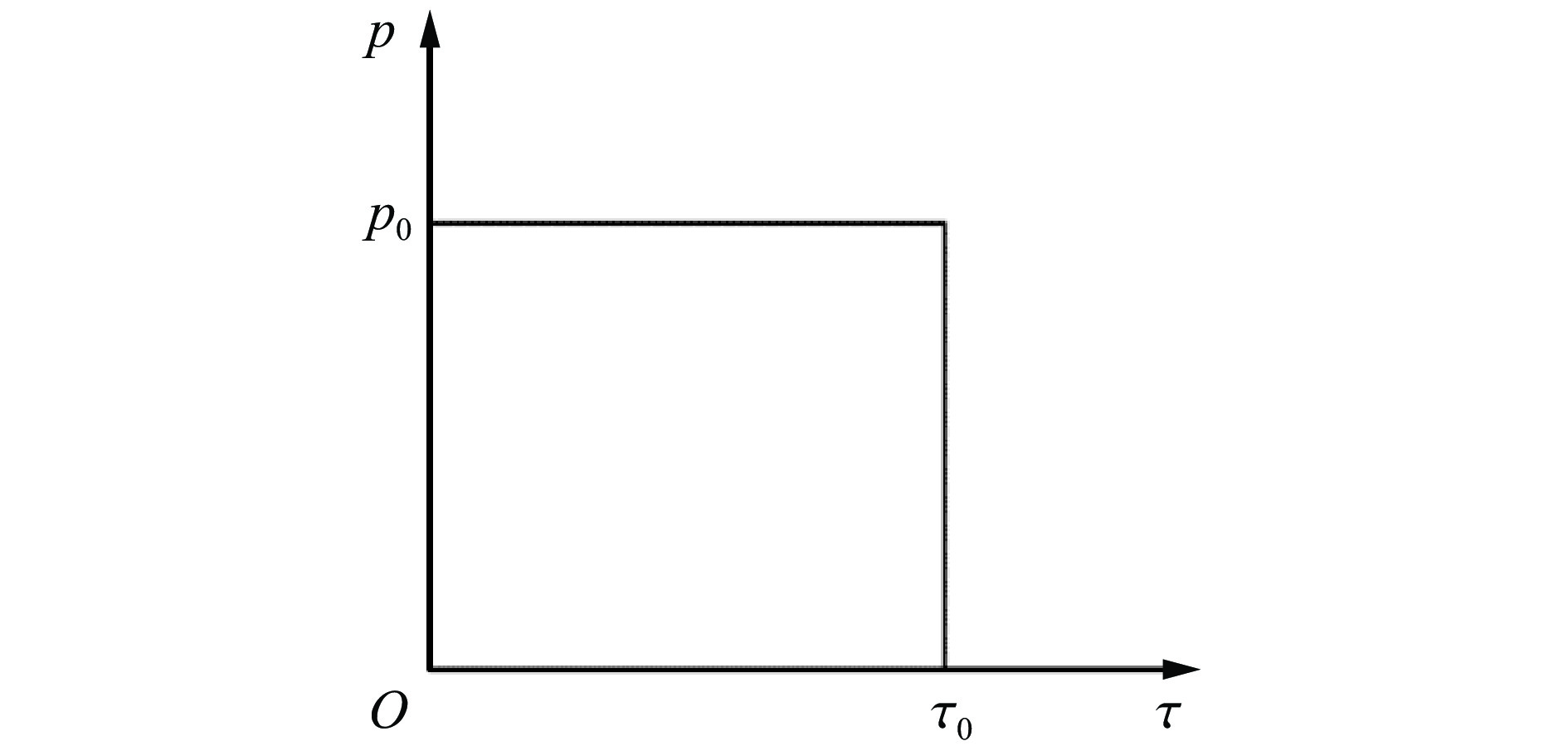

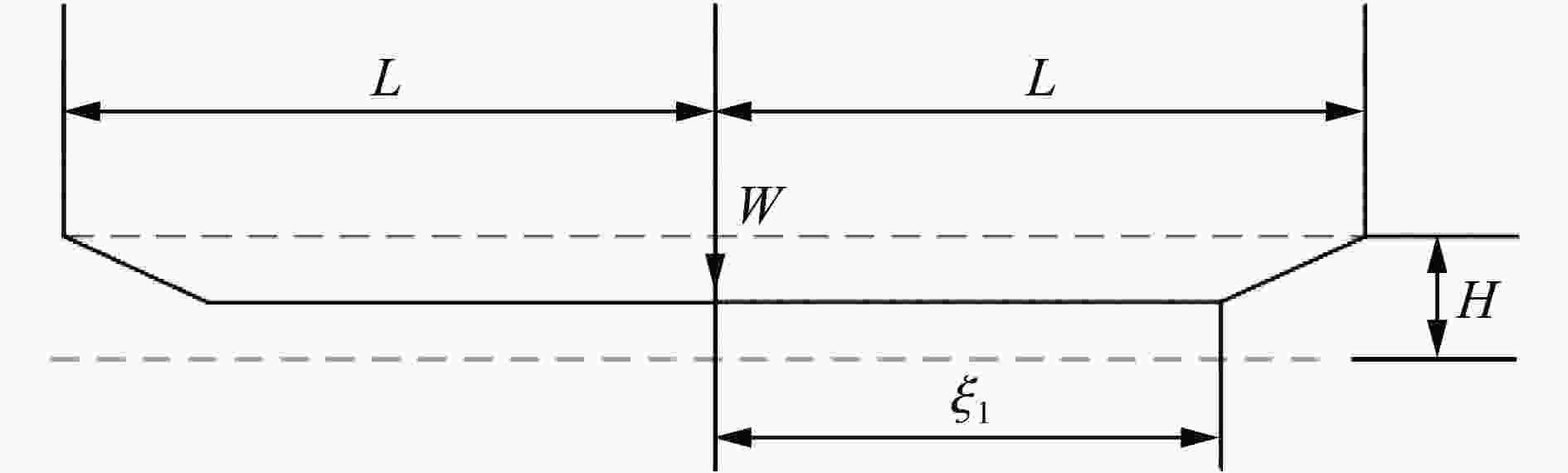

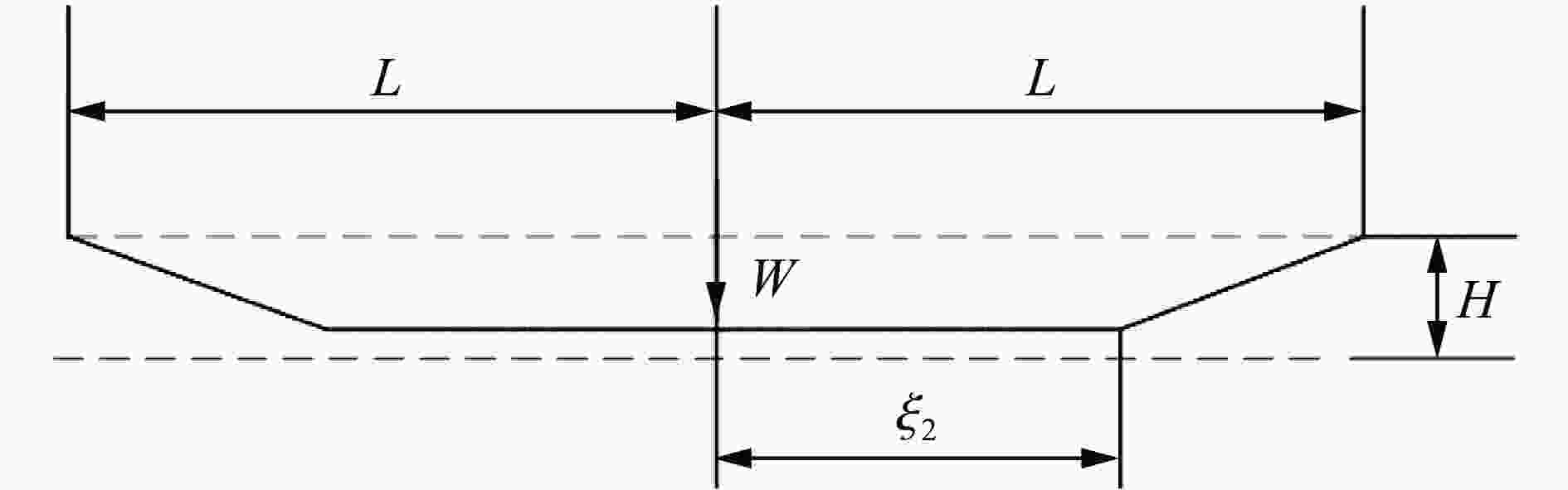

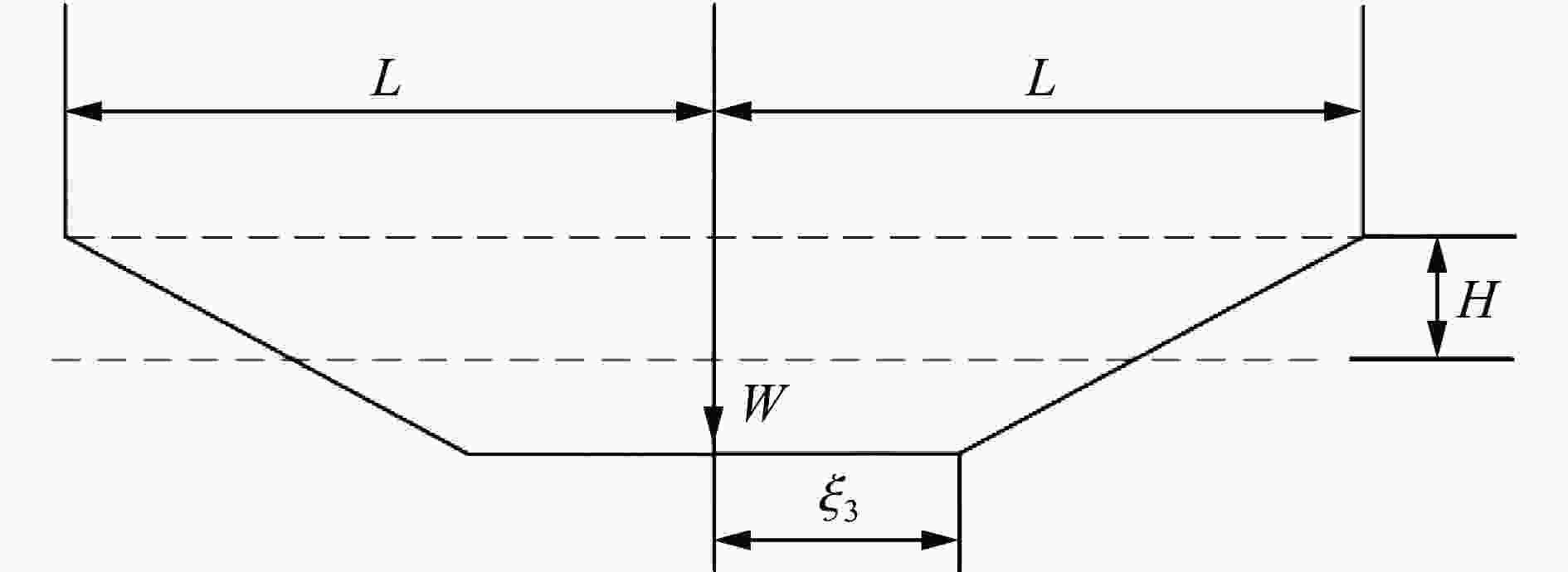

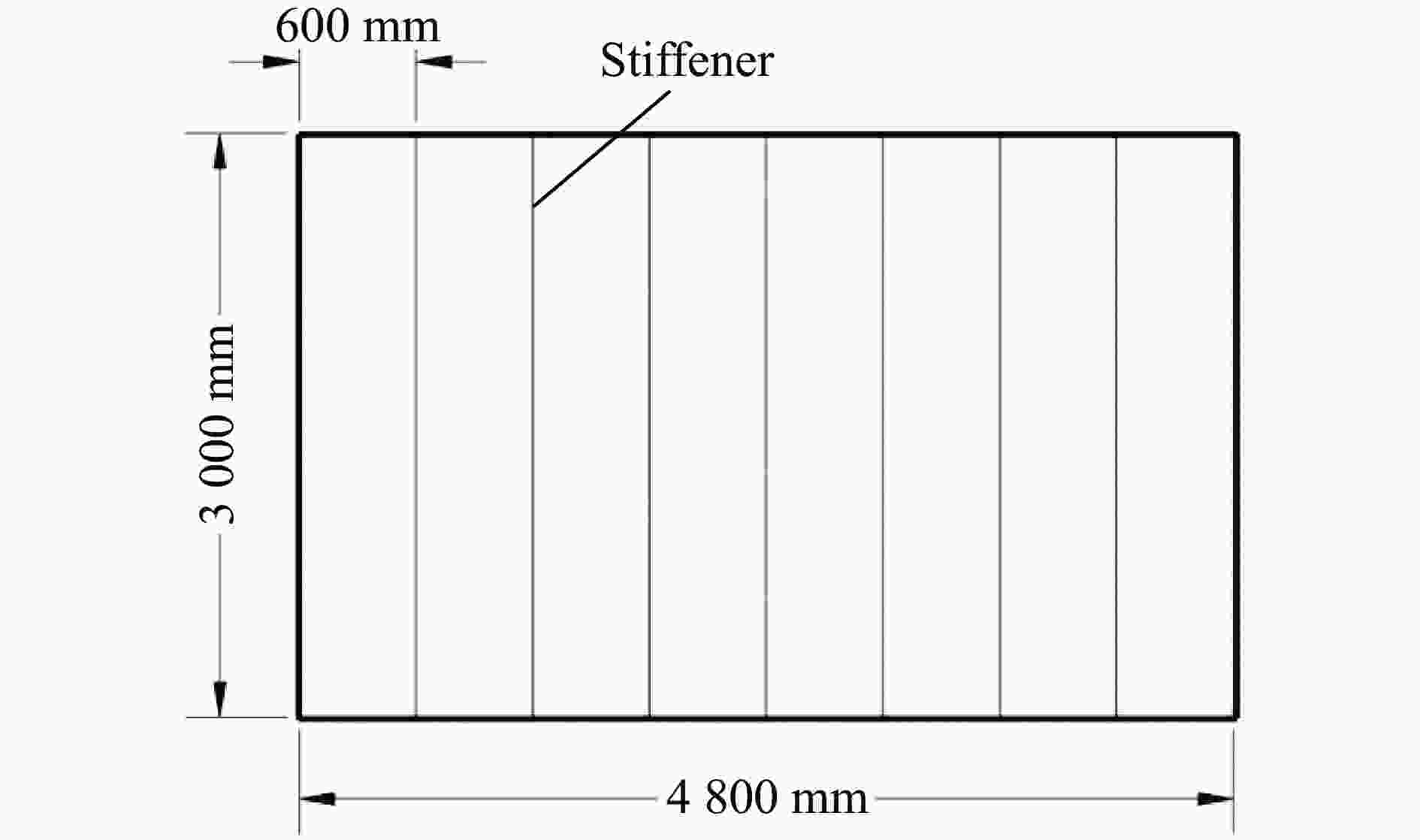

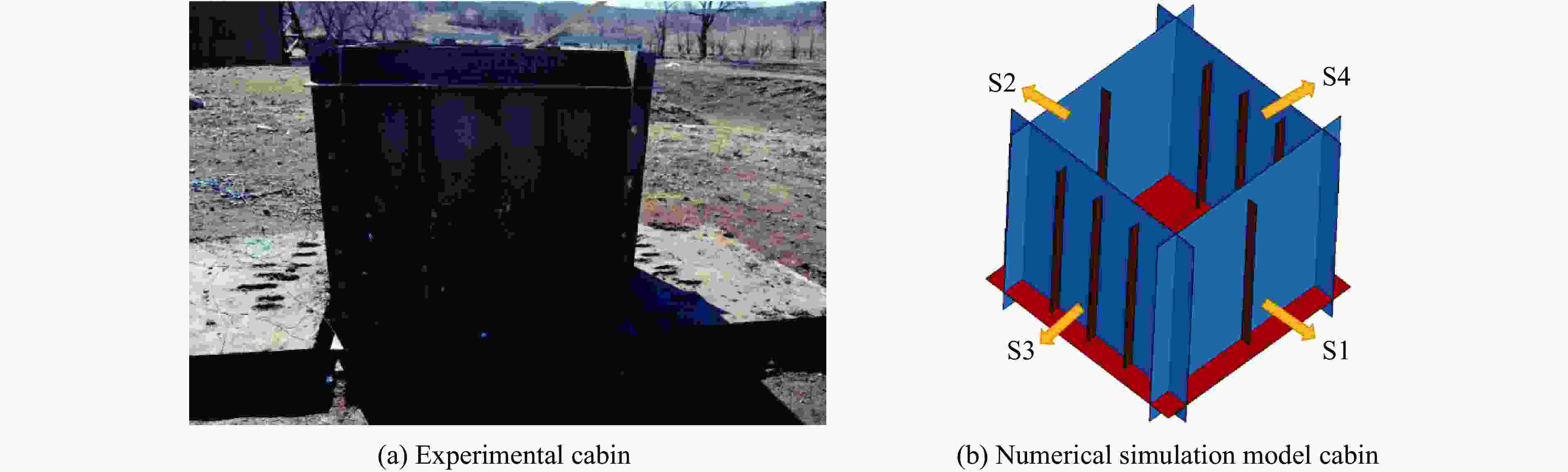

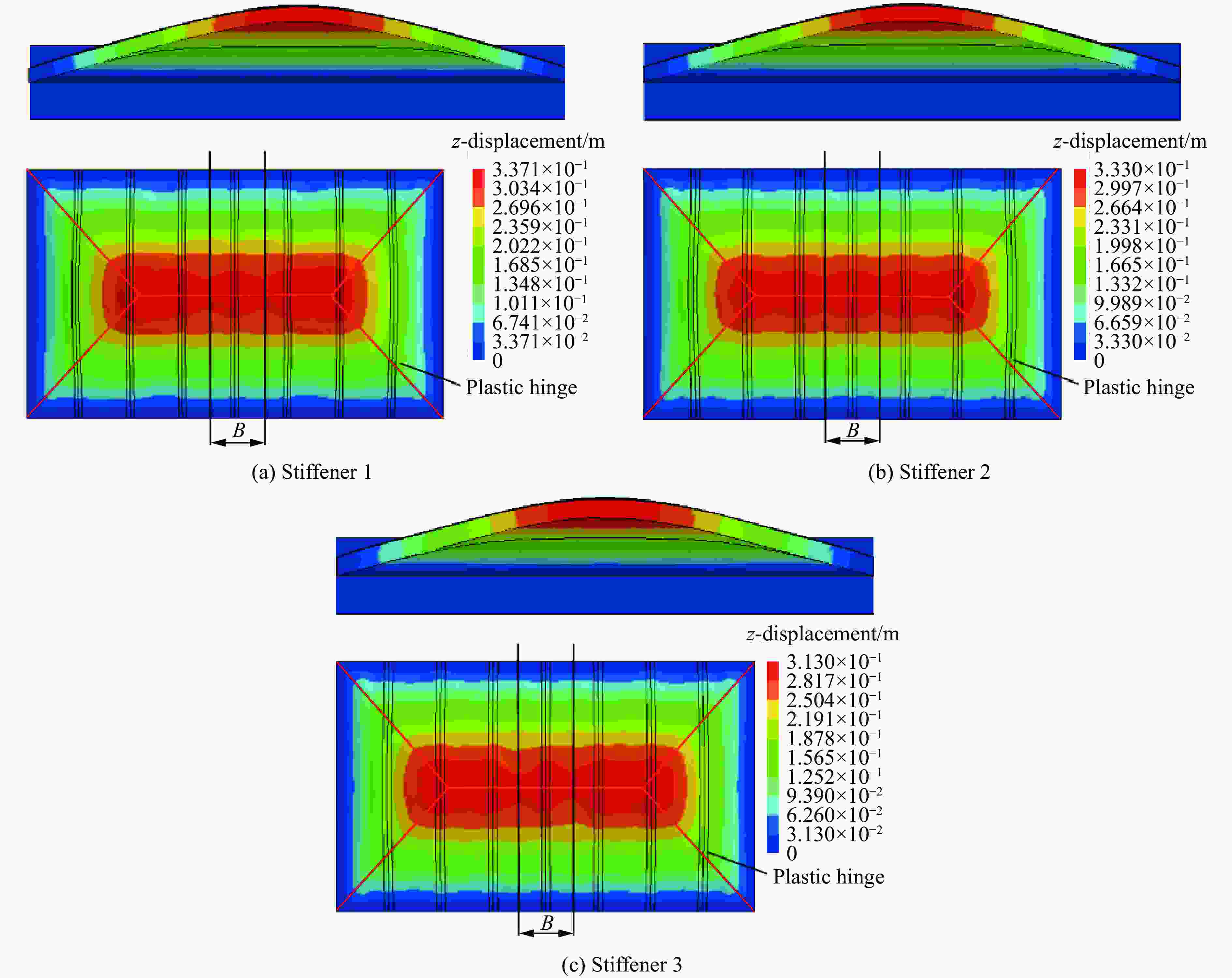

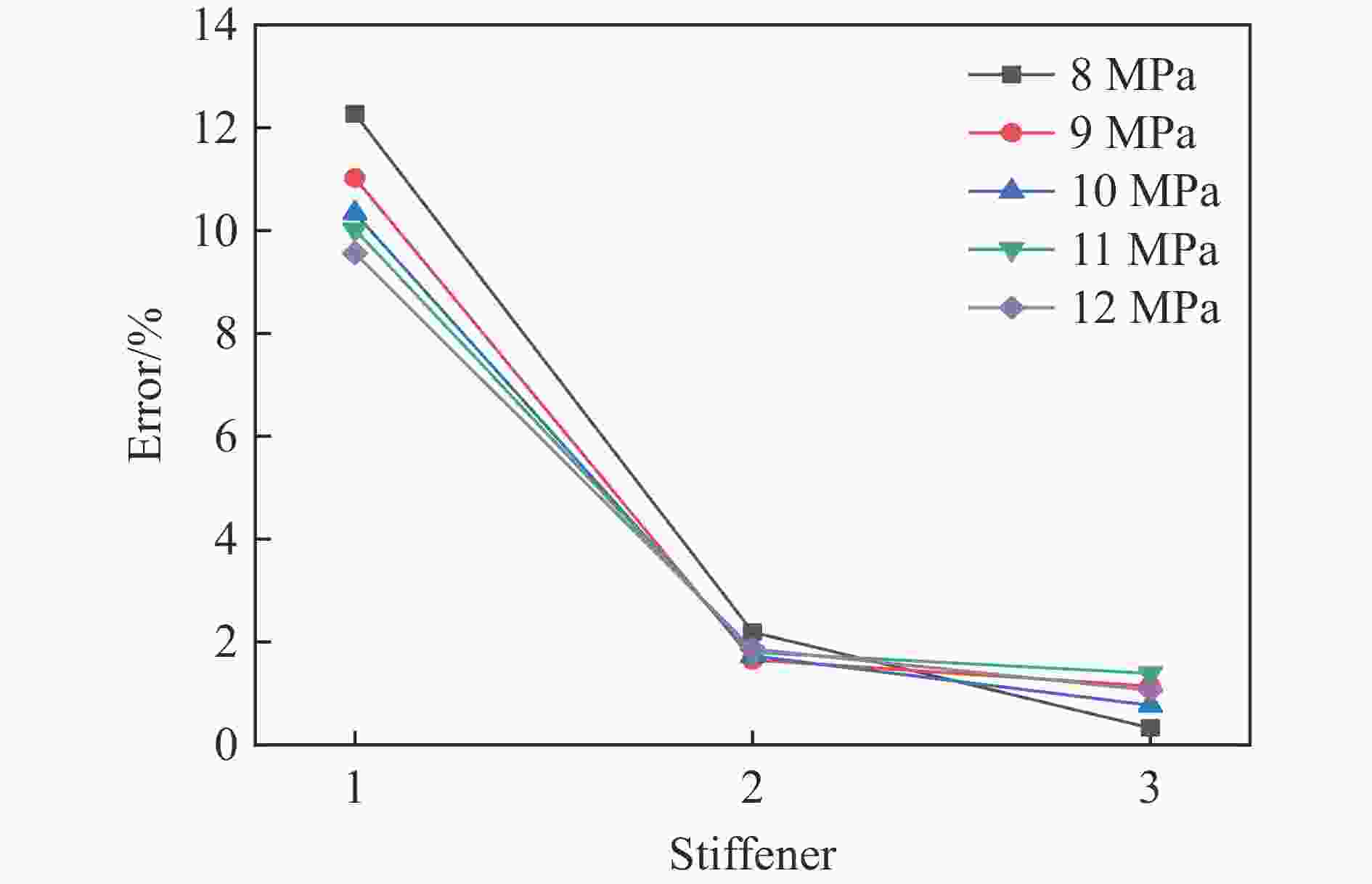

摘要: 针对固支单向加筋板在冲击载荷下的拉伸撕裂临界条件开展研究,首先将均布冲击载荷下的固支单向加筋板简化为带板梁模型,基于固支梁冲击变形理论解给出了加筋板最大永久变形理论解,之后基于复合运动场模型,修正了固支梁端点拉伸应变与最大永久变形关系式,并以等效应变达到失效应变作为拉伸撕裂条件,建立了加筋板在冲击载荷下的拉伸撕裂临界条件。经过数值模拟验证,该最大永久变形理论解和拉伸撕裂临界条件具有适用性,理论与数值误差小于15%。Abstract: The critical condition of tensile tearing failure of stiffened plate under impact load was studied. Firstly, the unidirectional stiffened plate with fixed support under uniform impact load was simplified into beam structure model attached with band plate. Based on the theoretical solution of the impact deformation of the fixed beam, the theoretical solution of the maximum deformation of the stiffened plate was given. At the same time, the applicable condition for calculating the large deformation of the unidirectional stiffened plate by using the “beam theory” model was given. Then, the motion mode of the fixed beam under strong impact load was divided into four stages. Based on the composite motion model, the relation between the tensile strain at the end of fixed beam and the maximum deformation of beam was corrected. Finally, taking equivalent strain equal to failure strain as the tensile tear condition, the critical condition of tensile tear of stiffened plate under impact load was established. In this paper, three unidirectional stiffened plates of T profile with different stiffness were selected, and the maximum deformation and critical tensile tearing load of the stiffened plates were analyzed by commercial finite element software LS-DYNA. The numerical simulation results show that the theoretical solution of maximum deformation of unidirectional stiffened plate and the critical condition of tensile tear failure based on the “beam theory” are applicable, and The error of theoretical and numerical simulation is less than 15%. Therefore, the theory in this paper can be applied to practical engineering prediction and has certain guiding significance.

-

Key words:

- stiffened plate /

- tensile tear /

- large plastic deformation /

- impact load /

- damage evaluation

-

表 1 T型钢结构参数

Table 1. Structural parameters of stiffeners

加强筋 尺寸/mm 1 $ \bot \dfrac{{5 \times 80}}{{8 \times 80}}$ 2 $ \bot \dfrac{{5 \times 80}}{{8 \times 100}}$ 3 $ \bot \dfrac{{5 \times 100}}{{8 \times 100}}$ 表 2 Q345钢参数

Table 2. Parameters of Q345 steel

$\rho $/(kg·m−3) $E$/GPa $\nu$ ${\sigma _{\text{0}}}$/MPa ${E_{\text{t}}}$/MPa $C$ $q$ $ {\varepsilon _{\text{f}}} $ 7870 212 0.31 345 1291 40 5 0.348 注:ρ为密度,ν为泊松比。 表 3 实验舱壁结构参数

Table 3. Experimental bulkhead structural parameters

舱壁编号 板厚/mm 加强筋尺寸/mm 加强筋间距/mm 加强筋方向 S1 8 $ \bot \dfrac{{8 \times 60}}{{8 \times 18}}$ 600 背爆 S2 600 迎爆 S3 300 背爆 S4 300 迎爆 表 4 实验与模拟结果对比

Table 4. Comparison of experimental and numerical simulation results

舱壁 最大永久变形量/mm 误差/% 实验 模拟 S1 39.0 41.7 6.92 S2 37.0 39.2 5.95 S3 31.5 33.4 6.03 S4 27.5 27.2 1.09 表 5 单向加筋板变形量对比

Table 5. Comparison of deformation of unidirectional stiffened plates

加强筋 矩形载荷/

MPa最大永久变形/mm 误差/

%加强筋 矩形载荷/

MPa最大永久变形/mm 误差/

%加强筋 矩形载荷/

MPa最大永久变形/mm 误差/

%理论 数值模拟 理论 数值模拟 理论 数值模拟 1 8 366 326 12.27 2 8 327 320 2.19 3 8 306 307 0.33 9 413 372 11.02 9 370 364 1.65 9 346 350 1.14 10 459 416 10.34 10 412 405 1.73 10 387 390 0.77 11 505 459 10.02 11 453 445 1.80 11 426 432 1.39 12 550 502 9.56 12 494 485 1.86 12 466 471 1.06 -

[1] NURICK G N, OLSON M D, FAGNAN J R, et al. Deformation and tearing of blast-loaded stiffened square plates [J]. International Journal of Impact Engineering, 1995, 16(2): 273–291. DOI: 10.1016/0734-743X(94)00046-Y. [2] CHUNG KIM YUEN S, NURICK G N. Experimental and numerical studies on the response of quadrangular stiffened plates. Part Ⅰ: subjected to uniform blast load [J]. International Journal of Impact Engineering, 2005, 31(1): 55–83. DOI: 10.1016/j.ijimpeng.2003.09.048. [3] RUDRAPATNA N S, VAZIRI R, OLSON M D. Deformation and failure of blast-loaded stiffened plates [J]. International Journal of Impact Engineering, 2000, 24(5): 457–474. DOI: 10.1016/S0734-743X(99)00172-4. [4] LANGDON G S, CHUNG KIM YUEN S, NURICK G N. Experimental and numerical studies on the response of quadrangular stiffened plates. Part Ⅱ: localised blast loading [J]. International Journal of Impact Engineering, 2005, 31(1): 85–111. DOI: 10.1016/j.ijimpeng.2003.09.050. [5] 牟金磊, 朱锡, 张振华, 等. 水下爆炸载荷作用下加筋板的毁伤模式 [J]. 爆炸与冲击, 2009, 29(5): 457–462. DOI: 10.3321/j.issn:1001-1455.2009.05.002.MOU J L, ZHU X, ZHANG Z H, et al. Failure modes of stiffened plates subjected to underwater explosion [J]. Explosion and Shock Waves, 2009, 29(5): 457–462. DOI: 10.3321/j.issn:1001-1455.2009.05.002. [6] 郑成, 孔祥韶, 徐维铮, 等. 舱内爆炸载荷作用下加筋板动态响应试验研究 [J]. 中国造船, 2018, 59(2): 129–139. DOI: 10.3969/j.issn.1000-4882.2018.02.014.ZHENG C, KONG X S, XU W Z, et al. Experimental study on dynamic response of stiffened plates subjected to internal blast loads [J]. Shipbuilding of China, 2018, 59(2): 129–139. DOI: 10.3969/j.issn.1000-4882.2018.02.014. [7] 焦立启, 侯海量, 陈鹏宇, 等. 爆炸冲击载荷下固支单向加筋板的动响应及破损特性研究 [J]. 兵工学报, 2019, 40(3): 592–600. DOI: 10.3969/j.issn.1000-1093.2019.03.019.JIAO L Q, HOU H L, CHEN P Y, et al. Research on dynamic response and damage characteristics of fixed supported one-way stiffened plates under blast loading [J]. Acta Armamentarii, 2019, 40(3): 592–600. DOI: 10.3969/j.issn.1000-1093.2019.03.019. [8] LI Y, REN X B, ZHAO T, et al. Dynamic response of stiffened plate under internal blast: experimental and numerical investigation [J]. Marine Structures, 2021, 77: 102957. DOI: 10.1016/j.marstruc.2021.102957. [9] SCHUBAK R B, OLSON M D, ANDERSON D L. Rigid-plastic modelling of blast-loaded stiffened plates-Part I: one-way stiffened plates [J]. International Journal of Mechanical Sciences, 1993, 35(3/4): 289–306. DOI: 10.1016/0020-7403(93)90083-7. [10] SCHUBAK R B, OLSON M D, ANDERSON D L. Rigid-plastic modelling of blast-loaded stiffened plates-Part II: partial end fixity, rate effects and two-way stiffened plates [J]. International Journal of Mechanical Sciences, 1993, 35(3/4): 307–324. DOI: 10.1016/0020-7403(93)90084-8. [11] 刘土光, 胡要武, 郑际嘉. 固支加筋方板在爆炸载荷作用下的刚塑性动力响应分析 [J]. 爆炸与冲击, 1994, 14(1): 55–65.LIU T G, HU Y W, ZHENG J J. Dynamic response analysis of rigid perfectly plastic clamped square plates with stiffener subjected to blast loading [J]. Explosion and Shock Waves, 1994, 14(1): 55–65. [12] 刘土光, 唐文勇. 加筋弧结构在冲击载荷作用下的塑性动力响应 [J]. 华中理工大学学报, 1996, 24(1): 106–109.LIU T G, TANG W Y. The dynamic plastic response of a structure with stiffened plates under impulsive loading [J]. Journal of Huazhong University of Science & Technology, 1996, 24(1): 106–109. [13] 刘敬喜, 刘尧, 汤皓泉, 等. 爆炸载荷作用下单向加筋方板的大挠度塑性动力响应分析 [J]. 振动与冲击, 2011, 30(4): 182–187. DOI: 10.3969/j.issn.1000-3835.2011.04.038.LIU J X, LIU Y, TANG H Q, et al. Plastic and large deflection dynamic response analysis of a one way stiffened square plate subjected to blast loads [J]. Journal of Vibration and Shock, 2011, 30(4): 182–187. DOI: 10.3969/j.issn.1000-3835.2011.04.038. [14] PENG Y, YANG P, HU K. Nonlinear dynamic response of blast-loaded stiffened plates considering the strain rate sensitivity [J]. Marine Structures, 2020, 70: 102699. DOI: 10.1016/j.marstruc.2019.102699. [15] YANG B, WANG D Y. Dynamic buckling of stiffened plates with elastically restrained edges under in-plane impact loading [J]. Thin-Walled Structures, 2016, 107: 427–442. DOI: 10.1016/j.tws.2016.06.019. [16] 张振华, 朱锡, 刘润泉. 潜艇典型结构在爆炸冲击载荷作用下开裂判据的试验研究 [J]. 爆炸与冲击, 2004, 24(6): 541–545.ZHANG Z H, ZHU X, LIU R Q. Experiment research of crack criterion of representative submarine structure subjected to explosive loading [J]. Explosion and Shock Waves, 2004, 24(6): 541–545. [17] 吴林杰, 朱锡, 侯海量, 等. 空中近距爆炸下加筋板架的毁伤模式仿真研究 [J]. 振动与冲击, 2013, 32(14): 77–81, 126. DOI: 10.3969/j.issn.1000-3835.2013.14.013.WU L J, ZHU X, HOU H L, et al. Simulations for damage modes of a stiffened plate subjected to close-range air-blast loading [J]. Journal of Vibration and Shock, 2013, 32(14): 77–81, 126. DOI: 10.3969/j.issn.1000-3835.2013.14.013. [18] 支旭东, 张荣, 林莉, 等. Q235B钢动态本构及在LS-DYNA中的应用 [J]. 爆炸与冲击, 2018, 38(3): 596–602. DOI: 10.11883/bzycj-2016-0286.ZHI X D, ZHANG R, LIN L, et al. Dynamic constitutive model of Q235B steel and its application in LS-DYNA [J]. Explosion and Shock Waves, 2018, 38(3): 596–602. DOI: 10.11883/bzycj-2016-0286. [19] 孙丽萍, 闫发锁. 船舶与海洋工程结构物强度 [M]. 哈尔滨: 哈尔滨工程大学出版社, 2017. [20] JONES N. Structural impact [M]. New York: Cambridge University Press, 2012. [21] 颜丰, 刘敬喜. 爆炸载荷下固支矩形板的大挠度塑性动力响应 [J]. 中国舰船研究, 2013, 8(1): 47–53. DOI: 10.3969/j.issn.1673-3185.2013.01.008.YAN F, LIU J X. The large deflection dynamic plastic response of rectangular plates subjected to blast load [J]. Chinese Journal of Ship Research, 2013, 8(1): 47–53. DOI: 10.3969/j.issn.1673-3185.2013.01.008. [22] NONAKA T. Some interaction effects in a problem of plastic beam dynamics—Part 2: analysis of a structure as a system of one degree of freedom [J]. Journal of Applied Mechanics, 1967, 34(3): 631–637. DOI: 10.1115/1.3607754. [23] SYMONDS P S, MENTEL T J. Impulsive loading of plastic beams with axial constraints [J]. Journal of the Mechanics and Physics of Solids, 1958, 6(3): 186–202. DOI: 10.1016/0022-5096(58)90025-5. [24] 米海珍, 胡燕妮. 塑性力学 [M]. 北京: 清华大学出版社, 2014. [25] 余同希, 邱信明. 冲击动力学 [M]. 北京: 清华大学出版社, 2011. [26] QIN Y Z, WANG Y, WANG Z, et al. Investigation on similarity laws of cabin structure under internal blast loading [J]. Ocean Engineering, 2022, 260: 111998. DOI: 10.1016/J.OCEANENG.2022.111998. -

下载:

下载: