Impact testing technique based on the principle of electromagnetic induction

-

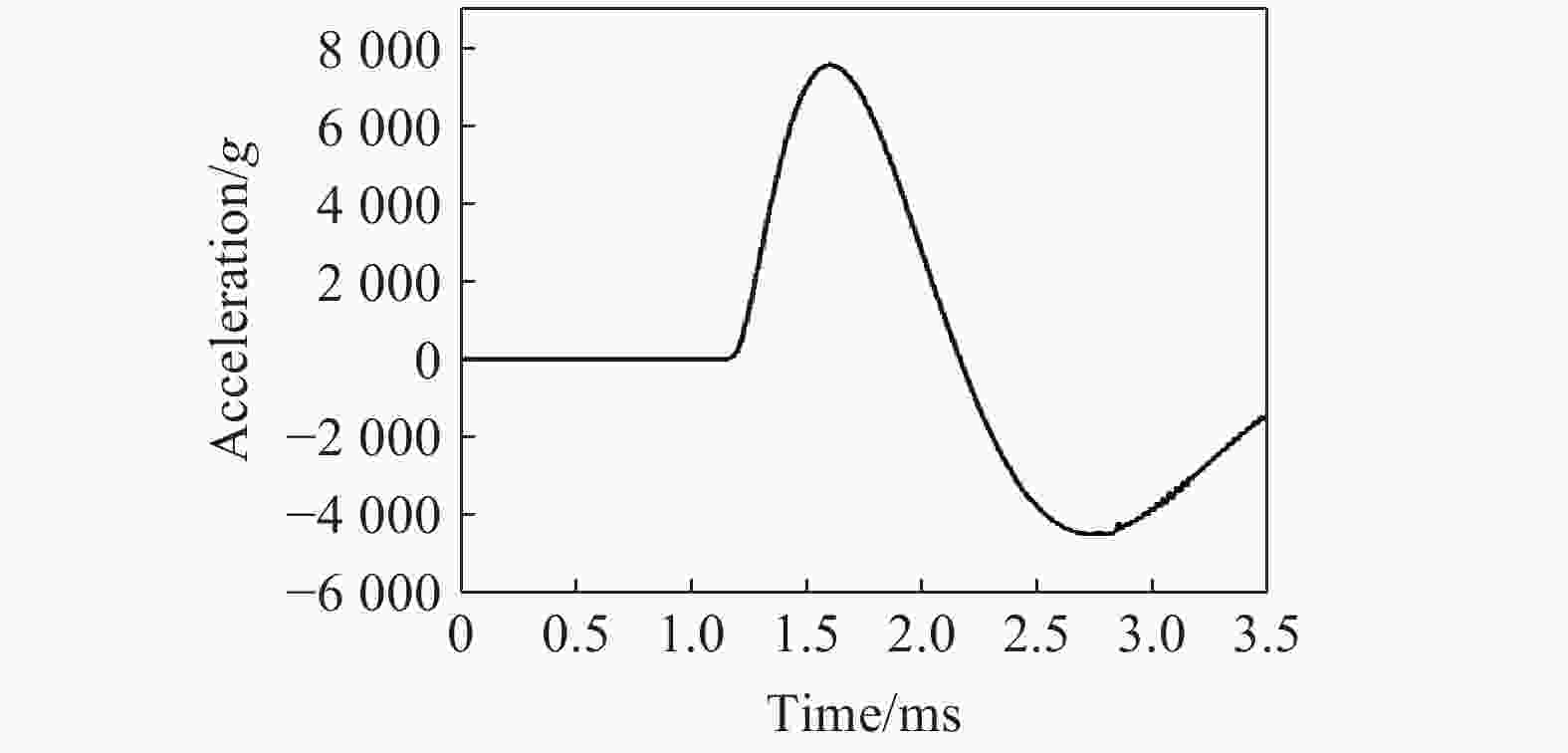

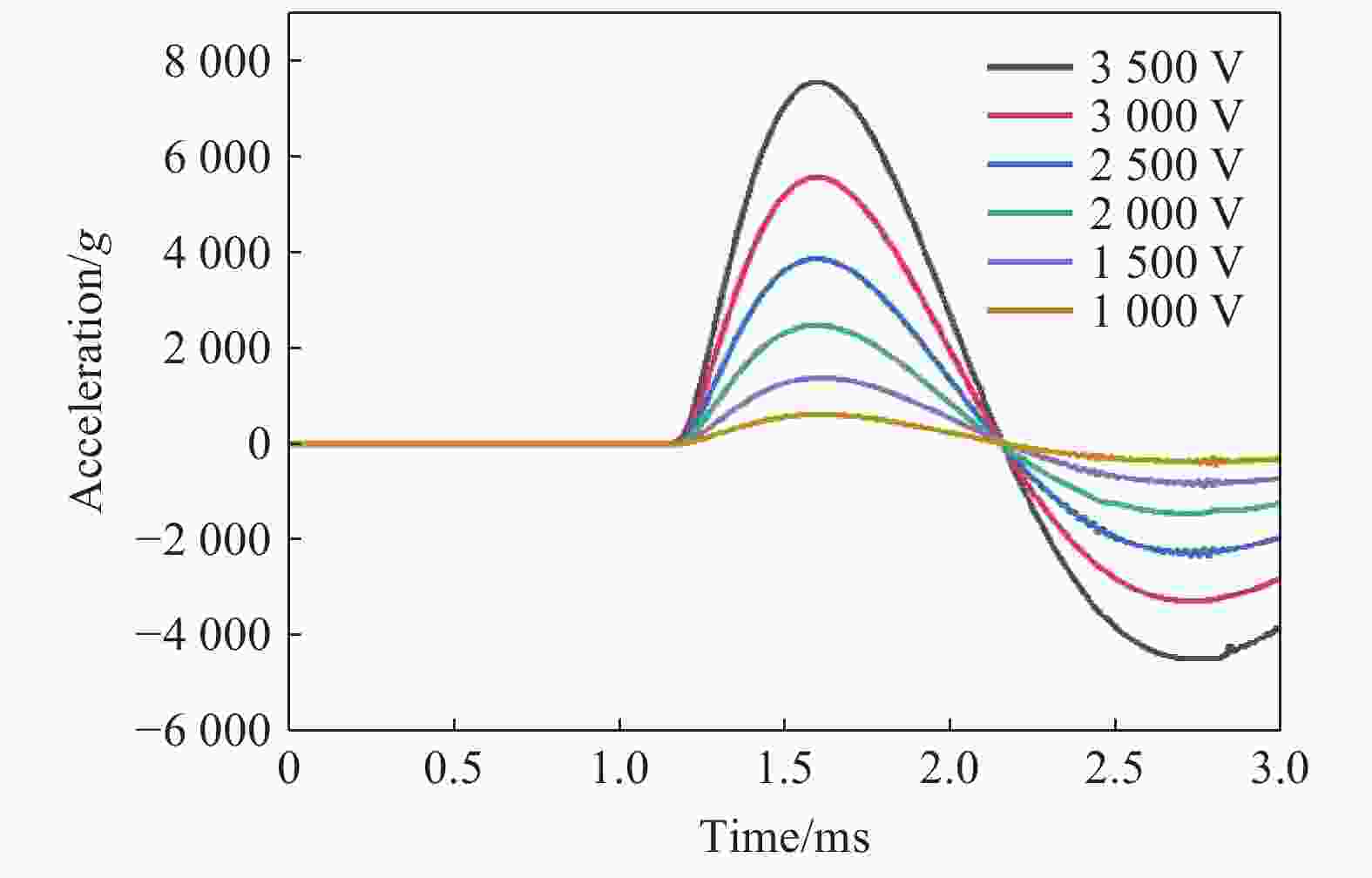

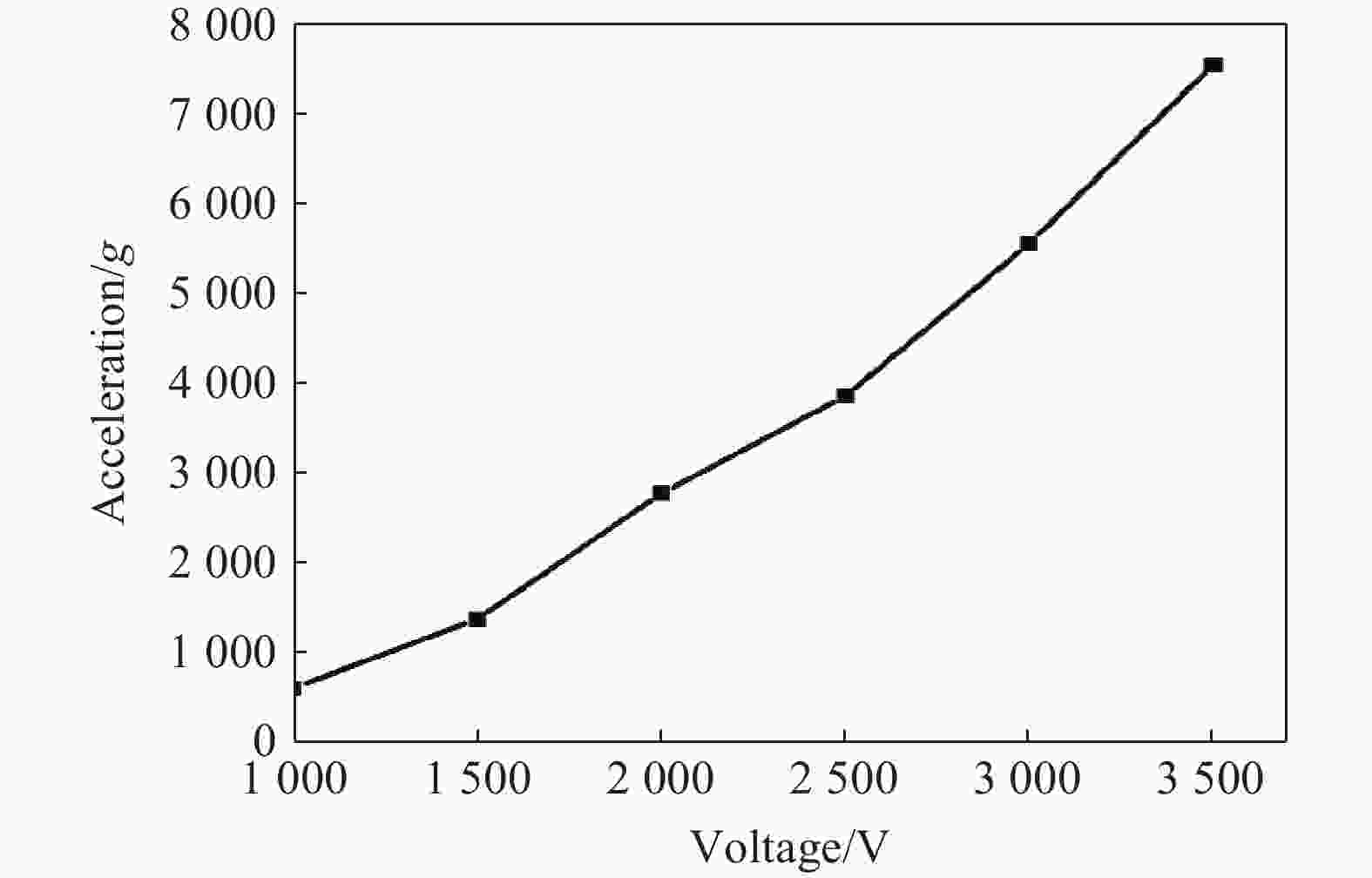

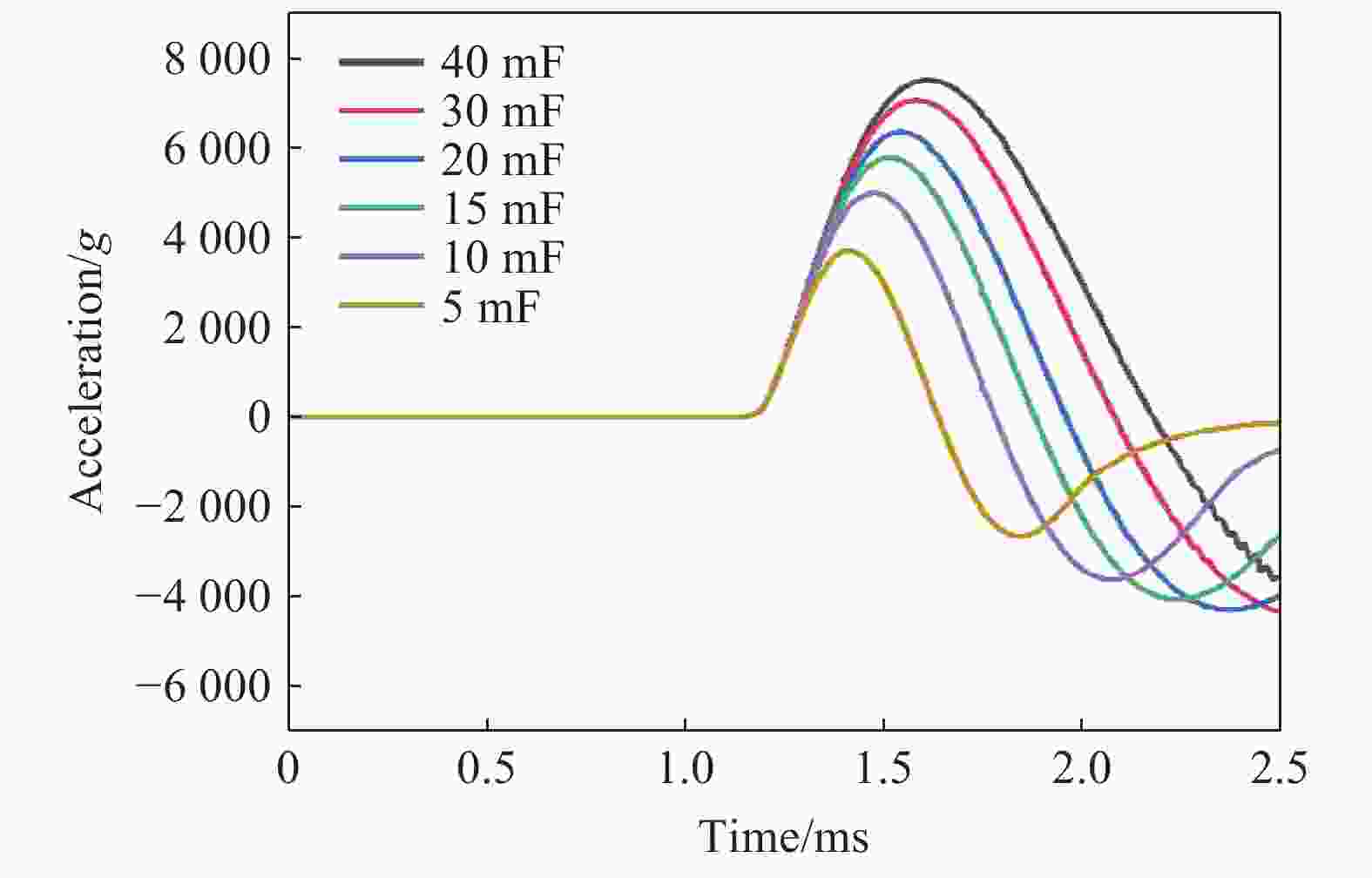

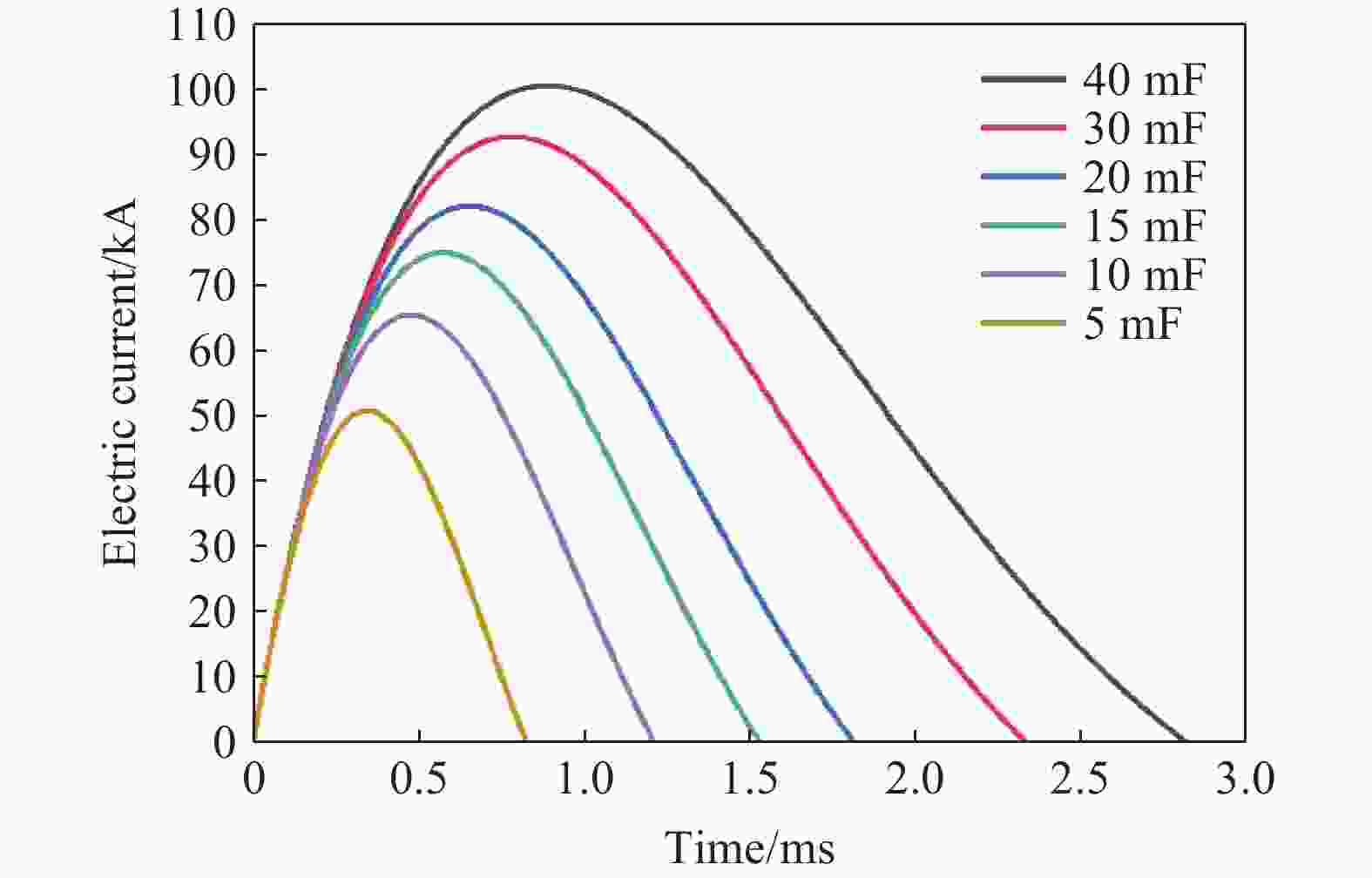

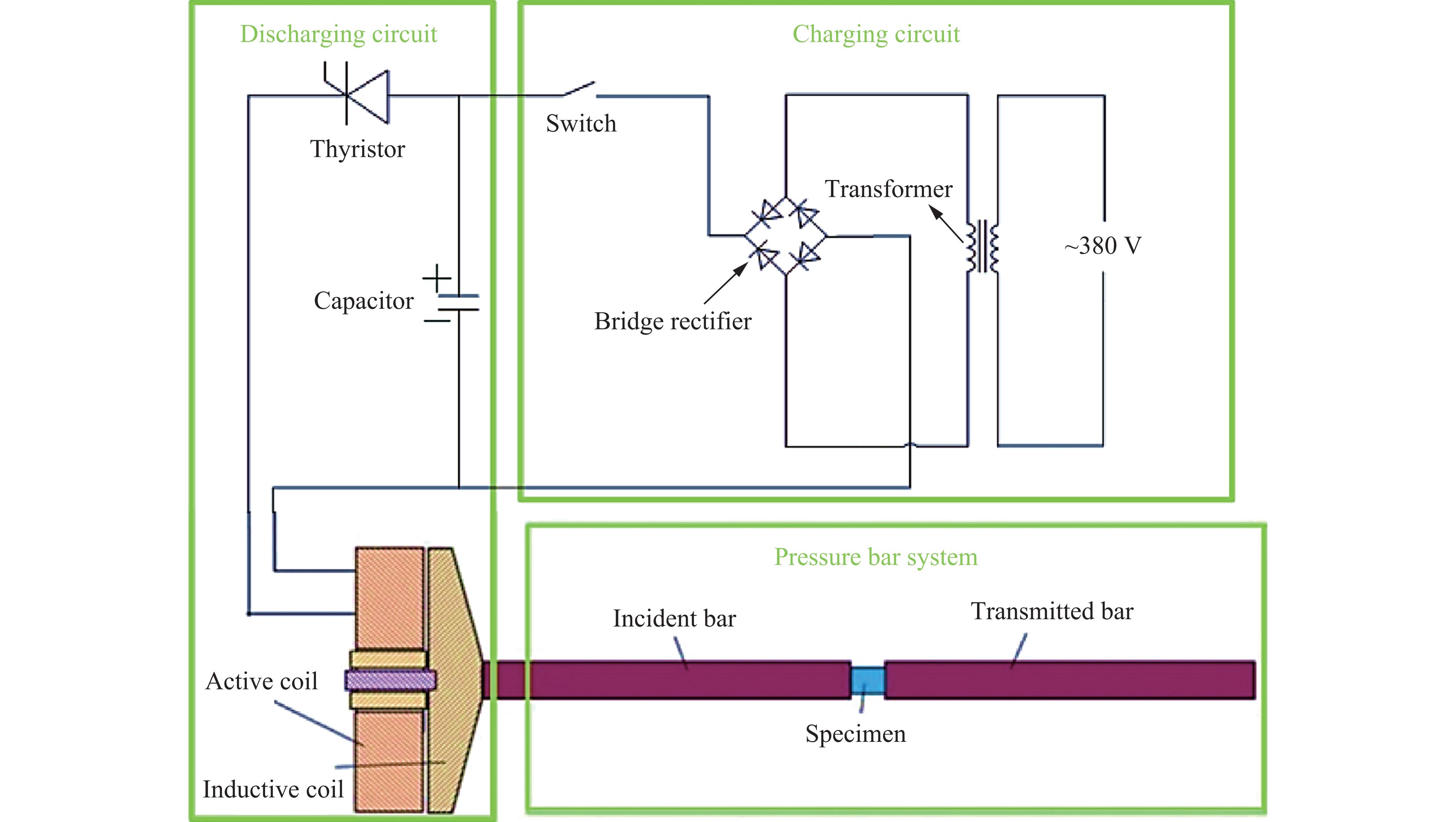

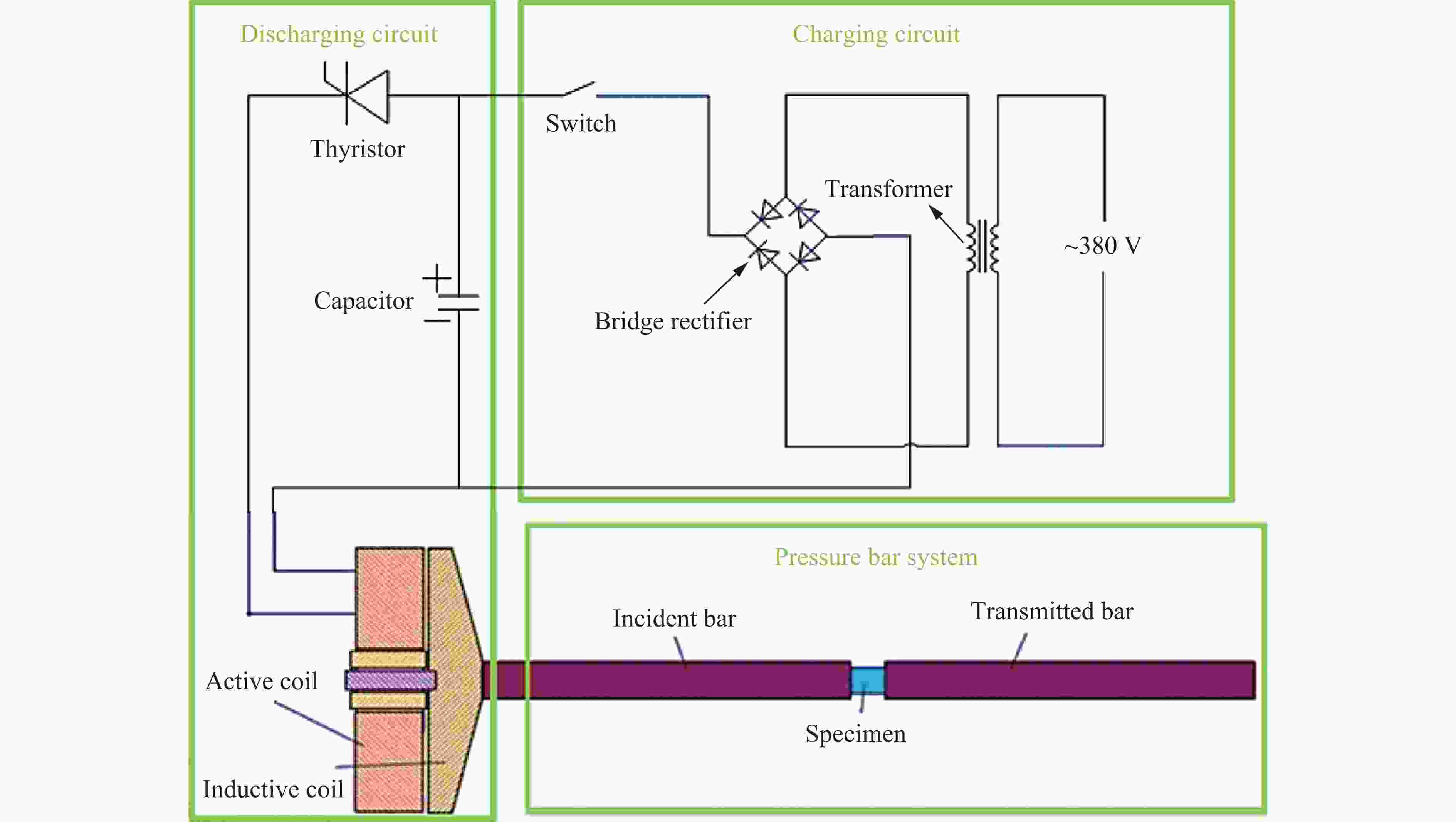

摘要: 基于电磁感应的基本原理,构建了一种由电磁力驱动产生高幅值长脉宽加速度载荷的冲击试验装置,弥补了现阶段地面冲击试验技术的缺陷。使用电磁Hopkinson杆进行了加速度冲击试验,得到了应力和加速度载荷。根据一维应力波原理,推导出细长杆中加速度与应力之间的关系式,计算结果表明试验值和理论值吻合较好,验证了试验方法的准确性。使用COMSOL有限元软件对电磁Hopkinson杆加速度冲击试验进行了数值模拟,模拟结果与试验结果一致性较好,验证了数值模型和方法的准确性。基于此有限元模型,构建了产生高幅值长脉宽加速度载荷的冲击试验装置,并对该装置进行了不同电压和电容下的数值模拟。结果表明,提出的试验装置能够产生长脉宽高幅值的加速度过载环境,且电容电压越大则加速度幅值越大,电容值越大加速度脉宽越宽。通过调控装置中的电路参数,可产生不同幅值和脉宽的加速度载荷。

-

关键词:

- 电磁感应 /

- 电磁Hopkinson杆 /

- 高幅值长脉宽 /

- 冲击试验

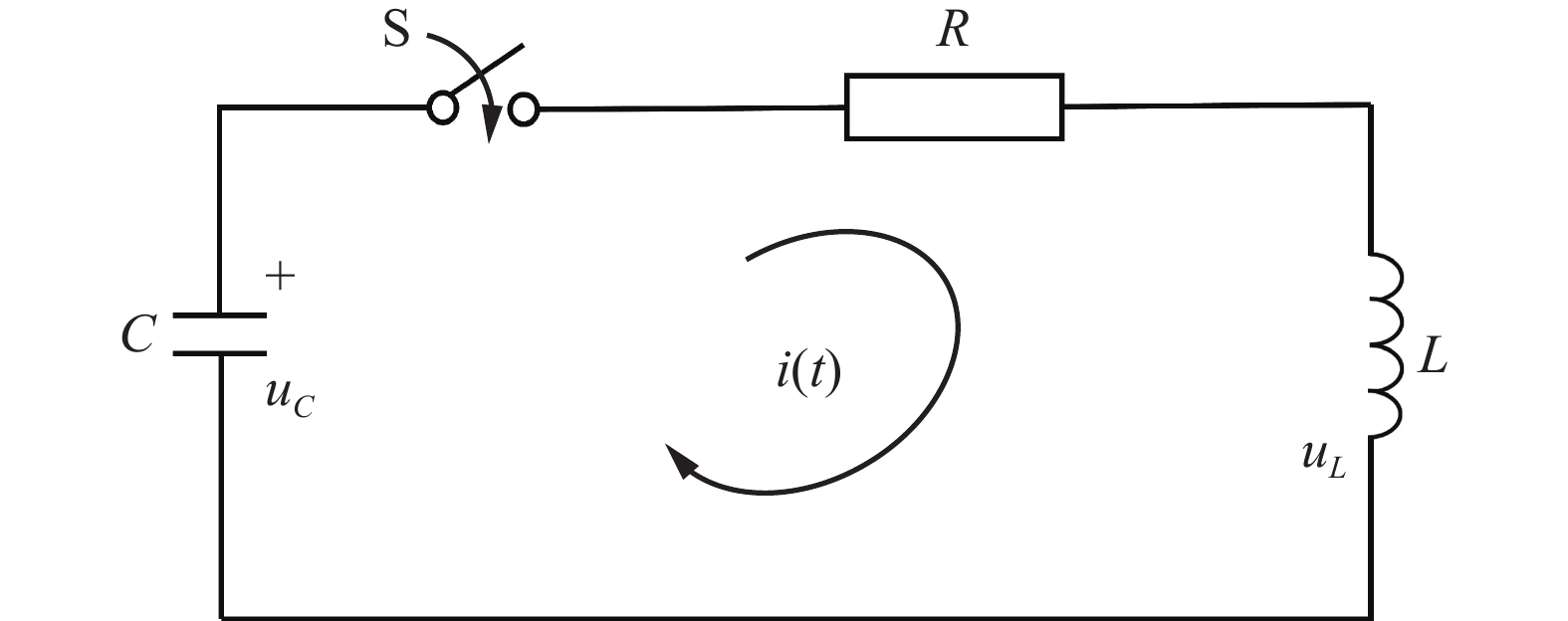

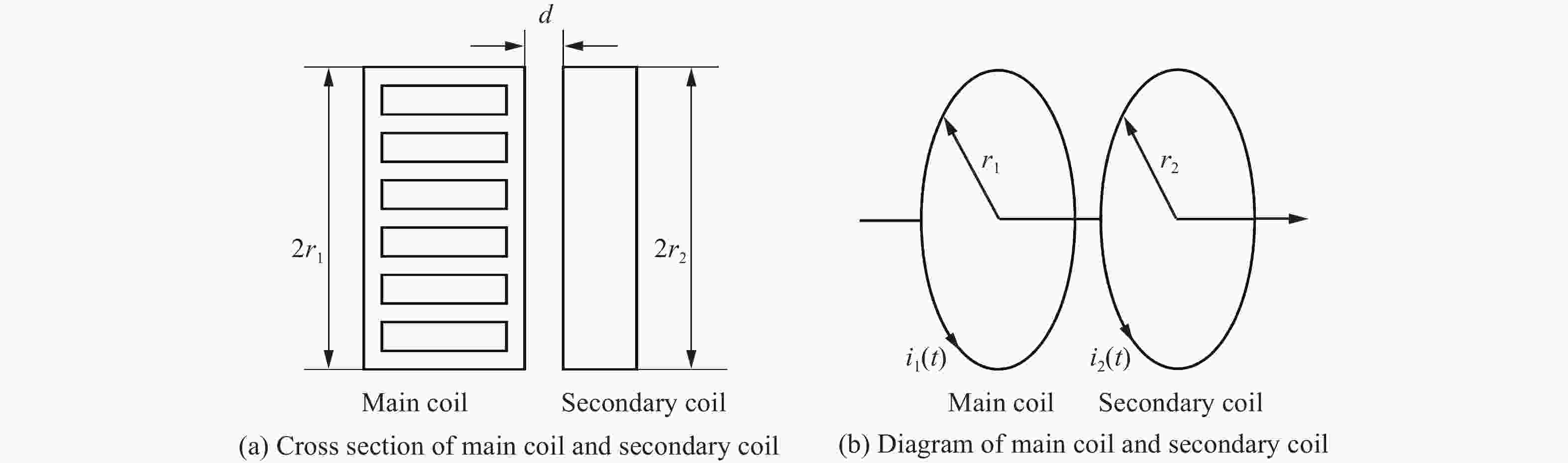

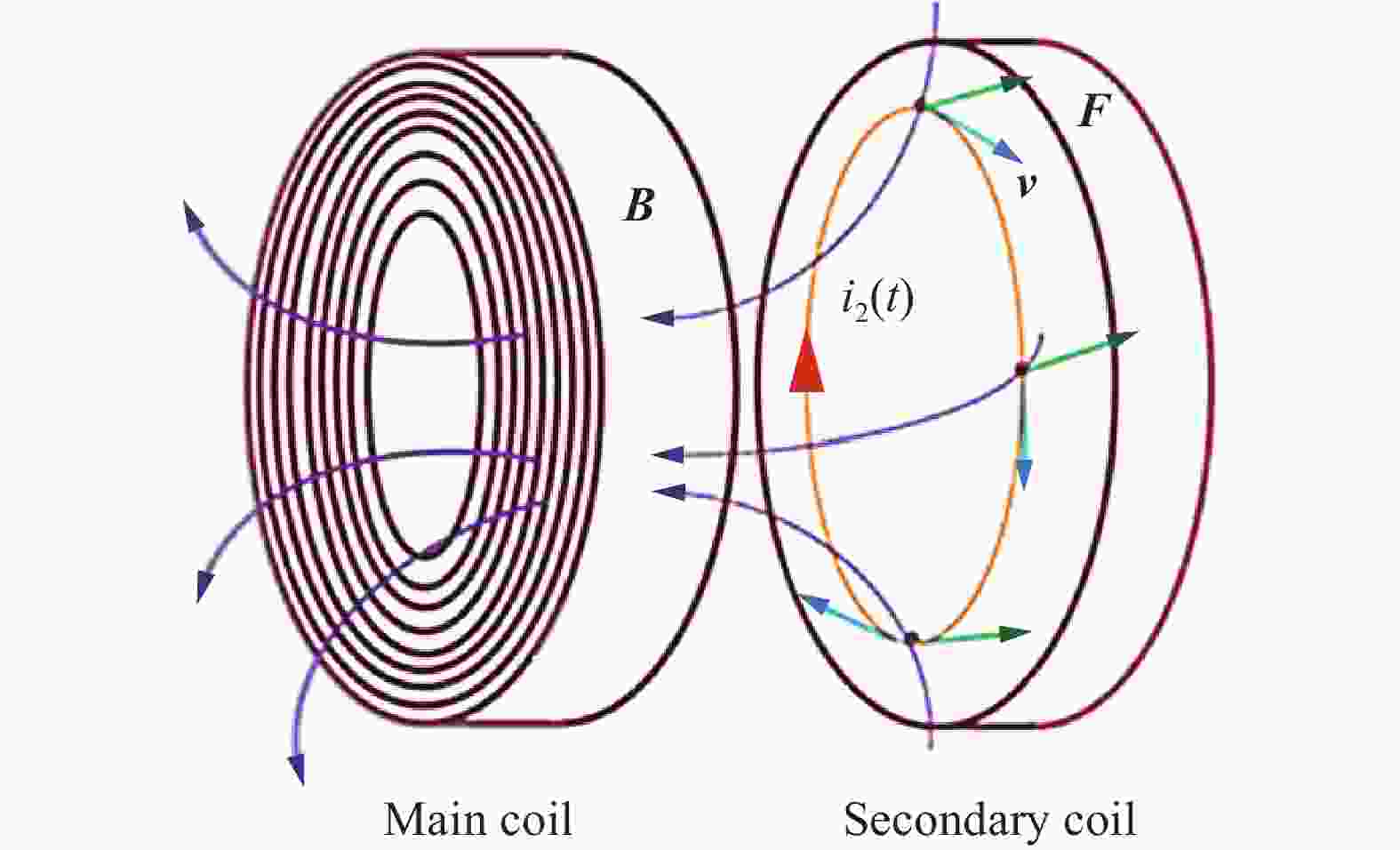

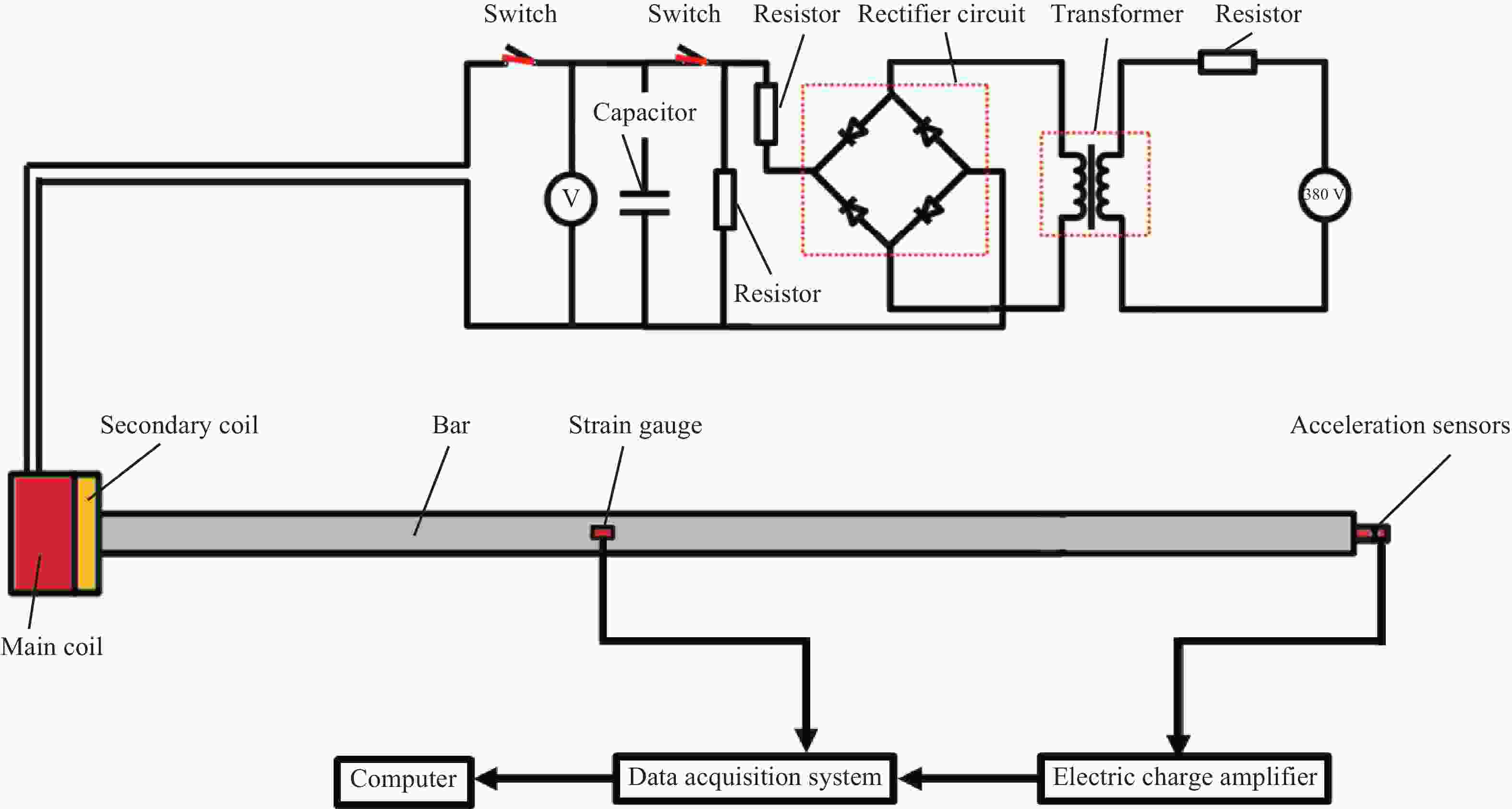

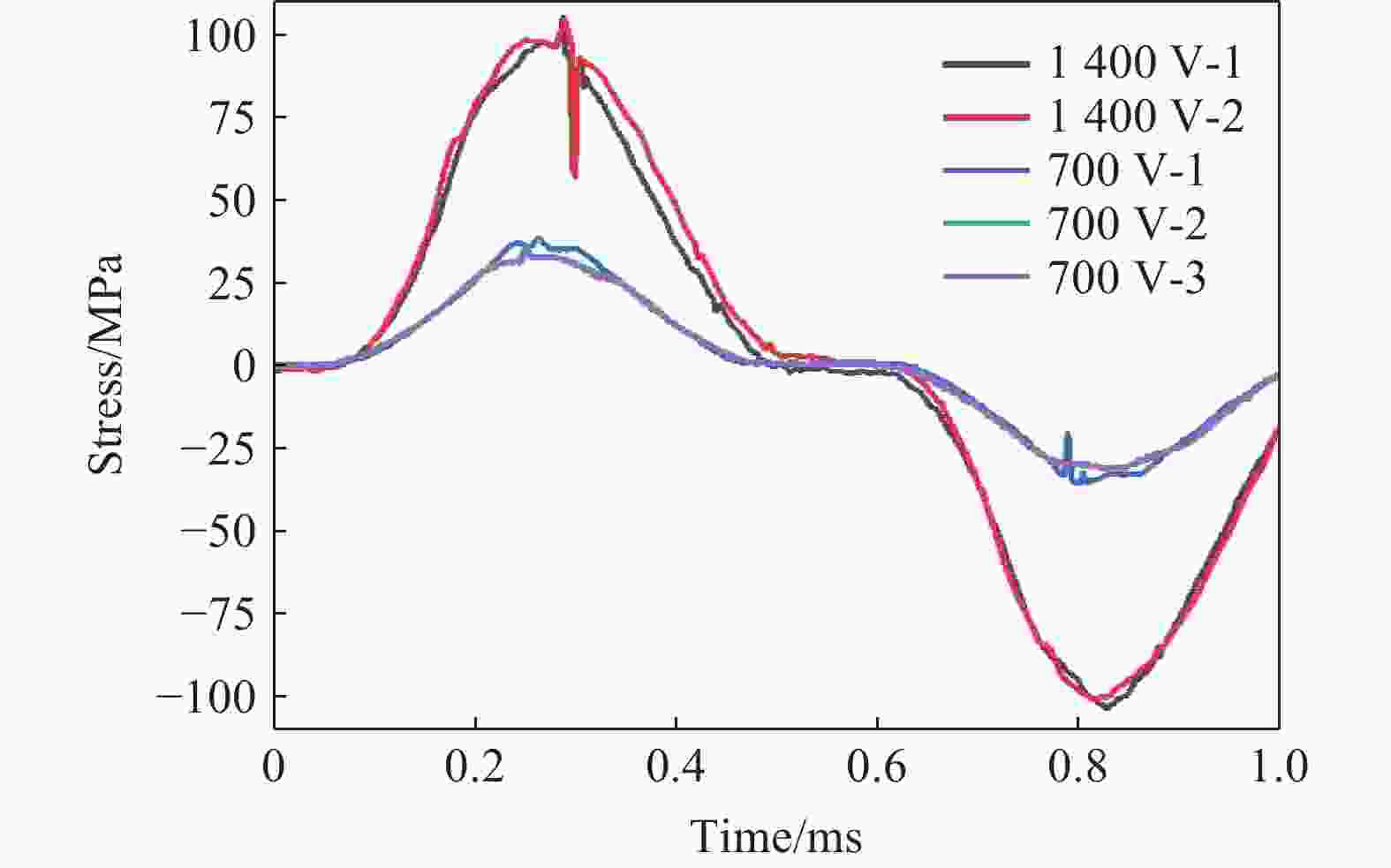

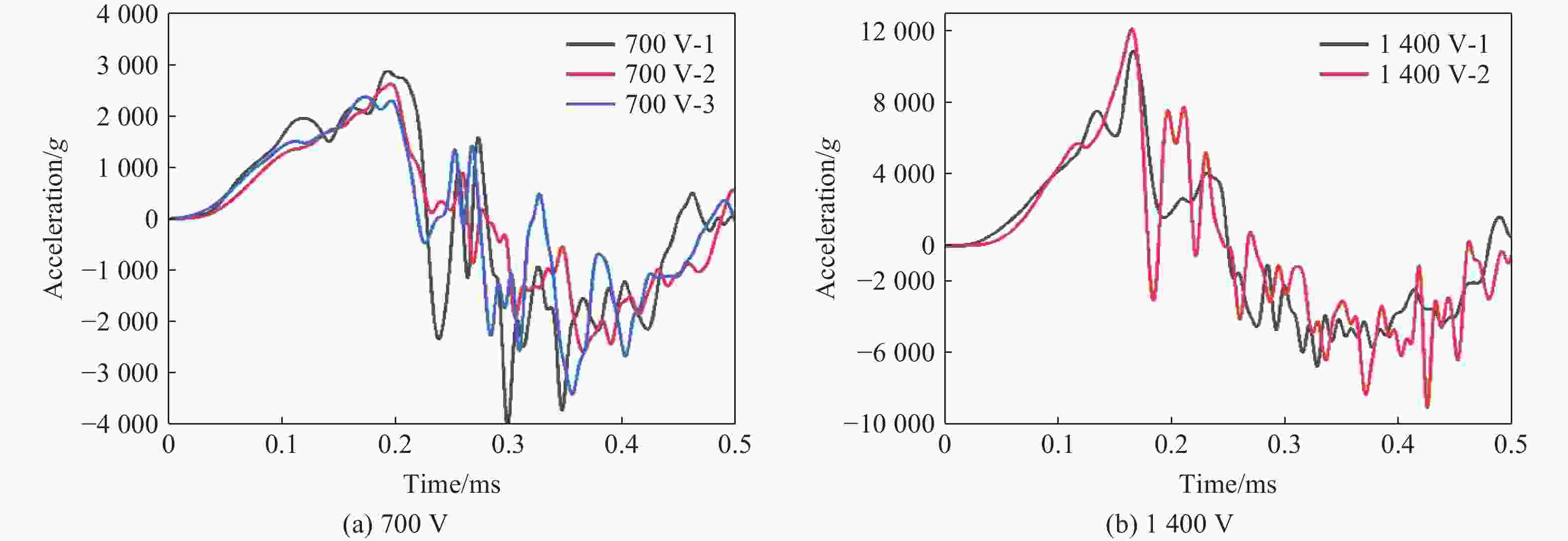

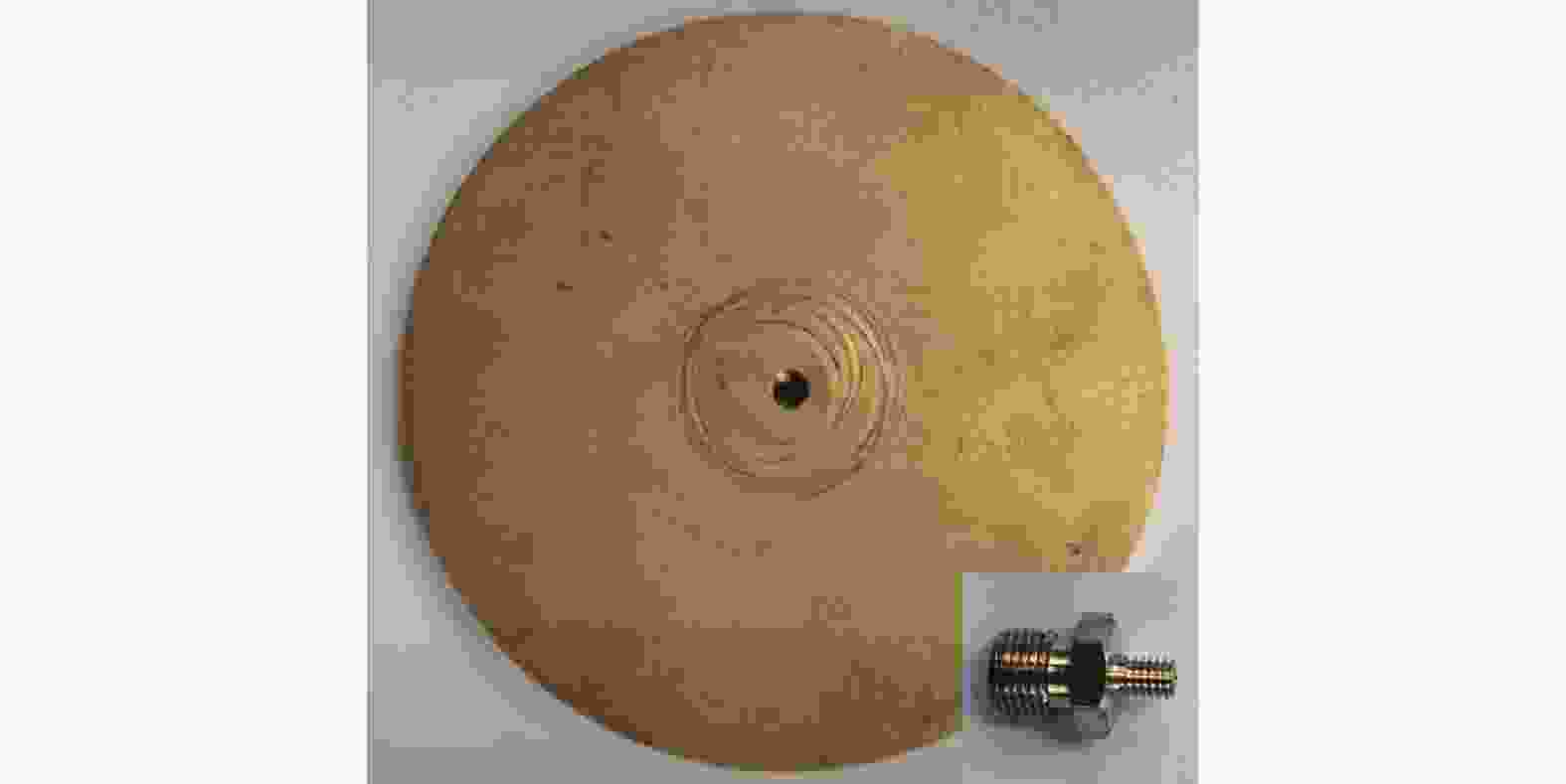

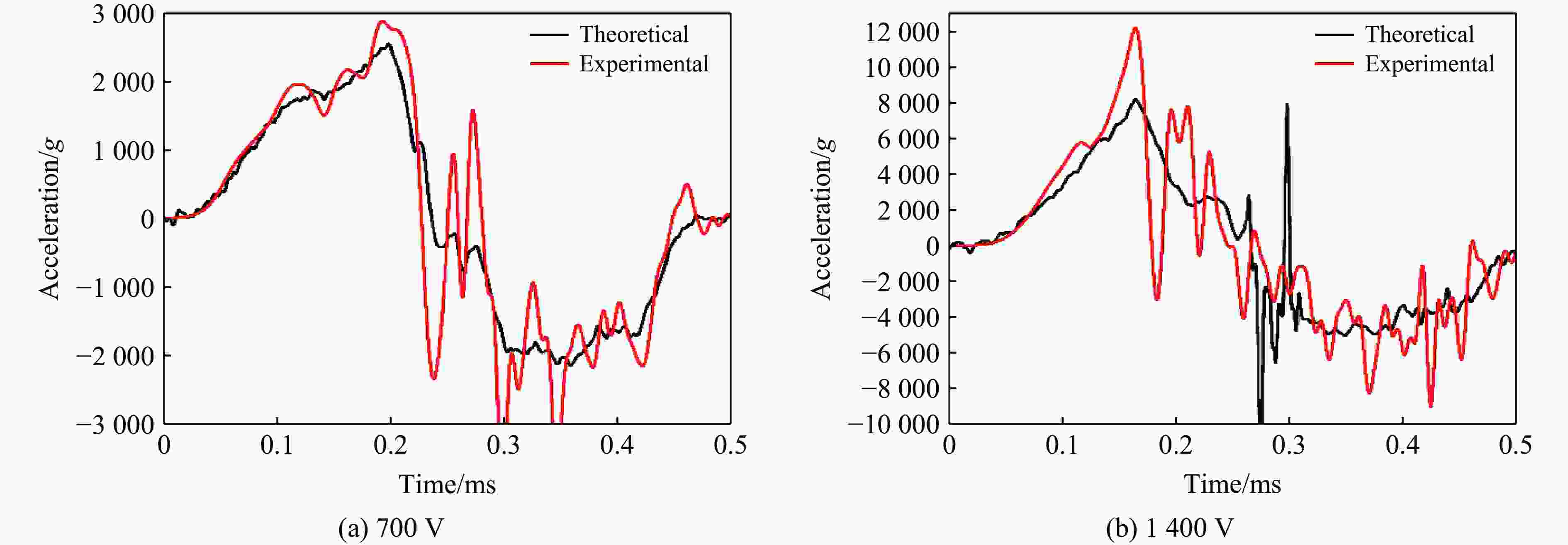

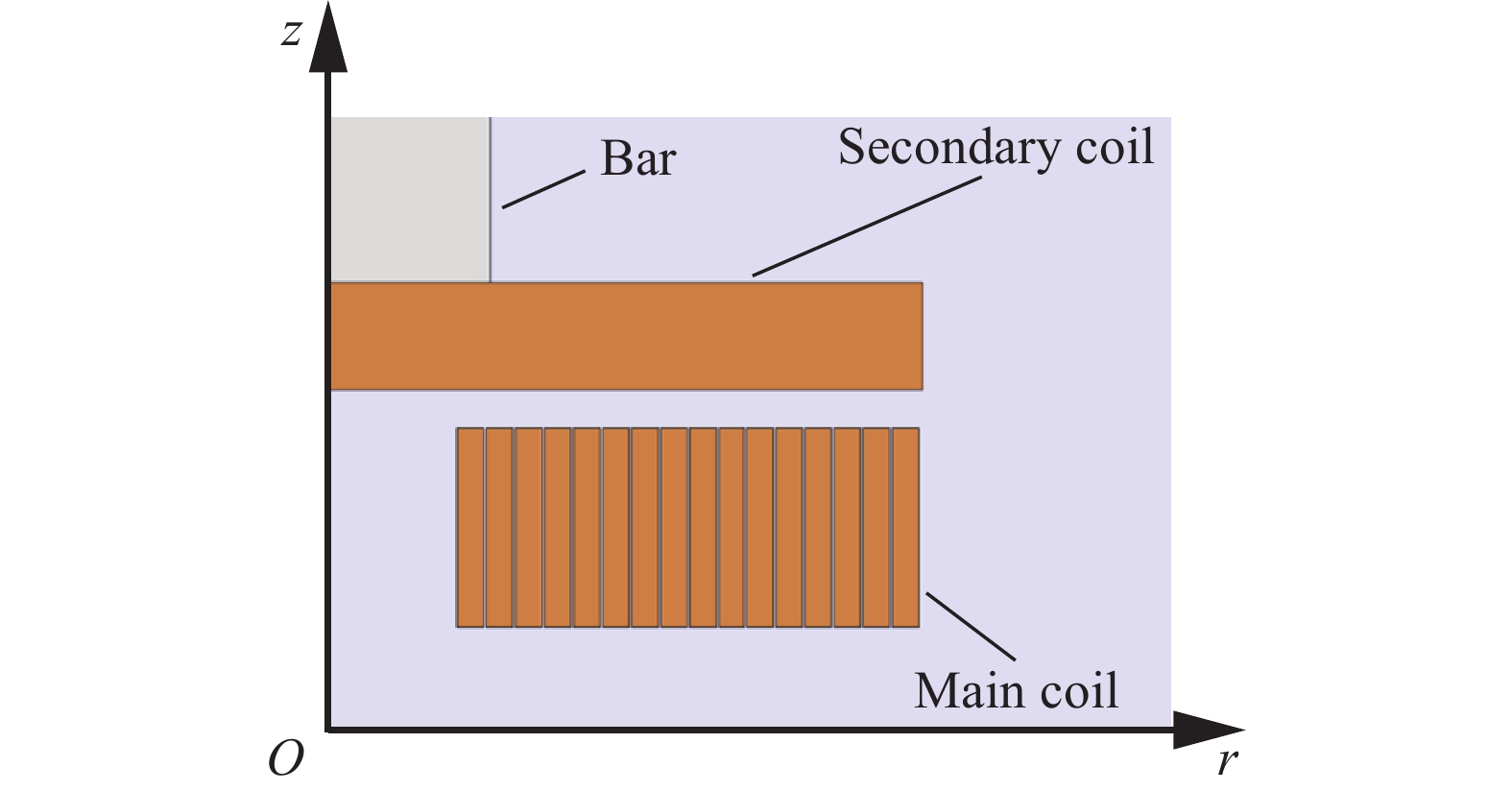

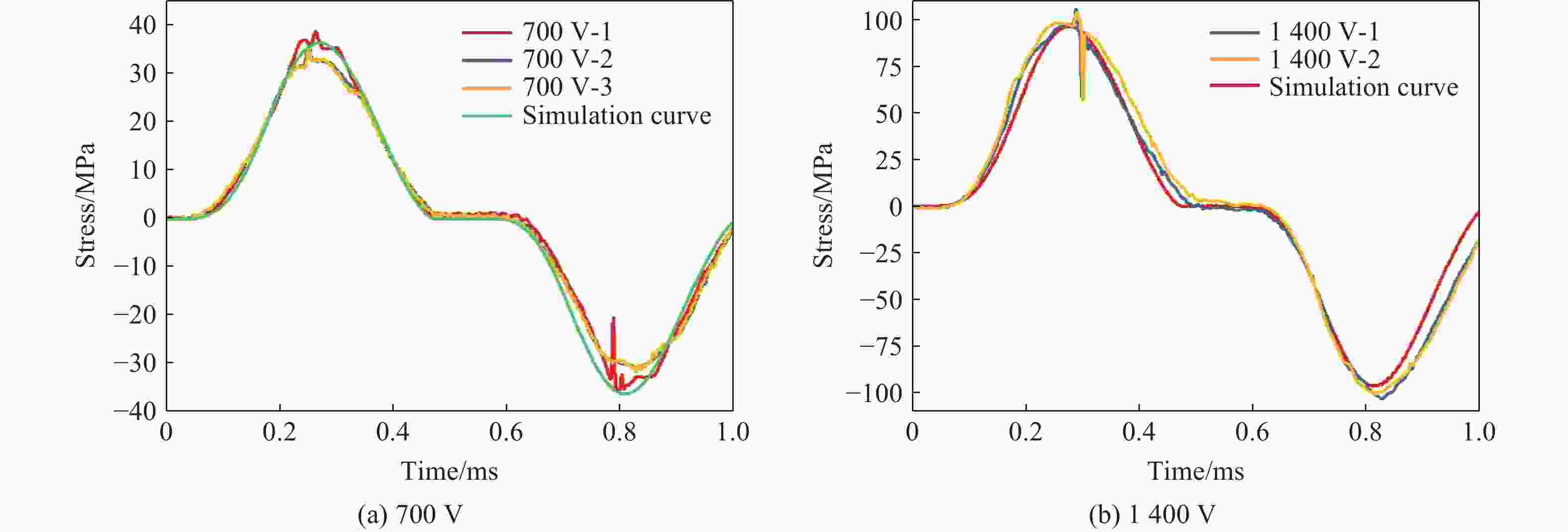

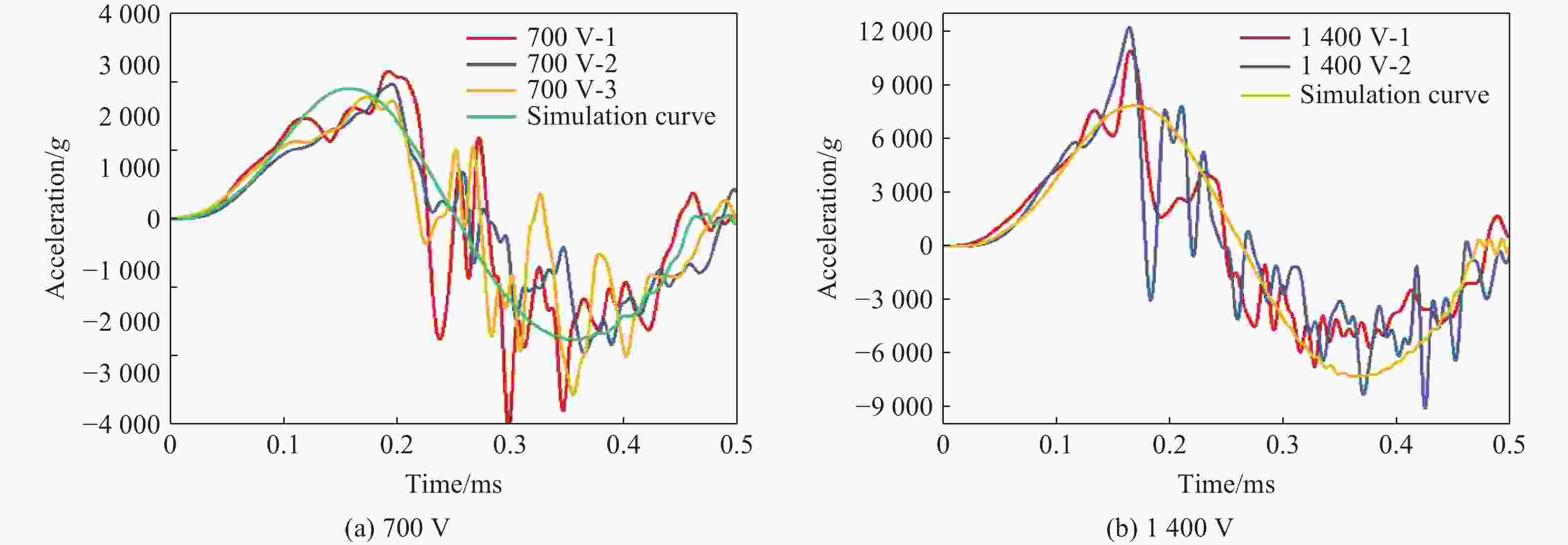

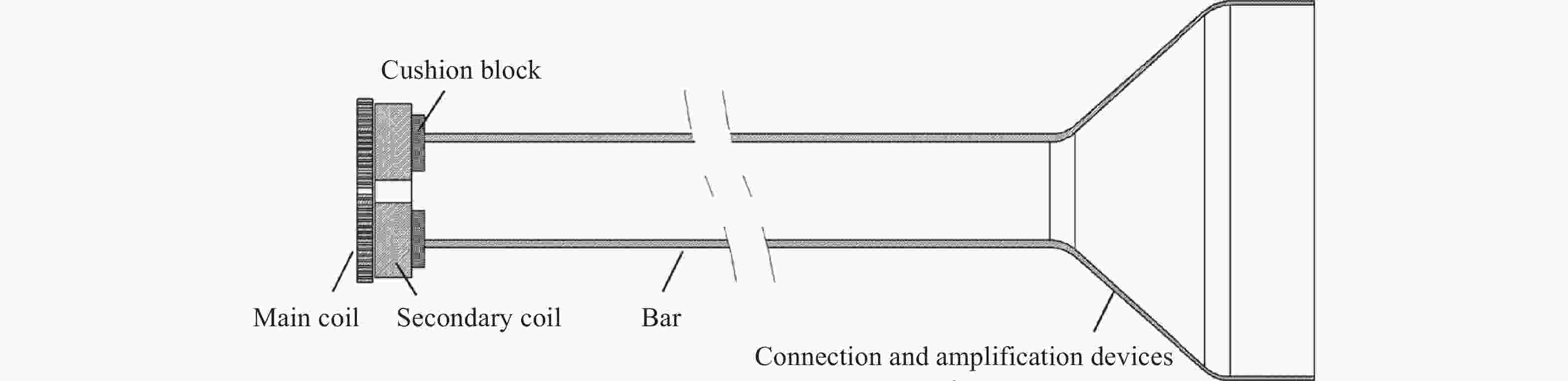

Abstract: Based on the basic principles of electromagnetic induction, an impact device is proposed that generates high-amplitude and long-pulse acceleration loads driven by electromagnetic forces. The impact device goes to make up for the shortcomings of the current stage of ground impact test technology. The disadvantages of the current stage of ground impact test technology include mainly time-consuming, high cost, low repeatability and controllability, and it is difficult to continuously improve the pulse width of acceleration load. Acceleration impact tests were performed using an electromagnetic Hopkinson bar, and the working process of the device from the generation of electromagnetic force to its transformation into impact load was analyzed. In the acceleration impact test, the stress on the bar was obtained by strain gauges and the acceleration loads at the end of the bar were obtained by acceleration transducers. A plurality of test results without loss of repeatability. The classical one-dimensional stress wave theory for predicting the relationship between acceleration and stress in slender bars is developed. Comparative analysis against experimental data are presented to demonstrate the effectiveness of the present approach. The electromagnetic Hopkinson bar acceleration impact test was numerically simulated using COMSOL finite element software, and the simulation results showed good consistency with the experimental results, indicating that the numerical model could simulate this kind of impact test more accurately and verifying the accuracy of the numerical model. Based on this finite element model, an impact device that generates high-amplitude, long-pulse acceleration is proposed, and numerical simulations of the device are carried out at different voltages and capacitances. The simulation results show that the device is able to generate the required acceleration. The acceleration amplitude increases with increasing capacitance voltage and the acceleration pulse width increases with increasing capacitance value. By regulating the values of the circuit parameters, the device can generate acceleration loads with different amplitudes and pulse widths. -

部件 材料 密度/(kg·m−3) 弹性模量/GPa 泊松比 相对磁导率 电导率/(S·m−1) 相对介电常数 主动线圈 紫铜 8960 110 0.35 1 6.0×107 1 次级线圈 无氧铜 8940 105 0.33 1 5.8×107 1 波导杆 钛合金 4400 110 0.34 1 7.4×105 1 空气 — — — — 1 0 1 表 2 模拟时主要部件最大应力

Table 2. Max stress of each part in simulation

部件 材料 屈服强度/

MPa模拟最大

应力/MPa主动线圈 紫铜 76 58 次级线圈 无氧铜 300 200 垫块 钨 1300 750 加载杆 TC4钛合金 900 735 连接与放大装置 TC4钛合金 900 845 -

[1] 金恂叔. 航天器动力学环境试验的发展概况和趋势 [J]. 航天器环境工程, 2003, 30(2): 15–21. DOI: 10.3969/j.issn.1673-1379.2003.02.003.JIN X S. The development status and trends of spacecraft dynamic environment testing [J]. Spacecraft Environment Engineering, 2003, 30(2): 15–21. DOI: 10.3969/j.issn.1673-1379.2003.02.003. [2] 丁继锋, 赵欣, 韩增尧. 航天器火工冲击技术研究进展 [J]. 宇航学报, 2014, 35(12): 1339–1349. DOI: 10.3873/j.issn.1000-1328.2014.12.001.DING J F, ZHAO X, HAN Z Y. Research development of spacecraft pyroshock technique [J]. Journal of Astronautics, 2014, 35(12): 1339–1349. DOI: 10.3873/j.issn.1000-1328.2014.12.001. [3] WU Z B, MA T H, ZHANG Y B, et al. Ground simulation test of 2D dynamic overload environment of fuze launching [J]. Shock and Vibration, 2020, 2020: 2858640. DOI: 10.1155/2020/2858640. [4] 朱广生, 刘瑞朝, 周松柏, 等. 基于爆炸激波管的火箭级间段强度考核和分离试验研究 [J]. 航空学报, 2015, 36(7): 2207–2213. DOI: 10.7527/S1000-6893.2015.0041.ZHU G S, LIU R C, ZHOU S B, et al. Experimental research of strength check and stage separation for a rocket’s stage section based on a blast simulator [J]. Acta Aeronauticaet Astronautica Sinica, 2015, 36(7): 2207–2213. DOI: 10.7527/S1000-6893.2015.0041. [5] 张学舜, 沈瑞琪. 火工品动态着靶模拟仿真技术研究 [J]. 火工品, 2003(4): 1–4. DOI: 10.3969/j.issn.1003-1480.2003.04.001.ZHANG X S, SHEN R Q. Study on dynamic touch-target analog simulation technique for initiating explosive devices [J]. Initiators & Pyrotechnics, 2003(4): 1–4. DOI: 10.3969/j.issn.1003-1480.2003.04.001. [6] DAI K R, WANG X F, YI F, et al. Triboelectric nanogenerators as self-powered acceleration sensor under high-g impact [J]. Nano Energy, 2018, 45: 84–93. DOI: 10.1016/j.nanoen.2017.12.022. [7] XU F J, MA T H. Modeling and studying acceleration-induced effects of piezoelectric pressure sensors using system identification theory [J]. Sensors, 2019, 19(5): 1052. DOI: 10.3390/s19051052. [8] 张伟, 沈瑞琪, 叶迎华, 等. 落球碰撞试验模拟火工品过载特性研究 [J]. 火工品, 2012(3): 4. DOI: 10.3969/j.issn.1003-1480.2012.03.002.ZHANG W, SHEN R Q, YE Y H, et al. Research on the overloading characteristics of initiator simulated by falling ball impacting experiment [J]. Initiators & Pyrotechnics, 2012(3): 4. DOI: 10.3969/j.issn.1003-1480.2012.03.002. [9] DUAN Z Y, LUO T H, TANG D Y, et al. Potential analysis of high-g shock experiment technology for heavy specimens based on air cannon [J]. Shock and Vibration, 2020: 5439785. DOI: 10.1155/2020/5439785. [10] TANG T, MA S J, LI F Y, et al. Research on overload signal of new impact body based on air cannon test and simulation [J]. Journal of Physics: Conference Series, 2021, 2029: 012008. DOI: 10.1088/1742-6596/2029/1/012008. [11] 杨华. 高过载加速度试验装置结构设计与分析 [D]. 南京: 南京理工大学, 2012: 1–6. [12] FOSTER J T, FREW D J, FORRESTAL M J, et al. Shock testing accelerometers with a Hopkinson pressure bar [J]. International Journal of Impact Engineering, 2012, 46: 56–61. DOI: 10.1016/j.ijimpeng.2012.02.006. [13] SHI Y B, ZHANG H, TANG J, et al. Anti-overload of a high-g acceleration sensor [J]. Advanced Materials Research, 2011, 291: 3103–3107. DOI: 10.4028/www.scientific.net/AMR.291-294.3103. [14] NIE H L, SUO T, WU B B, et al. A versatile split Hopkinson pressure bar using electromagnetic loading [J]. International Journal of Impact Engineering, 2018, 116: 94–104. DOI: 10.1016/j.ijimpeng.2018.02.002. [15] GUO Y Z, DU B, LIU H F, et al. Electromagnetic Hopkinson bar: a powerful scientific instrument to study mechanical behavior of materials at high strain rates [J]. Review of Scientific Instruments, 2020, 91(8): 081501. DOI: 10.1063/5.0006084. [16] 王维斌, 索涛, 郭亚洲, 等. 电磁霍普金森杆实验技术及研究进展 [J]. 力学进展, 2021, 51(4): 729–754. DOI: 10.6052/1000-0992-20-024.WANG W B, SUO T, GUO Y Z, et al. Experimental technique and research progress of electromagnetic Hopkinson bar [J]. Advances in Mechanics, 2021, 51(4): 729–754. DOI: 10.6052/1000-0992-20-024. [17] TAKATSU N, KATO M, SATO K, et al. High-speed forming of metal sheets by electromagnetic force [J]. JSME International Journal. Ser. 3, Vibration, Control Engineering, Engineering for Industry, 1988, 31(1): 142–148. DOI: 10.1299/jsmec1988.31.142. [18] 钟卫佳. 铜加工技术实用手册 [M]: 北京: 冶金工业出版社, 2007: 73–119. [19] 刘旭阳. TC4钛合金动态本构关系研究 [D]. 南京: 南京航空航天大学, 2010: 7–28. -

下载:

下载: