Dynamic responses of metallic hierarchical corrugated sandwich beams under shock loadings

-

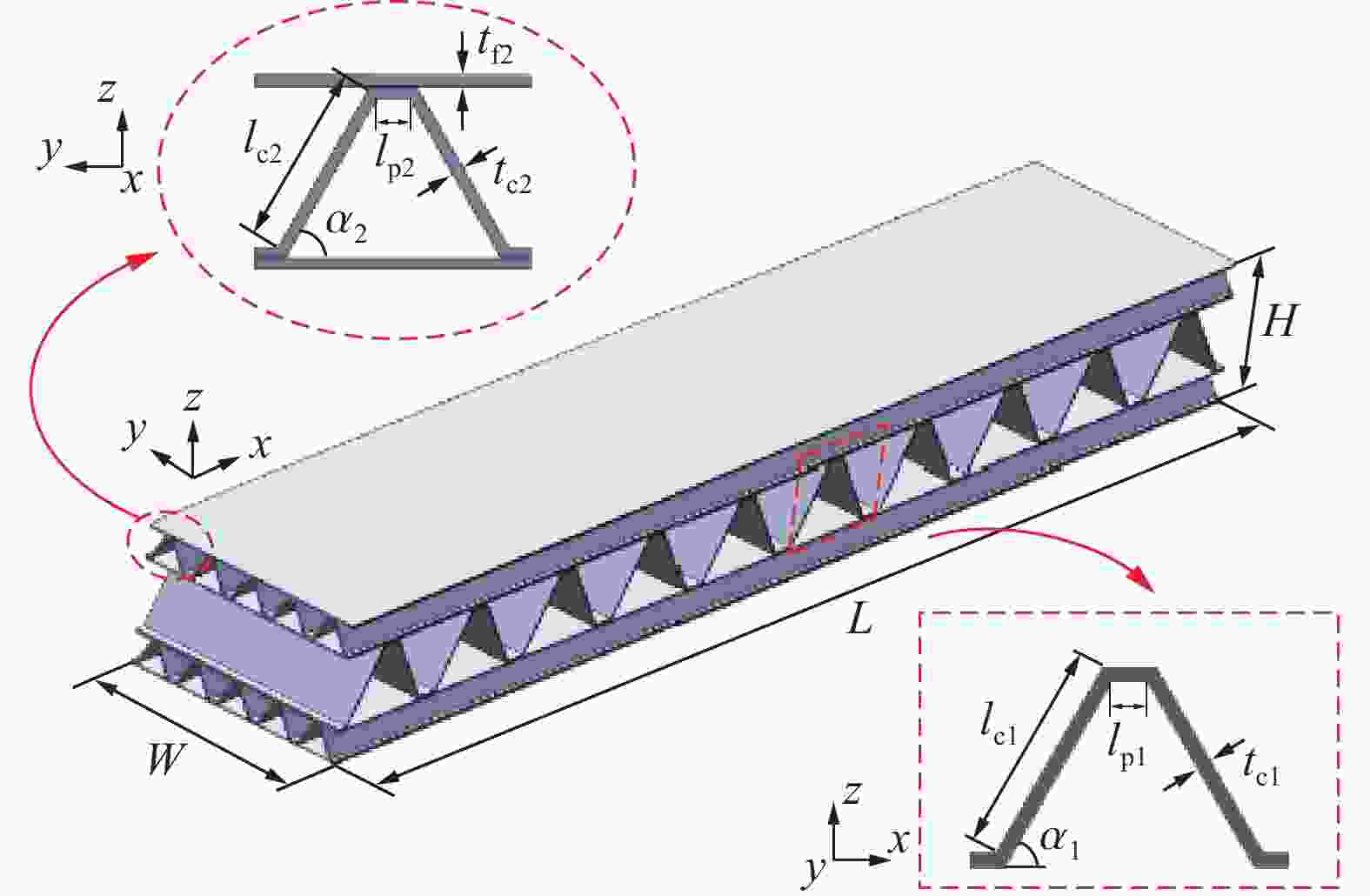

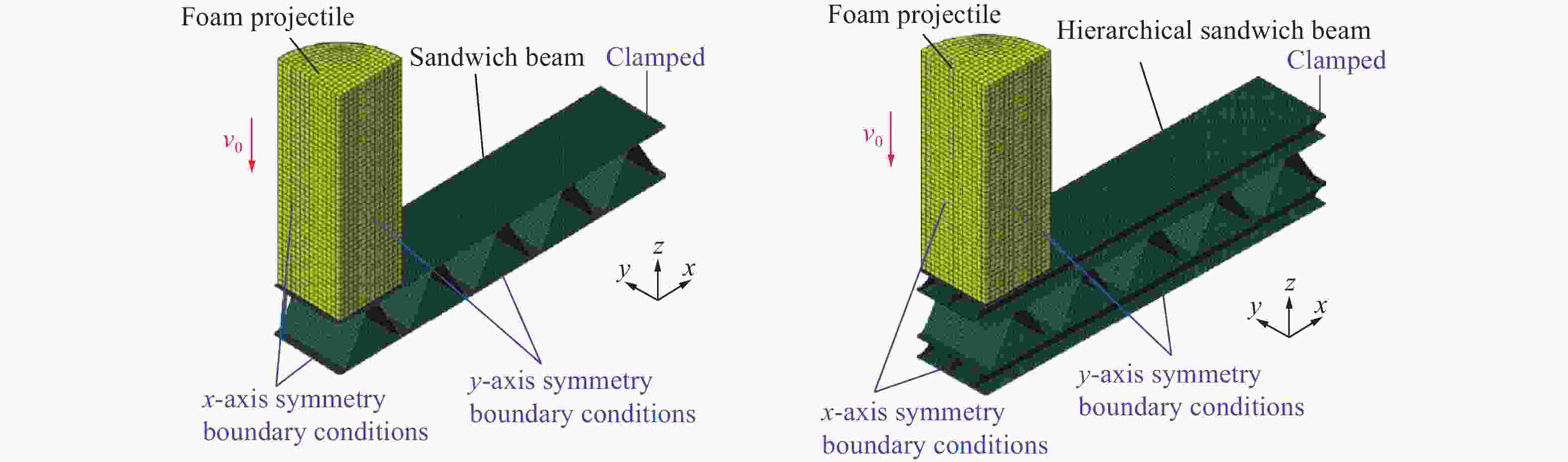

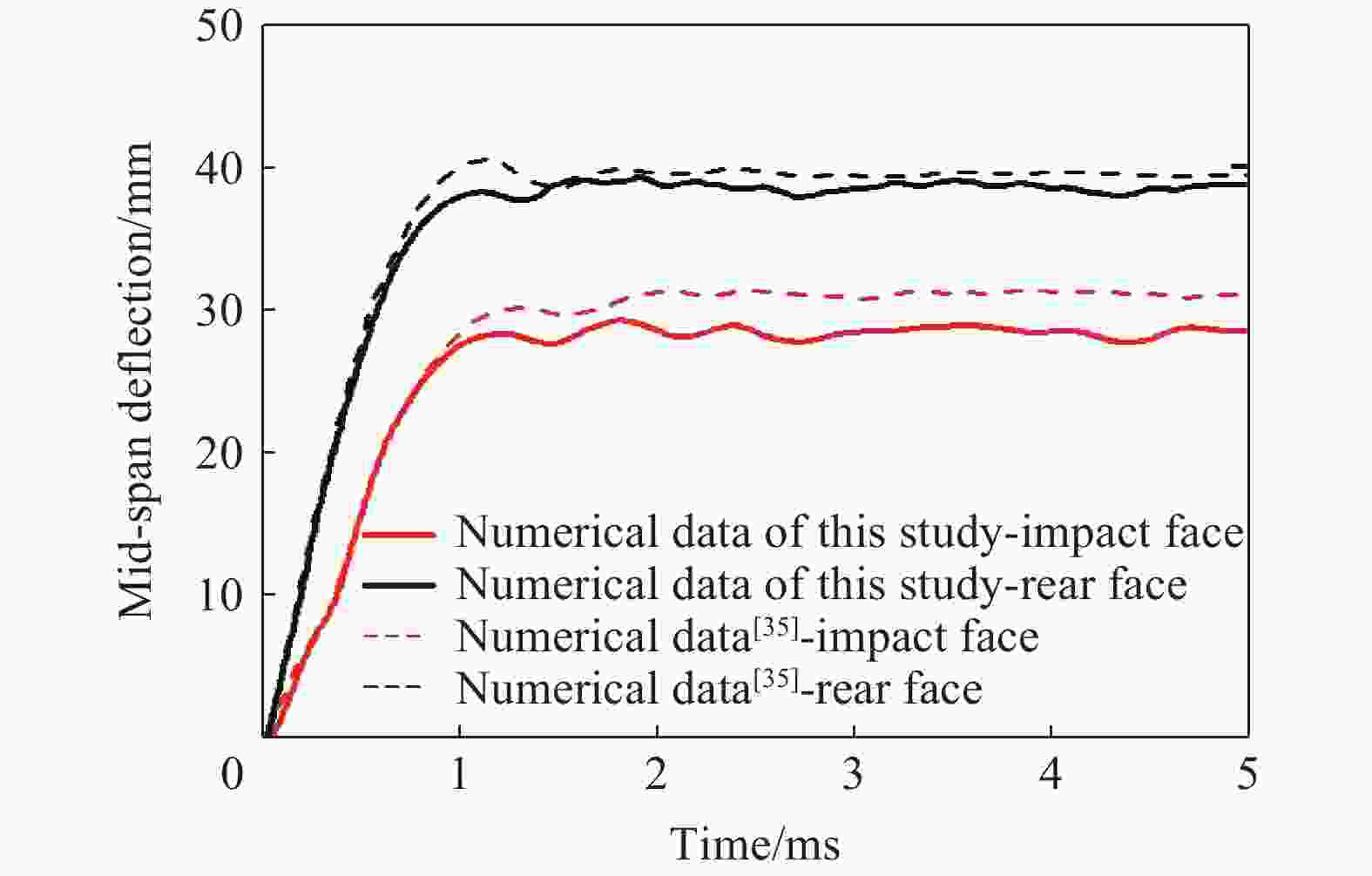

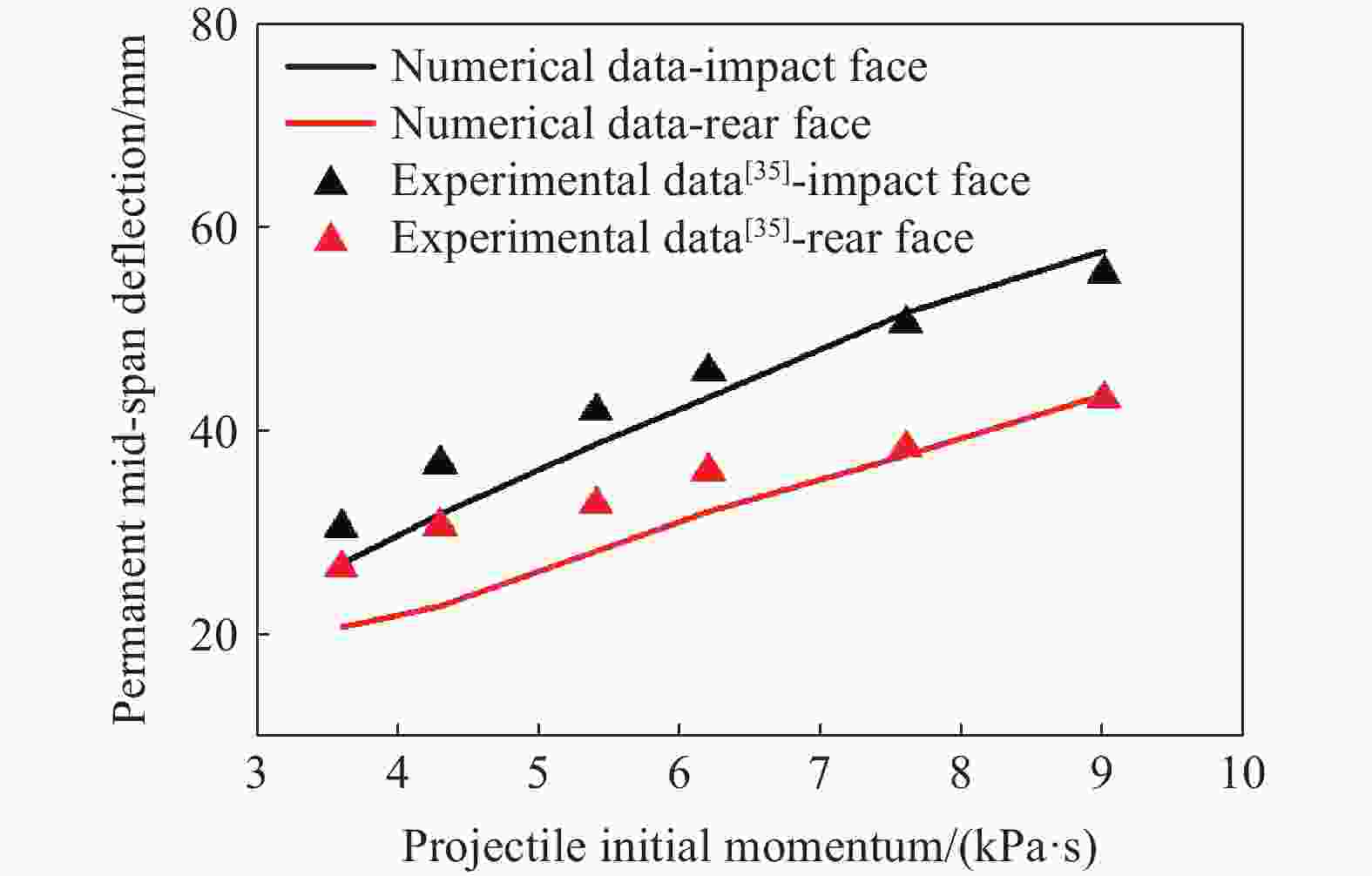

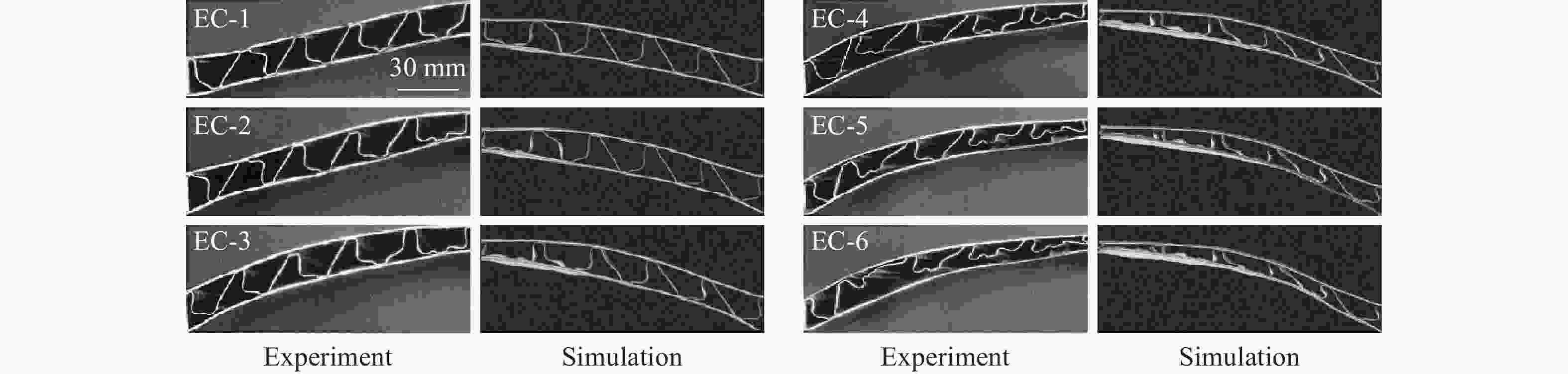

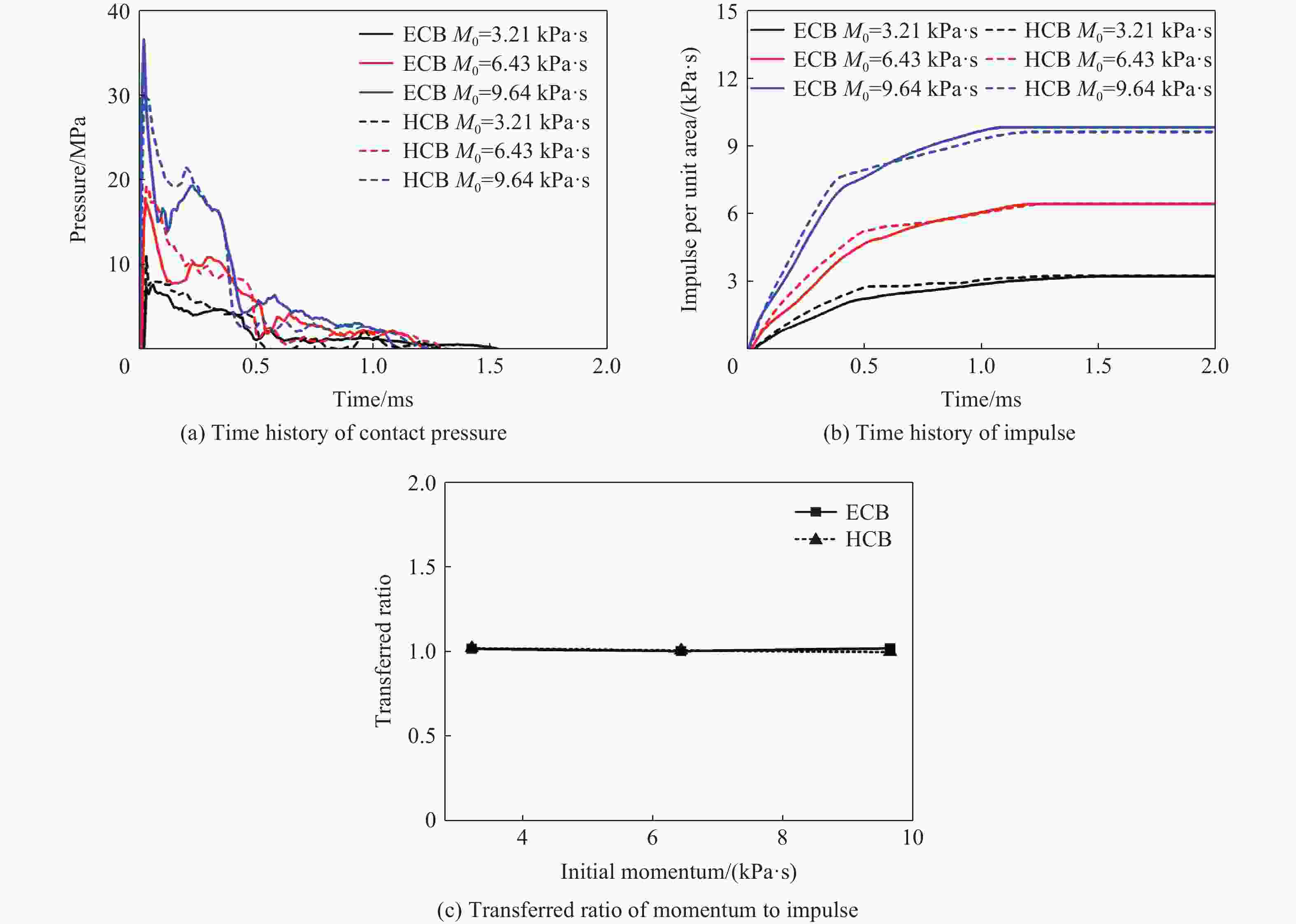

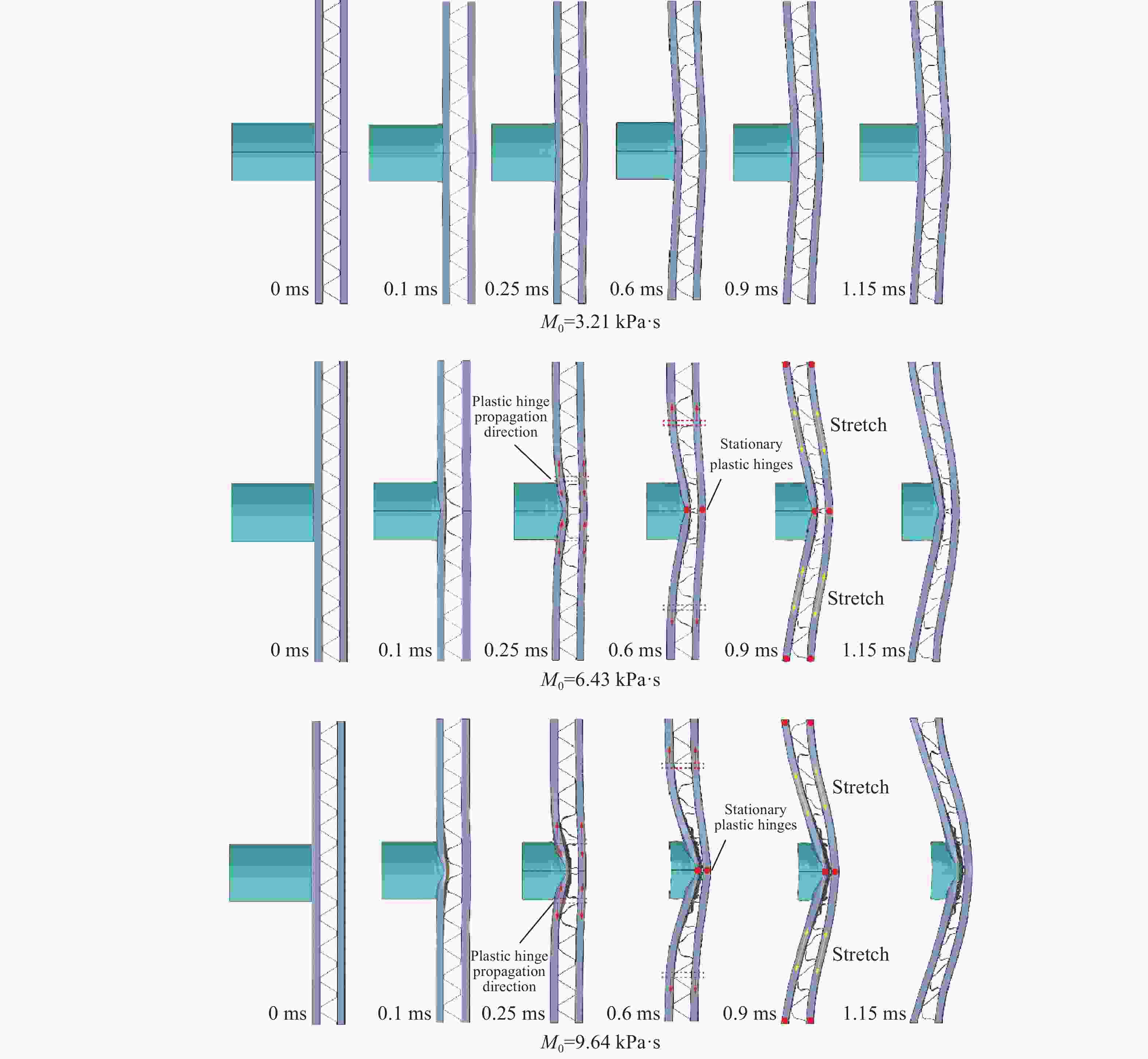

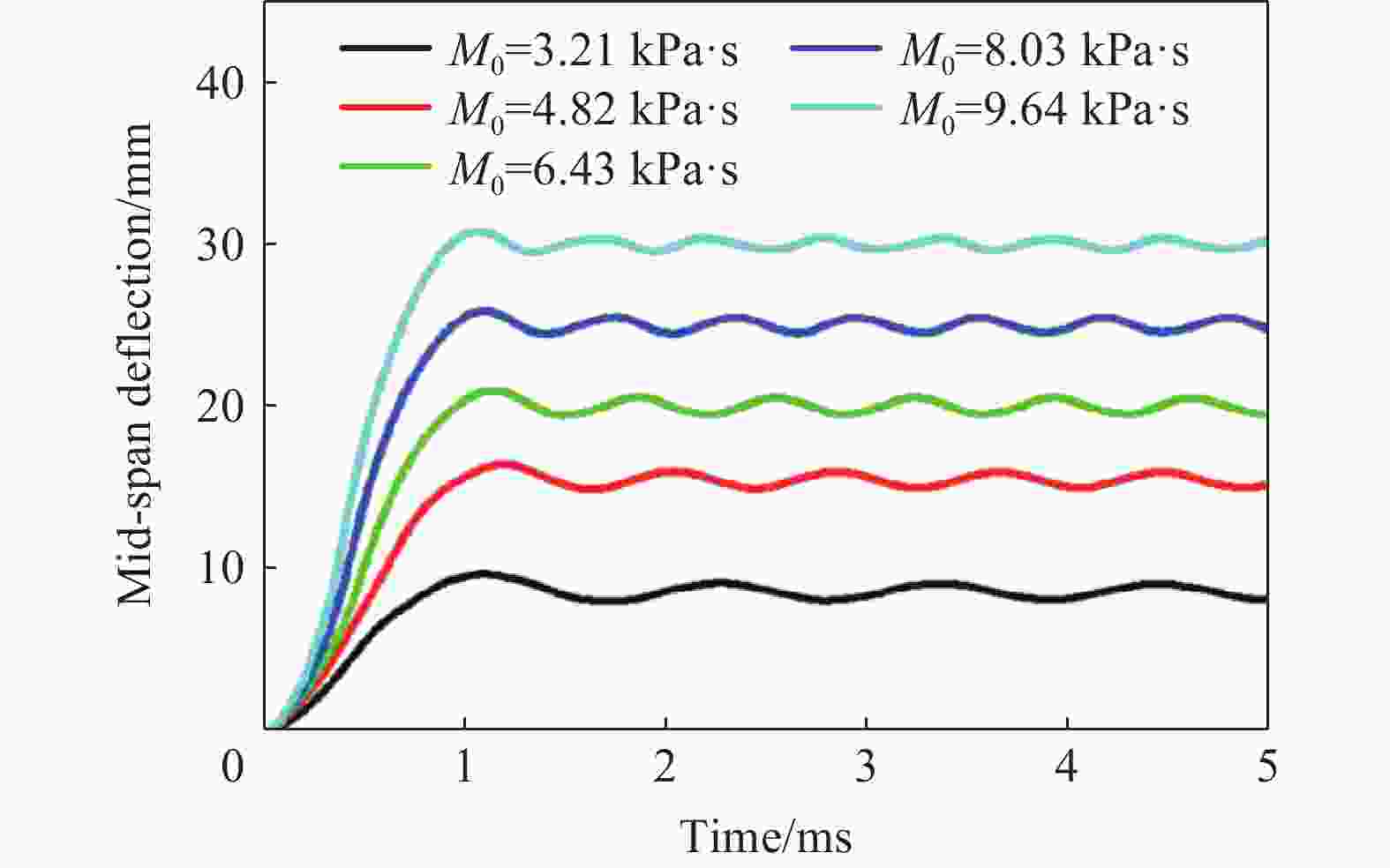

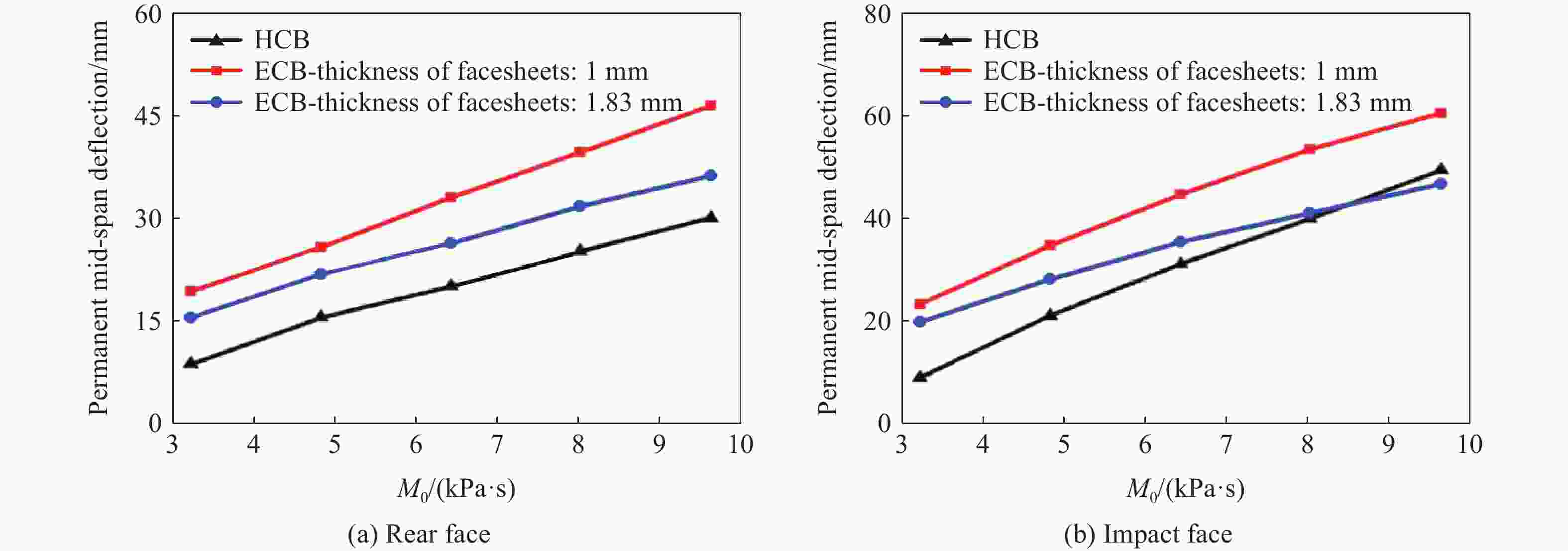

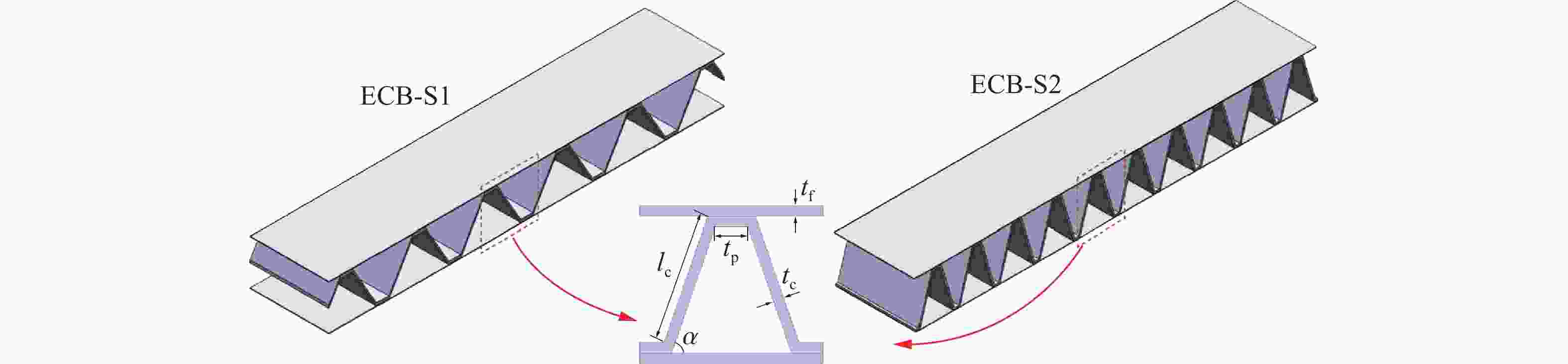

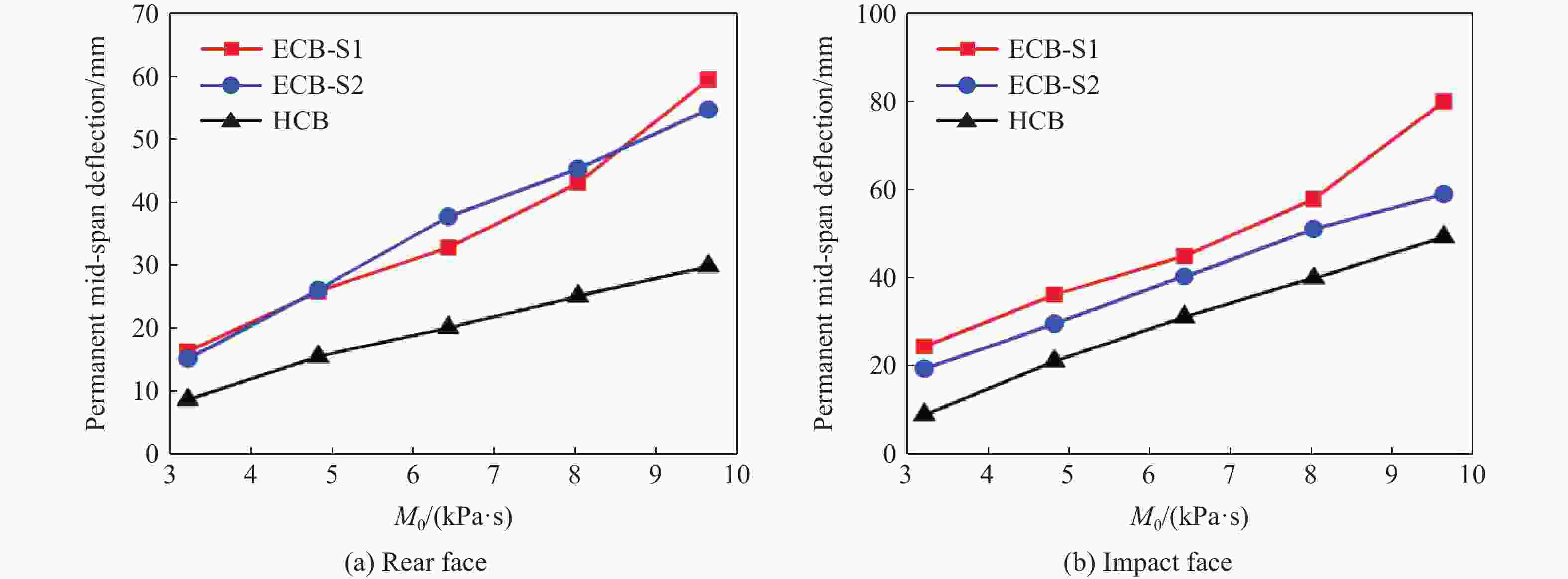

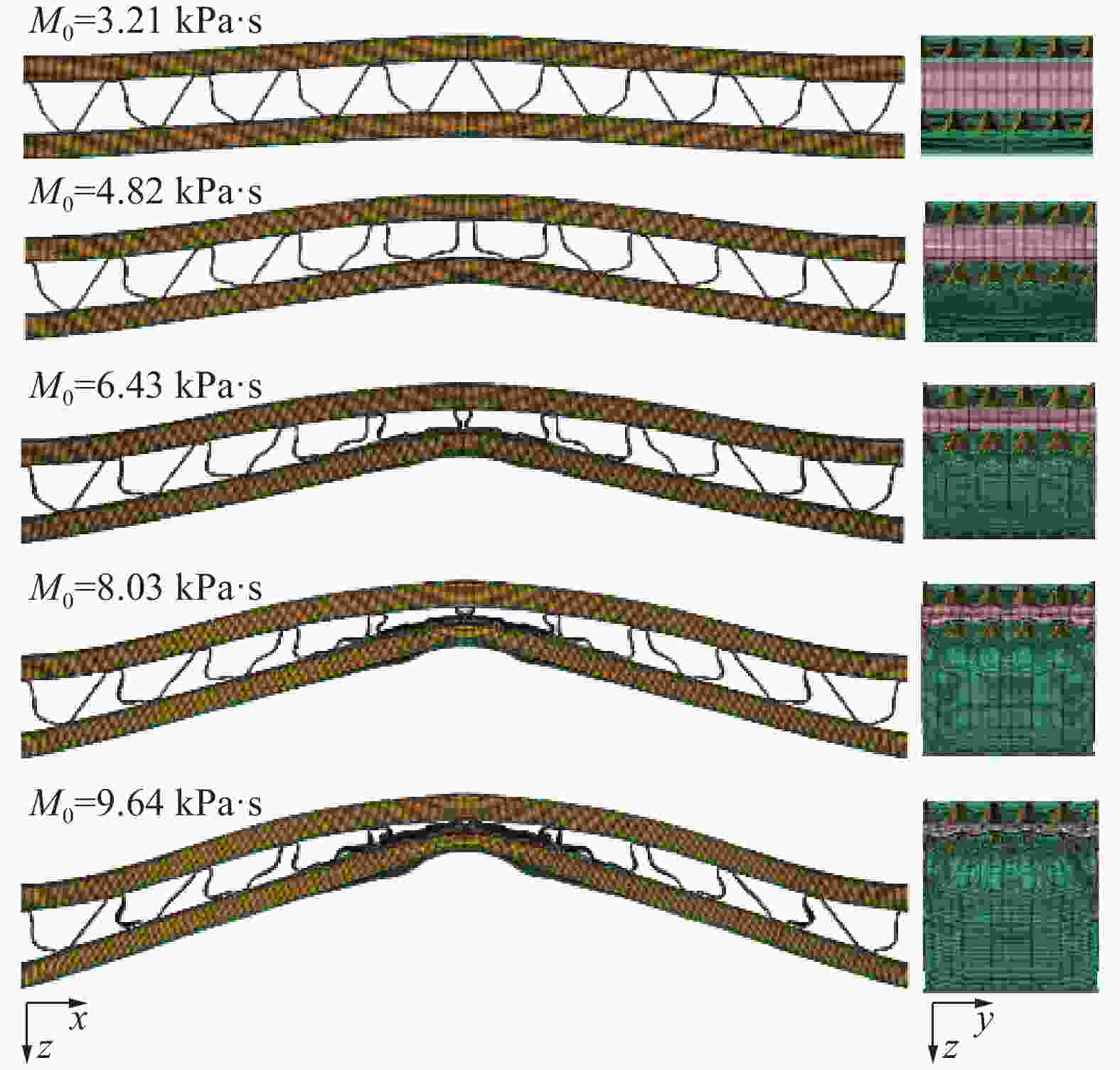

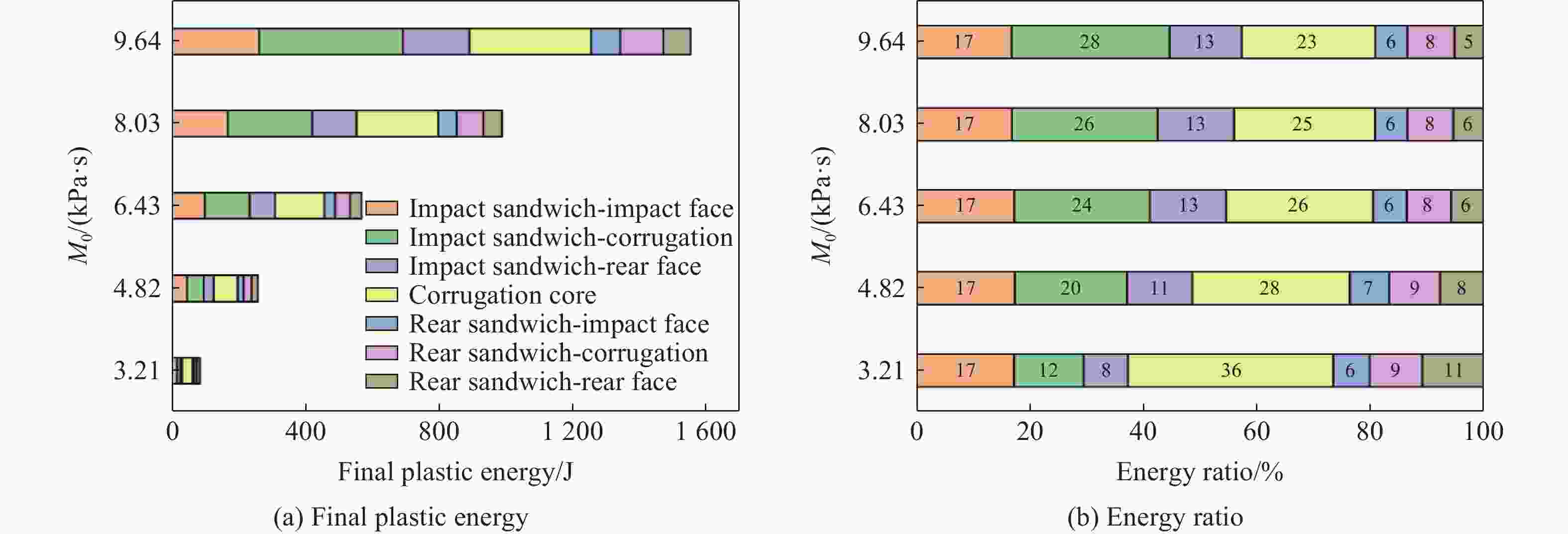

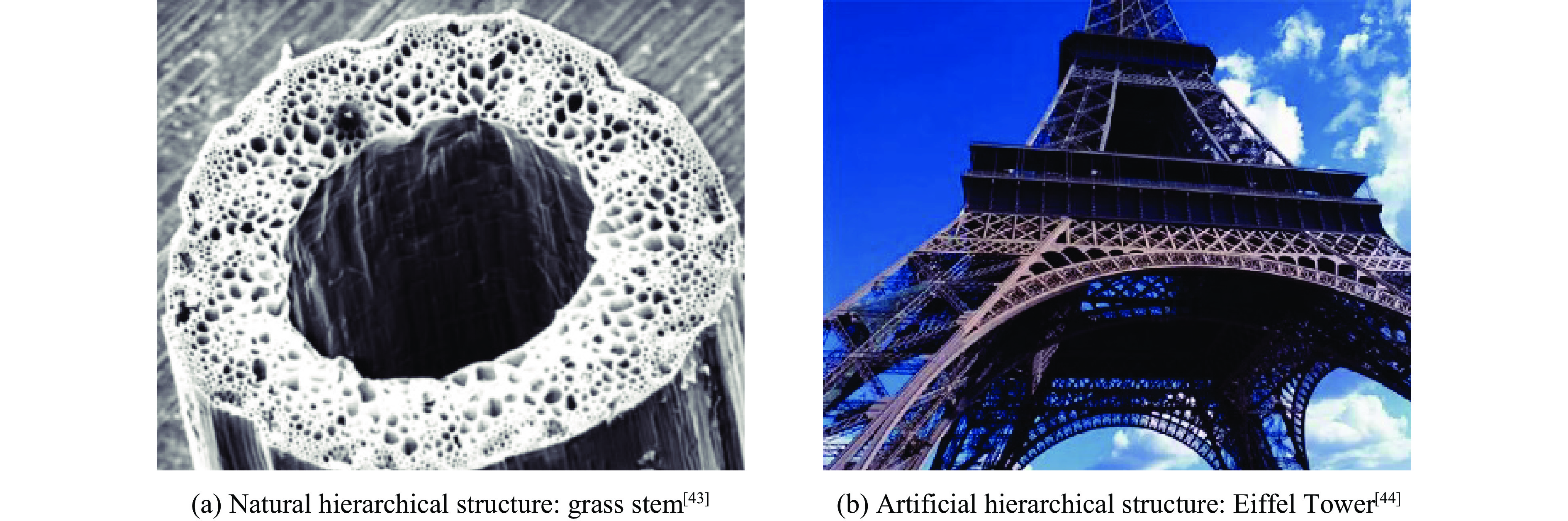

摘要: 为了研究采用多级夹层设计的金属多级波纹芯体夹层梁在泡沫子弹冲击下的动态力学行为,在验证数值方法可靠性的基础上,通过 Abaqus-Explicit 仿真分析了不同子弹动量水平下金属多级波纹芯体夹层梁的动态变形过程、定量挠度结果、变形破坏模式和能量吸收特性。进一步地,设计了3种不同几何参数的单层波纹夹层结构,比较了单层和多级波纹夹层结构在等质量条件下的抗冲击性能差异。结果表明,多级波纹夹层梁冲击侧夹层面板的二级波纹芯体和一级波纹芯体的压溃程度始终大于背侧夹层面板二级波纹芯体的压溃程度。多级波纹夹层梁背侧面板的最终跨中挠度始终小于等质量单级波纹夹层梁的相应挠度,体现出多级夹层梁的抗冲击防护性能优势。这种增强机理主要在于增加的多孔芯体压缩吸能保护了背侧面板,另外,多级夹层梁的塑性轴向拉伸强度几乎保持不变,而塑性弯曲强度因梁结构总厚度增加而增大,从而扩大了夹层结构的塑性屈服面。Abstract: The dynamic mechanical behavior of a metallic hierarchical corrugated sandwich beam subjected to foam projectile impact was systematically studied. After verifying the reliability of the numerical method, the dynamic deformation evolution, quantitative deflection results, deformation failure modes, and energy absorption characteristics of the metallic hierarchical corrugated sandwich beam under different projectile momentum levels were analyzed using Abaqus-Explicit simulations. Subsequently, three metallic single-layer empty corrugated sandwich beams with different geometric parameters were designed, aiming to compare the shock resistance between single-layer and hierarchical corrugated sandwich beams under equal mass conditions. The results showed that the degree of crushing of the secondary corrugated core on the impact side and the first-order corrugated core of the hierarchical sandwich beam was always greater than that of the rear sandwich’s secondary corrugated core. The final mid-span deflection of the rear face of the hierarchical corrugated sandwich beam was always smaller than the corresponding deflection value of the equivalent mass single-level empty corrugated sandwich beam, demonstrating the superior impact protection performance of the hierarchical sandwich beam. This enhancement mechanism is mainly attributed to the increased energy absorption because of the added cellular cores, which protects the rear face sheet. Besides, the plastic longitudinal stretching strength of the hierarchical sandwich beam remains almost unchanged, while the plastic bending strength increases due to the increase in the total beam thickness, thereby enlarging the plastic yield surface of the sandwich structure.

-

表 1 多级波纹夹层结构几何尺寸

Table 1. Geometric parameters of the hierarchical sandwich beam

L/mm W/mm lc1/mm lp1/mm tc1/mm α1/(°) lc2/mm lp2/mm tc2/mm α2/(°) tf2/mm 300 60 20 5 0.5 60 8 2 0.5 60 0.5 表 2 单层波纹夹层梁ECB-S1和ECB-S2的几何参数

Table 2. The geometry parameters of the empty corrugated sandwich beams ECB-S1 and ECB-S2

梁 lp/mm lc/mm tc/mm α/(°) tf/mm ECB-S1 9.12 36.46 2.10 60 0.5 ECB-S2 5.00 34.88 1.31 73.34 0.5 -

[1] RATHBUN H J, RADFORD D D, XUE Z, et al. Performance of metallic honeycomb-core sandwich beams under shock loading [J]. International Journal of Solids and Structures, 2006, 43(6): 1746–1763. DOI: 10.1016/j.ijsolstr.2005.06.079. [2] YUE Z S, WANG X, HE C, et al. Elevated shock resistance of all-metallic sandwich beams with honeycomb-supported corrugated cores [J]. Composites Part B: Engineering, 2022, 242: 110102. DOI: 10.1016/j.compositesb.2022.110102. [3] WANG X, HE C, YUE Z S, et al. Shock resistance of elastomer-strengthened metallic corrugated core sandwich panels [J]. Composites Part B: Engineering, 2022, 237: 109840. DOI: 10.1016/j.compositesb.2022.109840. [4] REN J W, ZHOU Y L, QIANG L S, et al. Enhancing impact resistance of metallic foam core sandwich constructions through encasing high-strength fibrous composites [J]. Thin-Walled Structures, 2024, 196: 111546. DOI: 10.1016/j.tws.2023.111546. [5] ZHANG D J, ZHAO Z Y, GAO H Y, et al. Dynamic response of sandwich panel attached with a double mass-spring-damping system to shallow-buried explosion: analytical modeling [J]. Science China Technological Sciences, 2024, 67(2): 568–586. DOI: 10.1007/s11431-023-2375-0. [6] 习会峰, 黄丽琴, 余同希, 等. 拓扑互锁结构研究现状及展望 [J]. 应用力学学报, 2023, 40(2): 241–252. DOI: 10.11776/j.issn.1000-4939.2023.02.001.XI H F, HUANG L Q, YU T X, et al. A review on the studies of topological interlocking structures [J]. Chinese Journal of Applied Mechanics, 2023, 40(2): 241–252. DOI: 10.11776/j.issn.1000-4939.2023.02.001. [7] YUE Z S, HAN B, WANG Z Y, et al. Data-driven multi-objective optimization of ultralight hierarchical origami-corrugation meta-sandwich structures [J]. Composite Structures, 2023, 303: 116334. DOI: 10.1016/j.compstruct.2022.116334. [8] 吴文旺, 夏热. 轻质点阵超结构设计及多功能力学性能调控方法 [J]. 力学进展, 2022, 52(3): 673–718. DOI: 10.6052/1000-0992-22-002.WU W W, XIA R. Design of lightweight lattice meta-structures and approaches to manipulate their multi-functional mechanical properties [J]. Advances in Mechanics, 2022, 52(3): 673–718. DOI: 10.6052/1000-0992-22-002. [9] CÔTÉ F, DESHPANDE V S, FLECK N A, et al. The compressive and shear responses of corrugated and diamond lattice materials [J]. International Journal of Solids and Structures, 2006, 43(20): 6220–6242. DOI: 10.1016/j.ijsolstr.2005.07.045. [10] RADFORD D D, FLECK N A, DESHPANDE V S. The response of clamped sandwich beams subjected to shock loading [J]. International Journal of Impact Engineering, 2006, 32(6): 968–987. DOI: 10.1016/j.ijimpeng.2004.08.007. [11] HAN B, YUE Z S, WU H, et al. Superior compressive performance of hierarchical origami-corrugation metallic sandwich structures based on selective laser melting [J]. Composite Structures, 2022, 300: 116181. DOI: 10.1016/j.compstruct.2022.116181. [12] RUBINO V, DESHPANDE V S, FLECK N A. The collapse response of sandwich beams with a Y-frame core subjected to distributed and local loading [J]. International Journal of Mechanical Sciences, 2008, 50(2): 233–246. DOI: 10.1016/j.ijmecsci.2007.07.007. [13] RUBINO V, DESHPANDE V S, FLECK N A. The dynamic response of end-clamped sandwich beams with a Y-frame or corrugated core [J]. International Journal of Impact Engineering, 2008, 35(8): 829–844. DOI: 10.1016/j.ijimpeng.2007.10.006. [14] ZHANG P, CHENG Y S, LIU J, et al. Experimental and numerical investigations on laser-welded corrugated-core sandwich panels subjected to air blast loading [J]. Marine Structures, 2015, 40: 225–246. DOI: 10.1016/j.marstruc.2014.11.007. [15] LIBOVE C, HUBKA R E. Elastic constants for corrugated-core sandwich plates [R]. Washington: National Advisory Committee for Aeronautics, 1951. [16] LOK T S, CHENG Q H, JACOB B P. Equivalent stiffness parameters of truss-core sandwich panel [C]//Proceedings of the Ninth International Offshore and Polar Engineering Conference. Brest, France: International Society of Offshore and Polar Engineers, 1999: 292–298. [17] BUANNIC N, CARTRAUD P, QUESNEL T. Homogenization of corrugated core sandwich panels [J]. Composite Structures, 2003, 59(3): 299–312. DOI: 10.1016/S0263-8223(02)00246-5. [18] CHANG W S, VENTSEL E, KRAUTHAMMER T, et al. Bending behavior of corrugated-core sandwich plates [J]. Composite Structures, 2005, 70(1): 81–89. DOI: 10.1016/j.compstruct.2004.08.014. [19] LU T J, ZHU G. The elastic constants of corrugated board panels [J]. Journal of Composite Materials, 2001, 35(20): 1868–1887. DOI: 10.1177/002199801772661498. [20] PENG L X, LIEW K M, KITIPORNCHAI S. Analysis of stiffened corrugated plates based on the FSDT via the mesh-free method [J]. International Journal of Mechanical Sciences, 2007, 49(3): 364–378. DOI: 10.1016/j.ijmecsci.2006.08.018. [21] SAMANTA A, MUKHOPADHYAY M. Finite element static and dynamic analyses of folded plates [J]. Engineering Structures, 1999, 21(3): 277–287. DOI: 10.1016/S0141-0296(97)90172-3. [22] 彭林欣, 严世涛, 杨绿峰. 波纹夹层板自由振动的移动最小二乘无网格法 [J]. 广西大学学报(自然科学版), 2010, 35(5): 703–710. DOI: 10.13624/j.cnki.issn.1001-7445.2010.05.016.PENG L X, YAN S T, YANG L F. Free vibration analysis of corrugated-core sandwich plate structures by the moving-least square meshfree method [J]. Journal of Guangxi University (Natural Science Edition), 2010, 35(5): 703–710. DOI: 10.13624/j.cnki.issn.1001-7445.2010.05.016. [23] NORDSTRAND T M. Parametric study of the post-buckling strength of structural core sandwich panels [J]. Composite Structures, 1995, 30(4): 441–451. DOI: 10.1016/0263-8223(94)00066-2. [24] LU T J, CHEN C, ZHU G. Compressive behaviour of corrugated board panels [J]. Journal of Composite Materials, 2001, 35(23): 2098–2126. DOI: 10.1177/002199801772661371. [25] VALDEVIT L, WEI Z, MERCER C, et al. Structural performance of near-optimal sandwich panels with corrugated cores [J]. International Journal of Solids and Structures, 2006, 43(16): 4888–4905. DOI: 10.1016/j.ijsolstr.2005.06.073. [26] TILBROOK M T, RADFORD D D, DESHPANDE V S, et al. Dynamic crushing of sandwich panels with prismatic lattice cores [J]. International Journal of Solids and Structures, 2007, 44(18/19): 6101–6123. DOI: 10.1016/j.ijsolstr.2007.02.015. [27] HOU S J, ZHAO S Y, REN L L, et al. Crashworthiness optimization of corrugated sandwich panels [J]. Materials & Design, 2013, 51: 1071–1084. DOI: 10.1016/j.matdes.2013.04.086. [28] ST-PIERRE L, DESHPANDE V S, FLECK N A. The low velocity impact response of sandwich beams with a corrugated core or a Y-frame core [J]. International Journal of Mechanical Sciences, 2015, 91: 71–80. DOI: 10.1016/j.ijmecsci.2014.02.014. [29] ST-PIERRE L, FLECK N A, DESHPANDE V S. The dynamic indentation response of sandwich panels with a corrugated or Y-frame core [J]. International Journal of Mechanical Sciences, 2015, 92: 279–289. DOI: 10.1016/j.ijmecsci.2014.11.021. [30] RUBINO V, DESHPANDE V S, FLECK N A. The dynamic response of clamped rectangular Y-frame and corrugated core sandwich plates [J]. European Journal of Mechanics-A/Solids, 2009, 28(1): 14–24. DOI: 10.1016/j.euromechsol.2008.06.001. [31] ZHANG P, LIU J, CHENG Y S, et al. Dynamic response of metallic trapezoidal corrugated-core sandwich panels subjected to air blast loading—an experimental study [J]. Materials & Design (1980-2015), 2015, 65: 221–230. DOI: 10.1016/j.matdes.2014.08.071. [32] LIU K, KE L, SHA Y Y, et al. Dynamic response of laser-welded corrugated sandwich panels subjected to plane blast wave [J]. International Journal of Impact Engineering, 2022, 164: 104203. DOI: 10.1016/j.ijimpeng.2022.104203. [33] WANG X, YUE Z S, XU X, et al. Ballistic impact response of elastomer-retrofitted corrugated core sandwich panels [J]. International Journal of Impact Engineering, 2023, 175: 104545. DOI: 10.1016/j.ijimpeng.2023.104545. [34] WANG X, YU R P, ZHANG Q C, et al. Dynamic response of clamped sandwich beams with fluid-filled corrugated cores [J]. International Journal of Impact Engineering, 2020, 139: 103533. DOI: 10.1016/j.ijimpeng.2020.103533. [35] YU R P, WANG X, ZHANG Q C, et al. Effects of sand filling on the dynamic response of corrugated core sandwich beams under foam projectile impact [J]. Composites Part B: Engineering, 2020, 197: 108135. DOI: 10.1016/j.compositesb.2020.108135. [36] ZHANG P, CHENG Y S, LIU J, et al. Experimental study on the dynamic response of foam-filled corrugated core sandwich panels subjected to air blast loading [J]. Composites Part B: Engineering, 2016, 105: 67–81. DOI: 10.1016/j.compositesb.2016.08.038. [37] KOOISTRA G W, DESHPANDE V, WADLEY H N G. Hierarchical corrugated core sandwich panel concepts [J]. Journal of Applied Mechanics, 2007, 74(2): 259–268. DOI: 10.1115/1.2198243. [38] FARROKHABADI A, TAGHIZADEH S A, MADADI H, et al. Experimental and numerical analysis of novel multi-layer sandwich panels under three point bending load [J]. Composite Structures, 2020, 250: 112631. DOI: 10.1016/j.compstruct.2020.112631. [39] GRYGOROWICZ M, PACZOS P, WITTENBECK L, et al. Experimental three-point bending of sandwich beam with corrugated core [J]. AIP Conference Proceedings, 2015, 1648(1): 800002. DOI: 10.1063/1.4913003. [40] WITTENBECK L, GRYGOROWICZ M, PACZOS P. Numerical analysis of sandwich beam with corrugated core under three-point bending [J]. AIP Conference Proceedings, 2015, 1648(1): 800007. DOI: 10.1063/1.4913008. [41] LAKES R. Materials with structural hierarchy [J]. Nature, 1993, 361(6412): 511–515. DOI: 10.1038/361511a0. [42] FRATZL P, WEINKAMER R. Nature’s hierarchical materials [J]. Progress in Materials Science, 2007, 52(8): 1263–1334. DOI: 10.1016/j.pmatsci.2007.06.001. [43] GIBSON L J. Biomechanics of cellular solids [J]. Journal of Biomechanics, 2005, 38(3): 377–399. DOI: 10.1016/j.jbiomech.2004.09.027. [44] 搜狗百科. 建筑艺术: 建筑的文化与审美价值 [EB/OL]. [2023-08-17]. https://baike.sogou.com/v64536923.htm?ch=zhihu.topic. [45] RADFORD D D, DESHPANDE V S, FLECK N A. The use of metal foam projectiles to simulate shock loading on a structure [J]. International Journal of Impact Engineering, 2005, 31(9): 1152–1171. DOI: 10.1016/j.ijimpeng.2004.07.012. [46] RADFORD D D, MCSHANE G J, DESHPANDE V S, et al. The response of clamped sandwich plates with metallic foam cores to simulated blast loading [J]. International Journal of Solids and Structures, 2006, 43(7/8): 2243–2259. DOI: 10.1016/j.ijsolstr.2005.07.006. [47] YAHAYA M A, RUAN D, LU G, et al. Response of aluminium honeycomb sandwich panels subjected to foam projectile impact—an experimental study [J]. International Journal of Impact Engineering, 2015, 75: 100–109. DOI: 10.1016/j.ijimpeng.2014.07.019. [48] JING L, WANG Z H, ZHAO L M. The dynamic response of sandwich panels with cellular metal cores to localized impulsive loading [J]. Composites Part B: Engineering, 2016, 94: 52–63. DOI: 10.1016/j.compositesb.2016.03.035. [49] DESHPANDE V S, FLECK N A. Isotropic constitutive models for metallic foams [J]. Journal of the Mechanics and Physics of Solids, 2000, 48(6/7): 1253–1283. DOI: 10.1016/S0022-5096(99)00082-4. [50] FLECK N A, DESHPANDE V S. The resistance of clamped sandwich beams to shock loading [J]. Journal of Applied Mechanics, 2004, 71(3): 386–401. DOI: 10.1115/1.1629109. -

下载:

下载: