Research on damage and cavitation characteristics of propellers under far field shock waves

-

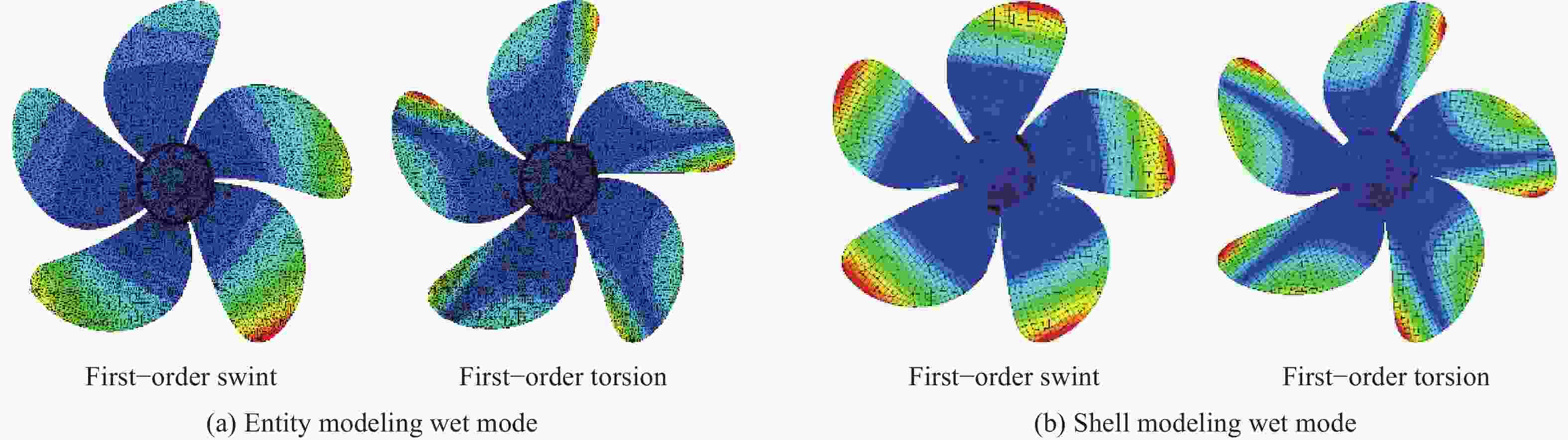

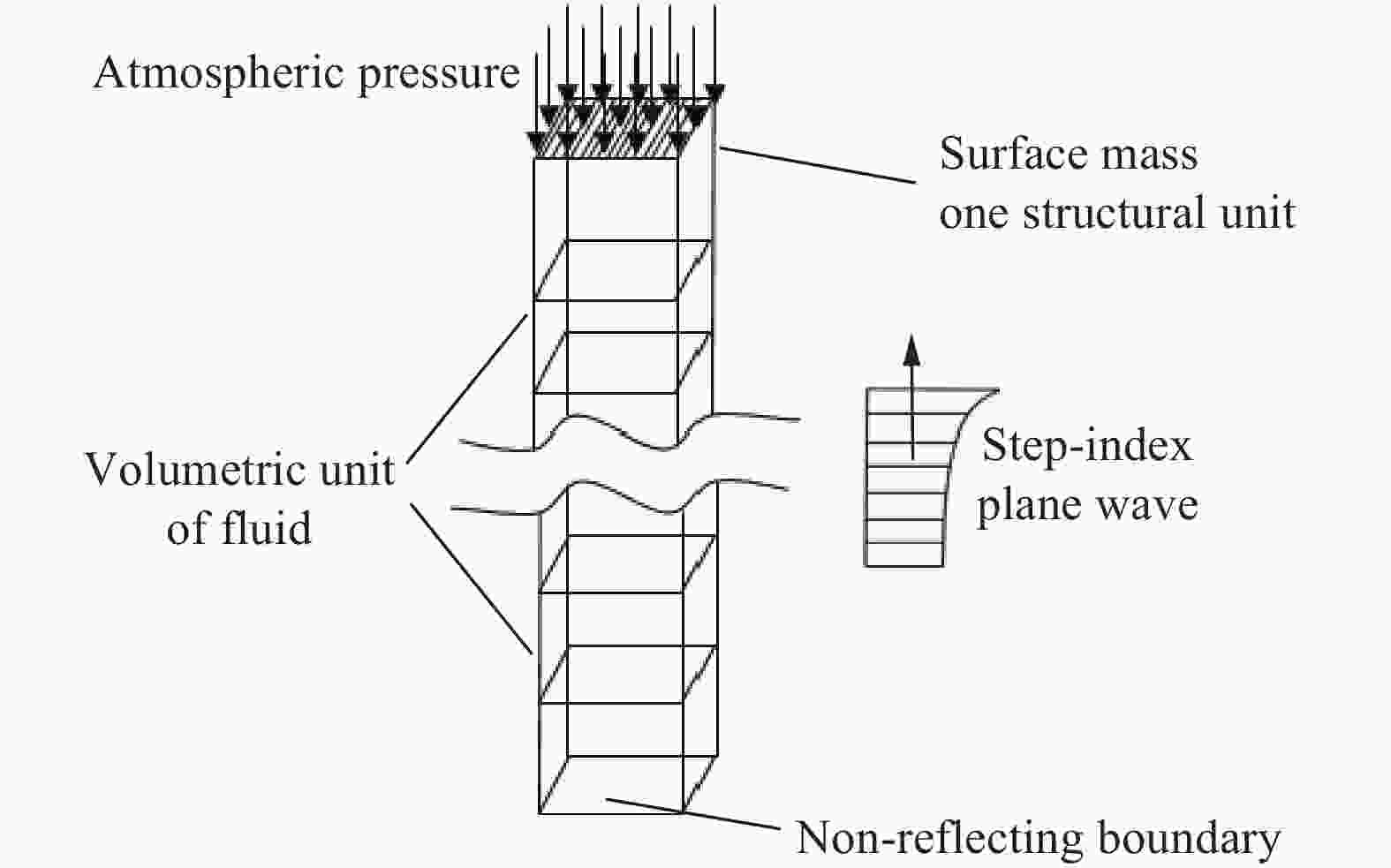

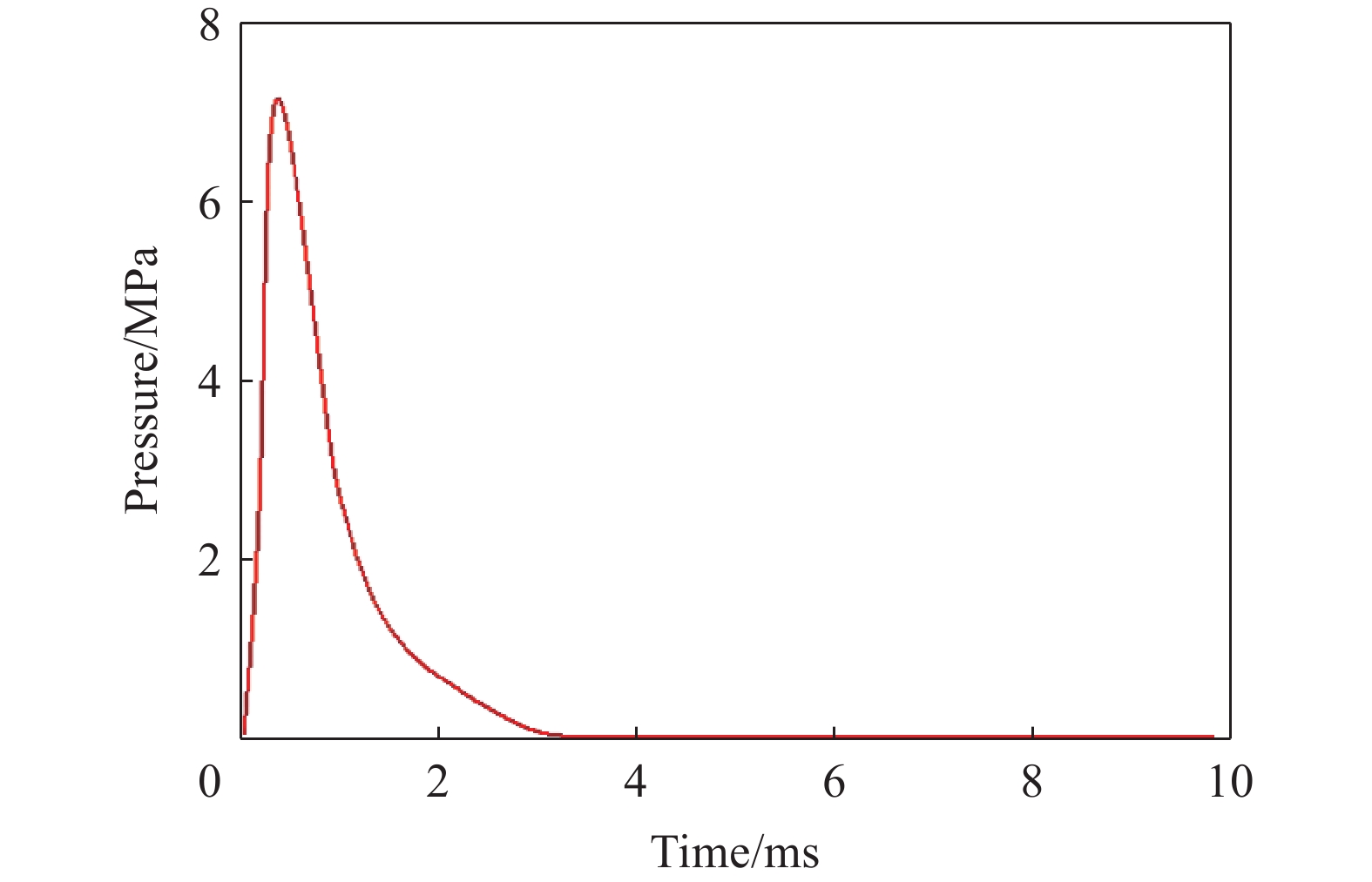

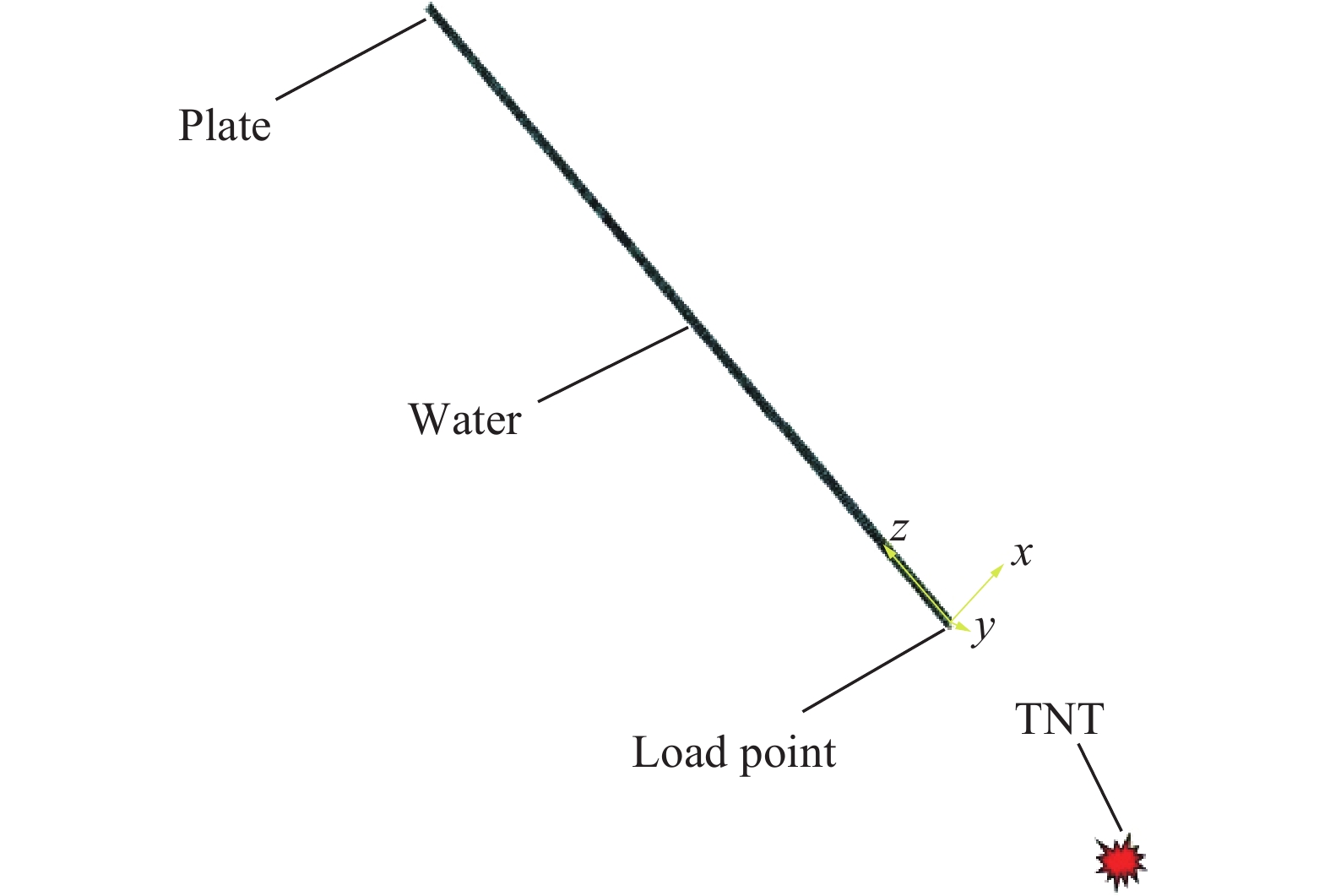

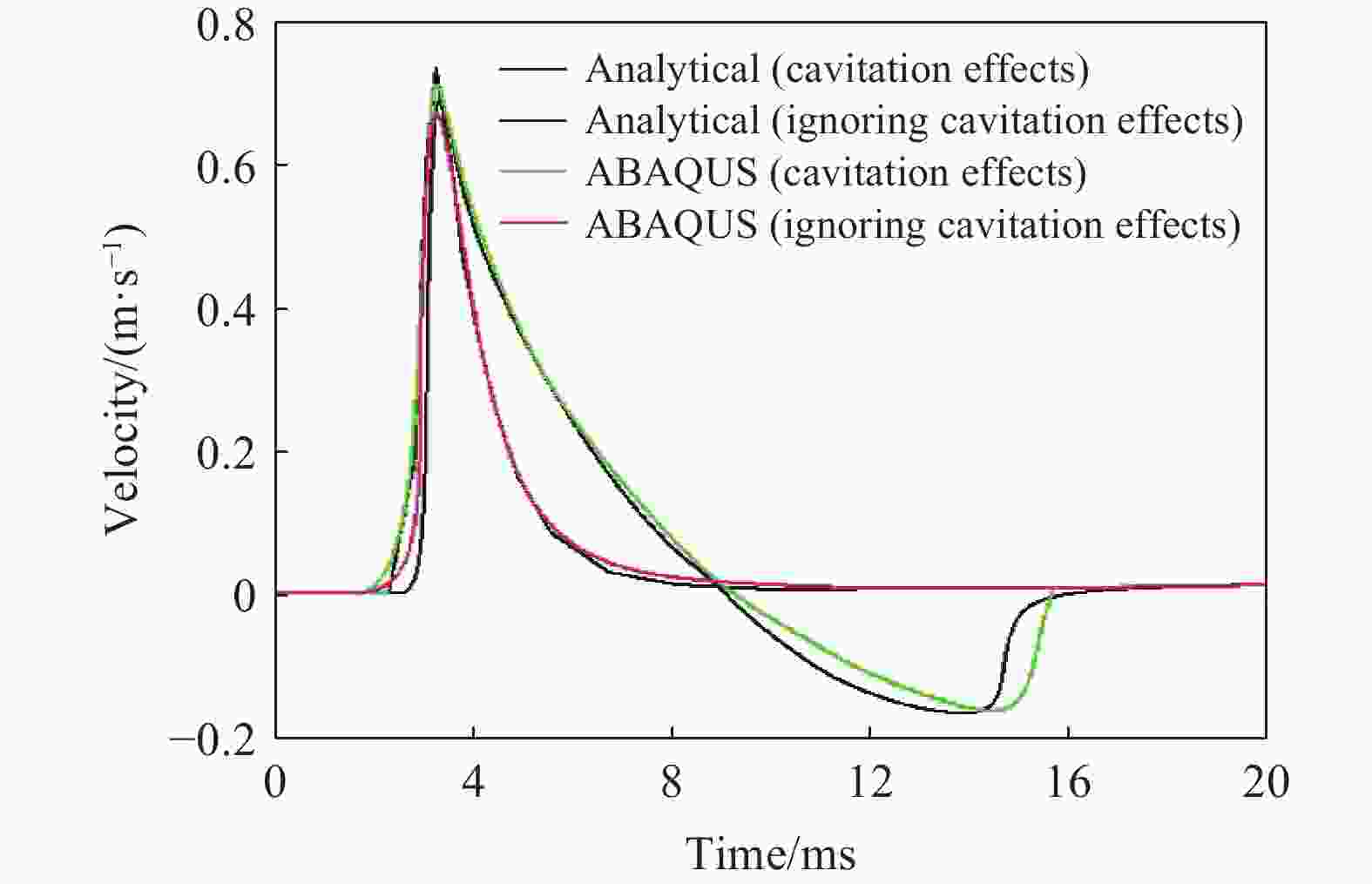

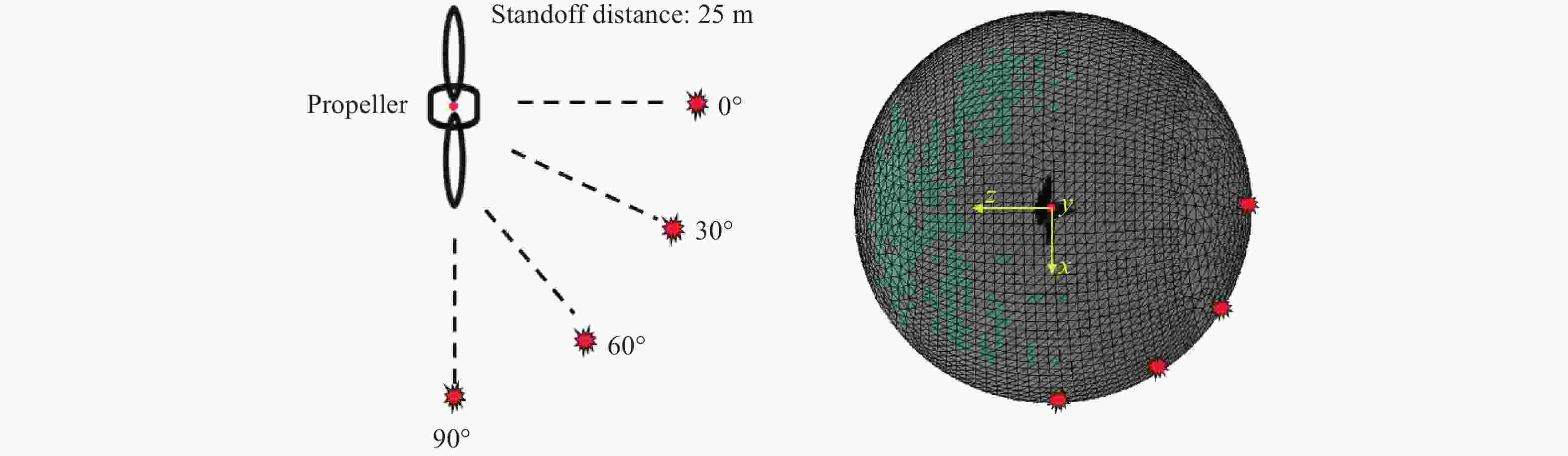

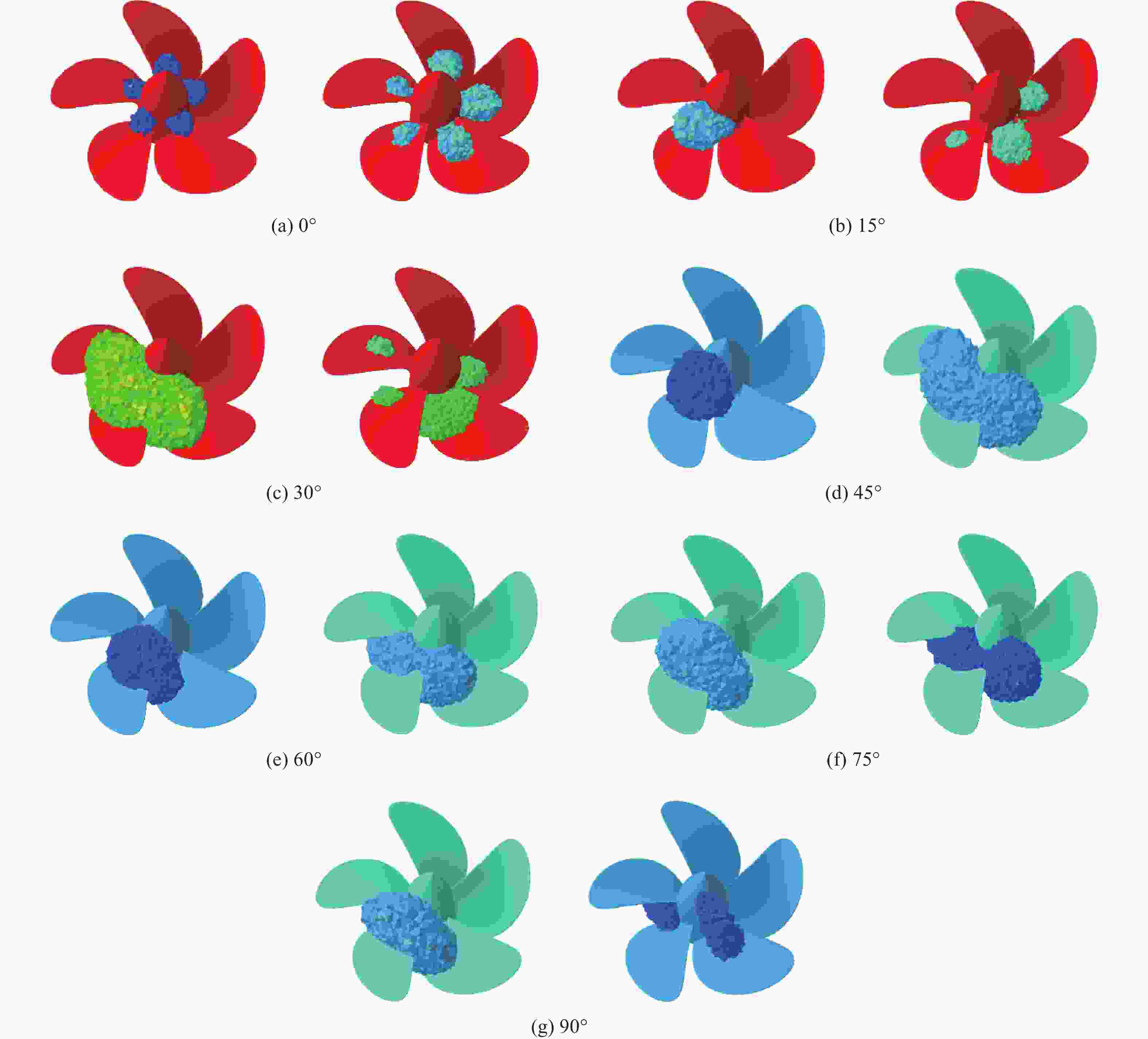

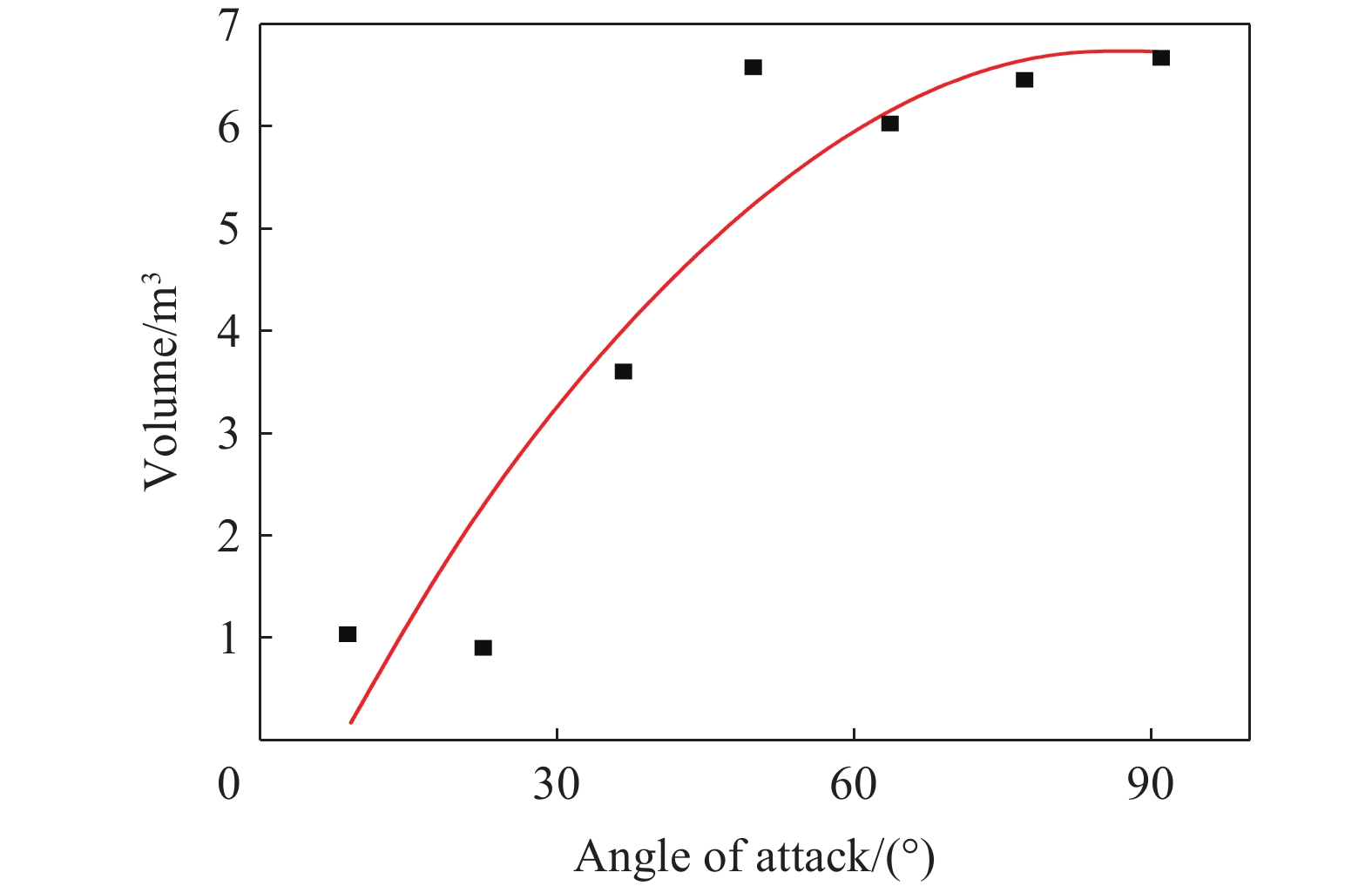

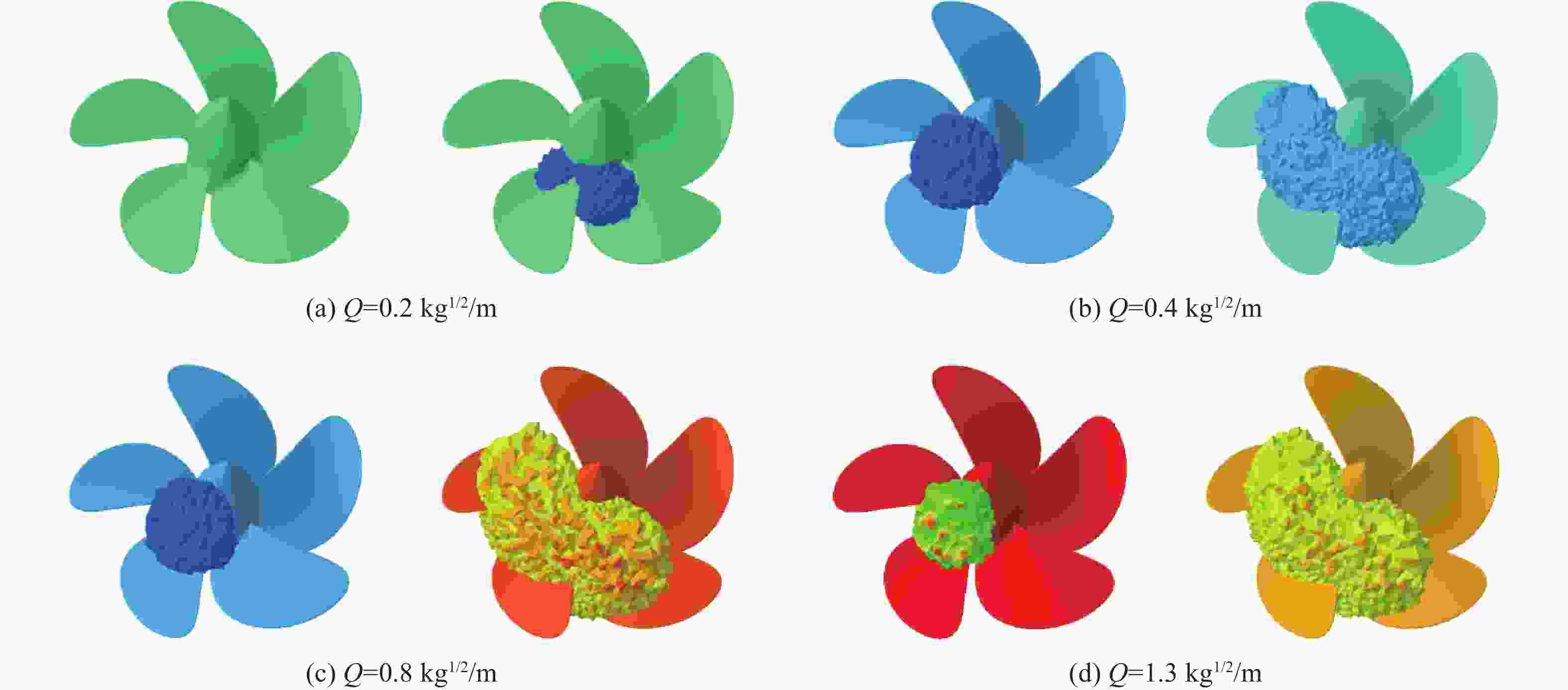

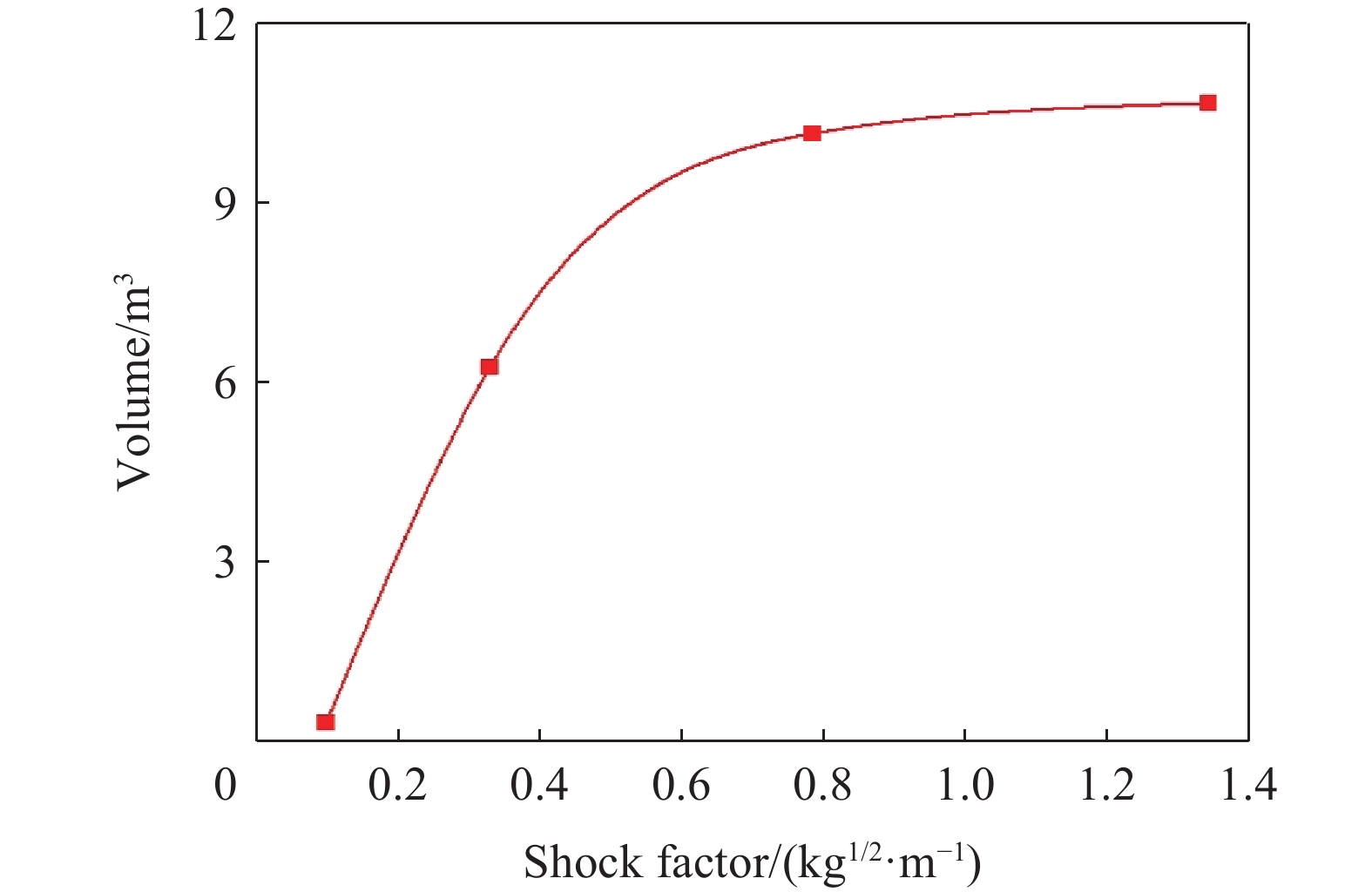

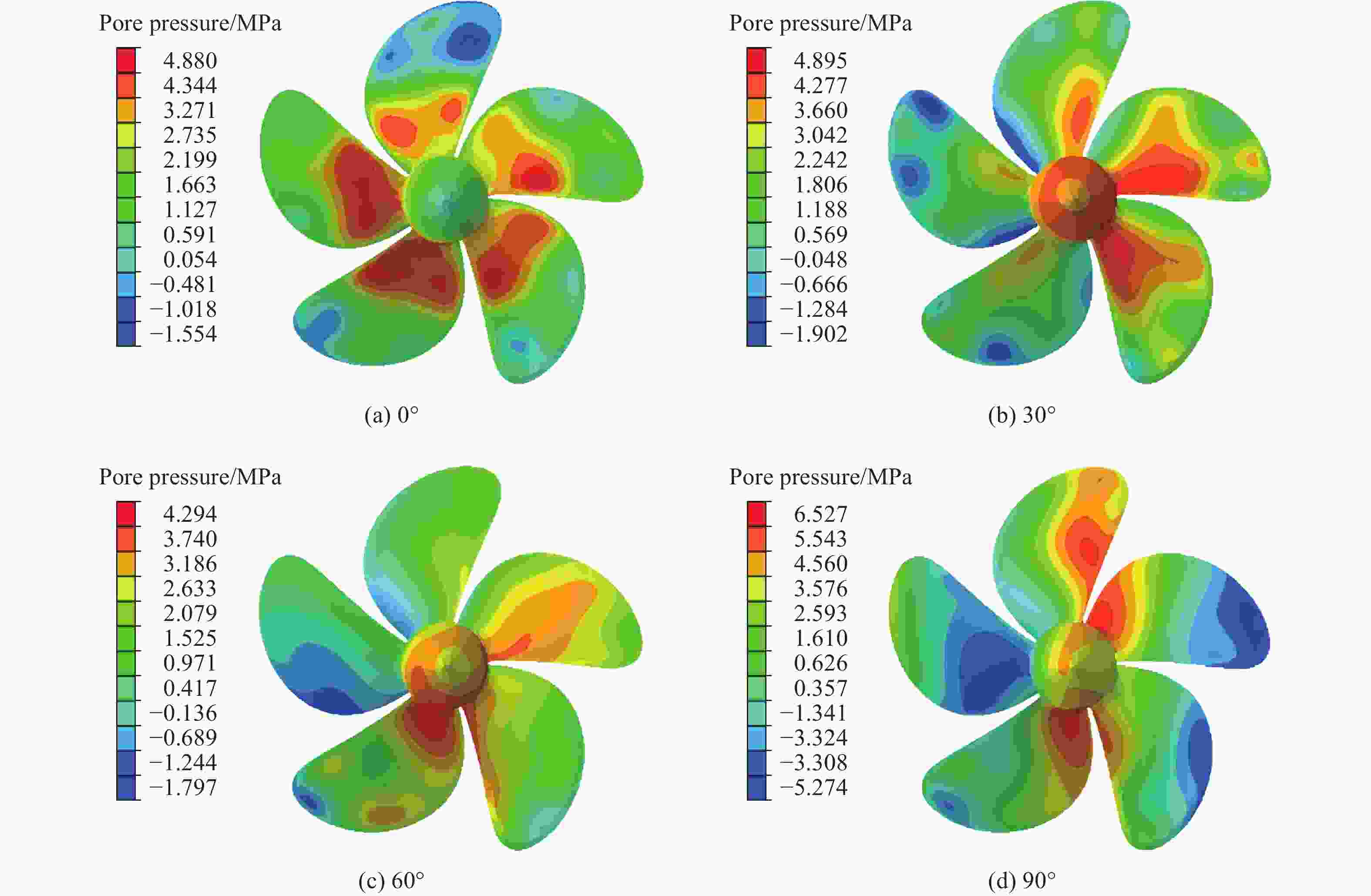

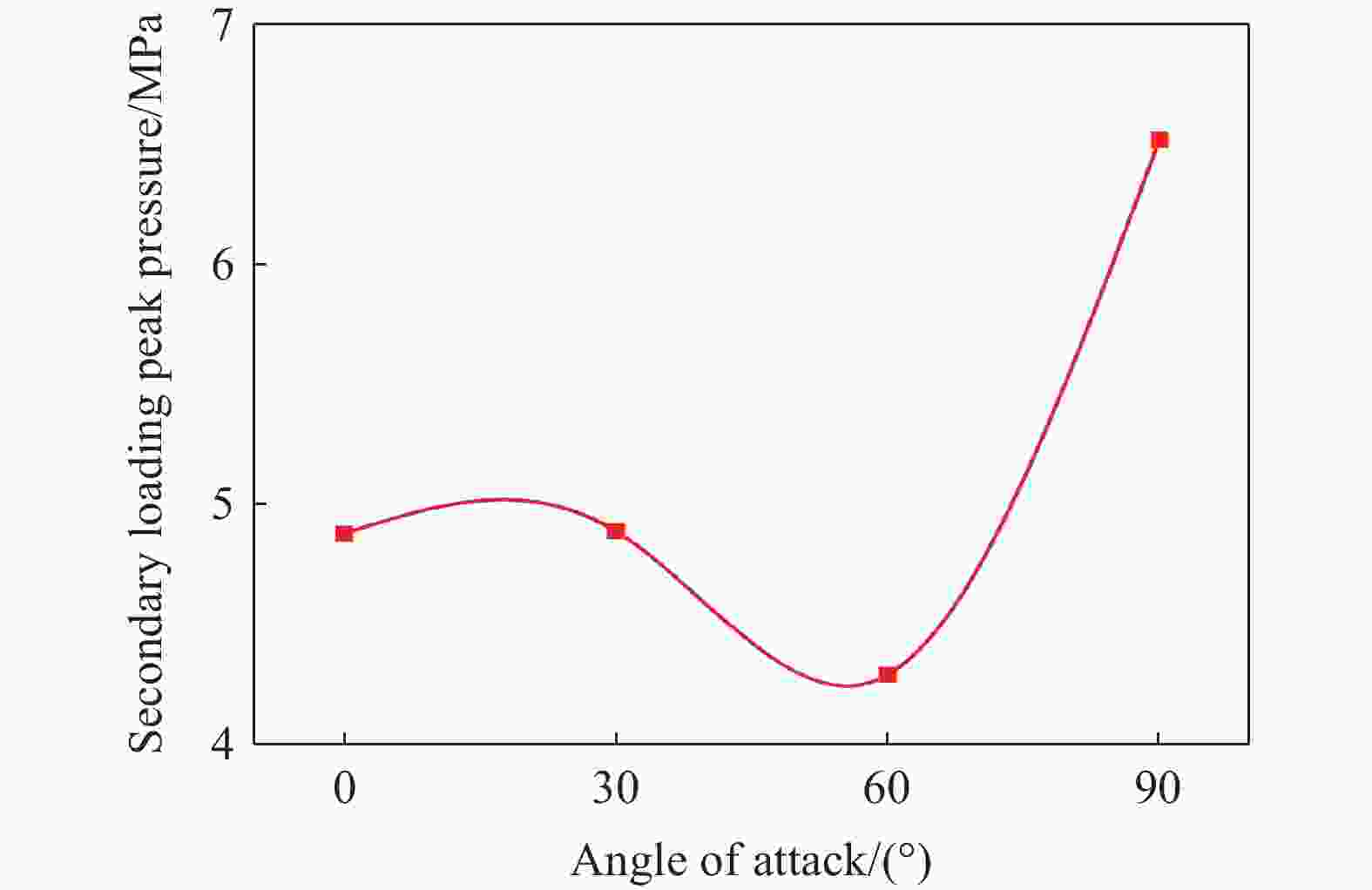

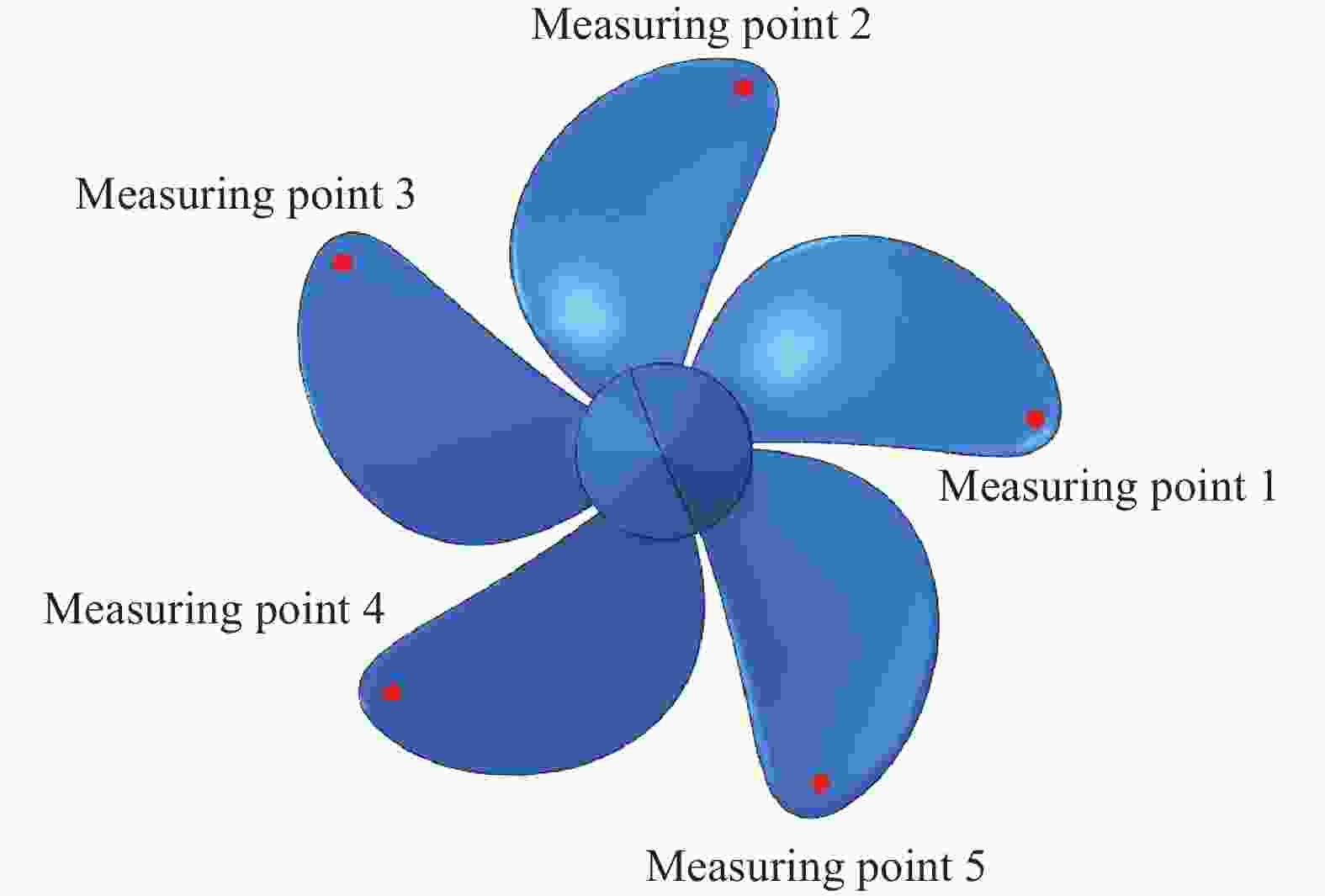

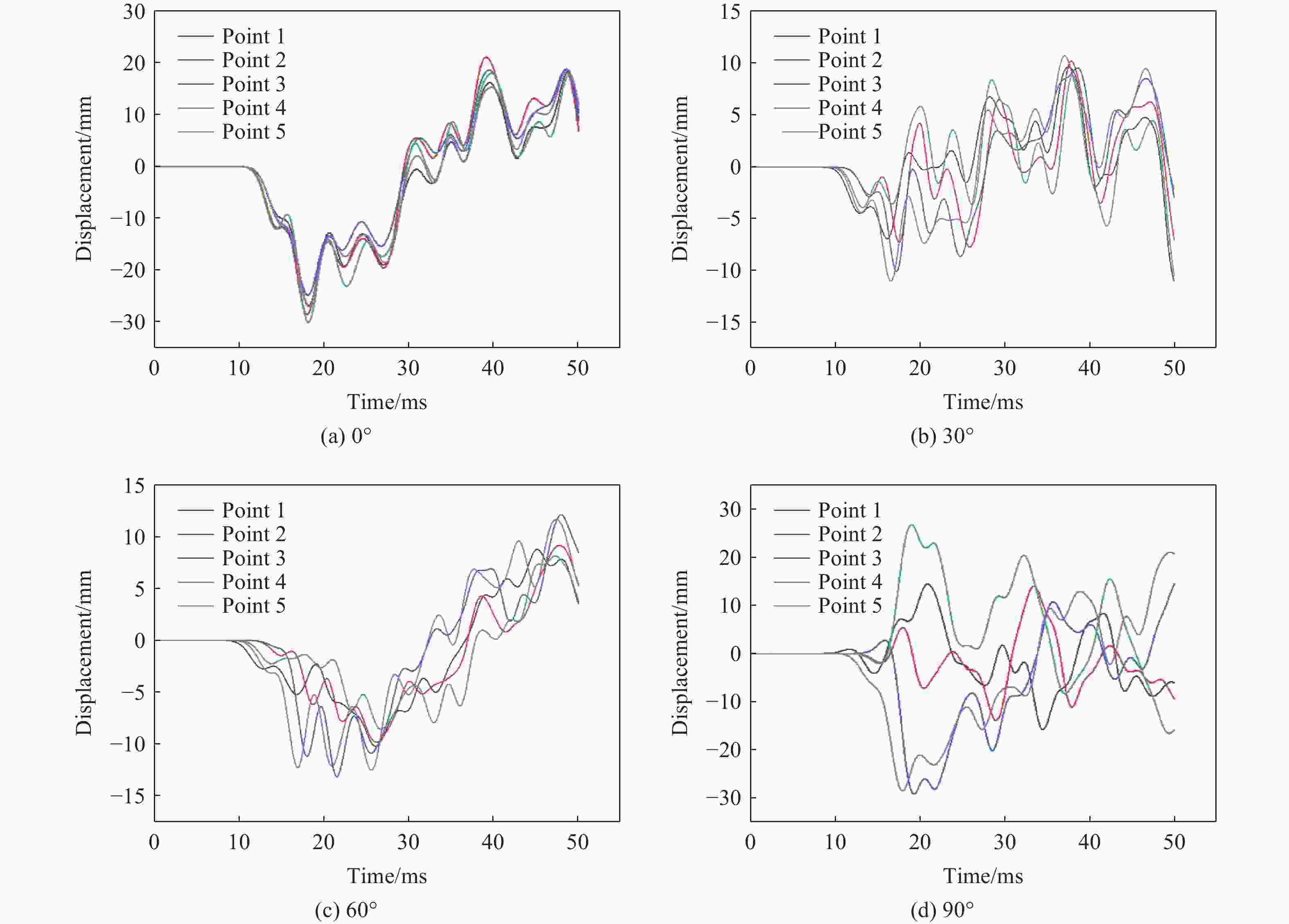

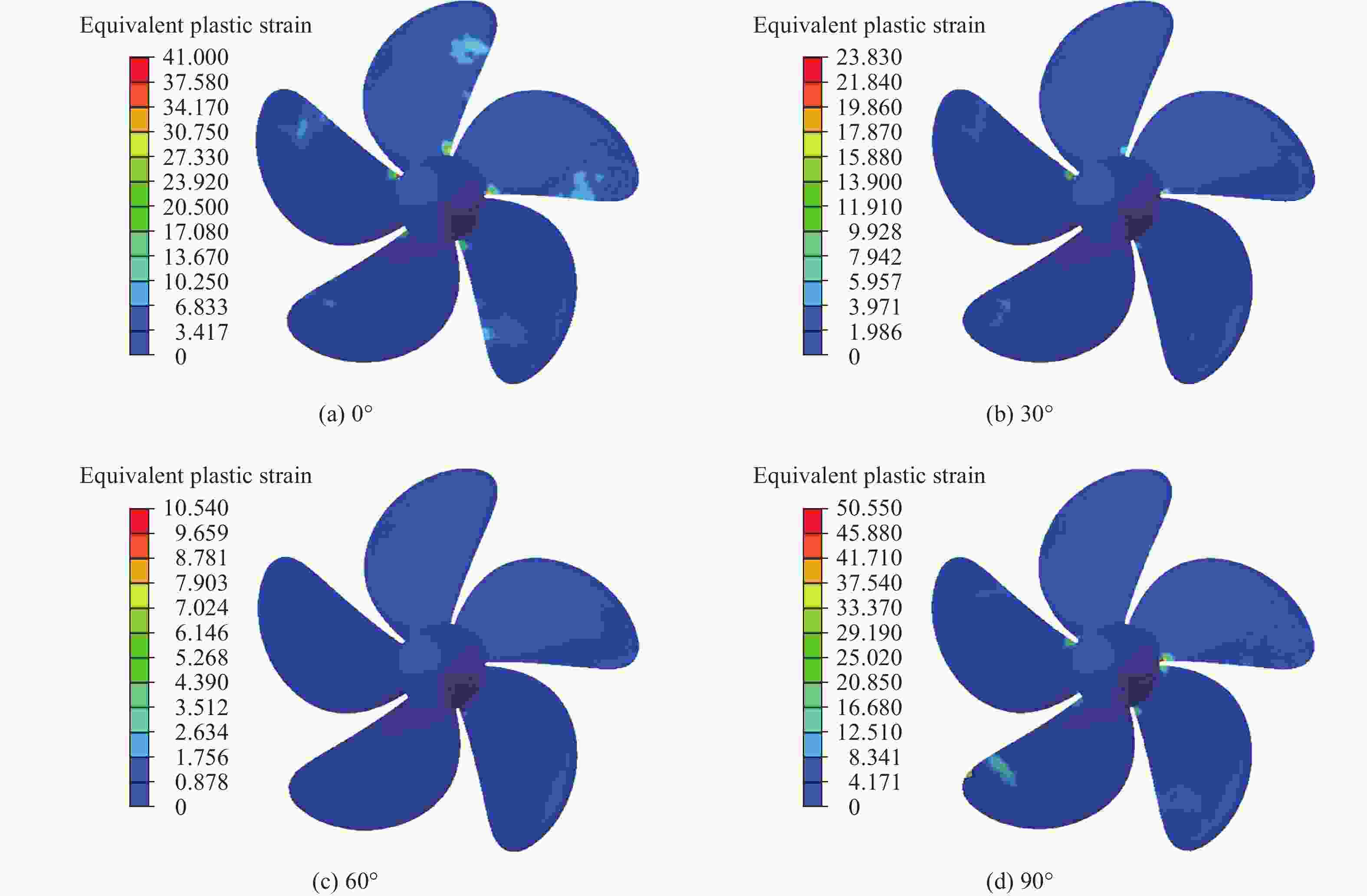

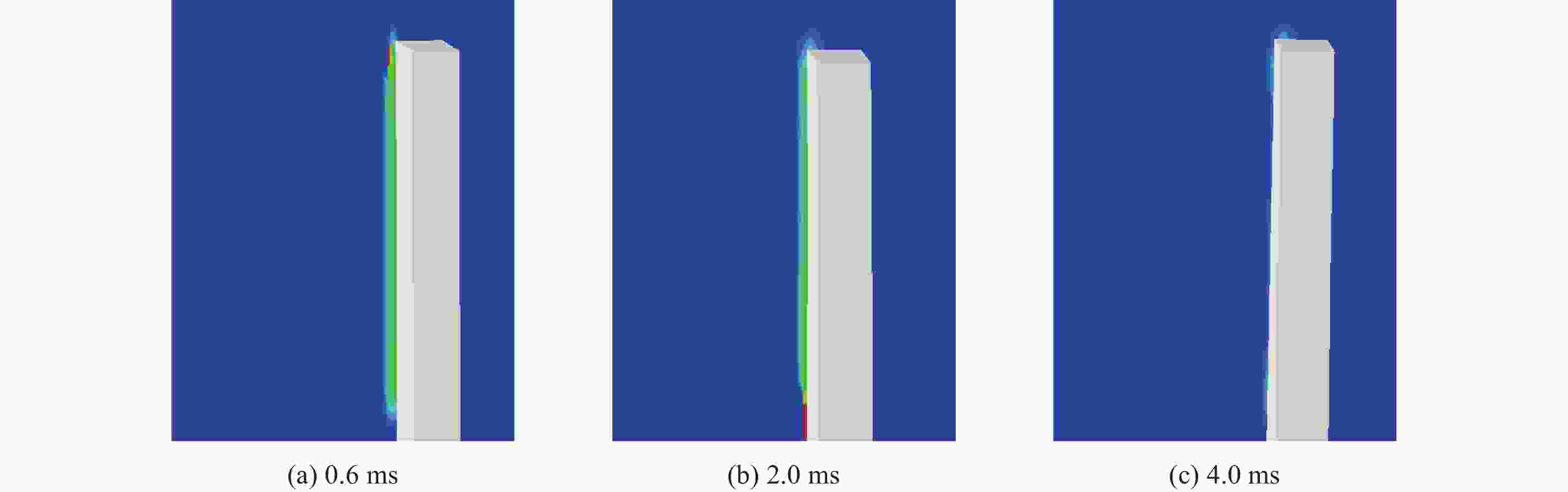

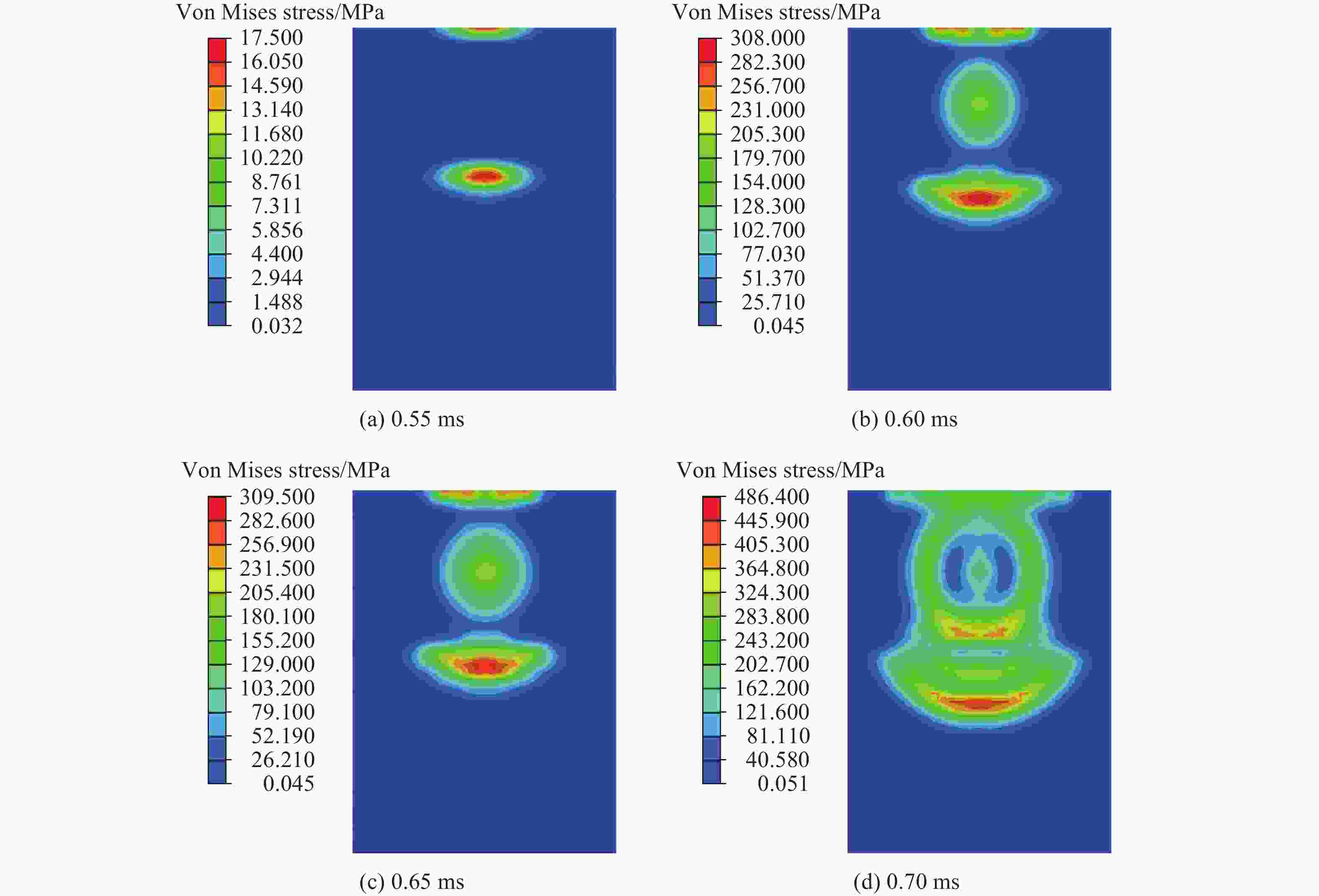

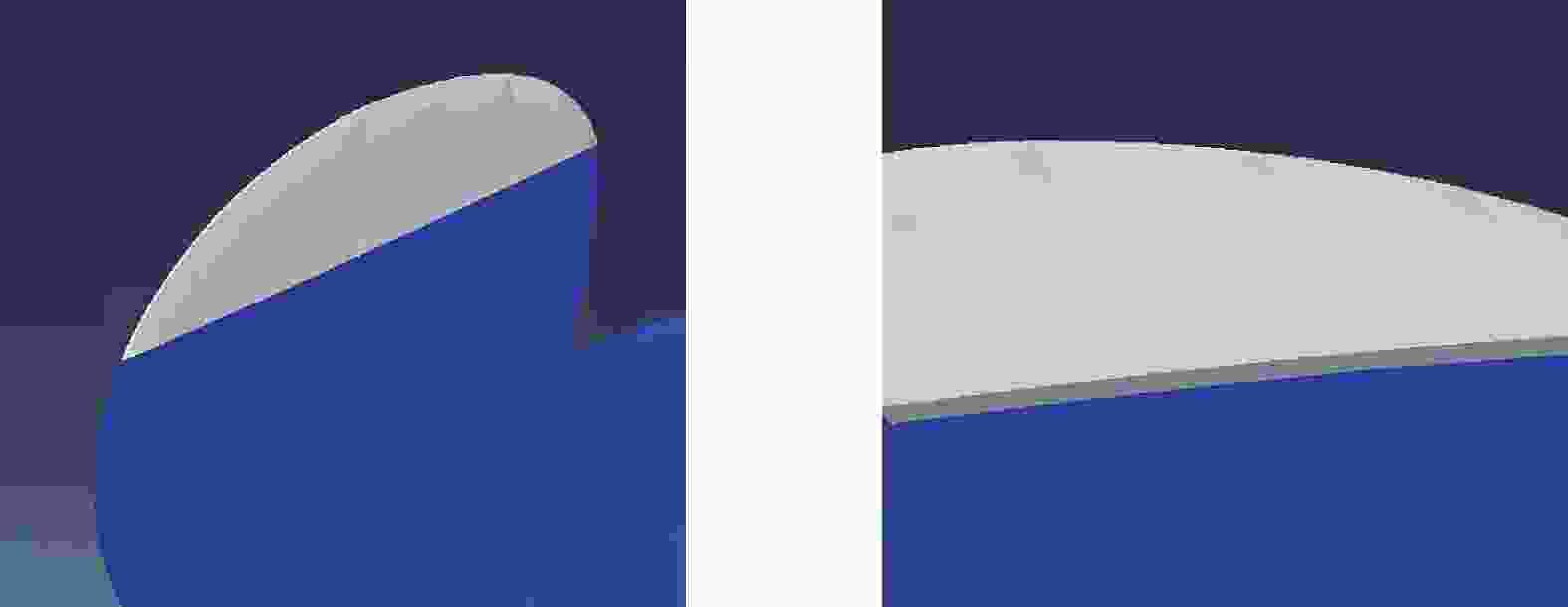

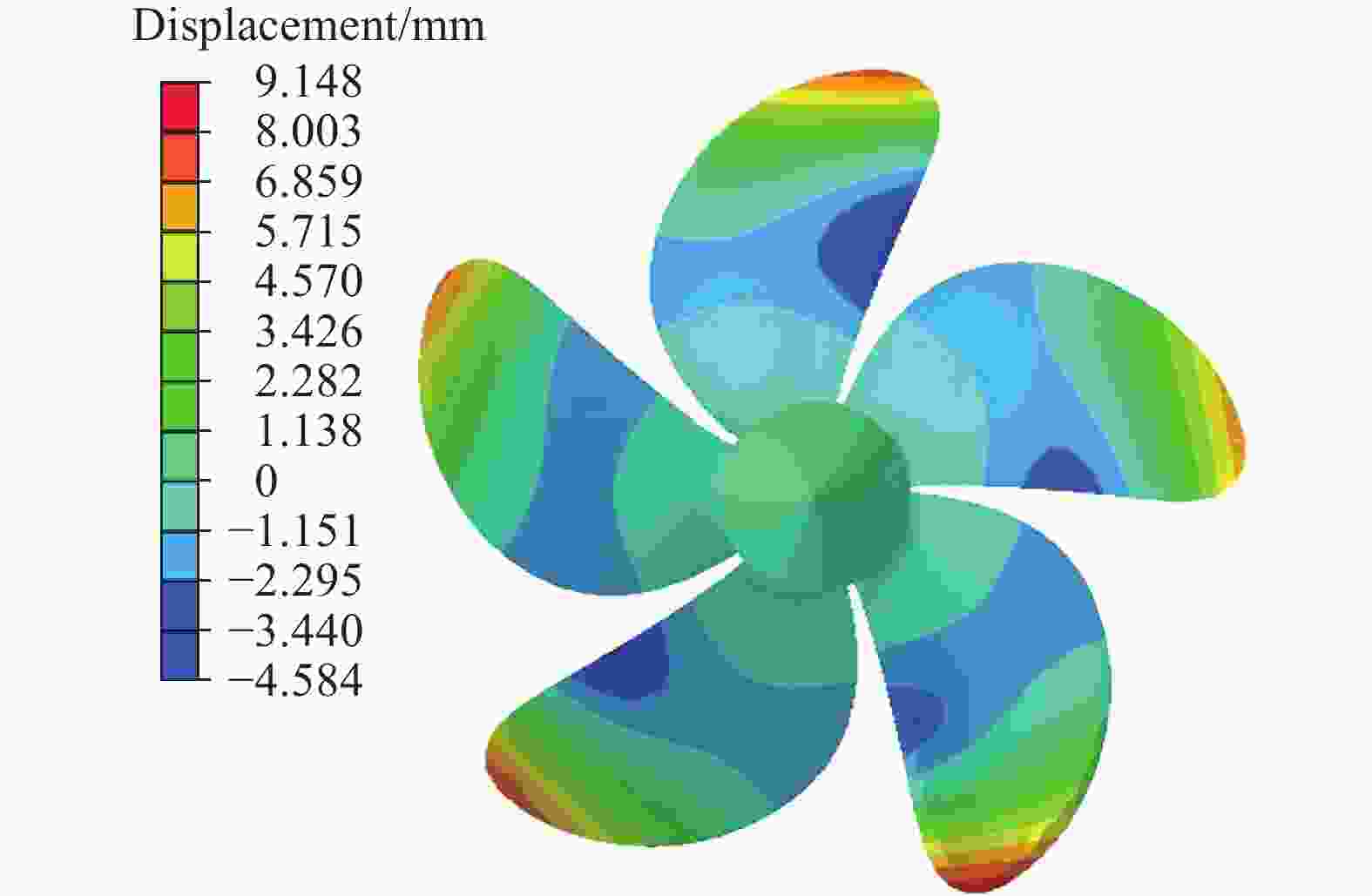

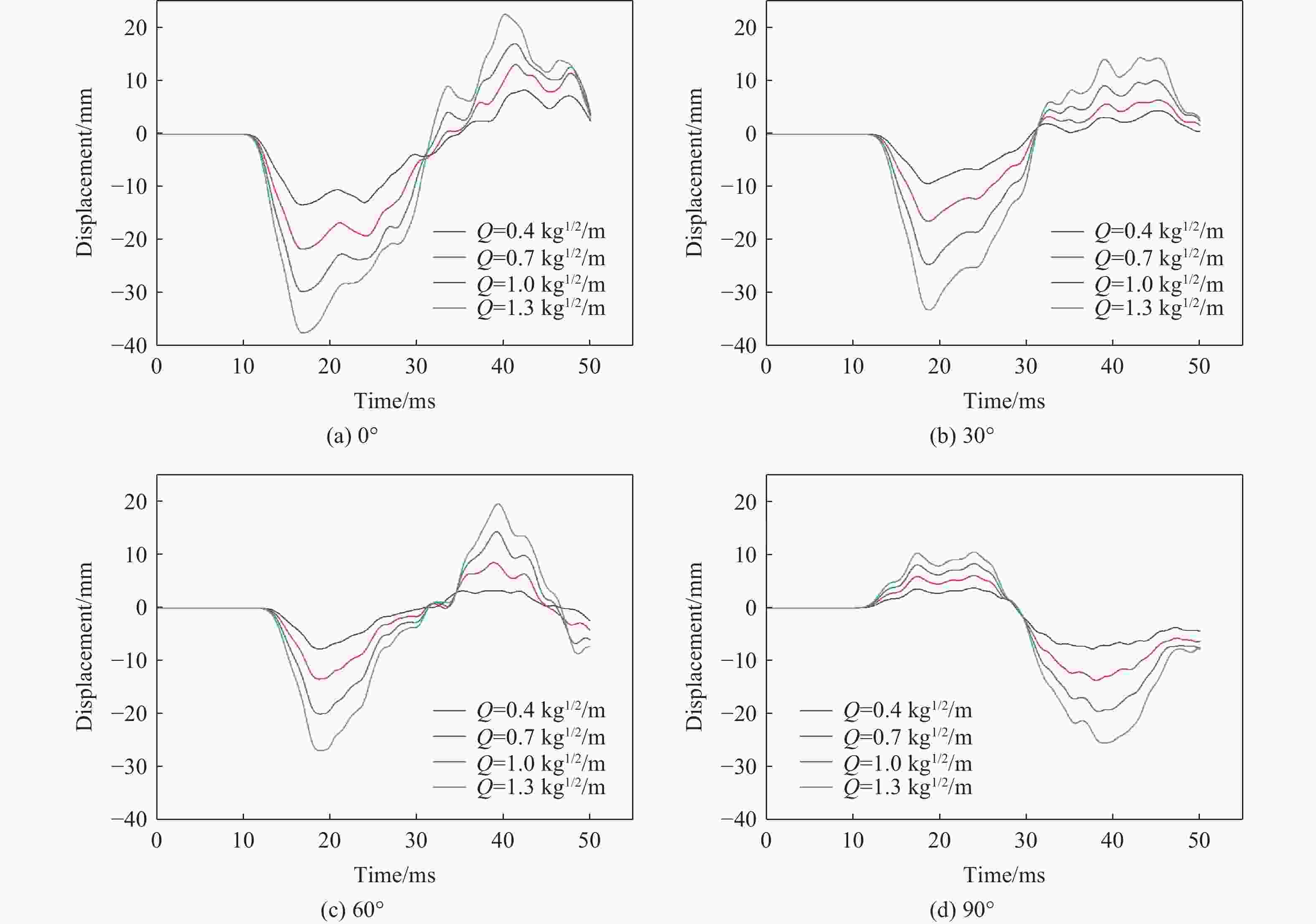

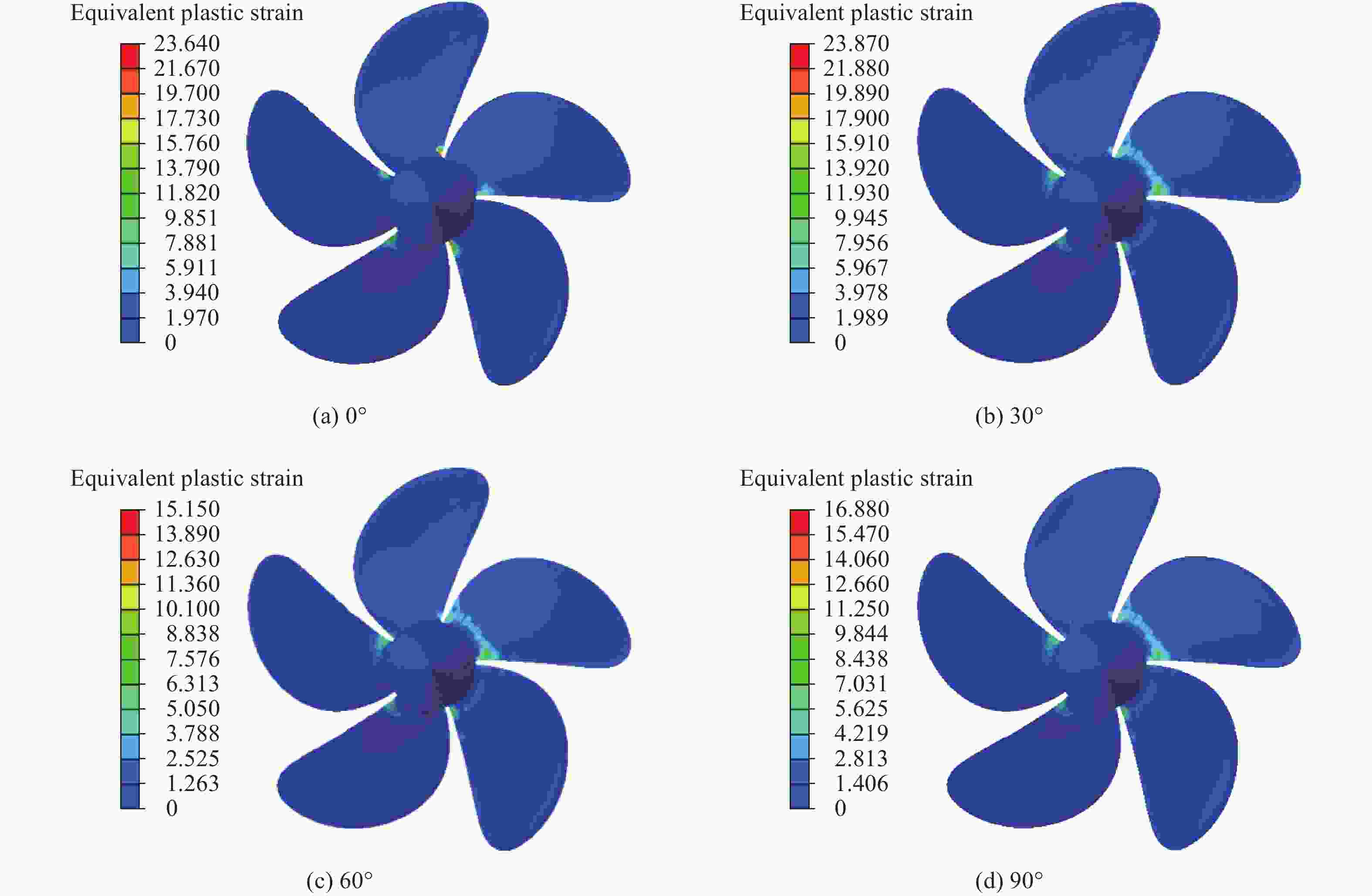

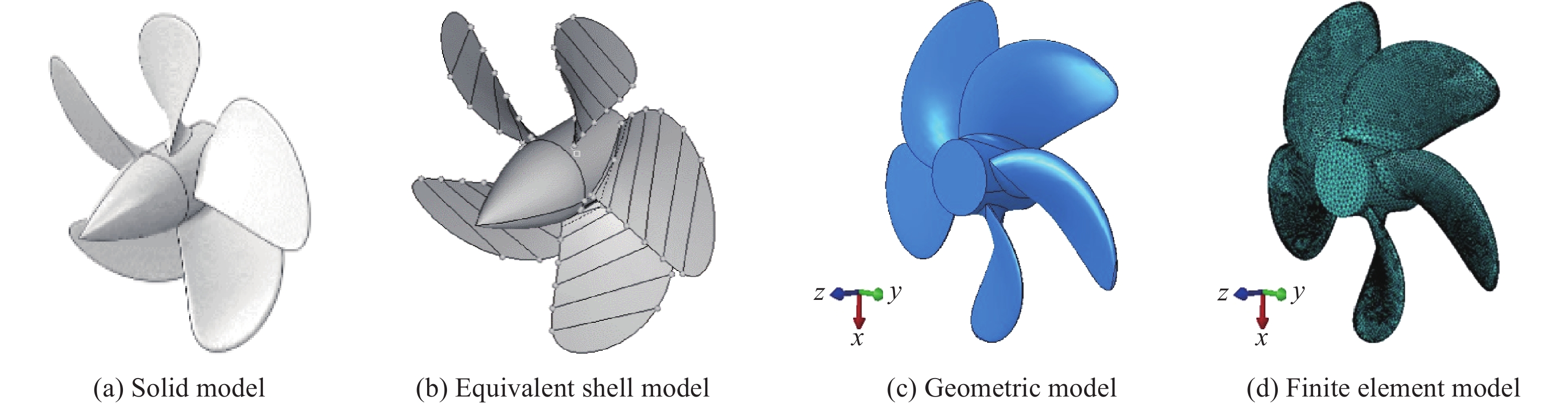

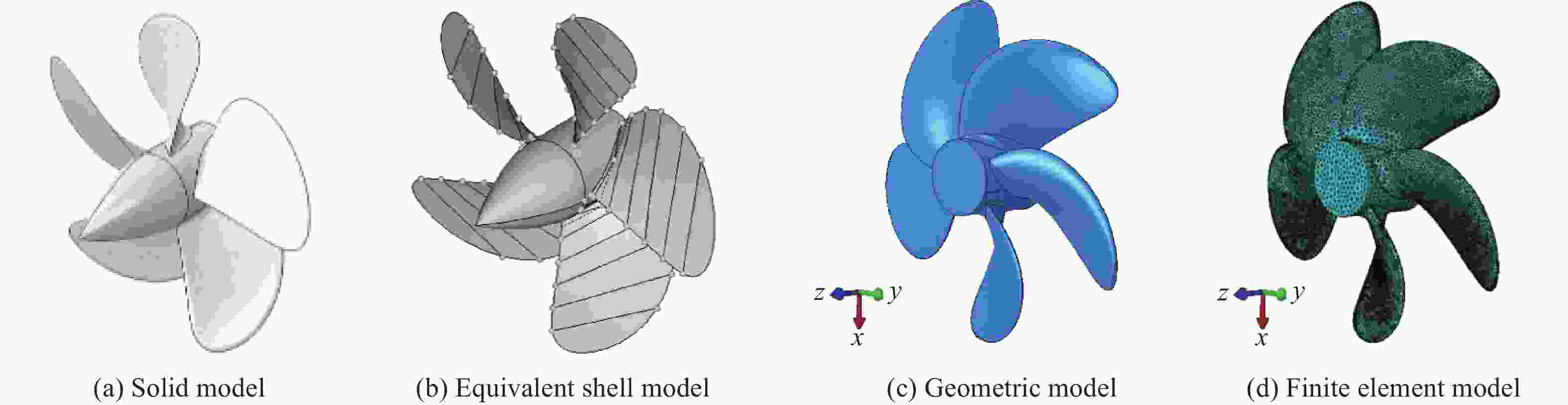

摘要: 螺旋桨是舰船推进系统的核心部件,其运动稳定性和效率直接影响舰船的性能。当前推进轴系抗冲击研究大多将螺旋桨等效成均质圆盘,忽略其结构特征,不能准确得到水下爆炸瞬态冲击下螺旋桨的瞬态毁伤特征。本文中针对螺旋桨的结构特征,基于湿模态分析法得到实体建模优于壳体建模,开展了远场冲击波作用下螺旋桨物面空化冲击动响应及毁伤特征分析,并结合螺旋桨高速旋转状态下产生的水动力空化现象,进一步分析螺旋桨瞬态毁伤特征规律。结果表明:在0°与90°攻角下,冲击波入射波作用于螺旋桨表面的物面载荷更高,但存在一个上限值,其与螺旋桨结构特征有关。在计及水动力空化状态下,桨叶的应力水平变化较为一致;桨叶主要塑性损伤区为叶根处,存在局部塑性和完全塑性两种模式。探讨了远场爆炸下螺旋桨毁伤与空化特征,研究结果可为推进轴系及螺旋桨抗冲击防护提供参考。Abstract: The propeller is a critical component of a ship’s propulsion system that significantly influences the vessel’s performance through its stability and efficiency. Current research on the propulsion shaft system’s anti-shock properties often oversimplifies the propeller as a uniform circular disk, which disregards its structural intricacies and leads to inaccuracies in the transient damage characteristics during underwater explosions. This research focused on the propeller’s structural details and developed both an equivalent shell model and a more intricate solid model. Through structural wet modal numerical simulations, the study had determined that solid modeling outperforms shell modeling in accuracy. This finding is corroborated by comparisons with empirical formulas, thereby validating the fluid-structure coupling analysis model. Building upon this foundation, the research examines the propeller’s transient shock response and damage characteristics when subjected to far-field shockwaves. Utilizing the total wave algorithm in ABAQUS, the investigation extends to the cavitation and damage patterns of the propeller under such conditions, with confirmation provided by the one-dimensional Bleich-Sandler finite element model. To delve deeper into the phenomenon of hydrodynamic cavitation caused by the propeller’s high-speed rotation, the coupled Eulerian-Lagrangian (CEL) method was applied. Initially, a simplified propeller model was created to confirm the cavitation bubble layer’s fragmentation due to the flow field load resulting from explosive product expansion. Subsequent modifications to the propeller’s transient fluid-structure coupling calculation model allow for a more thorough analysis of its transient damage characteristics. The findings indicate that at attack angles of 0° and 90°, the propeller surface experiences heightened shockwave loads, albeit with a threshold linked to the propeller’s structural properties. When hydrodynamic cavitation is factored in, the stress distribution on the propeller blade tends to be more uniform; the blade’s primary plastic damage is localized at the root, exhibiting both localized and complete plastic deformation patterns. This research elucidates the damage and cavitation effects on propellers due to far-field explosions, offering valuable insights for enhancing the anti-shock defenses of both the propulsion shaft system and the propeller itself.

-

Key words:

- underwater explosion /

- propeller /

- damage characteristics /

- cavitation effect

-

表 1 螺旋桨材料参数

Table 1. Propeller material parameters

密度/

(kg∙m−3)杨氏模量/

GPa泊松比 强度极限/

MPa7600 117 0.3 630 表 2 螺旋桨部分设计参数

Table 2. Design parameters of propeller part

直径D/

mm叶数Z 切面

形状螺距H/

mm螺距比

H/D后倾角α/(°) 毂径比

d/D6000 5 弓型 4200 0.7 15 0.183 表 3 螺旋桨固有频率数值模拟与理论值对比

Table 3. Comparison of propeller intrinsic frequency between simulation and theoretical values

方法 实体一阶湿模态固有频率/ Hz 壳体一阶湿模态固有频率/Hz 一阶挥舞 一阶扭转 一阶挥舞 一阶扭转 数值模拟 14.87 35.81 12.01 31.91 经验公式 14.09 33.38 14.09 30.54 相对误差/% 5.6 7.3 −14.7 −8.5 表 4 计算工况

Table 4. Working condition

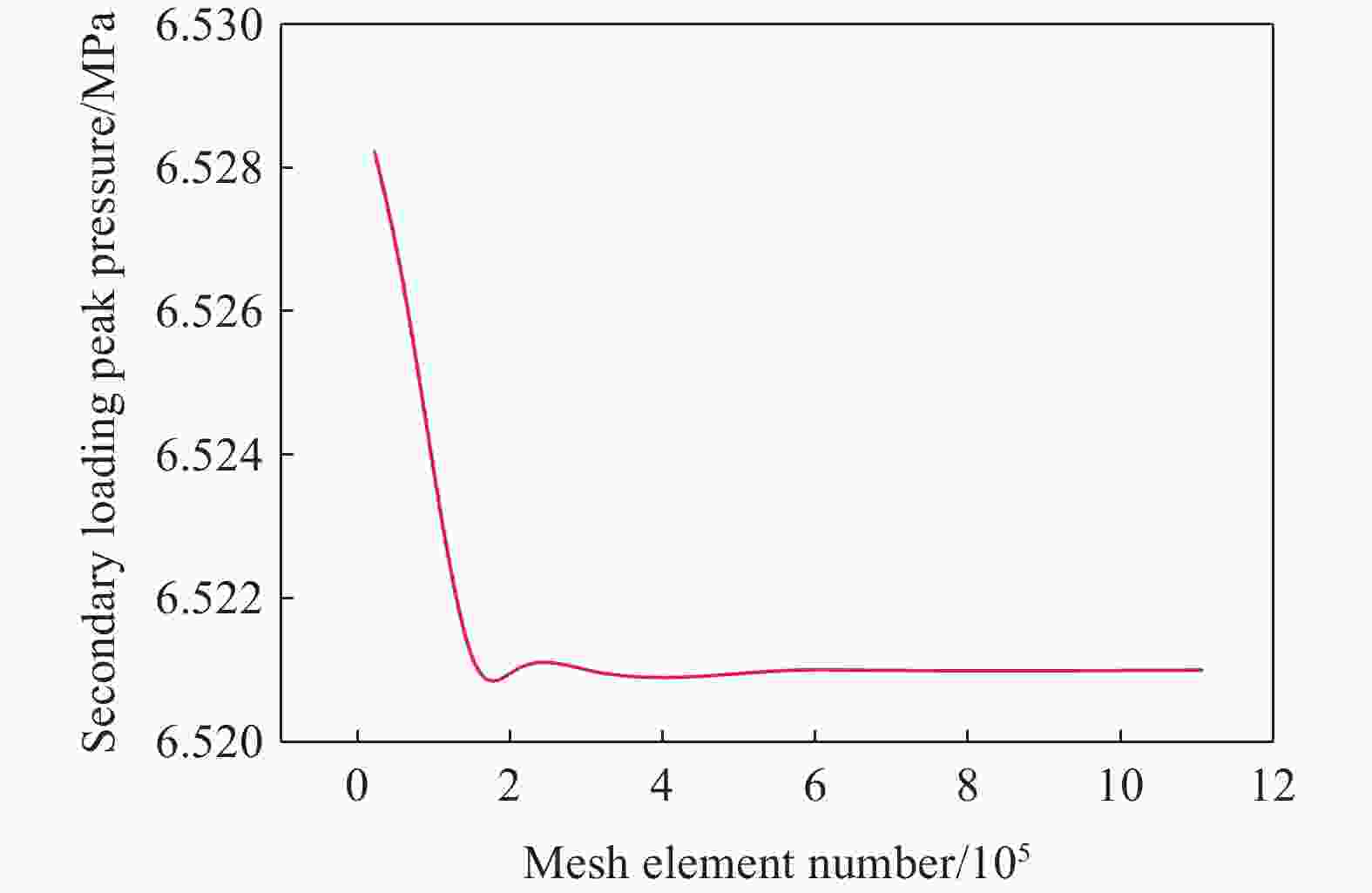

工况 攻角/(°) 冲击因子/(kg1/2·m−1) 工况 攻角/(°) 冲击因子/(kg1/2·m−1) 1 0 0.4 9 60 0.4 2 0.7 10 0.7 3 1.0 11 1.0 4 1.3 12 1.3 5 30 0.4 13 90 0.4 6 0.7 14 0.7 7 1.0 15 1.0 8 1.3 16 1.3 表 5 不同尺寸网格数量

Table 5. Mesh quantities for different sizes

轴体网格尺寸/ mm 桨叶网格尺寸/ mm 网格数量 200 100 23 343 160 80 57 599 100 50 153 536 90 45 207 462 80 40 302 294 70 35 576 104 60 30 654 490 50 25 1 105 909 表 6 不同攻角下螺旋桨的塑性损伤情况

Table 6. Plastic damage of propeler at different angles of attack

攻角/(°) 根部塑性

损伤叶片

数量3/4半径叶缘处

塑性损伤峰值

范围/%3/4半径叶缘处

塑性损伤平均值

范围/%塑性损伤

范围总值/%0 5 3.4 3.0 13.1 30 4 1.9 1.3 7.5 60 4 1.0 0.5 3.5 90 5 3.2 2.7 14.4 表 7 不同攻角塑性损伤情况

Table 7. Plastic damage at different angles of attack

攻角/(°) 叶根塑性损伤模式 塑性损伤范围/% 0 局部塑性 4.4 30 局部塑性 4.2 60 整体塑性 5.6 90 整体塑性 7.9 -

[1] RAJENDRAN R. Reloading effects on plane plates subjected to non-contact underwater explosion [J]. Journal of Materials Processing Technology, 2008, 206(1/2/3): 275–281. DOI: 10.1016/j.jmatprotec.2007.12.022. [2] 许斐, 周力, 宗智. 铝合金舰艇在水下冲击波作用下动态响应的数值研究 [J]. 舰船科学技术, 2011, 33(1): 31–40.XU F, ZHOU L, ZONG Z. A numerical analysis on dynamic responses of aluminum vessels subjected to underwater shock wave [J]. Ship Science and Technology, 2011, 33(1): 31–40. DOI: 10.3404/j.issn.1672-7649.2011.006. [3] 宗智, 陈岗, 叶帆, 等. 水下爆炸冲击波作用下的空化效应数值仿真研究 [J]. 船舶力学, 2014, 18(4): 385–394. DOI: 10.3969/j.issn.1007-7294.2014.04.005.ZONG Z, CHEN G, YE F, et al. Numerical simulation of cavitation caused by underwater explosion [J]. Journal of Ship Mechanics, 2014, 18(4): 385–394. DOI: 10.3969/j.issn.1007-7294.2014.04.005. [4] PAN J Y, FARAG N, LIN T, et al. Propeller induced structural vibration through the thrust bearing [C]//Proceedings of Australia Acoustical Society Annual Conference. Adelaide, 2002. [5] KOBAYASHI S. Effects of shaft vibration on occurrence of asymmetric cavitation in inducer [J]. JSME International Journal Series B Fluids and Thermal Engineering, 2006, 49(4): 1220–1225. DOI: 10.1299/jsmeb.49.1220. [6] 孙文林. 冰区航行船舶螺旋桨强度研究 [D]. 哈尔滨: 哈尔滨工程大学, 2016. DOI: 10.7666/d.D01105449.SUN W L. Research on the propeller strength of ice-going ships [D]. Harbin: Harbin Engineering University, 2016. DOI: 10.7666/d.D01105449. [7] 徐学伟, 刘寅桐, 张耀林. 爆炸声源对舰船螺旋桨效能损伤评估研究 [J]. 舰船电子工程, 2018, 38(10): 153–155, 164. DOI: 10.3969/j.issn.1672-9730.2018.10.038.XU X W, LIU Y T, ZHANG Y L. Research on evaluation of damage to ship propeller effectiveness for explosion sound source [J]. Ship Electronic Engineering, 2018, 38(10): 153–155, 164. DOI: 10.3969/j.issn.1672-9730.2018.10.038. [8] UCAR H. Dynamic response of a catamaran-hull ship subjected to underwater explosions [D]. Monterey: Naval Postgraduate School, 2006. [9] 孙帅, 常欣, 叶礼裕, 等. 四桨推进船舶螺旋桨负荷数值计算分析 [J]. 哈尔滨工程大学学报, 2017, 38(9): 1351–1358. DOI: 10.11990/jheu.201607004.SUN S, CHANG X, YE L Y, et al. Numerical analysis of the propeller load of a four-propeller propulsion ship [J]. Journal of Harbin Engineering University, 2017, 38(9): 1351–1358. DOI: 10.11990/jheu.201607004. [10] 刘强, 王永生, 董蕾, 等. 船用螺旋桨振动特性数值计算与分析 [J]. 海军工程大学学报, 2016, 28(3): 17–23. DOI: 10.7495/j.issn.1009-3486.2016.03.005.LIU Q, WANG Y S, DONG L, et al. Numerical analysis on vibration of marine propeller [J]. Journal of Naval University of Engineering, 2016, 28(3): 17–23. DOI: 10.7495/j.issn.1009-3486.2016.03.005. [11] 娄本强, 嵇春艳. 船用螺旋桨流固耦合振动特性分析 [J]. 大连理工大学学报, 2019, 59(2): 154–161. DOI: 10.7511/dllgxb201902007.LOU B Q, JI C Y. FSI vibrations characteristics analysis of marine propeller [J]. Journal of Dalian University of Technology, 2019, 59(2): 154–161. DOI: 10.7511/dllgxb201902007. [12] 李程辉. 基于声固耦合法的水下爆炸冲击波在复杂边界附近空化特性研究 [D]. 哈尔滨: 哈尔滨工程大学, 2018: 26–30.LI C H. Investigation on cavitation of underwater explosion shockwave near complex boundaries with coupled CEL method [D]. Harbin: Harbin Engineering University, 2018: 26–30. [13] 陈高杰, 贾则, 宗智, 等. 考虑空化效应的舰艇水下爆炸仿真研究 [J]. 爆破, 2012, 29(2): 1–3, 25. DOI: 10.3963/j.issn.1001-487X.2012.29.0213.CHEN G J, JIA Z, ZONG Z, et al. Investigation on simulation of underwater explosion cavitation surface ship [J]. Blasting, 2012, 29(2): 1–3, 25. DOI: 10.3963/j.issn.1001-487X.2012.29.0213. [14] BLEICH H H, SANDLER I S. Interaction between structures and bilinear fluids [J]. International Journal of Solids and Structures, 1970, 6(5): 617–639. DOI: 10.1016/0020-7683(70)90034-X. [15] 姚熊亮, 许维军, 梁德利. 水下爆炸时舰船冲击环境与冲击因子的关系 [J]. 哈尔滨工程大学学报, 2004, 25(1): 1–12. DOI: 10.3969/j.issn.1006-7043.2004.01.002.YAO X L, XU W J, LIANG D L. The relation of impulsive environment and impulsive factor on underwater explosion of ship [J]. Journal of Harbin Engineering University, 2004, 25(1): 1–12. DOI: 10.3969/j.issn.1006-7043.2004.01.002. [16] 马艳, 陆芳, 黄红波, 等. 集装箱船模型螺旋桨空泡与脉动压力比对试验研究 [C]//第二十五届全国水动力学研讨会暨第十二届全国水动力学学术会议文集 北京: 海洋出版社, 2013.MA Y, LU F, HUANG H B, et al. Experimental study on comparison of propeller cavitation and fluctuating pressure of container ship model [C]//Proceedings of the 25th National Hydrodynamics Symposium and the 12th National Hydrodynamics Conference. Beijing: China Ocean Press, 2013. [17] 王波, 熊鹰, 时立攀. 确定螺旋桨螺距及拱度分布的一种数值优化方法 [C]//2015年船舶水动力学学术会议. 哈尔滨: 中国造船工程学会, 2015.WANG B, XIONG Y, SHI L P. A numerical optimization method for determining propeller pitch and camber distribution [C]//Proceedings of the 2015 Ship Hydrodynamics Symposium. Harbin: Chinese Society of Naval Architects and Marine Engineers, 2015. [18] SALVATORE F. The INSEAN E779A database on propeller flow experimental investigations [R]. INSEAN Technical Report 99, 2006. [19] 寇晓枫, 王高辉, 卢文波, 等. 空气隔层对水下爆炸冲击波的缓冲效应 [J]. 振动与冲击, 2017, 36(3): 7–13. DOI: 10.13465/j.cnki.jvs.2017.03.002.KOU X F, WANG G H, LU W B, et al. Mitigation effects of air interlayer on underwater explosion shock wave [J]. Journal of Vibration and Shock, 2017, 36(3): 7–13. DOI: 10.13465/j.cnki.jvs.2017.03.002. -

下载:

下载: