Analysis of internal load and dynamic response of vacuum explosion containment vessel with sand covered for explosive welding

-

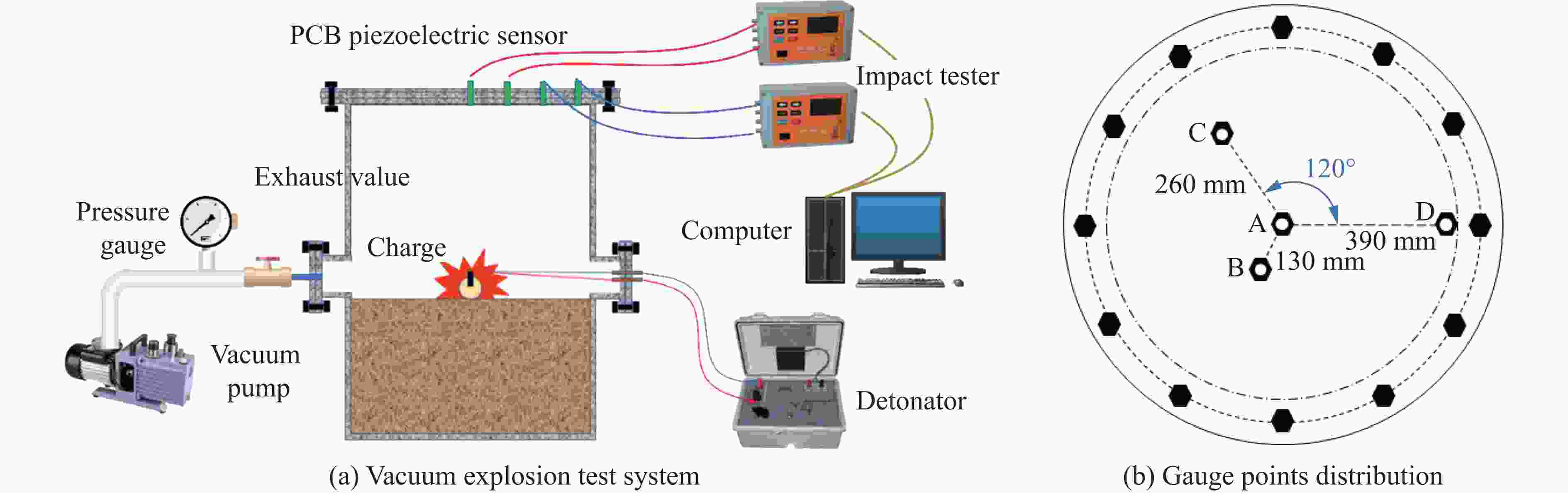

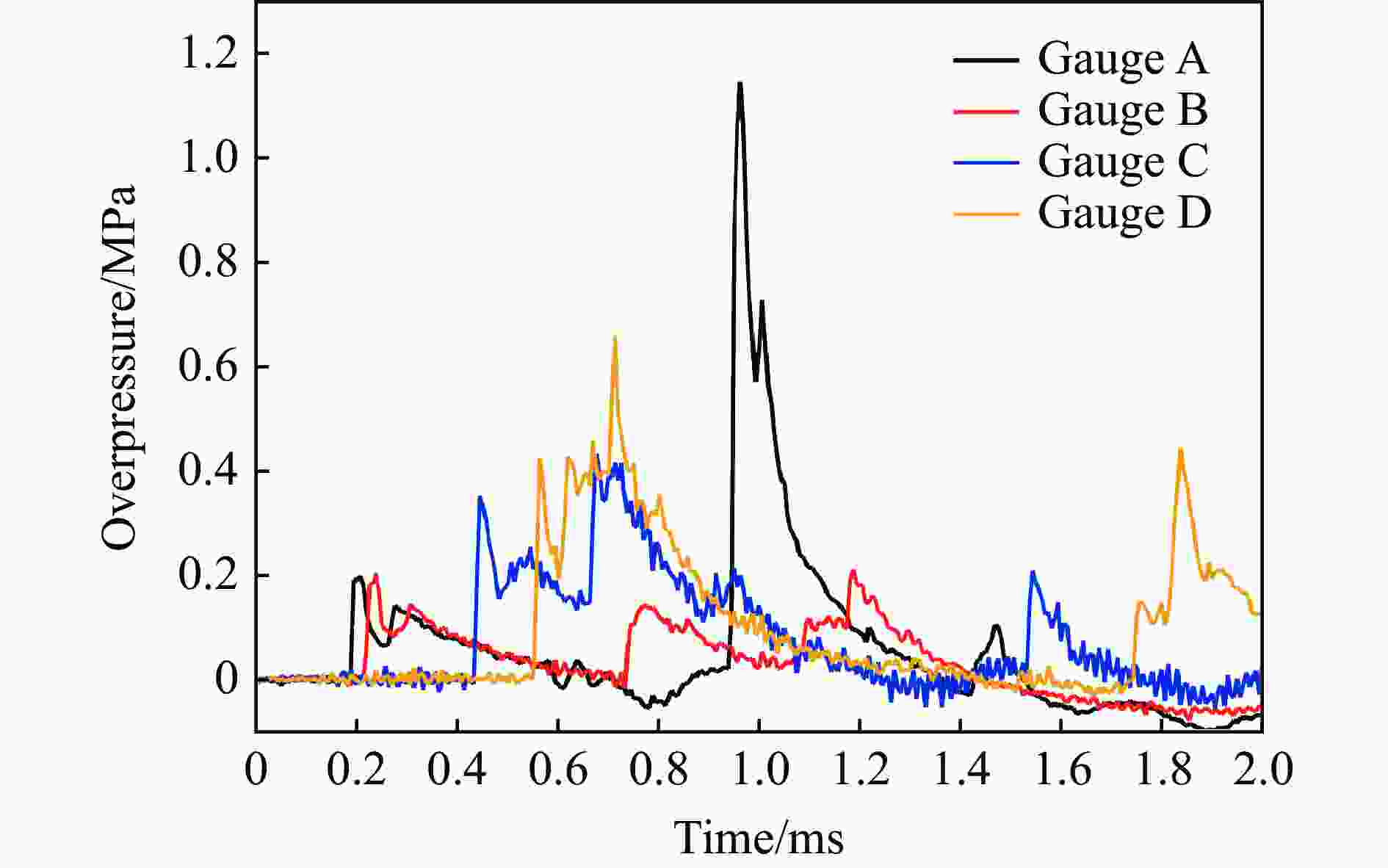

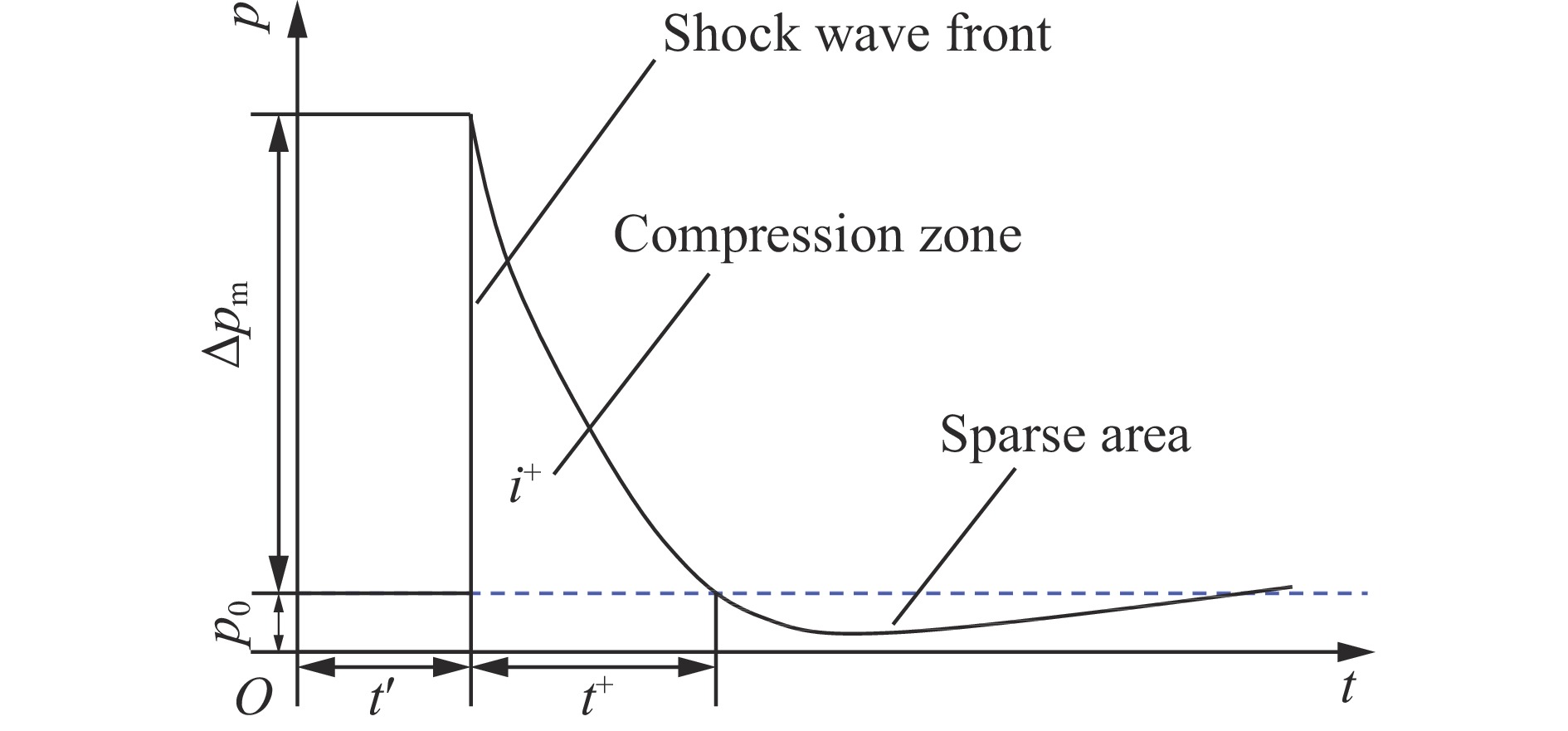

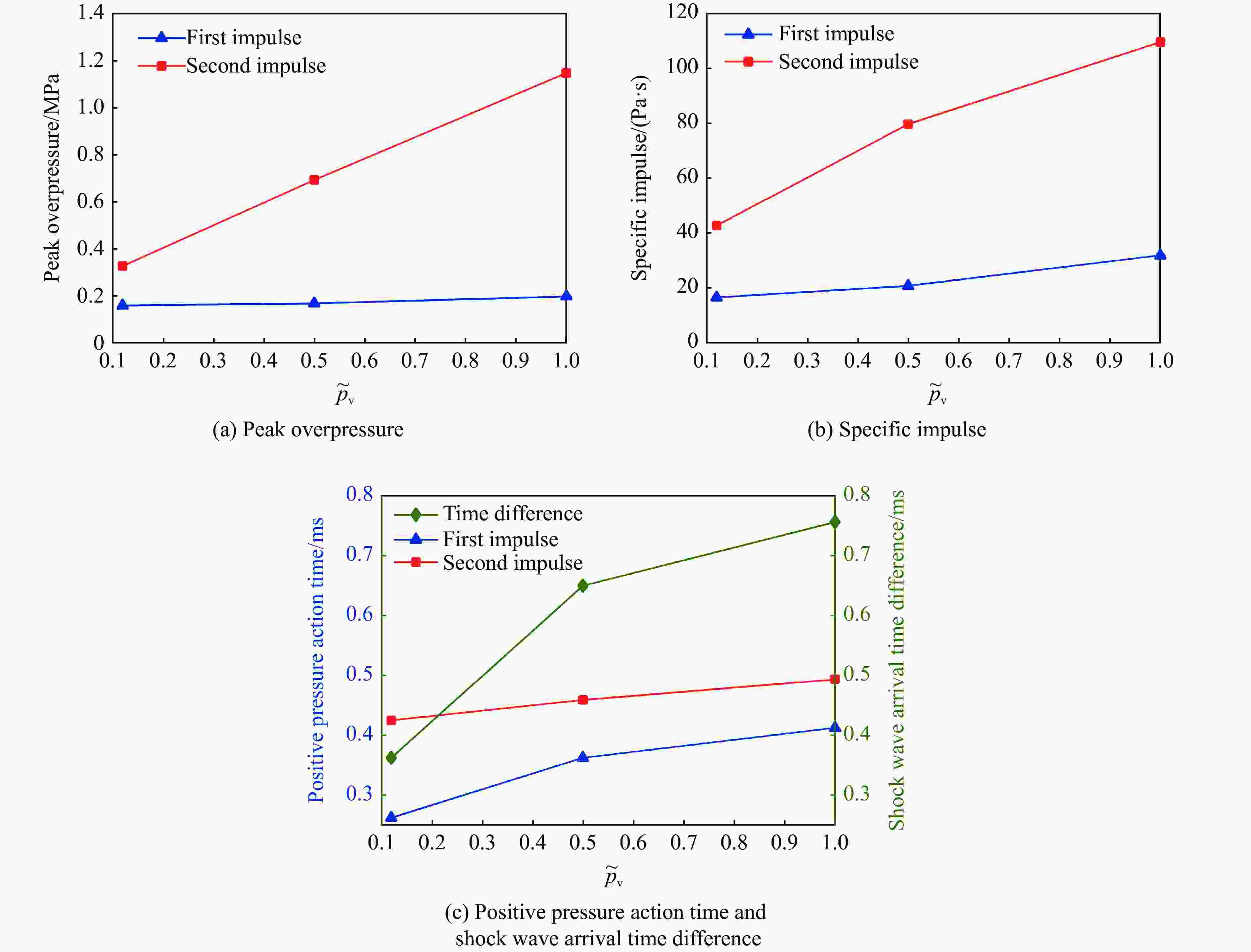

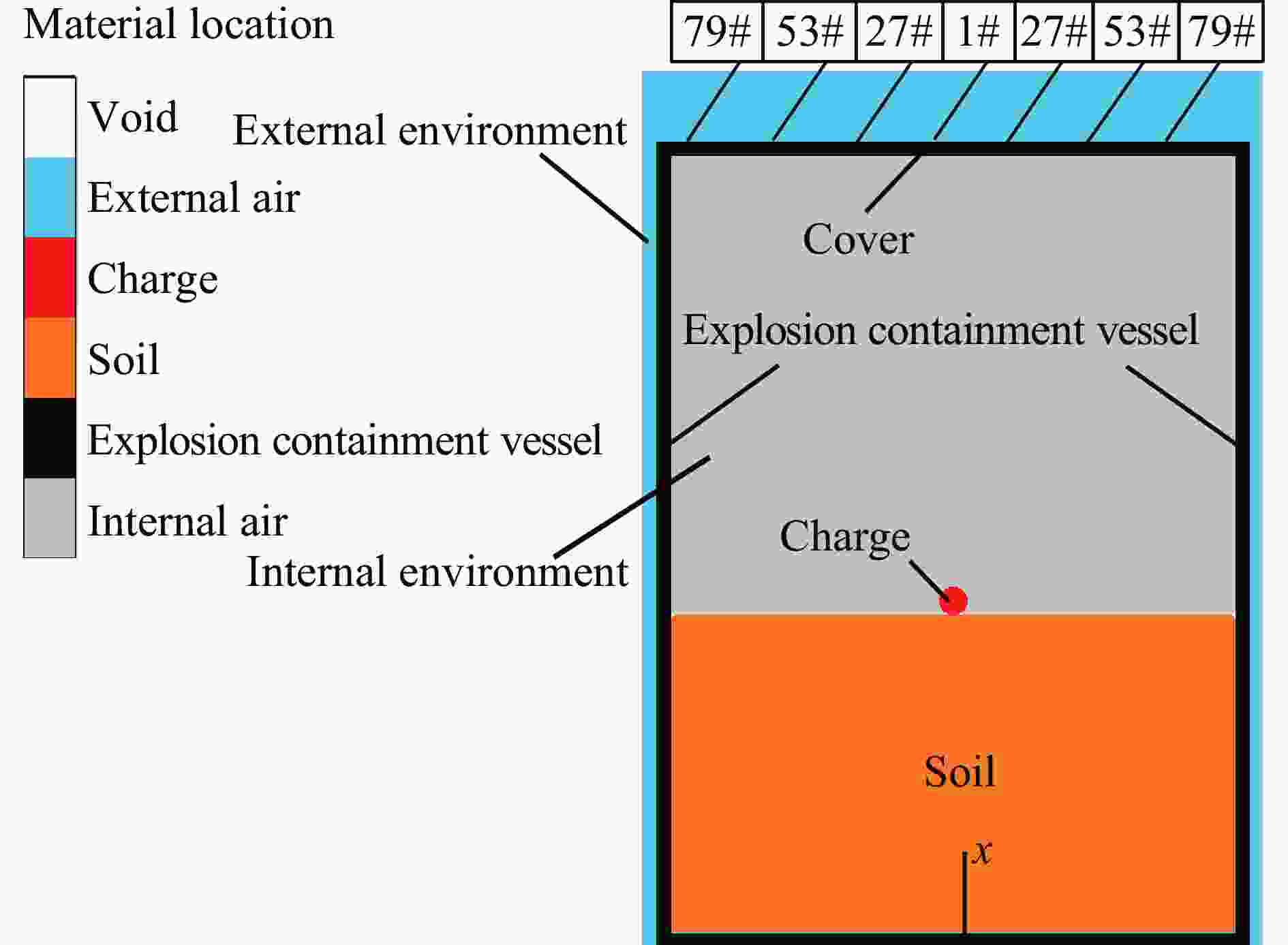

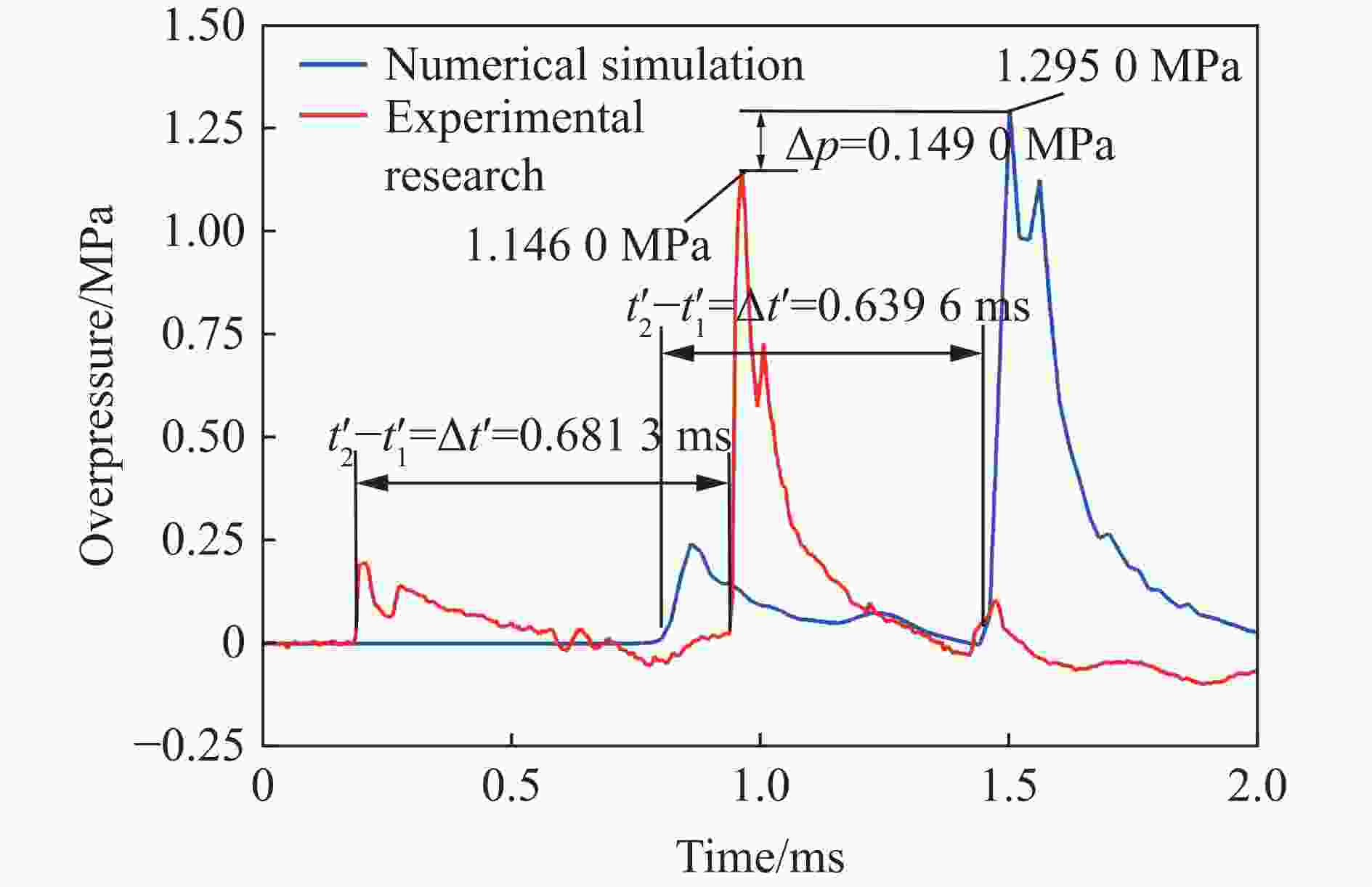

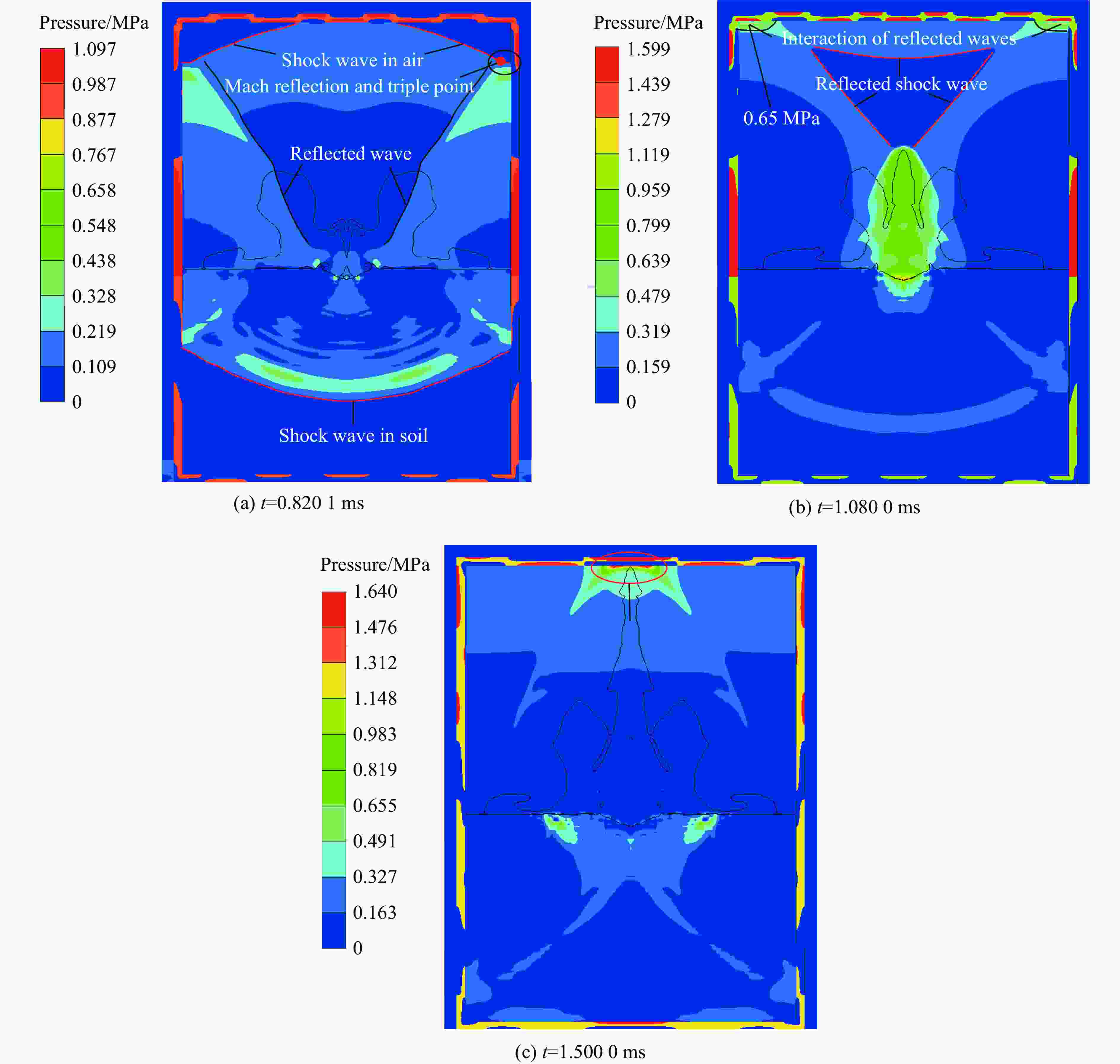

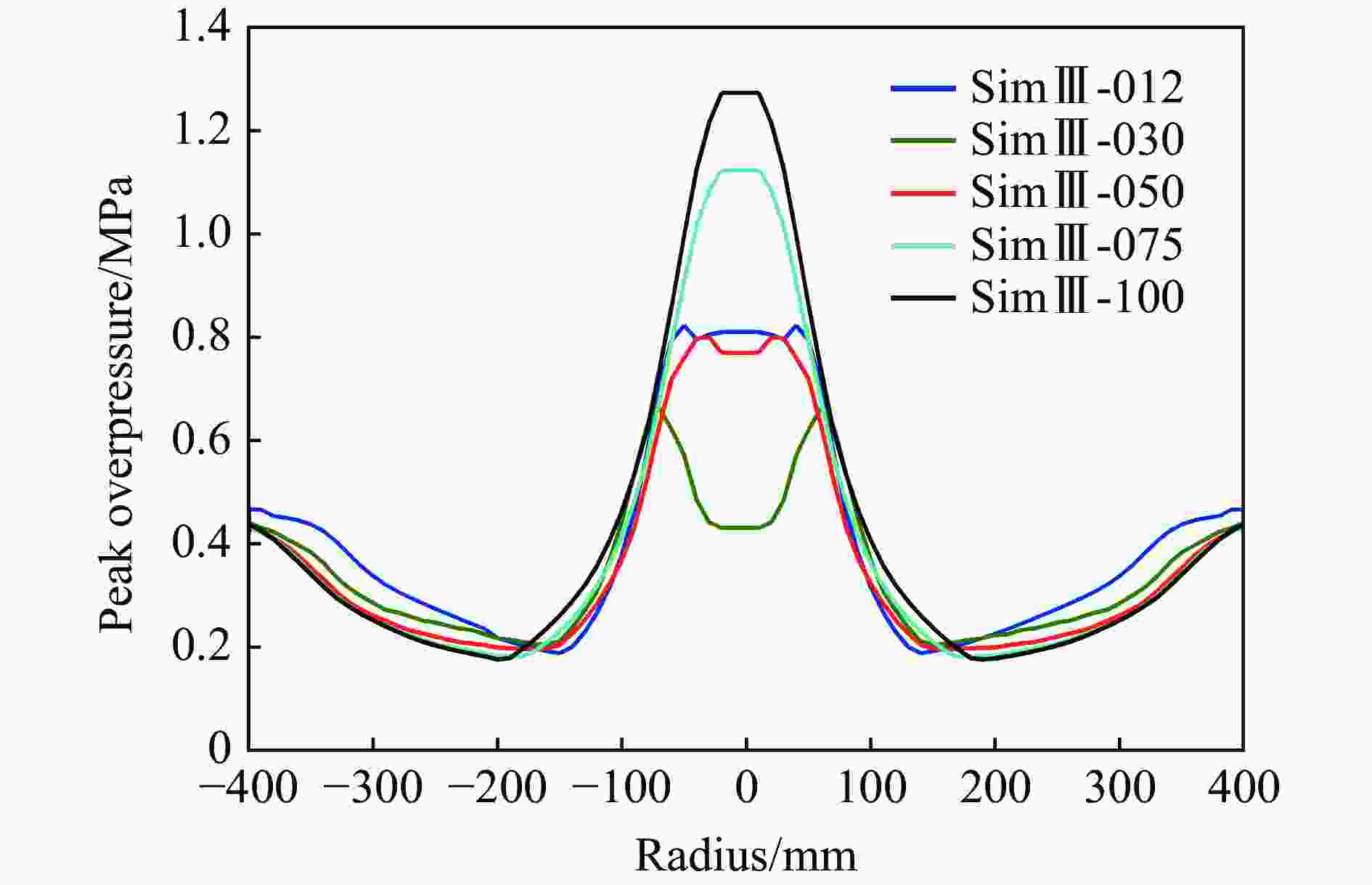

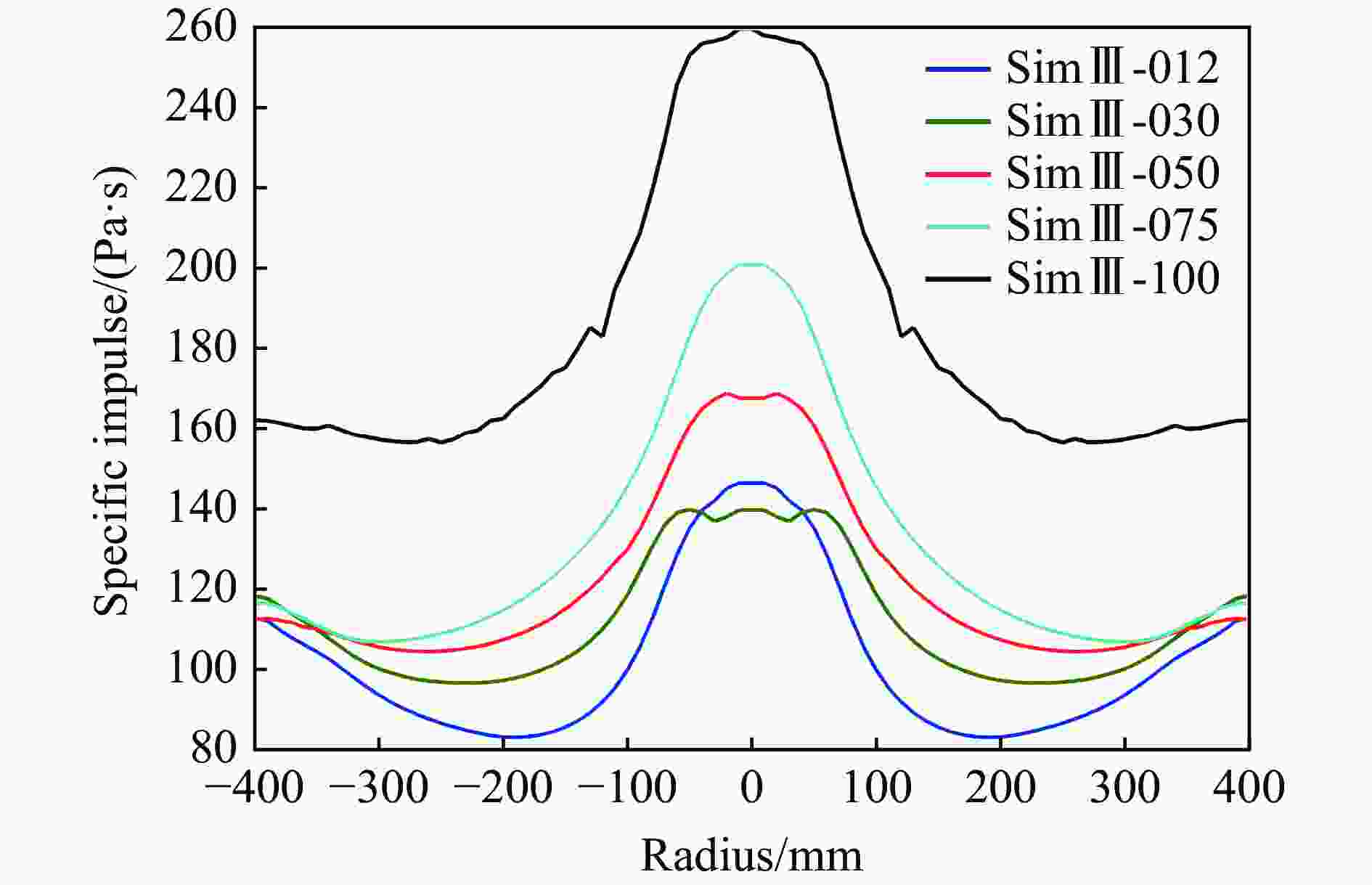

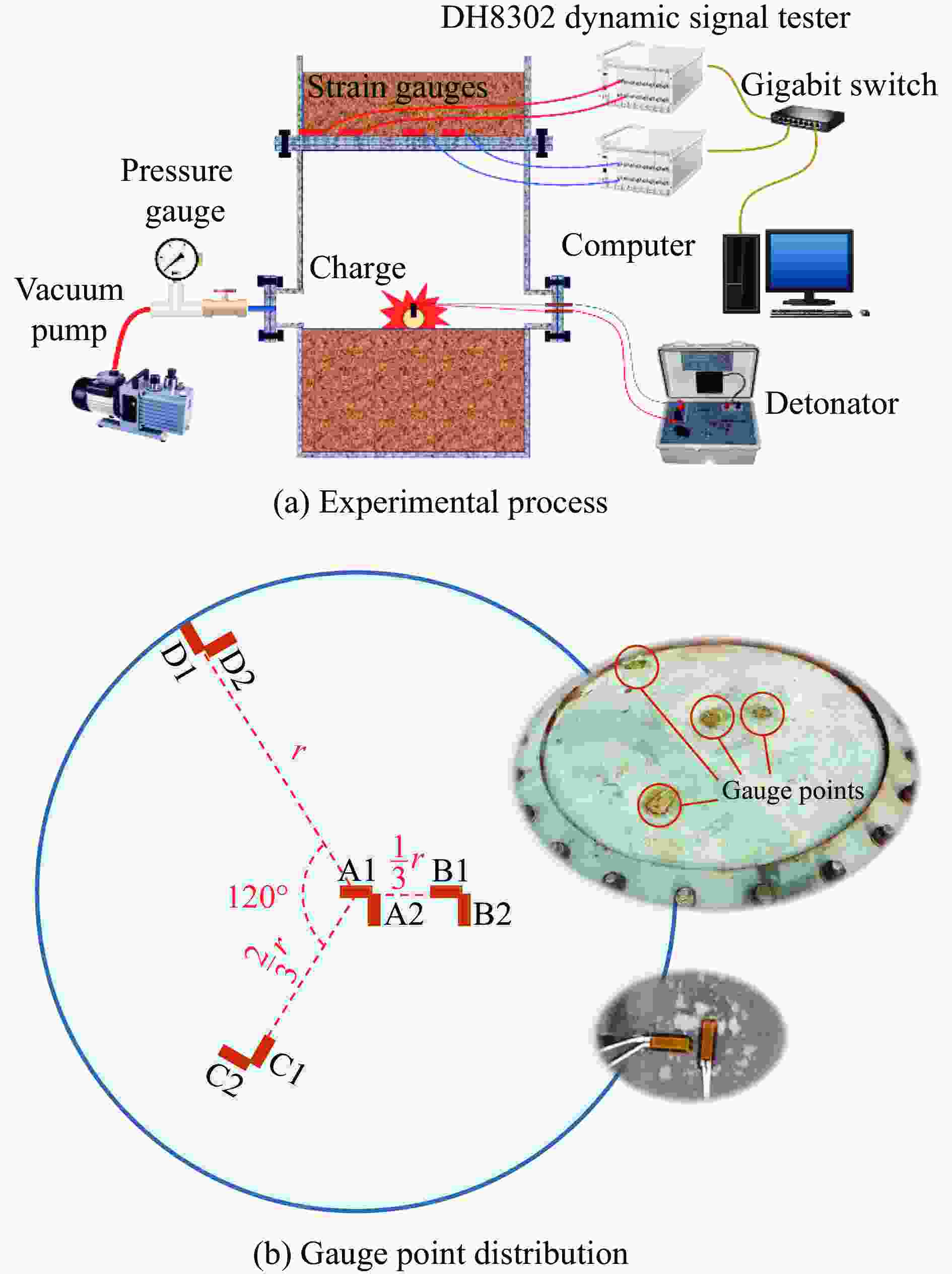

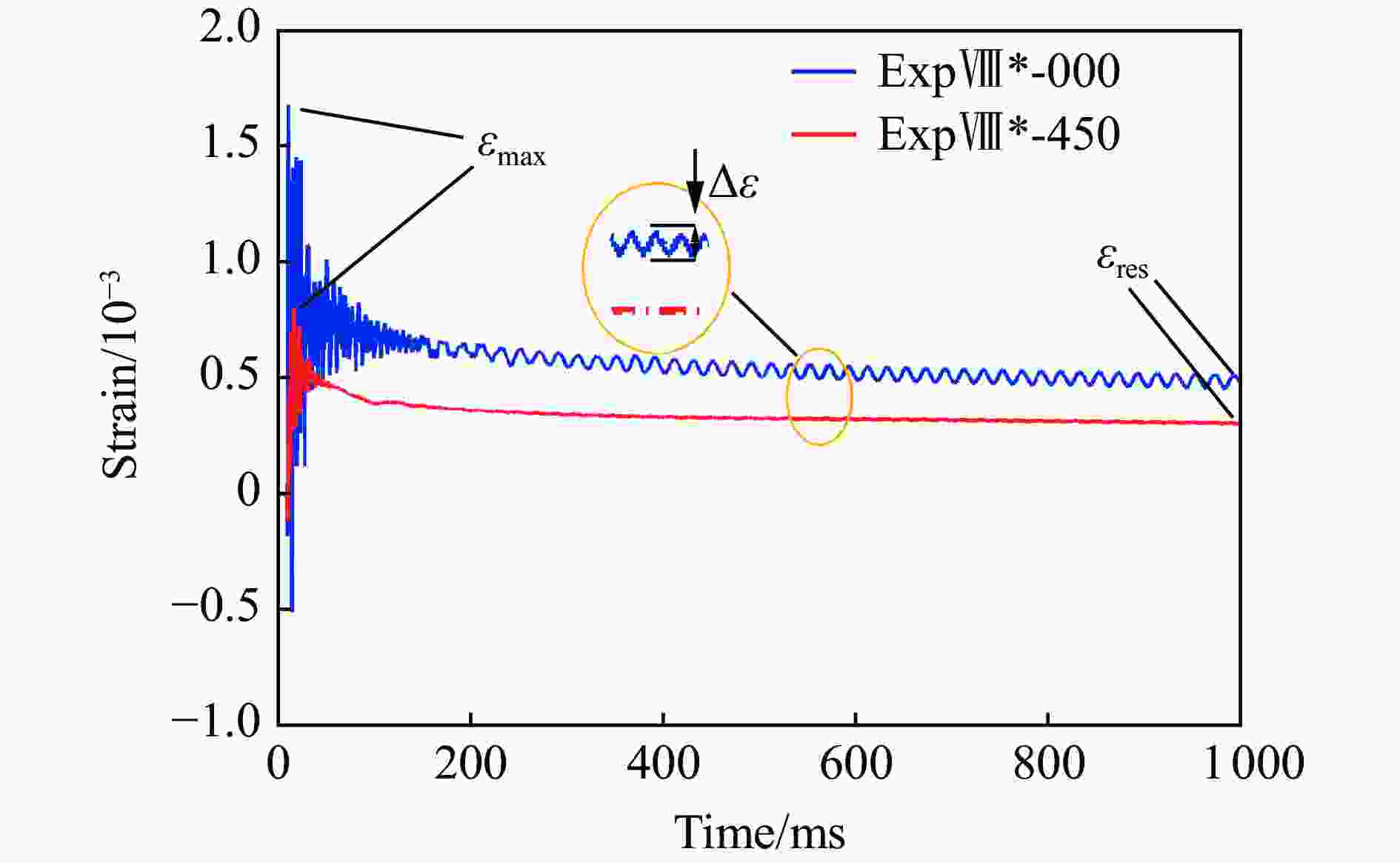

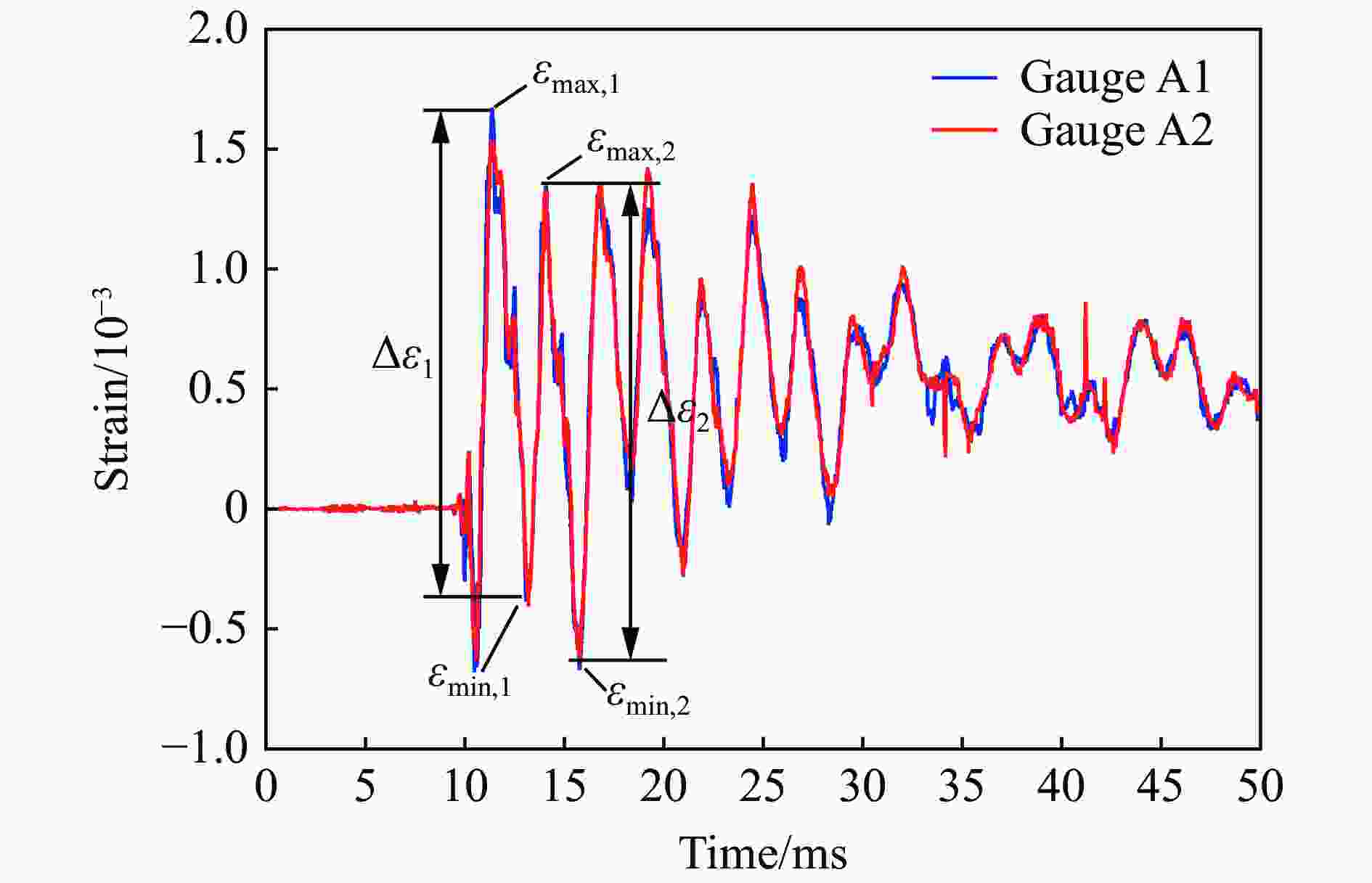

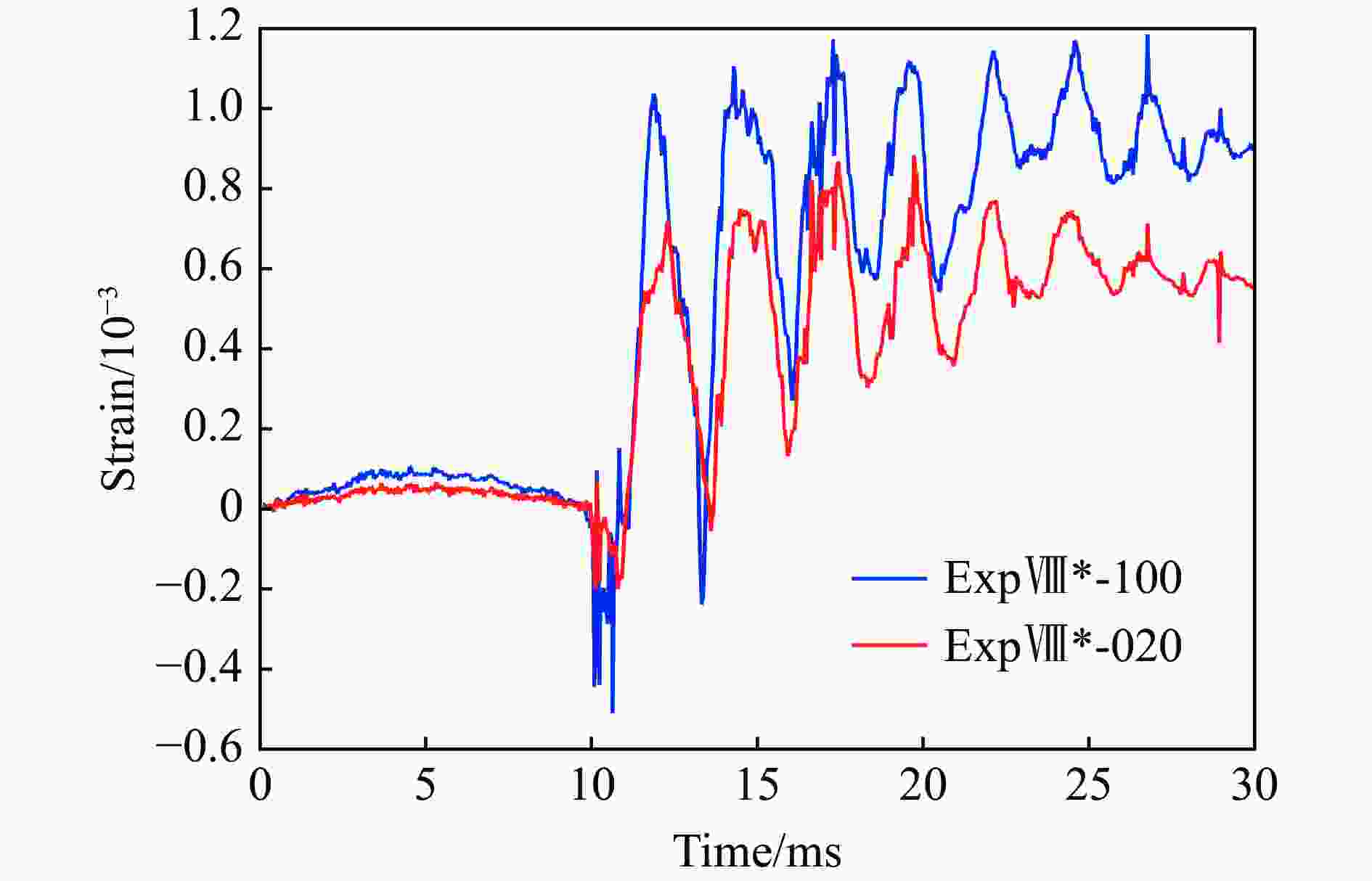

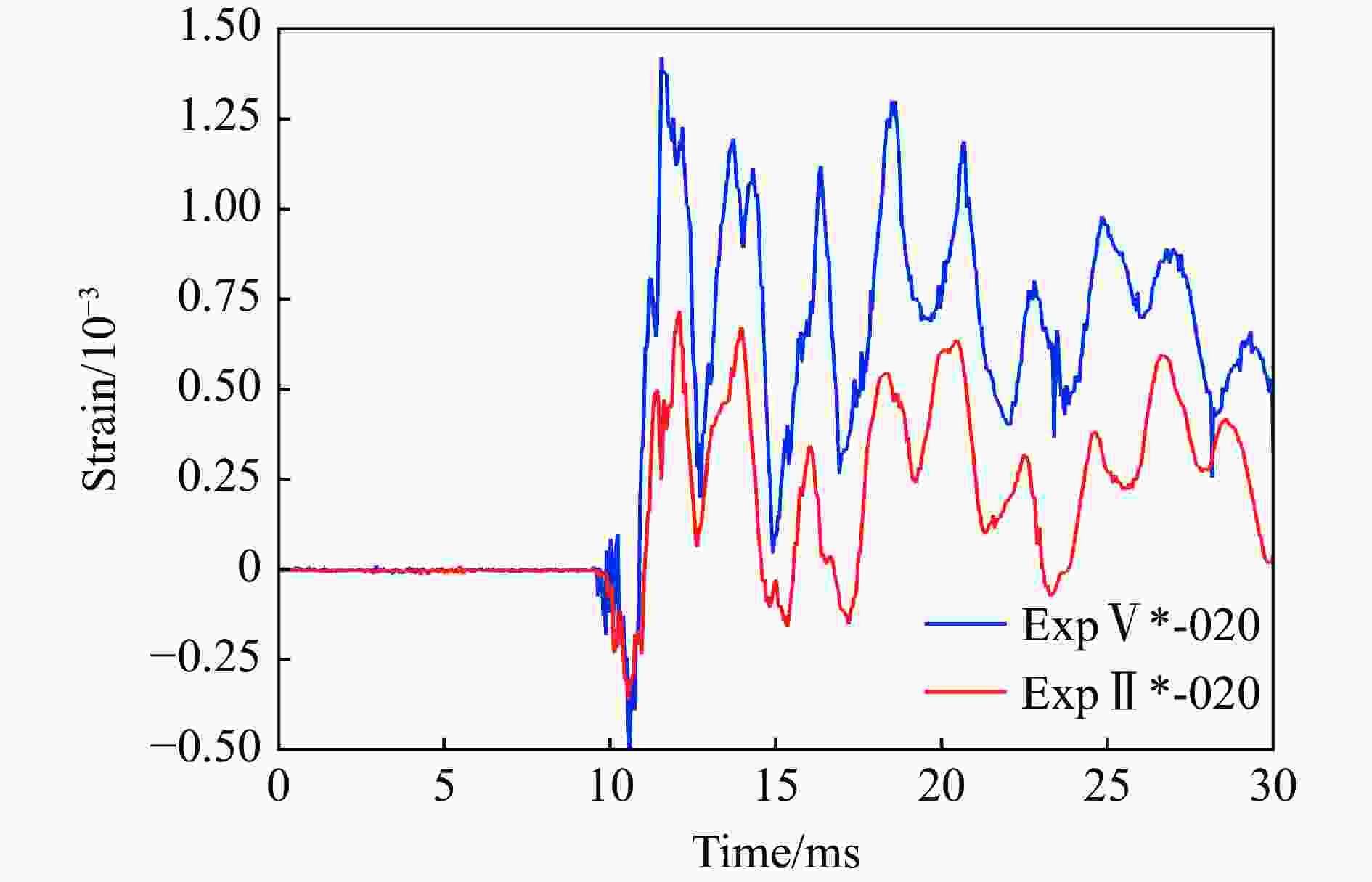

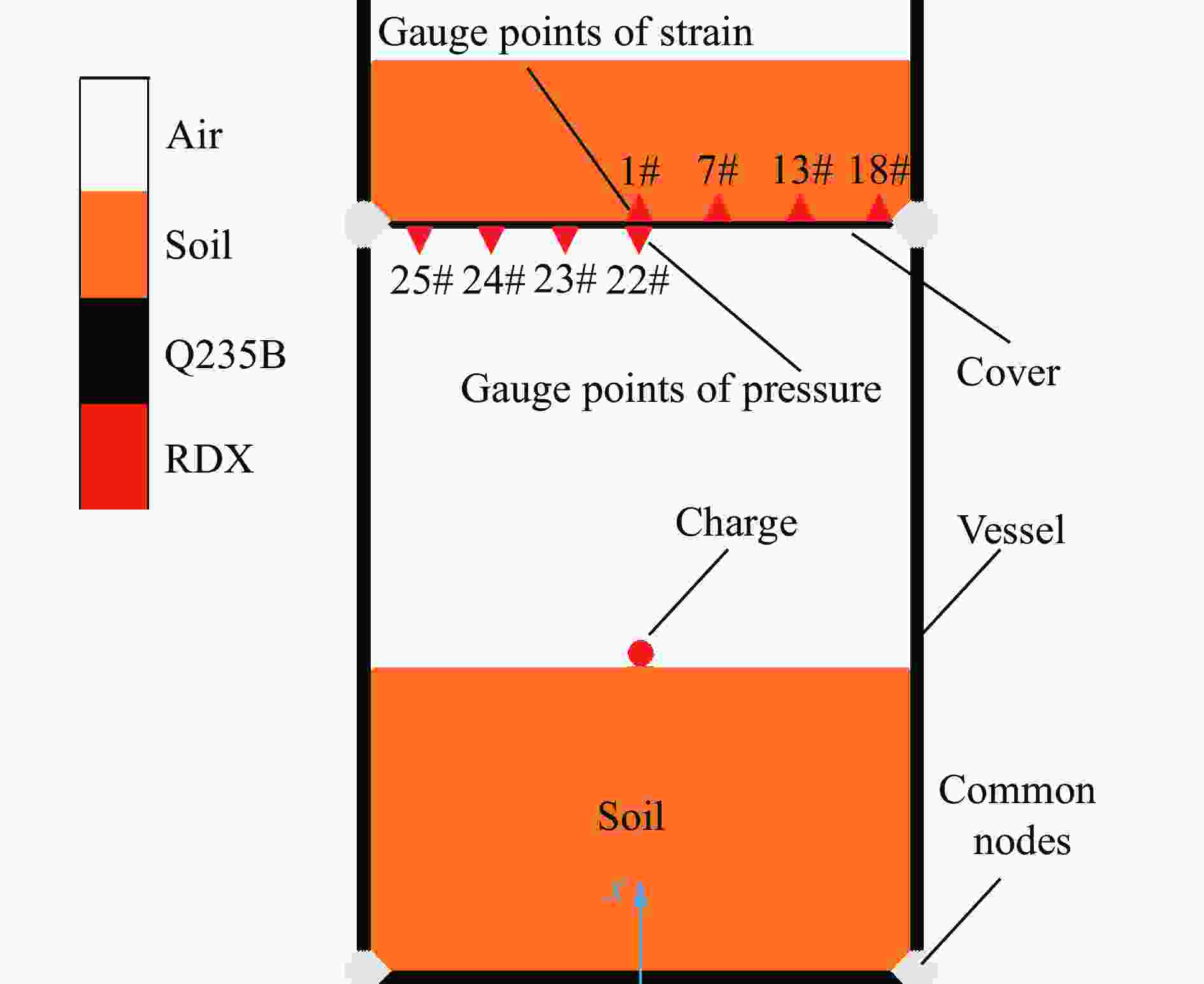

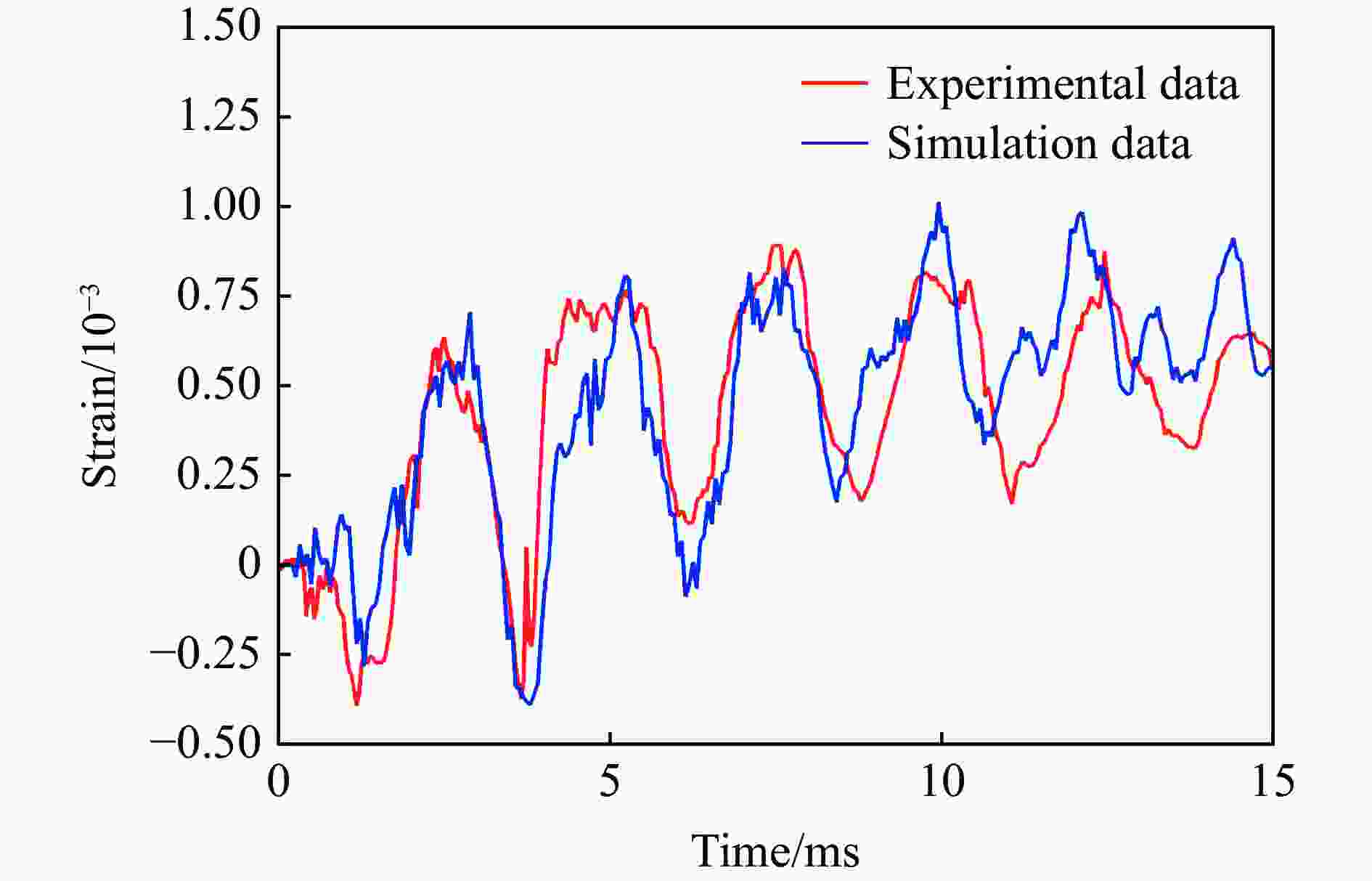

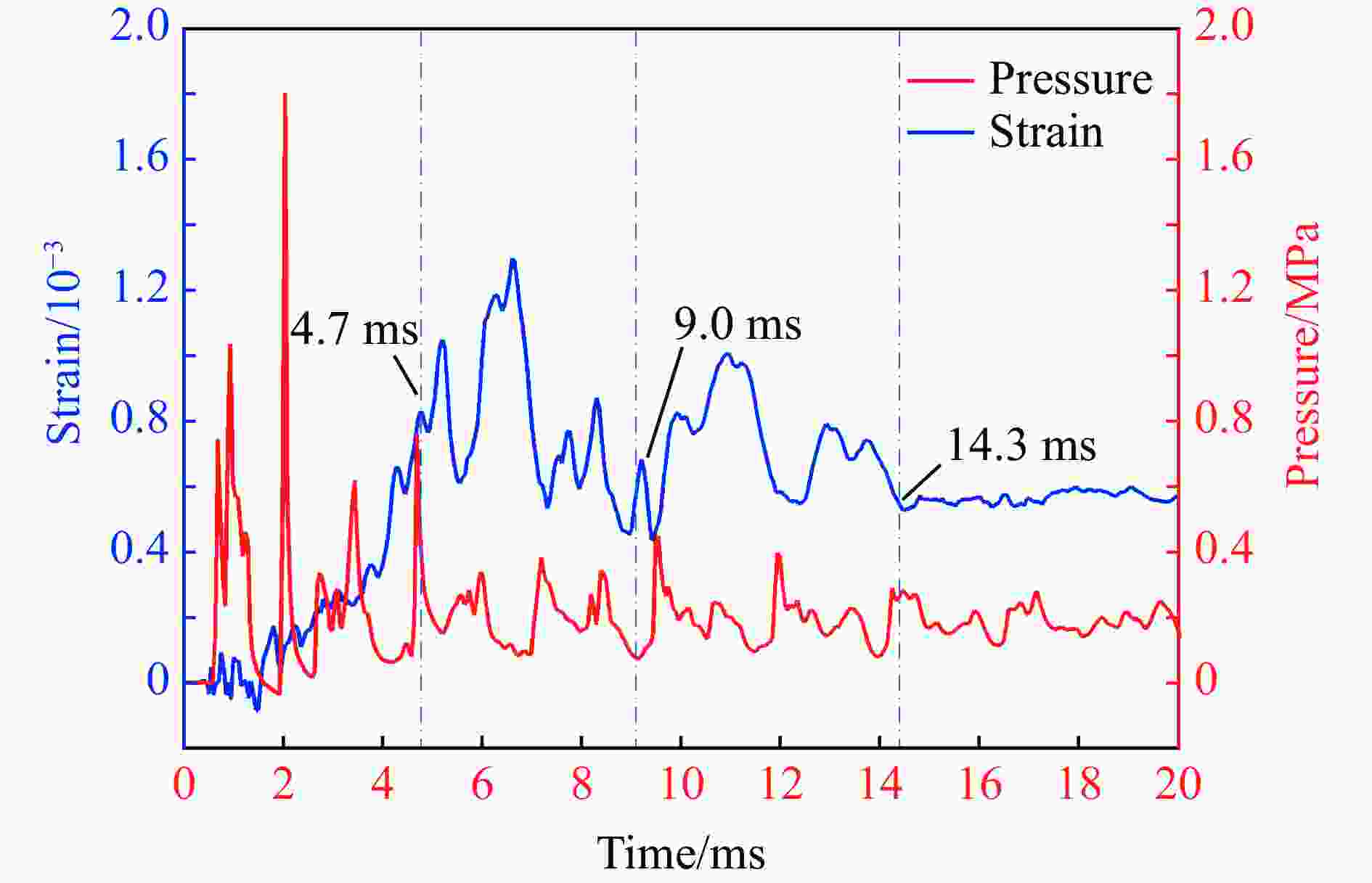

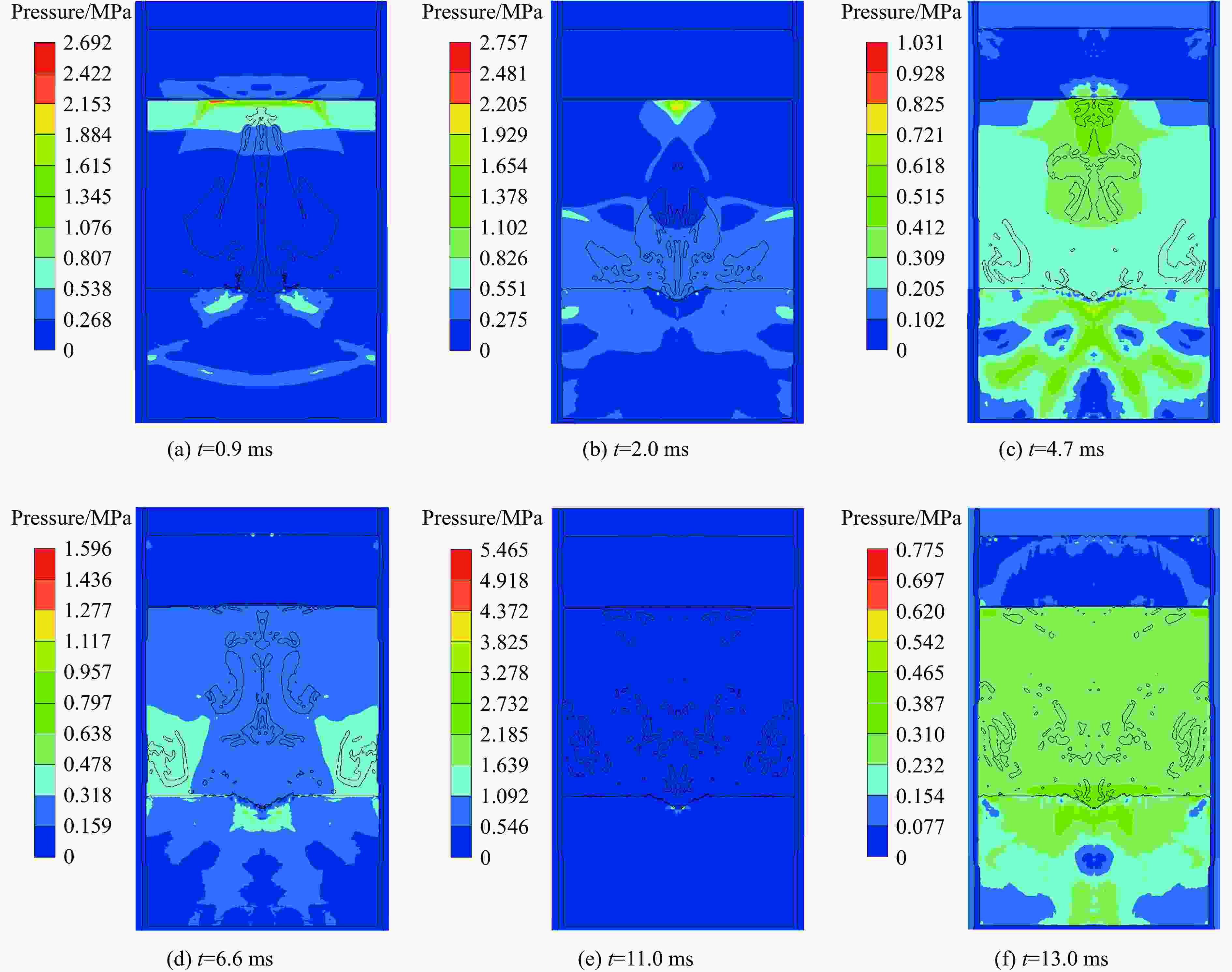

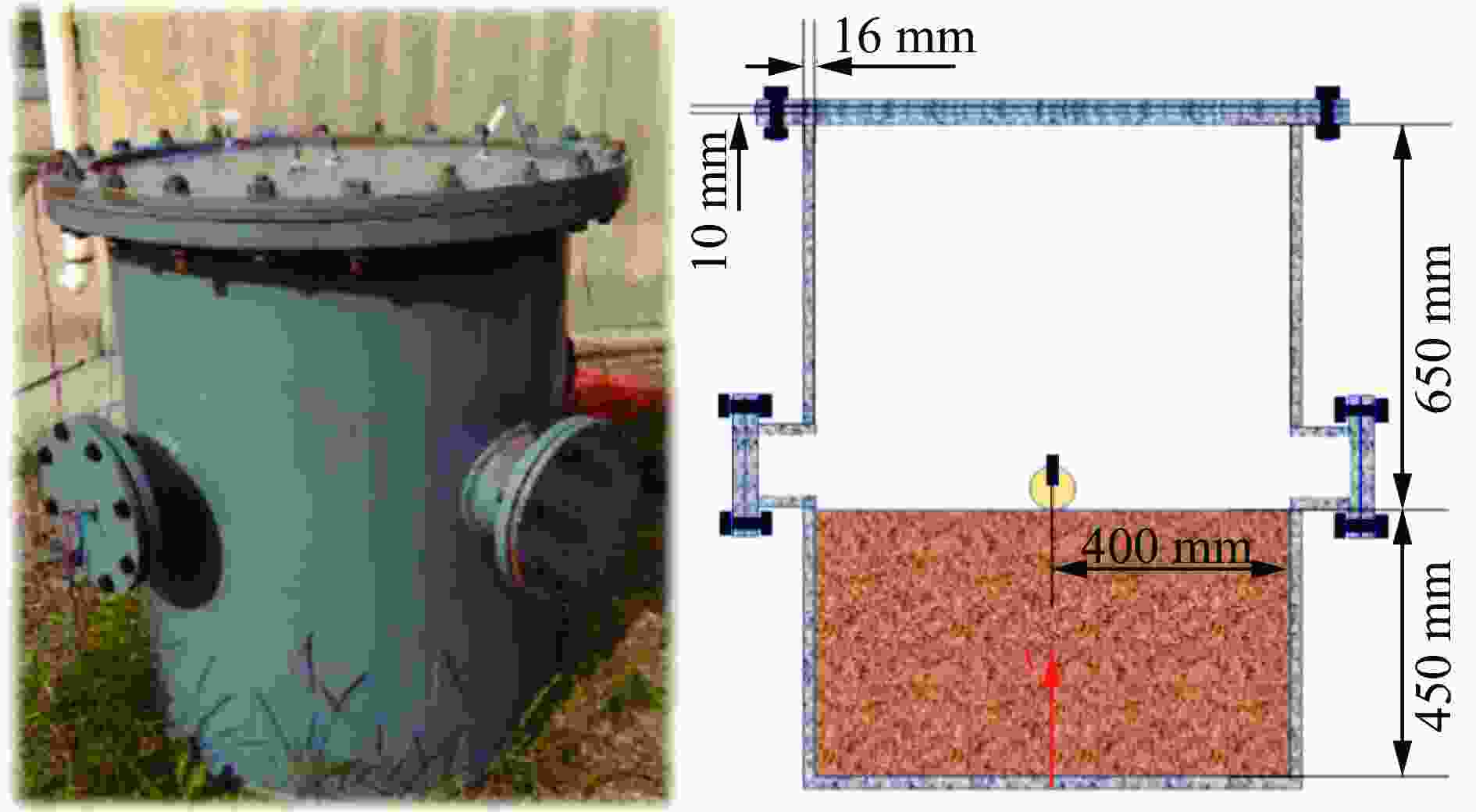

摘要: 为了研制超大型真空爆炸焊接容器,探索覆土真空爆炸容器内的冲击载荷及结构动态响应,设计了一座可以满足实验需要的0.55 m3小型真空爆炸容器,在其内部开展了一系列真空爆炸实验;应用AUTODYN有限元应用程序,对真空爆炸实验进行了数值模拟分析,深入探索了冲击波在容器内部的传播规律、冲击载荷分布状态、结构动态响应以及覆土厚度对平板结构消振作用的影响等问题。实验和数值模拟结果表明:爆炸容器内冲击载荷时程曲线的第2次脉冲峰值明显高于第1次脉冲峰值,且冲击波的叠加和反射总是发生在封盖内壁;随着容器内部真空度的不断下降,冲击载荷的峰值也被明显削弱;容器封盖的动态响应分为阶跃上升、脉冲随动、惯性滞后和静压稳定4个发展阶段;随着真空度的下降以及覆土厚度的增加,爆炸容器的动态响应逐渐被削弱。降低容器内部环境压力和增加覆土厚度均可削减爆炸容器的受迫振动,可为超大型真空爆炸容器的结构设计提供参考。Abstract: Explosive welding production in a vacuum explosion containment vessel can not only restrict the shock wave and noise generated by explosive explosion in a certain space range, but also effectively improve the quality of explosive welding products. Meanwhile, it also alleviates the problems of unstable product quality and rainy season shutdown caused by the influence of weather and climate during explosive welding production, which is an invention that can promote the development of the explosive processing industry. In order to develop a super large vacuum explosion containment vessel for explosive welding, it is necessary to explore the internal blast load and dynamic response of vacuum explosion containment vessel with sand covered for explosive welding. In order to meet the requirements of the experiment, a 0.55 m3 small cylindrical vacuum explosion containment vessel with the cap covered by a certain thickness of sand was designed, and a series of vacuum explosion experiments were carried out in it. At the same time, using the AUTODYN finite element analysis program, the numerical simulation analysis of the corresponding experimental groups is carried out. The evolution of shock wave inside the container, the distribution of blast load, the dynamic response of the structure, and the mechanism of sand covering on the end of the container on the damping of the plate structure are explored in depth. By analyzing the results of experiment and numerical simulation, it is concluded that the peak value of the second impulse of the time-history curve of the blast load in the explosion containment vessel is obviously higher than that of the first impulse, and the superposition and reflection of the shock wave always occur in the inner wall of the cover. With the decrease of vacuum degree inside the container, the peak value of the blast load is weakened obviously. According to the time-history curves of blast load and dynamic strain calculated by the numerical simulation, the dynamic response of the container cover is divided into four development phases: step-up phase, impulse follower phase, inertial lag phase and static pressure stabilization phase. With the decrease of vacuum degree, the amplitude of dynamic response is weakened obviously. With the increase of the thickness of sand cover, the dynamic response of explosion vessel is gradually weakened. Ultimately, it is concluded that reducing the environmental pressure inside the vessel and increasing the thickness of the sand covered on the cap of the container can be used as an effective method to reduce the forced vibration of the explosion containment vessel. The conclusions of the study are useful for the structural design of super large vacuum explosion containment vessels.

-

Key words:

- vacuum explosion containment vessel /

- blast load /

- dynamic response /

- shock wave /

- vacuum degree /

- sand covering

-

表 1 实验分组及实验参数

Table 1. Experimental grouping and experimental parameters

实验编号 铵油炸药量/g TNT当量/g $ \tilde{p}_{\mathrm{v}} $ ExpⅢ-012 30 22.80 0.12 ExpⅢ-050 30 22.80 0.50 ExpⅢ-100 30 22.80 1.00 ExpⅡ-100 20 15.20 1.00 表 2 覆土实验分组及实验参数

Table 2. Experimental grouping of soil covering and experimental parameters

实验编号 覆土厚度/mm 实验编号 覆土厚度/mm 实验编号 覆土厚度/mm ExpⅩ*-240 240 ExpⅧ*-450 450 ExpⅥ*-300 300 ExpⅩ*-180 180 ExpⅧ*-300 300 ExpⅥ*-150 150 ExpⅩ*-120 120 ExpⅧ*-150 150 ExpⅥ*-000 0 ExpⅩ*-060 60 ExpⅧ*-000 0 ExpⅩ*-000 0 ExpⅥ*-450 450 表 3 真空爆炸实验分组及实验参数

Table 3. Experimental grouping and experimental parameters of vacuum explosion

实验编号 黑索金炸药量/g TNT 当量/g $ \tilde{p}_{\mathrm{v}} $ ExpⅢ*-100 30 45 1.00 ExpⅢ*-075 30 45 0.75 ExpⅢ*-050 30 45 0.50 ExpⅢ*-020 30 45 0.20 ExpⅡ*-020 20 30 0.20 ExpⅣ*-020 40 60 0.20 ExpⅤ*-020 50 75 0.20 表 4 封盖厚度为8 mm时不同测试点处实验和模拟的应变峰值

Table 4. Peak strains at different gauge points obtained by experiment and numerical simulation on the cover with a thickness of 8 mm

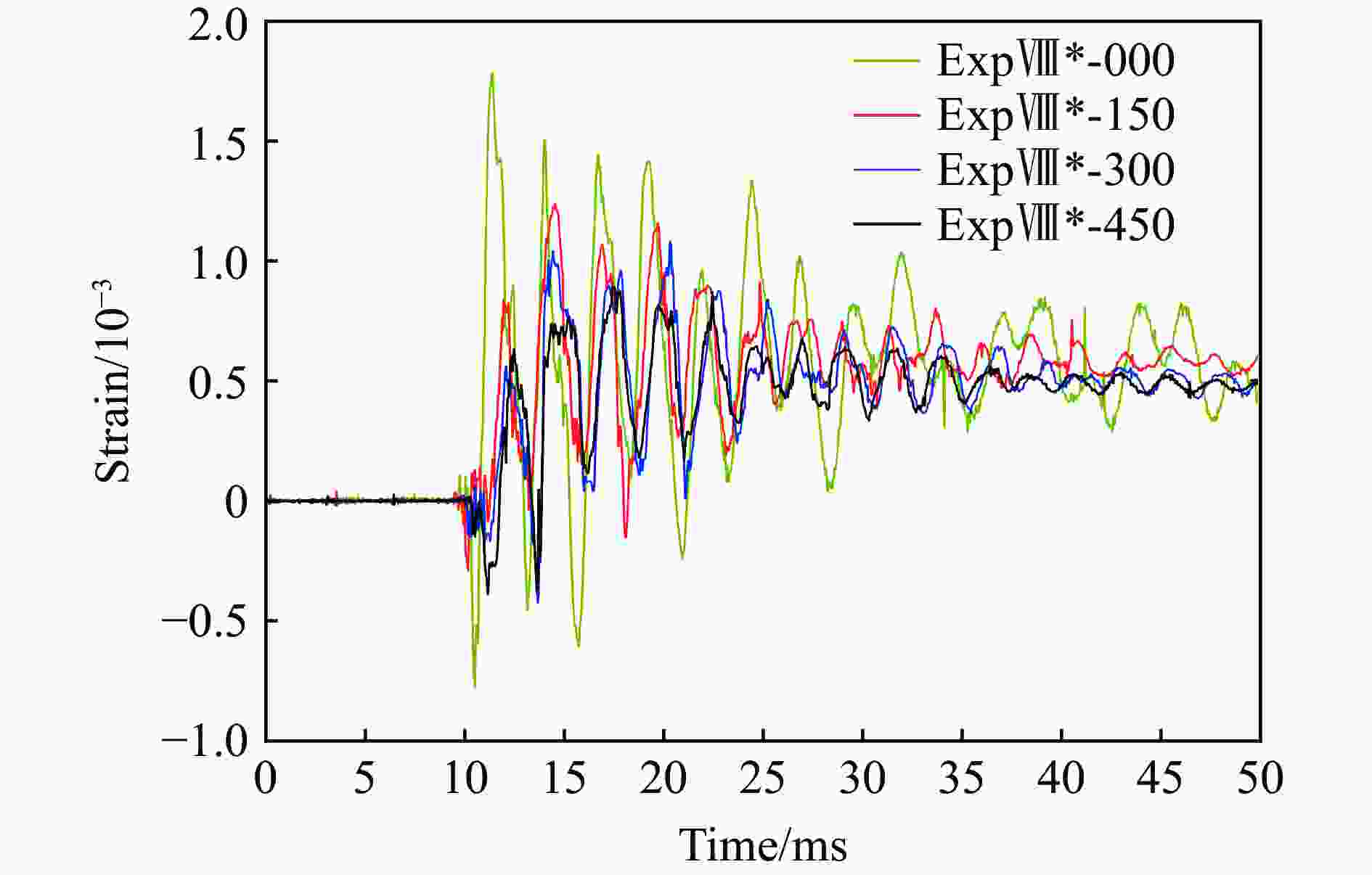

实验编号 εmax(A1) εmax(B1) 实验 模拟 误差/% 实验 模拟 误差/% ExpⅧ*-450 8.932×10−4 1.012×10−3 13.3 8.073×10−4 7.635×10−4 −5.4 ExpⅧ*-300 1.085×10−3 1.234×10−3 13.7 9.312×10−4 9.583×10−4 2.9 ExpⅧ*-150 1.239×10−3 1.431×10−3 15.5 1.041×10−3 1.039×10−3 −0.3 ExpⅧ*-000 1.784×10−3 1.724×10−3 −3.3 1.323×10−3 1.223×10−3 −7.5 实验编号 εmax(C1) εmax(D1) 实验 模拟 误差/% 实验 模拟 误差/% ExpⅧ*-450 6.977×10−4 6.662×10−4 −5.1 −5.801×10−4 −5.557×10−4 9.4 ExpⅧ*-300 8.336×10−4 8.939×10−4 7.2 −5.481×10−4 −5.908×10−4 7.8 ExpⅧ*-150 9.232×10−4 1.013×10−3 −2.3 −7.205×10−4 −6.662×10−4 −7.5 ExpⅧ*-000 1.196×10−3 1.167×10−3 −2.5 −6.313×10−4 −6.619×10−4 4.9 -

[1] RINEHART J S, PEARSON J. Explosive working of metals [M]. New York: Pergamon Press, 1963. [2] ZENG X Y, LI X J, CHEN X, et al. Numerical and experimental studies on the explosive welding of plates with different initial strength [J]. Welding in the World, 2019, 63(4): 967–974. DOI: 10.1007/s40194-019-00733-0. [3] WANG Y X, LI X J, WANG X H, et al. Fabrication of a thick copper-stainless steel clad plate for nuclear fusion equipment by explosive welding [J]. Fusion Engineering and Design, 2018, 137: 91–96. DOI: 10.1016/j.fusengdes.2018.08.017. [4] 闫鸿浩, 李晓杰. 爆炸焊接技术应用扩展 [J]. 爆破, 2005, 22(1): 13–15, 24. DOI: 10.3963/j.issn.1001-487X.2005.01.003.YAN H H, LI X J. The extended application of explosive welding technology [J]. Blasting, 2005, 22(1): 13–15, 24. DOI: 10.3963/j.issn.1001-487X.2005.01.003. [5] 牛爱红. 金属复合材料真空爆炸焊接实践与研究 [J]. 工程爆破, 2018, 24(4): 67–70. DOI: 10.3969/j.issn.1006-7051.2018.04.013.NIU A H. Research and practice of vacuum explosion welding for metal cladding product [J]. Engineering Blasting, 2018, 24(4): 67–70. DOI: 10.3969/j.issn.1006-7051.2018.04.013. [6] 秦小勇. 大型爆炸焊接半球消波器研究 [D]. 大连: 大连理工大学, 2008.QIN X Y. The study on large scale hemispherical shock-waves trap structure for explosive welding [D]. Dalian: Dalian University of Technology, 2008. [7] 李晓杰, 秦小勇, 闫鸿浩. 半球阻波结构体底部的约束形式 [J]. 爆炸与冲击, 2010, 30(1): 7–11. DOI: 10.11883/1001-1455(2010)01-0007-05.LI X J, QIN X Y, YAN H H. Base constraint forms of hemispherical shock-waves trap structures [J]. Explosion and Shock Waves, 2010, 30(1): 7–11. DOI: 10.11883/1001-1455(2010)01-0007-05. [8] 程赛伟. 大型真空爆炸容器用组合结构椭球抗爆门研究 [D]. 大连: 大连理工大学, 2022. [9] ZHOU D Z, LI X J, WANG Y X, et al. Research on evolution of shock wave of ground explosion in pit type explosion containment vessel [J]. Structures, 2023, 50: 1164–1172. DOI: 10.1016/j.istruc.2023.02.082. [10] 李科斌, 李晓杰, 闫鸿浩, 等. 不同真空度下空中爆炸近场特性的数值模拟研究 [J]. 振动与冲击, 2018, 37(17): 270–276. DOI: 10.13465/j.cnki.jvs.2018.17.038.LI K B, LI X J, YAN H H, et al. Numerical simulation for near-field characteristics of air explosion under different degrees of vacuum [J]. Journal of Vibration and Shock, 2018, 37(17): 270–276. DOI: 10.13465/j.cnki.jvs.2018.17.038. [11] ZHOU D Z, LI X J, WANG Y X, et al. Research on the influence of vacuum degree on the shock wave in pit type explosion containment vessel [J]. Structures, 2023, 56: 105033. DOI: 10.1016/j.istruc.2023.105033. -

下载:

下载: