On mechanism and prevention of sympathetic detonation of bench blasting in water-rich fissure open-pit mine

-

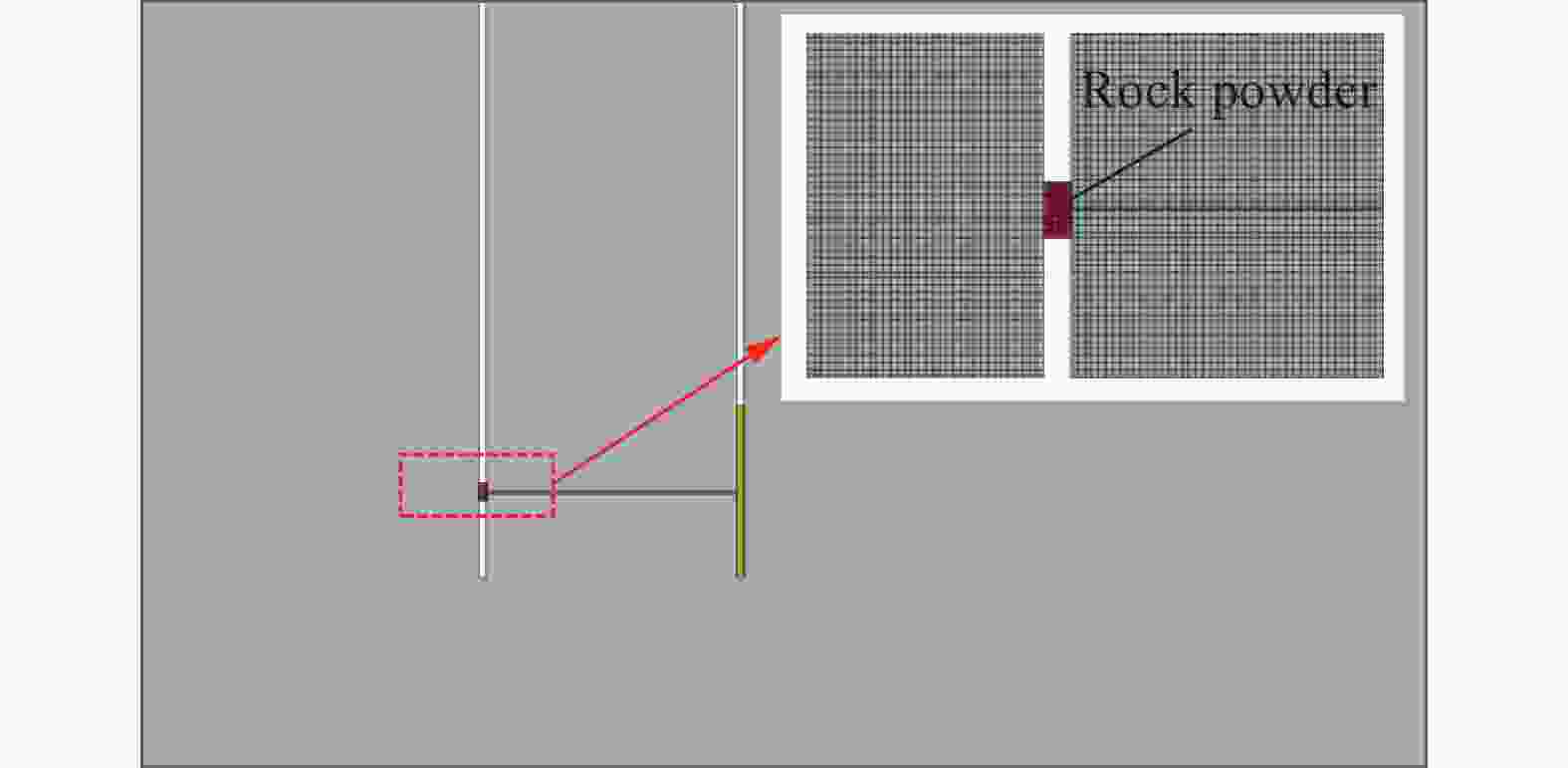

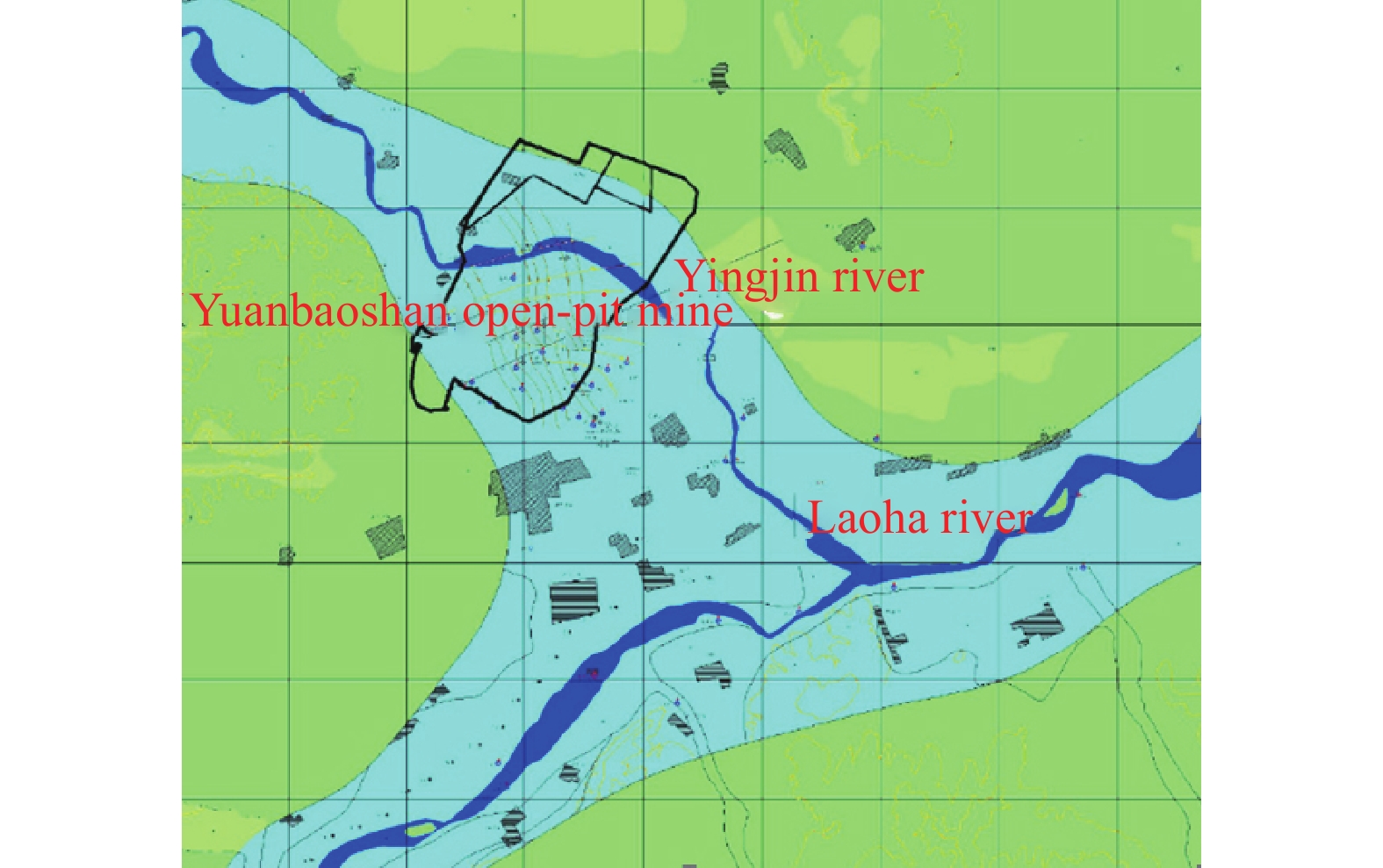

摘要: 殉爆现象会影响露天矿台阶爆破作业安全、边坡稳定性和爆破效果。在炸药冲击起爆机理基础上,并结合露天矿实际富水裂隙岩体台阶爆破振动监测结果,通过对比爆破振动信号波动差异来判别殉爆现象。为研究殉爆产生的机理和防殉爆方法,采用数值模拟和现场试验分析主发药量、裂隙宽度及药包之间的距离等参数对被发药包孔壁压力的影响。结果表明:孔壁冲击压力随着装药耦合系数的减小、炮孔间裂隙宽度(0.25~1.00 cm)的增大以及炮孔间距离的减小而提高。在裂隙位置装药使用阻波管、充填岩粉或设置空气间隔器,能显著降低通过富水裂隙传递到被发炮孔的冲击压力,并使其低于乳化炸药的起爆压力临界值。当炮孔内只有单条裂隙时,选择填充岩粉是便捷且有效防殉爆方法;当炮孔内有多条裂隙时,该试验条件下,炮孔内放置厚度为2.6 mm的阻波管是最佳防殉爆方法,并能保证爆破效果。Abstract: Sympathetic detonation is defined as the phenomenon where the detonation pressure in one borehole causes explosives in another adjacent borehole to be detonated through an inert medium. It can increase the stress wave and the value of peak particle velocity, even causing fly rock to be thrown far away. These effects can impact the safety of blasting operation, slope stability, and blasting effects. Sympathetic detonation was identified by comparing the fluctuation difference of recorded blast-induced vibration signals. To investigate the mechanism of sympathetic detonation and methods of preventing sympathetic detonation in water-rich fissure open-pit mines, numerical simulation and field tests were adopted to analyze the effects of parameters on the occurrence of sympathetic detonation, such as the quantity of donor charge, crack width, and distance between charges. These results indicated that the borehole pressure increased with the decrease in decoupled charge coefficient, the increase of the crack width between boreholes (0.25−1.00 cm), and the decrease in the distance between boreholes. By using a wave-blocking tube, filling rock power, or setting up an air gap, the impact pressure produced by the donor charge was transmitted to the acceptor charge through the water-rich cracks. These methods made impact pressure lower than the critical detonation pressure of the emulsion explosive, which could prevent the sympathetic detonation of the accepted charge. Based on the field tests and simulated results, rock power filling was the best method of preventing sympathetic detonation when there was a single crack between the boreholes. Meanwhile, using a wave-blocking tube with a thickness of 2.6 mm was the best method of preventing sympathetic detonation when there were multiple cracks between the boreholes. Above all, the proposed detection method and obtained technologies provide the theory and guidance for preventing sympathetic detonation, which leads to improved blasting effects and the safety of blasting operations.

-

表 1 现场试验参数

Table 1. Test parameters

组号 地质条件 孔径/mm 孔深/m 单孔药量/kg 排间延期/ms 孔间延期/ms 装药方式 起爆方式 1 岩体裂隙水丰富 200 13.5 96 65 42 分段装药 逐孔起爆 2 岩体无裂隙水 200 13.5 96 65 42 分段装药 逐孔起爆 $ {\rho _{\text{e}}} $/(g·cm−3) A/GPa B/GPa R1 R2 ω Ee0/GPa D/(km·s−1) 1.20 494.6 1.89 3.91 1.11 0.3 3.87 4.1 模型参数 说明 参数值 模型参数 说明 参数值 ρr0/(g·cm−3) 初始密度 2.23 ε0c/s−1 参考压缩应变率 2.9×10-11 fs* 相对抗剪强度 0.25 ε0t/s−1 参考拉伸应变率 2.9×10-12 ft* 相对抗拉强度 0.23 εc/s−1 失效压缩应变率 1.5×1019 G/GPa 剪切模量 0.22 εt/s−1 失效拉伸应变率 1.5×1019 fc/MPa 单轴抗压强度 120.22 βc 压缩应变率指数 0.0076 D1 损伤系数 0.10 βt 拉伸应变率指数 0.0094 D2 损伤系数 1.00 A 失效面参数 1.40 Q0 拉压-子午比参数 0.58 N 失效面指数 0.40 α 初始空隙率 1.10 pel/MPa 压碎压力 82.12 Np 孔隙度指数 3.20 pco/MPa 压实压力 4.00 B0 状态方程参数 1.51 Af 残余强度面参数 0.85 B1 状态方程参数 1.51 Nf 残余强度面参数 0.42 ${\rho _{\text{w}}}$/(g·cm−3) c/(km·s−1) S1 S2 S3 Ew $ {\gamma _0} $ 1.0 1.48 2.56 1.986 1.2268 0 1 表 5 不同参数的数值模拟方案

Table 5. Numerical simulation schemes with different parameters

方案 编号 炮孔间距/m 裂缝宽度/cm 装药量/kg 装药长度/m 填充长度/m Ⅰ Ⅰ-1 4 1.00 96 4.5 4 Ⅰ-2 5 Ⅰ-3 6 Ⅰ-4 7 Ⅰ-5 8 Ⅱ Ⅱ-1 6 0.25 96 4.5 4 Ⅱ-2 0.50 Ⅱ-3 0.75 Ⅱ-4 1.00 Ⅱ-5 1.50 Ⅱ-6 2.00 Ⅲ Ⅲ-1 6 1.00 24 4.5 4 Ⅲ-2 36 Ⅲ-3 48 Ⅲ-4 60 Ⅲ-5 72 Ⅲ-6 96 -

[1] 王玉杰. 爆破工程 [M]. 武汉: 武汉理工大学出版社, 2007: 20–22. [2] DERIBAS A A, MEDVEDEV E A, RESHETNYAK Y A, et al. Detonation of emulsion explosives containing hollow microspheres [J]. Doklady Physics, 2003, 48(4): 163–165. DOI: 10.1134/1.1574370. [3] 李铮, 项续章, 郭梓熙. 各种炸药的殉爆安全距离 [J]. 爆炸与冲击, 1994, 14(3): 231–241. DOI: 10.11883/1001-1455(1994)03-0231-11.LI Z, XIANG X Z, GUO Z X. Various explosives of safety distance of unsympathetic detonation [J]. Explosion and Shock Waves, 1994, 14(3): 231–241. DOI: 10.11883/1001-1455(1994)03-0231-11. [4] 费鸿禄. 爆破理论及其应用 [M]. 2版. 北京: 煤炭工业出版社, 2018: 89–92. [5] 汪成运, 魏志丰, 何鹏鹏. 炸药殉爆的研究进展与展望 [J]. 爆破器材, 2022, 51(6): 1–8. DOI: 10.3969/j.issn.1001-8352.2022.06.001.WANG C Y, WEI Z F, HE P P. Research progress of sympathetic detonation of explosives [J]. Explosive Materials, 2022, 51(6): 1–8. DOI: 10.3969/j.issn.1001-8352.2022.06.001. [6] 余德运, 谢烽, 王旭耀. ANFO在炮孔中的殉爆起爆试验研究 [J]. 爆破器材, 2020, 49(5): 59–64. DOI: 10.3969/j.issn.1001-8352.2020.05.011.YU D Y, XIE F, WANG X Y. Experimental study on sympathetic detonation of ANFO in hole [J]. Explosive Materials, 2020, 49(5): 59–64. DOI: 10.3969/j.issn.1001-8352.2020.05.011. [7] ZHANG Z F, WANG C, HU H L, et al. Investigation of underwater sympathetic detonation [J]. Propellants, Explosives, Pyrotechnics, 2020, 45(11): 1736–1744. DOI: 10.1002/prep.202000099. [8] YANG J X, SHI C, YANG W K, et al. Numerical simulation of column charge explosive in rock masses with particle flow code [J]. Granular Matter, 2019, 21(4): 96. DOI: 10.1007/s10035-019-0950-2. [9] 姜颖资, 王伟力, 黄雪峰, 等. 带壳炸药在高速运动炸药作用下殉爆效应研究 [J]. 工程爆破, 2014, 20(3): 1–4. DOI: 10.3969/j.issn.1006-7051.2014.03.001.JIANG Y Z, WANG W L, HUANG X F, et al. Research on the sympathetic detonation effect of shelled explosive by highspeed movement explosive [J]. Engineering Blasting, 2014, 20(3): 1–4. DOI: 10.3969/j.issn.1006-7051.2014.03.001. [10] SHIN H, LEE W. Material design guidelines for explosive confinements to control impact shock-induced detonations based on shock transmission/reflection analysis [J]. International Journal of Impact Engineering, 2003, 28(5): 465–478. DOI: 10.1016/S0734-743X(2)00075-1. [11] STARKENBERG J, HUANG Y, ARBUCKLE A. Numerical modeling of projectile impact shock initiation of bare and covered composition-B [J]. Journal of Energetic Materials, 1984, 2(1/2): 1–41. DOI: 10.1080/07370658408012327. [12] 李凯, 詹勇, 程波, 等. 爆炸冲击波经隔板衰减后的起爆能力数值研究 [C]//2014’(第六届)含能材料与钝感弹药技术学术研讨会论文集. 北京: 中国兵工学会爆炸与安全技术专业委员会, 2014: 474–478. [13] 李顺波, 东兆星, 齐燕军, 等. 爆炸冲击波在不同介质中传播衰减规律的数值模拟 [J]. 振动与冲击, 2009, 28(7): 115–117. DOI: 10.13465/j.cnki.jvs.2009.07.001.LI S B, DONG Z X, QI Y J, et al. Numerical simulation for spread decay of blasting shock wave in different media [J]. Journal of Vibration and Shock, 2009, 28(7): 115–117. DOI: 10.13465/j.cnki.jvs.2009.07.001. [14] 赵根, 季荣, 郑晓宁, 等. 乳化炸药水中爆炸冲击波传播规律试验研究 [J]. 爆破, 2011, 28(2): 1–4. DOI: 10.3963/j.issn.1001-487X.2011.02.001.ZHAO G, JI R, ZHENG X N, et al. Experimental investigation on propagation rule of shock wave by emulsion explosives underwater blasting [J]. Blasting, 2011, 28(2): 1–4. DOI: 10.3963/j.issn.1001-487X.2011.02.001. [15] 花宝玲, 李建军, 丁淳彤. 乳化炸药冲击起爆过程的研究 [J]. 工程爆破, 1998, 4(1): 30–33.HUA B L, LI J J, DING C T. Study on shock initiation process for emulsion explosives [J]. Engineering Blasting, 1998, 4(1): 30–33. [16] 李建军, 汪旭光, 欧育湘, 等. 乳化炸药冲击起爆的实验研究 [J]. 工程爆破, 1995, 1(1): 14–19.LI J J, WANG X G, OU Y X, et al. Experimental study on shock initiations of emulsion explosives [J]. Engineering Blasting, 1995, 1(1): 14–19. [17] 马晶晶, 龙运杰, 唐虹靖, 等. 炮孔约束下炸药殉爆距离试验研究 [J]. 采矿技术, 2023, 23(6): 165–169. DOI: 10.13828/j.cnki.ckjs.2023.06.037.MA J J, LONG Y J, TANG H J, et al. Experimental study on explosive detonation distance under blast hole constraints [J]. Mining Technology, 2023, 23(6): 165–169. DOI: 10.13828/j.cnki.ckjs.2023.06.037. [18] 陈庆凯, 夏亚伟, 刘占富, 等. 约束条件对乳化炸药殉爆距离影响的研究 [J]. 矿业研究与开发, 2017, 37(1): 45–49. DOI: 10.13827/j.cnki.kyyk.2017.01.011.CHEN Q K, XIA Y W, LIU Z F, et al. The effect of constraint conditions on the gap distance of emulsion explosive [J]. Mining Research and Development, 2017, 37(1): 45–49. DOI: 10.13827/j.cnki.kyyk.2017.01.011. [19] 陈朗, 王晨, 鲁建英, 等. 炸药殉爆实验和数值模拟 [J]. 北京理工大学学报, 2009, 29(6): 497–500,524. DOI: 10.15918/j.tbit1001-0645.2009.06.004.CHEN L, WANG C, LU J Y, et al. Experiment simulation of sympathetic detonation tests [J]. Transactions of Beijing Institute of Technology, 2009, 29(6): 497–500,524. DOI: 10.15918/j.tbit1001-0645.2009.06.004. [20] 张所硕, 聂建新, 张剑, 等. 约束空间内壳装炸药殉爆及防护 [J]. 爆炸与冲击, 2023, 43(8): 085101. DOI: 10.11883/bzycj-2022-0456.ZHANG S S, NIE J X, ZHANG J, et al. Sympathetic detonation of explosive charge in confined space and its protection [J]. Explosion and Shock Waves, 2023, 43(8): 106–119. DOI: 10.11883/bzycj-2022-0456. [21] 胡宏伟, 王健, 卞云龙, 等. 带壳装药水中殉爆特性分析 [J]. 水下无人系统学报, 2022, 30(3): 308–313. DOI: 10.11993/j.issn.2096-3920.2022.03.005.HU H W, WANG J, BIAN Y L, et al. Experiments of sympathetic detonation performance of explosives with shell in water [J]. Journal of Unmanned Undersea Systems, 2022, 30(3): 308–313. DOI: 10.11993/j.issn.2096-3920.2022.03.005. [22] 刘晓文, 高玉刚. 炸药在水介质中殉爆特性分析 [J]. 工程爆破, 2022, 28(4): 102–107. DOI: 10.19931/j.EB.20210241.LIU X W, GAO Y G. Analysis of explosive martyrdom in water medium [J]. Engineering Blasting, 2022, 28(4): 102–107. DOI: 10.19931/j.EB.20210241. [23] KO Y H, KIM S J, YANG H S. Assessment for the sympathetic detonation characteristics of underwater shaped charge [J]. Geosystem Engineering, 2017, 20(5): 286–293. DOI: 10.1080/12269328.2017.1323679. [24] 中华人民共和国国家质量监督检验检疫总局. 爆破安全规程: GB 6722–2014 [S]. 北京: 冶金工业出版社, 2014. [25] 张忠伟, 任舸, 李洪涛. 锦屏二级水电站导流隧洞进口围堰拆除爆破 [J]. 爆破, 2011, 28(4): 77–80. DOI: 10.3963/j.issn.1001-487X.2011.04.021.ZHANG Z W, REN G, LI H T. Explosive demolition of intake cofferdam of diversion tunnel on Jingping Ⅱ Hydropower Station [J]. Blasting, 2011, 28(4): 77–80. DOI: 10.3963/j.issn.1001-487X.2011.04.021. [26] 李文焱. 元宝山露天矿富水裂隙台阶爆破的殉爆机理及防止殉爆技术研究 [D]. 辽宁工程技术大学, 2023. DOI: 10.27210/d.cnki.glnju.2023.000910. [27] 凌天龙, 王宇涛, 刘殿书 等. 修正RHT模型在岩体爆破响应数值模拟中的应用 [J]. 煤炭学报, 2018, 43(S2): 434–442. DOI: 10.13225/j.cnki.jccs.2017.1698.LING T L, WANG Y T, LIU D S, et al. Modified RHT model for numerical simulation of dynamic response of rock mass under blasting load [J]. Journal of China Coal Society, 2018, 43(S2): 434–442. DOI: 10.13225/j.cnki.jccs.2017.1698. [28] SHINY S, LEE M, LAM K Y, et al. Modeling mitigation effects of watershield on shock waves [J]. Shock and Vibration, 1998, 5(4): 225–234. DOI: 10.1155/1998/782032. -

下载:

下载: