| [1] |

LANDROCK A H. Handbook of plastic foams: types, properties, manufacture and applications [M]. Park Ridge: Noyes Publications, 1995.

|

| [2] |

MAITI A, WEISGRABER T H, GEE R H. Modeling the mechanical and aging properties of silicone rubber and foam-stockpile-historical & additively manufactured materials: LLNL-TR-661699 [R]. Livermore: Lawrence Livermore National Laboratory, 2014.

|

| [3] |

SANBORN B, SONG B, SMITH S. Pre-strain effect on frequency-based impact energy dissipation through a silicone foam pad for shock mitigation [J]. Journal of Dynamic Behavior of Materials, 2016, 2(1): 138–145. DOI: 10.1007/s40870-015-0043-1.

|

| [4] |

DOWELL F. Simple EOS for the silicone rubber Sylgard 184: LA-10164-MS [R]. United States: Los Alamos National Laboratory, 1984.

|

| [5] |

CARTER W J, MARSH S P. Hugoniot equation of state of polymers: LA-13006-MS [R]. USA: Los Alamos National Laboratory, 1995.

|

| [6] |

KONDO K, YASUMOTO Y, SUGIURA H, et al. Multiple shock reverberations in a layer structure observed by particle-velocity and pressure gauges [J]. Journal of Applied Physics, 1981, 52(2): 772–776. DOI: 10.1063/1.328761.

|

| [7] |

WINTER R E, WHITEMAN G, HAINING G S, et al. Measurement of equation of state of silicone elastomer [J]. AIP Conference Proceedings, 2004, 706(1): 679–684.

|

| [8] |

DATTELBAUM D M, JENSEN J D, SCHWENDT A M, et al. A novel method for static equation-of state-development: equation of state of a cross-linked poly (dimethylsiloxane) (PDMS) network to 10 GPa [J]. The Journal of Chemical Physics, 2005, 122(14): 144903. DOI: 10.1063/1.1879872.

|

| [9] |

曾鉴荣, 刘勇, 杜保国, 等. 低密度硅橡胶冲击雨贡纽曲线测量 [J]. 高压物理学报, 1996, 10(4): 299–303. DOI: 10.11858/gywlxb.1996.04.010.ZENG J R, LIU Y, DU B G, et al. Measurement of shock-Hugoniot curve of low-density silastic [J]. Chinese Journal of High Pressure Physics, 1996, 10(4): 299–303. DOI: 10.11858/gywlxb.1996.04.010.

|

| [10] |

王青松. 泡沫态硅橡胶冲击绝热线的近似计算 [J]. 高压物理学报, 2010, 24(2): 120–124. DOI: 10.11858/gywlxb.2010.02.007.WANG Q S. Calculation of the Hugoniot of silicon rubber foam [J]. Chinese Journal of High Pressure Physics, 2010, 24(2): 120–124. DOI: 10.11858/gywlxb.2010.02.007.

|

| [11] |

李欣竹, 吴强, 张汉钊, 等. 泡沫硅橡胶冲击压缩性实验研究 [J]. 高压物理学报, 1998, 12(4): 291–297. DOI: 10.11858/gywlxb.1998.04.008.LI X Z, WU Q, ZHANG H Z, et al. Study on the shock compression of foam silicon rubber [J]. Chinese Journal of High Pressure Physics, 1998, 12(4): 291–297. DOI: 10.11858/gywlxb.1998.04.008.

|

| [12] |

MORRIS C E, FRITZ J N, MCQUEEN R G. The equation of state of polytetrafluoroethylene to 80 GPa [J]. The Journal of Chemical Physics, 1984, 80(10): 5203–5218. DOI: 10.1063/1.446591.

|

| [13] |

DATTELBAUM D M, COE J D, RIGG P A, et al. Shockwave response of two carbon fiber-polymer composites to 50 GPa [J]. Journal of Applied Physics, 2014, 116: 194308. DOI: 10.1063/1.4898313.

|

| [14] |

KERLEY G I. Equation of state and constitutive models for numerical simulations of dust impacts on the solar probe: KTS09-1 [R]. Maryland: Johns Hopkins University Applied Physics Laboratory, 2013.

|

| [15] |

HAMDANI S, LONGUET C, PERRIN D, et al. Flame retardancy of silicone-based materials [J]. Polymer Degradation and Stability, 2009, 94(4): 465–495. DOI: 10.1016/j.polymdegradstab.2008.11.019.

|

| [16] |

GRASSIE N, MACFARLANE I G. The thermal degradation of polysiloxanes-Ⅰ: poly(dimethylsiloxane) [J]. European Polymer Journal, 1978, 14(11): 875–884. DOI: 10.1016/0014-3057(78)90084-8.

|

| [17] |

CAMINO G, LOMAKIN S M, LAZZARI M. Polydimethylsiloxane thermal degradation: Part 1. kinetic aspects [J]. Polymer, 2001, 42(6): 2395–2402. DOI: 10.1016/S0032-3861(00)00652-2.

|

| [18] |

CAMINO G, LOMAKIN S M, LAGEARD M. Thermal polydimethylsiloxane degradation: Part 2. the degradation mechanisms [J]. Polymer, 2002, 43(7): 2011–2015. DOI: 10.1016/S0032-3861(01)00785-6.

|

| [19] |

JOVANOVIC J D, GOVEDARICA M N, DVORNIC P R, et al. The thermogravimetric analysis of some polysiloxanes [J]. Polymer Degradation and Stability, 1998, 61(1): 87–93. DOI: 10.1016/S0141-3910(97)00135-3.

|

| [20] |

RADHAKRISHNAN T S. New method for evaluation of kinetic parameters and mechanism of degradation from pyrolysis-GC studies: thermal degradation of polydimethylsiloxanes [J]. Journal of Applied Polymer Science, 1999, 73(3): 441–450. DOI: 10.1002/(SICI)1097-4628(19990718)73:3<441::AID-APP16>3.0.CO;2-J.

|

| [21] |

HAYASHIDA K, TSUGE S, OHTANI H. Flame retardant mechanism of polydimethylsiloxane material containing platinum compound studied by analytical pyrolysis techniques and alkaline hydrolysis gas chromatography [J]. Polymer, 2003, 44(19): 5611–5616. DOI: 10.1016/S0032-3861(03)00622-0.

|

| [22] |

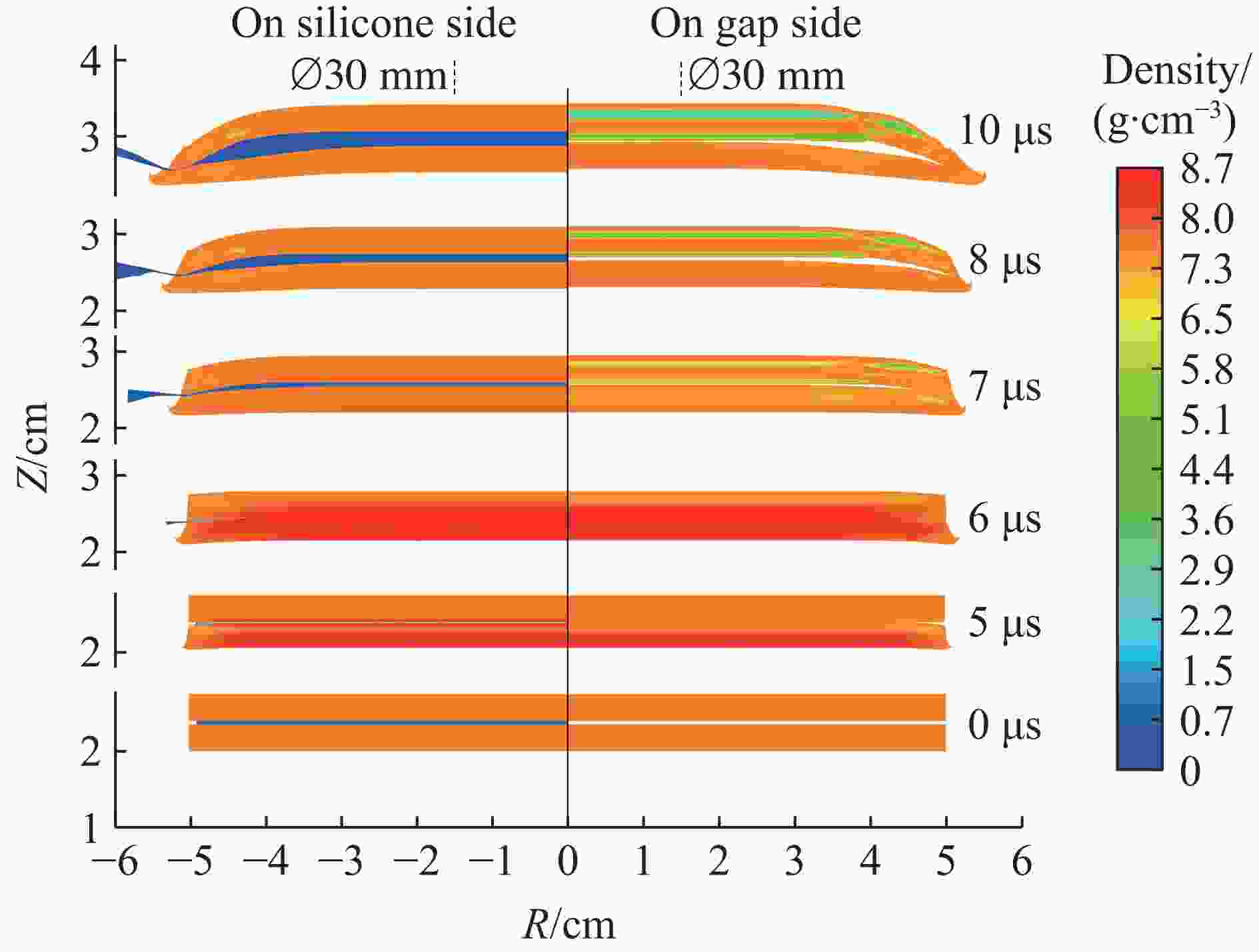

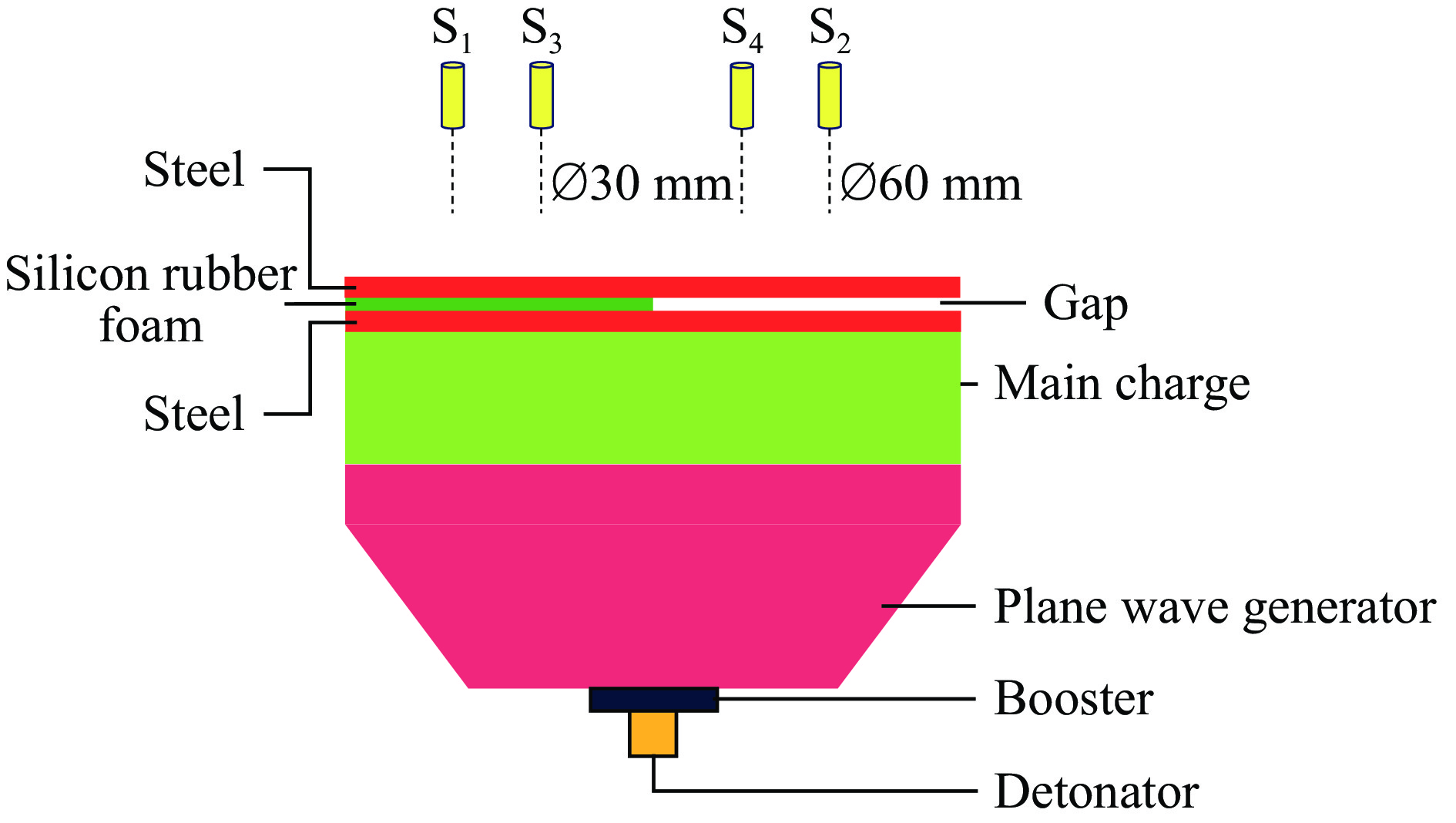

李涛, 刘明涛, 王晓燕, 等. 装配垫层与间隙对爆轰加载下金属飞片运动特征的影响 [J]. 高压物理学报, 2018, 32(4): 044202. DOI: 10.11858/gywlxb.20170576.LI T, LIU M T, WANG X Y, et al. Effects of explosive device with foam cushion and air clearance on kinetic characteristic of steel flyer under detonation loading [J]. Chinese Journal of High Pressure Physics, 2018, 32(4): 044202. DOI: 10.11858/gywlxb.20170576.

|

| [23] |

刘军, 孙致远, 张凤国, 等. 间隙对爆轰加载下金属飞片运动特征影响的模拟分析 [J]. 爆炸与冲击, 2023, 43(4): 042201. DOI: 10.11883/bzycj-2022-0239.LIU J, SUN Z Y, ZHANG F G, et al. Simulation analysis of the effect of clearance on motion characteristic of metal flyer under detonation loading [J]. Explosion and Shock Waves, 2023, 43(4): 042201. DOI: 10.11883/bzycj-2022-0239.

|

| [24] |

WHIRLEY R G, ENGELMANN B E. DYNA2D: a nonlinear, explicit, two-dimensional finite element code for solid mechanics: user manual: UCRL-MA-110630 [R]. USA: Lawrence Livermore National Laboratory, 1992.

|

| [25] |

孙承纬. 炸药平面波透镜的有效药量 [C]//爆轰研究论文集(第3卷). 绵阳: 中国工程物理研究院流体物理研究所, 1998: 307–316.

|

| [26] |

STEINBERG D J. Equation of state and strength properties of selected materials: UCRL-MA-106439 [R]. USA: Lawrence Livermore National Laboratory, 1991.

|

| [27] |

张林, 张祖根, 秦晓云, 等. D6A、921和45钢的动态破坏与低压冲击特性 [J]. 高压物理学报, 2003, 17(4): 305–310. DOI: 10.11858/gywlxb.2003.04.011.ZHANG L, ZHANG Z G, QIN X Y, et al. Dynamic fracture and mechanical property of D6A, 921 and 45 steels under low shock pressure [J]. Chinese Journal of High Pressure Physics, 2003, 17(4): 305–310. DOI: 10.11858/gywlxb.2003.04.011.

|

| [28] |

胡昌明, 贺红亮, 胡时胜. 45号钢的动态力学性能研究 [J]. 爆炸与冲击, 2003, 23(2): 188–192. DOI: 10.11883/1001-1455(2003)02-0188-5.HU C M, HE H L, HU S S. A study on dynamic mechancial behaviors of 45 steel [J]. Explosion and Shock Waves, 2003, 23(2): 188–192. DOI: 10.11883/1001-1455(2003)02-0188-5.

|

| [29] |

HERRMANN W. Constitutive equation for the dynamic compaction of ductile porous materials [J]. Journal of Applied Physics, 1969, 40(6): 2490–2499. DOI: 10.1063/1.1658021.

|

| [30] |

CARROLL M, HOLT A C. Suggested modification of the P-α model for porous materials [J]. Journal of Applied Physics, 1972, 43(2): 759–761. DOI: 10.1063/1.1661203.

|

| [31] |

DOBRATZ B M, CRAWFORD P C. LLNL explosives handbook properties of chemical explosives and explosive simulants: UCRL-52997 [R]. Livermore: Lawrence Livermore National Laboratory, 1985.

|

| [32] |

董海山, 周芬芬. 高能炸药及相关物性能 [M]. 北京: 科学出版社, 1989.

|

| [33] |

DOBRATZ B M. Properties of chemical explosives and explosive simulants: UCRL-51319 [R]. Livermore: Lawrence Livermore National Laboratory, 1972.

|

| [34] |

PARTOM Y. Detonation products EOS by specifying Gamma (V) for the principal isentrope [J]. Journal of Energetic Materials, 2011, 29(3): 193–208. DOI: 10.1080/07370652.2010.514888.

|

| [35] |

PARTOM Y. Calibrating Grüneisen-Gamma (V) in the framework of the adiabatic-Gamma (V) EOS for detonation products [J]. Journal of Energetic Materials, 2012, 30(3): 252–264. DOI: 10.1080/07370652.2011.573524.

|

| [36] |

YANG D, ZHANG W, JIANG B Z, et al. Silicone rubber ablative composites improved with zirconium carbide or zirconia [J]. Composites Part A: Applied Science and Manufacturing, 2013, 44: 70–77. DOI: 10.1016/j.compositesa.2012.09.002.

|

| [37] |

BELYAEV A F, BOBOLEV V K, KOROTKOV A I, et al. Shock-initiated detonation: determination of critical initiation pressures: SAND-76-6016 [R]. Albuquence, USA: Sandia National Laboratories, 1976.

|

下载:

下载: