Rock breaking effect of plasma blasting under confining pressure

-

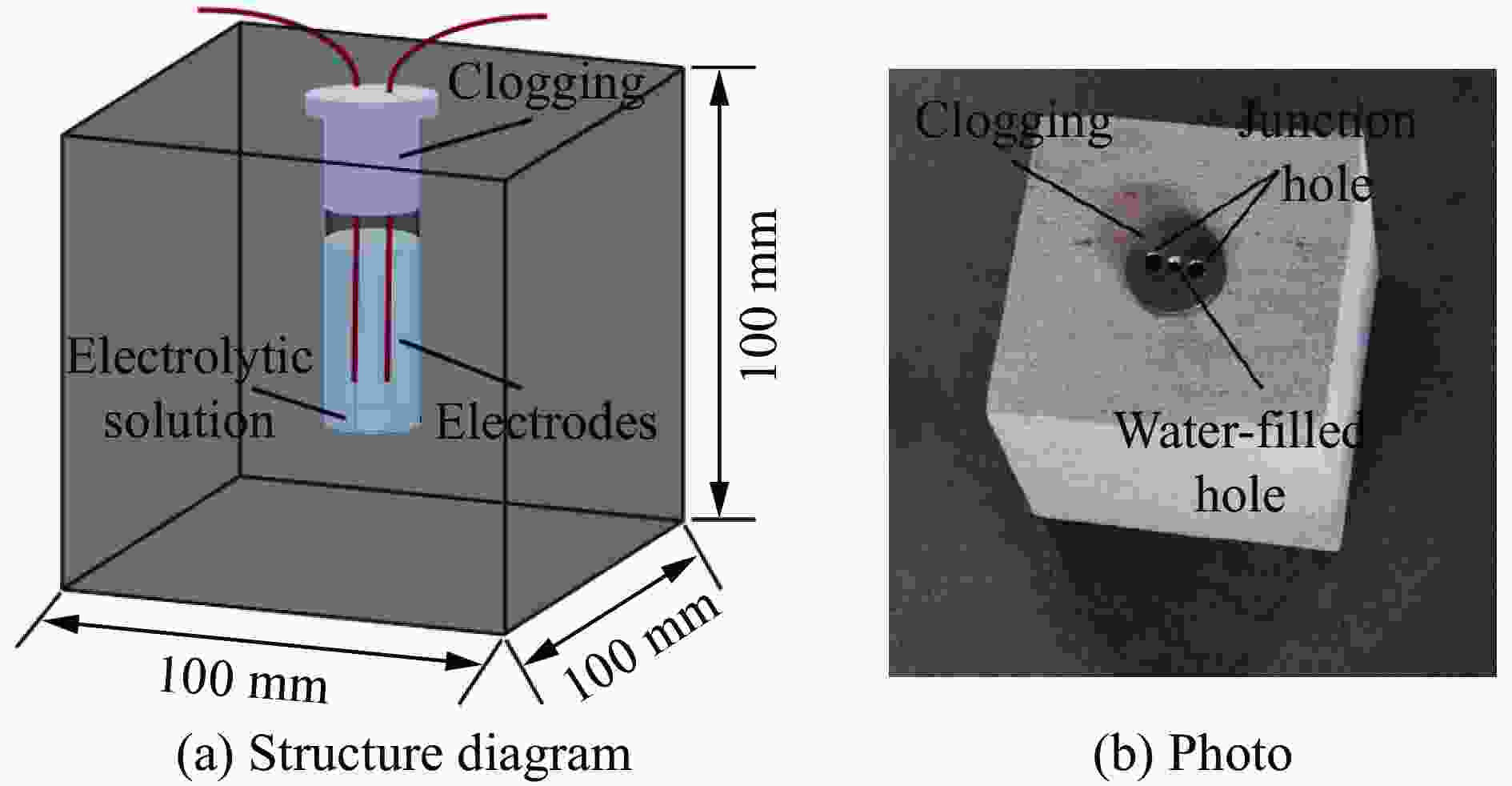

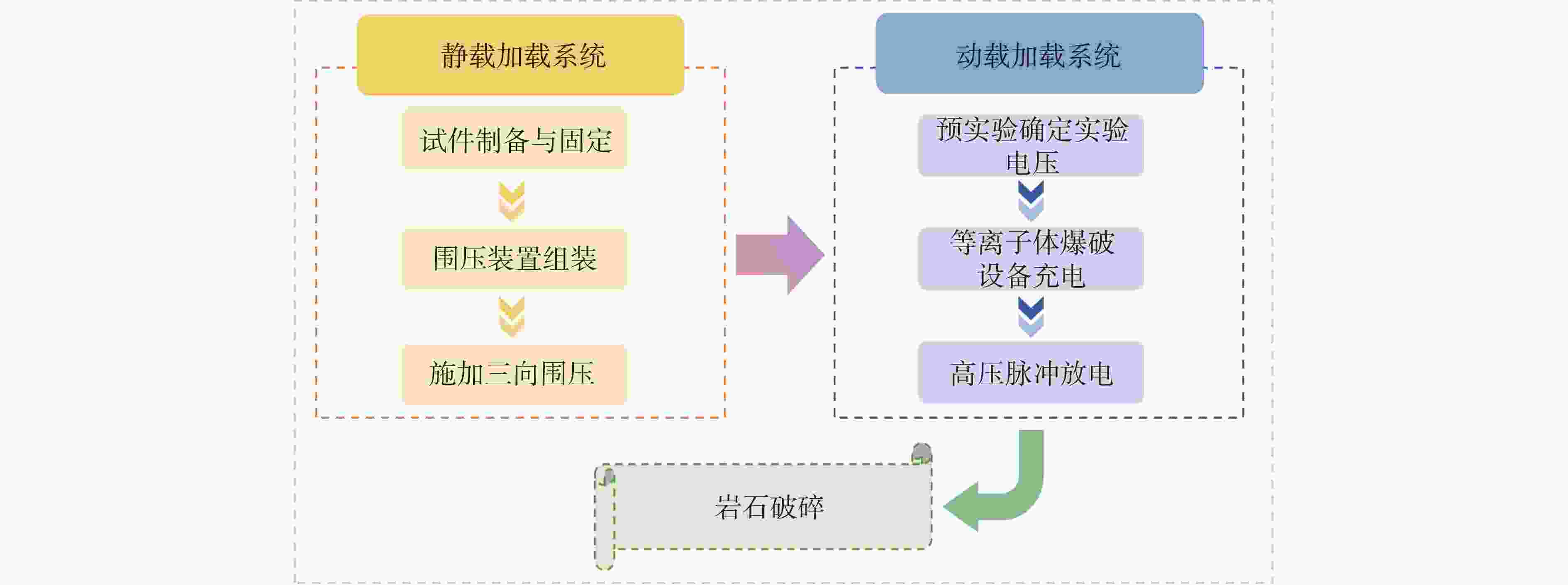

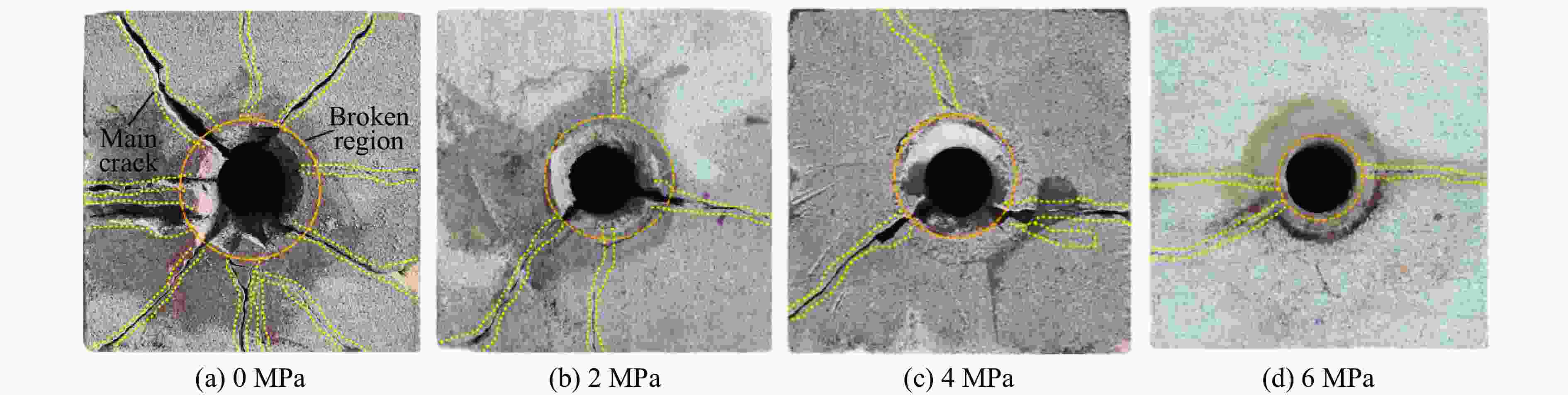

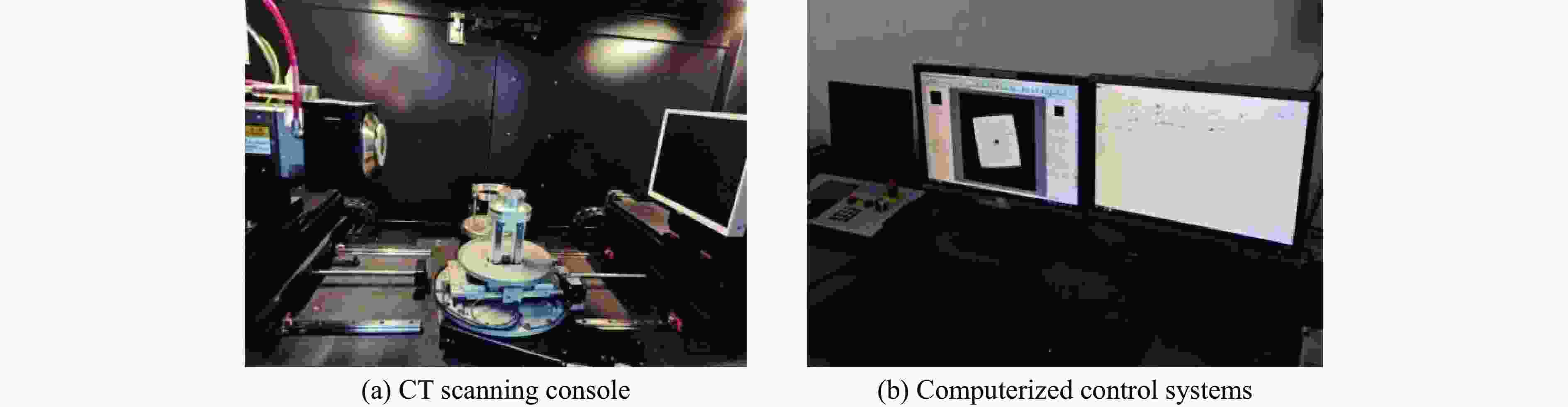

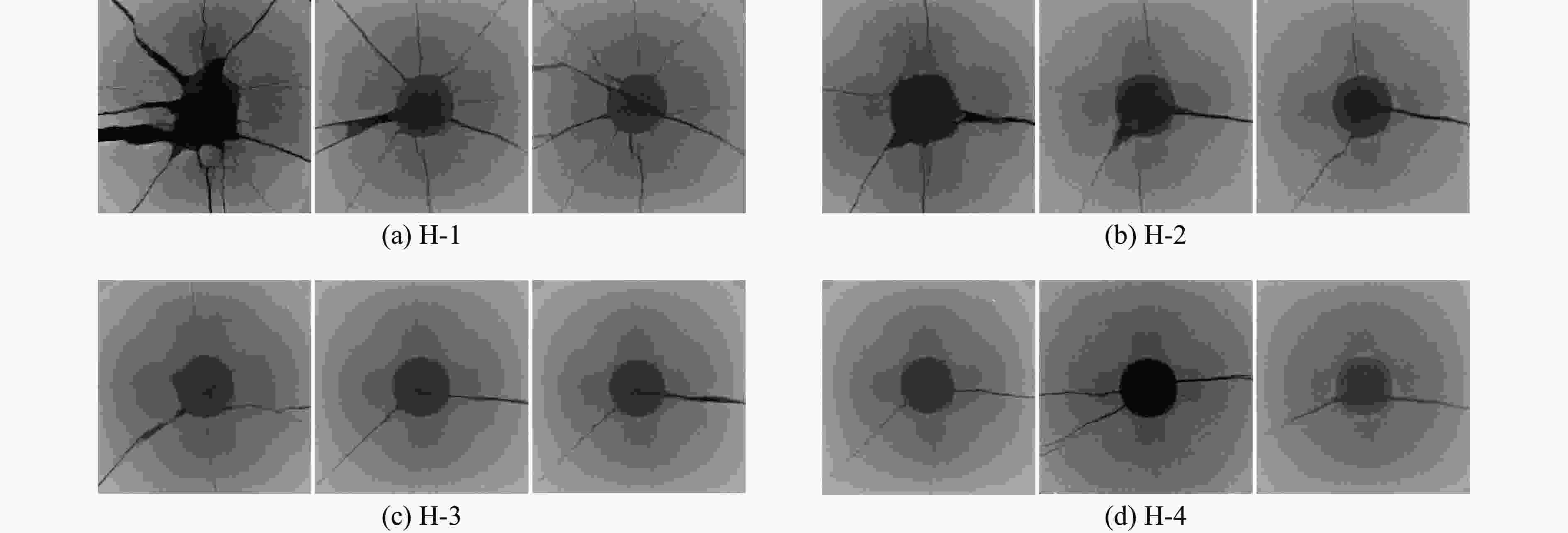

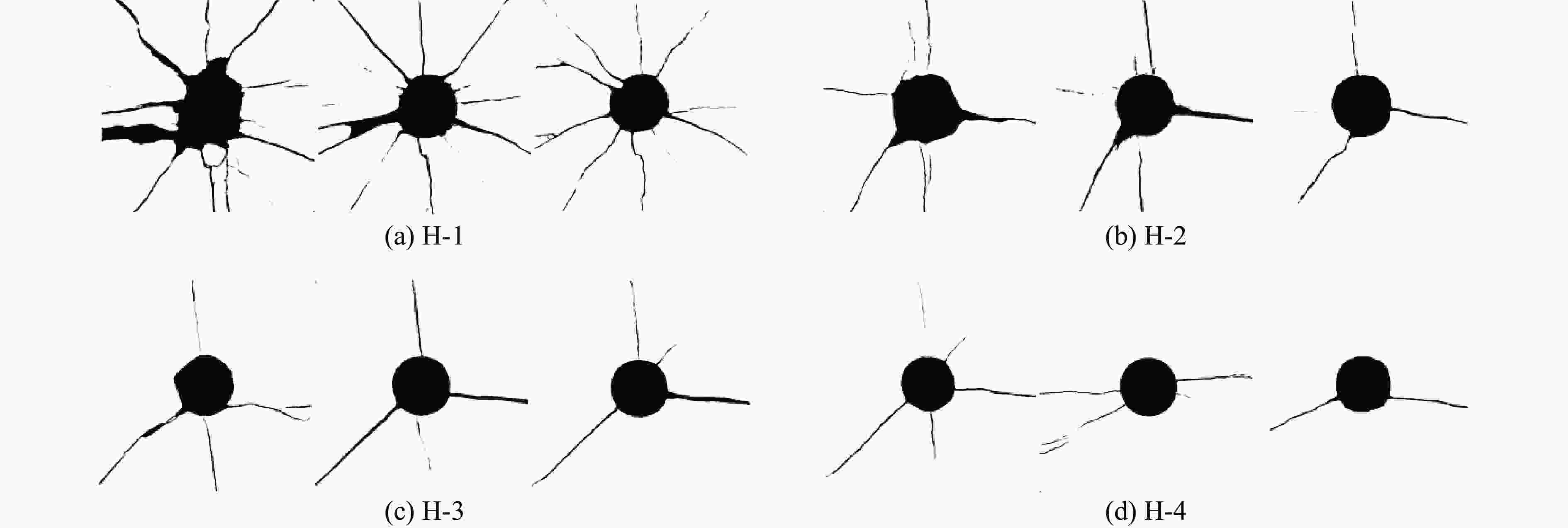

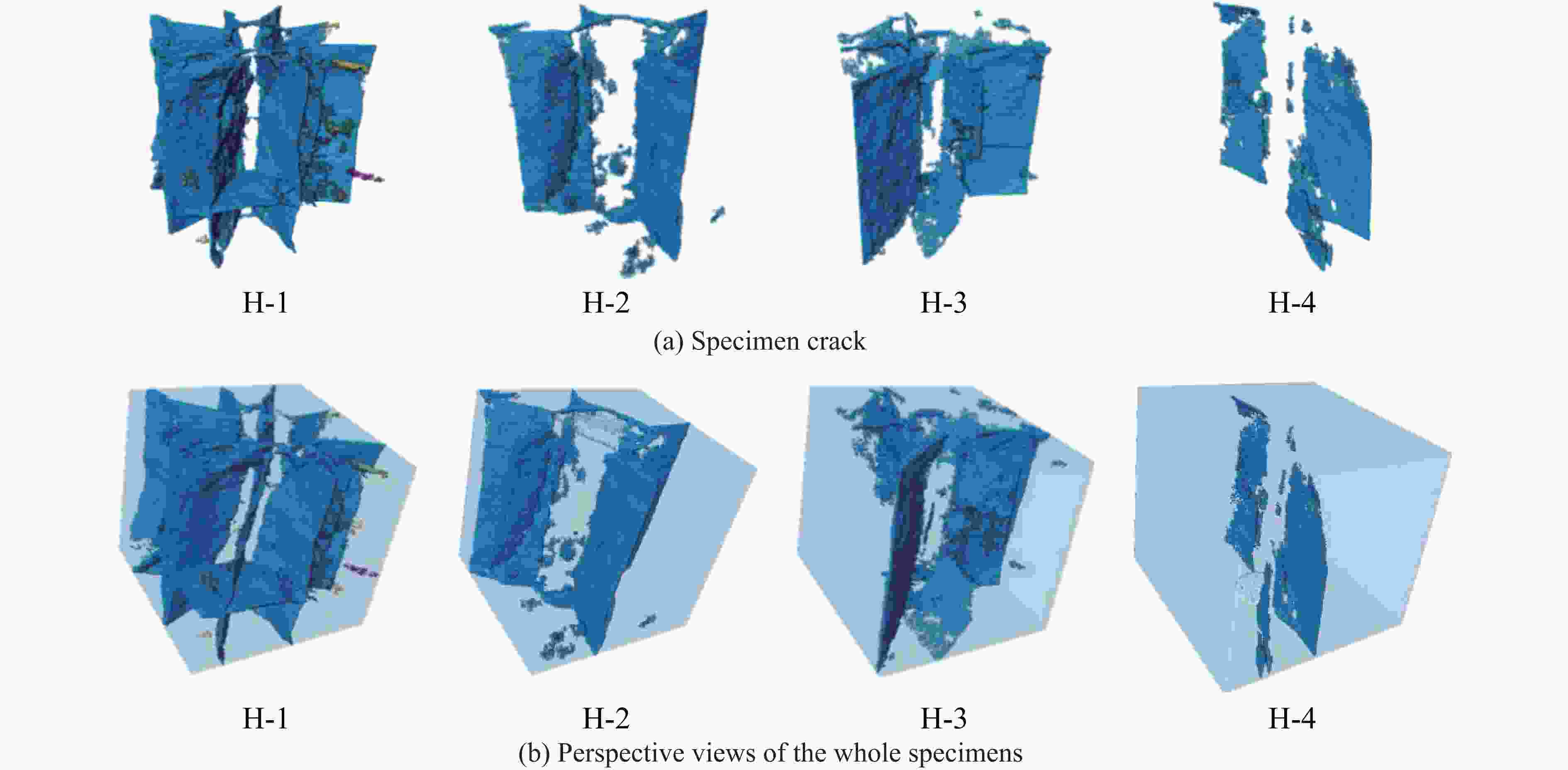

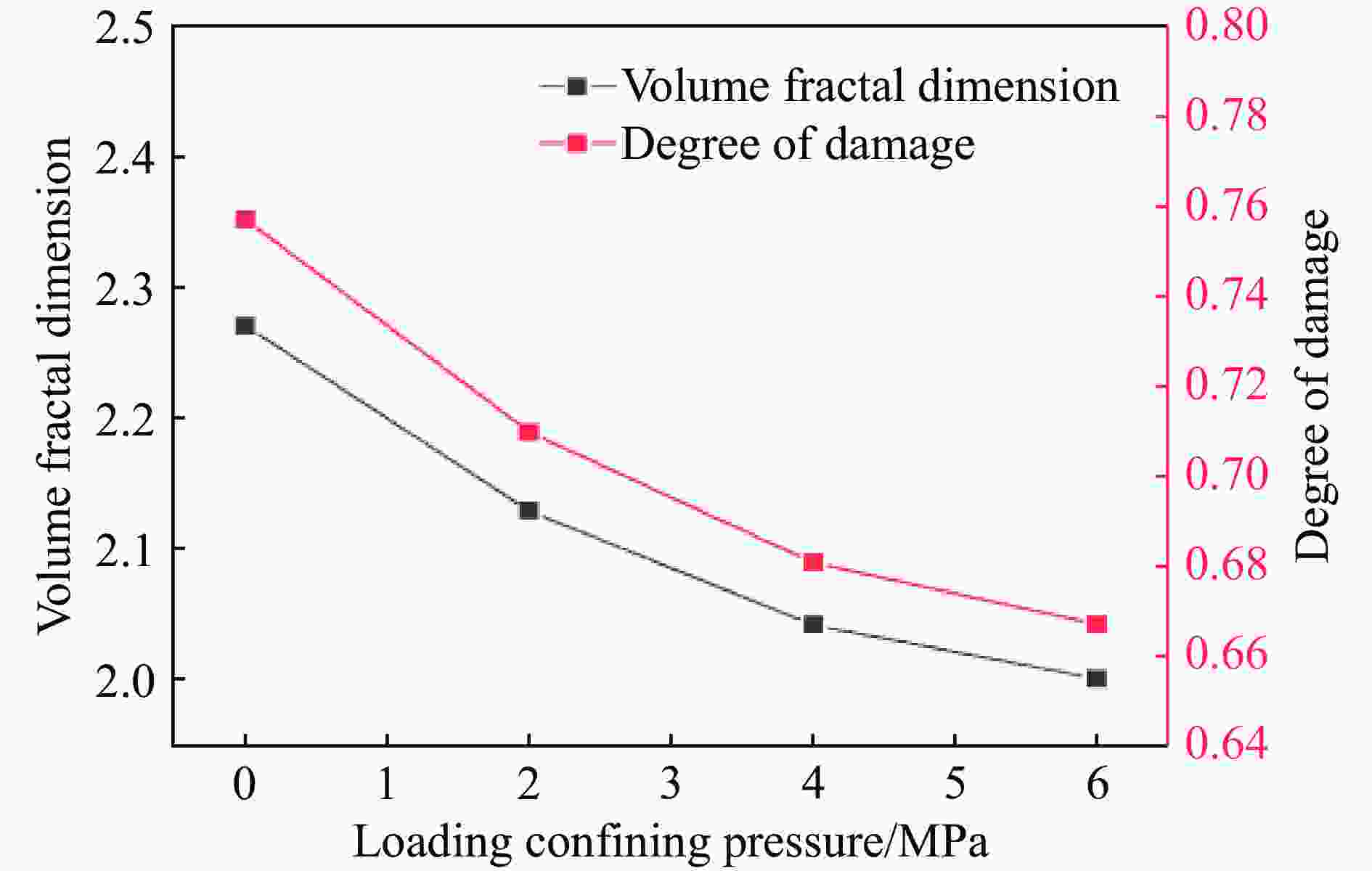

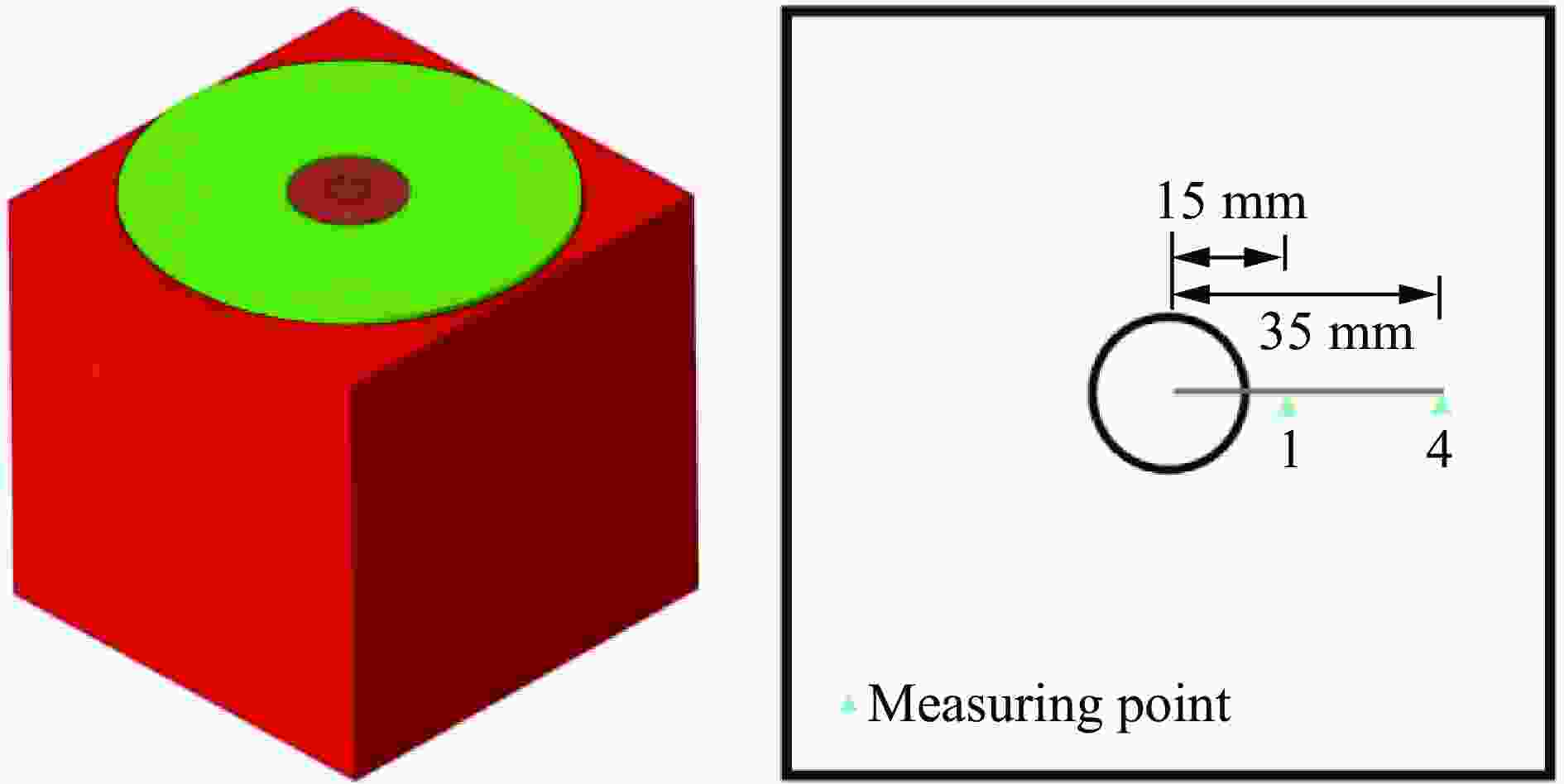

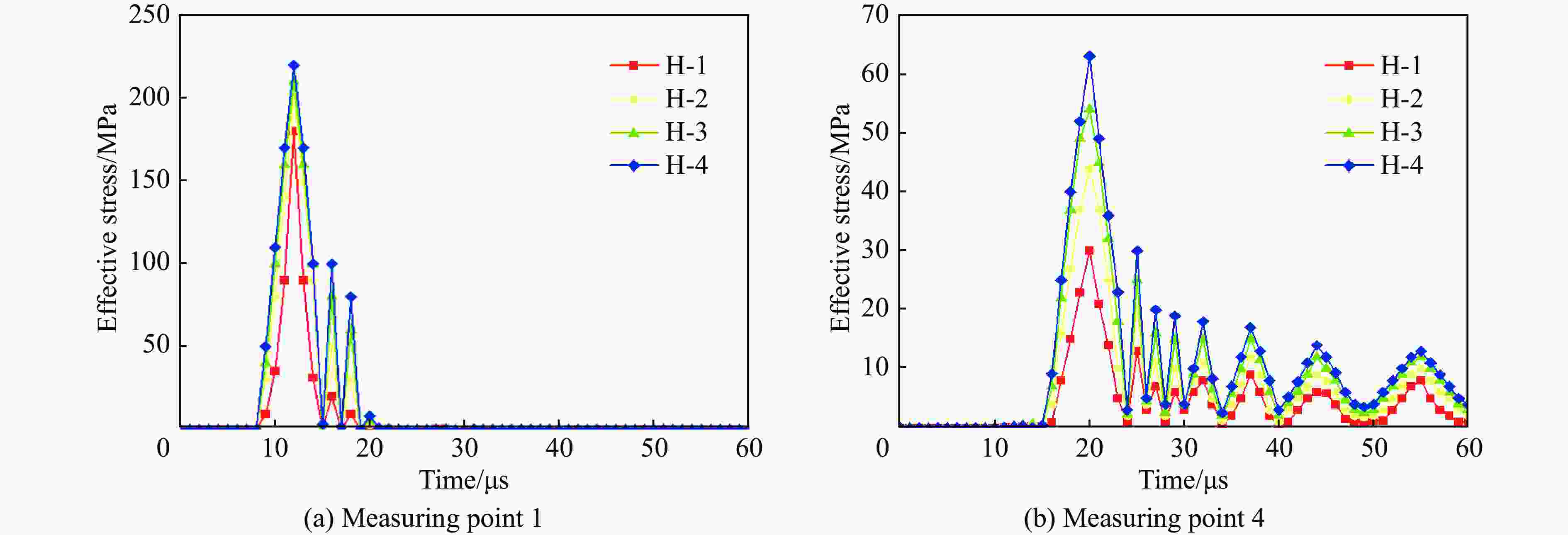

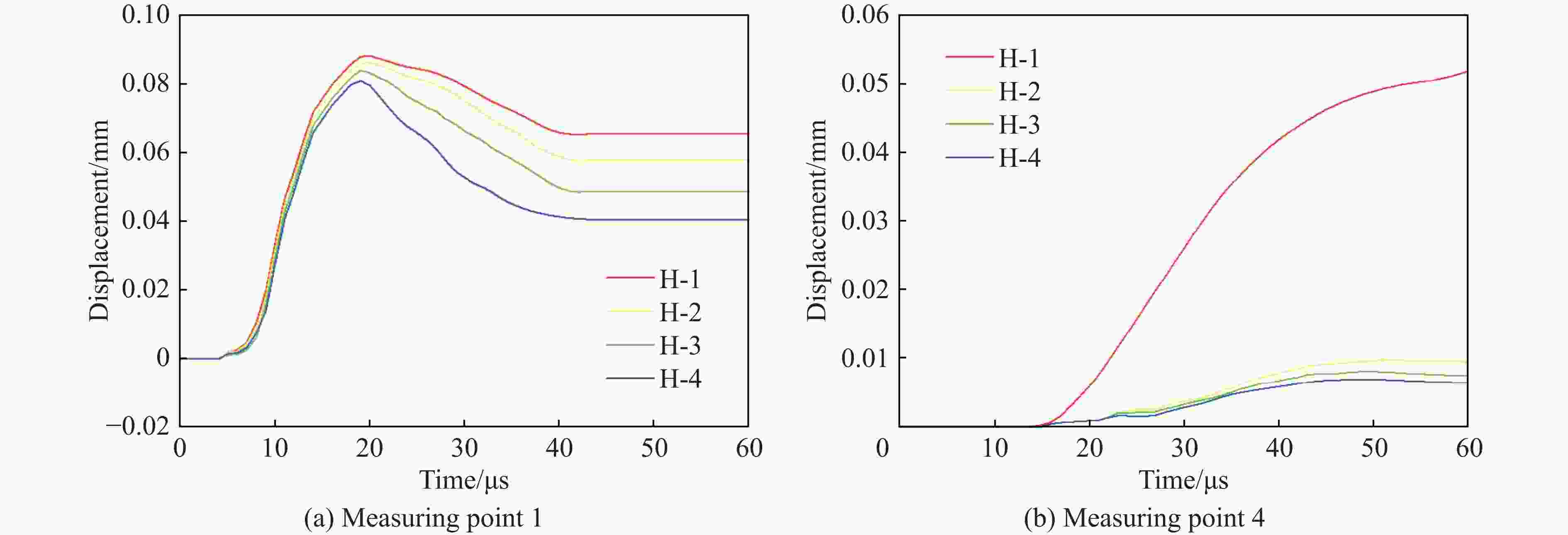

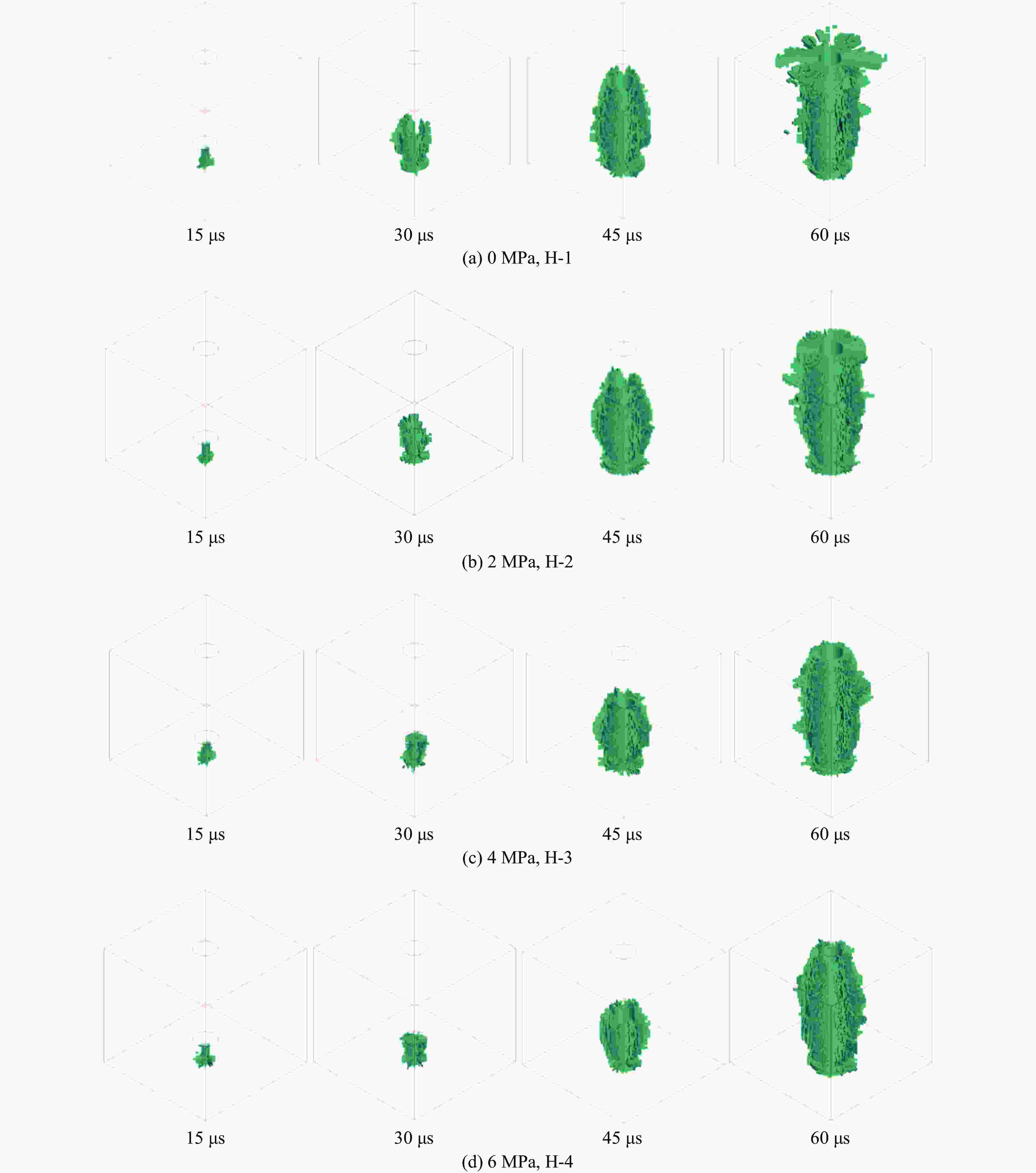

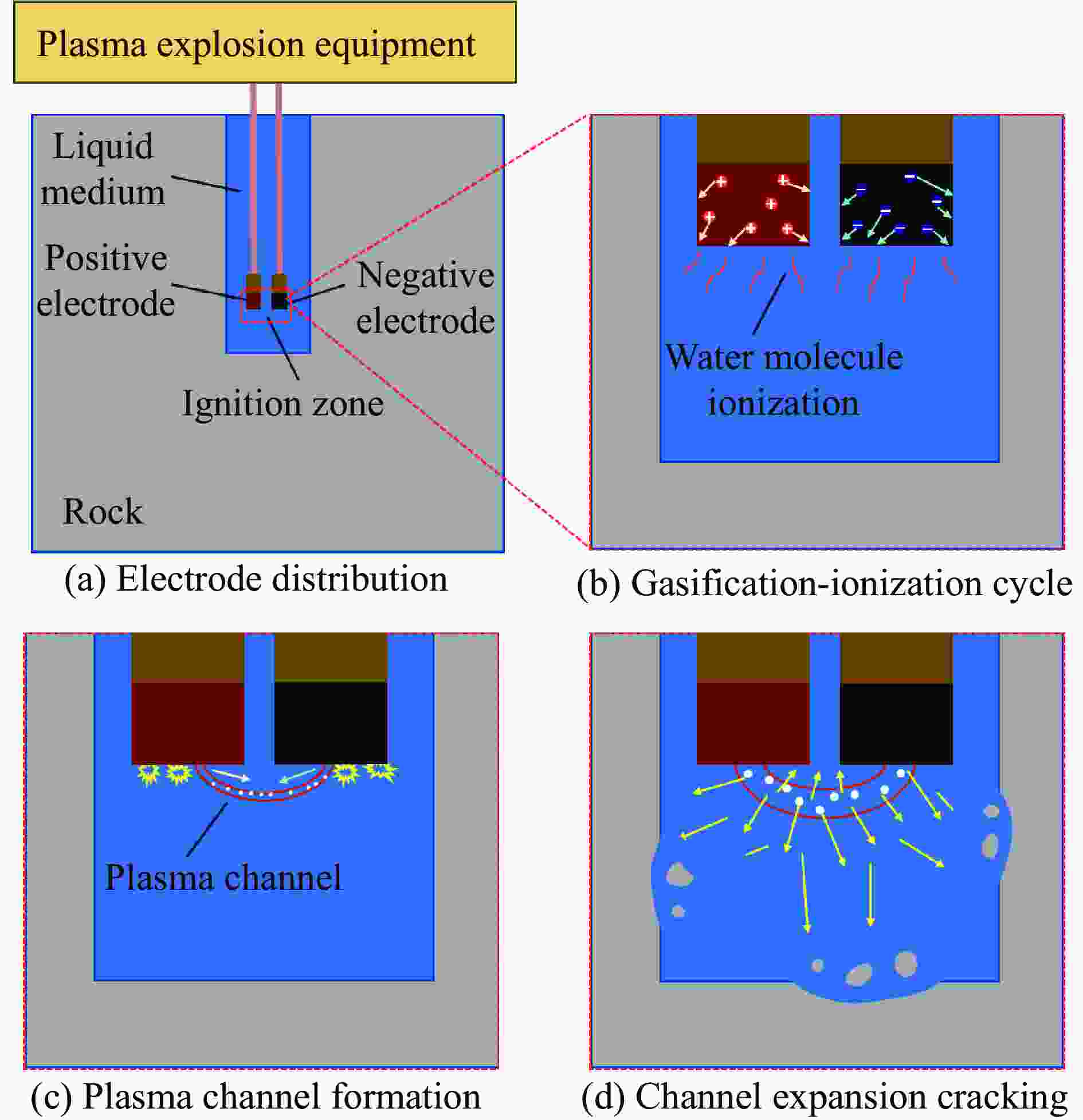

摘要: 为给深部应力作用下爆破破岩工程提供新型破岩方法,开展了4组不同围压作用下的等离子体砂岩爆破实验,通过CT扫描和三维重构,对比分析了岩石内部三维裂纹的形态结构和分布状况,研究了等离子体爆破破岩技术在不同围压作用下的破岩效果,并通过LS-DYNA进行了数值模拟,建立了等离子体等效炸药模型,补充验证了耦合应力场中等离子体爆破的作用规律,探究了不同围压作用下等离子体爆破破岩机理以及在爆破过程中岩体内部的裂纹扩展、分布及损伤演化规律。结果表明:相同电压作用下,随着三向围压的升高,岩石表面裂纹的数量和分布范围都呈逐渐减小的趋势,砂岩内部裂纹的复杂程度和贯通程度显著降低。由于在等离子体爆破产生的动态应力场和围压作用产生的静态应力耦合场中,等离子体爆破产生的冲击波在爆炸初始阶段发挥主要作用,不同围压作用下岩石的裂纹形态和中心膨胀区域未出现明显差异,随着冲击波的衰减,三向围压在等离子体爆破过程的中后期发挥决定作用,抑制岩体的裂纹扩展和损伤演化。同时,围压越高,其对岩体内部裂纹扩展的抑制效果越显著,导致岩石内部三维裂纹的体分形维数和损伤度与围压均近似呈线性减小关系。Abstract: Plasma blasting rock breaking technology is characterized by green, high efficiency, controllability, and has a good application prospect in deep rock breaking. In order to provide a new rock-breaking method for the rock-breaking engineering under deep stress, four groups of plasma sandstone blasting tests under different peripheral pressures were carried out. The morphology, structure and distribution of three-dimensional cracks inside the rock were comparatively analyzed by CT scanning and three-dimensional reconstruction, so as to study the effectiveness of the plasma blasting technology in rock breaking under different peripheral pressures. Meanwhile numerical simulation was conducted by using LS-DYNA to establish the plasma equivalent explosive model, supplementing the verification of the role of plasma blasting in the coupled stress field, and investigating the mechanism of plasma blasting under different pressures, as well as the internal crack expansion, distribution and damage evolution laws in the rock body in the blasting process. The results show that under the same voltage, with the increase of the 3D peripheral pressure, the number and distribution range of cracks on the surface of the rock exhibit a trend of gradual reduction, while the complexity of the cracks within the sandstone and the depth of penetration are significantly reduced. Due to the dynamic stress field generated by plasma blasting and the static stress coupling field generated by the surrounding pressure, the shock wave generated by the plasma blasting in the initial stage of the explosion plays a major role for the effect of different pressures under the action of the rock crack morphology and the center of the expansion of the region does not show obvious differences. With the attenuation of the shock wave, the 3D surrounding pressure in the middle and late stages of the plasma blasting process plays a decisive role in inhibiting the cracks of the rock mass expansion and damage evolution. At the same time, with the increase of the surrounding pressure, the more significant inhibition effect on the expansion of cracks in the rock body, resulting in the body fractal dimension and damage degree of 3D cracks in the rock body, while the role of the surrounding pressure approximately follows a linearly decreasing relationship.

-

表 1 爆后砂岩试件的上表面测量参数

Table 1. Upper surface measurement parameters of sandstone specimens after explosion

砂岩试件 施加围压/MPa 中心粉碎区面积/mm2 裂纹平均宽度/mm 最大裂纹长度/mm H-1 0 1193.99 3.90 53.40 H-2 2 778.92 2.30 49.40 H-3 4 514.46 1.30 46.00 H-4 6 349.49 0.60 43.00 表 2 不同围压下岩石试件裂纹的特征参数

Table 2. Fracture characteristic parameters for sandstone specimens under different confining pressures

岩石试件 加载围压/

MPa裂纹表面积/

mm2裂纹密度/

mm−1裂纹有效

直径/mmH-1 0 28558.44 0.029 4.75 H-2 2 17146.92 0.017 4.20 H-3 4 12401.51 0.012 3.74 H-4 6 9503.69 0.010 3.39 -

[1] 庞宁波, 杨永康. 地应力下岩石多孔爆破损伤演化数值模拟 [J]. 矿业研究与开发, 2023, 43(10): 119–125. DOI: 10.13827/j.cnki.kyyk.2023.10.018.PANG N B, YANG Y K. Numerical simulation on damage evolution of rock porous blasting under in-situ stress [J]. Mining Research and Development, 2023, 43(10): 119–125. DOI: 10.13827/j.cnki.kyyk.2023.10.018. [2] 吴立, 张时忠, 林峰. 现代破岩方法综述 [J]. 探矿工程(岩土钻掘工程), 2000(2): 49–51. DOI: 10.3969/j.issn.1672-7428.2000.02.022.WU L, ZHANG S Z, LIN F. Synthesizing comment on modern rock fragmentation methods [J]. Exploration Engineering (Rock & Soil Drilling and Tunneling), 2000(2): 49–51. DOI: 10.3969/j.issn.1672-7428.2000.02.022. [3] 孙冰. 液相放电等离子体及其应用 [M]. 北京: 科学出版社, 2013: 7–11.SUN B. Discharge plasma in liquid and its applications[M]. Beijing: Science Press, 2013: 7–11. [4] 何满潮, 谢和平, 彭苏萍, 等. 深部开采岩体力学研究 [J]. 岩石力学与工程学报, 2005, 24(16): 2803–2813. DOI: 10.3321/j.issn:1000-6915.2005.16.001.HE M C, XIE H P, PENG S P, et al. Study on rock mechanics in deep mining engineering [J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(16): 2803–2813. DOI: 10.3321/j.issn:1000-6915.2005.16.001. [5] 陈明, 卢文波, 周创兵, 等. 初始地应力对隧洞开挖爆生裂隙区的影响研究 [J]. 岩土力学, 2009, 30(8): 2254–2258. DOI: 10.16285/j.rsm.2009.08.024.CHEN M, LU W B, ZHOU C B, et al. Influence of initial in-situ stress on blasting-induced cracking zone in tunnel excavation [J]. Rock and Soil Mechanics, 2009, 30(8): 2254–2258. DOI: 10.16285/j.rsm.2009.08.024. [6] 杨栋, 李海波, 夏祥, 等. 高地应力条件下爆破开挖诱发围岩损伤的特性研究 [J]. 岩土力学, 2014, 35(4): 1110–1116, 1122. DOI: 10.16285/j.rsm.2014.04.012.YANG D, LI H B, XIA X, et al. Study of blasting-induced dynamic damage of tunnel surrounding rocks under high in-situ stress [J]. Rock and Soil Mechanics, 2014, 35(4): 1110–1116, 1122. DOI: 10.16285/j.rsm.2014.04.012. [7] 梁瑞, 李生荣, 包娟, 等. 高地应力下岩体的爆破损伤及能量特性 [J]. 高压物理学报, 2022, 36(6): 064202. DOI: 10.11858/gywlxb.20220599.LIANG R, LI S R, BAO J, et al. Blasting damage and energy characteristics of rock mass under high in-situ stress [J]. Chinese Journal of High Pressure Physics, 2022, 36(6): 064202. DOI: 10.11858/gywlxb.20220599. [8] 马泗洲, 刘科伟, 杨家彩, 等. 初始应力下岩体爆破损伤特性及破裂机理 [J]. 爆炸与冲击, 2023, 43(10): 105201. DOI: 10.11883/bzycj-2023-0151.MA S Z, LIU K W, YANG J C, et al. Blast-induced damage characteristics and fracture mechanism of rock mass under initial stress [J]. Explosion and Shock Waves, 2023, 43(10): 105201. DOI: 10.11883/bzycj-2023-0151. [9] LI X D, LU K W, YANG J C, et al. Numerical study on blast-induced fragmentation in deep rock mass [J]. International Journal of Impact Engineering, 2022, 170: 104367. DOI: 10.1016/j.ijimpeng.2022.104367. [10] TIMOSHKIN I V, MACKERSIE J W, MACGREGOR S J. Plasma channel miniature hole drilling technology [J]. IEEE Transactions on Plasma Science, 2004, 32(5): 2055–2061. DOI: 10.1109/TPS.2004.835489. [11] 韩育宏, 陆彬, 李庆, 等. 高压脉冲放电等离子体水处理技术研究进展 [J]. 河北大学学报(自然科学版), 2007, 27(S1): 190–194. DOI: 10.3969/j.issn.1000-1565.2007.z1.050.HAN Y H, LU B, LI Q, et al. Research on wastewater treatment by high-voltage plused discharge plasma [J]. Journal of Hebei University (Natural Science Edition), 2007, 27(S1): 190–194. DOI: 10.3969/j.issn.1000-1565.2007.z1.050. [12] 苏尤特金Л A. 液电效应[M]. 于家珊, 译, 北京: 科学出版社,1962: 50.YUTKIN Л A. Electrohydraulic effect [M]. YU J S, trans. Beijing: Science Press, 1962: 50. [13] PENG J Y, ZHANG F P, YANG X H. Dynamic fracture and fragmentation of rock-like materials under column charge blasting using electrical explosion of wires [J]. Powder Technology, 2020, 367: 517–526. DOI: 10.1016/j.powtec.2020.04.012. [14] 张辉, 蔡志翔, 陈安明, 等. 液相放电等离子体破岩室内实验与破岩机理 [J]. 石油学报, 2020, 41(5): 615–628. DOI: 10.7623/syxb202005010.ZHANG H, CAI Z X, CHEN A M, et al. Experiments and mechanism of rock breaking by the plasma shock wave generated by underwater discharge [J]. Acta Petrolei Sinica, 2020, 41(5): 615–628. DOI: 10.7623/syxb202005010. [15] 李铮. 脉冲放电破碎岩石影响规律仿真模拟研究 [D]. 大庆: 东北石油大学, 2022. DOI: 10.26995/d.cnki.gdqsc.2022.000906.LI Z. Simulation research on influence law of pulse discharge on rock breaking [D]. Daqing: Northeast Petroleum University, 2022. DOI: 10.26995/d.cnki.gdqsc.2022.000906. [16] WANG G, QIN X J, SHEN J N, et al. Quantitative analysis of microscopic structure and gas seepage characteristics of low-rank coal based on CT three-dimensional reconstruction of CT images and fractal theory [J]. Fuel, 2019, 256: 115900. DOI: 10.1016/j.fuel.2019.115900. [17] PARK H, LEE S R, KIM T H, et al. Numerical modeling of ground borehole expansion induced by application of pulse discharge technology [J]. Computers and Geotechnics, 2011, 38(4): 532–545. DOI: 10.1016/j.compgeo.2011.03.002. [18] 余庆, 张辉, 杨睿智. 基于LS-DYNA的液电效应冲击波数值模拟[J]. 爆炸与冲击, 2022, 42(2): 024201. DOI: 10.11883/bzycj-2021-0214.YU Q, ZHANG H, YANG R Z. Numerical simulation of the shock wave generated by electro-hydraulic effect based on LS-DYNA [J]. Explosion and Shock Waves, 2022, 42(2): 024201. DOI: 10.11883/bzycj-2021-0214. [19] 黄佑鹏, 王志亮, 杨辉, 等. 流固耦合法模拟岩石爆破时耦合范围的确定 [J]. 合肥工业大学学报(自然科学版), 2019, 42(12): 1672–1678, 1694. DOI: 10.3969/j.issn.1003-5060.2019.12.016.HUANG Y P, WANG Z L, YANG H, et al. Determination of coupling range in the simulation of rock blasting using fluid-solid coupling algorithm [J]. Journal of Hefei University of Technology (Natural Science), 2019, 42(12): 1672–1678, 1694. DOI: 10.3969/j.issn.1003-5060.2019.12.016. [20] 姜鹏飞, 唐德高, 龙源. 不耦合装药爆破对硬岩应力场影响的数值分析 [J]. 岩土力学, 2009, 30(1): 275–279. DOI: 10.16285/j.rsm.2009.01.005.JIANG P F, TANG D G, LONG Y. Numerical analysis of influence of uncoupled explosive-charge structure on stress field in hard rocks [J]. Rock and Soil Mechanics, 2009, 30(1): 275–279. DOI: 10.16285/j.rsm.2009.01.005. [21] 闫国斌, 于亚伦. 空气与水介质不耦合装药爆破数值模拟 [J]. 工程爆破, 2009, 15(4): 13–19, 65. DOI: 10.3969/j.issn.1006-7051.2009.04.004.YAN G B, YU Y L. Numerical simulation of air and water medium decoupling charge blasting [J]. Engineering Blasting, 2009, 15(4): 13–19, 65. DOI: 10.3969/j.issn.1006-7051.2009.04.004. -

下载:

下载: