Analysis on influencing factors of gas explosion overpressure peak in a U-shaped ventilation coal face based on orthogonal test

-

摘要: 为探究U形通风采煤工作面瓦斯爆炸的传播规律,并探讨瓦斯爆炸超压衰减对不同影响因素的敏感性,利用Fluent模拟软件并结合某矿3906工作面情况开展了数值模拟研究。首先,根据瓦斯爆炸机理搭建了数学模型,并依据前人实验方案进行了数值模拟,以此验证了该数学模型的可靠性;其次,依序进行了模拟关键参数的优化,并得到了关键参数网格尺寸、迭代步长和点火温度的最合理设置分别为0.2 m、0.05 ms和

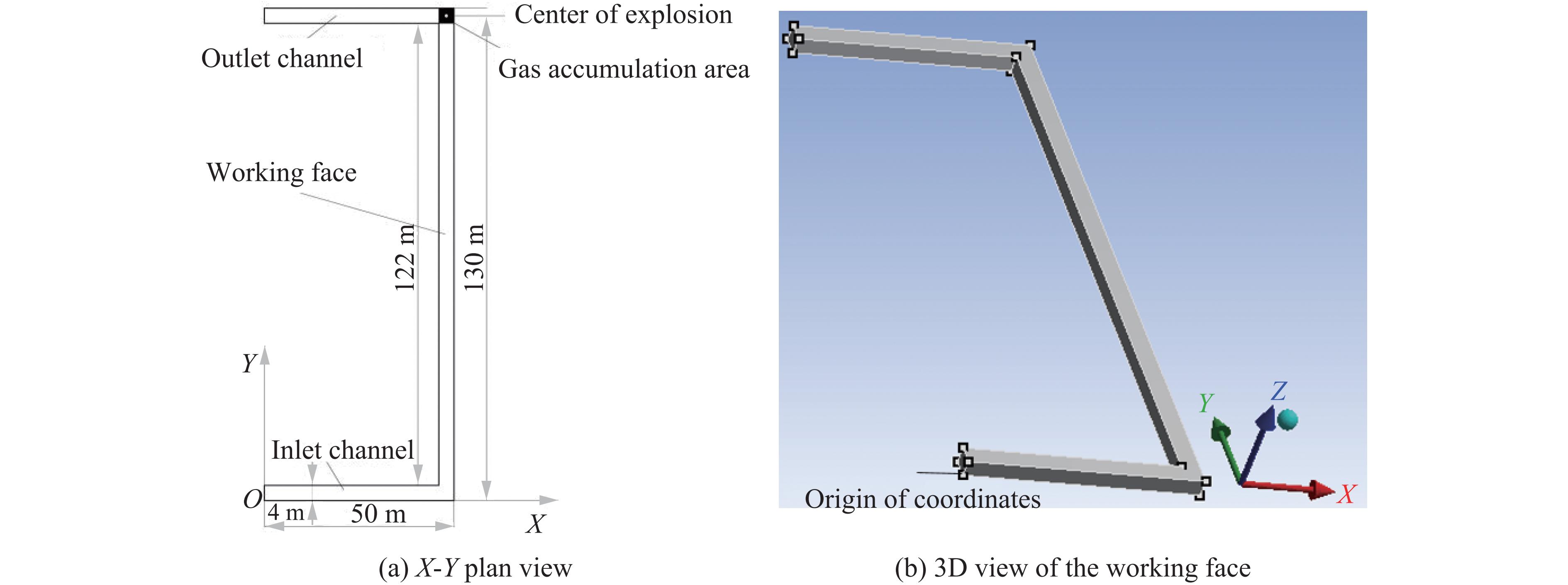

1900 K,通过拟合得到了工作面爆炸超压峰值及其到达时间与爆心距之间的函数关系。通过正交试验分析了瓦斯爆炸超压衰减对不同影响因素的敏感性。极差分析结果表明,温度、瓦斯体积分数和瓦斯积聚区压力3个主控因素的极差值依次减小,温度对于爆炸超压衰减的影响最显著,其中R值达到5.928。运用方差分析对影响瓦斯爆炸超压衰减率的主控因素进行了显著性研究,结果表明,温度的方差值最大,瓦斯积聚区压力的方差值次之,瓦斯体积分数的方差值最小,其中温度的显著值F达到31.835,其余两项不显著。Abstract: Numerical simulation was carried out by using the Fluent simulation software and combining it with the situation of the working face 3906 in a mine to investigate the propagation law of gas explosion in a U-shaped ventilation coal mining face and to explore the sensitivities of the overpressure attenuation of a gas explosion to different influencing factors. The relative errors between the numerically-simulated results and experimental ones are less than 15%, which verifies the reliability of the mathematical model developed in this paper. Then, the key parameters, namely, grid size, iteration time step, and ignition temperature are optimized to 0.2 m, 0.05 ms, and1900 K, respectively. Numerical simulation indicates that the relationship between the peak of the explosion overpressure and the distance away from the explosion center of the coal face meets an exponential function relationship. The relationship between the arrival time of the peak explosion overpressure and the distance away from the explosion center meets a linear function. By designing an orthogonal array, 16 sets of data were obtained through simulation, and the following analyses were conducted based on this data. The extreme difference values of the three main control factors were obtained by using extreme difference analysis. The extreme difference value of the temperature is the greatest, the one of the gas concentration take the second, and the one of the gas accumulation area pressure is the least. The most significant impact of the temperature on the explosion overpressure attenuation in the numerical simulation, in which the R-value reaches 5.928. ANOVA analysis was carried out to study the significances of the main control factors affecting the explosion overpressure attenuation rate. In the three main control factors, the significance of the temperature is the most, the one of the gas accumulation zone pressure comes second, and the one of the gas concentration is the weakest. And the temperature shows a significance level of 31.835, while the other two factors are not significant. -

表 1 网格分布

Table 1. Grid distribution

网格尺寸/m 瓦斯充填区网格数 点火区域网格数 0.15 16284 154 0.20 7200 56 0.25 3584 32 0.30 2148 18 0.35 1310 14 0.40 900 12 0.45 648 6 表 2 监测点的分布

Table 2. Distribution of monitoring points

监测点设置范围 监测点数量 监测点间距/m 120 m≤Y≤125 m 2 5 90 m≤Y<120 m 15 2 30 m≤Y<90 m 12 5 4 m<Y<30 m 13 2 表 3 同等间距下爆炸超压的衰减情况

Table 3. Explosion overpressure attenuation at the same spacing

爆心距区间/m 超压衰减/kPa 时间间隔/ms 超压衰减率/% 爆心距区间/m 超压衰减/kPa 时间间隔/ms 超压衰减率/% 8~18 248.950 13.30 49.0 68~78 11.320 21.05 9.9 18~28 58.417 17.25 22.6 78~88 5.234 21.40 5.1 28~38 29.993 18.15 14.9 88~98 5.491 21.65 5.7 38~48 26.713 19.25 15.6 98~108 6.516 22.00 7.1 48~58 13.329 19.90 9.3 108~118 4.887 22.30 5.8 58~68 17.308 20.45 13.3 表 4 瓦斯爆炸超压传播影响因素的水平设置

Table 4. Level setting of influencing factors of gas explosion overpressure propagation

水平 温度/K 瓦斯积聚区压力/MPa 瓦斯体积分数/% 1 300 0.2 7.5 2 350 0.4 9.5 3 400 0.6 11.5 4 450 0.8 13.5 表 5 瓦斯爆炸超压传播影响因素的正交试验方案

Table 5. Orthogonal test scheme of influencing factors of gas explosion overpressure propagation

组别 温度/K 瓦斯积聚区压力/MPa 瓦斯体积分数/% 组别 温度/K 瓦斯积聚区压力/MPa 瓦斯体积分数/% 1 350 0.4 13.5 9 400 0.8 13.5 2 350 0.2 9.5 10 300 0.4 11.5 3 450 0.2 13.5 11 450 0.4 9.5 4 400 0.4 7.5 12 450 0.8 11.5 5 400 0.2 11.5 13 350 0.8 7.5 6 300 0.6 13.5 14 400 0.6 9.5 7 300 0.2 7.5 15 450 0.6 7.5 8 300 0.8 9.5 16 350 0.6 11.5 表 6 不同影响因素对瓦斯爆炸超压衰减率的影响

Table 6. Influence of different influencing factors on attenuation rate of gas explosion overpressure

组别 影响因素 爆炸超压

衰减率/%组别 影响因素 爆炸超压

衰减率/%瓦斯体积分数/% 温度/K 瓦斯积聚区压力/MPa 瓦斯体积分数/% 温度/K 瓦斯积聚区压力/MPa 1 7.5 400 0.4 87.671 9 11.5 400 0.2 84.191 2 7.5 300 0.2 81.582 10 11.5 300 0.4 80.533 3 7.5 350 0.8 82.149 11 11.5 450 0.8 85.951 4 7.5 450 0.6 85.985 12 11.5 350 0.6 81.035 5 9.5 350 0.2 82.298 13 13.5 350 0.4 81.336 6 9.5 300 0.8 79.163 14 13.5 450 0.2 86.373 7 9.5 450 0.4 86.935 15 13.5 300 0.6 80.255 8 9.5 400 0.6 82.851 16 13.5 400 0.8 83.019 表 7 极差分析

Table 7. Range analysis

因素 K ${K_{ij}} $ 最佳水平 Rj 水平1 水平2 水平3 水平4 水平1 水平2 水平3 水平4 A 337.387 331.247 331.710 330.983 84.346 82.812 82.928 82.746 1 1.6 B 321.533 326.818 337.732 345.244 80.383 81.705 84.433 86.311 4 5.928 C 334.444 336.475 330.126 330.282 83.611 84.119 82.532 82.571 2 1.587 注:K为i水平j因素下4组试验结果瓦斯爆炸超压衰减率之和,$ {K_{ij}} $为对应的K的平均值,i = 1,2,3,4,j = 1,2,3; $ {R_j} = \max \{ {K_{1j}}, $$ {K_{2j}},{K_{3j}},{K_{4j}}\} - \min \{ {K_{1j}}, {K_{2j}},{K_{3j}},{K_{4j}}\} $, R为某一因素下不同水平之间的极差,即最大值减去最小值,其中R越大,表明该因素水平的改变对爆炸超压衰减的影响越大。 表 8 试验方案及数据分析

Table 8. Test scheme and data analysis

方差来源 $ K_{1j}^2 $ $ K_{2j}^2 $ $K_{3j}^2 $ $K_{4j}^2 $ Sj ST Se 瓦斯体积分数 113829.988 109724.575 110031.524 109549.746 6.98 105.249 5.369 温度 103383.47 106810.005 14062.904 119193.42 85.476 瓦斯积聚区压力 111852.789 113215.426 108983.176 109086.2 7.424 表 9 瓦斯爆炸超压衰减率主控因素方差分析

Table 9. Variance analysis of the main controlling factors of gas explosion overpressure decay ratio

主控因素 离差平方和 自由度 平均离差平方和 F 显著性 瓦斯体积分数 6.98 3 2.327 2.6 温度 85.476 3 28.492 31.835 *** 瓦斯积聚区压力 7.424 3 2.475 2.765 误差 5.369 6 0.895 注:$ {F_{0.01}}(3, 6) = 9.78 $, $ {F_{0.05}}(3, 6) = 4.76 $, $ {F_{0.1}}(3, 6) = 3.29 $;若F>$ {F_{0.01}} $,认为显著性高,用***表示;若$ {F_{0.01}} $>F >$ {F_{0.05}} $,认为显著性中等,用**表示;若$ {F_{0.05}} $>F>$ {F_{0.1}} $,认为显著性低,用*表示;若$ {F_{0.1}} $> F,则该因素无显著性。 -

[1] WANG Y X, FU G, LYU Q, et al. Accident case-driven study on the causal modeling and prevention strategies of coal-mine gas-explosion accidents: a systematic analysis of coal-mine accidents in China [J]. Resources Policy, 2024, 88: 104425. DOI: 10.1016/j.resourpol.2023.104425. [2] LI Z, CHEN L, YAN H C, et al. Gas explosions of methane-air mixtures in a large-scale tube [J]. Fuel, 2021, 285: 119239. DOI: 10.1016/j.fuel.2020.119239. [3] GUO C W, SHAO H, JIANG S G, et al. Effect of low-concentration coal dust on gas explosion propagation law [J]. Powder Technology, 2020, 367: 243–252. DOI: 10.1016/j.powtec.2020.03.045. [4] 贾泉升, 司荣军, 李润之, 等. 初始瓦斯浓度对爆炸温度影响实验研究 [J]. 中国安全生产科学技术, 2021, 17(12): 37–42. DOI: 10.11731/j.issn.1673-193x.2021.12.006.JIA Q S, SI R J, LI R Z, et al. Experimental research on influence of initial gas concentration on explosion temperature [J]. Journal of Safety Science and Technology, 2021, 17(12): 37–42. DOI: 10.11731/j.issn.1673-193x.2021.12.006. [5] 高娜. 初始温度和初始压力对瓦斯爆炸特性的影响研究 [D]. 南京: 南京理工大学, 2016: 38-43.GAO N. Study on influence of initial temperature and pressure on gas explosion characteristics [D]. Nanjing: Nanjing University of Science and Technology, 2016: 38-43. [6] 李润之, 黄子超, 司荣军. 环境温度对瓦斯爆炸压力及压力上升速率的影响 [J]. 爆炸与冲击, 2013, 33(4): 415–419. DOI: 10.11883/1001-1455(2013)04-0415-05.LI R Z, HUANG Z C, SI R J. Influence of environmental temperature on gas explosion pressure and its rise rate [J]. Explosion and Shock Waves, 2013, 33(4): 415–419. DOI: 10.11883/1001-1455(2013)04-0415-05. [7] 高娜, 张延松, 胡毅亭. 温度压力对瓦斯爆炸危险性影响的实验研究 [J]. 爆炸与冲击, 2016, 36(2): 218–223. DOI: 10.11883/1001-1455(2016)02-0218-06.GAO N, ZHANG Y S, HU Y T. Experimental study on gas explosion hazard under different temperatures and pressures [J]. Explosion and Shock Waves, 2016, 36(2): 218–223. DOI: 10.11883/1001-1455(2016)02-0218-06. [8] ZHANG X B, GAO J L, REN J Z, et al. Analysis of the characteristics and influencing factors of gas explosion in heading face [J]. Shock and Vibration, 2020, 2020: 8871865. DOI: 10.1155/2020/8871865. [9] 赵军凯, 王磊, 滑帅, 等. 瓦斯浓度对瓦斯爆炸影响的数值模拟研究 [J]. 矿业安全与环保, 2012, 39(4): 1–4. DOI: 10.3969/j.issn.1008-4495.2012.04.001.ZHAO J K, WANG L, HUA S, et al. Numerical simulation study on effect of gas concentration upon gas explosion [J]. Mining Safety and Environmental Protection, 2012, 39(4): 1–4. DOI: 10.3969/j.issn.1008-4495.2012.04.001. [10] YE Q, WANG G G X, JIA Z Z, et al. Experimental study on the influence of wall heat effect on gas explosion and its propagation [J]. Applied Thermal Engineering, 2017, 118: 392–397. DOI: 10.1016/j.applthermaleng.2017.02.084. [11] 余明高, 陈传东, 王雪燕, 等. 管道内瓦斯非均匀预混火焰传播特性实验研究 [J]. 煤炭学报, 2021, 46(6): 1781–1790. DOI: 10.13225/j.cnki.jccs.HZ21.0426.YU M G, CHEN C D, WANG X Y, et al. Experimental study on combustion characteristics of non-uniform premixed gas within a pipeline [J]. Journal of China Coal Society, 2021, 46(6): 1781–1790. DOI: 10.13225/j.cnki.jccs.HZ21.0426. [12] 贾智伟, 许胜铭, 景国勋. 瓦斯爆炸冲击波在单向分叉管道内的传播规律试验研究 [J]. 中国安全科学学报, 2015, 25(12): 51–55. DOI: 10.16265/j.cnki.issn1003-3033.2015.12.009.JIA Z W, XU S M, JING G X. Experimental study on propagation law of gas explosion shock wave in one-way bifurcated pipeline [J]. China Safety Science Journal, 2015, 25(12): 51–55. DOI: 10.16265/j.cnki.issn1003-3033.2015.12.009. [13] EMAMI S D, RAJABI M, HASSAN C R C, et al. Experimental study on premixed hydrogen/air and hydrogen-methane/air mixtures explosion in 90 degree bend pipeline [J]. International Journal of Hydrogen Energy, 2013, 38(32): 14115–14120. DOI: 10.1016/j.ijhydene.2013.08.056. [14] LI Q Z, LIN B Q, DAI H M, et al. Explosion characteristics of H2/CH4/air and CH4/coal dust/air mixtures [J]. Powder Technology, 2012, 229: 222–228. DOI: 10.1016/j.powtec.2012.06.036. [15] BLANCHARD R, ARNDT D, GRÄTZ R, et al. Explosions in closed pipes containing baffles and 90 degree bends [J]. Journal of Loss Prevention in the Process Industries, 2010, 23(2): 253–259. DOI: 10.1016/j.jlp.2009.09.004. [16] EMAMI S D, KASMANI R M, NASERZADEH Z, et al. Experimental study on the flame acceleration of premixed hydrocarbons-hydrogen/air mixtures in tee pipes [J]. Journal of Loss Prevention in the Process Industries, 2017, 45: 229–241. DOI: 10.1016/j.jlp.2017.01.005. [17] JING G X, GUO S S, WU Y L. Investigation on methane-air explosion overpressure in bifurcated tubes according to methane concentrations and bifurcation angles [J]. Energy Sources, Part A: Recovery, Utilization, and Environmental Effects, 2020, 47(7): 1–12. DOI: 10.1080/15567036.2020.1824036. [18] 张学博, 高建良, 沈帅帅, 等. 矿井大尺度冲击波传播规律数值模拟研究 [J]. 中国矿业大学学报, 2021, 50(4): 676–684. DOI: 10.13247/j.cnki.jcumt.001311.ZHANG X B, GAO J L, SHEN S S, et al. Numerical simulation of shock wave propagation law in large-scale mine [J]. Journal of China University of Mining and Technology, 2021, 50(4): 676–684. DOI: 10.13247/j.cnki.jcumt.001311. [19] 孟显华, 谢岩森. 甲烷体积分数及巷道结构对甲烷爆炸特性影响研究 [J]. 中国安全科学学报, 2021, 31(S1): 136–142. DOI: 10.16265/j.cnki.issn1003-3033.2021.S1.024.MENG X H, XIE Y S. Study on influence of methane’s volume fraction and roadway structure on methane explosion characteristics [J]. China Safety Science Journal, 2021, 31(S1): 136–142. DOI: 10.16265/j.cnki.issn1003-3033.2021.S1.024. [20] LIN B Q, GUO C, SUN Y M, et al. Effect of bifurcation on premixed methane-air explosion overpressure in pipes [J]. Journal of Loss Prevention in the Process Industries, 2016, 43: 464–470. DOI: 10.1016/j.jlp.2016.07.011. [21] 欧益宏, 李润, 袁广强, 等. 置障条件下半密闭空间油气爆炸特性实验与数值模拟 [J]. 化工学报, 2017, 68(11): 4437–4444. DOI: 10.11949/j.issn.0438-1157.20170526.OU Y H, LI R, YUAN G Q, et al. Experimental and numerical simulation of gasoline-air mixture explosion characteristics in semi-confined space [J]. CIESC Journal, 2017, 68(11): 4437–4444. DOI: 10.11949/j.issn.0438-1157.20170526. [22] 张增亮, 王昕, 王昊平. 带孔障碍物对管道中可燃气体爆炸特性的影响 [J]. 化工学报, 2019, 70(11): 4497–4503. DOI: 10.11949/0438-1157.20190469.ZHANG Z L, WANG X, WANG H P. Influence of installation of perforated obstacles in pipelines on explosive characteristics of combustible gases [J]. CIESC Journal, 2019, 70(11): 4497–4503. DOI: 10.11949/0438-1157.20190469. [23] 余明高, 马梓茂, 韩世新, 等. 障碍物阻塞率梯度对甲烷爆炸特性影响研究 [J]. 化工学报, 2021, 72(10): 5430–5439. DOI: 10.11949/0438-1157.20210525.YU M G, MA Z M, HAN S X, et al. Study on influence of obstacle blockage rate gradient on methane explosion characteristics [J]. CIESC Journal, 2021, 72(10): 5430–5439. DOI: 10.11949/0438-1157.20210525. [24] 马恒, 陈晓军, 荆德吉. H型通风巷道瓦斯爆炸及泄爆过程模拟研究 [J]. 中国安全科学学报, 2021, 31(1): 45–51. DOI: 10.16265/j.cnkj.issn1003-3033.2021.01.007.MA H, CHEN X J, JING D J. Simulation study on gas explosion and discharge process in H-type ventilation roadway [J]. China Safety Science Journal, 2021, 31(1): 45–51. DOI: 10.16265/j.cnkj.issn1003-3033.2021.01.007. [25] 王维建, 叶青, 贾真真. H型巷道不同聚积范围瓦斯爆炸模型数值模拟研究 [J]. 矿业安全与环保, 2023, 50(4): 13–18. DOI: 10.19835/j.issn.1008-4495.2023.04.003.WANG W J, YE Q, JIA Z Z. Numerical simulation of gas explosion model in different accumulation range of H-type roadway [J]. Mining Safety and Environmental Protection, 2023, 50(4): 13–18. DOI: 10.19835/j.issn.1008-4495.2023.04.003. [26] 叶青, 王维建, 贾真真, 等. H型巷道内采用不同布置方式的双爆源瓦斯爆炸传播特性 [J]. 高压物理学报, 2024, 38(2): 025201. DOI: 10.11858/gywlxb.20230760.YE Q, WANG W J, JIA Z Z, et al. Propagation Characteristics of dual explosive sources gas explosion in different arrangements in H-type tunnel [J]. Chinese Journal of High Pressure Physics, 2024, 38(2): 025201. DOI: 10.11858/gywlxb.20230760. [27] 刘佳佳, 张扬, 张翔, 等. Y型通风采煤工作面瓦斯爆炸传播规律模拟研究 [J]. 爆炸与冲击, 2023, 43(8): 085401. DOI: 10.11883/bzycj-2023-0018.LIU J J, ZHANG Y, ZHANG X, et al. Simulation study on propagation characteristics of gas explosion in Y-shaped ventilated coal face [J]. Explosion and Shock Waves, 2023, 43(8): 085401. DOI: 10.11883/bzycj-2023-0018. [28] 高建良, 吴泽琳, 王文祺, 等. 瓦斯爆炸冲击波在角、并联巷道内传播规律对比研究 [J]. 安全与环境学报, 2021, 21(6): 2494–2499. DOI: 10.13637/j.issn.1009-6094.2020.1012.GAO J L, WU Z L, WANG W Q, et al. Comparative study on the propagation law of gas explosion shock wave in the diagonal and parallel roadway [J]. Journal of Safety and Environment, 2021, 21(6): 2494–2499. DOI: 10.13637/j.issn.1009-6094.2020.1012. [29] 高智慧, 李雨成, 张欢, 等. 瓦斯爆炸在角联通风管网中的传播特性研究 [J]. 中国安全生产科学技术, 2022, 18(8): 72–78. DOI: 10.11731/j.issn.1673-193x.2022.08.011.GAO Z H, LI Y C, ZHANG H, et al. Study on propagation characteristics of gas explosion in diagonal ventilation pipe network [J]. Journal of Safety Science and Technology, 2022, 18(8): 72–78. DOI: 10.11731/j.issn.1673-193x.2022.08.011. [30] 张保勇, 崔嘉瑞, 陶金, 等. 不同迎爆面结构的泡沫金属对甲烷气体爆炸传播阻隔性能的实验研究 [J]. 爆炸与冲击, 2023, 43(2): 025402. DOI: 10.11883/bzycj-2021-0531.ZHANG B Y, CUI J R, TAO J, et al. Experimental study on barrier performances of foamed metals with different blast front structures to prevent methane explosion propagation [J]. Explosion and Shock Waves, 2023, 43(2): 025402. DOI: 10.11883/bzycj-2021-0531. [31] CARSON R A, SAHNI O. Study of the relevant geometric parameters of the channel leak method for blast overpressure attenuation for a large caliber cannon [J]. Computer and Fluids, 2015, 115: 211–225. DOI: 10.1016/j.compfluid.2015.03.018. [32] LIU J J, ZHANG Y, CHEN S Q, et al. Simulation study of gas explosion propagation law in coal mining face with different ventilation modes [J]. Frontiers in Energy Research, 2022, 10: 846500. DOI: 10.3389/fenrg.2022.846500. [33] LIU J J, SHEN M Q, CHEN S Q, et al. Influence of roadway cross-section shape on gas explosion shock wave law in U-type ventilation working faces [J]. Shock and Vibration, 2021: 5893179. DOI: 10.1155/2021/5893179. [34] 洪溢都, 林柏泉, 朱传杰. 开口型管道内瓦斯爆炸冲击波动压的数值模拟 [J]. 爆炸与冲击, 2016, 36(2): 198–209. DOI: 10.11883/1001-1455(2016)02-0198-12.HONG Y D, LIN B Q, ZHU C J. Simulation on dynamic pressure of premixed methane/air explosion in open-end pipes [J]. Explosion and Shock Waves, 2016, 36(2): 198–209. DOI: 10.11883/1001-1455(2016)02-0198-12. [35] 张秀华, 张春巍, 段忠东. 基于爆能等效原理大型模爆器燃气爆炸冲击加载的数值模拟 [J]. 爆炸与冲击, 2014, 34(1): 80–86. DOI: 10.11883/1001-1455(2014)01-0080-07.ZHANG X H, ZHANG C W, DUAN Z D. Numerical simulation on shock waves generated by explosive mixture gas from large nuclear blast load generator based on equivalent-energy principles [J]. Explosion and Shock Waves, 2014, 34(1): 80–86. DOI: 10.11883/1001-1455(2014)01-0080-07. [36] 刘伟韬, 穆殿瑞, 杨利, 等. 倾斜煤层底板破坏深度计算方法及主控因素敏感性分析 [J]. 煤炭学报, 2017, 42(4): 849–859. DOI: 10.13225/j.cnki.jccs.2016.0863.LIU W T, MU D R, YANG L, et al. Calculation method and main factor sensitivity analysis of inclined coal floor damage depth [J]. Journal of China Coal Society, 2017, 42(4): 849–859. DOI: 10.13225/j.cnki.jccs.2016.0863. -

下载:

下载: