Design of passive flexible barrier against rockfall impact with 8 000 kJ energy level

-

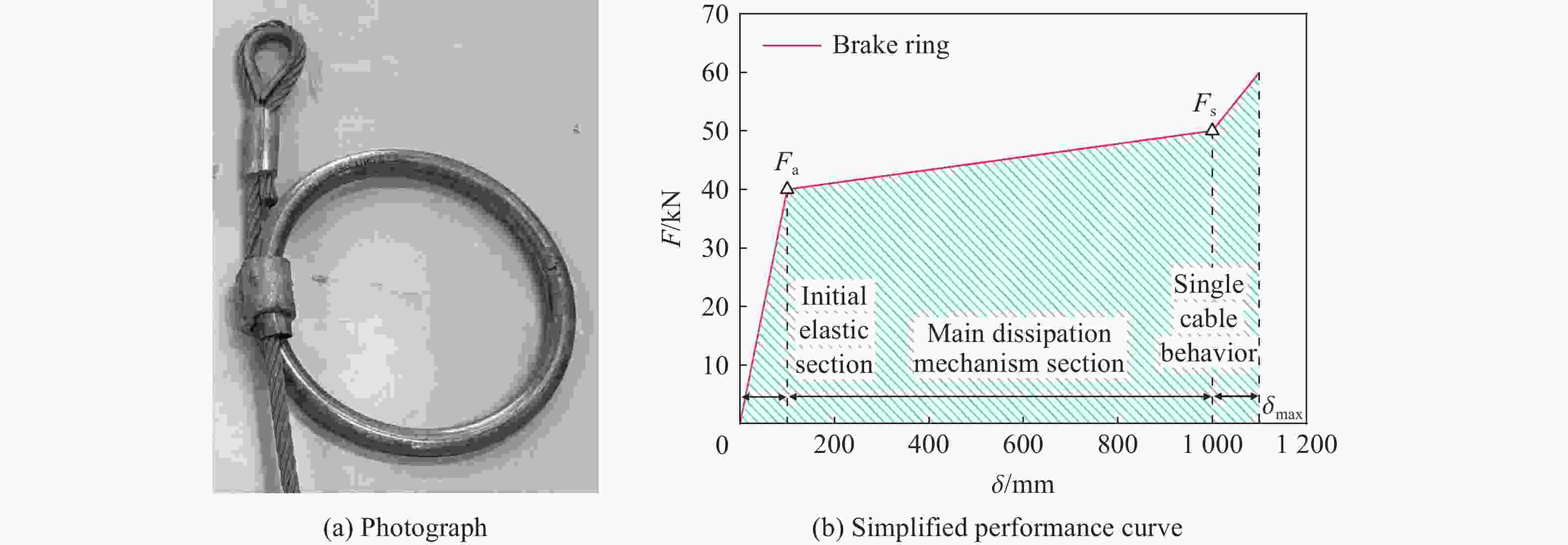

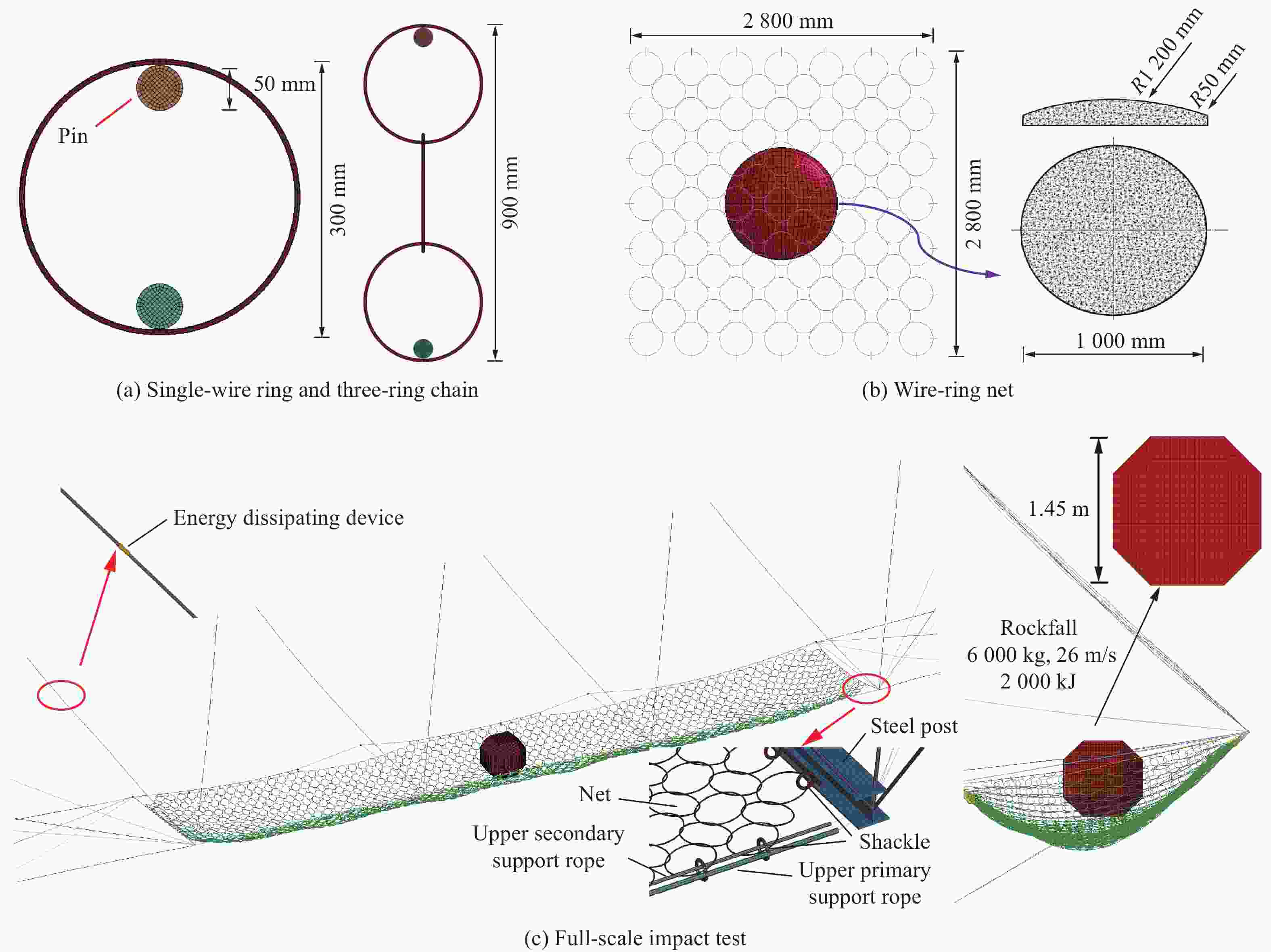

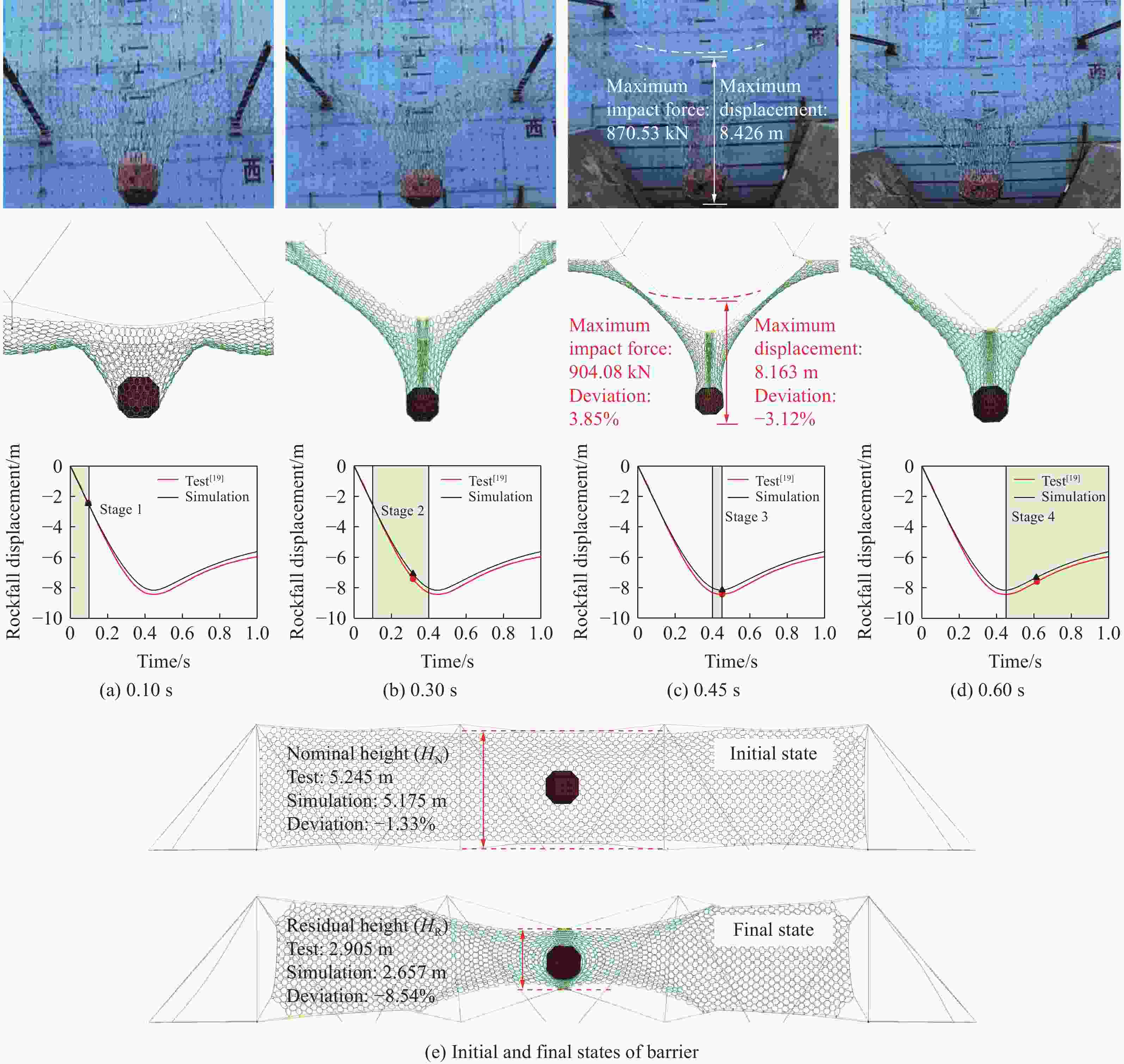

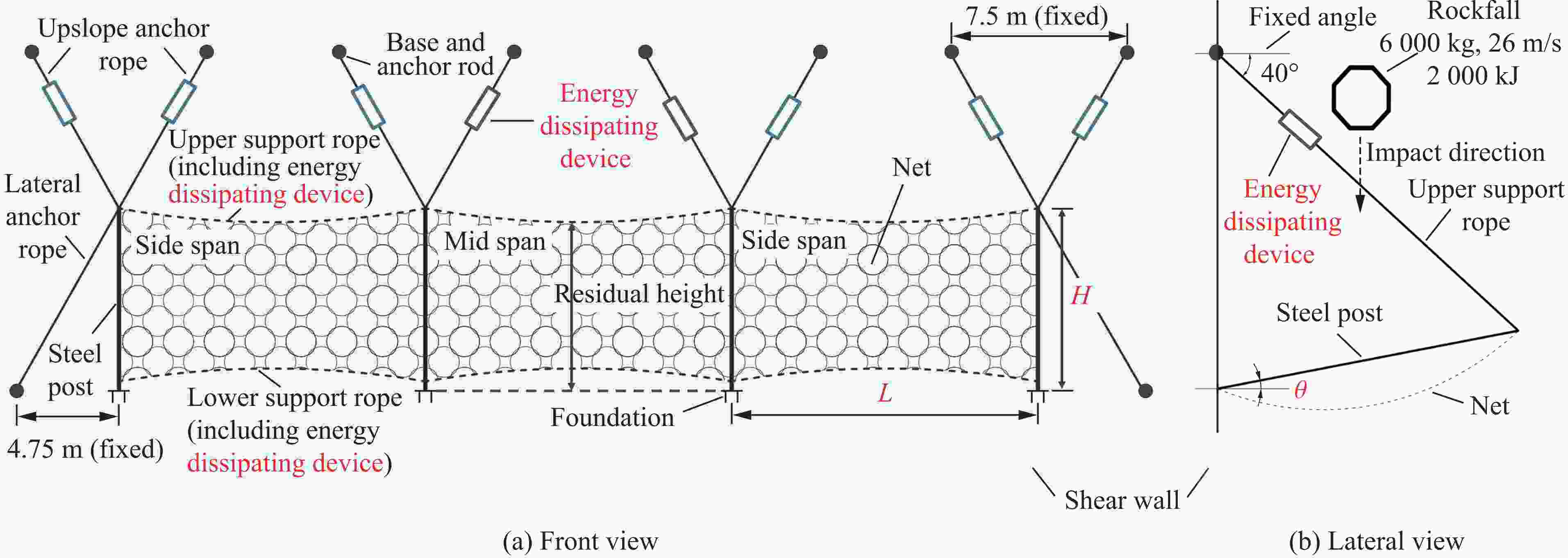

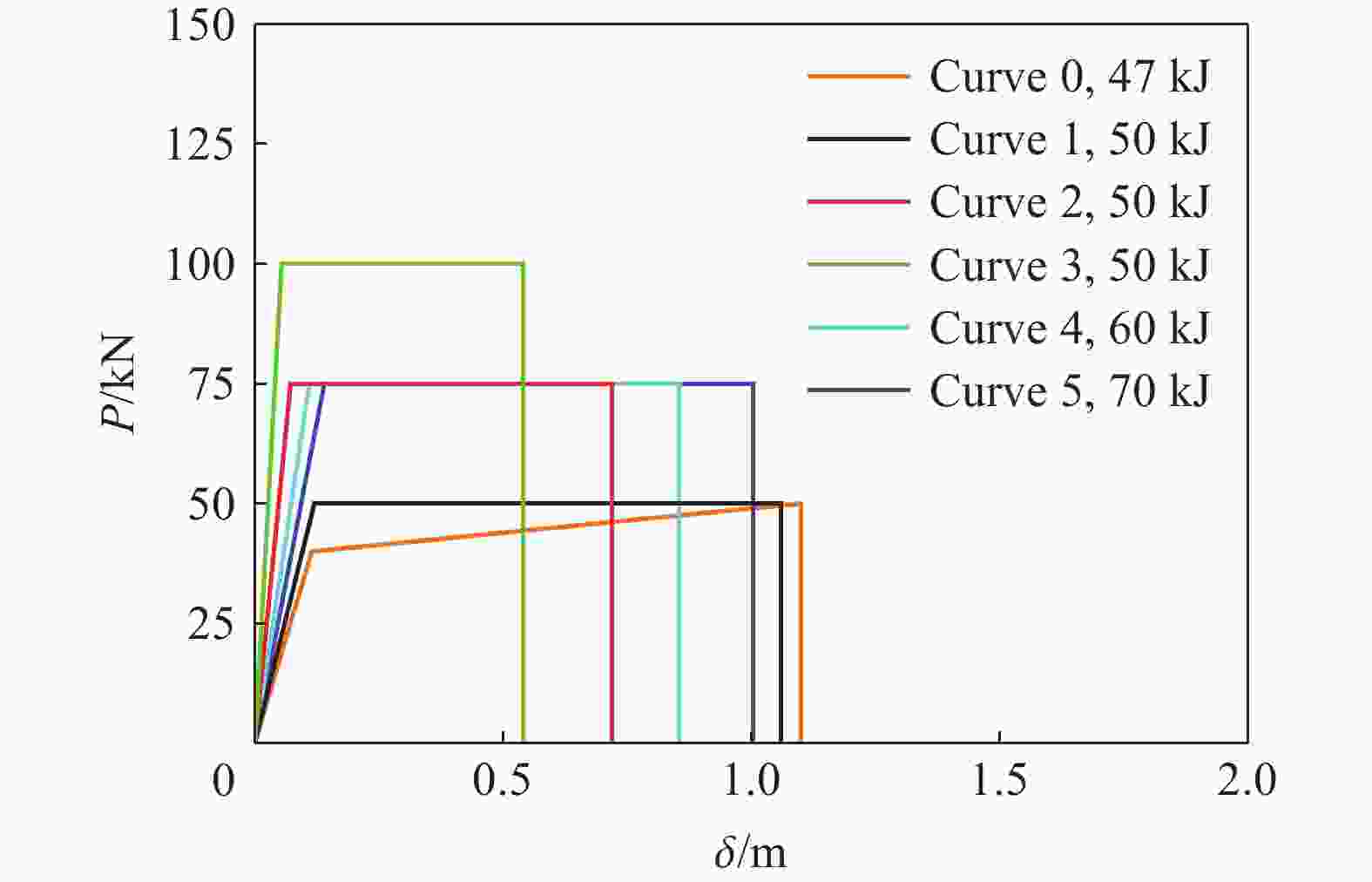

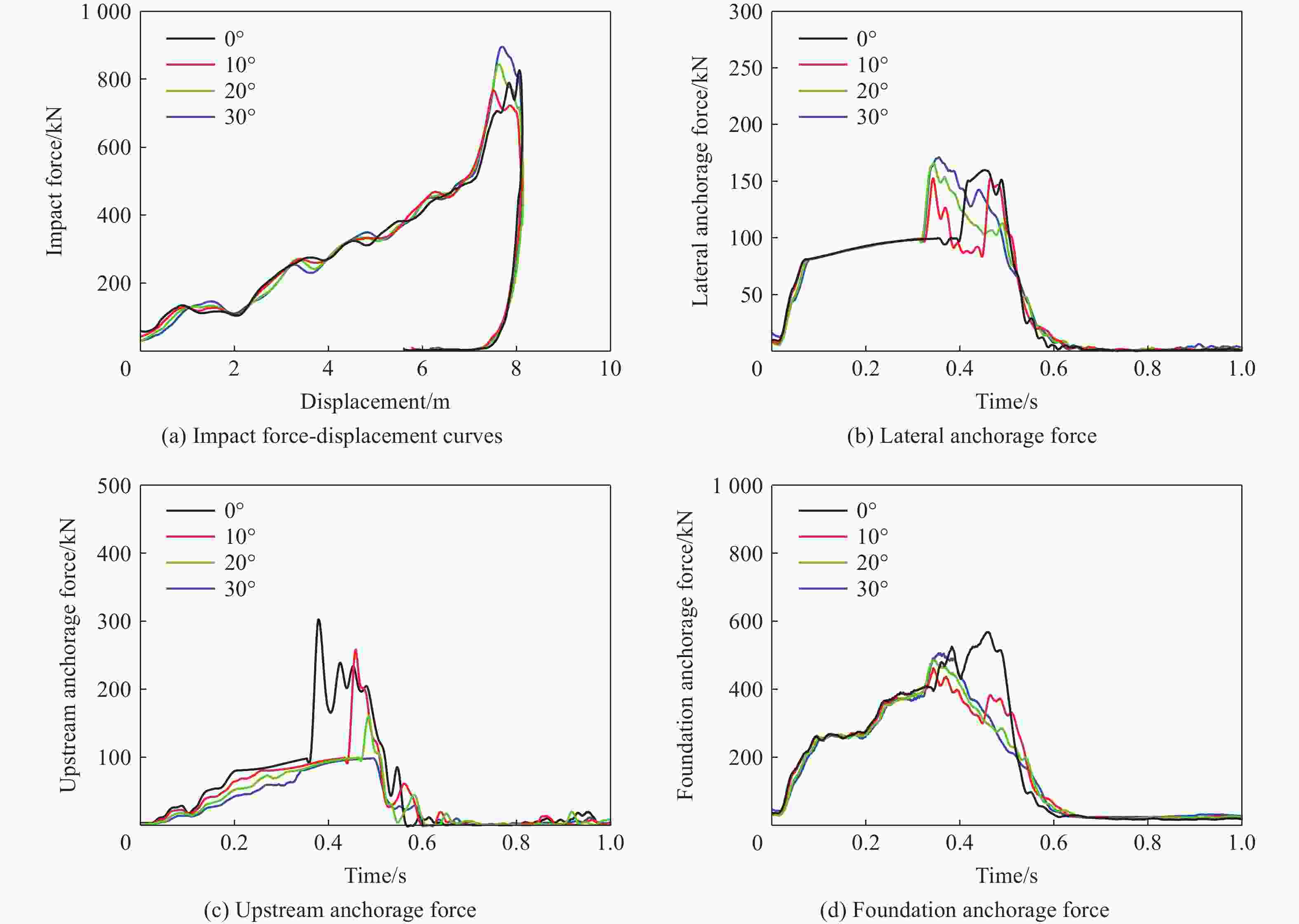

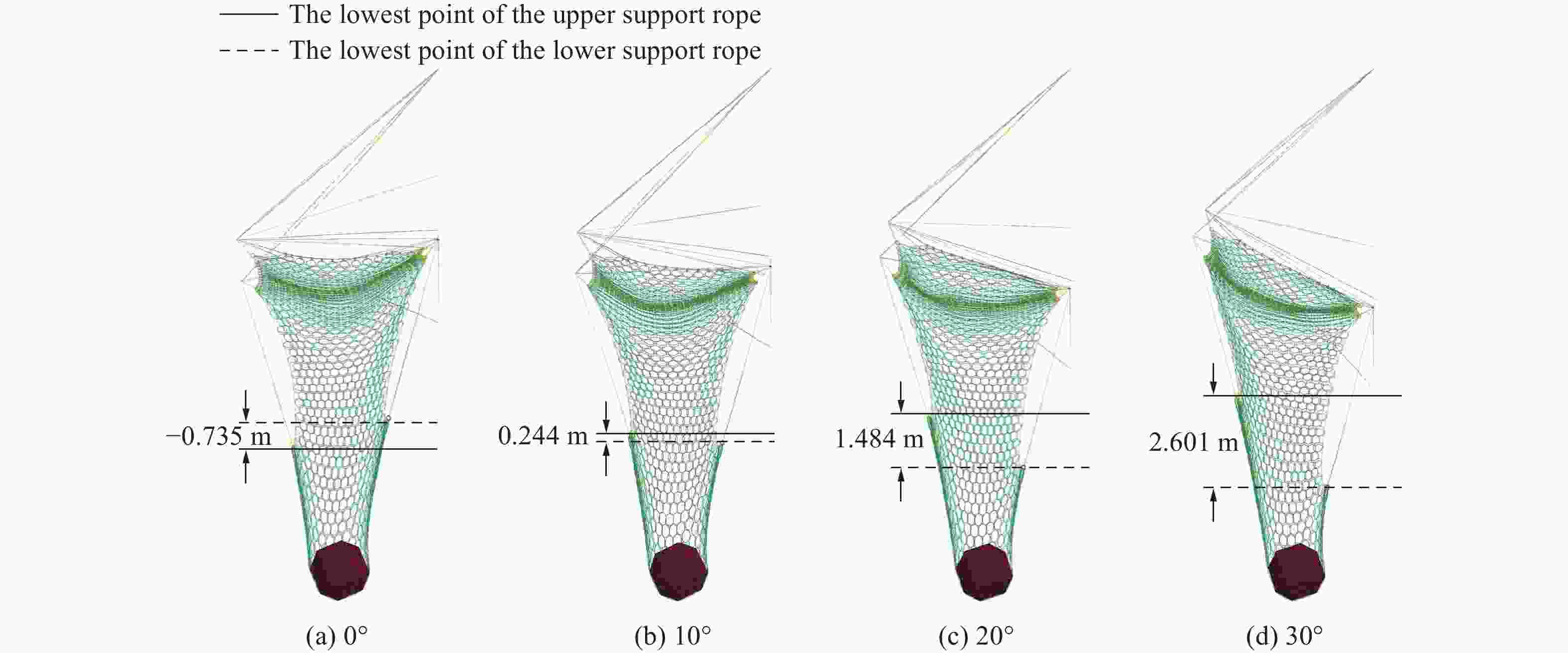

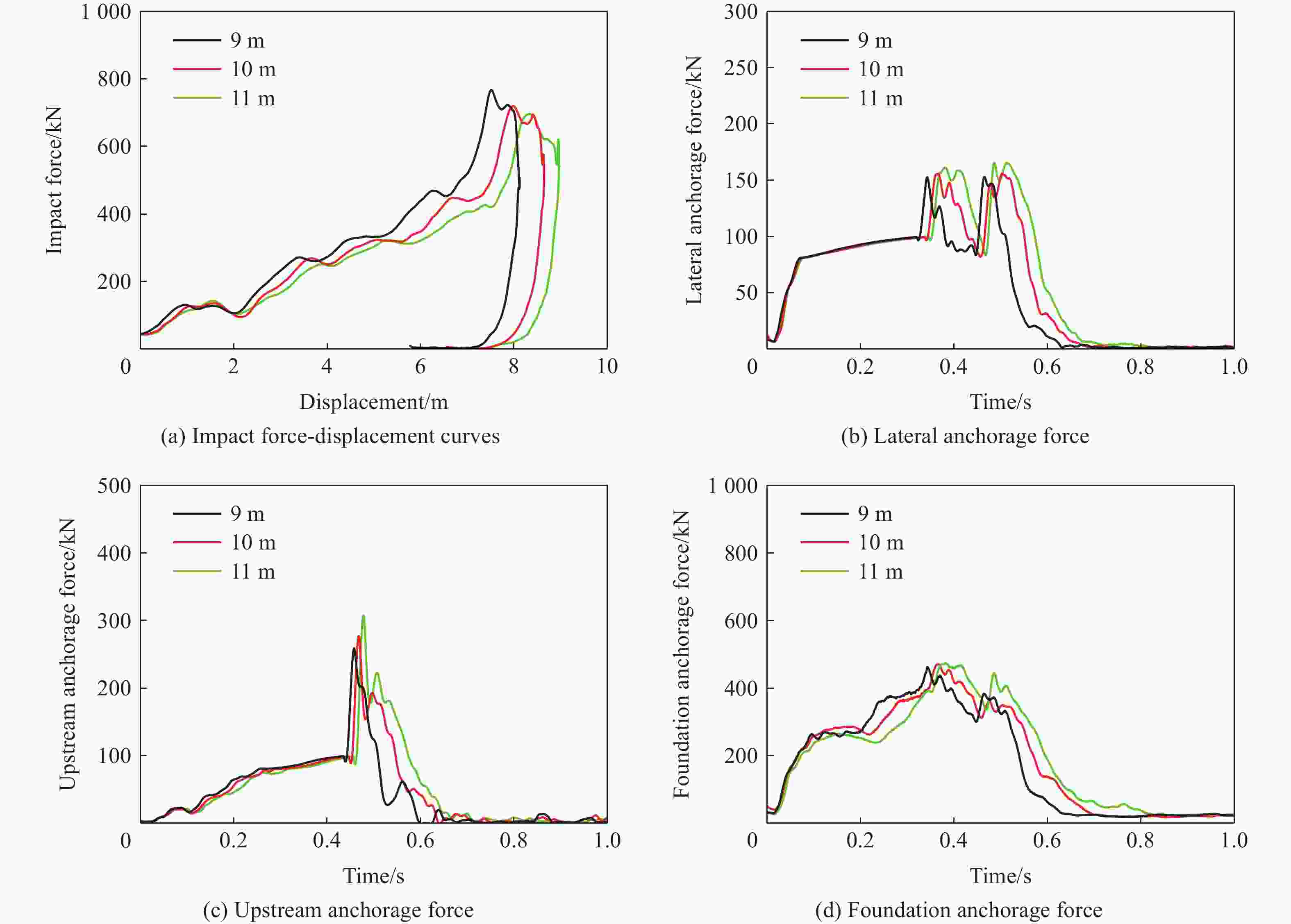

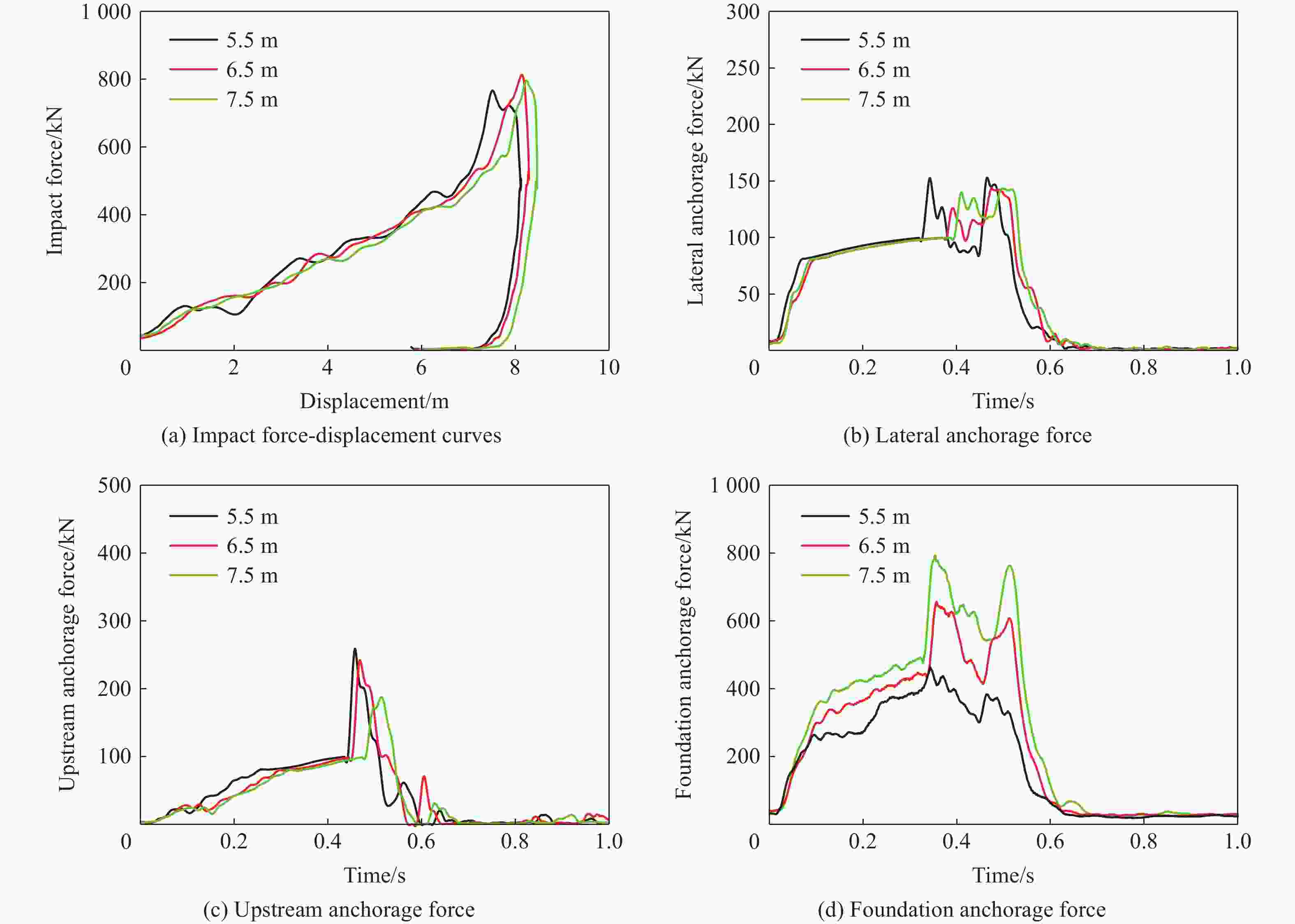

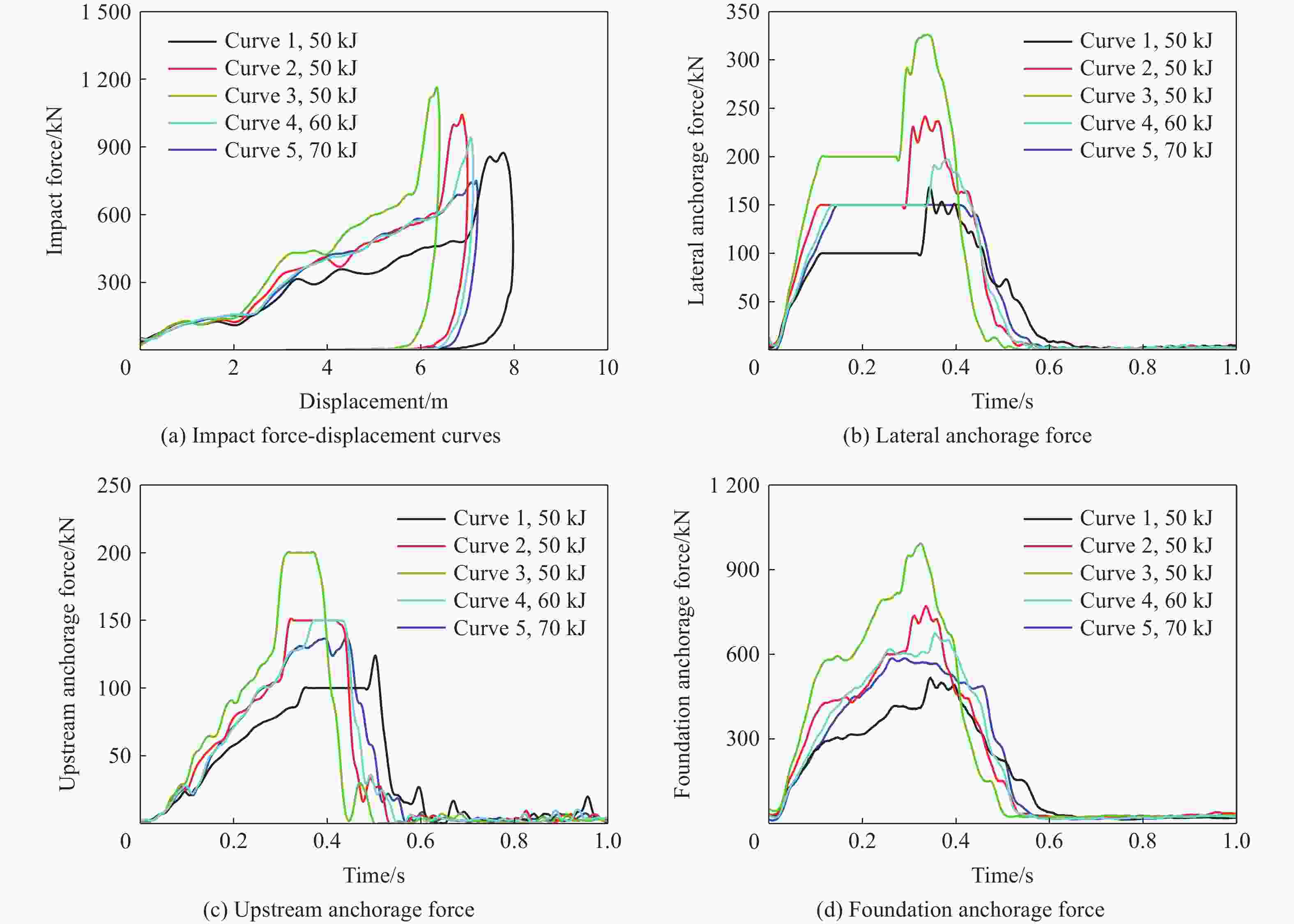

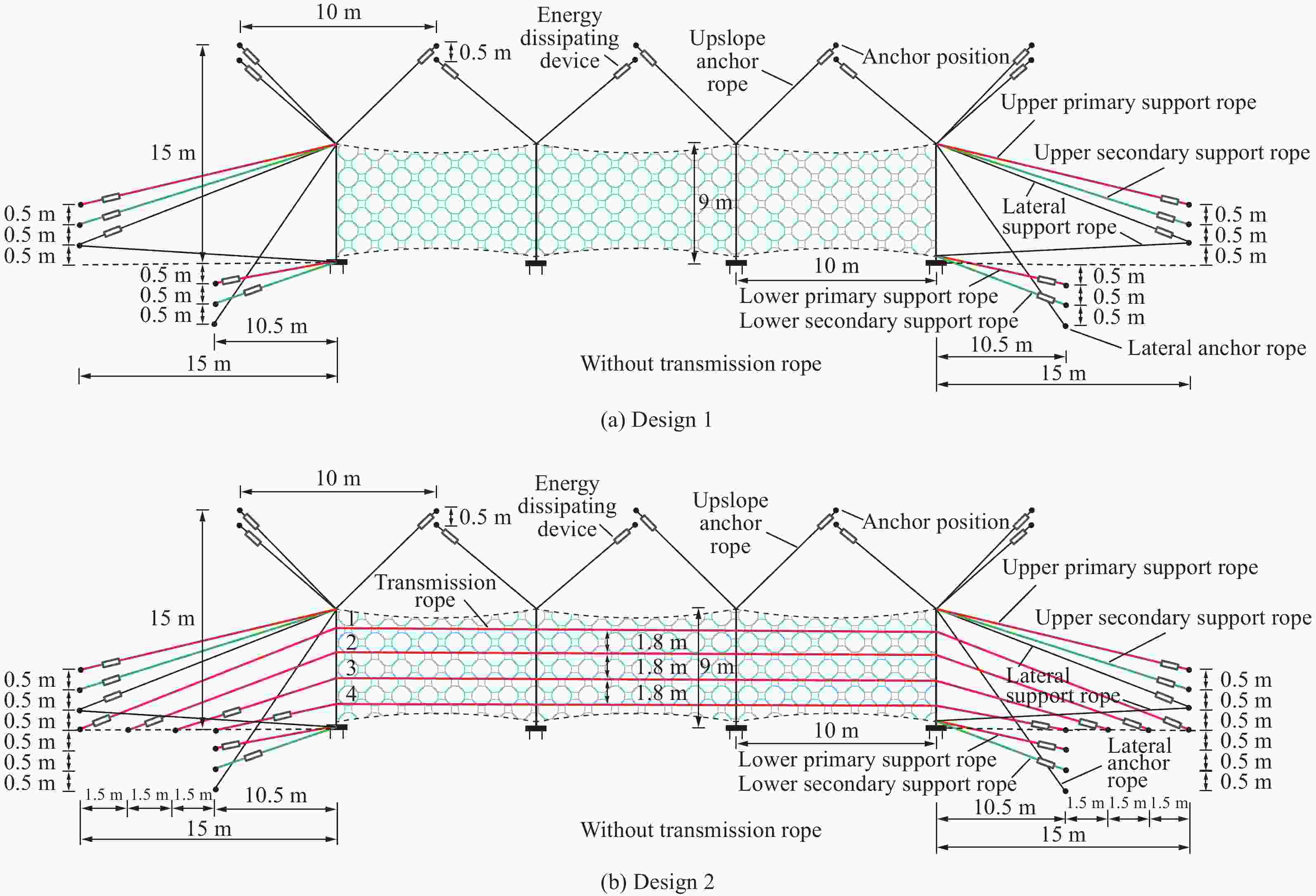

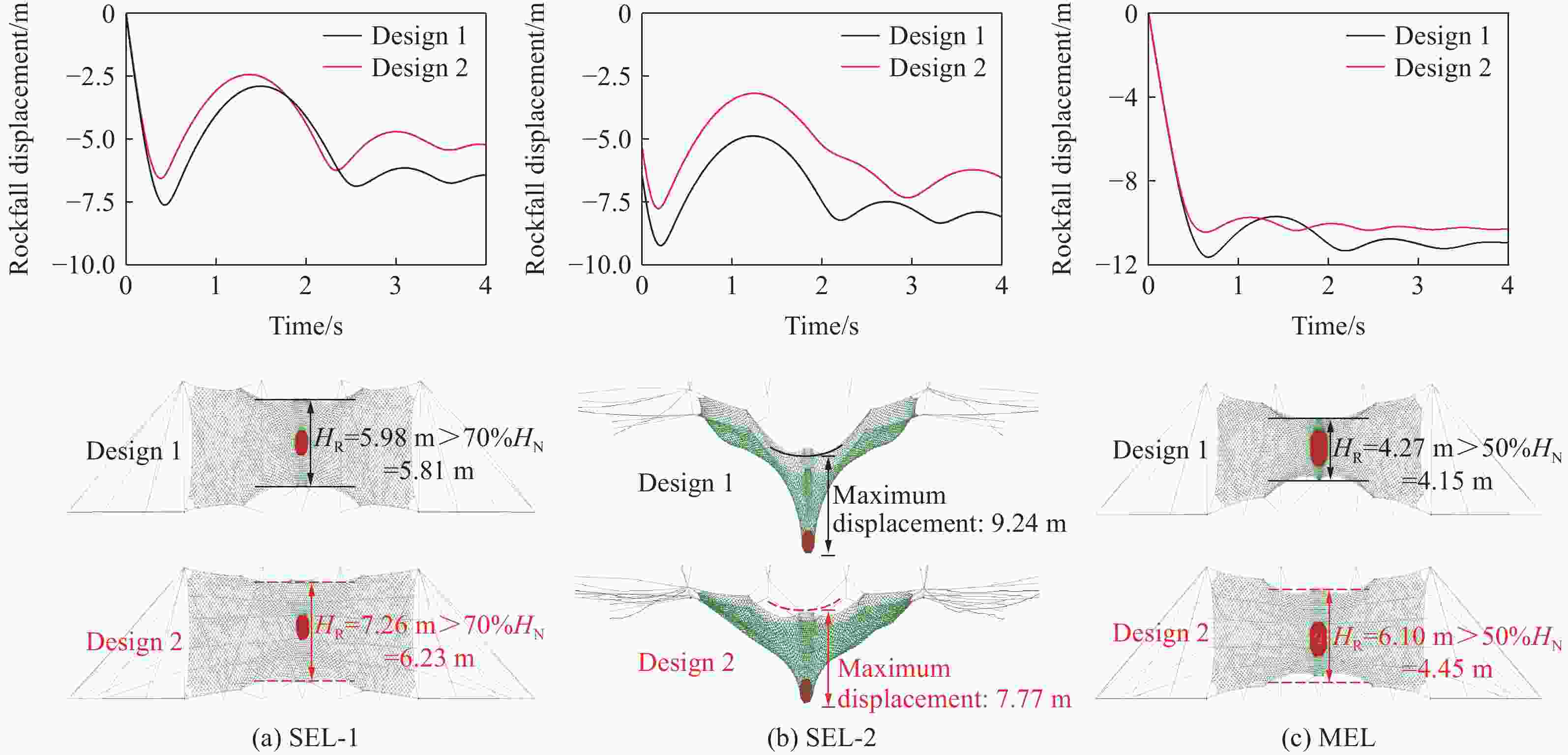

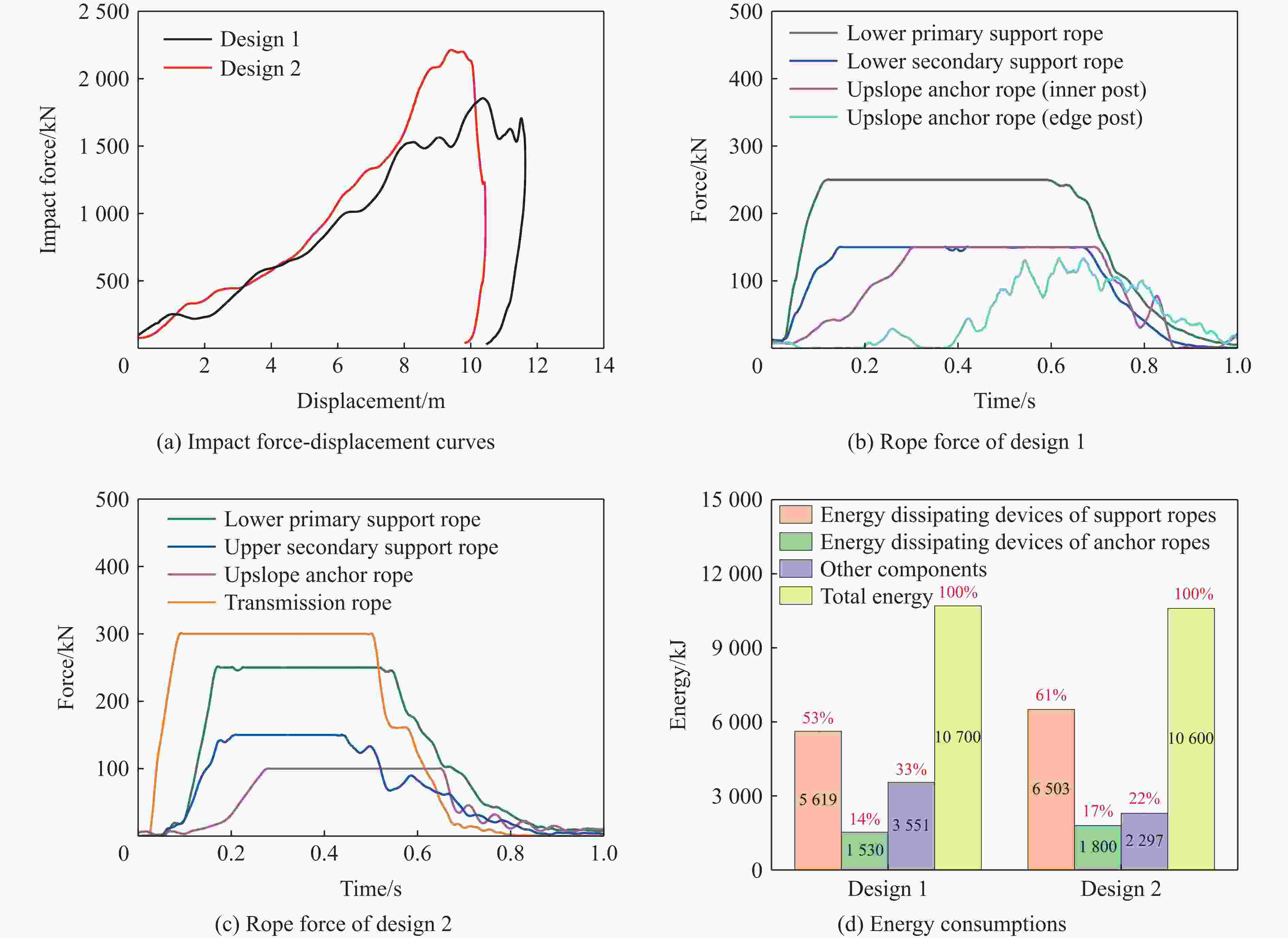

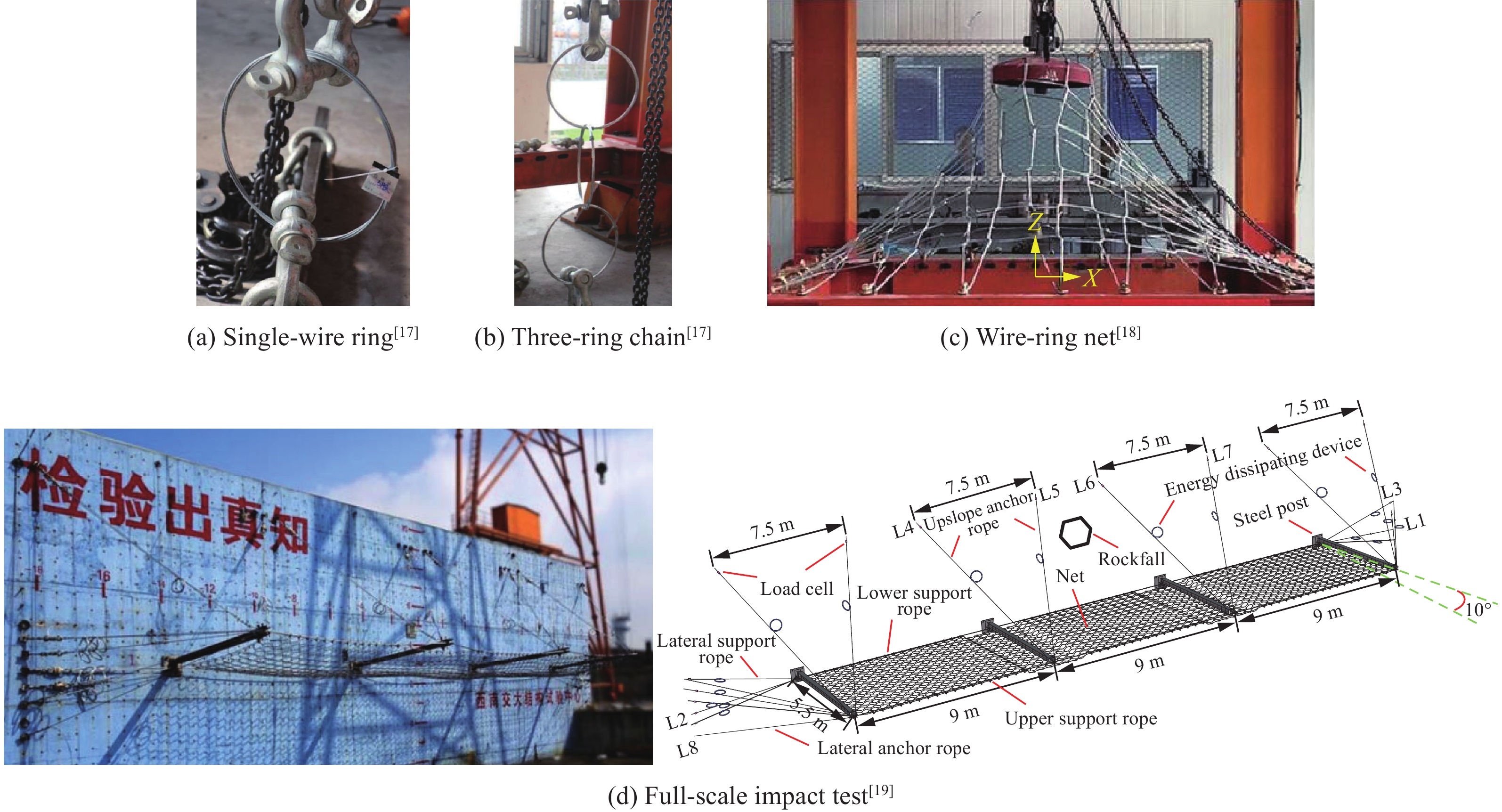

摘要: 采用数值模拟方法开展了8 000 kJ能级被动柔性防护网的抗落石冲击分析与设计工作。首先,基于显式动力学有限元软件ANSYS/LS-DYNA对典型被动柔性防护网单环和三环环链拉伸试验、网片顶破试验以及2 000 kJ能级落石冲击足尺防护网试验进行数值模拟复现,通过与网环最大破断力、破断位移和破坏特征、落石冲击全过程以及防护网钢丝绳内力时程等试验数据进行对比,验证了所采用数值模拟方法的可靠性。然后,分析了钢柱倾角、跨距、高度以及消能装置规格等参数对落石冲击下防护网动力行为的影响,结果表明:消能装置规格是控制防护网内力与位移的关键参数;钢柱倾角建议取10°;增大钢柱跨距会降低结构的面内刚度,而对横向锚固力的影响较小;增加钢柱高度会显著提升柱底支反力;改变钢柱高度和跨距需同时合理调整各钢丝绳的锚固位置。最后,通过调整防护网几何尺寸、消能装置规格和添加横向辅助支撑绳等措施给出了2种8 000 kJ能级防护网设计方案,均通过EAD 340059-00-0106标准检验。Abstract: The protection level and domestic standard test level of commonly used passive flexible barriers against rockfall impact are not higher than 5 000 kJ, while bridges in mountains and other important transportation infrastructures are facing rockfall disaster threats with higher impact energy levels. Considering that the design method for passive flexible barriers with higher impact energy levels is lacking, to provide a feasible and reliable tool for the infrastructure engineers, the analysis and design of 8 000 kJ-level passive flexible barrier against rockfall impact were carried out at present based on the numerical simulation method. Firstly, by adopting the explicit dynamic software ANSYS/LS-DYNA, quasi-static tests, including the tensile test on single wire ring and three-ring chain, net puncturing test, and the dynamic impact test, i.e., 2 000 kJ rockfall impacting the full-scale passive flexible barrier, were numerically reproduced, and the reliability of the numerical simulation method was fully verified by comparing with the test data, i.e., the maximum breaking force and breaking displacement of the wire ring and its failure characteristics, the whole impact process of rockfall, and the cable force-time history curves, the influencing factors, i.e., the inclining angle, span, and height of the steel post and different specifications of energy dissipating devices ranging from 50 kJ to 70 kJ, on the dynamic behavior of the passive flexible barrier were further analyzed. The results show that the specification of the energy dissipation device is the most critical parameter controlling the internal force and displacement of the passive flexible barrier. The inclining angle of the steel post is recommended to be 10°. An increase in the post spacing can reduce the in-plane stiffness of the structure while having less effect on the transverse anchorage. An increase in the post height will cause a significant increase in the support reaction force at the post bottom. A reasonable adjustment of the anchorage position of each wire rope is required when the post height and spacing are changed. Finally, based on the results of parameter analysis, two design schemes for a passive flexible barrier against 8 000 kJ rockfall impact were given by adjusting the geometry of the structure, the specification of the energy dissipating device, and the addition of transmission support ropes. Both of them passed the test of the European standard EAD 340059-00-0106.

-

Key words:

- passive flexible barrier /

- rockfall impact /

- parameter influence /

- structural design

-

部件 规格 破断力/kN 消能装置 (Fa~Fs)/kN δmax/m 网片 R16/3/300 上主支撑绳 2$\varnothing $22 610 80~100 2.1 下主支撑绳 2$\varnothing $22 610 80~100 2.1 上次支撑绳 1$\varnothing $22 305 40~50 2.1 下次支撑绳 1$\varnothing $22 305 40~50 2.1 侧向支撑绳 1$\varnothing $22 305 40~50 1.1 上拉锚绳 1$\varnothing $22 305 80~100 1.1 侧向拉锚绳 1$\varnothing $22 305 钢柱 HW200×200×8×12 表 2 防护网各部件材料模型和参数[19]

Table 2. Material models and corresponding parameters of barrier components[19]

部件 材料模型 密度/(kg·m–3) 泊松比 弹性模量/GPa 单元类型 网片 *MAT_PIECEWISE_LINEAR_PLASTICITY 7 850 0.3 200 梁单元 卸扣 *MAT_PLASTIC_KINEMATIC 7 850 0.3 206 梁单元 支撑绳 *MAT_CABLE_DISCRETE_BEAM 7 850 0.3 150 索单元 落石 *MAT_RIGID 2 873 0.3 20 实体单元 消能装置 *MAT_PIECEWISE_LINEAR_PLASTICITY 7 850 0.3 200 梁单元 表 3 冲击工况

Table 3. Impact scenarios

工况 钢柱角度/(°) 钢柱跨度/m 钢柱高度/m 消能装置规格曲线 1-1 0 9 5.5 0 1-2 10 9 5.5 0 1-3 20 9 5.5 0 1-4 30 9 5.5 0 2-1 10 10 5.5 0 2-2 10 11 5.5 0 3-1 10 9 6.5 0 3-2 10 9 7.5 0 4-1 10 9 5.5 1 4-2 10 9 5.5 2 4-3 10 9 5.5 3 4-4 10 9 5.5 4 4-5 10 9 5.5 5 表 4 防护网各部件耗能情况

Table 4. Energy consumption of each barrier component

部件 耗能比例系数[25] 放大系数 设计总耗能能力/kJ 支撑绳上消能装置 0.6 1.5 7 200 拉锚绳上消能装置 0.2 1.5 2 400 其他 0.2 1.5 2 400 表 5 防护网各部件规格参数

Table 5. Specifications of each barrier component

部件 规格 破断力/kN 消能装置设计值 (Fa~Fs)/kN δmax/m 方案一 方案二 网片 R19/3/300 上主支撑绳 2$\varnothing $22 610 250~250 4.00 2.00 下主支撑绳 2$\varnothing $22 610 250~250 5.00 2.50 上次支撑绳 1$\varnothing $22 305 150~150 2.50 1.00 下次支撑绳 1$\varnothing $22 305 150~150 2.50 1.00 辅助支撑绳1和4 2$\varnothing $22 610 300~300 1.50 辅助支撑绳2和3 2$\varnothing $22 610 300~300 3.00 侧向支撑绳 1$\varnothing $22 305 150~150 1.50 1.00 上拉锚绳(内柱) 1$\varnothing $22 305 150~150 3.00 上拉锚绳(边柱) 1$\varnothing $22 305 100~100 1.00 上拉锚绳 1$\varnothing $22 305 100~100 2.00 侧向拉锚绳 1$\varnothing $22 305 试验 冲击条件 通过标准 通过后分级标准 SEL-1 落石连续2次冲击网片中心,

且2次冲击之间无维护落石被拦截,连接结构无破坏,残余拦截

高度HR大于标称高度HN的70%SEL-2 落石被拦截 MEL 落石单次冲击网片中心 落石被拦截 A类:HR≥50%HN

B类:30%HN<HR<50%HN

C类:HR<30%HN或上下支撑绳发生断裂表 7 检验能级

Table 7. Test energy levels

落石试块 冲击能量/kJ 冲击速度/(m·s−1) 质量/kg 名义直径/m SEL-1试验 2 660 26 7 870 1.567 SEL-2试验 2 660 26 7 870 1.567 MEL试验 8 000 26 23 669 2.266 表 8 消能装置拉伸变形长度数值模拟结果

Table 8. Simulation results of the elongations of energy dissipating devices

布置位置 (Fa~Fs)/kN 拉伸变形长度/m 方案一 方案二 设计值 模拟值 设计值 模拟值 上主支撑绳 250~250 4.00 3.53 2.00 1.48 下主支撑绳 250~250 5.00 4.58 2.50 2.09 上次支撑绳 150~150 2.50 2.25 1.00 0.83 下次支撑绳 150~150 2.50 2.18 1.00 0.86 辅助支撑绳1和4 300~300 1.50 0.90/1.28 辅助支撑绳2和3 300~300 3.00 2.07/2.83 侧向支撑绳 150~150 1.50 1.18 1.00 0.46 上拉锚绳(内柱) 150~150 3.00 2.84 上拉锚绳(边柱) 100~100 1.00 0.28 上拉锚绳 100~100 2.00 1.87 -

[1] SMITH D, DUFFY J D. Field tests and evaluation of rockfall restraining nets: CA/TL-90/05 [R]. USA: State of California Department of Transportation, 1990. [2] PEILA D, PEIZZA S, SASSUDELLI F. Evaluation of behaviour of rockfall restraining nets by full scale tests [J]. Rock Mechanics and Rock Engineering, 1998, 31(1): 1–24. DOI: 10.1007/s006030050006. [3] GRASSL H, VOLKWEIN A, ANDERHEGGEN E, et al. Steel-net rockfall protection-experimental and numerical simulation [C]//Proceedings of the 7th International Conference on Structures Under Shock and Impact. Montreal, Canada: Wit Press, 2002: 143–153. [4] BUZZI O, LEONARDUZZI E, KRUMMENACHER B, et al. Performance of high strength rock fall meshes: effect of block size and mesh geometry [J]. Rock Mechanics and Rock Engineering, 2015, 48(3): 1221–1231. DOI: 10.1007/s00603-014-0640-7. [5] YU Z X, LIU C, GUO L, et al. Nonlinear numerical modeling of the wire-ring net for flexible barriers [J]. Shock and Vibration, 2019: 3040213. DOI: 10.1155/2019/3040213. [6] ZHAO L, YU Z X, LIU Y P, et al. Numerical simulation of responses of flexible rockfall barriers under impact loading at different positions [J]. Journal of Constructional Steel Research, 2020, 167: 105953. DOI: 10.1016/j.jcsr.2020.105953. [7] 赵雷, 邹定富, 张丽君, 等. 落石被动柔性防护网冲击力学响应的参数化研究 [J]. 振动与冲击, 2023, 42(12): 8–17. DOI: 10.13465/j.cnki.jvs.2023.012.002.ZHAO L, ZOU D F, ZHANG L J, et al. Parametric study on the mechanical response of a flexible rockfall barrier [J]. Vibration and Shock, 2023, 42(12): 8–17. DOI: 10.13465/j.cnki.jvs.2023.012.002. [8] KOO R C H, KWAN J S H, LAM C, et al. Dynamic response of flexible rockfall barriers under different loading geometries [J]. Landslides, 2017, 14(3): 905–916. DOI: 10.1007/s10346-016-0772-9. [9] QI X, PEI X J, HAN R, et al. Analysis of the effects of a rotating rock on rockfall protection barriers [J]. Geotechnical and Geological Engineering, 2018, 36(5): 3255–3267. DOI: 10.1007/s10706-018-0535-6. [10] MOON T, OH J, MUN B. Practical design of rockfall catchfence at urban area from a numerical analysis approach [J]. Engineering Geology, 2014, 172: 41–56. DOI: 10.1016/j.enggeo.2014.01.004. [11] YU Z X, LUO L, LIU C, et al. Dynamic response of flexible rockfall barriers with different block shapes [J]. Landslides, 2021, 18(7): 2621–2637. DOI: 10.1007/s10346-021-01658-w. [12] GERBER W. Guideline for the approval of rockfall protection kits: environment in practice [R]. Bern, Switzerland: Swiss Agency for the Environment, Forest and Landscape (SAEFL), Swiss Federal Research Institute (WSL), 2001. [13] HIGGINS J D. Recommended procedure for the testing of rock-fall barriers: NCHRP Project 20–07, Task 138 [R]. Washington, USA: National Cooperative Highway Research Program, Transportation Research Board, 2003. [14] EOTA. Falling rock protection kits: EAD 340059-00-0106 [S]. Brussels: European Organization for Technical Approvals, 2018. [15] 国家铁路局. 铁路边坡柔性被动防护产品落石冲击试验方法与评价: TB/T 3449—2016 [S]. 北京: 中国铁道出版社, 2016.National Railway Administration of People’s Republic of China. Rock fall impact test method and evaluation of railway slope flexible passive protection product: TB/T 3449—2016 [S]. Beijing: China Railway Publishing House, 2016. [16] 中华人民共和国交通运输部. 边坡柔性防护网系统: JT/T 1328—2020 [S]. 北京: 人民交通出版社, 2020.Ministry of Transport of the People’s Republic of China. Flexible protection net system of slope: JT/T 1328—2020 [S]. Beijing: China Communications Press, 2020. [17] 李自名. 柔性拦截网顶破力学行为研究 [D]. 成都: 西南交通大学, 2019: 19–29.LI Z M. Study on the mechanical behavior of the flexible intercepting net [D]. Chengdu: Southwest Jiaotong University, 2019: 19–29. [18] 郭立平. 柔性防护工程环连网静动力行为与破坏力学模型 [D]. 成都: 西南交通大学, 2023: 32–41. [19] YU Z X, QIAO Y K, ZHAO L, et al. A simple analytical method for evaluation of flexible rockfall barrier: part 2: application and full-scale test [J]. Advanced Steel Construction, 2017, 14(2): 142–165. DOI: 10.18057/IJASC.2018.14.2.2. [20] 齐欣. 柔性被动拦截网结构力学性能研究 [D]. 成都: 西南交通大学, 2014: 126–131.QI X. The mechanics performance of passive flexible protection structure [D] Chengdu: Southwest Jiaotong University, 2014: 126–131. [21] 罗祥, 石少卿, 汪敏. 边坡柔性防护网中RECCO圆环力学性能研究 [J]. 路基工程, 2010(6): 45–47. DOI: 10.3969/j.issn.1003-8825.2010.06.016.LUO X, SHI S Q, WANG M. Study on mechanic properties of RECCO ring in slope flexible protecting fence [J]. Subgrade Engineering, 2010(6): 45–47. DOI: 10.3969/j.issn.1003-8825.2010.06.016. [22] ESCALLÓN J P, WENDELER C, CHATZI E N, et al. Parameter identification of rockfall protection barrier components through an inverse formulation [J]. Engineering Structures, 2014, 77: 1–16. DOI: 10.1016/j.engstruct.2014.07.019. [23] BOYCE B L, DILMORE M F. The dynamic tensile behavior of tough, ultrahigh-strength steels at strain-rates from 0.000 2 s–1 to 200 s–1 [J]. International Journal of Impact Engineering, 2009, 36(2): 263–271. DOI: 10.1016/j.ijimpeng.2007.11.006. [24] LSTC. LS-DYNA keyword userʼs manual volume Ⅰ [M]. California: Livermore Software Technology Corporation (LSTC), 2013: 2068–2073. [25] 四川省质量技术监督局. 公路被动柔性防护网技术规程: DB51/T 2432—2017 [S]. 北京: 人民交通出版社, 2017. -

下载:

下载: