Experiment on dynamic mechanical properties of sandstone based on Lagrangian inverse analysis method

-

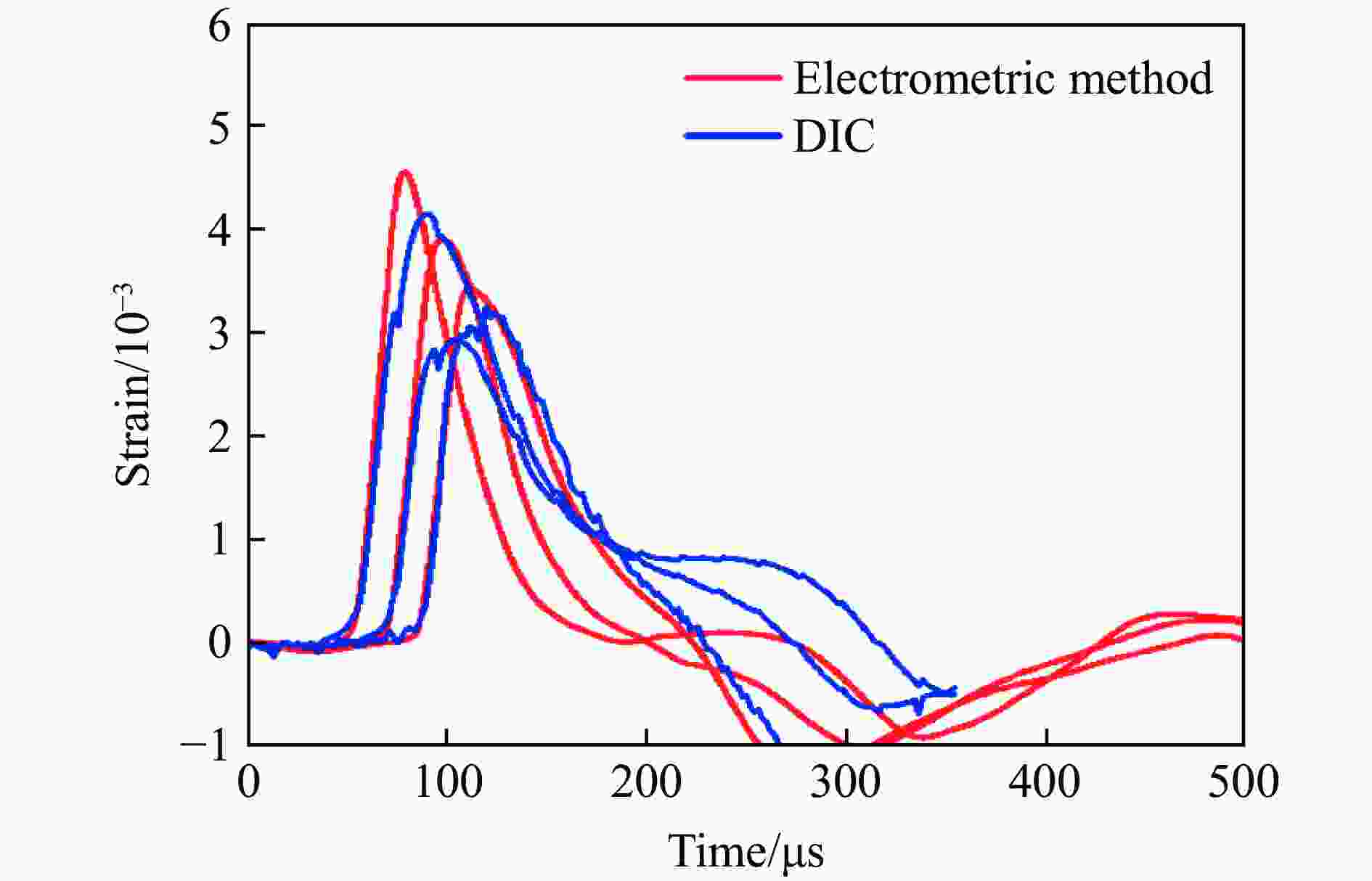

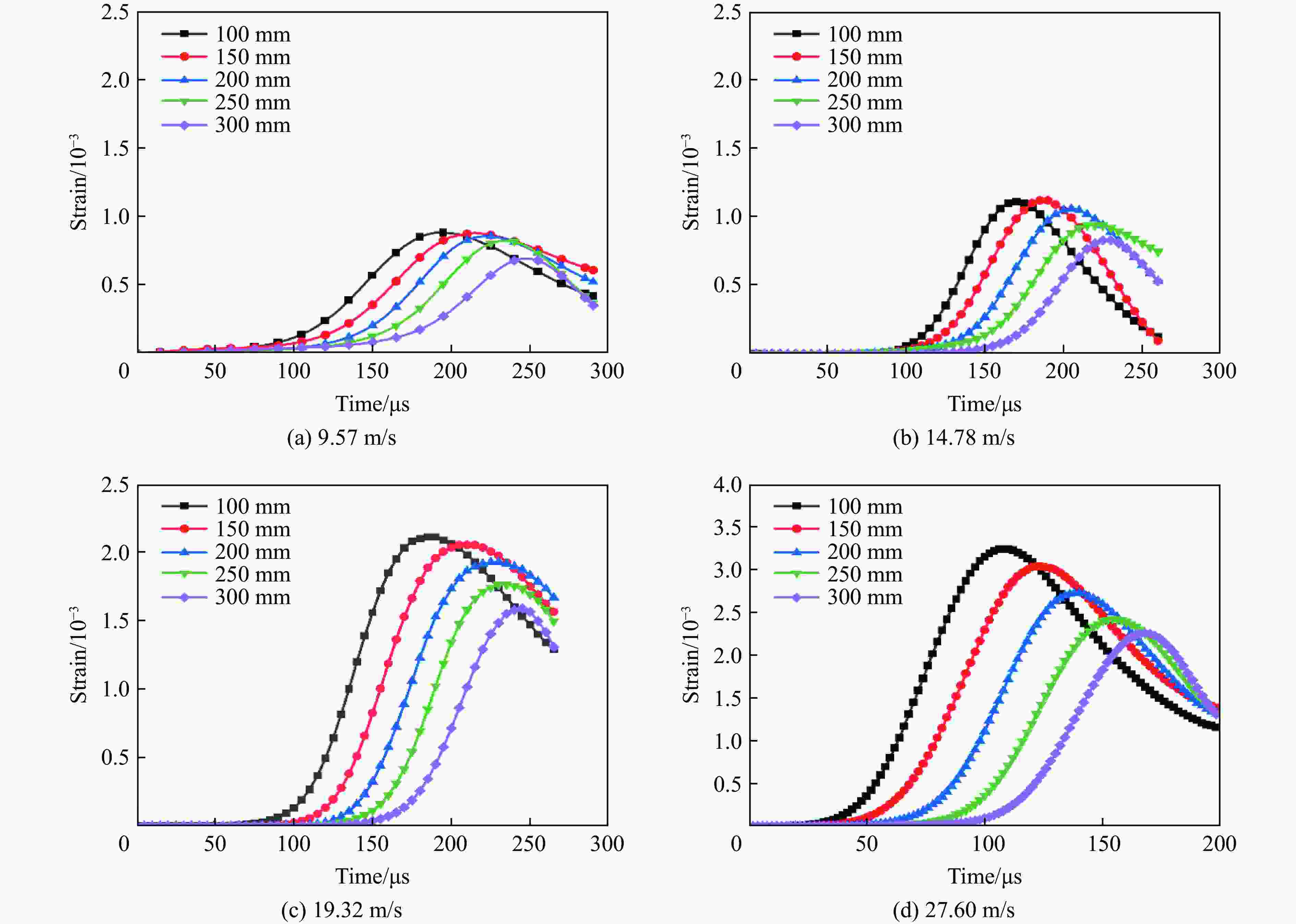

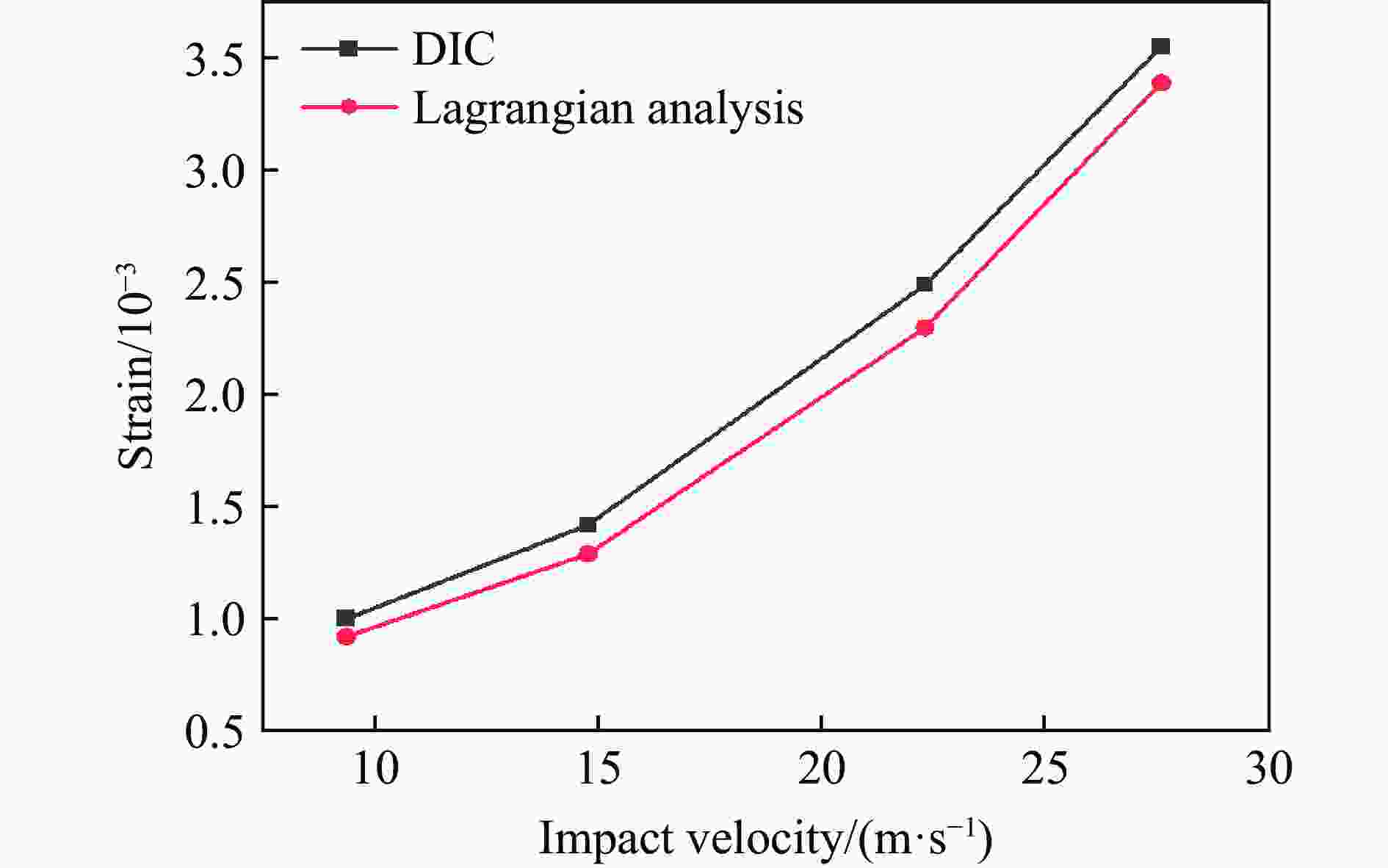

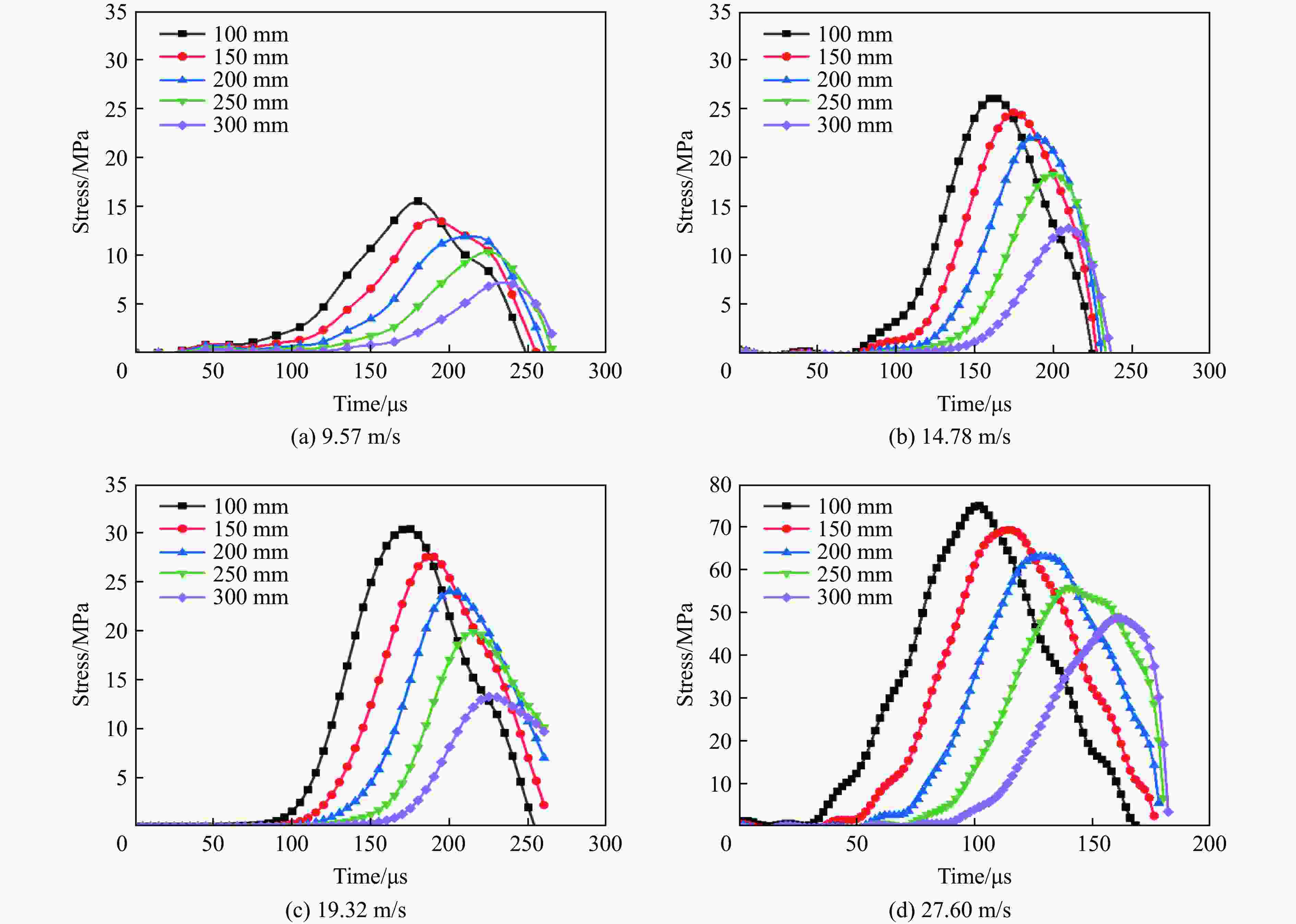

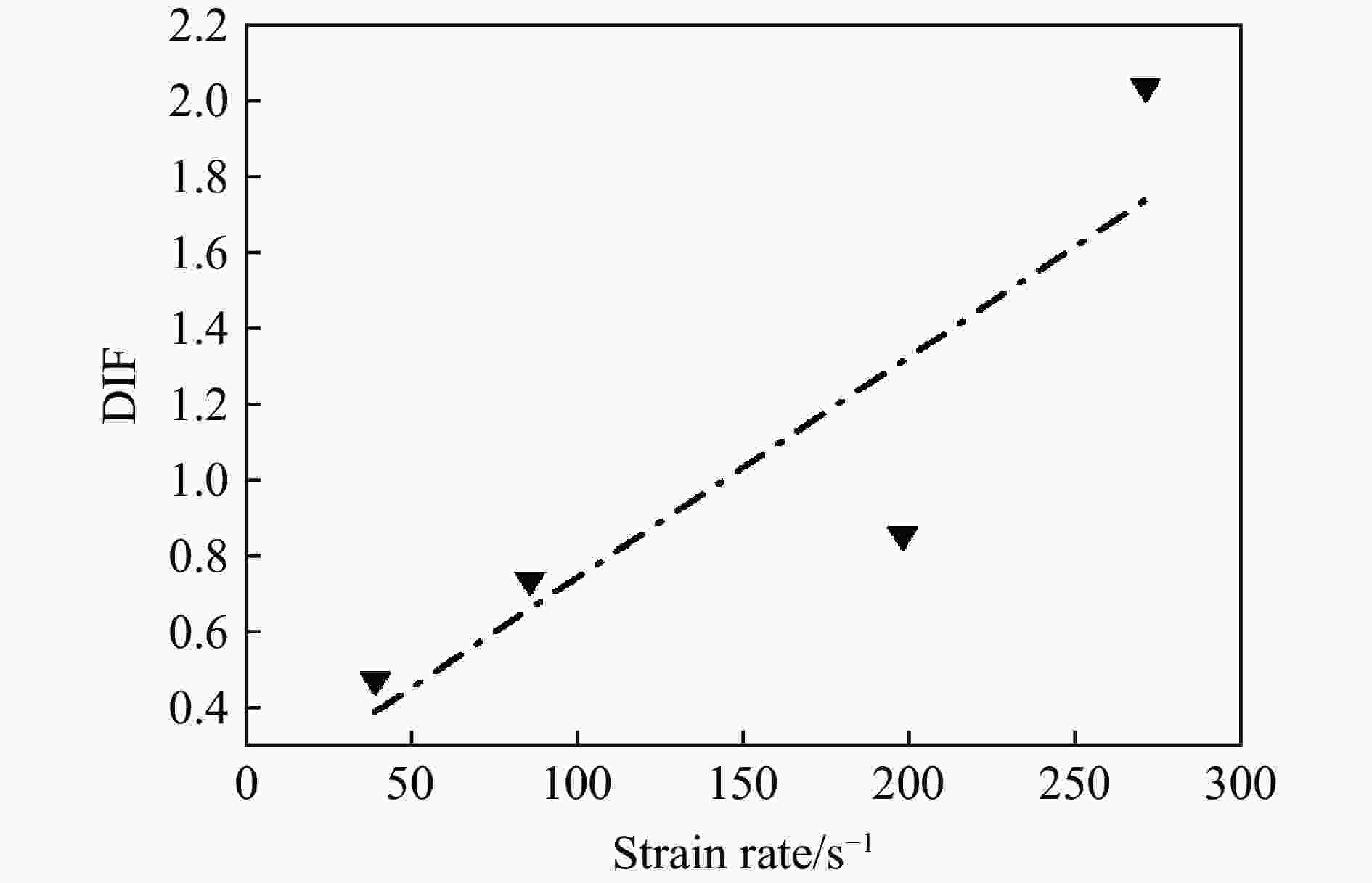

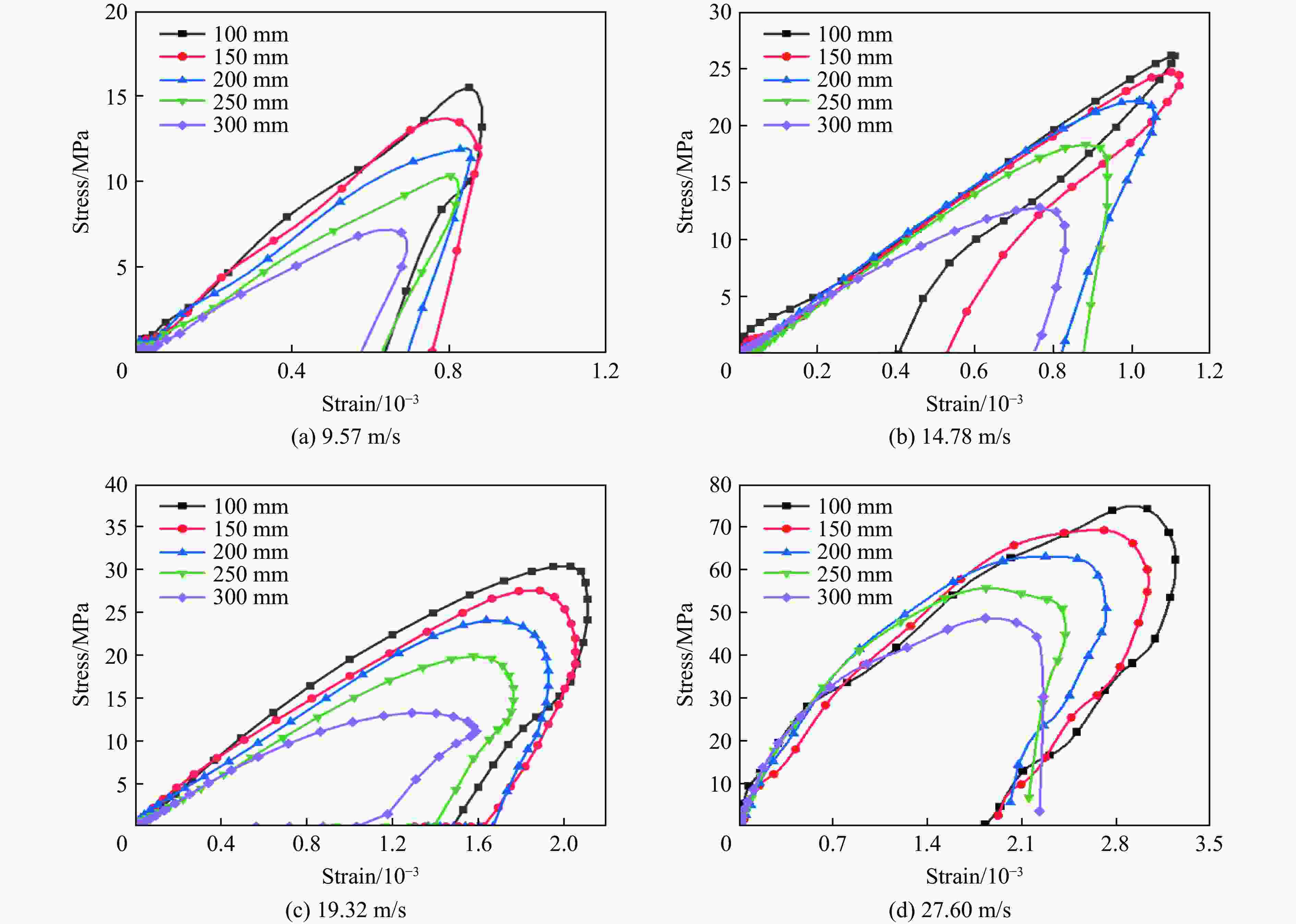

摘要: 为深入研究深部地层中砂岩在冲击荷载作用下的动态力学特性,建立了一种改进的霍普金森压杆实验系统,对灰砂岩长杆试件开展了不同加载速率的动态压缩实验,并结合高速数字图像相关技术(DIC)监测试件表面位移场和应变场的演化过程,探讨了灰砂岩在近场冲击加载下的拉伸破坏的规律。从 DIC 分析得到的位移场中提取出不同质点位移时程曲线,进行了拉格朗日反分析算法计算,获得了灰砂岩材料的全场应力-应变规律。结果表明:灰砂岩长杆试件以拉伸破坏为主,且出现了近加载端破碎、远离加载端层裂的现象;灰砂岩长杆试件的动态抗压强度因子随应变率增大而增大,有明显的应变率效应;随着加载速率升高,各测点应力峰值与应变峰值均呈增大趋势;在同一加载速率下,灰砂岩长杆的应力-应变曲线呈现出近端测点曲线包络远端测点曲线的现象。Abstract: To investigate the dynamic mechanical properties of sandstone in deep strata under impact loads, an improved Hopkinson pressure bar experimental system was established. The traditional Hopkinson pressure bar’s transmission rod was replaced with a long rod specimen made of gray sandstone to better simulate deep geological conditions. Point spalling treatment was applied to the specimen, and strain gauges were meticulously affixed at critical measurement points.Dynamic compression experiments were meticulously conducted on the gray sandstone long rod specimen at various loading rates (9.57, 14.78, 19.32 and 27.60 m/s). Utilizing high-speed digital image correlation (DIC) technology, the evolution of displacement and strain fields on the surface of the specimen throughout each test was closely monitored. This advanced technique enabled a detailed exploration of how the gray sandstone responded to near-field impact loading, particularly focusing on its tensile failure characteristics.Employing the Lagrangian inverse analysis method, displacement-time curves for different mass points derived from the DIC analysis of displacement fields were extracted. These curves provided critical data to compute the stress-strain behavior of the gray sandstone material under dynamic loading conditions. The study reveals several key findings: the gray sandstone long rod specimen predominantly exhibits tensile failure, with distinct patterns of fragmentation near the loading end and layer cracking away from it. Moreover, the dynamic compressive strength factor of the gray sandstone long rod specimen shows a notable increase with higher strain rates, indicating a significant strain rate effect. Correspondingly, both stress and strain peaks observe an upward trend at various measurement points with increasing loading rates. Remarkably, under identical loading rates, stress-strain curves of the gray sandstone long rod specimen exhibit a unique phenomenon where curves from measurement points closer to the loading end envelop those from points farther away. This observation underscores the complex nature of dynamic loading responses in geological materials. Overall, this comprehensive investigation provides essential theoretical insights and methodological references for understanding the dynamic behavior of sandstone within deep geological formations under impact loads. The findings offer valuable contributions to engineering practices concerned with the stability and resilience of underground structures subjected to dynamic loading conditions.

-

表 1 灰砂岩的物理参数

Table 1. physical parameters of gray sandstone

密度/(kg·m−3) 泊松比 抗压强度/MPa 抗拉强度/MPa 弹性模量/GPa 2680 0.19 36.38 3.29 4.43 表 2 DIF计算参数

Table 2. The calculated parameters of the DIF

冲击速度/(m·s−1) 动态抗压强度/MPa DIF 应变率/s−1 9.57 17.3 0.4755 38.9 14.78 26.9 0.7394 85.5 19.32 31.2 0.8576 257.9 27.60 74.2 2.0396 271.2 -

[1] 谢和平. 深部岩体力学与开采理论研究进展 [J]. 煤炭学报, 2019, 44(5): 1283–1305. DOI: 10.13225/j.cnki.jccs.2019.6038.XIE H P. Research review of the state key research development program of China: deep rock mechanics and mining theory [J]. Journal of China Coal Society, 2019, 44(5): 1283–1305. DOI: 10.13225/j.cnki.jccs.2019.6038. [2] HEBIG K H, ITO N, SCHEYTT T, et al. Review: deep groundwater research with focus on Germany [J]. Hydrogeology Journal, 2012, 20(2): 227–243. DOI: 10.1007/s10040-011-0815-1. [3] 卢爱红, 茅献彪, 逄增伟. 扰动载荷对冲击矿压危险性的影响研究 [J]. 采矿与安全工程学报, 2014, 31(2): 175–179. DOI: 10.13545/j.issn1673-3363.2014.02.002.LU A H, MAO X B, PANG Z W. The influence of stress disturbance on the danger of rock burst [J]. Journal of Mining & Safety Engineering, 2014, 31(2): 175–179. DOI: 10.13545/j.issn1673-3363.2014.02.002. [4] 杨敬轩, 刘长友, 于斌, 等. 坚硬厚层顶板群结构破断的采场冲击效应 [J]. 中国矿业大学学报, 2014, 43(1): 8–15. DOI: 10.13247/j.cnki.jcumt.000008.YANG J X, LIU C Y, YU B, et al. Impact effect caused by the fracture of thick and hard roof structures in a longwall face [J]. Journal of China University of Mining & Technology, 2014, 43(1): 8–15. DOI: 10.13247/j.cnki.jcumt.000008. [5] 解北京, 李晓旭, 栾铮, 等. 应力波作用下红砂岩复合动态断裂特征研究 [J]. 矿业科学学报, 2024, 9(1): 42–52. DOI: 10.19606/j.cnki.jmst.2024.01.005.XIE B J, LI X X, LUAN Z, et al. Study on the dynamic fracture characteristics of red sandstone composite under stress waves [J]. Journal of Mining Science and Technology, 2024, 9(1): 42–52. DOI: 10.19606/j.cnki.jmst.2024.01.005. [6] LI D Y, WANG T, CHENG T J, et al. Static and dynamic tensile failure characteristics of rock based on splitting test of circular ring [J]. Transactions of Nonferrous Metals Society of China, 2016, 26(7): 1912–1918. DOI: 10.1016/S1003-6326(16)64307-8. [7] 康一强, 张祥, 贾文豪, 等. 张开型节理角度和长度对类岩石材料动力学特性的影响 [J]. 矿业科学学报, 2022, 7(3): 296–303. DOI: 10.19606/j.cnki.jmst.2022.03.004.KANG Y Q, ZHANG X, JIA W H, et al. Effects of dip angle and length of open joints on dynamic properties of materials like rock [J]. Journal of Mining Science and Technology, 2022, 7(3): 296–303. DOI: 10.19606/j.cnki.jmst.2022.03.004. [8] 赖华伟, 王占江, 杨黎明, 等. 由球面波径向质点速度实测数据反演材料黏弹性本构参数 [J]. 高压物理学报, 2013, 27(2): 245–252. DOI: 10.11858/gywlxb.2013.02.012.LAI H W, WANG Z J, YANG L M, et al. Inversion of constitutive parameters for visco-elastic materials from radial velocity measurements of spherical wave experiments [J]. Chinese Journal of High Pressure Physics, 2013, 27(2): 245–252. DOI: 10.11858/gywlxb.2013.02.012. [9] 唐晓明, 王鹤鸣, 苏远大, 等. 用孔隙、裂隙介质弹性波理论反演岩石孔隙分布特征 [J]. 地球物理学报, 2021, 64(8): 2941–2951. DOI: 10.6038/cjg2021O0478.TANG X M, WANG H M, SU Y D, et al. Inversion for micro-pore structure distribution characteristics using cracked porous medium elastic wave theory [J]. Chinese Journal of Geophysics, 2021, 64(8): 2941–2951. DOI: 10.6038/cjg2021O0478. [10] 崔伟雄, 王保利, 王云宏. 基于透射槽波的工作面煤层厚度高精度反演方法 [J]. 煤炭学报, 2020, 45(7): 2482–2490. DOI: 10.13225/j.cnki.jccs.dz20.0670.CUI W X, WANG B L, WANG Y H. High-precision inversion method of coal seam thickness based on transmission channel wave [J]. Journal of China Coal Society, 2020, 45(7): 2482–2490. DOI: 10.13225/j.cnki.jccs.dz20.0670. [11] 平琦, 马芹永, 袁璞. SHPB试验岩石试件应力平衡时间预估分析 [J]. 振动与冲击, 2013, 32(12): 55–60. DOI: 10.13465/j.cnki.jvs.2013.12.004.PING Q, MA Q Y, YUAN P. Prediction for stress equilibrium time in rock SHPB test [J]. Journal of Vibration and Shock, 2013, 32(12): 55–60. DOI: 10.13465/j.cnki.jvs.2013.12.004. [12] 王礼立, 朱珏, 赖华伟. 冲击动力学研究中实测波信息的解读分析 [J]. 高压物理学报, 2010, 24(4): 279–285. DOI: 10.11858/gywlxb.2010.04.007.WANG L L, ZHU J, LAI H W. Understanding and interpreting of the measured wave signals in impact dynamics studies [J]. Chinese Journal of High Pressure Physics, 2010, 24(4): 279–285. DOI: 10.11858/gywlxb.2010.04.007. [13] FOWLES R. Conservation relations for spherical and cylindrical stress waves [J]. Journal of Applied Physics, 1970, 41(6): 2740–2741. DOI: 10.1063/1.1659298. [14] COWPERTHWAITE M, WILLIAMS R F. Determination of constitutive relationships with multiple gauges in nondivergent waves [J]. Journal of Applied Physics, 1971, 42(1): 456–462. DOI: 10.1063/1.1659623. [15] GRADY D E. Experimental analysis of spherical wave propagation [J]. Journal of Geophysical Research, 1973, 78(8): 1299–1307. DOI: 10.1029/JB078i008p01299. [16] WANG L, ZHU J, LAI H. A new method combining Lagrangian analysis with Hopkinson pressure bar technique [J]. Strain, 2011, 47(2): 173–182. DOI: 10.1111/j.1475-1305.2008.00533.x. [17] 赖华伟, 王礼立. 用改进的基于质点速度测量的拉格朗日分析方法研究尼龙动态力学特性 [J]. 实验力学, 2011, 26(2): 221–227.LAI H W, WANG L L. Nylon dynamic mechanical behavior study through a modified Lagrangian analysis based on particle velocity profile measurement [J]. Journal of Experimental Mechanics, 2011, 26(2): 221–227. [18] DING Y Y, WANG S L, ZHENG Z J, et al. Dynamic crushing of cellular materials: a unique dynamic stress-strain state curve [J]. Mechanics of Materials, 2016, 100: 219–231. DOI: 10.1016/j.mechmat.2016.07.001. [19] 丁圆圆, 张振, 赖华伟, 等. 基于全光纤激光干涉测速技术的拉氏反分析方法应用于脆性材料动态本构关系研究 [J]. 振动与冲击, 2019, 38(11): 116–120,131. DOI: 10.13465/j.cnki.jvs.2019.11.018.DING Y Y, ZHANG Z, LAI H W, et al. Lagrangian inverse analysis method for studying dynamic constitutive relation of brittle materials based on all-fiber laser interference velocity measurement technique [J]. Journal of Vibration and Shock, 2019, 38(11): 116–120,131. DOI: 10.13465/j.cnki.jvs.2019.11.018. [20] 陶为俊, 浣石, 蒋国平. 基于最小二乘法的Lagrange分析方法研究 [J]. 振动与冲击, 2012, 31(21): 98–101, 142. DOI: 10.13465/j.cnki.jvs.2012.21.001.TAO W J, HUAN S, JIANG G P. Lagrangian analysis method based on least square [J]. Journal of Vibration and Shock, 2012, 31(21): 98–101, 142. DOI: 10.13465/j.cnki.jvs.2012.21.001. [21] 李运良, 李进, 景吉勇, 等. 重塑黄土一维应变实验粒子速度测试波形的拉格朗日分析 [J]. 工程力学, 2017, 34(3): 29–35. DOI: 10.6052/j.issn.1000-4750.2015.09.0786.LI Y L, LI J, JING J Y, et al. Lagrangian analysis for a set of particle velocity profiles measured in remolding loess under one-dimensional strain experiment [J]. Engineering Mechanics, 2017, 34(3): 29–35. DOI: 10.6052/j.issn.1000-4750.2015.09.0786. [22] 丁圆圆, 杨黎明, 王礼立. 对基于质点速度测量的拉格朗日分析法的进一步探讨 [J]. 宁波大学学报(理工版), 2012, 25(4): 83–87. DOI: 10.3969/j.issn.1001-5132.2012.04.017.DING Y Y, YANG L M, WANG L L. A further discussion on the Lagrangian analysis method based on particle velocity wave-profiles measurements [J]. Journal of Ningbo University (Natural Science & Engineering Edition), 2012, 25(4): 83–87. DOI: 10.3969/j.issn.1001-5132.2012.04.017. [23] 朱珏. 混凝土类材料冲击本构特性的SHPB技术及Lagrange反解法的研究 [D]. 合肥: 中国科学技术大学, 2006.ZHU J. On SHPB technique and Lagrangian analysis used for studying the impact response of concrete-like materials [D]. Hefei: University of Science and Technology of China, 2006. [24] 胡良鹏, 孙阳阳, 岳松林, 等. 基于高速DIC的近场冲击下高强混凝土动态压缩性能研究 [J]. 振动与冲击, 2023, 42(12): 77–87,117. DOI: 10.13465/j.cnki.jvs.2023.012.009.HU L P, SUN Y Y, YUE S L, et al. Investigation of dynamic compression performance of high-strength concrete under near-field impact based on high-speed DIC [J]. Journal of Vibration and Shock, 2023, 42(12): 77–87,117. DOI: 10.13465/j.cnki.jvs.2023.012.009. [25] 邢灏喆, 王明洋, 范鹏贤, 等. 基于高速3D-DIC技术的砂岩动力特性粒径效应研究 [J]. 爆炸与冲击, 2021, 41(11): 113101. DOI: 10.11883/bzycj-2021-0088.XING H Z, WANG M Y, FAN P X, et al. Grain-size effect on dynamic behavior of sandstone based on high-speed 3D-DIC technique [J]. Explosion and Shock Waves, 2021, 41(11): 113101. DOI: 10.11883/bzycj-2021-0088. [26] 俞鑫炉, 付应乾, 董新龙, 等. 混凝土一维应力层裂实验的全场DIC分析 [J]. 力学学报, 2019, 51(4): 1064–1072. DOI: 10.6052/0459-1879-19-008.YU X L, FU Y Q, DONG X L, et al. Full field DIC analysis of one-dimensional spall strength for concrete [J]. Chinese Journal of Theoretical and Applied Mechanics, 2019, 51(4): 1064–1072. DOI: 10.6052/0459-1879-19-008. [27] 申海艇, 蒋招绣, 王贝壳, 等. 基于超高速相机的数字图像相关性全场应变分析在SHTB实验中的应用 [J]. 爆炸与冲击, 2017, 37(1): 15–20. DOI: 10.11883/1001-1455(2017)01-0015-06.SHEN H T, JIANG Z X, WANG B K, et al. Full field strain measurement in split Hopkinson tension bar experiments by using ultra-high-speed camera with digital image correlation [J]. Explosion and Shock Waves, 2017, 37(1): 15–20. DOI: 10.11883/1001-1455(2017)01-0015-06. [28] HUANG Y, JI J J, LEE K M. Model-based digital image correlation for noncontact deformation measurement of strain field and mechanical property [J]. IEEE Transactions on Industrial Informatics, 2019, 15(9): 5109–5118. DOI: 10.1109/TII.2019.2896167. [29] 陈静静. 基于高速DIC方法的脆性材料动态力学性能研究 [D]. 北京: 北京理工大学, 2014.CHEN J J. Study on the dynamic mechanical properties of brittle materials by high-speed DIC [D]. Beijing: Beijing Institute of Technology, 2014. [30] 李二强, 冯吉利, 朱天宇, 等. 基于数字图像相关方法的层状板岩Ⅰ型断裂特性研究 [J]. 采矿与安全工程学报, 2021, 38(5): 979–987. DOI: 10.13545/j.cnki.jmse.2020.0375.LI E Q, FENG J L, ZHU T Y, et al. Examining type I fracture characteristics in layered slates with digital image correlation [J]. Journal of Mining & Safety Engineering, 2021, 38(5): 979–987. DOI: 10.13545/j.cnki.jmse.2020.0375. [31] 张沛. 基于数字图像相关方法的煤岩表面应变场及裂纹演化特征 [J]. 煤炭技术, 2024, 43(4): 52–56. DOI: 10.13301/j.cnki.ct.2024.04.011.ZHANG P. Surface strain field and crack evolution characteristics of coal-rock based on digital image correlation method [J]. Coal Technology, 2024, 43(4): 52–56. DOI: 10.13301/j.cnki.ct.2024.04.011. [32] SATO K, YU Q, HIRAMOTO J, et al. A method to investigate strain rate effects on necking and fracture behaviors of advanced high-strength steels using digital imaging strain analysis [J]. International Journal of Impact Engineering, 2015, 75: 11–26. DOI: 10.1016/j.ijimpeng.2014.07.001. [33] LINGGA B A, APEL D B, SEPEHRI M, et al. Assessment of digital image correlation method in determining large scale cemented rockfill strains [J]. International Journal of Mining Science and Technology, 2019, 29(5): 771–776. DOI: 10.1016/j.ijmst.2018.12.002. [34] 丁圆圆, 张振, 赖华伟, 等. 基于数字图像相关性方法的脆性材料拉氏反分析实验技术 [J]. 爆炸与冲击, 2018, 38(6): 1310–1316. DOI: 10.11883/bzycj-2018-0049.DING Y Y, ZHANG Z, LAI H W, et al. A Lagrangian inverse analysis technique for studying dynamic mechanical properites of brittle materials based on digital image correlation [J]. Explosion and Shock Waves, 2018, 38(6): 1310–1316. DOI: 10.11883/bzycj-2018-0049. -

下载:

下载: