Influence of longitudinal air gaps within charge structure on the detonation performance of explosives

-

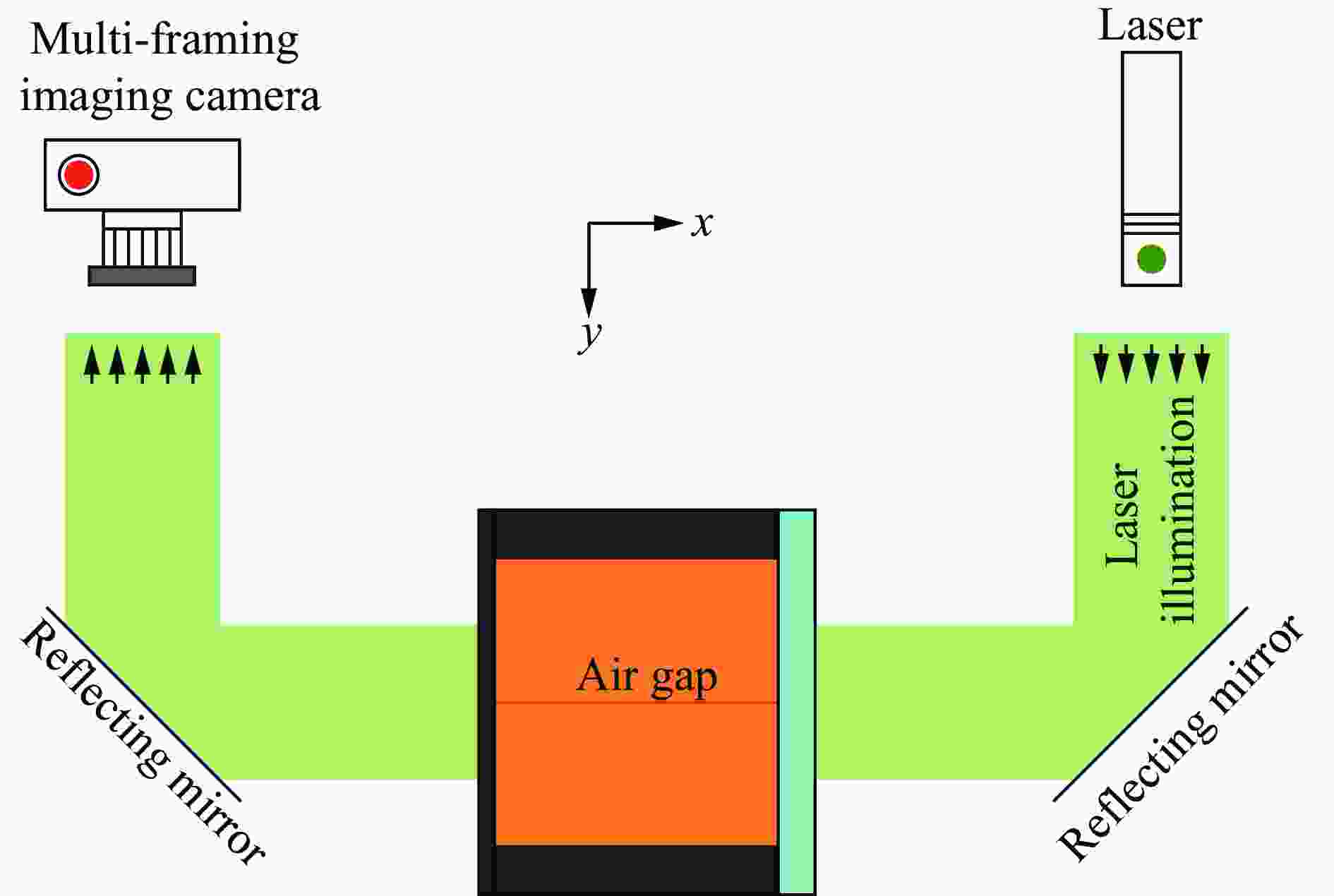

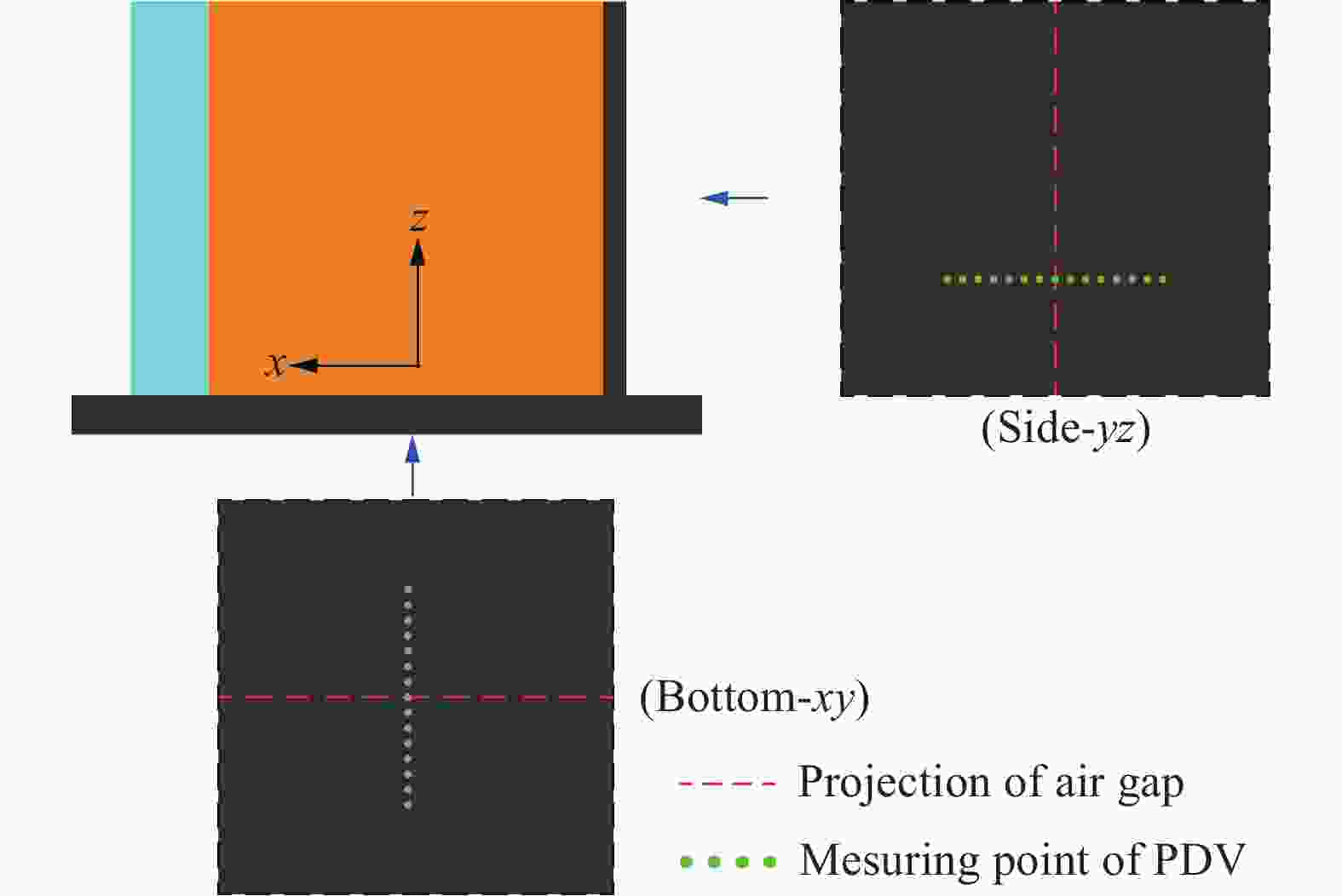

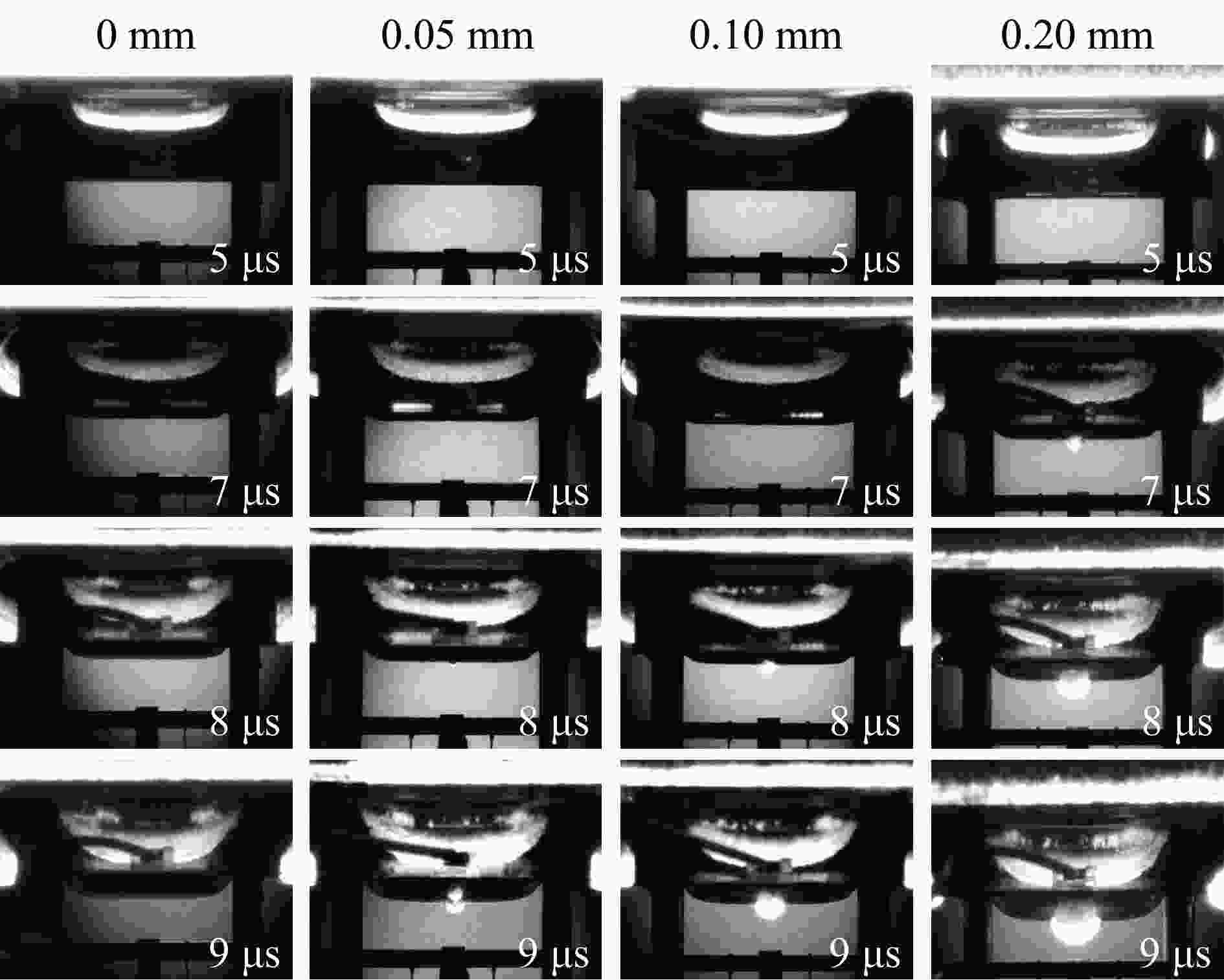

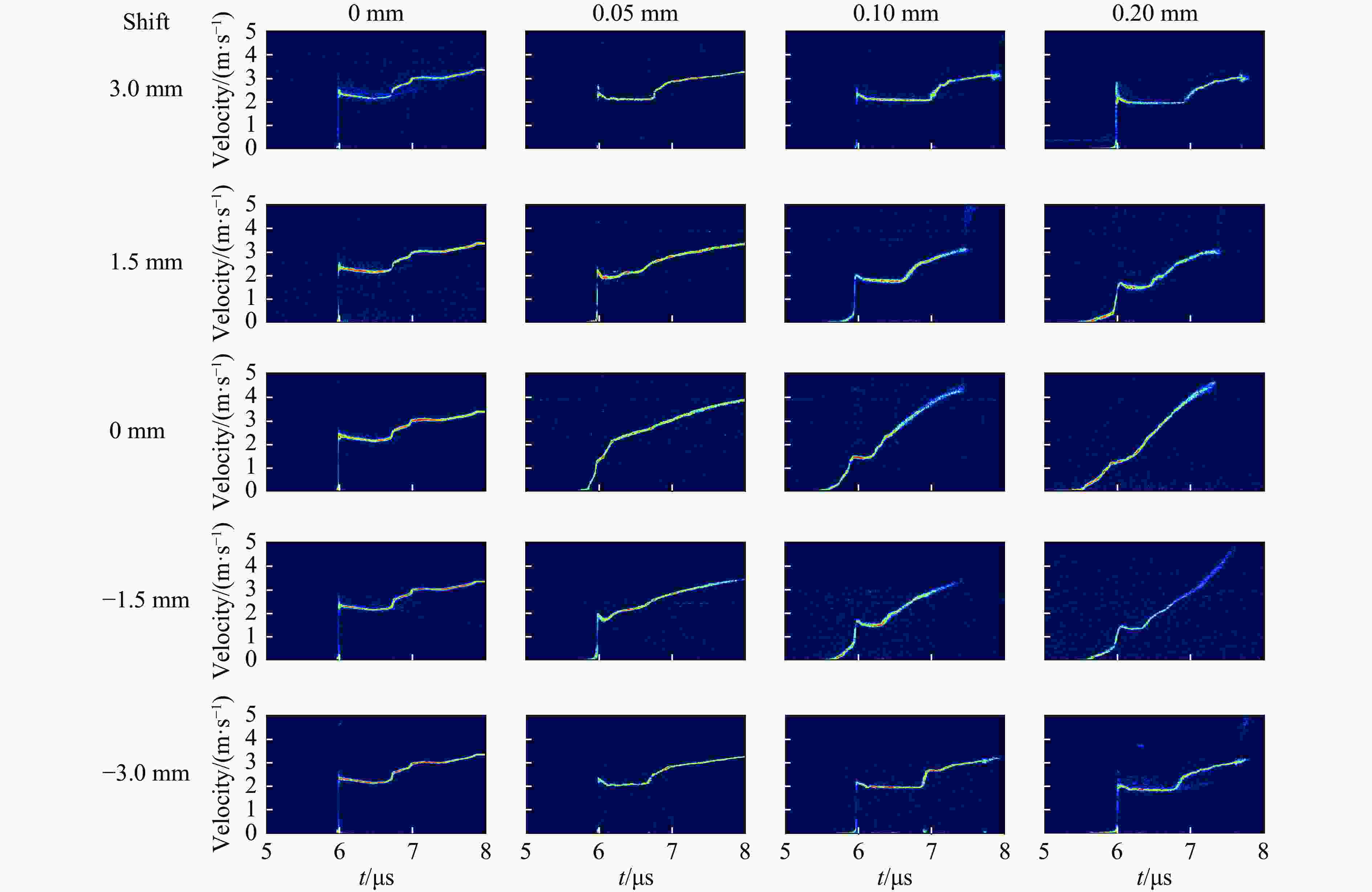

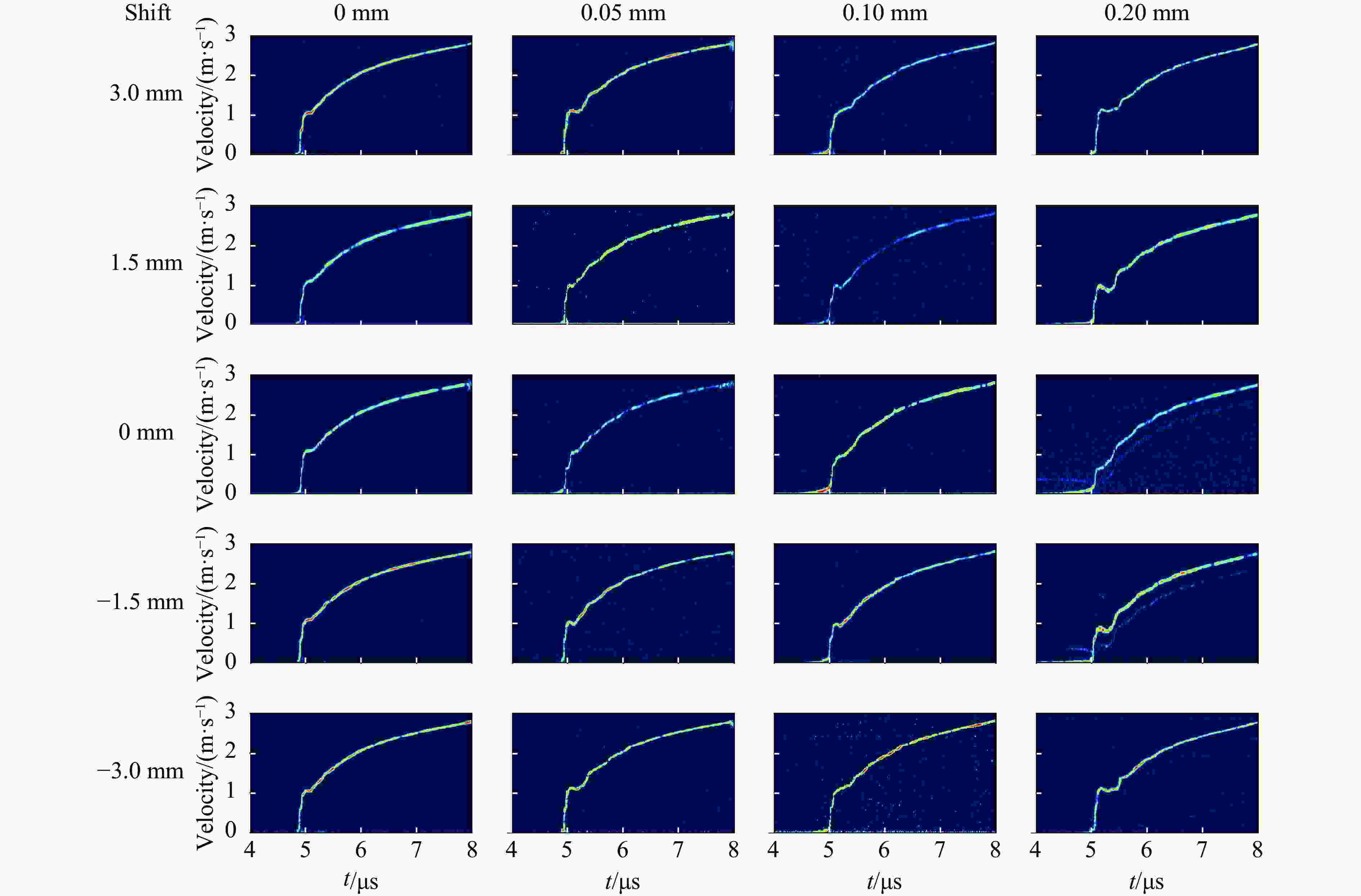

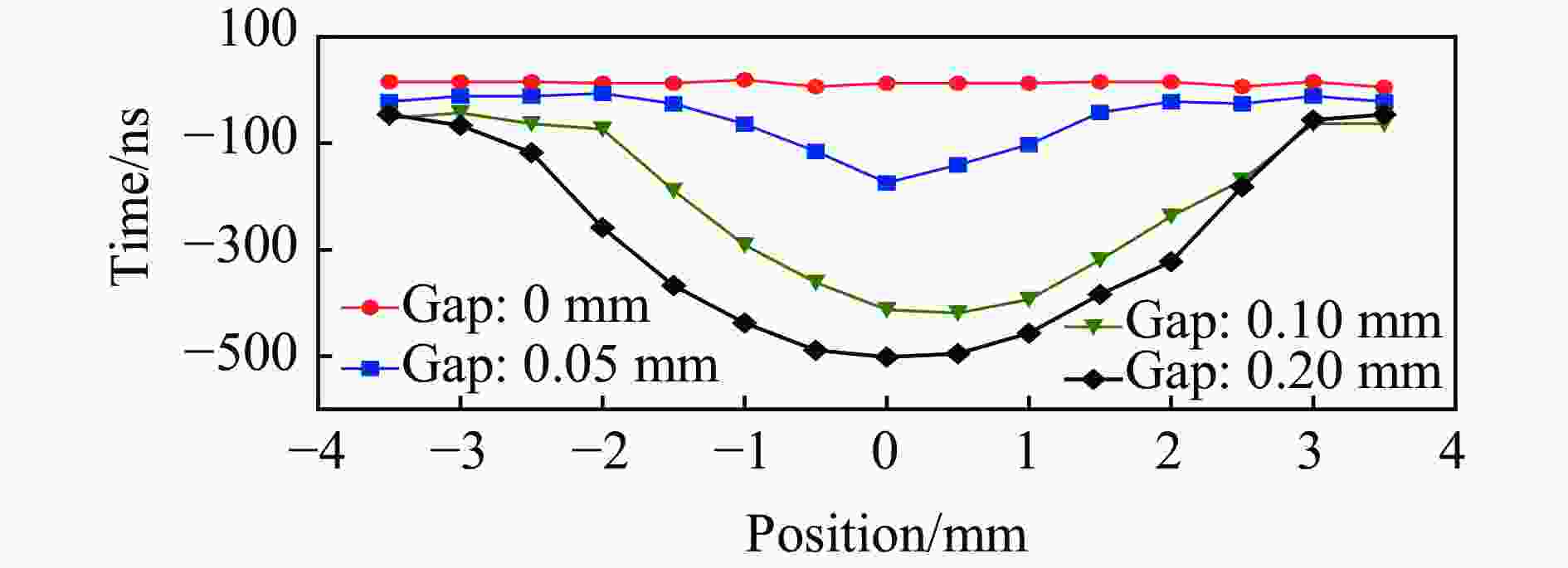

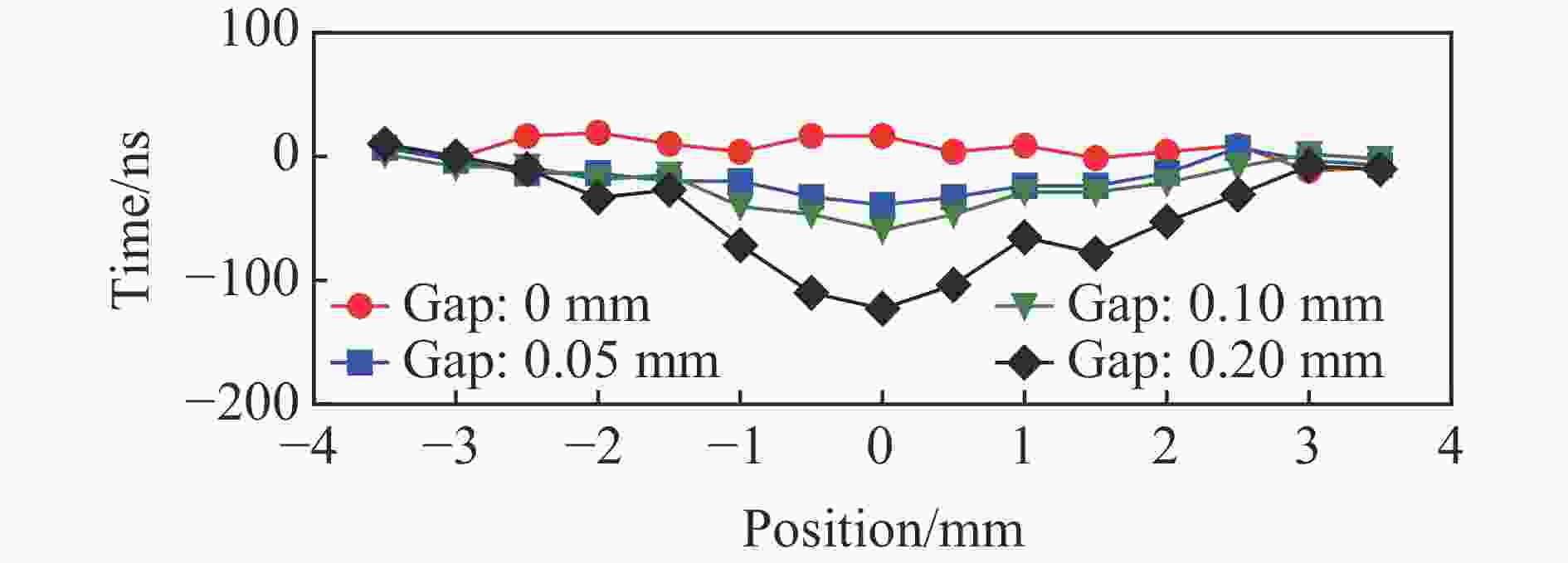

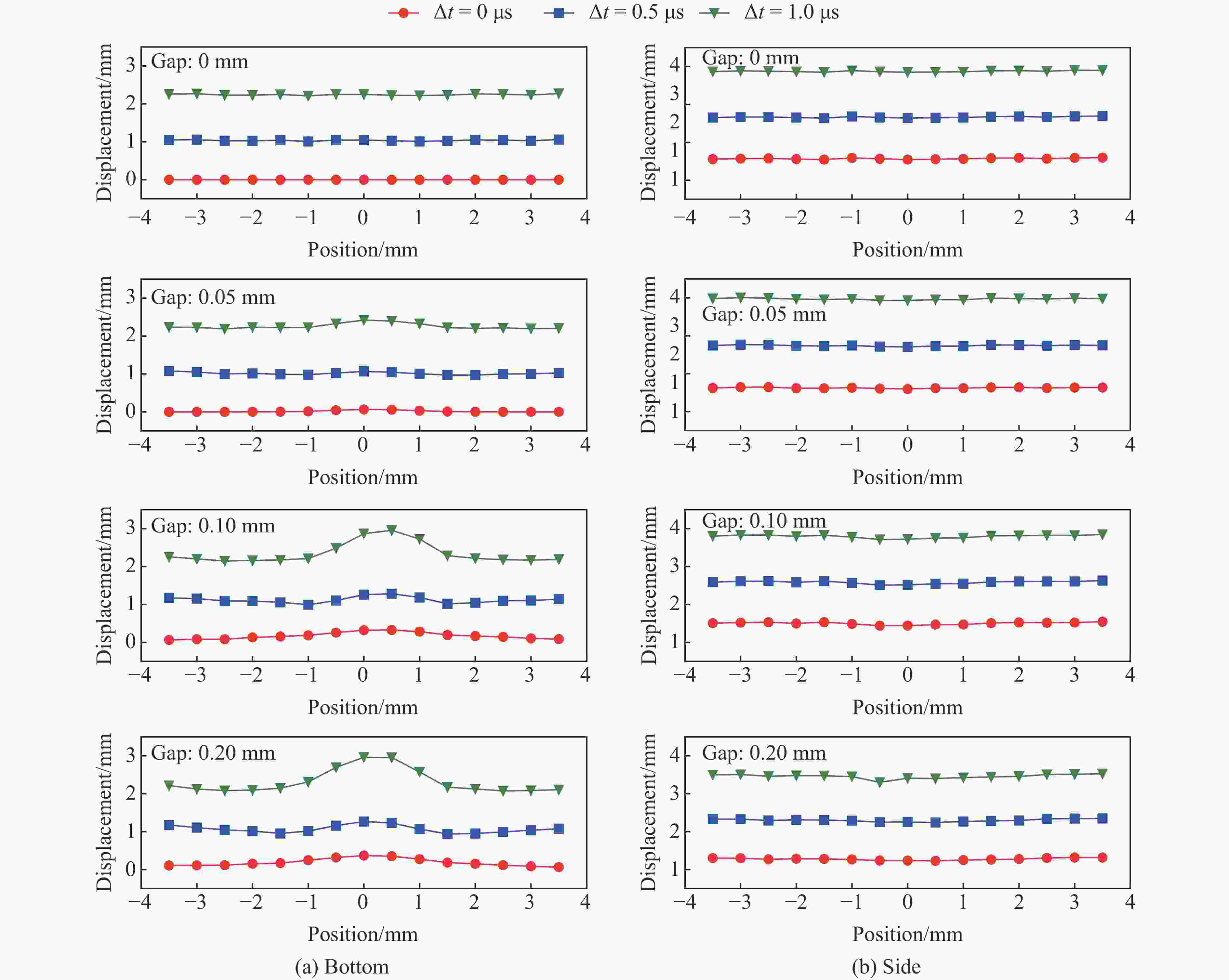

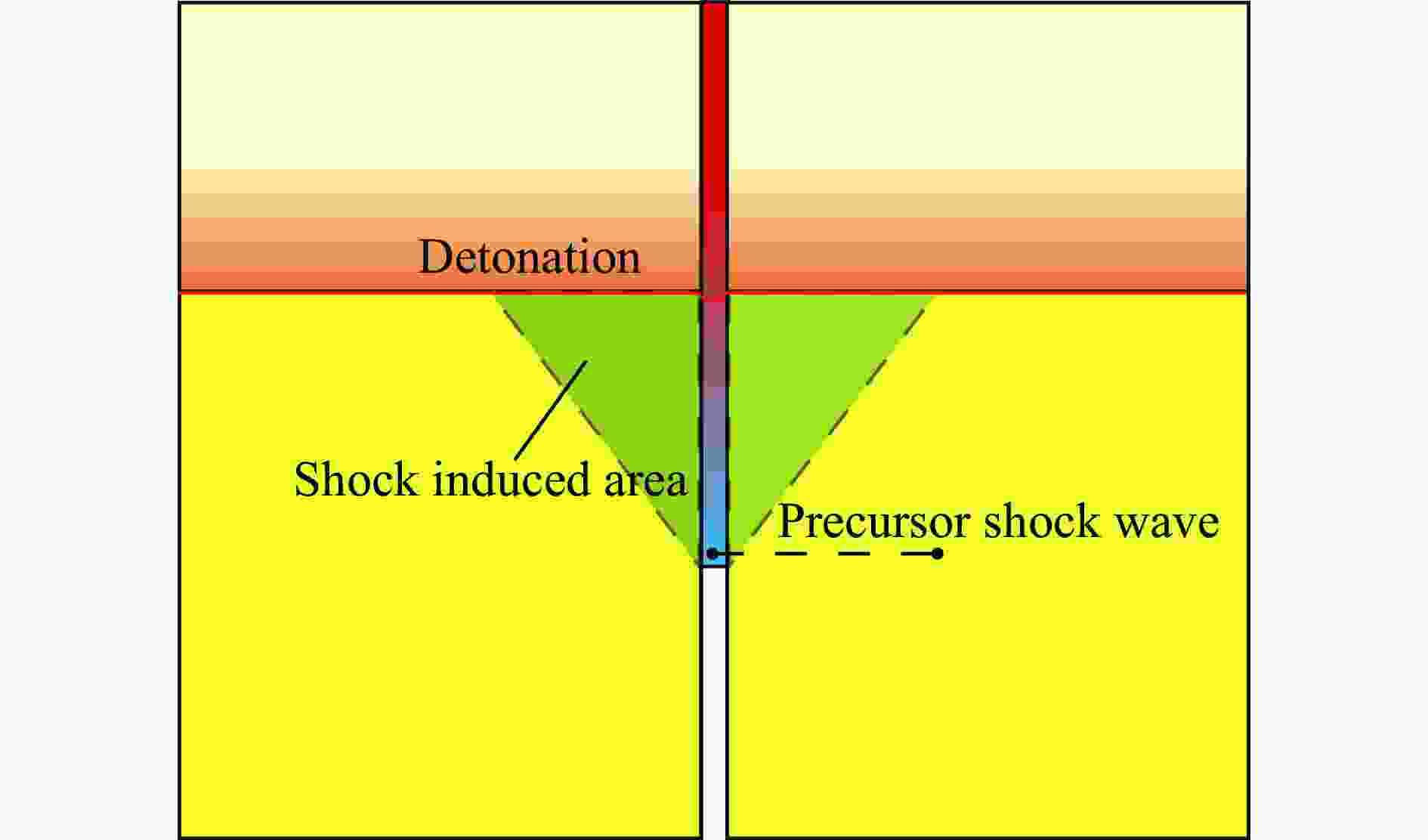

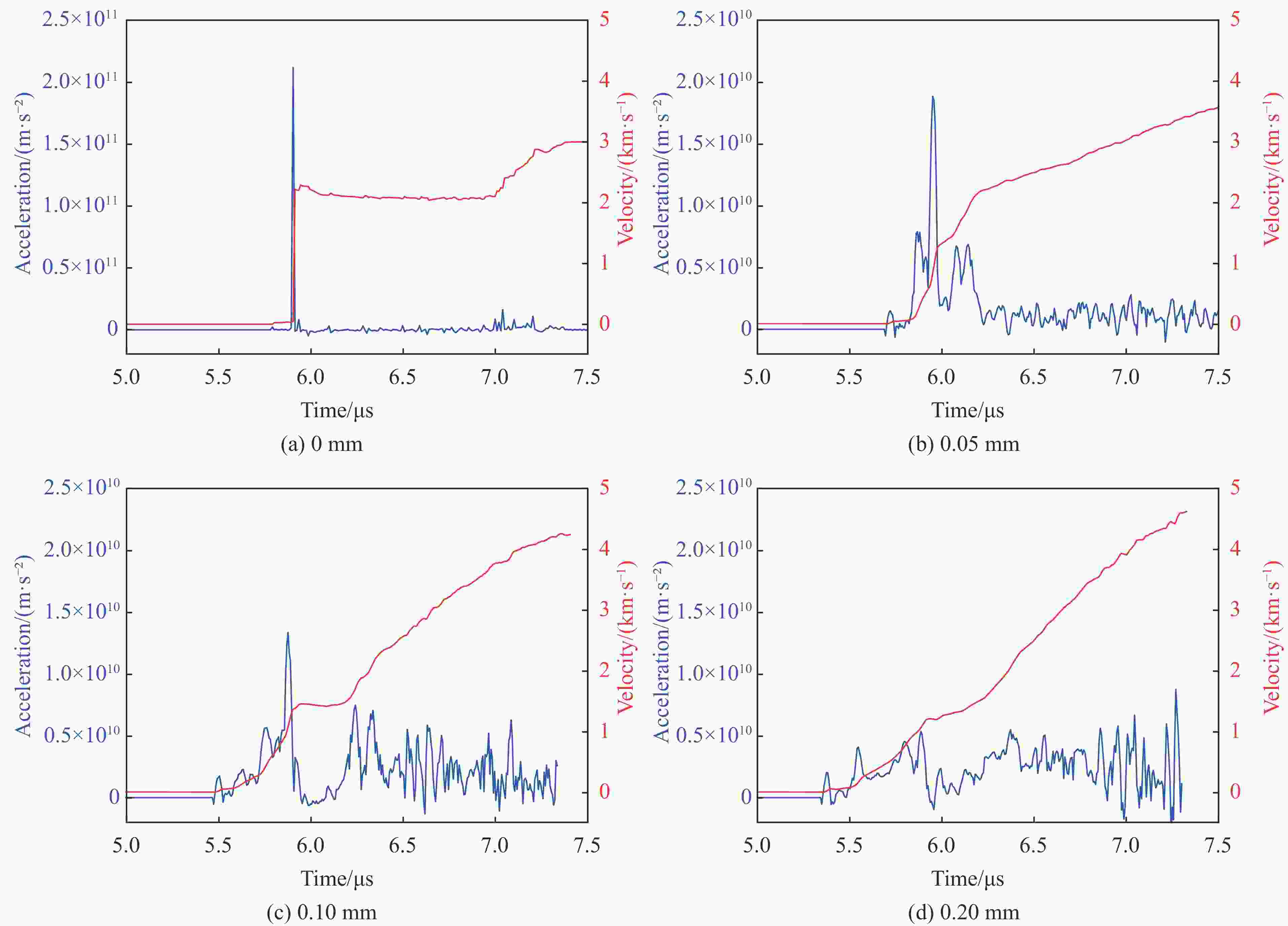

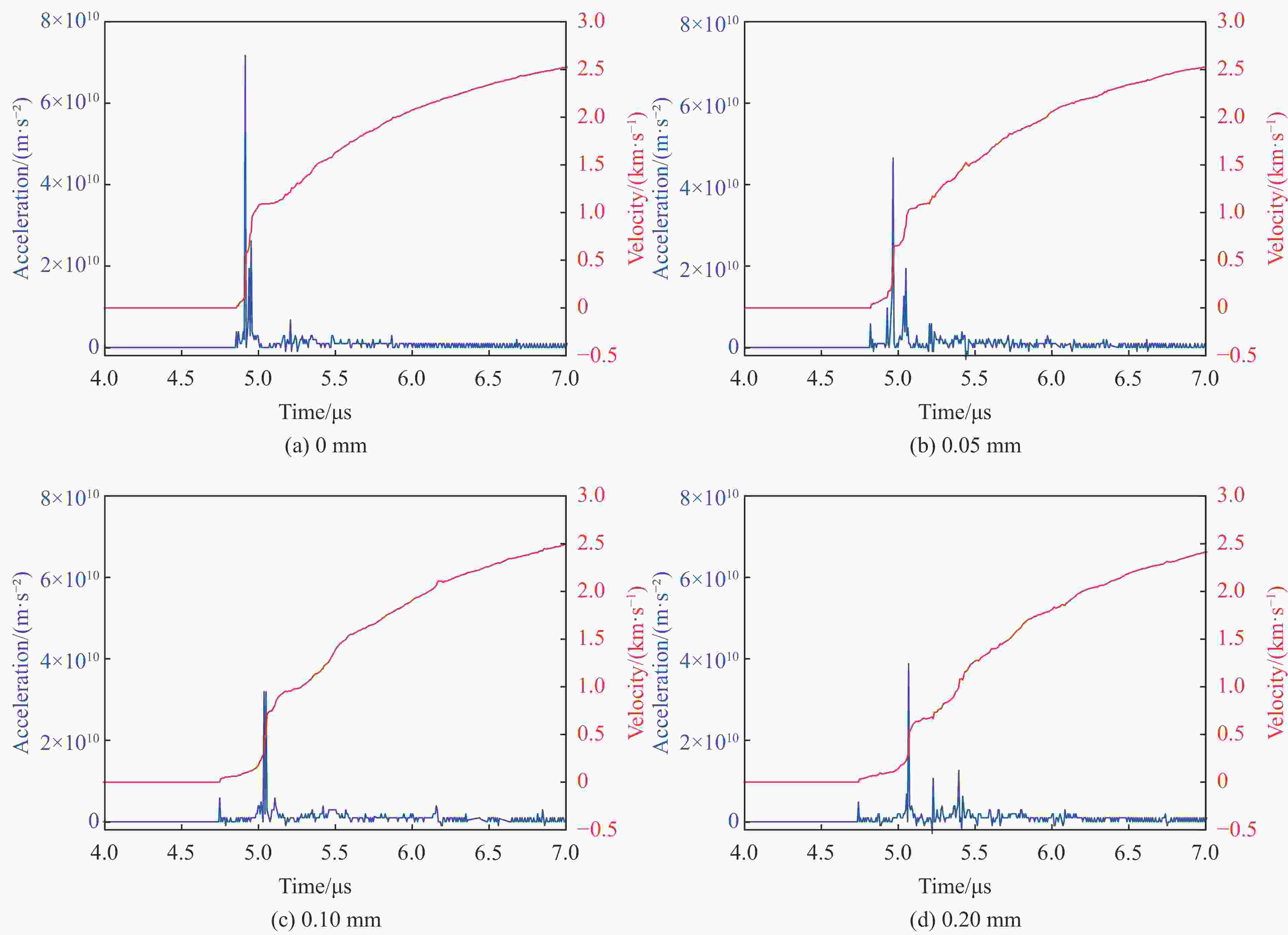

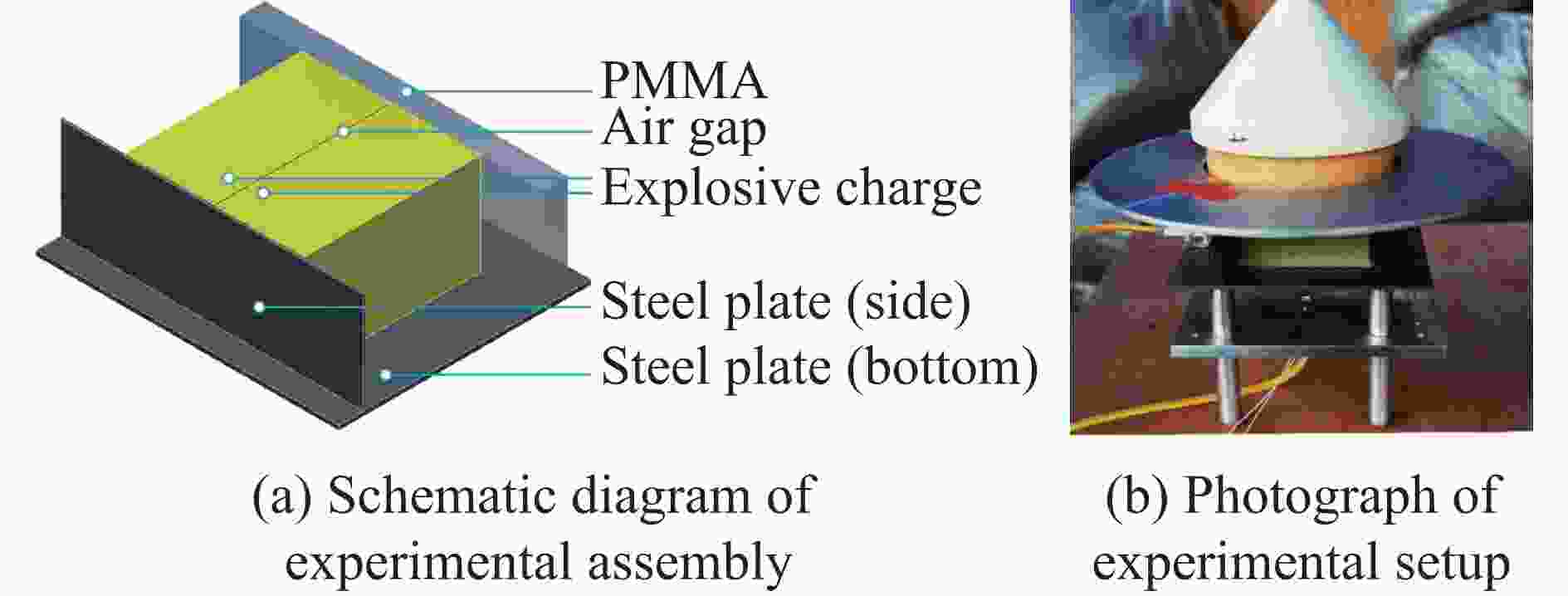

摘要: 为阐明装药结构中纵向气隙对炸药爆轰输出性能的影响,基于激光照明结合超高速分幅成像技术研究了HMX基炸药爆轰正向驱动及滑移驱动下钢板的变形及损伤情况,并通过密排光纤测速技术测量了钢板的运动速度,实现了气隙影响下钢板附带损失的量化表征。结果表明,纵向气隙宽度为0.05、0.10和0.20 mm时,爆轰正向驱动下,钢板的运动模式发生了显著变化,中心点的运动趋势由阶跃式上升转变为斜波式上升,且爆轰波的超前时间大幅度增加,钢板有明显的变形和破坏击穿现象;爆轰滑移驱动下,钢板的运动模式和爆轰波的超前时间基本不变,钢板没有出现明显的变形和击穿现象。爆轰正向驱动下,前驱冲击波和两侧爆轰波构成的楔形波系是造成底部钢板破坏击穿的关键;爆轰滑移驱动下,前驱冲击波和爆轰波作用于侧面钢板的动量分量较小,不会造成明显的变形和损伤。Abstract: To investigate the effect of the longitudinal air gap on the detonation performance of HMX-based explosive, direct observation of steel plate deformation and damage under forward and slipping detonation of HMX based explosive was conducted based on the laser illumination combined with the ultra-high speed framing imaging technology. The multi-position optical speed measurement technology was also introduced to continuously measure the speed of steel plate, which enables a multidimensional characterization and quantitative research on steel plate damage under the influence of air gaps. It is found that when the air gap width is 0.05, 0.10 and 0.20 mm, the motion mode of the steel plate changes obviously under the forward detonation. The trend of the center point movement changes from step rising to oblique wave rising, indicating a notable elongation of the lead time of detonation wave. And the steel plate also has an obvious deformation and breakdown. Driven by slipping detonation, the motion patterns across various points of the steel plate are largely uniform, with only marginal variations in the lead time of detonation wave. No significant deformation or rupture of the steel plate is observed. It is considered that the wedge-shaped wave formed by the precursor shock wave and detonation waves is the key to the breakdown of the bottom of steel plate in the case of forward detonation. However, the momentum component of the precursor shock wave and detonation wave acting on the side of steel plate in the case of slipping detonation is small, so that no obvious damage occurs. This article also provides a lot of quantitative data on the deformation of steel plates subjected to longitudinal air gaps, which can provide high-precision experimental data for the related numerical simulations and theoretical analysis work.

-

Key words:

- air gap /

- detonation /

- explosives /

- crack

-

-

[1] DUBNOV L V, KHOTINA L D. Channel effect mechanism in the detonation of condensed explosives [J]. Combustion, Explosion and Shock Waves, 1966, 2(4): 59–63. DOI: 10.1007/BF01261518. [2] BJARNHOLT G, SMEDBERG U. On detonation driven air shocks in the air gap between a charge and its confinement [C]//Proceedings of the 8th Symposium (International) on Detonation. Albuquerque, NM, 1985: 1069. [3] SOUERS P C, AULT S, AVARA R, et al. Air gap effects in LX-17 [J]. Propellants, Explosives, Pyrotechnics, 2006, 31(4): 294–298. DOI: 10.1002/prep.200600040. [4] DAVIS W C, HILL L G. Joints, cracks, holes and gaps in detonating explosives [C]//Proceedings of the 12th Symposium (International) on Detonation. San Diego, CA, 2002: 220. [5] TANGUAY V, HIGGINS A J. The channel effect: coupling of the detonation and the precursor shock wave by precompression of the explosive [J]. Journal of Applied Physics, 2004, 96(9): 4894–4902. DOI: 10.1063/1.1787913. [6] BRAILOVSKY I, SIVASHINSKY G. Precursors in two-phase detonation: an elementary model for the channel effect [J]. Combustion Theory and Modelling, 2014, 18(1): 117–147. DOI: 10.1080/13647830.2013.870354. [7] BRAILOVSKY I, SIVASHINSKY G. Precursors in two-phase detonation: occurrence of a contact discontinuity [J]. Combustion Theory and Modelling, 2015, 19(6): 833–855. DOI: 10.1080/13647830.2015.1105385. -

下载:

下载: