Numerical modeling of the energy dissipation and fragmentation of copper-bearing rock under impact load

-

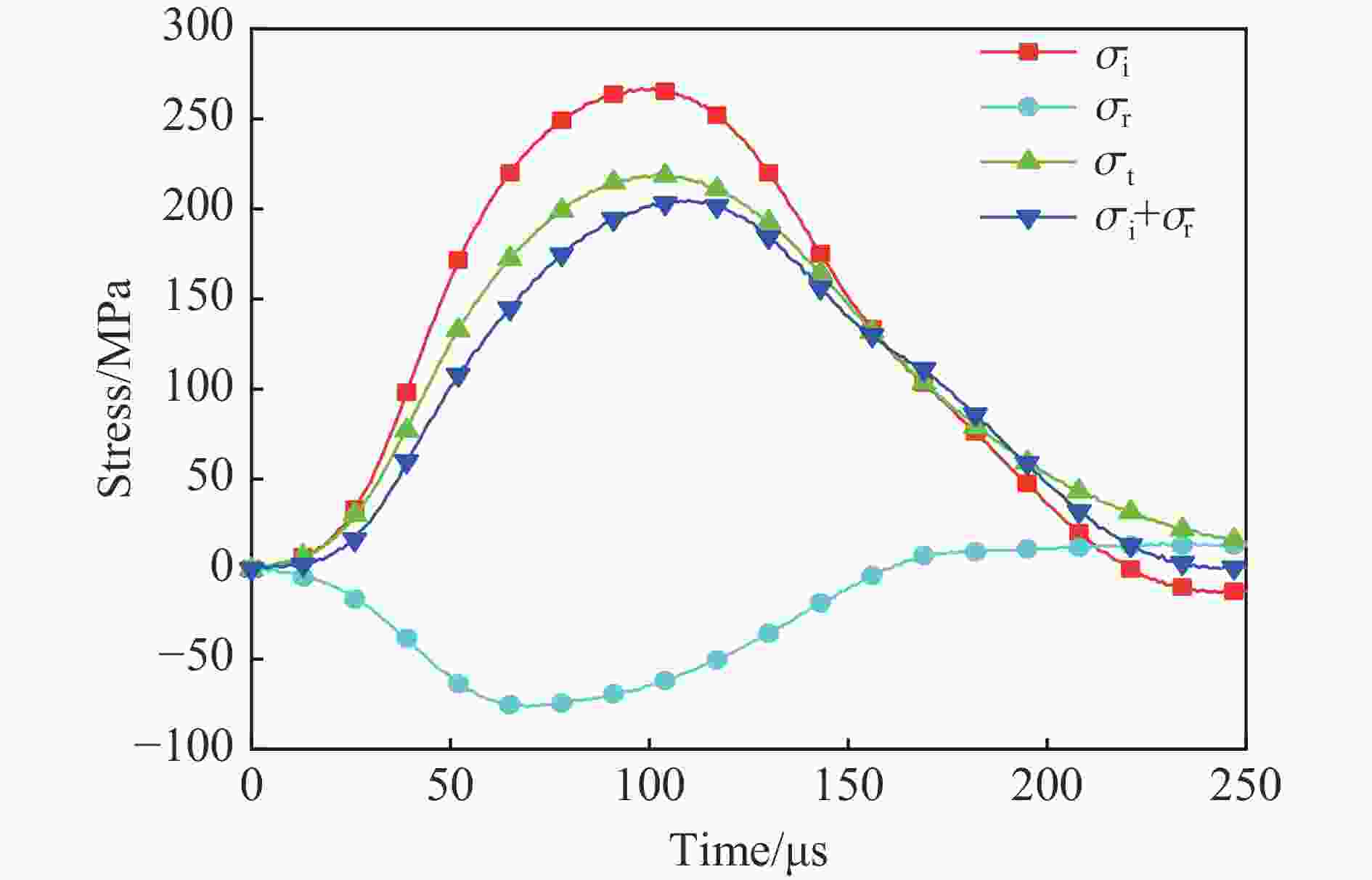

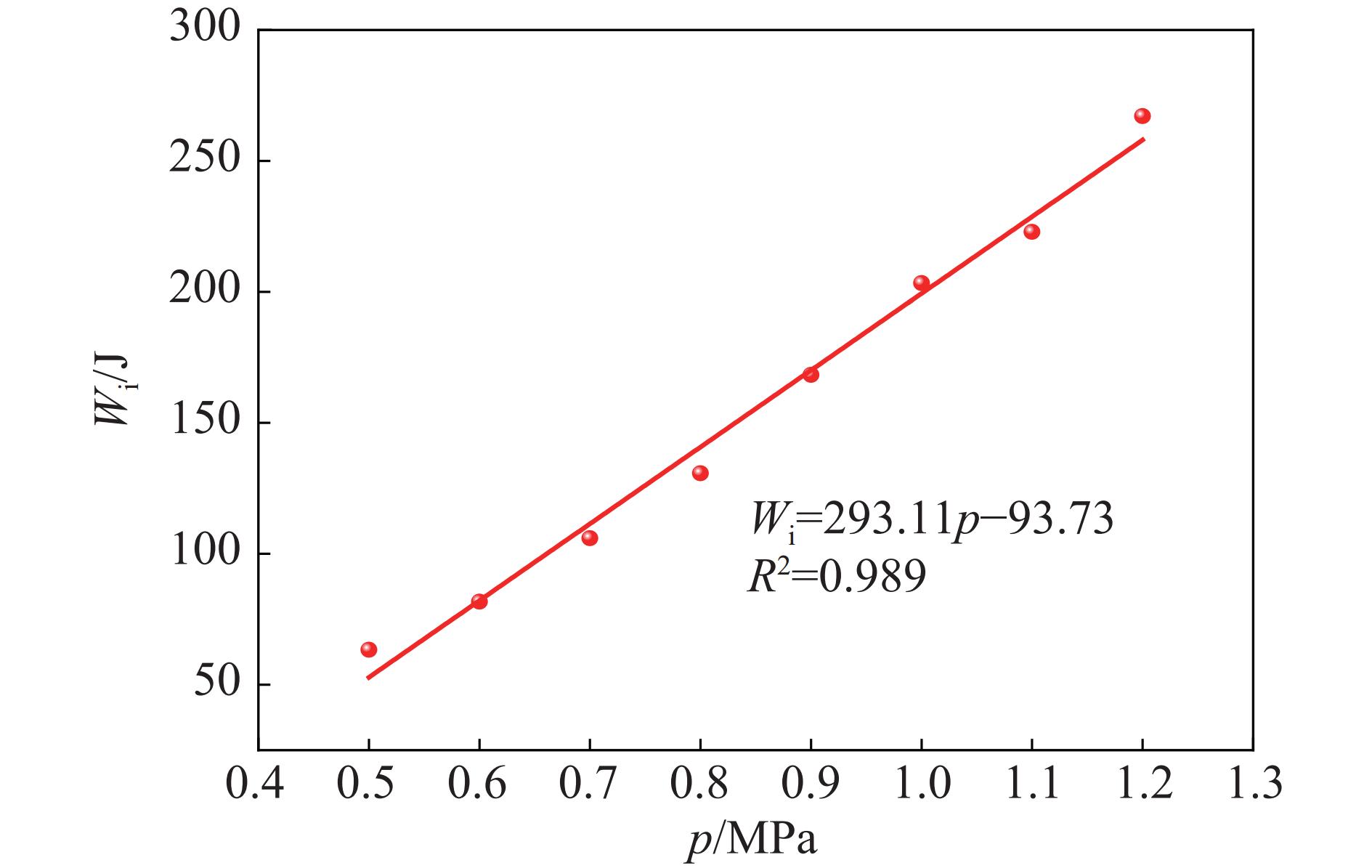

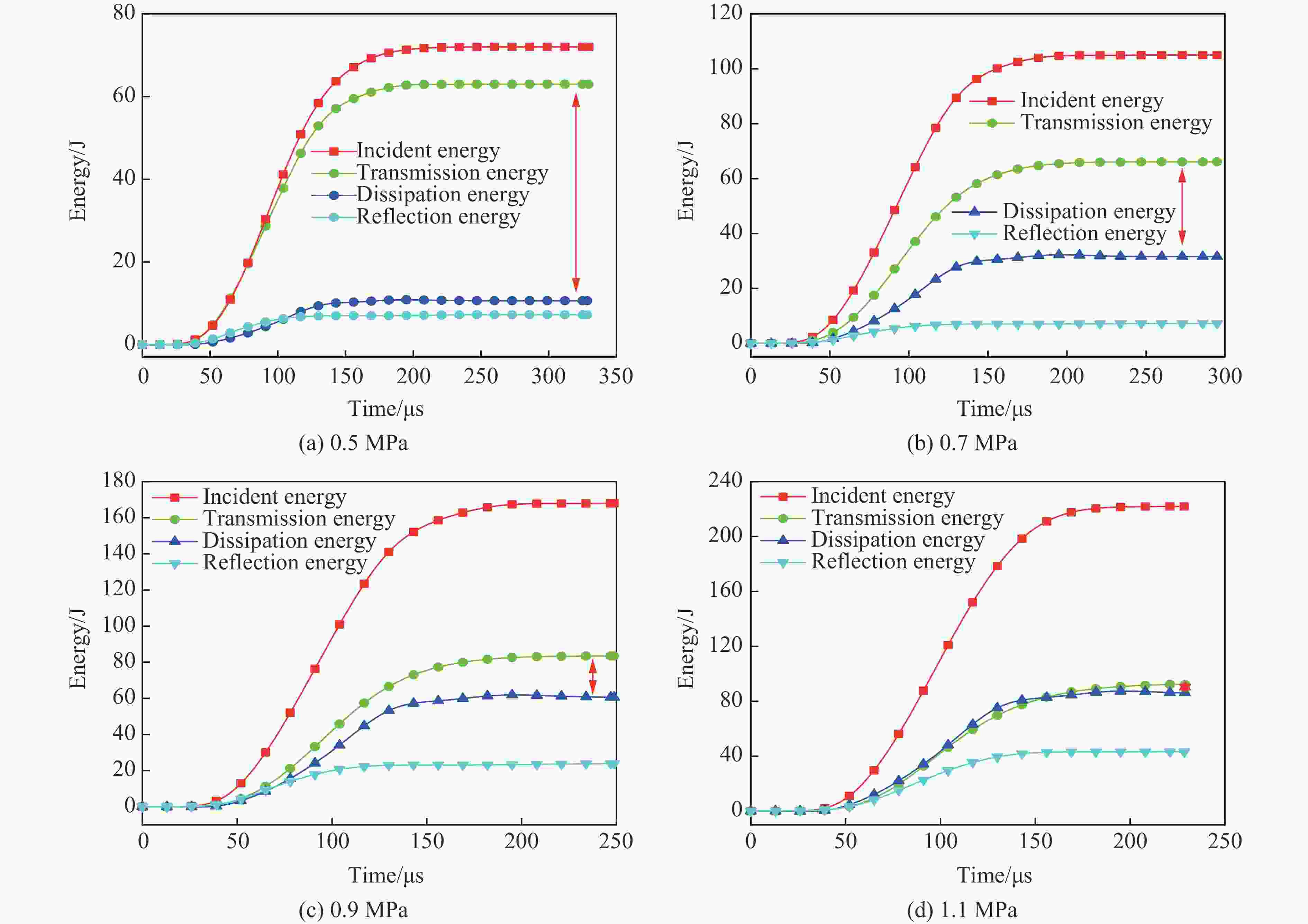

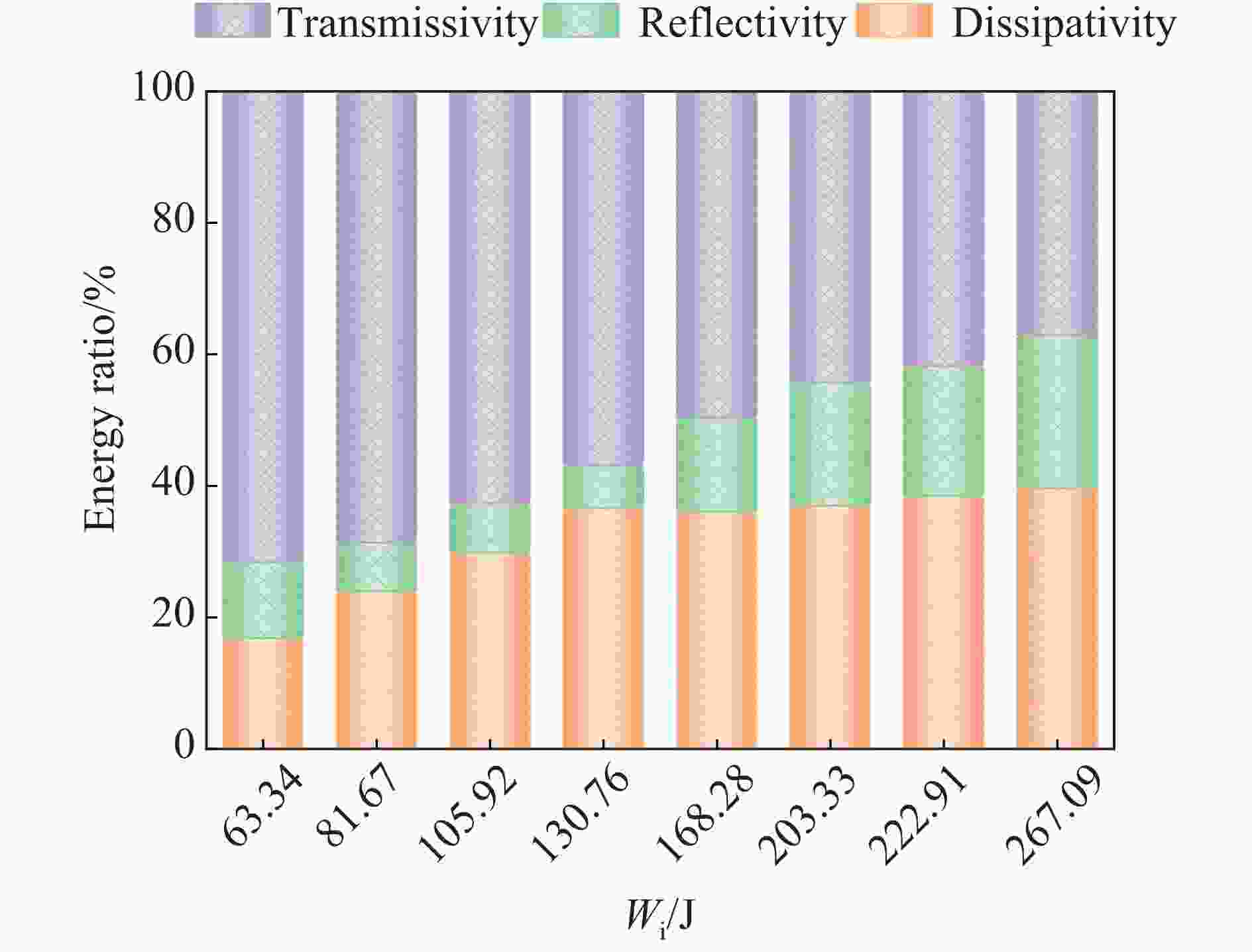

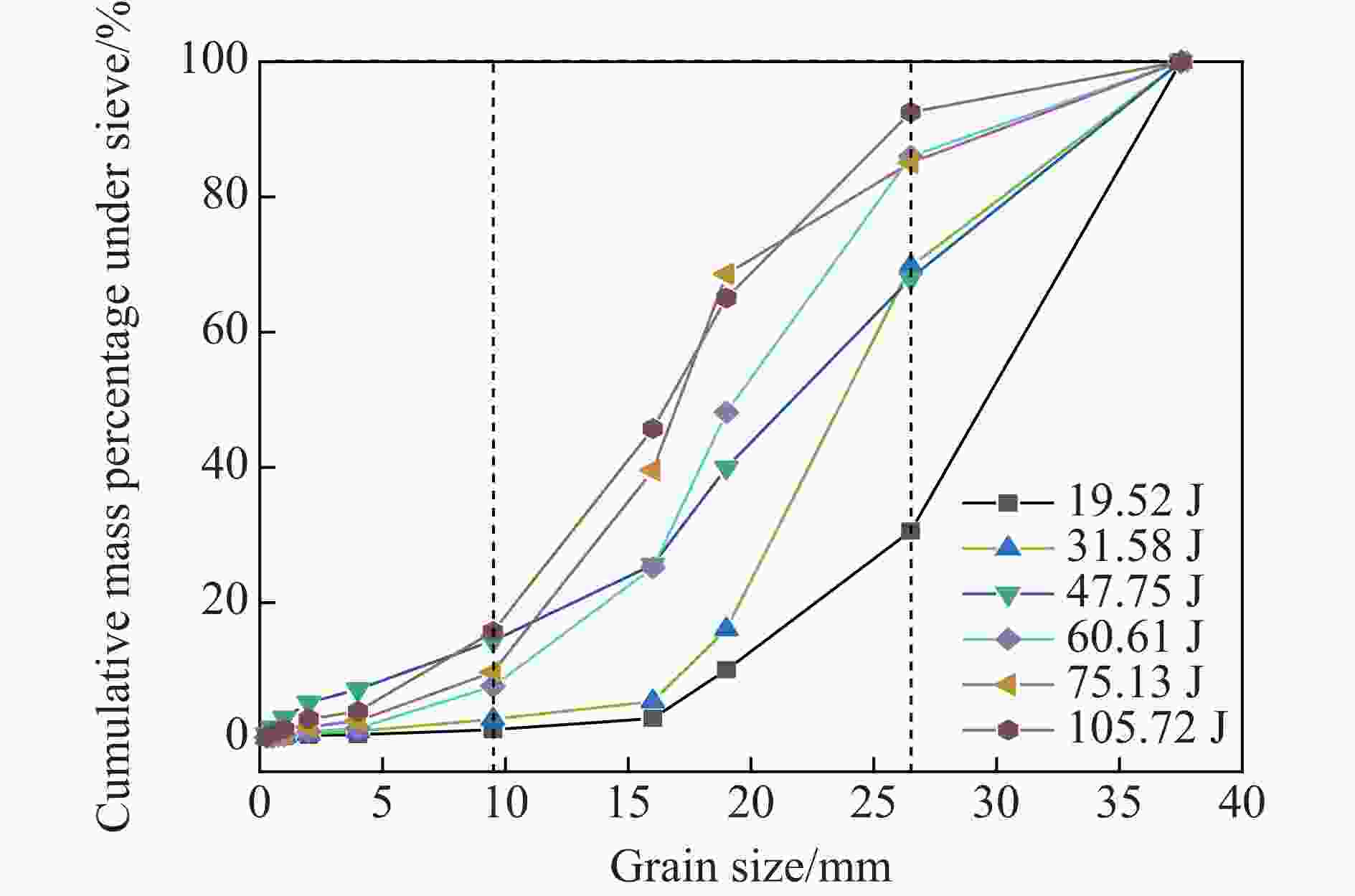

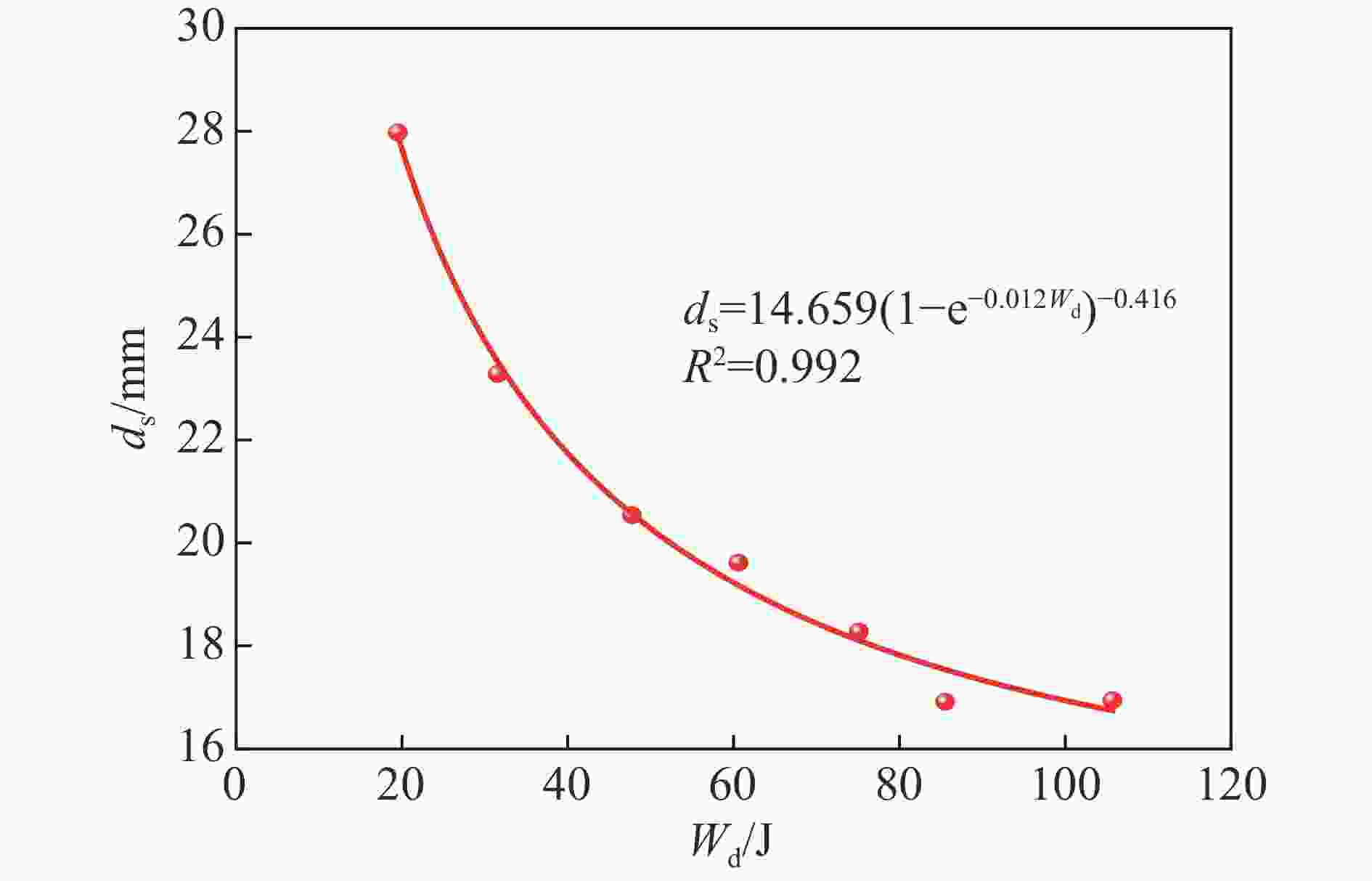

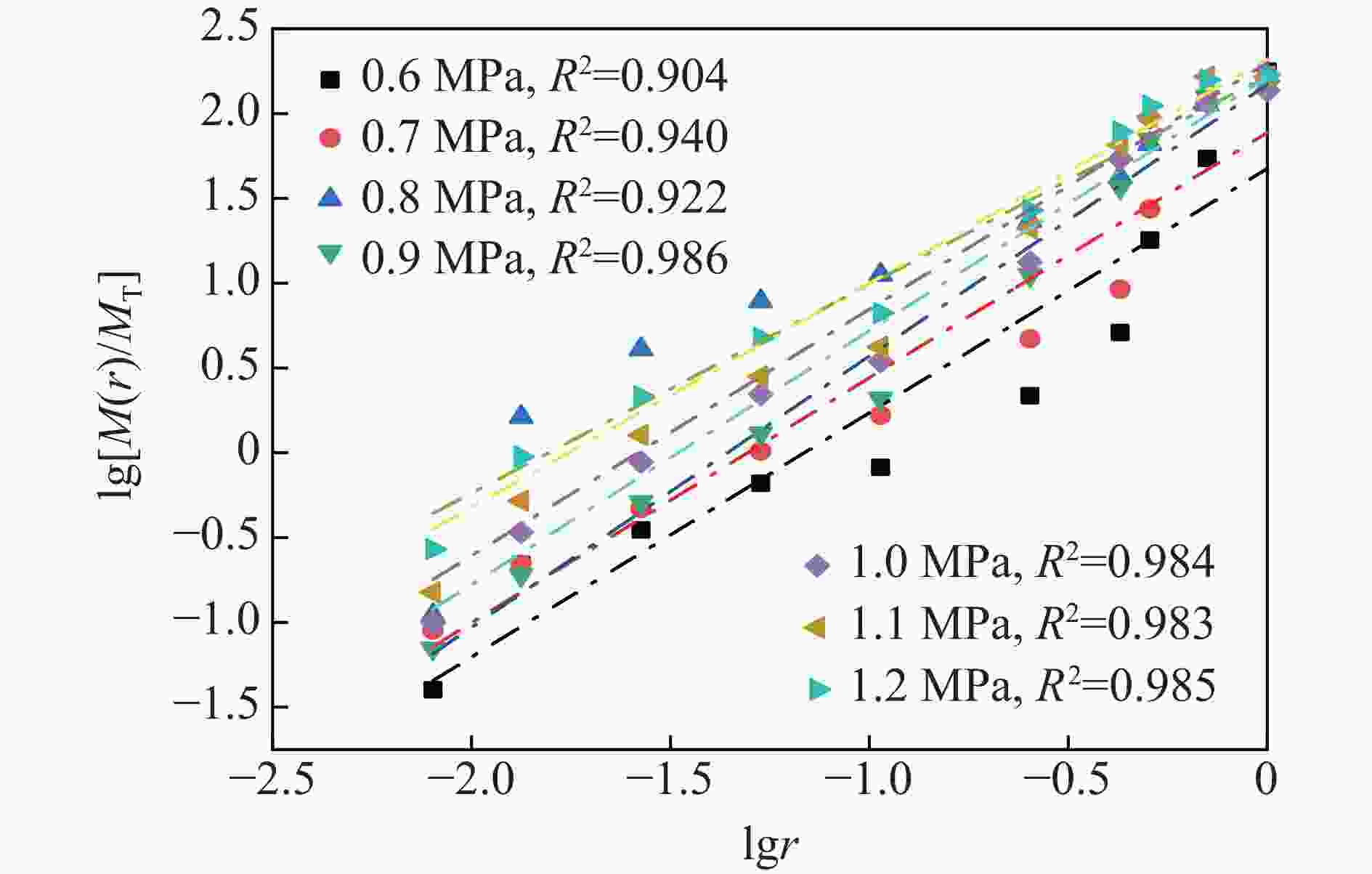

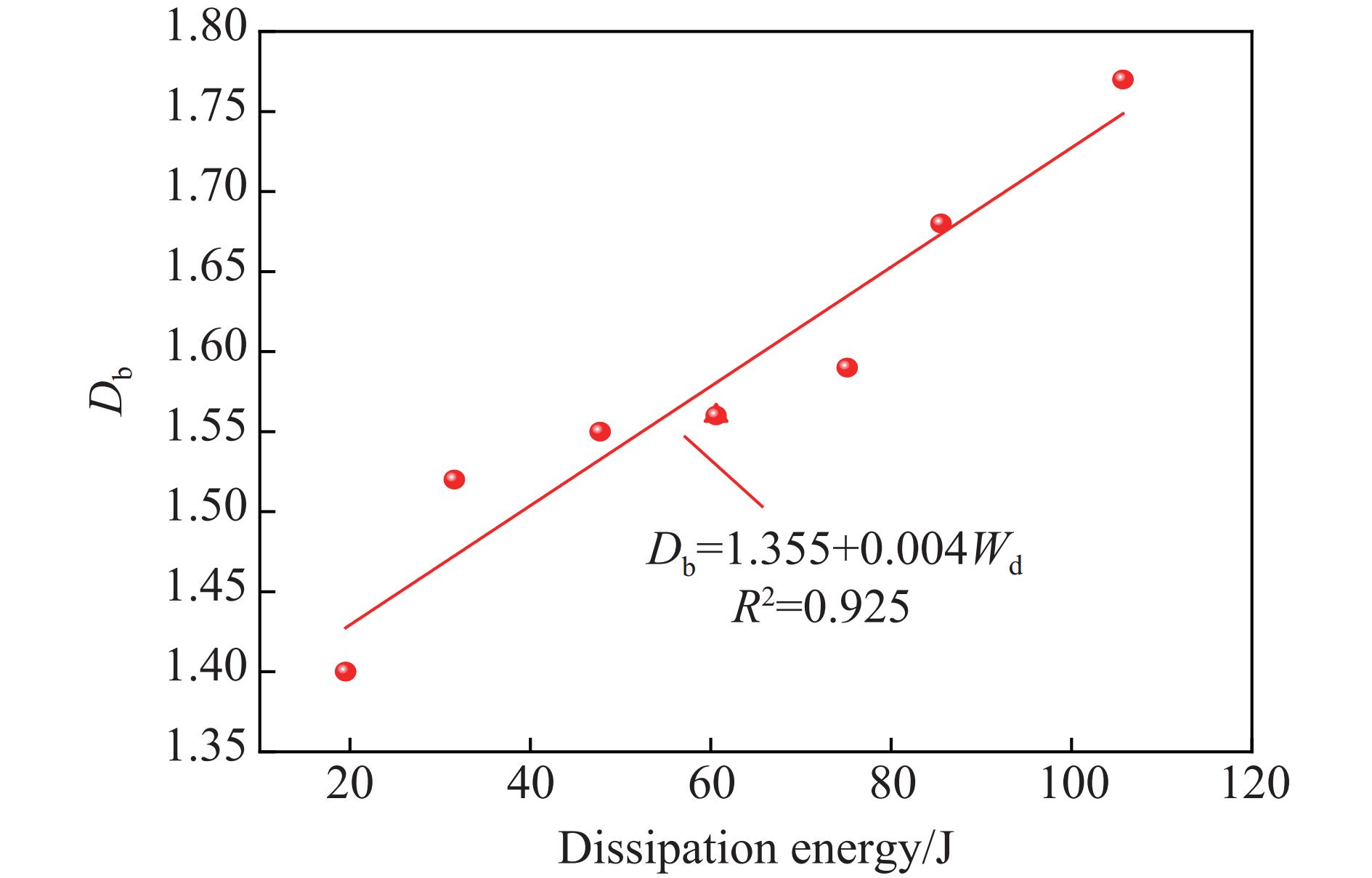

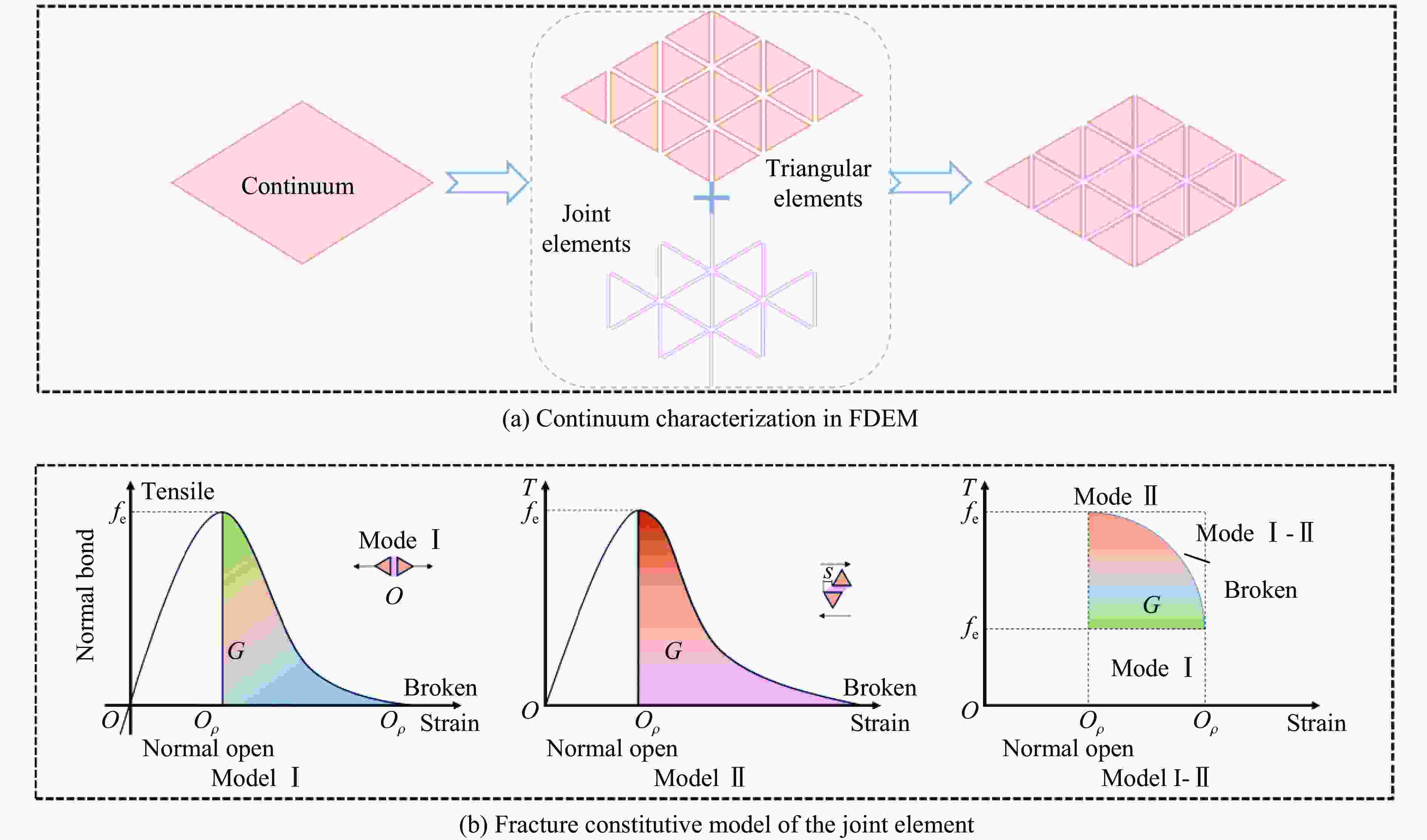

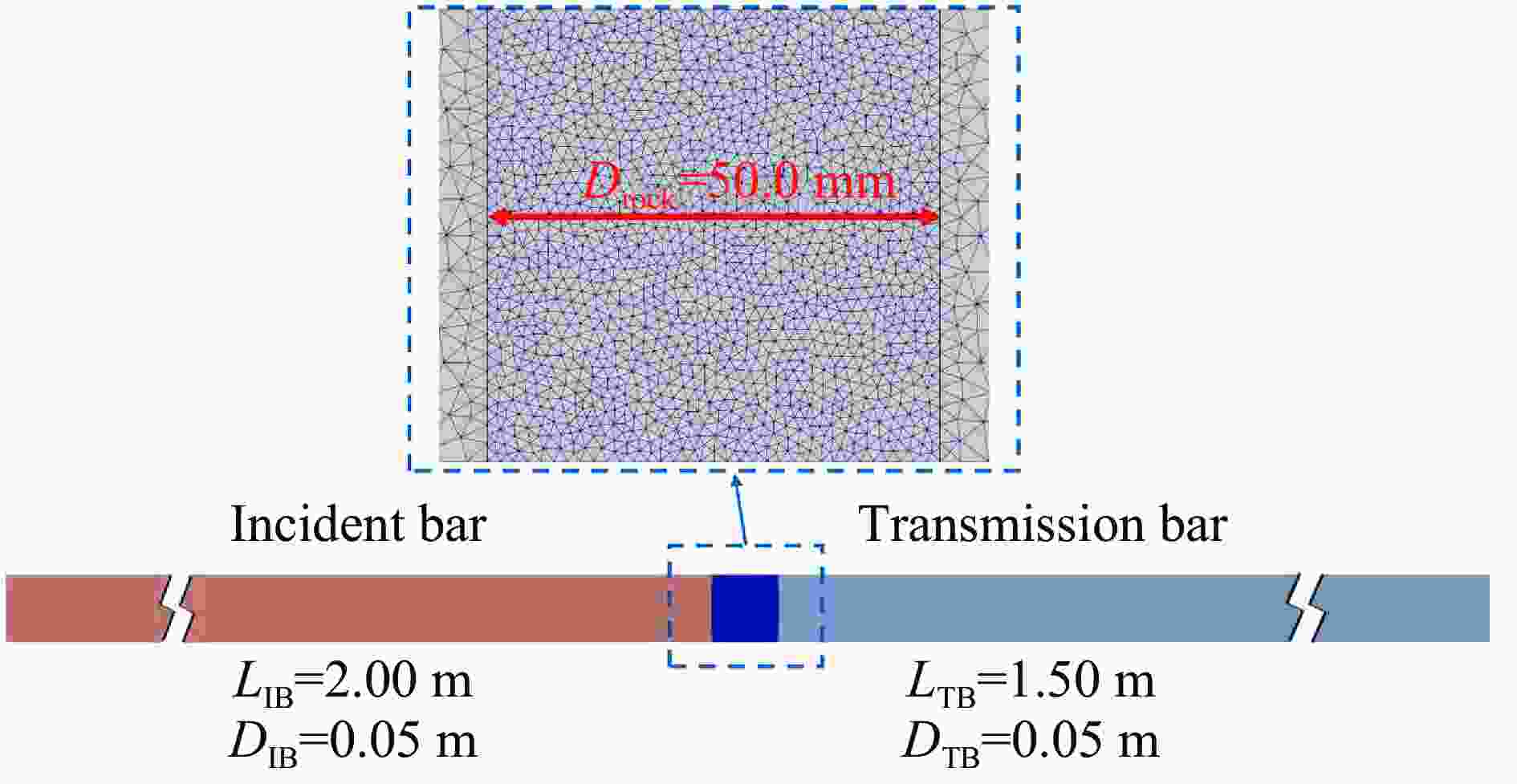

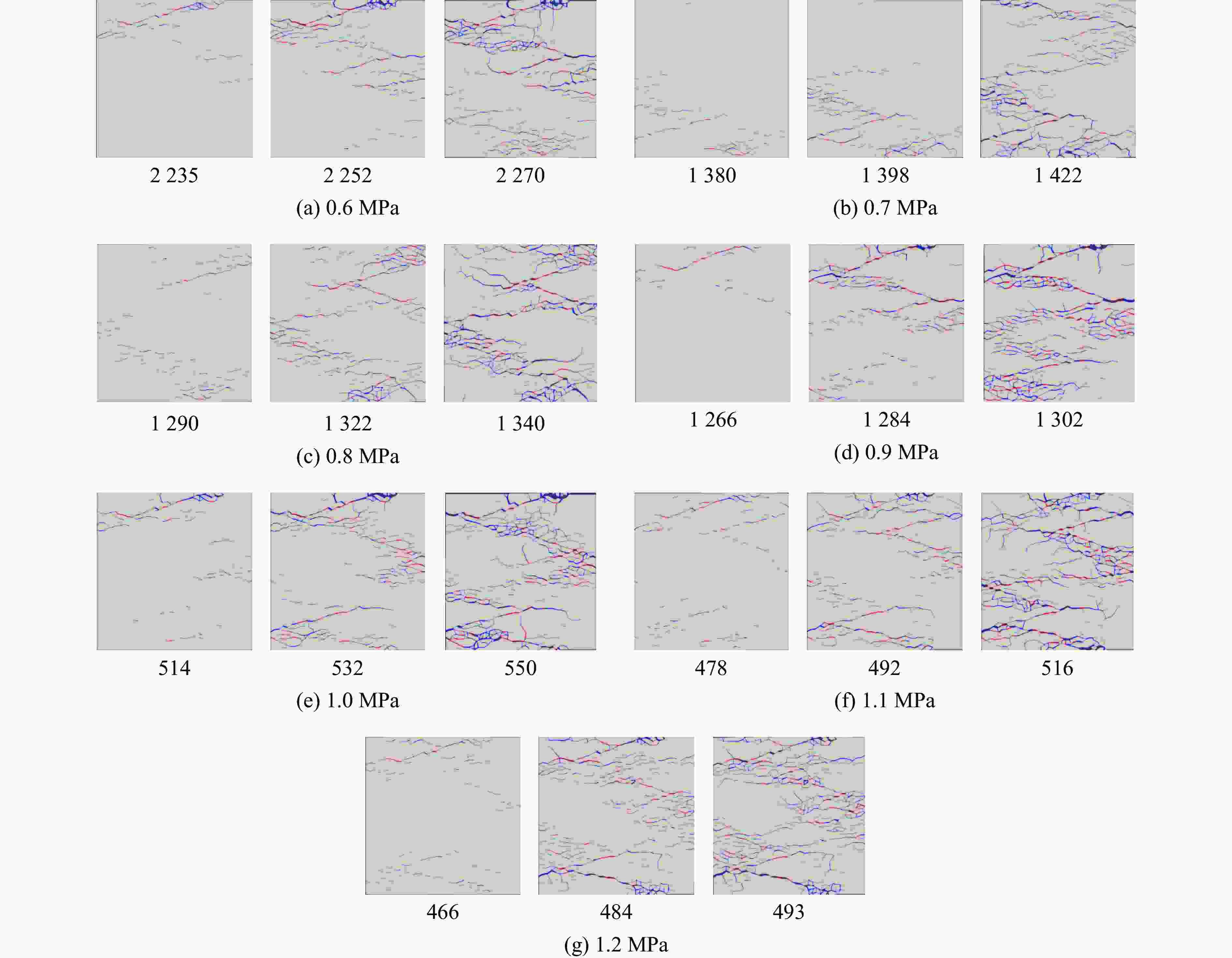

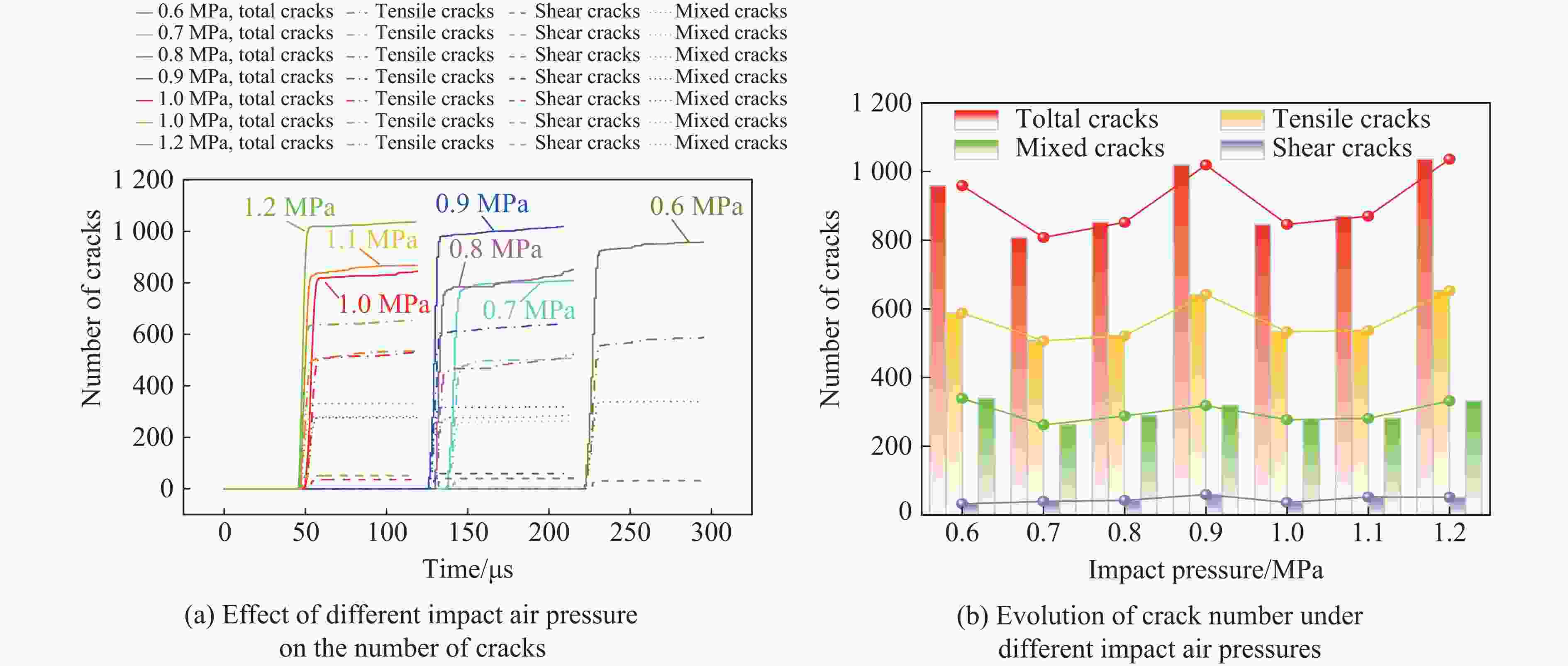

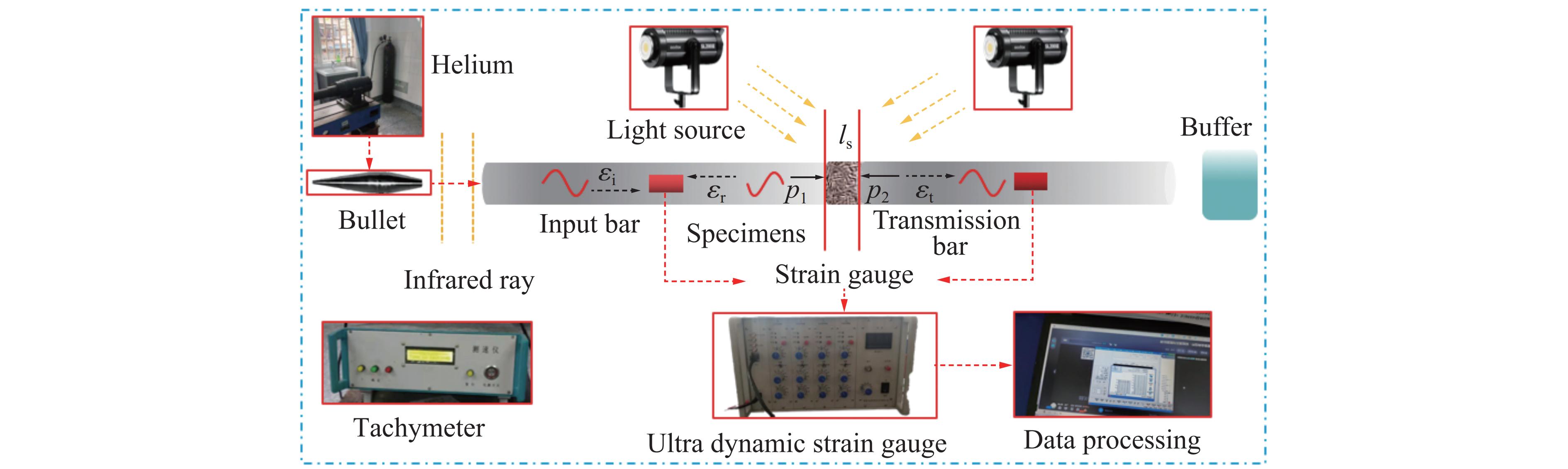

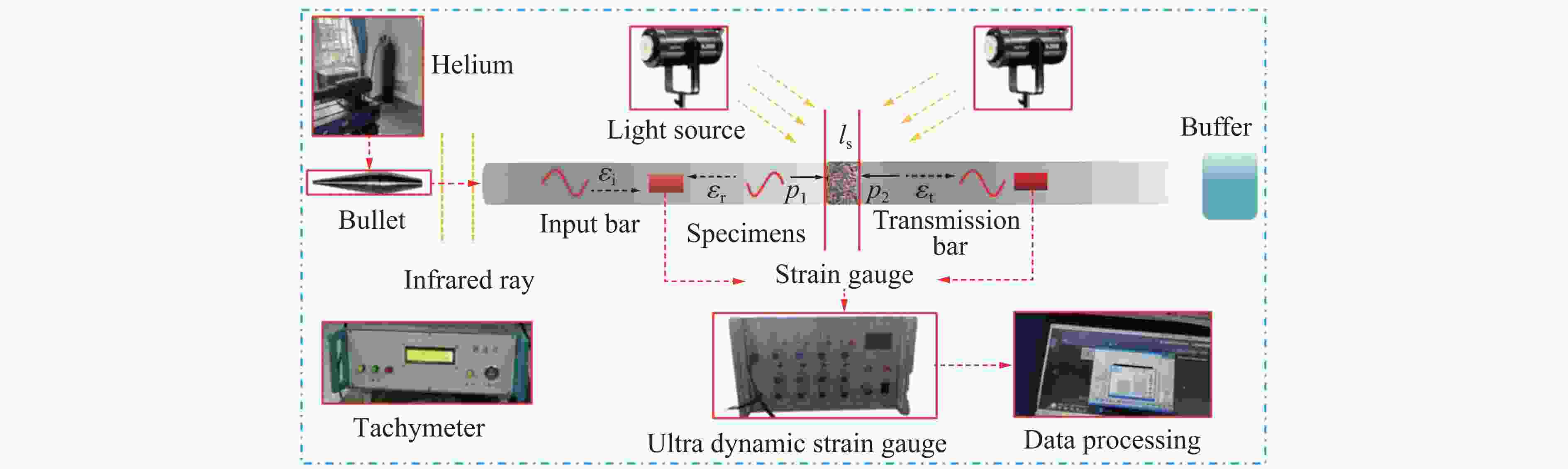

摘要: 为了研究冲击荷载作用下含铜矿岩的破碎块度与能量耗散关系,借助分离式霍普金森压杆试验装置,分析不同冲击荷载下含铜凝灰岩的力学特性及能量传递规律,结合分形理论构建耗散能与矿岩破碎块度之间的关系;同时,基于有限离散元方法(finite discrete element method,FDEM)模拟矿岩的裂纹扩展行为。结果表明:随着入射能的增加,透射能、耗散能、反射能三者的能量分布规律基本保持一致,即透射能、耗散能、反射能依次减小;根据耗散能的不同,碎石块度分布也呈现出明显的差异性。当耗散能由19.52 J增加至105.72 J时,矿岩的平均块度从27.98 mm降低至16.94 mm,分形维数提升了26.43%,表明耗散能越高,矿岩的宏观破碎程度越剧烈,破碎块度的数目越多,碎块粒径越小,均匀性越好;随着冲击荷载的增大,裂纹起裂时间缩短,拉伸裂纹数量占总裂纹数量的比重提高。FDEM数值计算方法的应用可为深入解析岩石断裂破坏特性提供新的思路。Abstract: To understand the relationship between fragmentation and energy dissipation in copper-bearing ore rock subjected to impact loading, a split Hopkinson pressure bar (SHPB) testing apparatus was employed to study the mechanical properties and energy transfer mechanisms of copper-bearing tuff under varying impact loads. Additionally, fractal theory was used to establish the correlation between dissipated energy and rock fragmentation. Utilizing the finite discrete element method (FDEM), numerical simulations of crack propagation within the rock were conducted. The results indicate that as the incident energy increases, the distribution patterns of the transmission energy, dissipated energy and reflection energy remain consistent, which are characterized by transmission energy, dissipated energy and reflection energy decreased successively. Furthermore, significant variations in fragment size distribution are observed with changes in dissipated energy. Specifically, as dissipated energy increases from 19.52 J to 105.72 J, the average fragment size decreases from 27.98 mm to 16.94 mm, while the fractal dimension increases by 26.43%. This suggests that higher dissipated energy results in more extensive macroscopic fragmentation, an increase in the number of fragments, smaller particle sizes and enhanced uniformity. As the impact load intensifies, the time to crack initiation decreases, and the proportion of tensile cracks relative to total cracks increases. The application of the FDEM offers new insights into the fracture and failure characteristics of rocks.

-

表 1 含铜矿岩基本物理力学参数

Table 1. Basic physical and mechanical parameters of copper-bearing rock specimen

编号 密度/

(g·cm−3)纵波波速/

(m·s−1)弹性模量/

GPa泊松比 抗压强度/

MPaJ-1 3.10 3 549 93.35 0.33 59.23 表 2 含铜矿岩的冲击实验数据

Table 2. SHPB test data of copper-bearing rock samples

编号 冲击气压/

MPa平均应

变率/s−1峰值应力/

MPaWi/J Wr/J Wt/J Wd/J A-3 0.5 30.68 108.03 63.34 7.24 45.13 10.62 B-2 0.6 35.71 119.72 81.67 5.73 55.75 19.51 C-4 0.7 44.25 141.35 105.92 7.32 66.10 31.57 D-1 0.8 50.93 163.19 130.76 8.05 74.19 47.75 E-3 0.9 53.62 189.55 168.28 23.94 83.45 60.60 F-2 1.0 59.15 200.93 203.33 37.88 89.99 75.12 G-4 1.1 64.81 249.80 222.91 43.46 93.01 85.52 H-1 1.2 77.39 265.90 267.09 62.21 99.06 105.72 表 3 含铜矿岩破碎块度筛分试验结果

Table 3. Test screening results of crushed copper-bearing rock fragments

编号 Wd/J 各等级粒径岩矿碎块的质量/g 平均块度/

mm<0.3 mm <0.5 mm <1.0 mm <2.0 mm <4.0 mm <9.5 mm <16.0 mm <19.0 mm <26.5 mm <37.5 mm B2-0.6 19.52 0.04 0.18 0.13 0.31 0.16 1.35 2.95 12.8 36.44 123.42 27.98 C4-0.7 31.58 0.09 0.13 0.25 0.55 0.64 3.03 4.50 18.16 91.39 51.51 23.29 D1-0.8 47.75 0.11 1.52 2.46 3.74 3.39 12.10 18.87 24.19 47.12 53.92 20.54 E3-0.9 60.61 0.07 0.12 0.32 0.79 0.78 9.06 25.52 33.49 55.18 20.42 19.62 F2-1 75.13 0.10 0.24 0.54 1.33 1.25 9.85 40.75 39.61 22.46 20.47 18.28 G4-1.1 85.53 0.15 0.37 0.75 1.55 1.38 16.84 44.16 30.27 69.63 0 16.92 H3-1.2 105.72 0.27 0.68 1.20 2.60 1.92 20.17 51.22 32.99 46.95 12.74 16.94 -

[1] 李鹏远, 周平, 唐金荣, 等. 中国铜矿资源供应风险识别与评价: 基于长周期历史数据分析预测法 [J]. 中国矿业, 2019, 28(7): 44–51. DOI: 10.12075/j.issn.1004-4051.2019.07.027.LI P Y, ZHOU P, TANG J R, et al. Identification and evaluation of copper supply risk for China: using method of long-term historical data analysis [J]. China Mining Magazine, 2019, 28(7): 44–51. DOI: 10.12075/j.issn.1004-4051.2019.07.027. [2] 黎立云, 谢和平, 鞠杨, 等. 岩石可释放应变能及耗散能的实验研究 [J]. 工程力学, 2011, 28(3): 35–40. DOI: 10.6052/j.issn.1000-4750.2009.08.0584.LI L Y, XIE H P, JU Y, et al. Experimental investigations of releasable energy and dissipative energy within rock [J]. Engineering Mechanics, 2011, 28(3): 35–40. DOI: 10.6052/j.issn.1000-4750.2009.08.0584. [3] 武仁杰, 李海波. SHPB冲击作用下层状千枚岩多尺度破坏机理研究 [J]. 爆炸与冲击, 2019, 39(8): 083106. DOI: 10.11883/bzycj-2019-0187.WU R J, LI H B. Multi-scale failure mechanism analysis of layered phyllite subject to impact loading [J]. Explosion and Shock Waves, 2019, 39(8): 083106. DOI: 10.11883/bzycj-2019-0187. [4] CHO S H, OGATA Y, KANEKO K. Strain-rate dependency of the dynamic tensile strength of rock [J]. International Journal of Rock Mechanics and Mining Sciences, 2003, 40(5): 763–777. DOI: 10.1016/S1365-1609(03)00072-8. [5] 江益辉. 冲击荷载作用下岩石峰后损伤破坏特性研究 [D]. 长沙: 中南大学, 2014: 48–53.JIANG Y H. Study on post failure behaviors of rock under impact loading [D]. Changsha: Central South University, 2014: 48–53. [6] 尤业超, 李二兵, 谭跃虎, 等. 基于能量耗散原理的盐岩动力特性及破坏特征分析 [J]. 岩石力学与工程学报, 2017, 36(4): 843–851. DOI: 10.13722/j.cnki.jrme.2016.0503.YOU Y C, LI E B, TAN Y H, et al. Analysis on dynamic properties and failure characteristics of salt rock based on energy dissipation principle [J]. Chinese Journal of Rock Mechanics and Engineering, 2017, 36(4): 843–851. DOI: 10.13722/j.cnki.jrme.2016.0503. [7] PING Q, WU M J, YUAN P, et al. Dynamic splitting experimental study on sandstone at actual high temperatures under different loading rates [J]. Shock and Vibration, 2020, 2020: 8867102. DOI: 10.1155/2020/8867102. [8] LI E B, GAO L, JIANG X Q, et al. Analysis of dynamic compression property and energy dissipation of salt rock under three-dimensional pressure [J]. Environmental Earth Sciences, 2019, 78(14): 388. DOI: 10.1007/s12665-019-8389-7. [9] YU L Y, FU A Q, YIN Q, et al. Dynamic fracturing properties of marble after being subjected to multiple impact loadings [J]. Engineering Fracture Mechanics, 2020, 230: 106988. DOI: 10.1016/j.engfracmech.2020.106988. [10] WU Z J, CUI W J, FAN L F, et al. Mesomechanism of the dynamic tensile fracture and fragmentation behaviour of concrete with heterogeneous mesostructure [J]. Construction and Building Materials, 2019, 217: 573–591. DOI: 10.1016/j.conbuildmat.2019.05.094. [11] FUKUDA D, MOHAMMADNEJAD M, LIU H Y, et al. Development of a 3D hybrid finite-discrete element simulator based on GPGPU-parallelized computation for modelling rock fracturing under quasi-static and dynamic loading conditions [J]. Rock Mechanics and Rock Engineering, 2020, 53(3): 1079–1112. DOI: 10.1007/s00603-019-01960-z. [12] WU D, LI H B, FUKUDA D, et al. Development of a finite-discrete element method with finite-strain elasto-plasticity and cohesive zone models for simulating the dynamic fracture of rocks [J]. Computers and Geotechnics, 2023, 156: 105271. DOI: 10.1016/j.compgeo.2023.105271. [13] 柴少波, 王昊, 井彦林, 等. 充填节理岩石累积损伤动力压缩特性试验研究 [J]. 岩石力学与工程学报, 2020, 39(10): 2025–2037. DOI: 10.13722/j.cnki.jrme.2020.0310.CHAI S B, WANG H, JING Y L, et al. Experimental study on dynamic compression characteristics of rock with filled joints after cumulative damage [J]. Chinese Journal of Rock Mechanics and Engineering, 2020, 39(10): 2025–2037. DOI: 10.13722/j.cnki.jrme.2020.0310. [14] 滕骁, 卢玉斌, 陈兴, 等. 再生混凝土动态直接拉伸的试验研究 [J]. 振动与冲击, 2016, 35(9): 43–51. DOI: 10.13465/j.cnki.jvs.2016.09.008.TENG X, LU Y B, CHEN X, et al. Tests for dynamic direct tensile of recycled aggregate concrete [J]. Journal of Vibration and Shock, 2016, 35(9): 43–51. DOI: 10.13465/j.cnki.jvs.2016.09.008. [15] 魏威. 冲击载荷作用下活性材料的响应特性研究 [D]. 北京: 北京理工大学, 2016: 35–39.WEI W. Study on the dynamic responses of the active materialsunder impact loadings [D]. Beijing: Beijing Institute of Technology, 2016: 35–39. [16] 王建国, 雷振, 杨阳, 等. 饱水冻结花岗岩动态力学性状的应变率效应 [J]. 地下空间与工程学报, 2018, 14(5): 1292–1297.WANG J G, LEI Z, YANG Y, et al. Strain rate effect of dynamic mechanical characteristics of saturated freezing granite [J]. Chinese Journal of Underground Space and Engineering, 2018, 14(5): 1292–1297. [17] 袁芝斌. 大红山铜矿深部巷道围岩动态破碎耗能规律研究 [D]. 昆明: 昆明理工大学, 2021: 53–56. DOI: 10.27200/d.cnki.gkmlu.2021.000385.YUAN Z B. Research on the energy dissipation mechanism of dynamic fragmentation in surrounding rock of deep shafts in the Dahongshan copper mine [D]. Kunming: Kunming University of Science and Technology, 2021: 53–56. DOI: 10.27200/d.cnki.gkmlu.2021.000385. [18] 王浩. 大红山铜矿深埋变质灰岩动态响应特征研究 [D]. 昆明: 昆明理工大学, 2021: 68–69. DOI: 10.27200/d.cnki.gkmlu.2021.001943.WANG H. Study on the dynamic response characteristics of deeply buried metamorphic limestone in the Dahongshan copper mine [D]. Kunming: Kunming University of Science and Technology, 2021: 68–69. DOI: 10.27200/d.cnki.gkmlu.2021.001943. [19] 谢和平, 高峰. 岩石类材料损伤演化的分形特征 [J]. 岩石力学与工程学报, 1991, 10(1): 74–82.XIE H P, GAO F. The fractal features of the damage evolution of rock materials [J]. Chinese Journal of Rock Mechanics and Engineering, 1991, 10(1): 74–82. [20] 梁正召, 唐春安, 唐世斌, 等. 岩石损伤破坏过程中分形与逾渗演化特征 [J]. 岩土工程学报, 2007, 29(9): 1386–1391. DOI: 10.3321/j.issn:1000-4548.2007.09.017.LIANG Z Z, TANG C A, TANG S B, et al. Characteristics of fractal and percolation of rocks subjected to uniaxial compression during their failure process [J]. Chinese Journal of Geotechnical Engineering, 2007, 29(9): 1386–1391. DOI: 10.3321/j.issn:1000-4548.2007.09.017. [21] 李祥龙, 何丽华, 栾龙发, 等. 露天煤矿高台阶抛掷爆破爆堆形态模拟 [J]. 煤炭学报, 2011, 36(9): 1457–1462. DOI: 10.13225/j.cnki.jccs.2011.09.014.LI X L, HE L H, LUAN L F, et al. Simulation model for muckpile shape of high bench cast blasting in surface coal mine [J]. Journal of China Coal Society, 2011, 36(9): 1457–1462. DOI: 10.13225/j.cnki.jccs.2011.09.014. [22] 杨军, 王国生. 分形几何在岩石爆破研究中的应用 [J]. 爆破, 1995(4): 1–5. [23] 丁希平, 冯叔瑜, 魏伴云. 硐室爆破法采石级配预测 [J]. 爆炸与冲击, 1997, 17(4): 326–332. DOI: 10.11883/1001-1455(1997)04-0326-7.DING X P, FENG S Y, WEI B Y. Prediction of rock fragment distribution for chamber blasting [J]. Explosion and Shock Waves, 1997, 17(4): 326–332. DOI: 10.11883/1001-1455(1997)04-0326-7. [24] 杨仁树, 李炜煜, 杨国梁, 等. 炸药类型对富铁矿爆破效果影响的试验研究 [J]. 爆炸与冲击, 2020, 40(6): 065201. DOI: 10.11883/bzycj-2019-0396.YANG R S, LI W Y, YANG G L, et al. Experimental study on the blasting effects of rich-iron ore with different explosives [J]. Explosion and Shock Waves, 2020, 40(6): 065201. DOI: 10.11883/bzycj-2019-0396. [25] MUNJIZA A, OWEN D R J, BICANIC N. A combined finite-discrete element method in transient dynamics of fracturing solids [J]. Engineering Computations, 1995, 12(2): 145–174. DOI: 10.1108/02644409510799532. [26] MUNJIZA A. Special issue on the discrete element method: aspects of recent developments in computational mechanics of discontinua [J]. Engineering Computations, 2009, 26(6). DOI: 10.1108/ec.2009.18226faa.001. [27] YAN C Z, ZHENG Y C, WANG G. A 2D adaptive finite-discrete element method for simulating fracture and fragmentation in geomaterials [J]. International Journal of Rock Mechanics and Mining Sciences, 2023, 169: 105439. DOI: 10.1016/j.ijrmms.2023.105439. [28] YAN C Z, LUO Z Q, ZHENG Y C, et al. A 2D discrete moisture diffusion model for simulating desiccation fracturing of soil [J]. Engineering Analysis with Boundary Elements, 2022, 138: 42–64. DOI: 10.1016/j.enganabound.2022.02.006. [29] YAN C Z, WANG T, KE W H, et al. A 2D FDEM-based moisture diffusion-fracture coupling model for simulating soil desiccation cracking [J]. Acta Geotechnica, 2021, 16(8): 2609–2628. DOI: 10.1007/s11440-021-01297-4. [30] YAN C Z, FAN H W, HUANG D R, et al. A 2D mixed fracture-pore seepage model and hydromechanical coupling for fractured porous media [J]. Acta Geotechnica, 2021, 16(10): 3061–3086. DOI: 10.1007/s11440-021-01183-z. [31] OÑATE E, ROJEK J. Combination of discrete element and finite element methods for dynamic analysis of geomechanics problems [J]. Computer Methods in Applied Mechanics and Engineering, 2004, 193(27/28/29): 3087–3128. DOI: 10.1016/j.cma.2003.12.056. [32] YAN C Z, ZHAO Z H, YANG Y, et al. A three-dimensional thermal-hydro-mechanical coupling model for simulation of fracturing driven by multiphysics [J]. Computers and Geotechnics, 2023, 155: 105162. DOI: 10.1016/j.compgeo.2022.105162. [33] YAN C Z, MA H, TANG Z C, et al. A two-dimensional moisture diffusion continuous model for simulating dry shrinkage and cracking of soil [J]. International Journal of Geomechanics, 2022, 22(10): 04022172. DOI: 10.1061/(ASCE)GM.1943-5622.0002570. [34] YAN C Z, ZHENG H, SUN G H, et al. Combined finite-discrete element method for simulation of hydraulic fracturing [J]. Rock Mechanics and Rock Engineering, 2016, 49(4): 1389–1410. DOI: 10.1007/s00603-015-0816-9. [35] LISJAK A, TATONE B S A, MAHABADI O K, et al. Hybrid finite-discrete element simulation of the EDZ formation and mechanical sealing process around a microtunnel in opalinus clay [J]. Rock Mechanics and Rock Engineering, 2016, 49(5): 1849–1873. DOI: 10.1007/s00603-015-0847-2. [36] WANG T, YAN C Z, HAN D, et al. Insights into the breaking mechanism and fragment pattern of soft rock assisted by free face under TBM wedge cutter indentation [J]. Engineering Fracture Mechanics, 2023, 291: 109580. DOI: 10.1016/j.engfracmech.2023.109580. [37] WANG T, YAN C Z, ZHENG H, et al. Optimum spacing and rock breaking efficiency of TBM double disc cutters penetrating in water-soaked mudstone with FDEM [J]. Tunnelling and Underground Space Technology, 2023, 138: 105174. DOI: 10.1016/j.tust.2023.105174. [38] FUKUDA D, NIHEI E, CHO S H, et al. Development of a numerical simulator for 3-D dynamic fracture process analysis of rocks based on hybrid FEM-DEM using extrinsic cohesive zone model [J]. Materials Transactions, 2020, 61(9): 1767–1774. DOI: 10.2320/matertrans.Z-M2020833. [39] DENG P H, LIU Q S, HUANG X, et al. Sensitivity analysis of fracture energies for the combined finite-discrete element method (FDEM) [J]. Engineering Fracture Mechanics, 2021, 251: 107793. DOI: 10.1016/j.engfracmech.2021.107793. [40] ZUO T, LI X L, WANG J G, et al. Insights into natural tuff as a building material: effects of natural joints on fracture fractal characteristics and energy evolution of rocks under impact load [J]. Engineering Failure Analysis, 2024, 163: 108584. DOI: 10.1016/j.engfailanal.2024.108584. -

下载:

下载: