A buring-crack network theoretical model for reaction evolution of explosives considering the inertial confinement effect of the shell motion

-

摘要: 为合理描述机械约束下炸药装药点火后的反应演化行为,深入分析壳体变形运动特征,将壳体响应变化过程分为弹塑性准静态阶段、完全屈服运动阶段和壳体破裂后惯性运动约束阶段。考虑装药燃烧裂纹网络反应演化与壳体变形运动的耦合作用,建立了反映壳体运动惯性约束效应的装药反应演化模型,通过与典型实验结果进行对比,验证了模型及参数的适应性。壳体运动速度和内部压力的变化本质表征了装药能量释放与产物气体对外做功的关系,考虑壳体运动惯性约束效应可以更全面地表征装药反应演化过程,利用该模型,可以根据壳体壁面运动速度历史计算得到弹内压力、反应速率和反应度变化历史,可为约束装药在意外刺激下的安全性设计与评估提供理论支撑。

-

关键词:

- 非冲击点火 /

- 反应演化行为 /

- 惯性约束效应 /

- 广义等效惯性约束刚度

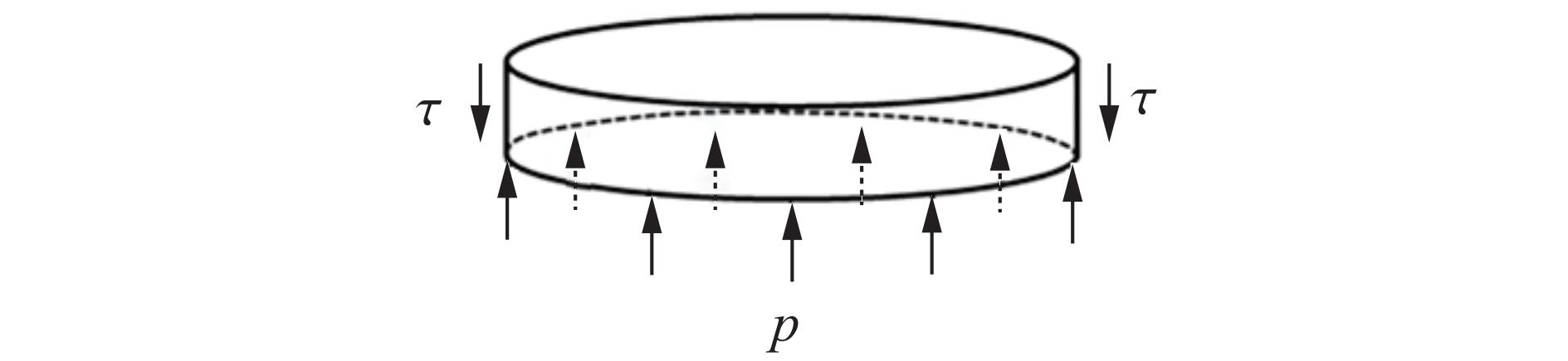

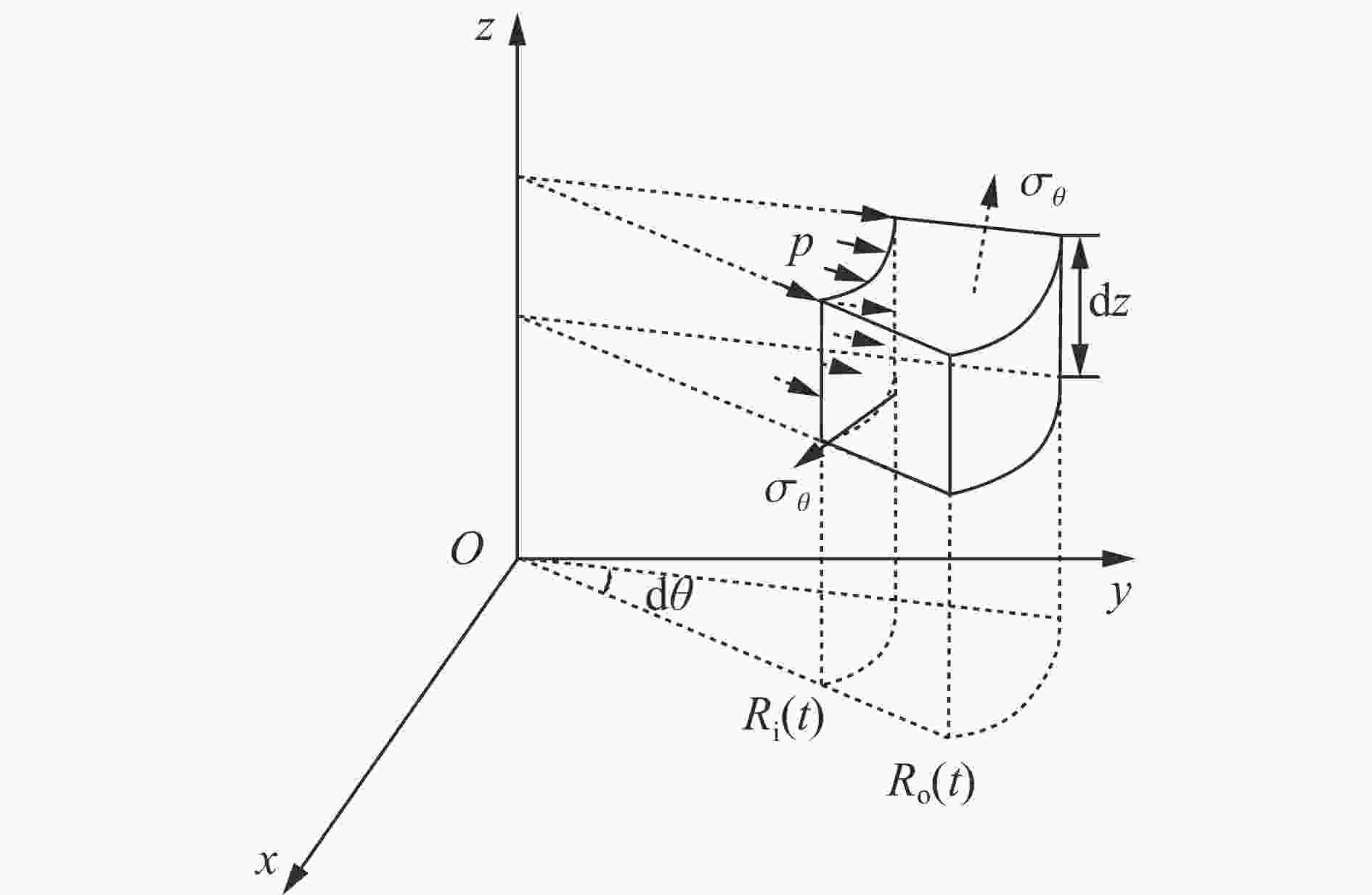

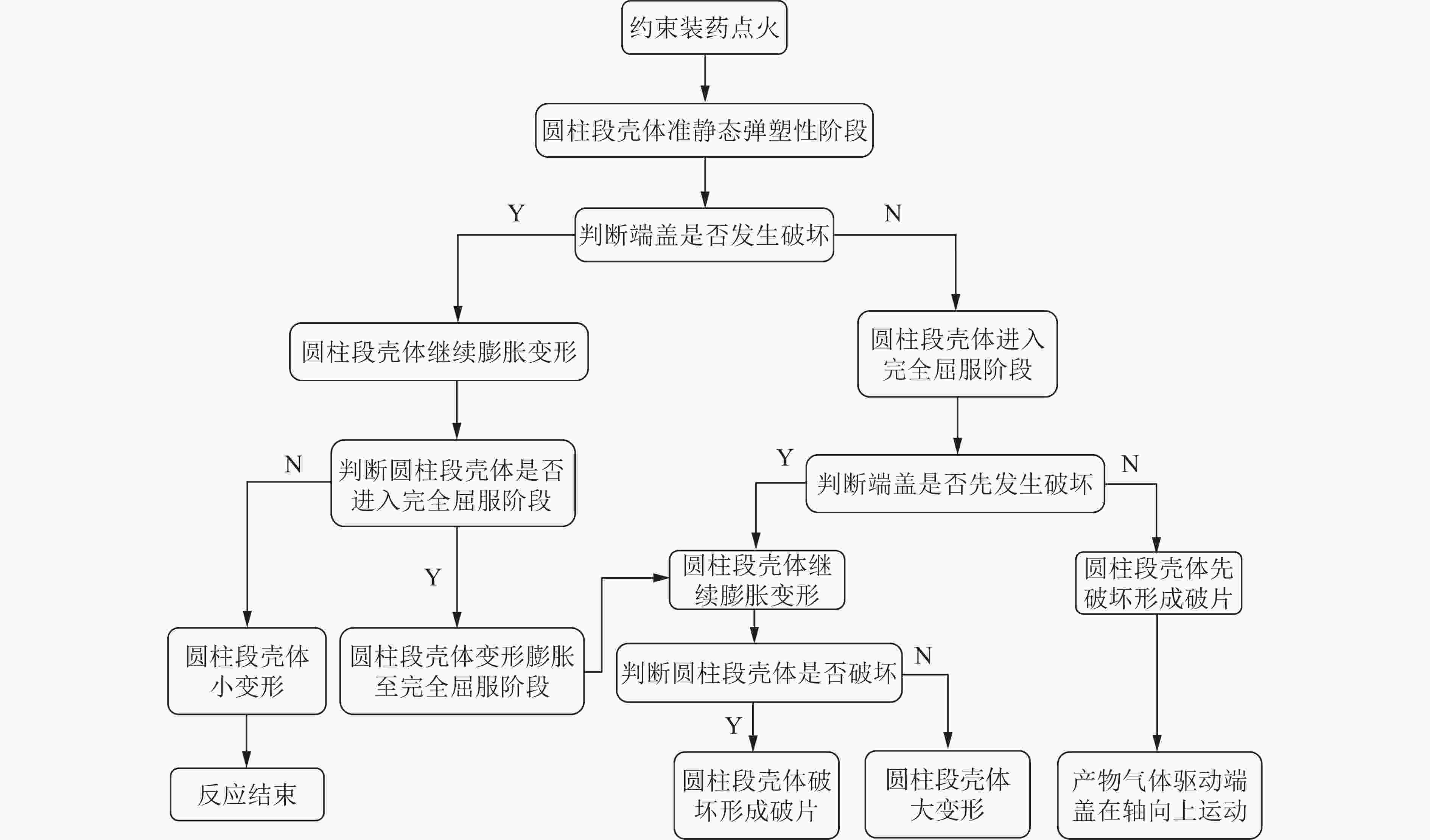

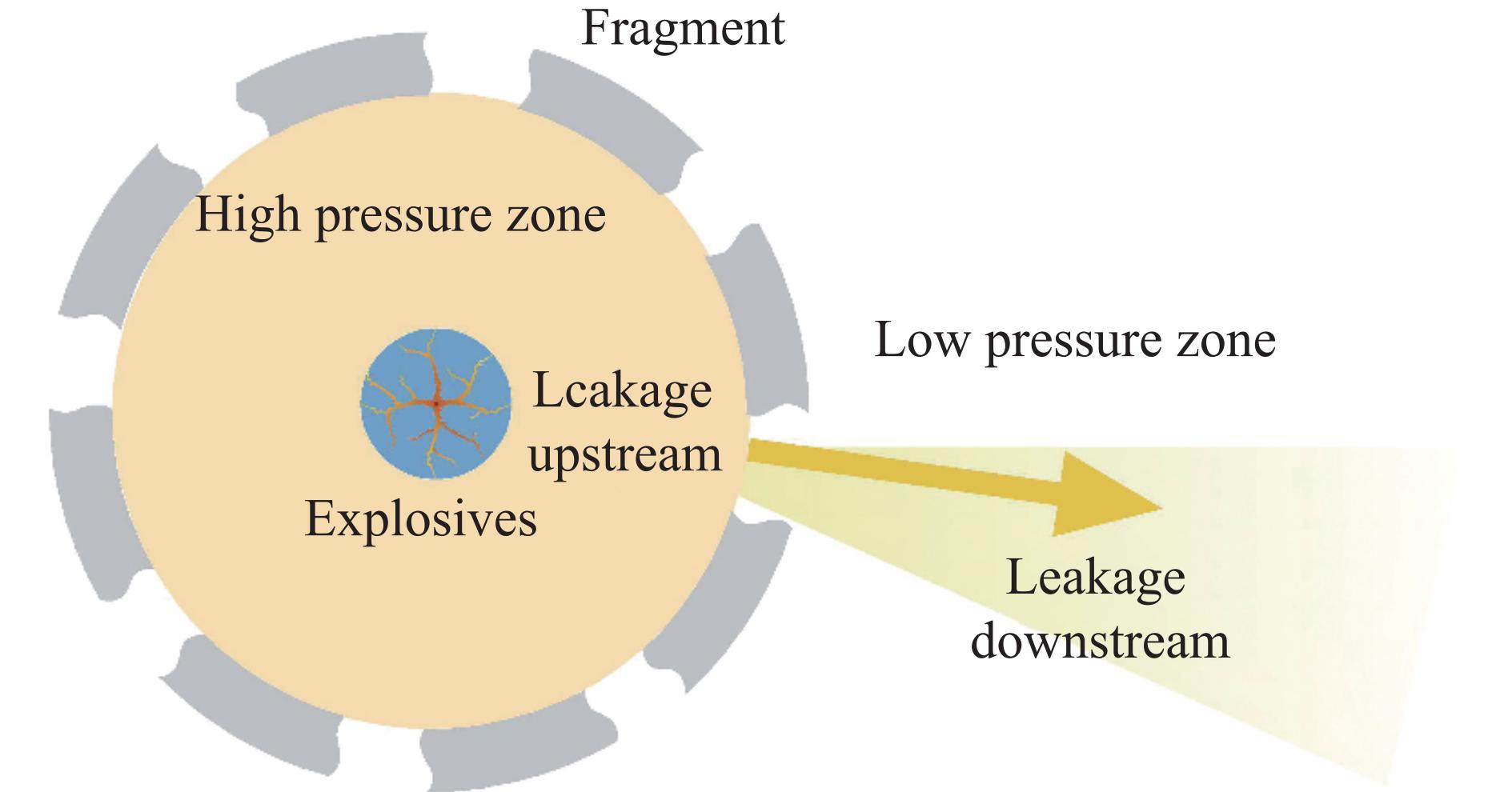

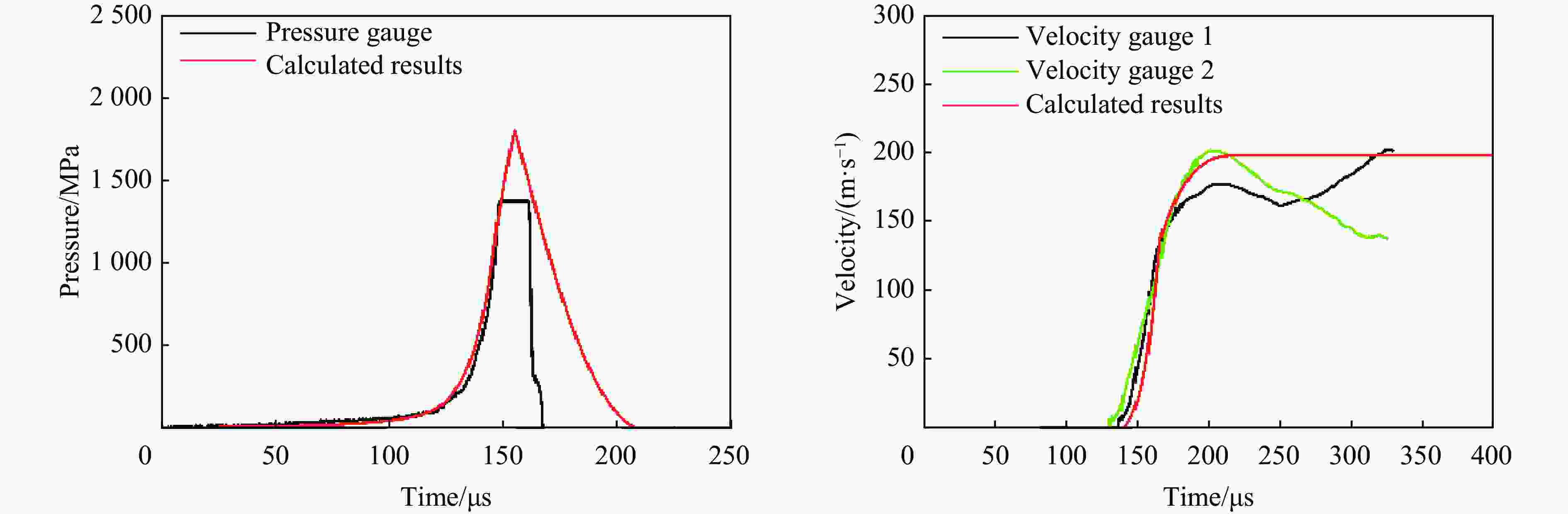

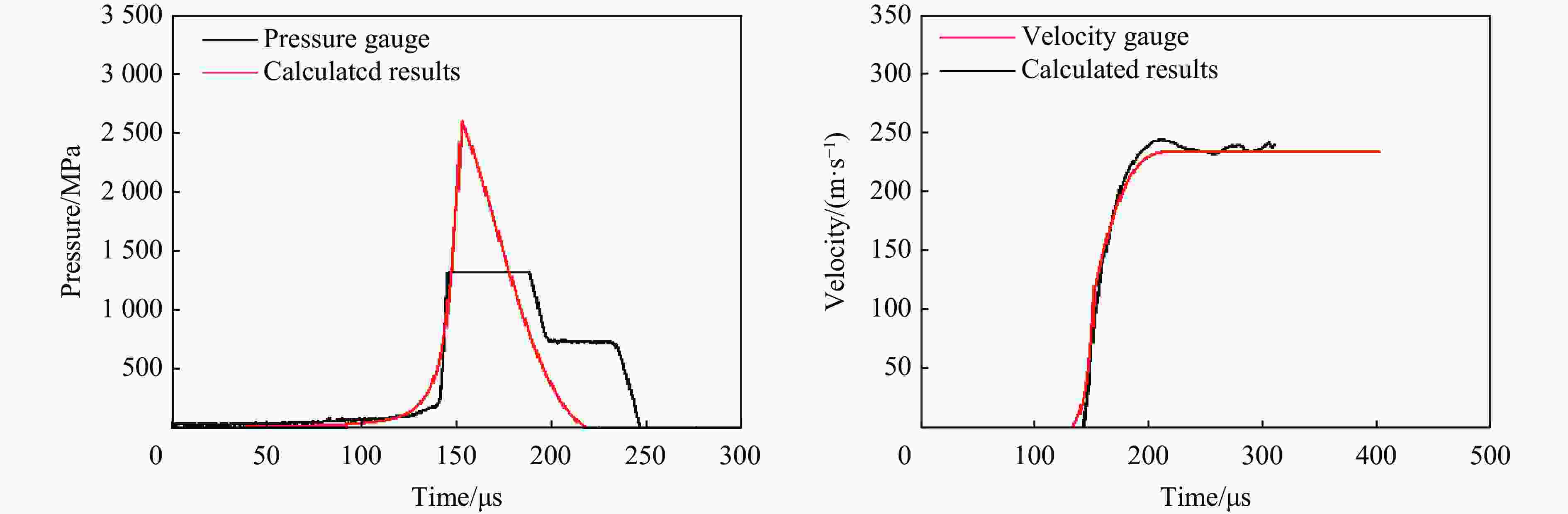

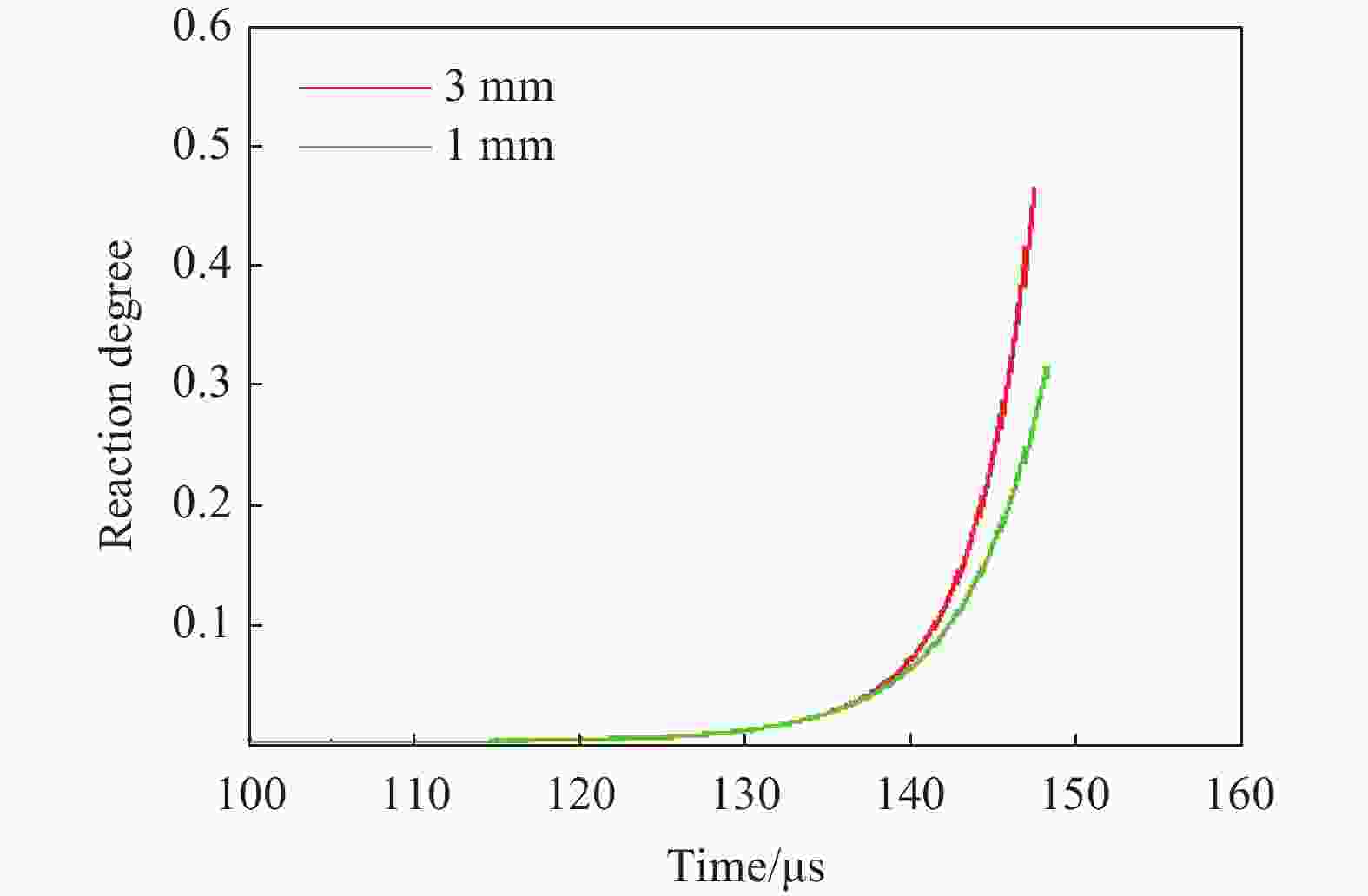

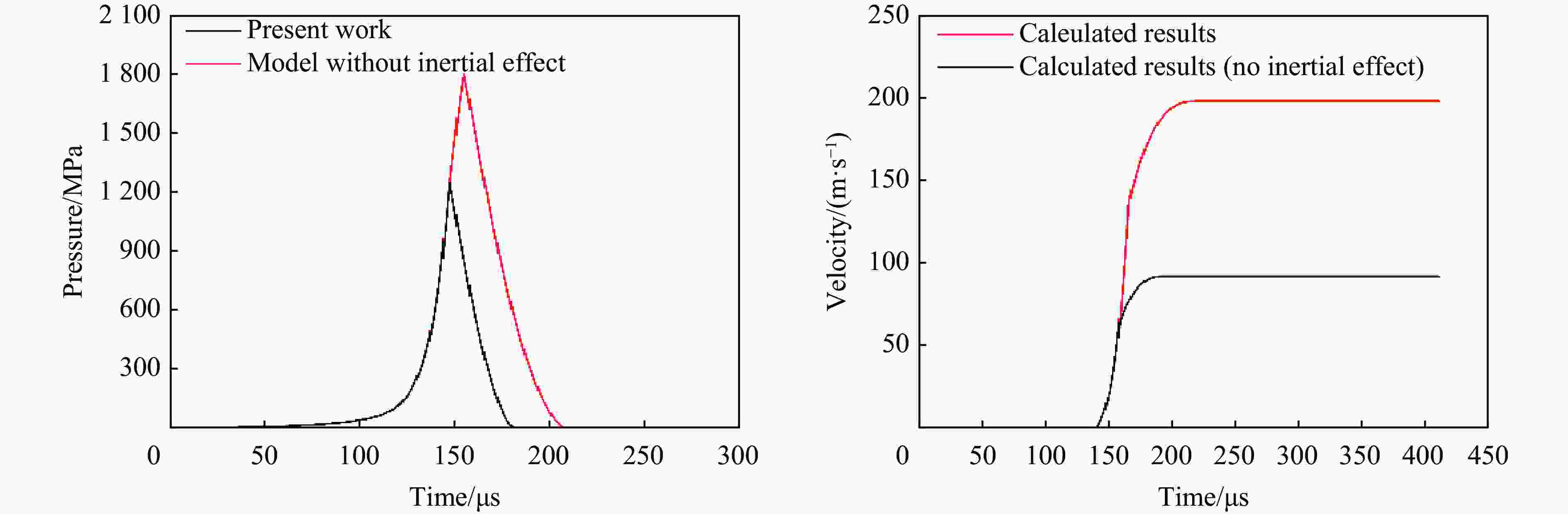

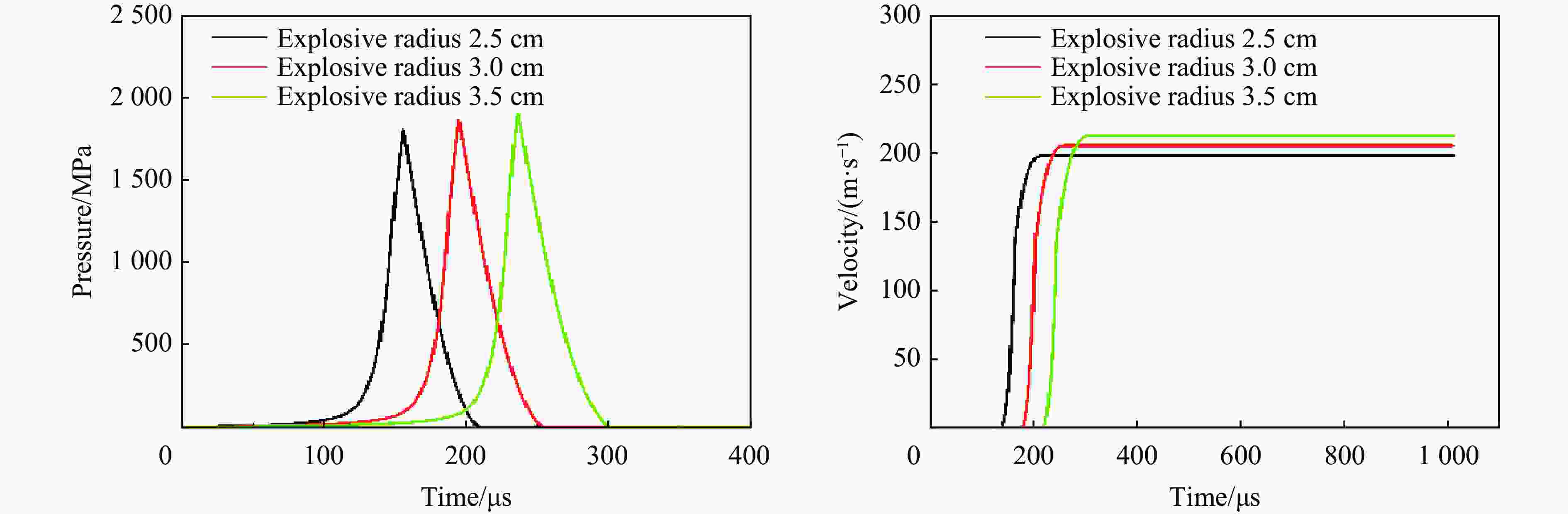

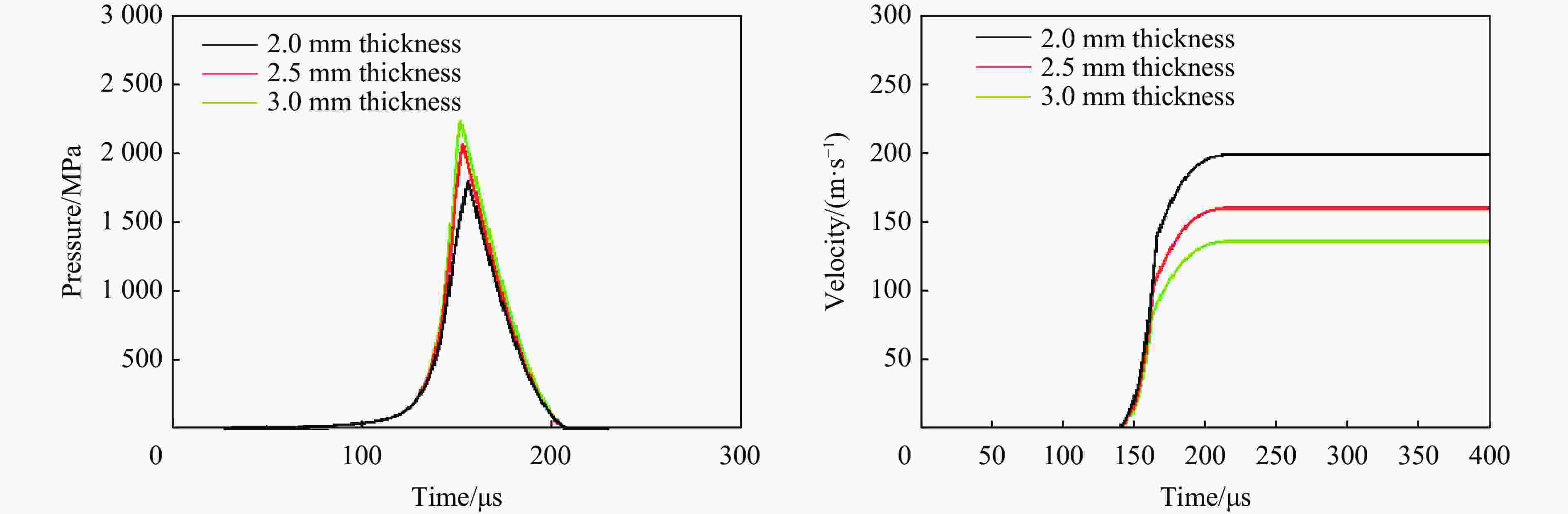

Abstract: To reasonably describe the reaction evolution behavior of explosives after ignition under mechanical confinement, we conduct in-depth analysis of the deformation and movement characteristics of the shell, and divide the response process of the shell into three stages: elastoplastic stage, complete yield stage, and shell rupture stage with inertial motion constraint. The combustion rate theory and the combustion crack-network theory are employed as pivotal parameters for the reaction evolution of the explosives. In the initial stage, the mechanical properties of the shell are taken into consideration, with the material properties serving as the upper limit for structural constraint strength. During this stage, the deformation of the shell remains relatively small. In the second stage, a generalized equivalent stiffness concept is introduced in order to account for the inertial confinement effect of the shell movement. Furthermore, a mechanical deformation analysis of cylindrical shells and end caps is conducted, which takes into account the coupled effects of combustion crack network reaction evolution and shell deformation movement based on a kinematic theory. The third stage is building upon the foundation established in preceding stages, the impact of gas leakage following shell rupture on the progression of the explosive reaction process is considered, The integration of these three stages yields a formula for pressure, shell velocity, and time in the non-impact ignition reaction evolution process of solid explosives. A model for explosives reaction evolution is established to characterize the inertial confinement effects of the shell movement. This model and the related parameters are verified by comparing the calculating results with typical experimental data. It is found that the velocity of shell motion and the changes in internal pressure fundamentally characterize the relationship between the energy release of the explosives and the work done by the product gas. Considering the inertial confinement effects of shell motion is more indicative for the evolution process of explosives reaction, by using this model, the internal pressure of the shell, reaction rate and reaction degree of solid explosives can be calculated based on the historical changes in the velocity of the shell’s motion, thus providing a theoretical method for the explosive safety design and for evaluation under unexpected stimuli. -

表 1 计算所需PBX8701炸药的热力学参数及壳体参数

Table 1. Thermodynamic parameters of PBX8701 and physical parameters of wall

表 2 约束体厚度为1和3 mm时实验与理论模型壳体膨胀速度的对比

Table 2. Comparison between the experimental data and calculating results of wall velocity of the steel case with 1 and 3 mm wall thickness

约束体厚度/mm 壳体膨胀速度/(m·s−1) 误差/% 精度提高/% 实验峰值 模型峰值 无惯性 1 202.5/177.1 197.8 91.6 4.0 47.52 3 243.6 234.2 140.1 3.9 38.63 -

[1] DICKSON P M, ASAY B W, HENSOPM B F, et al. Thermal cook-off response of confined PBX 9501 [J]. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences, 2004, 460(2052): 3447–3455. DOI: 10.1098/rspa.2004.1348. [2] PARKER G R, PETERSON P D, ASAY B, et al. Examination of morphological changes that affect gas permeation through thermally damaged explosives [J]. Propellants Explosives Pyrotechnics, 2010, 29(5): 274–281. DOI: 10.1002/prep.200400057. [3] HOLMES M D, PARKER G R, HEATWOLE E M, et al. Center-ignited spherical-mass explosion (CISME), FY 2018 report: LA-UR-18-29651 [R]. USA: Los Alamos National Laboratory, 2018. [4] HOLMES M D, PARKER G R, BROILO R M, et al. Fracture effects on explosive response (FEER), FY 2018 report: LA-UR-18-29694 [R]. USA: Los Alamos National Laboratory, 2018. [5] WANG S, LIANG W, LU F Y, et al. Simulation of convective combustion reactions in PBX based on DEM-CPM [J]. AIP Advances, 2021, 11(8): 085326. DOI: 10.1063/5.0062549. [6] 姚奎光, 王淑娟, 樊星, 等. 不同机械约束下压装PBX炸药反应演化行为 [J]. 兵工学报, 2022, 43(8): 1772–1778. DOI: 10.12382/bgxb.2021.0445.YAO K G, WANG S J, FAN X, et al. Reaction evolution behaviors of pressed plastic-bonded explosive (PBX) under different mechanical confinement conditions [J]. Acta Armamentarii, 2022, 43(8): 1772–1778. DOI: 10.12382/bgxb.2021.0445. [7] TRINGE J W, MOLITORIS J D, SMILOWITZ L, et al. Time-sequenced X-ray observation of a thermal explosion [J]. American Institute of Physics, 2009, 1195: 424–427. DOI: 10.1063/1.3295164. [8] SMILOWITZ L. The evolution of solid density within a thermal explosion Ⅱ. dynamic proton radiography of cracking and solid consumption by burning [J]. Journal of Applied Physics, 2012, 111(10): 617–1214. DOI: 10.1063/1.4711072. [9] HILL L G. Burning crack networks and combustion bootstrapping in cookoff explosions [C]//Conference of the American Physical-Society Topical Group on Shock Compression of Condensed Matter. Baltimore, MD: American Institute of Physics, 2006. DOI: 10.1063/1.2263377. [10] 段卓平, 白志玲, 白孟璟, 等. 强约束固体炸药燃烧裂纹网络反应演化模型 [J]. 兵工学报, 2021, 42(11): 2291–2299. DOI: 10.3969/j.issn.1000-1093.2021.11.001.DUAN Z P, BAI Z L, BAI M J, et al. Burning-crack networks model for combustion reaction growth of solid explosives with strong confinement [J]. Acta Armamentarii, 2021, 42(11): 2291–2299. DOI: 10.3969/j.issn.1000-1093.2021.11.001. [11] DUAN Z P, BAI M J, BAI Z L, et al. Combustion crack-network reaction evolution model for highly-confined explosives [J]. Defence Technology, 2023, 26: 54–67. DOI: 10.1016/j.dt.2022.06.011. [12] 白志玲, 段卓平, 李治, 等. 热刺激约束DNAN基不敏感熔铸炸药装药点火后反应演化调控模型 [J]. 含能材料, 2023, 31(10): 1004–1012. DOI: 10.11943/cjem2023160.BAI Z L, DUAN Z P, LI Z, et al. Regulation model for reaction evolution of confined DNAN-based cast explosives after ignition under thermal stimulation [J]. Chinese Journal of Energetic Materials, 2023, 31(10): 1004–1012. DOI: 10.11943/cjem2023160. [13] 胡海波, 傅华, 李涛, 等. 压装密实炸药装药非冲击点火反应传播与烈度演化实验研究进展 [J]. 爆炸与冲击, 2020, 40(1): 011401. DOI: 10.11883/bzycj-2019-0346.HU H B, FU H, LI T, et al. Progress in experimental studies on the evolution behaviors of non-shock initiation reaction in low porosity pressed explosive with confinement [J]. Explosion and Shock Waves, 2020, 40(1): 011401. DOI: 10.11883/bzycj-2019-0346. [14] 李涛, 胡海波, 尚海林, 等. 强约束球形装药反应裂纹传播和反应烈度表征实验 [J]. 爆炸与冲击, 2020, 40(1): 011402. DOI: 10.11883/bzycj-2019-0348.LI T, HU H B, SHANG H L, et al. Propagation of reactive cracks and characterization of reaction violence in spherical charge under strong confinement [J]. Explosion and Shock Waves, 2020, 40(1): 011402. DOI: 10.11883/bzycj-2019-0348. [15] BERGHOUT H L, SON S F, ASAY B W, et al. Convective burning in gaps of PBX 9501 [J]. Proceedings of the Combustion Institute, 2000, 28(1): 911–917. DOI: 10.1016/S0082-0784(00)80297-0. [16] ASAY B W. Shock wave science and technology reference library, vol. 5: non-shock initiation of explosives [M]. Heidelberg, Baden-Württemberg, Germany: Springer, 2010: 245–401. [17] 陈明详. 弹塑性力学 [M]. 2版. 北京: 科学出版社, 2021: 297–302.CHEN M X. Elasticity and plasticity [M]. 2nd ed. Beijing: Science Press, 2021: 297–302. [18] 奥尔连科. 爆炸物理学 [M]. 孙承纬, 译. 北京: 科学出版社, 2011: 797–803. [19] 赵衡阳. 气体和粉尘爆炸原理 [M]. 北京: 北京理工大学出版社, 1996: 186–196. [20] ZHANG W Y, DENG X Y, CHEN S J, et al. Molecular dynamics simulation of thermal sensitivity, thermal expansion and mechanical properties of PBX9501 [J]. 2016, 39(3): 32–36. DOI: 10.14077/j.issn.1007-7812.2016.03.006. [21] 祝明水, 龙新平, 蒋小华, 等. 不同粒径RDX的燃烧特性研究 [J]. 含能材料, 2004, 12(1): 40–42. DOI: 10.3969/j.issn.1006-9941.2004.01.012.ZHU M S, LONG X P, JIANG X H, et al. Study on the combustion characteristics of RDX with different particle sizes [J]. Chinese Journal of Energetic Materials, 2004, 12(1): 40–42. DOI: 10.3969/j.issn.1006-9941.2004.01.012. [22] JACKSOPN S I, HILL L G. Runaway reaction due to gas-dynamic choking in solid explosive containing a single crack [J]. Proceedings of the Combustion Institute, 2009, 32(2): 2307–2313. DOI: 10.1016/j.proci.2008.05.089. [23] GREBENKIN K. Comparative analysis of physical mechanisms of detonation initiation in HMX and in a low-sensitive explosive (TATB) [J]. Combustion, Explosion, and Shock Waves, 2009, 45(1): 78–87. DOI: 10.1007/s10573-009-0011-y. [24] 范钦珊, 殷雅俊, 唐靖林, 等. 材料力学 [M]. 3版. 北京: 清华大学出版社, 2014: 42–49. [25] 张震宇, 田占东, 陈军, 等. 爆轰物理 [M]. 长沙: 国防科技大学出版社, 2016: 68–73. -

下载:

下载: