Passive protection containment of high temperature and impact hazards from thermal runaway in aviation power lithium-ion batteries

-

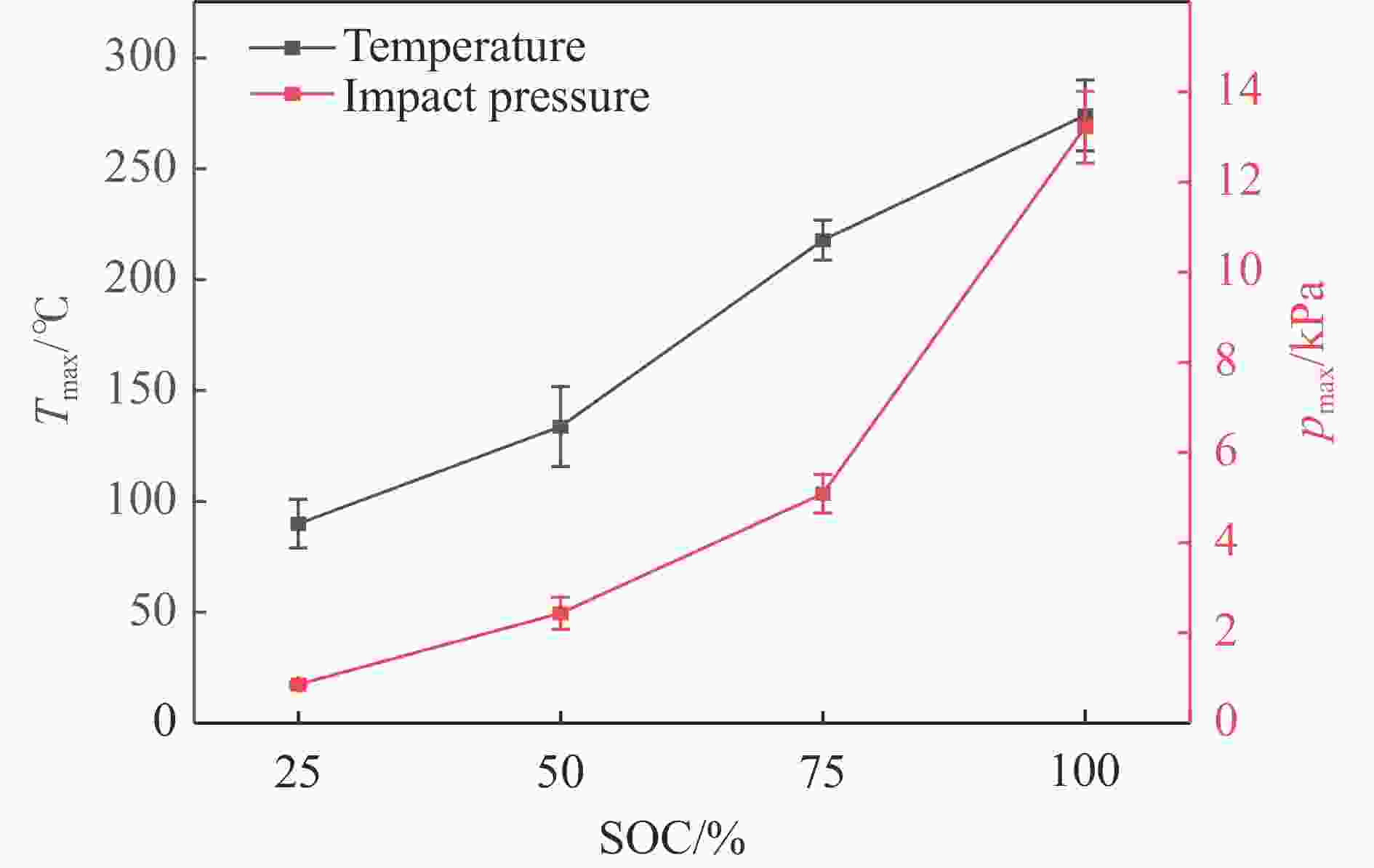

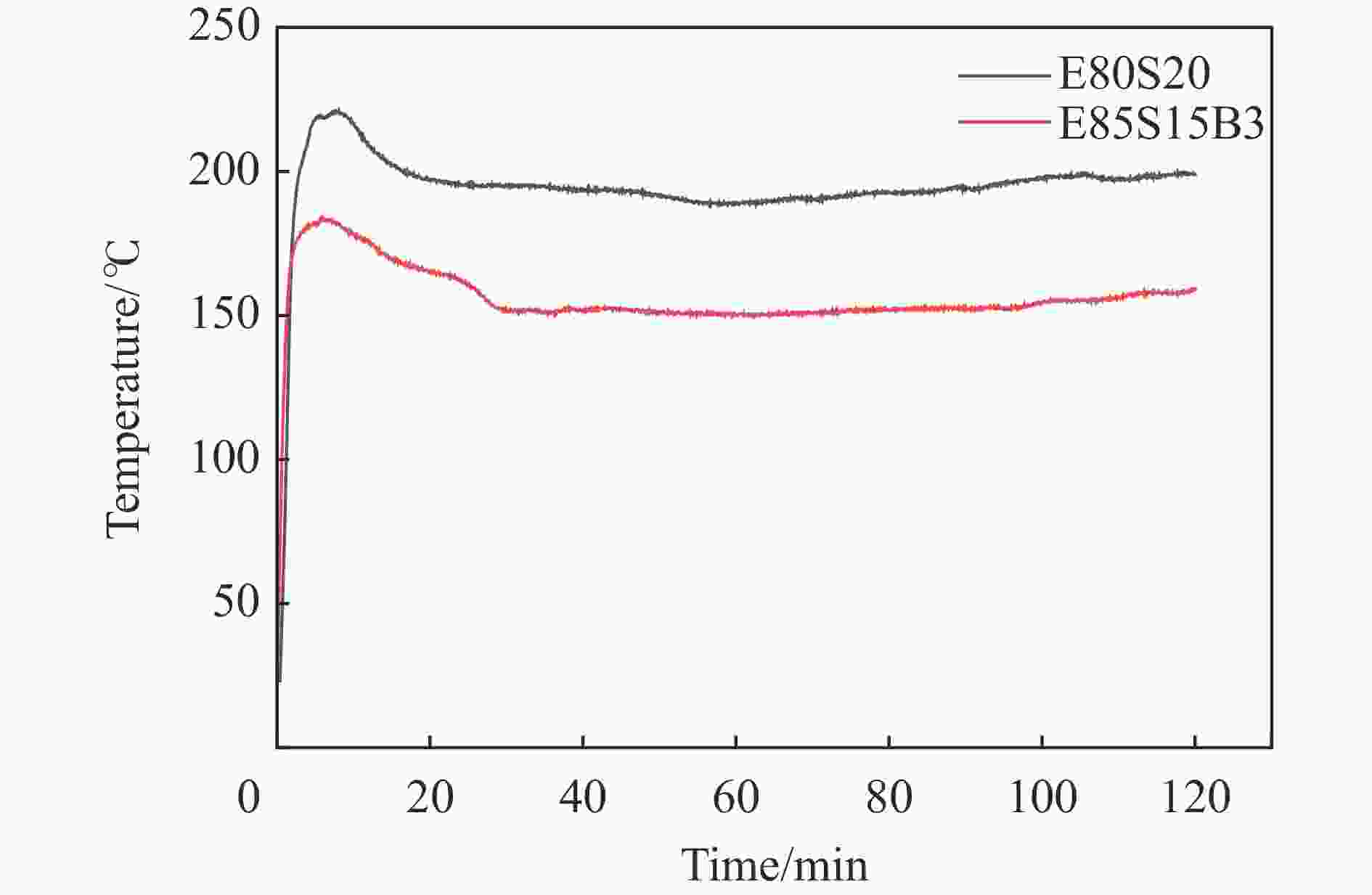

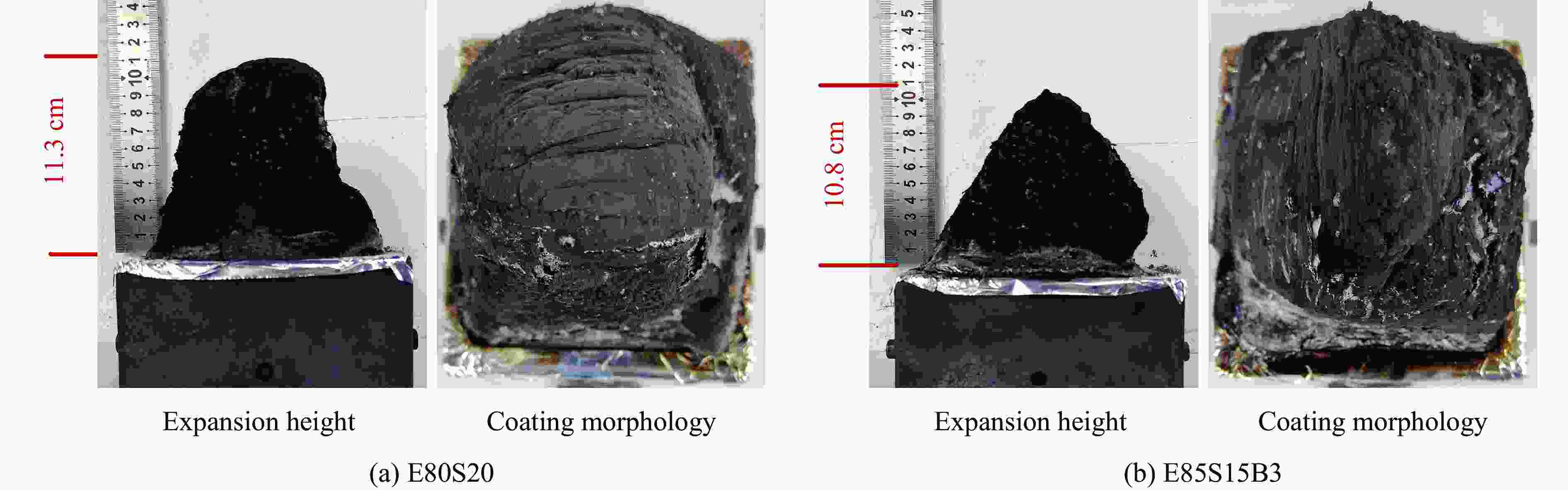

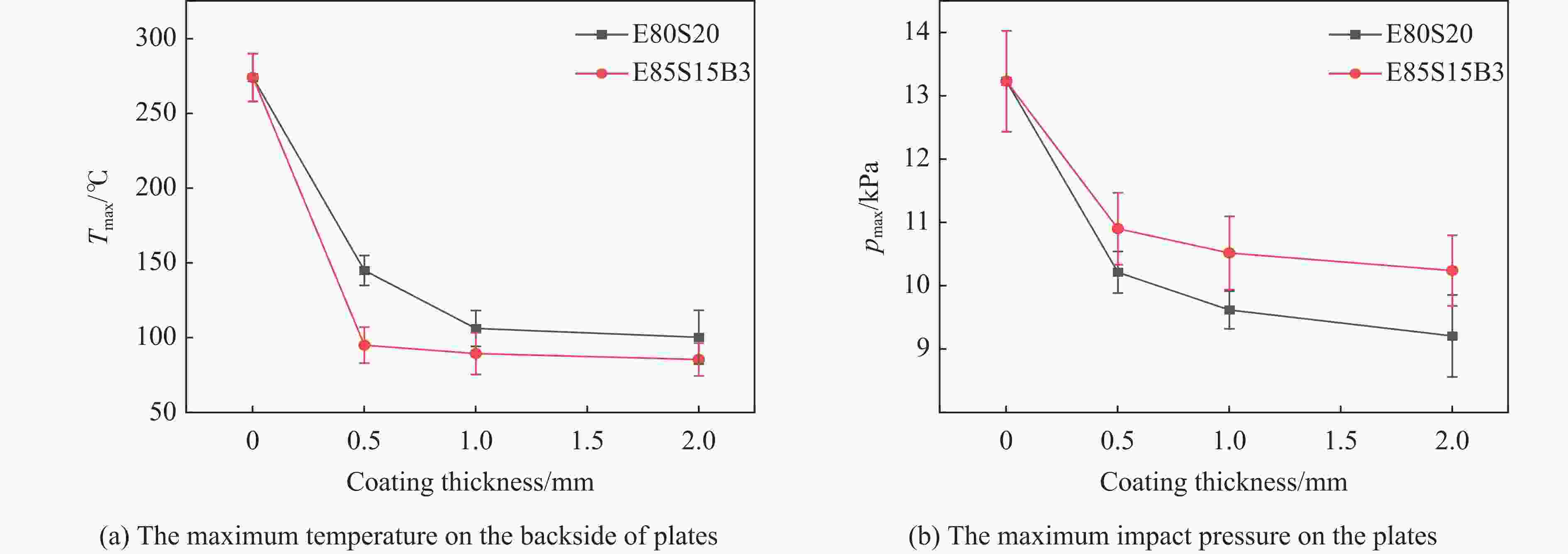

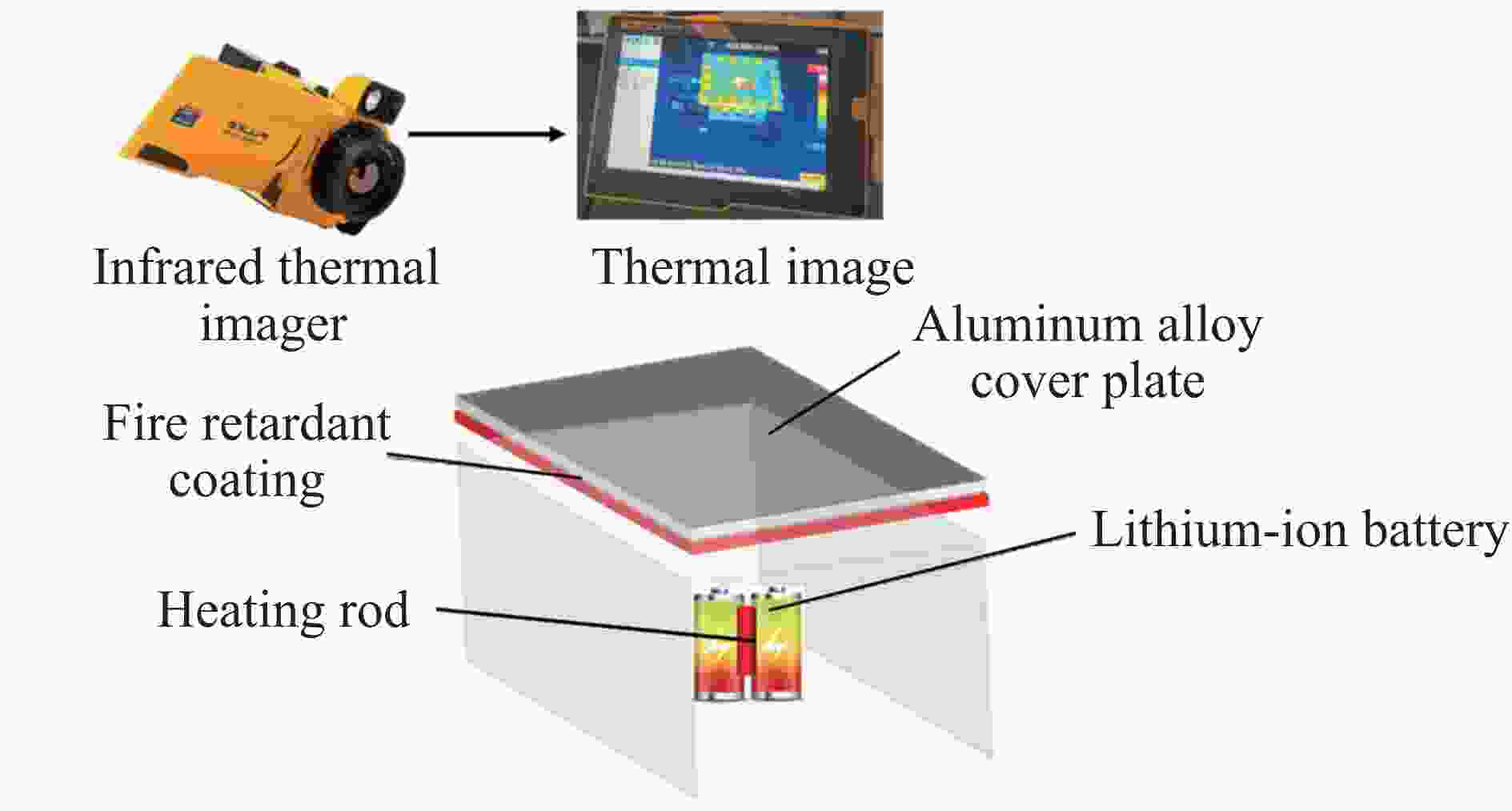

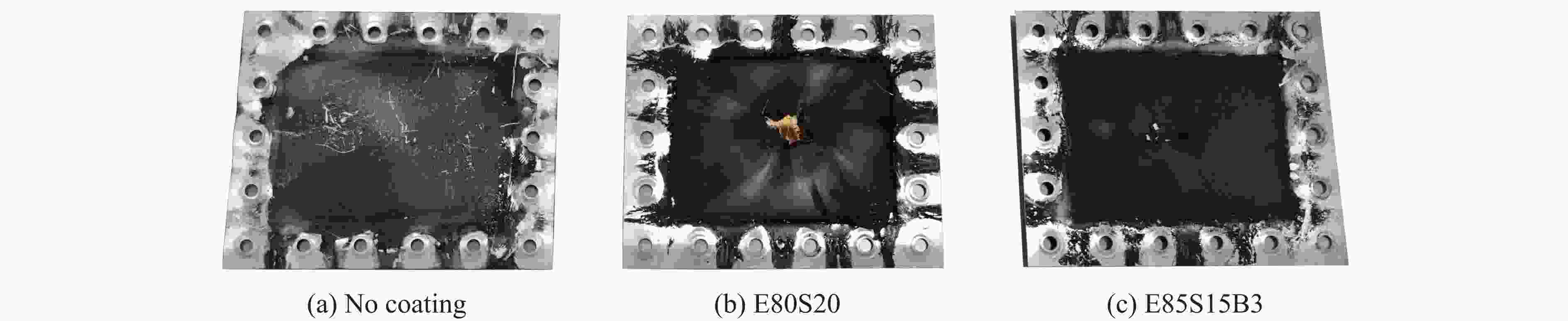

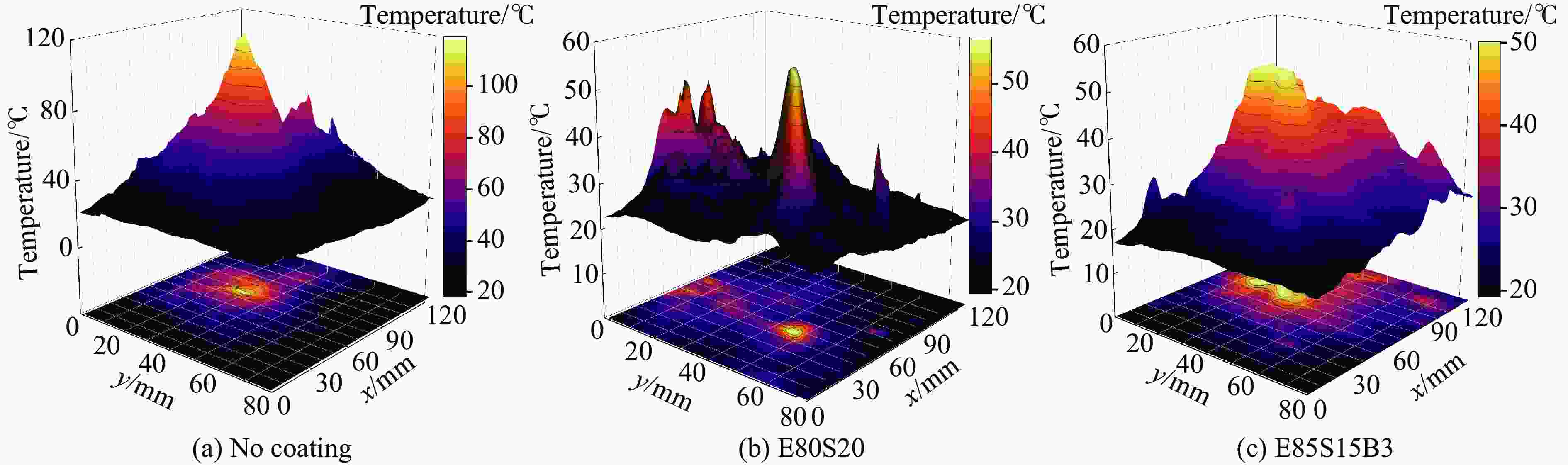

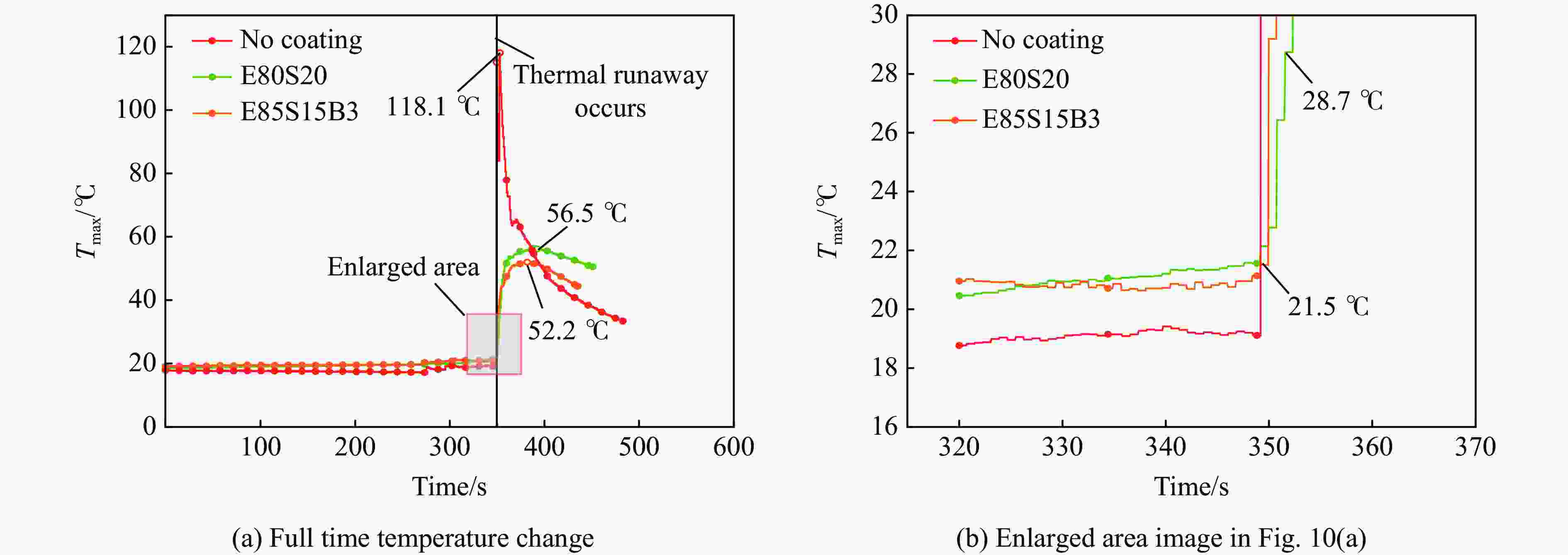

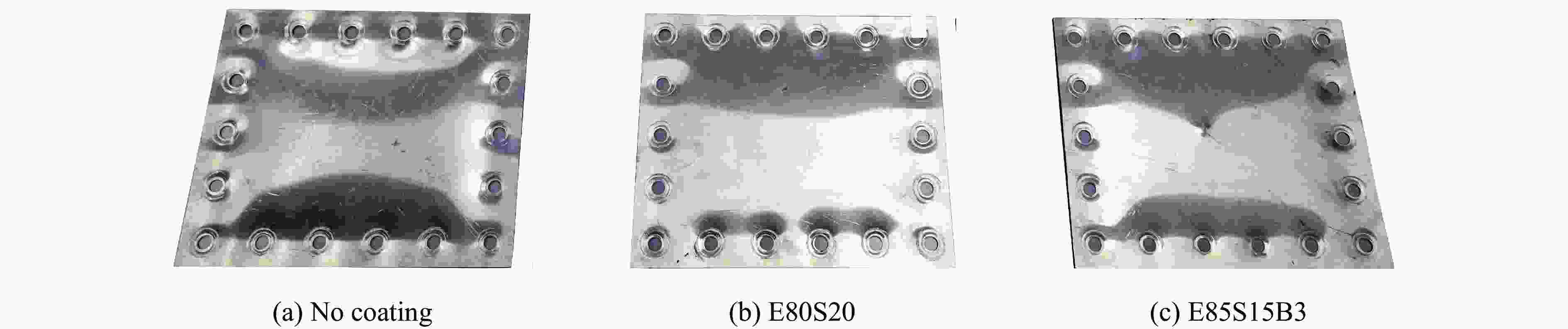

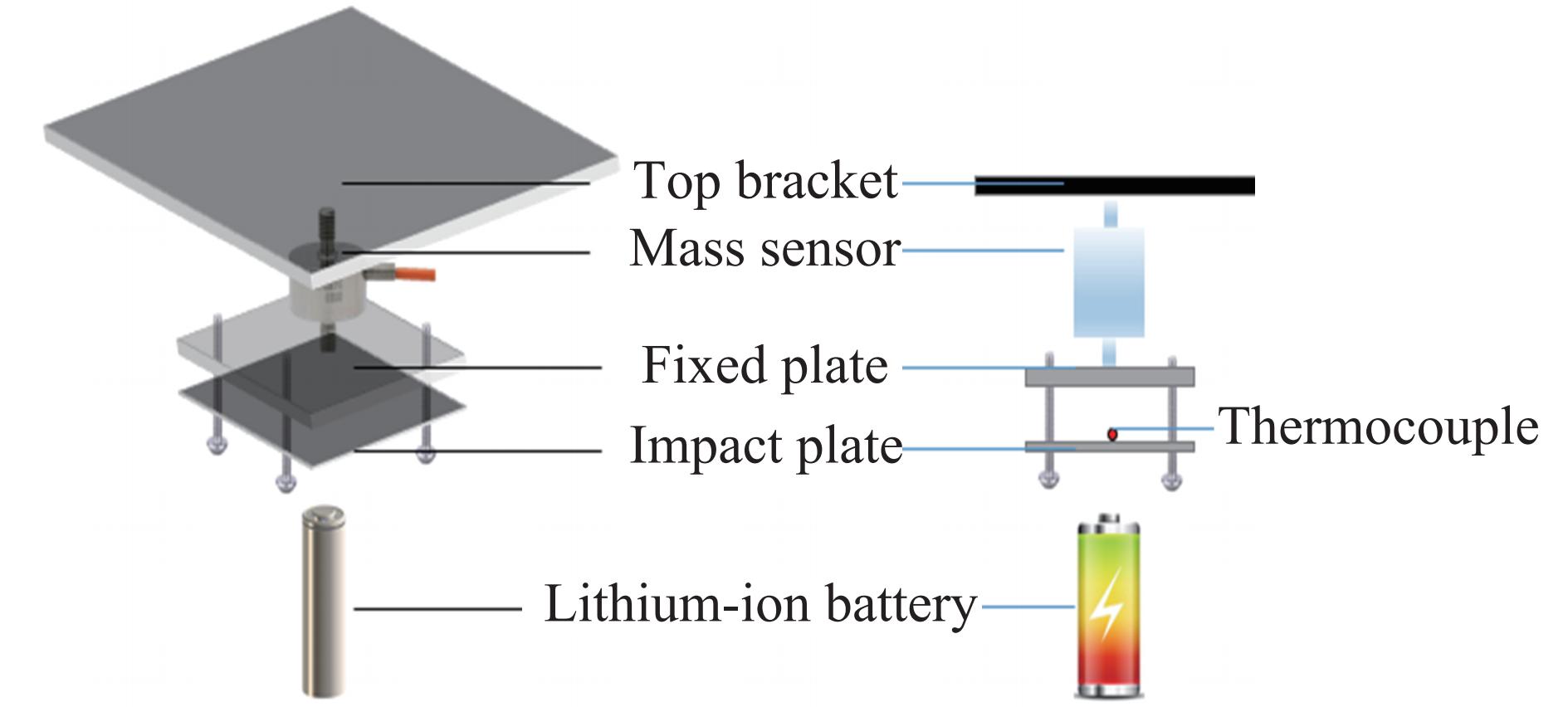

摘要: 锂离子电池热失控造成的热冲击将损坏安装结构,对周围人员和设备安全构成威胁,是限制其在航空领域应用的关键问题。通过自主搭建的锂离子电池热失控高温冲击实验平台研究发现,单节电池热冲击对电池包顶板的冲击压力高达13.23 kPa,致使其外表面温度高达274 ℃。为了有效包容锂离子电池热失控造成的高温冲击危害,提出了电池包顶板涂敷防火涂层的被动防护方法。通过实验研究发现,环氧树脂基膨胀型防火涂层可通过膨胀有效阻隔锂离子电池热失控冲击压力的影响,通过吸收热量降低并延缓电池包顶板的温度上升。分析锂离子电池热失控包容性验证实验结果可知,1.0 mm厚的E80S20涂层和E85S15B3涂层分别使电池包顶板最高温度下降52.16%和55.80%,结构最高形变分别降低72.2%和44.4%。研究结果表明,防火涂层被动防护技术能够有效提升电池舱体对热失控高温和冲击危害的包容性,可作为航空动力锂离子电池系统安全性设计的有效措施。Abstract: The thermal shock caused by thermal runaway of lithium-ion batteries causes damage in the installation structure and poses a threat to the safety of surrounding personnel and equipment, which is a key issue limiting their aviation applications. Through a self-built high-temperature impact experimental platform for thermal runaway of lithium battery, it was found that the impact pressure on the pack top plate of battery from single-cell thermal shock can reach up to 13.23 kPa, causing the external surface temperature beyond 274 °C. The combined effect of high temperature and impact pressure increases the risk of the casing undergoing plastic deformation, buckling, or even failure. To effectively mitigate such risks, a passive protection method that involves applying a fireproof coating to the top plate of the battery pack. is proposed. Through large panel combustion experiments and cone calorimeter tests, it was found that the epoxy resin-based intumescent fireproof coatings can effectively block the impact pressure induced by thermal runaway of a lithium-ion battery by expanding, and absorbing heat, thereby reducing and delaying the temperature rise of the top plate of the battery pack, demonstrating excellent thermal shock resistance. By comparing the containment effects of fireproof coatings of different thicknesses, it was found that the 1.0-mm-thickness coating is more suitable for practical application requirements. Referring to relevant airworthiness regulations, verification tests were conducted on the thermal runaway containment of lithium battery. The analysis of the experiment results shows that the 1.0-mm-thickness E80S20 coating and E85S15B3 coating reduced the maximum temperature of the top plate of the battery pack by 52.16% and 55.80%, respectively. Additionally, the maximum structural deformation decreased by 72.2% and 44.4%, respectively. The study indicates that the passive protection technology of fireproof coating can effectively enhance the containment of high temperatures and impact hazards caused by thermal runaway. This approach can serve as an effective measure in the safety design of aviation power lithium-ion battery systems.

-

表 1 涂料中不同组分的质量分数

Table 1. Mass fractions of different components in coatings

% 涂料 环氧树脂 坡缕石+海泡石 有机硅树脂 APP+MEL+PER 593固化剂 碳化硼 E80S20 50.79 4.76 12.70 19.05 12.70 0.00 E85S15B3 52.95 2.34 9.35 18.69 12.46 4.21 表 2 不同涂层的锥形量热测试参数

Table 2. Cone calorimeter test parameters for different coatings

样品 TTI/s PHRR/(kW·m−2) THR/(MJ·m−2) MRR/% E80S20 31 181.34 39.31 56.88 E85S15B3 29 170.53 35.62 58.32 表 3 不同厚度涂层的包容效果

Table 3. Containment effects of coatingswith different thicknesses

涂层材料 厚度/mm Tmax/℃ CT/% pmax/kPa Cp/% E80S20 0.5 144.95 47.1 10.21 22.8 1.0 106.31 61.2 9.61 27.3 2.0 100.28 63.4 9.21 30.4 E85S15B3 0.5 95.08 65.3 10.92 17.6 1.0 89.32 67.4 10.50 20.5 2.0 85.49 68.8 10.25 22.6 -

[1] ZHAO C Y, JU S H, XUE Y, et al. China’s energy transitions for carbon neutrality: challenges and opportunities [J]. Carbon Neutrality, 2022, 1(1): 7. DOI: 10.1007/s43979-022-00010-y. [2] 黄俊, 杨凤田. 新能源电动飞机发展与挑战 [J]. 航空学报, 2016, 37(1): 57–68. DOI: 10.7527/S1000-6893.2015.0274.HUANG J, YANG F T. Development and challenges of electric aircraft with new energies [J]. Acta Aeronautica et Astronautica Sinica, 2016, 37(1): 57–68. DOI: 10.7527/S1000-6893.2015.0274. [3] YANG J, BAO X W, YANG Z G. Load identification for the more electric aircraft distribution system based on intelligent algorithm [J]. Aerospace, 2022, 9: 350. DOI: 10.3390/aerospace9070350. [4] 陈农田, 李俊辉, 王志宏, 等. B787-800飞机锂电池起火事故原因及分析 [J]. 电池, 2022, 52(2): 204–207. DOI: 10.19535/j.1001-1579.2022.02.020.CHEN N T, LI J H, WANG Z H, et al. Cause and analysis of lithium battery fire accident of B787-800 aircraft [J]. Battery, 2022, 52(2): 204–207. DOI: 10.19535/j.1001-1579.2022.02.020. [5] 杨娟, 牛江昊, 张青松, 等. 循环老化对锂离子电池热失控气体爆炸危险性影响实验研究 [J]. 航空学报, 2024, 45(3): 428529. DOI: 10.7527/S1000-6893.2023.28529.YANG J, NIU J H, ZHANG Q S, et al. Experimental research on the effect of cyclic aging on the detonation risk of thermal runaway gas explosion in lithium-ion batteries [J]. Acta Aeronautica et Astronautica Sinica, 2024, 45(3): 428529. DOI: 10.7527/S1000-6893.2023.28529. [6] YANG J, LIU W, ZHAO H, et al. Experimental investigation of lithium-ion batteries thermal runaway propagation consequences under different triggering modes [J]. Aerospace, 2024, 11(6): 438. DOI: 10.3390/aerospace11060438. [7] 袁帅, 台枫, 钱新明, 等. 磷酸铁锂离子电池热失控产物爆炸下限预测方法 [J]. 爆炸与冲击, 2025, 45(2): 021434. DOI: 10.11883/bzycj-2023-0452.YUAN S, TAI F, QIAN X M, et al. Prediction methods for lower explosion limit of thermal runawayproducts of lithium-iron phosphate batteries [J]. Explosion and Shock Waves, 2025, 45(2): 021434. DOI: 10.11883/bzycj-2023-0452. [8] SHAN T, ZHANG P, WANG Z, et al. Insights into extreme thermal runaway scenarios of lithium-ion batteries fire and explosion: a critical review [J]. Journal of Energy Storage, 2024, 88: 111532. DOI: 10.1016/j.est.2024.111532. [9] WANG Z R, CHEN S C, HE X R, et al. A multi-factor evaluation method for the thermal runaway risk of lithium-ion batteries [J]. Journal of Energy Storage, 2022, 45: 103767. DOI: 10.1016/j.est.2021.103767. [10] STERLING J, TATTERSALL L, BAMBER N, et al. Composite structure failure analysis post lithium-ion battery fire [J]. Engineering Failure Analysis, 2024, 160: 108163. DOI: 10.1016/j.engfailanal.2024.108163. [11] RTCA Inc. Environmental conditions and test procedures for airborne equipment: RTCA DO-160G [S]. Washington: Radio Technical Commission for Aeronautics, 2010. [12] RTCA Inc. Minimum operational performance standards for rechargeable lithium batteries and battery systems: RTCA DO-311A [S]. Washington: Radio Technical Commission for Aeronautics, 2017. [13] CAI G S, WU J X, GUO J Y, et al. A novel inorganic aluminum phosphate-based flame retardant and thermal insulation coating and performance analysis [J]. Materials, 2023, 16(13): 4498. DOI: 10.3390/ma16134498. [14] 吴沛沛, 张依晴, 田爱琴, 等. 膨胀型钢结构防火涂料的研究进展 [J]. 涂料工业, 2024, 54(3): 59–65. DOI: 10.12020/j.issn.0253-4312.2024-015.WU P P, ZHANG Y Q, TIAN A Q, et al. Research progress on the intumescent fire retardant coatings for steel structure [J]. Paint & Coatings Industry, 2024, 54(3): 59–65. DOI: 10.12020/j.issn.0253-4312.2024-015. [15] CAI G S, WAN Y G, LIU J X, et al. Preparation and performance analysis of methyl-silicone resin-modified epoxy resin-based intumescent flame retardant thermal insulation coating [J]. Journal of Micromechanics and Molecular Physics, 2023, 8(2/3): 61–82. DOI: 10.1142/S2424913023410011. [16] CHEN H D, BUSTON J E H, GILL J, et al. An experimental study on thermal runaway characteristics of lithium-ion batteries with high specific energy and prediction of heat release rate [J]. Journal of Power Sources, 2020, 472: 228585. DOI: 10.1016/j.jpowsour.2020.228585. [17] KONG D P, WANG G Q, PING P, et al. A coupled conjugate heat transfer and CFD model for the thermal runaway evolution and jet fire of 18650 lithium-ion battery under thermal abuse [J]. eTransportation, 2022, 12: 100157. DOI: 10.1016/j.etran.2022.100157. [18] WANG S P, SONG L F, LI C H, et al. Experimental study of gas production and flame behavior induced by the thermal runaway of 280 Ah lithium iron phosphate battery [J]. Journal of Energy Storage, 2023, 74: 109368. DOI: 10.1016/j.est.2023.109368. [19] CHEN M Y, OUYANG D X, LIU J H, et al. Investigation on thermal and fire propagation behaviors of multiple lithium-ion batteries within the package [J]. Applied Thermal Engineering, 2019, 157: 113750. DOI: 10.1016/j.applthermaleng.2019.113750. [20] CHEN S C, WANG Z R, YAN W, et al. Investigation of impact pressure during thermal runaway of lithium ion battery in a semi-closed space [J]. Applied Thermal Engineering, 2020, 175: 115429. DOI: 10.1016/j.applthermaleng.2020.115429. [21] LI H X, GAO Q, LING J J, et al. Thermal runaway propagation and combustion characteristics of enclosed LiNi0.8Co0.1Mn0.1O2 pouch battery modules in an open environment [J]. Journal of Energy Storage, 2024, 85: 110877. DOI: 10.1016/j.est.2024.110877. [22] ZHANG Y H, CHEN S Q, SHAHIN M E, et al. Multi-objective optimization of lithium-ion battery pack casing for electric vehicles: key role of materials design and their influence [J]. International Journal of Energy Research, 2020, 44(12): 9414–9437. DOI: 10.1002/er.4965. [23] European Committee for Standardization. Eurocode 9: design of aluminum structures, Part 1−2: general rules: structural fire design: BS EN 1999−1−2 [S]. London: European Committee for Standardization, 2007. [24] 罗星娜, 张青松, 戚瀚鹏, 等. 基于计算流体动力学的锂离子电池热失控多米诺效应研究 [J]. 科学技术与工程, 2014, 14(33): 327–332. DOI: 10.3969/j.issn.1671-1815.2014.33.062.LUO X N, ZHANG Q S, QI H P, et al. Lithium-ion battery thermal runaway domino effect analysis based on the CFD [J]. Science Technology and Engineering, 2014, 14(33): 327–332. DOI: 10.3969/j.issn.1671-1815.2014.33.062. [25] YANG X K, WAN Y G, YANG N, et al. The effect of different diluents and curing agents on the performance of epoxy resin-based intumescent flame-retardant coatings [J]. Materials, 2024, 17(2): 348. DOI: 10.3390/ma17020348. [26] 全国建筑防火标准化技术委员会. 饰面型防火涂料: GB/T 12441-2018 [S]. 北京: 中国标准出版社, 2018.National Technical Committee on Fire Protection in Building. Fire-resistant coatings for decorative finishes: GB/T 12441-2018 [S]. Beijing: Standards Press of China, 2018. [27] International Organization for Standardization. Reaction-to-fire tests: heat release, smoke production and mass loss rate: ISO 5660-1: 2015 [S]. Geneva: International Organization for Standardization, 2015. [28] 吕仲菲, 唐宇建, 王俊杰, 等. 纳米填料对多功能防火涂料性能的影响 [J]. 涂料工业, 2024, 54(3): 21–25. DOI: 10.12020/j.issn.0253-4312.2023-347.LÜ Z F, TANG Y J, WANG J J, et al. The effect of nanometer-structured fillers on properties of multifunctional fire retardant coatings [J]. Paint & Coatings Industry, 2024, 54(3): 21–25. DOI: 10.12020/j.issn.0253-4312.2023-347. [29] LI J Y, GAO P, TONG B, et al. Revealing the mechanism of pack ceiling failure induced by thermal runaway in NCM batteries: a coupled multiphase fluid-structure interaction model for electric vehicles [J]. eTransportation, 2024, 20: 100335. DOI: 10.1016/j.etran.2024.100335. -

下载:

下载: