| [1] |

刘晨. 基于数字图像相关方法的PBX断裂行为研究 [D]. 绵阳: 中国工程物理研究院, 2016.LIU C. Study on fracture behavior of PBX based on digital image correlation method [D]. Mianyang: China Academy of Engineering Physics, 2016.

|

| [2] |

巩天元. 冲击载荷下PBX损伤与断裂行为研究 [D]. 太原: 中北大学, 2023. DOI: 10.27470/d.cnki.ghbgc.2023.001323.GONG T Y. Research on the damage and fracture behavior of PBX under impact load [D]. Taiyuan: North University of China, 2023. DOI: 10.27470/d.cnki.ghbgc.2023.001323.

|

| [3] |

杨存丰, 田勇, 张伟斌, 等. 基于X射线显微CT的PBX热冲击损伤特征 [J]. 含能材料, 2022, 30(9): 959–965. DOI: 10.11943/CJEM2021247.YANG C F, TIAN Y, ZHANG W B, et al. Thermal shock damage characteristics of polymer bonded explosive based on X-ray micro-computed tomography [J]. Chinese Journal of Energetic Materials, 2022, 30(9): 959–965. DOI: 10.11943/CJEM2021247.

|

| [4] |

李俊玲. PBX炸药装药的力学性能及损伤破坏研究 [D]. 长沙: 国防科学技术大学, 2012.LI J L. Study on PBX’s mechanical behavior and damage feature [D]. Changsha: National University of Defense Technology, 2012.

|

| [5] |

高霞, 赵天波, 郑保辉, 等. 不同壁材石蜡微胶囊与HTPB型黏结剂的表界面研究 [J]. 火炸药学报, 2020, 43(2): 161–166. DOI: 10.14077/j.issn.1007-7812.201905012.GAO X, ZHAO T B, ZHENG B H, et al. Surface and interface study on the MePWs with different shells and HTPB-type binder [J]. Chinese Journal of Explosives and Propellants, 2020, 43(2): 161–166. DOI: 10.14077/j.issn.1007-7812.201905012.

|

| [6] |

陈世雄, 钱华, 芮久后, 等. 高品质RDX的抗压性能研究 [J]. 爆破器材, 2023, 52(6): 1–8. DOI: 10.3969/j.issn.1001-8352.2023.06.001.CHEN S X, QIAN H, RUI J H, et al. Research on the compressive performance of H-RDX [J]. Explosive Materials, 2023, 52(6): 1–8. DOI: 10.3969/j.issn.1001-8352.2023.06.001.

|

| [7] |

张催. 基于CT成像的炸药造型颗粒集特征参量表征方法: ZWCF-2021-050 [R]. 绵阳: 中国工程物理研究院化工材料研究所, 2022.ZHANG C. Characterization method of characteristic parameters of explosive modeling particle set based on CT imaging: ZWCF-2021-050 [R]. Mianyang: Institute of Chemical Materials, China Academy of Engineering Physics, 2022.

|

| [8] |

杨昆, 吴艳青, 金朋刚, 等. 典型压装与浇注PBX炸药缝隙挤压损伤-点火响应 [J]. 含能材料, 2020, 28(10): 975–983. DOI: 10.11943/CJEM2020170.YANG K, WU Y Q, JIN P G, et al. Damage-ignition simulation for typical pressed and casted PBX under crack-extruded loading [J]. Chinese Journal of Energetic Materials, 2020, 28(10): 975–983. DOI: 10.11943/CJEM2020170.

|

| [9] |

YANG K, DONG L Y, WU Y Q. Viscous shear flow and heating of impact-extruded composite energetic materials [J]. International Journal of Mechanical Sciences, 2023, 258: 108588. DOI: 10.1016/j.ijmecsci.2023.108588.

|

| [10] |

陈鹏, 屈可朋, 李亮亮, 等. PBX炸药剪切流动点火性能的实验研究 [J]. 火炸药学报, 2020, 43(1): 69–73, 80. DOI: 10.14077/j.issn.1007-7812.201901003.CHEN P, QU K P, LI L L, et al. Experimental study on shear-flow ignition performance of PBX explosive [J]. Chinese Journal of Explosives and Propellants, 2020, 43(1): 69–73, 80. DOI: 10.14077/j.issn.1007-7812.201901003.

|

| [11] |

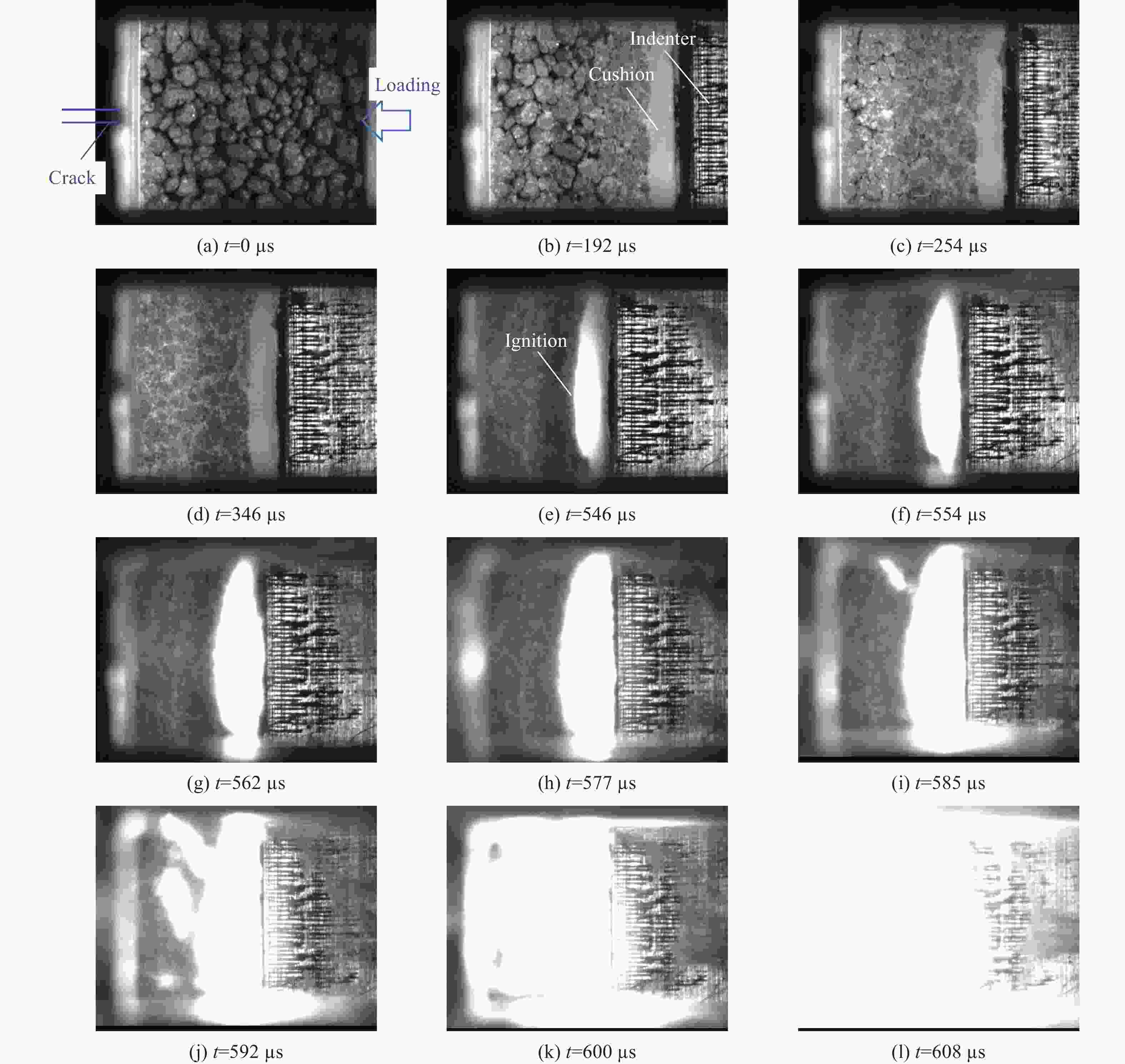

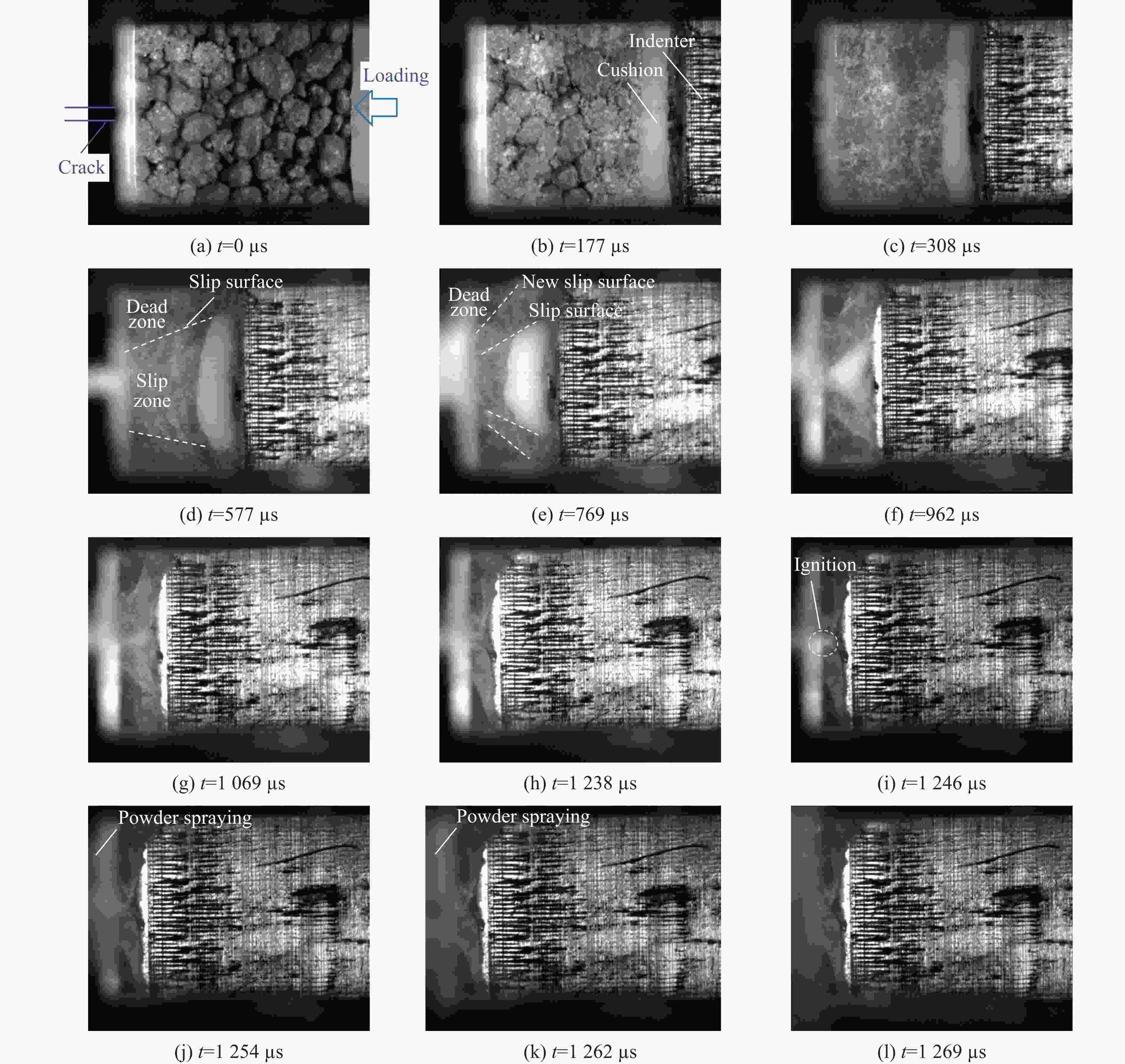

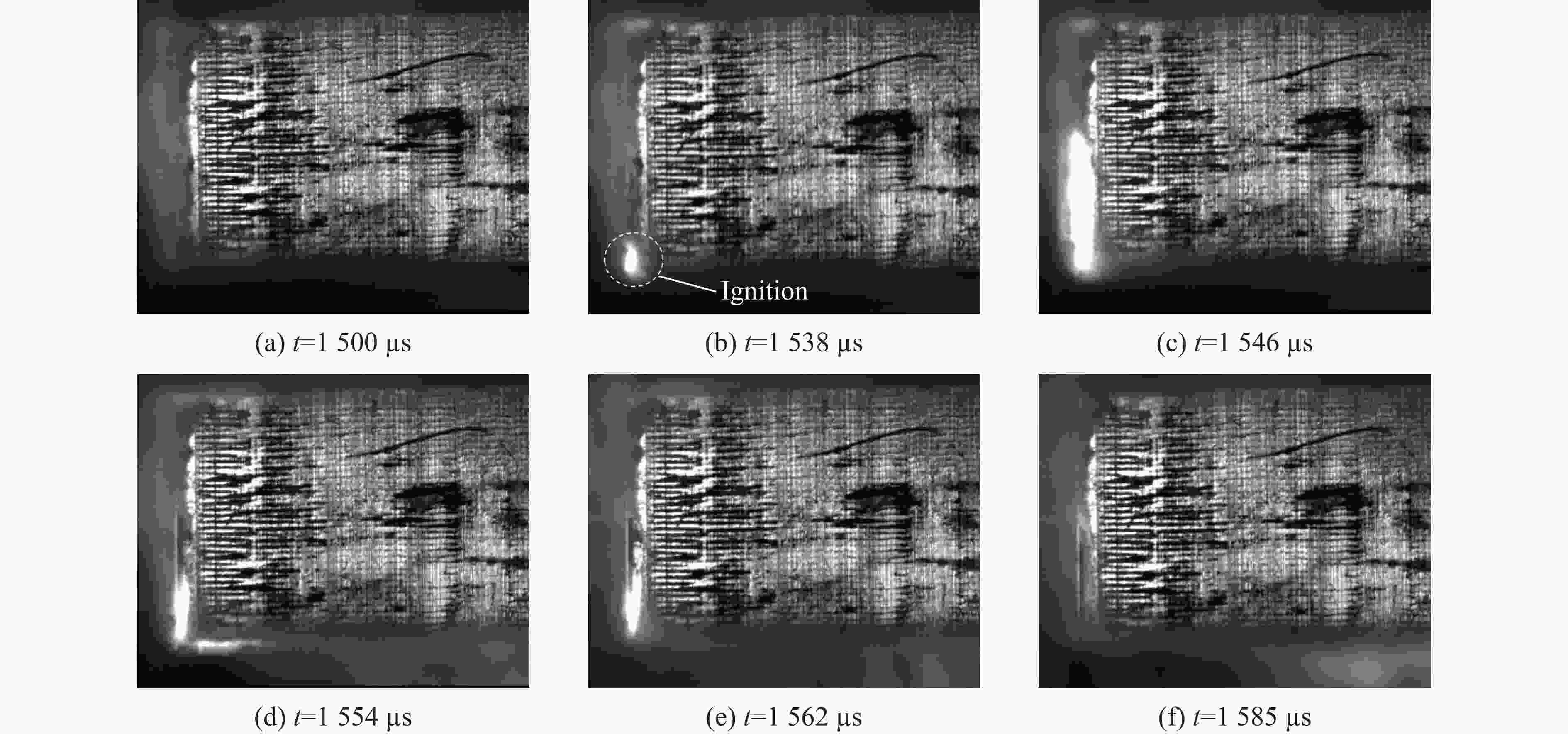

胡秋实, 尚海林, 吴兆奎, 等. PBX炸药缝隙挤压加载下的破裂模式及点火响应 [J]. 兵工学报, 2024, 45(9): 3135–3146. DOI: 10.12382/bgxb.2023.0809.HU Q S, SHANG H L, WU Z K, et al. Fracture mode and ignition response of PBX explosives under crack extrusion loading [J]. Acta Armamentarii, 2024, 45(9): 3135–3146. DOI: 10.12382/bgxb.2023.0809.

|

| [12] |

董军, 王晶禹, 梁磊, 等. LLM-105/EPDM造型粉的制备及性能 [J]. 火炸药学报, 2009, 32(5): 14–17. DOI: 10.3969/j.issn.1007-7812.2009.05.005.DONG J, WANG J Y, LIANG L, et al. Preparation and properties of LLM-105/EPDM molding powders [J]. Chinese Journal of Explosives and Propellants, 2009, 32(5): 14–17. DOI: 10.3969/j.issn.1007-7812.2009.05.005.

|

| [13] |

牛磊, 曹少庭, 金大勇, 等. 含α-AlH3的HMX基凝聚相炸药的安全性和爆轰性能 [J]. 含能材料, 2021, 29(10): 957–963. DOI: 10.11943/CJEM2021079.NIU L, CAO S T, JIN D Y, et al. Safety and detonation performance of HMX-based condensed phase explosives containing α-AlH3 [J]. Chinese Journal of Energetic Materials, 2021, 29(10): 957–963. DOI: 10.11943/CJEM2021079.

|

| [14] |

刘意, 朱瑞, 时嘉辉, 等. 液滴微流控技术制备亚微米级HNS基PBX复合微球 [J]. 含能材料, 2023, 31(2): 121–129. DOI: 10.11943/CJEM2022184.LIU Y, ZHU R, SHI J H, et al. Preparation of submicron HNS-based PBX composite microspheres by droplet microfluidics [J]. Chinese Journal of Energetic Materials, 2023, 31(2): 121–129. DOI: 10.11943/CJEM2022184.

|

| [15] |

朱玉宇, 霍宏彪, 王杰超, 等. NC/F2602/RDX复合微球悬浮组装成型及其性能研究 [J]. 火工品, 2023(1): 58–62. DOI: 10.3969/j.issn.1003-1480.2023.01.012.ZHU Y Y, HUO H B, WANG J C, et al. The suspension assembly and properties of NC/F2602/RDX composite microspheres [J]. Initiators and Pyrotechnics, 2023(1): 58–62. DOI: 10.3969/j.issn.1003-1480.2023.01.012.

|

| [16] |

谢林, 刘迎彬, 范志强, 等. 基于复合压电效应的PVDF传感器测量性能调控 [J]. 高压物理学报, 2023, 37(4): 043401. DOI: 10.11858/gywlxb.20230645.XIE L, LIU Y B, FAN Z Q, et al. Measurement performance regulation of PVDF sensor based on composite piezoelectricity [J]. Chinese Journal of High Pressure Physics, 2023, 37(4): 043401. DOI: 10.11858/gywlxb.20230645.

|

| [17] |

刘昊. 基于光纤干涉降频技术的高速测量系统研究 [D]. 太原: 中北大学, 2023. DOI: 10.27470/d.cnki.ghbgc.2023.001041.LIU H. Research on high-speed measurement system based on fiber optic interference frequency reduction technology [D]. Taiyuan: North University of China, 2023. DOI: 10.27470/d.cnki.ghbgc.2023.001041.

|

| [18] |

王琦, 智小琦, 肖游, 等. 基于UCM模型的B炸药慢烤泄压结构的作用分析 [J]. 爆炸与冲击, 2022, 42(4): 042301. DOI: 10.11883/bzycj-2021-0253.WANG Q, ZHI X Q, XIAO Y, et al. Analysis of the effect of a venting structure on slow cookoff of Comp-B based on a universal cookoff model [J]. Explosion and Shock Waves, 2022, 42(4): 042301. DOI: 10.11883/bzycj-2021-0253.

|

| [19] |

王平, 崔建忠. 金属塑性成形力学 [M]. 北京: 冶金工业出版社, 2006.WANG P, CUI J Z. Mechanics of metal plastic forming [M]. Beijing: Metallurgical Industry Press, 2006.

|

| [20] |

郝鹏程, 冯其京, 洪滔, 等. 钝感炸药点火增长模型的欧拉数值模拟 [J]. 爆炸与冲击, 2012, 32(3): 243–250. DOI: 10.3969/j.issn.1001-1455.2012.03.004.HAO P C, FENG Q J, HONG T, et al. Eulerian simulation on insensitive explosives with the ignition-growth reactive model [J]. Explosion and Shock Waves, 2012, 32(3): 243–250. DOI: 10.3969/j.issn.1001-1455.2012.03.004.

|

| [21] |

孙承纬. 应用爆轰物理 [M]. 北京: 国防工业出版社, 2000.SUN C W. Applied detonation physics [M]. Beijing: National Defense Industry Press, 2000.

|

| [22] |

WEN H N, TANG X F, JIN J S, et al. Effect of extrusion ratios on microstructure evolution and strengthening mechanisms of a novel P/M nickel-based superalloy [J]. Materials Science and Engineering: A, 2022, 847: 143356. DOI: 10.1016/j.msea.2022.143356.

|

| [23] |

NEWHALL K A, DURIAN D J. Projectile-shape dependence of impact craters in loose granular media [J]. Physical Review E, 2003, 68(6): 060301. DOI: 10.1103/PhysRevE.68.060301.

|

| [24] |

EGAWA K, KATSURAGI H. Bouncing of a projectile impacting a dense potato-starch suspension layer [J]. Physics of Fluids, 2019, 31(5): 053304. DOI: 10.1063/1.5095678.

|

| [25] |

DINOVITZER H A, LARONCHE A, ALBERT J. Fiber Bragg grating high impact force sensors with adjustable sensitivity and dynamic range [J]. IEEE Sensors Journal, 2019, 19(14): 5670–5679. DOI: 10.1109/JSEN.2019.2907867.

|

下载:

下载: