Rapid assessment of local damage in reinforced concrete T-beam bridge decks under blast loading

-

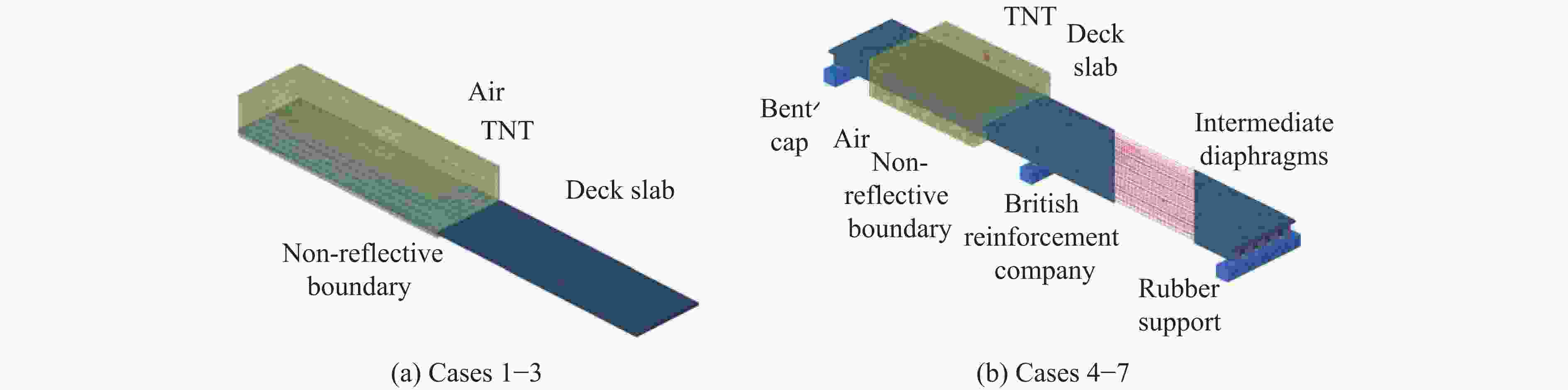

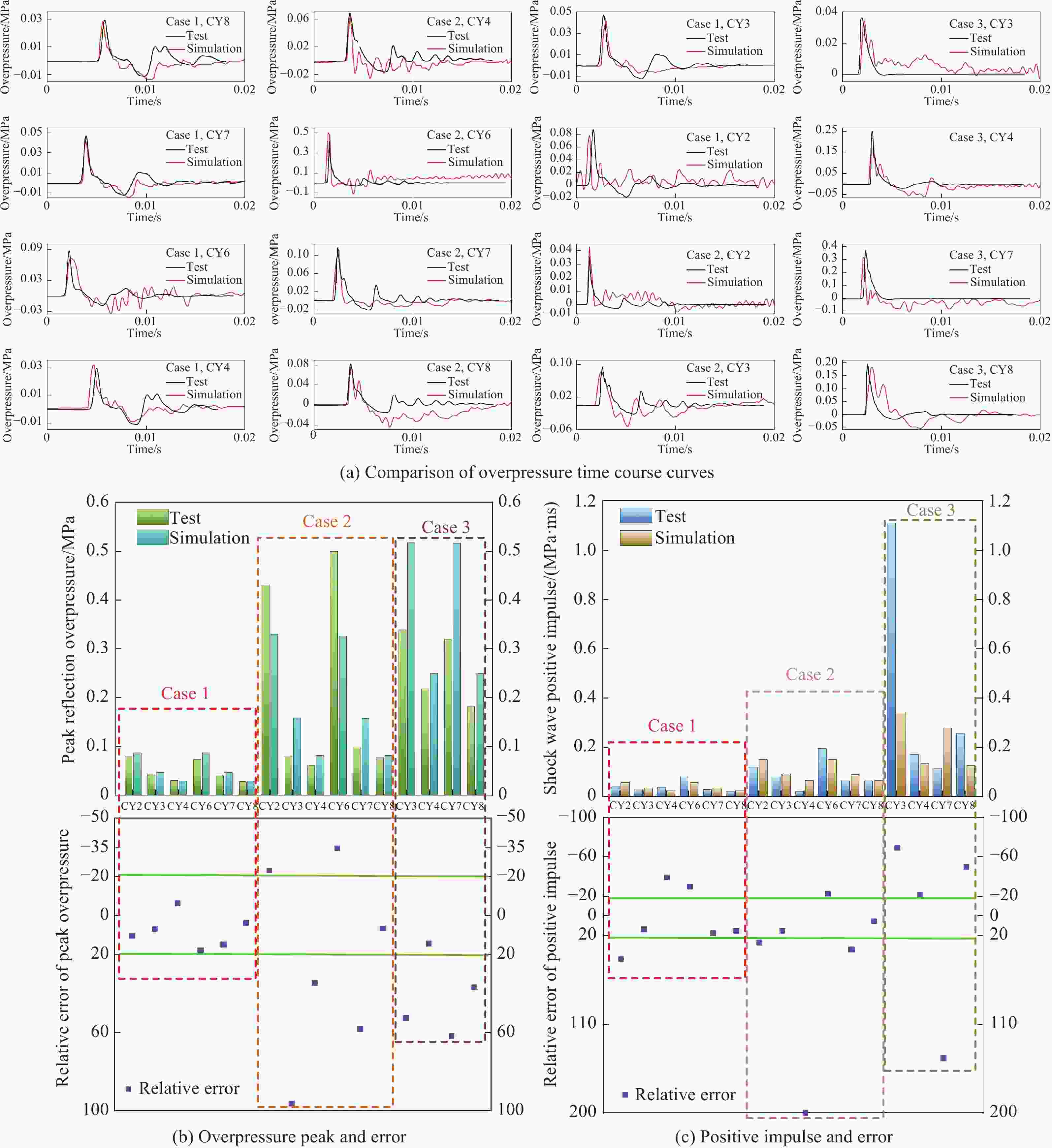

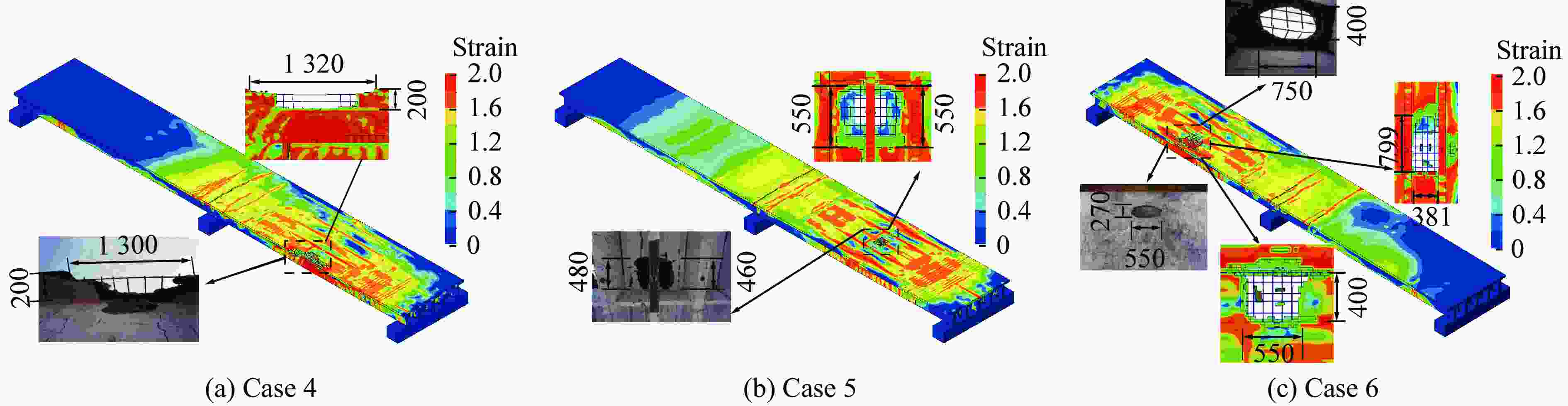

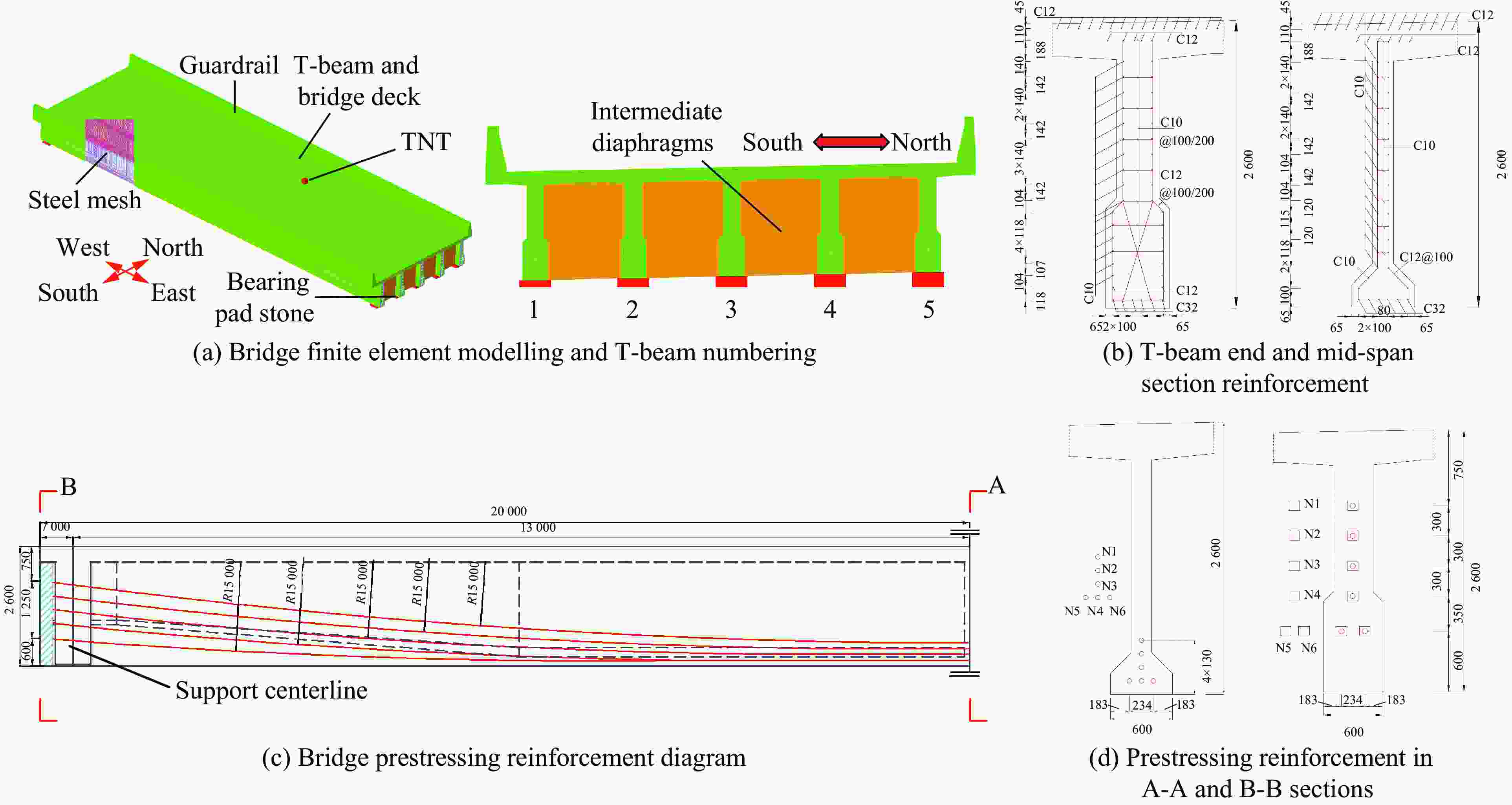

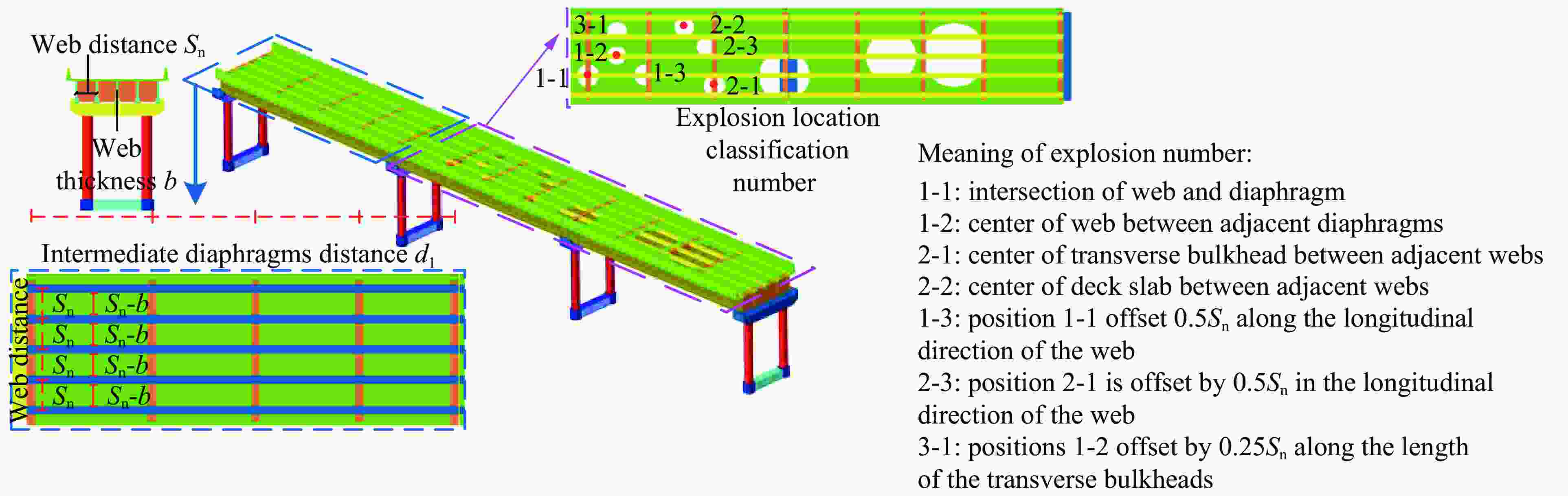

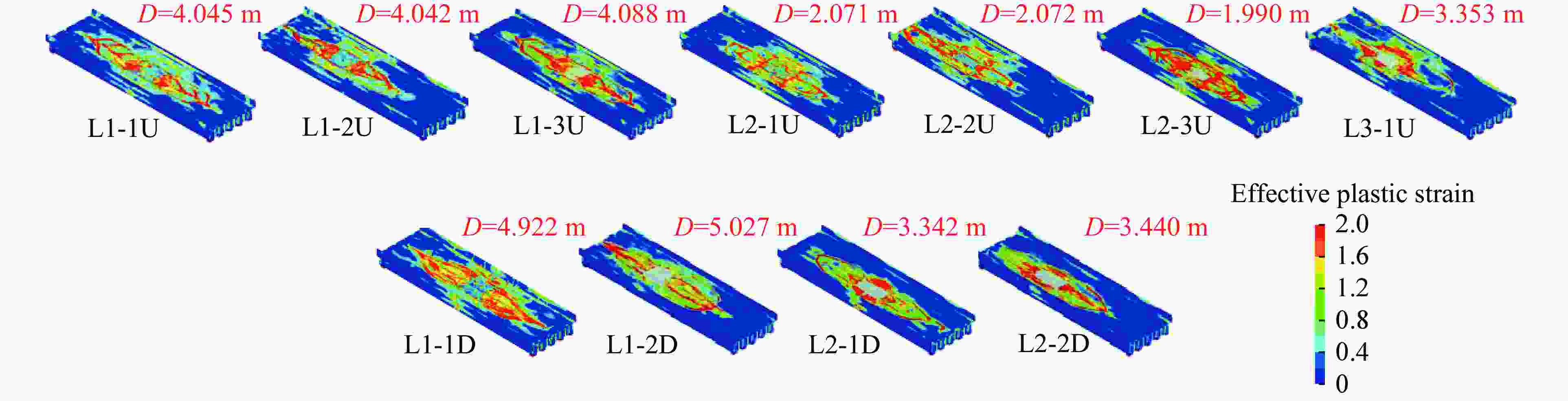

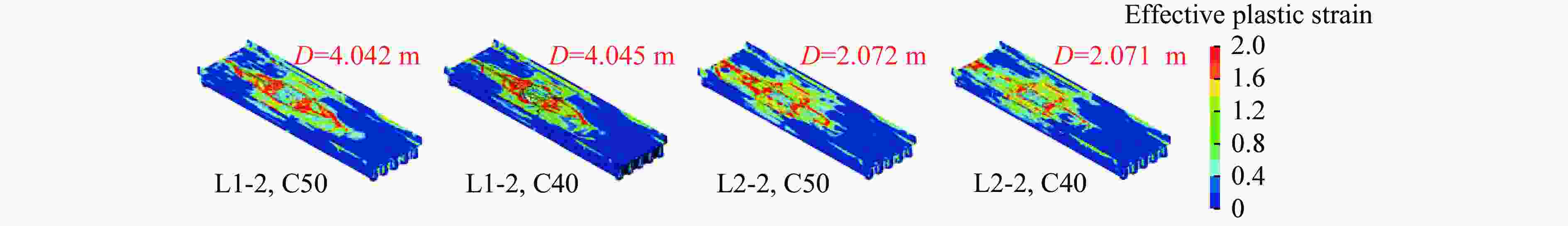

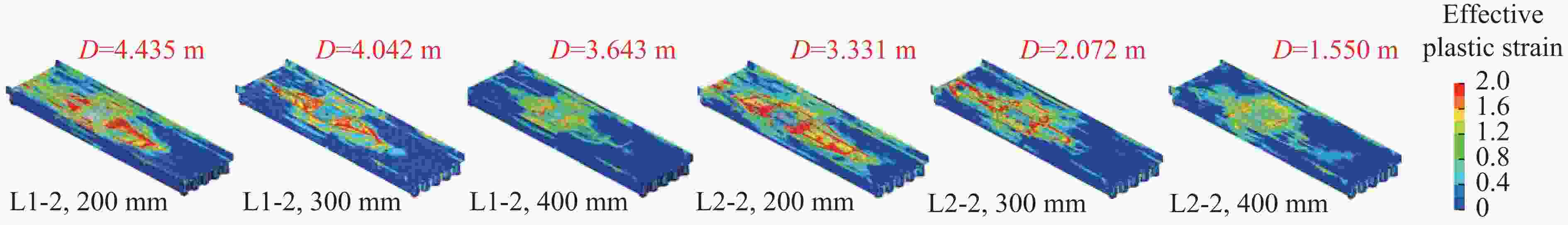

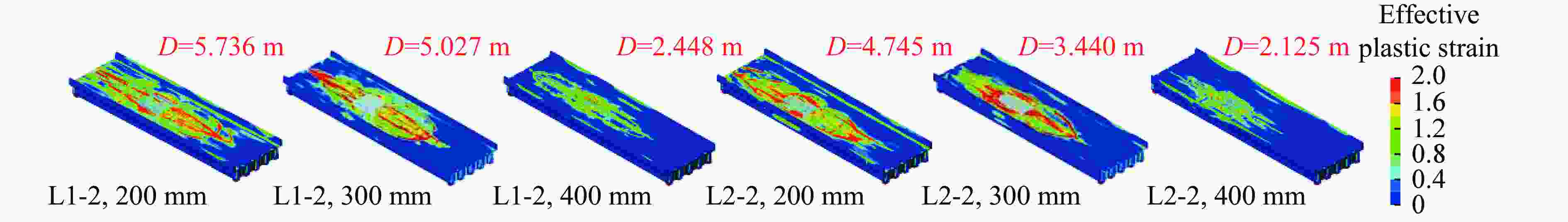

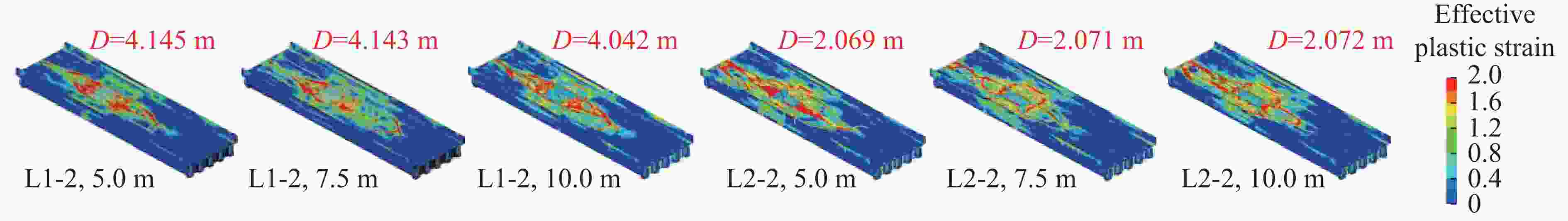

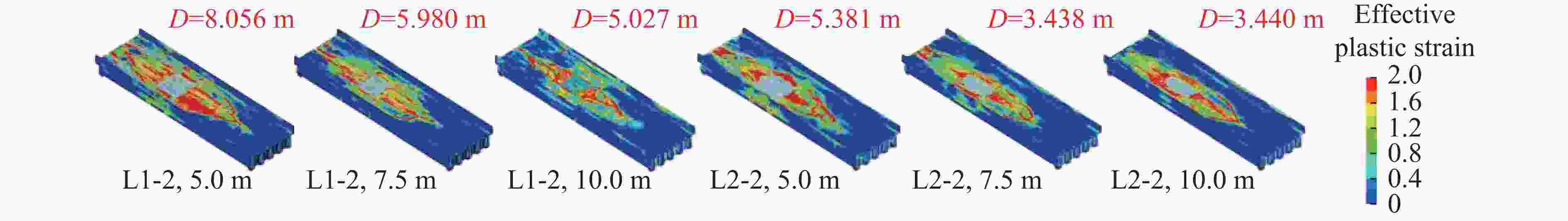

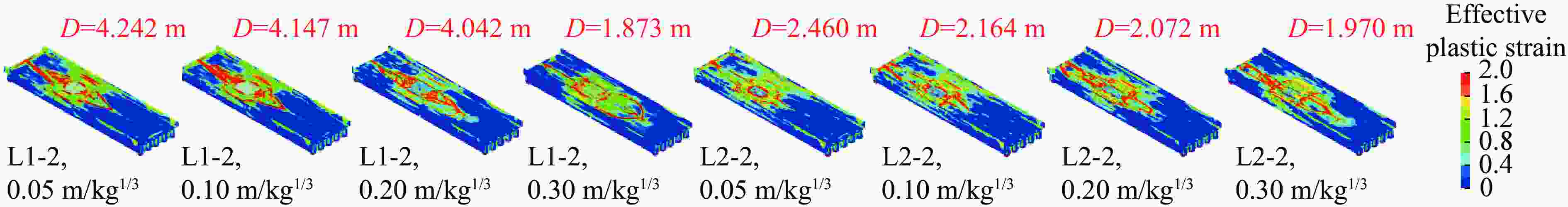

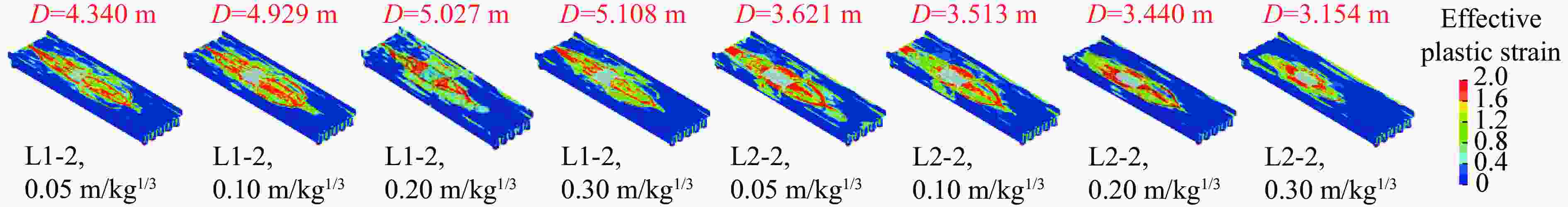

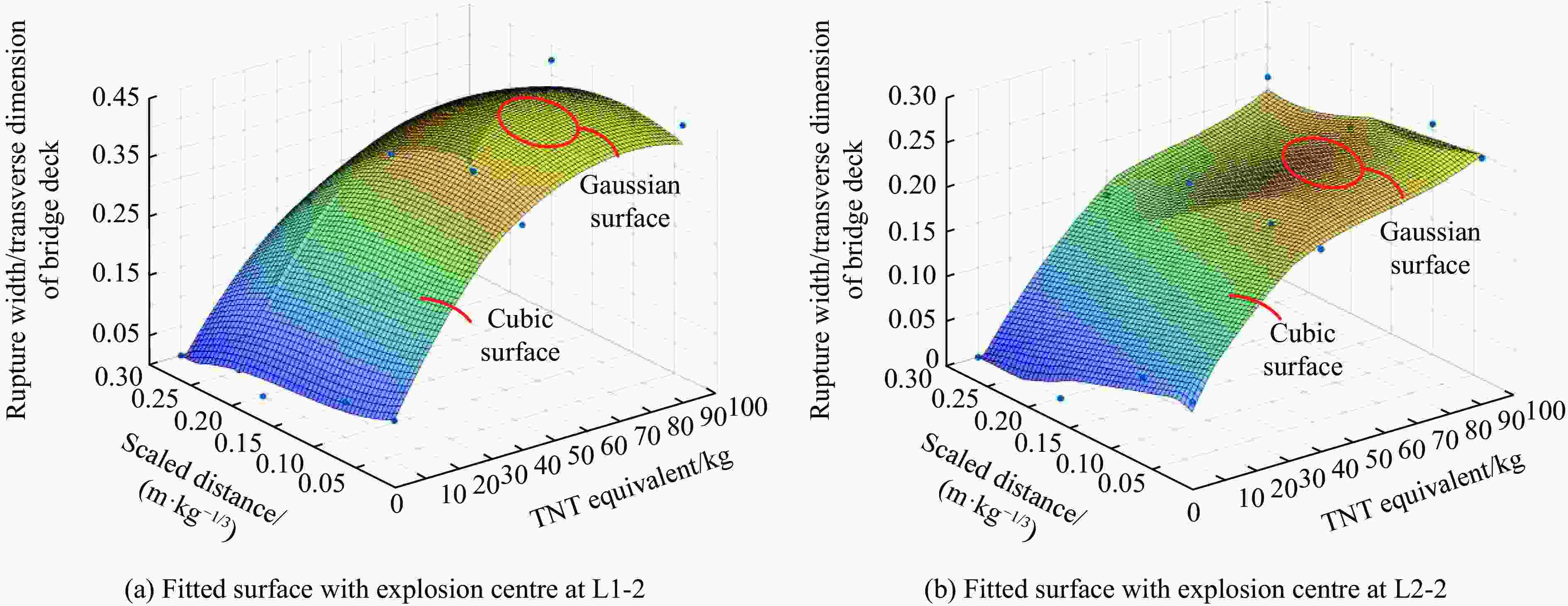

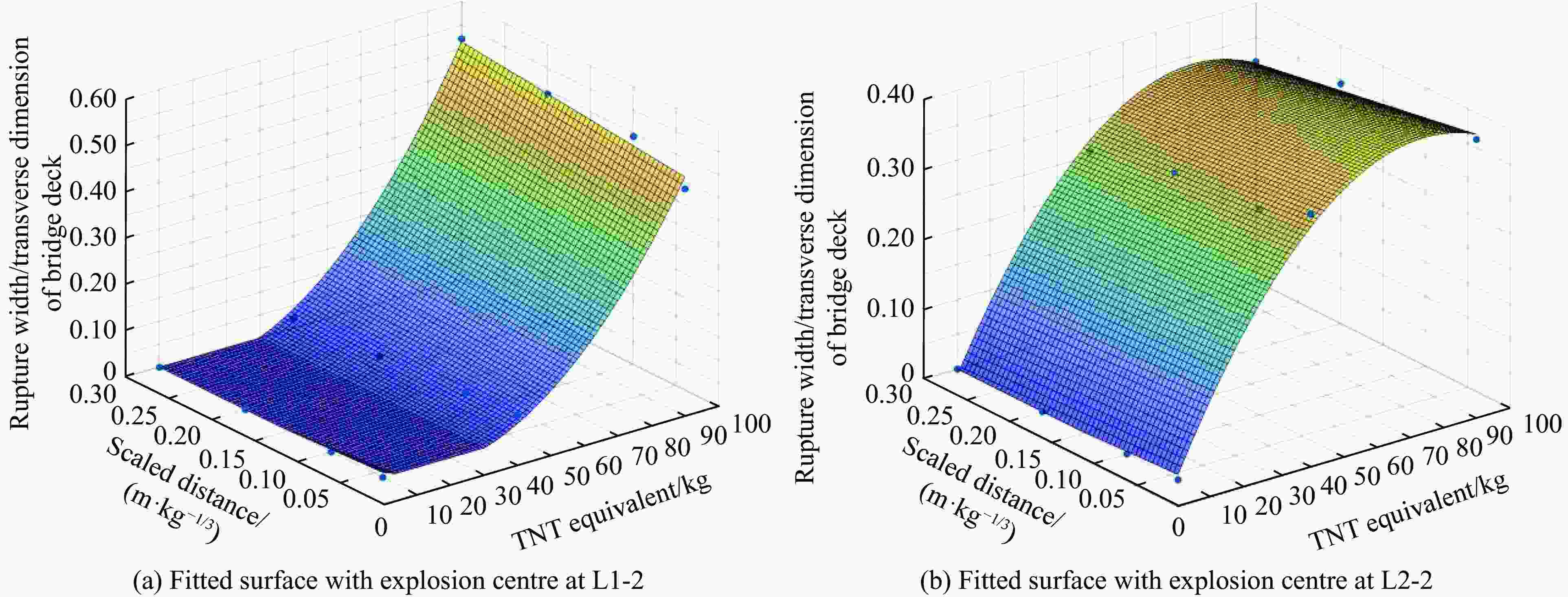

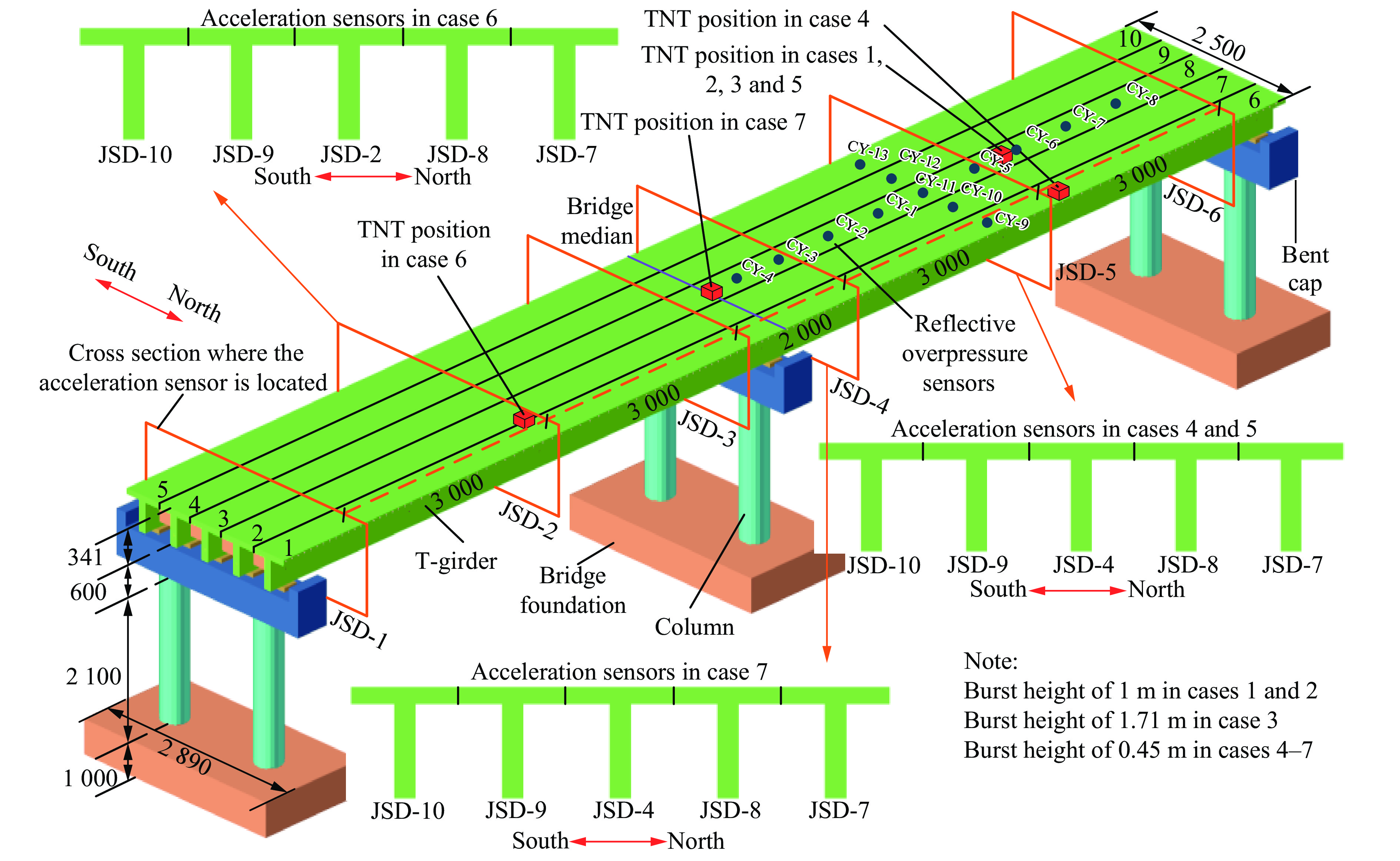

摘要: 以预应力钢筋混凝土(reinforced concrete, RC) T型梁桥桥面板经爆炸荷载作用后的破口尺寸为损伤指标,结合数值模拟与多元非线性回归分析,开展桥面损伤快速评估研究。结果表明:通过比较爆炸作用下桥面板破口的横向尺寸,发现混凝土强度的影响相对较小,而爆炸位置、桥面厚度、横隔板间距、TNT当量及比例爆距等参数的影响较显著;由于腹板和横隔板对桥面板具有较强的增强和约束作用,在其他条件相同的情况下,腹板与横隔板之间的桥面板上方爆炸产生的破口横向尺寸显著小于腹板正上方爆炸,且桥上爆炸的损伤程度显著小于桥下爆炸。基于上述影响较大的参数,提出以破口横向尺寸为损伤指标构建预测桥梁炸后通行能力的爆炸快速损伤评估公式。Abstract: Prestressed reinforced concrete (RC) T-beam bridges are commonly employed in highway bridges construction. After explosive attacks, the deck damage mostly exists in the form of breaches and affects its traffic capacity. While significant attention has been devoted to evaluating post-blast residual capacity of RC beam bridge piers and girders in existing blast damage assessment studies, there remains a critical gap in methodologies enabling intuitive and rapid damage assessment method for bridge serviceability. Therefore, the rapid assessment of bridge deck damage is investigated in this study by combining numerical simulation with multivariate nonlinear regression analysis, in which the breach size of the prestressed RC T-beam bridge deck subjected to explosive loading is taken as the damage index. Through comparative analysis of the transverse size of the deck breach under blast loading, it was revealed that concrete strength exhibits relatively minor influence, whereas parameters including explosion location, deck thickness, diaphragm spacing, TNT equivalent, and scaled distance demonstrate more pronounced effects. Owing to the pronounced reinforcing and constraining effects of webs and diaphragms on the bridge deck, comparative analyses under identical conditions demonstrate that transverse size of the breach caused by explosion above deck areas between webs and diaphragms is significantly smaller than that by explosion directly above the web, while on-bridge explosion exhibit lower damage compared to under-bridge explosion. Based upon the aforementioned parameters with significant influence, utilizing transverse size of the breach as the damage index, a rapid blast damage assessment formula is proposed for predicting the post-blast traffic capacity of bridges.

-

Key words:

- prestressed RC beam bridge /

- blast loading /

- LS-DYNA /

- bridge deck breach /

- rapid damage assessment

-

表 1 混凝土材料模型参数

Table 1. Parameters of concrete material model

密度/(kg·m−3) 圆柱体单轴抗压强度/MPa 最大失效主应变 2 400 45 0.01 表 2 钢筋和预应力筋材料模型参数

Table 2. Parameters of material model for reinforcing steel material and prestressing steel reinforcement

材料 密度/(kg·m−3) C/s−1 P 泊松比 屈服应力/MPa 弹性模量/GPa 失效应变 钢筋 7 800 40 5 0.3 300/465/420 206 0.15 预应力筋 7 800 40 5 0.3 1 860 199 0.05 表 3 橡胶支座材料模型参数

Table 3. Parameters of material model for rubber bearing

密度/(kg·m−3) 体积模量/GPa 短时剪切模量/MPa 长时剪切模量/MPa 2 300 182 18.35 17.32 表 4 TNT材料模型参数

Table 4. TNT material parameters

密度/(kg·m−3) 爆速/(m·s−1) C-J压力/GPa A/GPa B/GPa R1 R2 ω E/(J·m−3) 1 630 6 930 21 373.8 3.747 4.15 0.9 0.35 6×109 表 5 空气材料模型参数

Table 5. Air material parameters

密度/(kg·m−3) 动态黏性系数 截断压力 初始能量/(J·m−3) C0 C1 C2 C3 C4 C5 C6 1.29 0 0 2.5×105 0 0 0 0 0.4 0.4 0 表 6 T型梁构件尺寸

Table 6. T-beam member dimensions

桥梁跨度

l0/mT型梁

数量T型梁高度

h/m腹板宽度

b/m腹板间净距

sn/mT型梁宽度

$b_{\rm{f}}' $/m40 5 2.5 0.25 2 2.25 表 7 参数影响分析爆炸工况

Table 7. Explosion cases for parameter influence analysis

爆炸位置 混凝土

强度T型梁翼缘

厚度/mm横隔板

间距/mTNT当量/

kg比例爆距/

(m·kg−1/3)L1-2U/L2-2U C50 300 10.0 100 0.20 C40 300 10.0 0.20 C50 200 10.0 0.20 C50 400 10.0 0.20 C50 300 5.0 0.20 C50 300 7.5 0.20 C50 300 10.0 0.05 C50 300 10.0 0.10 C50 300 10.0 0.30 L1-2D/L2-2D C50 200 10.0 100 0.20 C50 400 10.0 0.20 C50 300 5.0 0.20 C50 300 7.5 0.20 C50 300 10.0 0.05 C50 300 10.0 0.10 C50 300 10.0 0.30 表 8 预测值与数值模拟结果的对比

Table 8. Comparison of predicted values and numerical simulation results

TNT当量/kg 比例爆距/(m·kg–1/3) 破口宽度/m 预测值/m 相对误差/% 50 0.20 1.973 1.681 –15 0.10 1.973 2.047 3 0.30 1.381 1.519 10 0.05 1.974 2.010 2 10 0.20 0 0.10 0.690 0.598 –13 0.30 0 0.05 0.691 0.563 –19 -

[1] Transportation Officials, Subcommittee on Bridges. AASHTO guide specifications for LRFD seismic bridge design [S]. AASHTO, 2011. [2] WILLIAMSON E B. Blast-resistant highway bridges: design and detailing guidelines [S]. Transportation Research Board, 2010. [3] WILLIAMSON E B, BAYRAK O, DAVIS C, et al. Performance of bridge columns subjected to blast loads. Ⅰ: experimental program [J]. Journal of Bridge Engineering, 2011, 16(6): 693–702. DOI: 10.1061/(ASCE)BE.1943-5592.0000220. [4] WILLIAMSON E B, BAYRAK O, DAVIS C, et al. Performance of bridge columns subjected to blast loads. Ⅱ: results and recommendations [J]. Journal of Bridge Engineering, 2011, 16(6): 703–710. DOI: 10.1061/(ASCE)BE.1943-5592.0000221. [5] 刘路. 不同防护方式下钢筋混凝土墩柱的抗爆性能试验研究 [D]. 南京: 东南大学, 2016.LIU L. Experimentalstudy of differently protective RC piers under blast loading [D]. Nanjing: Southeast University, 2016. [6] 刘路, 宗周红, 周海飞, 等. 近场爆炸作用下节段预制拼装RC桥墩的易损性评估 [J]. 中国公路学报, 2024, 37(4): 212–223. DOI: 10.19721/j.cnki.1001-7372.2024.04.017.LIU L, ZONG Z H, ZHOU H F, et al. Vulnerability assessment of precast segmental RC bridge piers under near-field explosion [J]. China Journal of Highway and Transport, 2024, 37(4): 212–223. DOI: 10.19721/j.cnki.1001-7372.2024.04.017. [7] 唐彪. 钢筋混凝土墩柱的抗爆性能试验研究 [D]. 南京: 东南大学, 2016.TANG B. Experimental investigation of reinforced concrete bridge piers under blast loading [D]. Nanjing: Southeast University, 2016. [8] XU J P, WU H, MA L L, et al. Residual axial capacity of seismically designed RC bridge pier after near-range explosion of vehicle bombs [J]. Engineering Structures, 2022, 265: 114487. DOI: 10.1016/j.engstruct.2022.114487. [9] XU J P, WANG Z G, CHENG Y H, et al. Blast resistance of ultra high performance concrete-filled steel tube (UHPC-FST) pier against vehicular bombs [J]. Thin-Walled Structures, 2023, 190: 110990. DOI: 10.1016/j.tws.2023.110990. [10] ZHANG R, LIU J, XU J, et al. Low-damage performance of blast resilient steel rocking column base with friction connection [J]. Thin-Walled Structures, 2024, 197: 111598. DOI: 10.1016/j.tws.2024.111598. [11] SHI Y C, HONG H, LI Z X. Numerical derivation of pressure-impulse diagrams for prediction of RC column damage to blast loads [J]. International Journal of Impact Engineering, 2008, 35(11): 1213–1227. DOI: 10.1016/j.ijimpeng.2007.09.001. [12] 师燕超. 爆炸荷载作用下钢筋混凝土结构的动态响应行为与损伤破坏机理 [D]. 天津: 天津大学, 2009.SHI Y C. Dynamic response and damage mechanism of reinforced concrete structures under blast loading [D]. Tianjin: Tianjin University, 2009. [13] 张想柏, 杨秀敏, 陈肇元, 等. 接触爆炸钢筋混凝土板的震塌效应 [J]. 清华大学学报(自然科学版), 2006(6): 765–768. DOI: 10.16511/j.cnki.qhdxxb.2006.06.004.ZHANG X B, YANG X M, CHEN Z Y, et al. Explosion spalling of reinforced concrete slabs with contact detonations [J]. Journal of Tsinghua University (Science and Technology), 2006(6): 765–768. DOI: 10.16511/j.cnki.qhdxxb.2006.06.004. [14] WANG W, ZHANG D, LU F Y, et al. Experimental study on scaling the explosion resistance of a one-way square reinforced concrete slab under a close-in blast loading [J]. International Journal of Impact Engineering, 2012, 49: 158–164. DOI: 10.1016/j.ijimpeng.2012.03.010. [15] 李宝岩. 爆炸荷载下预应力T梁动态响应研究 [D]. 长沙: 国防科技大学, 2021.LI B Y. Dynamic response study of prestressed T-beams under blasting loads [D]. Changsha: National University of Defense Technology, 2021. [16] 王硕. 预应力T梁梁端爆炸毁伤机理及T梁桥毁伤评估 [D]. 长沙: 国防科技大学, 2023.WANG S. Damage mechanisms of prestressed T-beam ends and damage assessments of T-beam bridges under blasting loads [D]. Changsha: National University of Defense Technology, 2023. [17] 蔡路军, 杜刚, 高琴, 等. 爆破冲击荷载下混凝土T梁桥实验 [J]. 工程爆破, 2018, 24(1): 8–12, 19. DOI: 10.3969/j.issn.1006-7051.2018.01.002.CAI L J, DU G, GAO Q, et al. Experimental of concrete T beam bridge under blasting load [J]. Engineering Blasting, 2018, 24(1): 8–12, 19. DOI: 10.3969/j.issn.1006-7051.2018.01.002. [18] YI Z, AGRAWAL A K, ETTOUNEY M, et al. Blast load effects on highway bridges. Ⅱ: failure modes and multihazard correlations [J]. Journal of Bridge Engineering, 2014, 19(4): 04013024. DOI: 10.1061/(ASCE)BE.1943-5592.0000548. [19] 王向阳, 冯英骥. 爆炸冲击作用下连续梁桥动力响应和影响因素研究 [J]. 爆破, 2017, 34(3): 104–113. DOI: 10.3963/j.issn.1001-487X.2017.03.019.WANG X Y, FENG Y J. Study of dynamic response and inf1uence factors of continuous girder bridge under blast loading [J]. Blasting, 2017, 34(3): 104–113. DOI: 10.3963/j.issn.1001-487X.2017.03.019. [20] 娄凡. 预应力混凝土连续T梁的抗爆性能试验研究 [D]. 南京: 东南大学, 2018.LOU F. Experimental study on blast resistance of prestressed concrete continuous T beams [D]. Nanjing: Southeast University, 2018. [21] 院素静. 爆炸荷载作用下混凝土梁桥倒塌破坏机理研究 [D]. 南京: 东南大学, 2019.YUAN S J. Study on collapse failure mechanism of concrete girder bridge under explosion load [D]. Nanjing: Southeast University, 2019. [22] 院素静, 宗周红, 娄凡, 等. 预应力混凝土连续梁桥桥面爆炸损伤试验研究 [J]. 中国公路学报, 2022, 35(11): 160–170. DOI: 10.19721/j.cnki.1001-7372.2022.11.015.YUAN S J, ZONG Z H, LOU F, et al. Experimental study on damage of prestressed concrete continuous girder bridge subjected to explosions above the deck [J]. China Journal of Highway and Transport, 2022, 35(11): 160–170. DOI: 10.19721/j.cnki.1001-7372.2022.11.015. [23] 院素静, 宗周红, 林津, 等. 接触爆炸下混凝土连续梁桥倒塌破坏试验研究 [J]. 中国公路学报, 2024, 37(11): 139–151. DOI: 10.19721/j.cnki.1001-7372.2024.11.011.YUAN S J, ZONG Z H, LIN J, et al. Experimental study on collapse failure of concrete continuous girder bridges under contact explosion [J]. China Journal of Highway and Transport, 2024, 37(11): 139–151. DOI: 10.19721/j.cnki.1001-7372.2024.11.011. [24] MA L L, WU H, FANG Q. Damage mode and dynamic response of RC girder bridge under explosions [J]. Engineering Structures, 2021, 243: 112676. DOI: 10.1016/j.engstruct.2021.112676. [25] MA L L, WU H, FANG Q, et al. Displacement-based blast-resistant evaluation for simply-supported RC girder bridge under below-deck explosions [J]. Engineering Structures, 2022, 266: 114637. DOI: 10.1016/j.engstruct.2022.114637. [26] 马亮亮, 吴昊. 爆炸作用下预应力RC梁桥的损伤评估 [J]. 工程力学, 2025, 42(11): 159–172. DOI: 10.6052/j.issn.1000-4750.2023.05.0378.MA L L, WU H. Damage assessment of prestressed RC girderbridge under explosion [J]. Engineering Mechanics, 2025, 42(11): 159–172. DOI: 10.6052/j.issn.1000-4750.2023.05.0378. [27] HU J H, DENG Y J, JIAO W J, et al. Dynamic response and damage assessment of a prestressed T-shaped simply supported girder bridge under contact explosion [C]//Structures. Elsevier, 2023, 48: 40–52. DOI: 10.1016/j.istruc.2022.12.077. [28] Livermore Software Technology Corporation (LSTC). LS-DYNA keyword user’s manual [M]. Livermore Software Technology Corporation, 2022. [29] Comité Euro-International du Béton. CEB-FIP model code 1990: design code [M]. Thomas Telford Publishing, 1993. [30] 民用建筑防爆设计标准: T/CECS736 2020 [S]. 2020.Standard for blast protection design of civil buildings: T/CECS736 2020 [S]. 2020. [31] 交通运输部. 2023年交通运输行业发展统计公报 [N]. 中国交通报, 2024-06-18(002). DOI: 10.28099/n.cnki.ncjtb.2024.001085. [32] 交通运输部公路局, 中交第一公路勘察设计研究院有限公司. 公路工程技术标准: JTG B01—2014 [S]. 北京: 人民交通出版社, 2014.Ministry of Transport Highway Bureau, CCCC First Highway Consultants Co. Ltd. Technical standard of highway engineering: JTG B01—2014 [S]. Beijing: China Communications Press, 2014. [33] 中交公路规划设计院有限公司. 公路钢筋混凝土及预应力混凝土桥涵设计规范: JTG 3362—2018 [S]. 北京: 人民交通出版社, 2018. [34] 姚玲森. 桥梁工程 [M]. 北京: 人民交通出版社, 2021. [35] XIAO Y, ZHU W Q, LI M H, et al. Concrete spalling behavior and damage evaluation of concrete members with different cross-sectional properties under contact explosion [J]. International Journal of Impact Engineering, 2023, 181: 104753. DOI: 10.1016/j.ijimpeng.2023.104753. [36] 中交第二公路勘察设计研究院有限公司. 公路装配式混凝土桥梁设计规范: JTG/T 3365-05—2022 [S]. 北京: 人民交通出版社, 2022. [37] Unified Facilities Criteria. Structures to resist the effects of accidental explosions available from national institute of building sciences: UFC3-340-02 [S]. Washington DC, USA: 1090 Vermont Avenue NW, Suite 700, 2008. -

下载:

下载: