Experimental study on dynamic responses of aluminum honeycomb sandwich plates subjected to water-entry impact

-

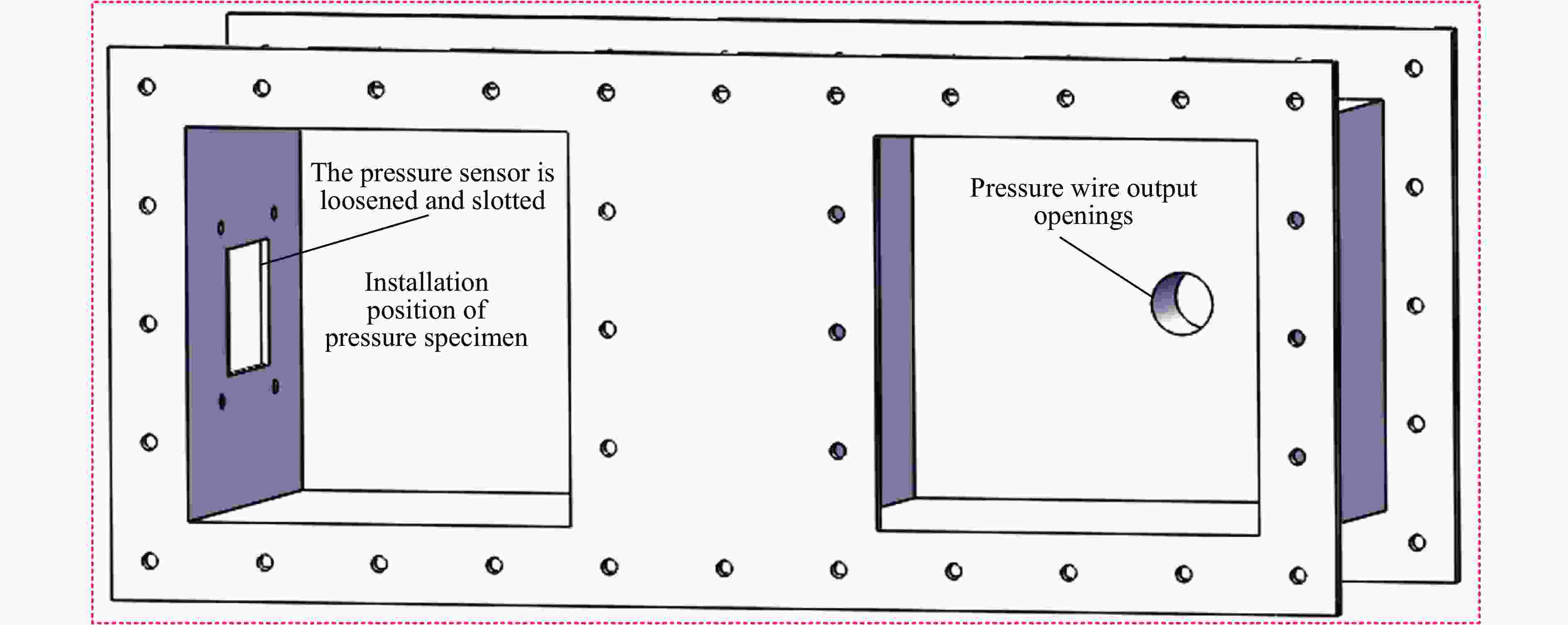

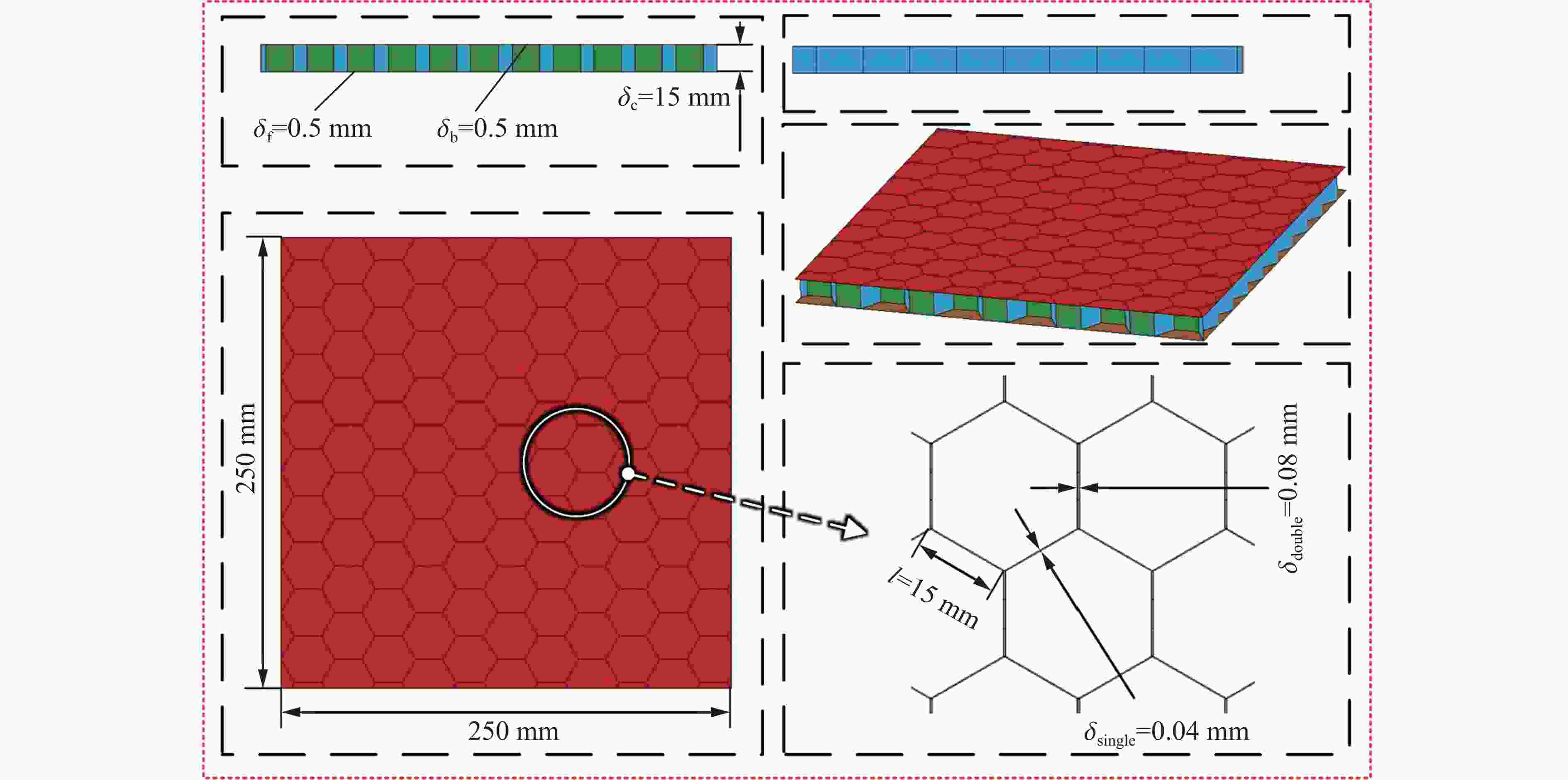

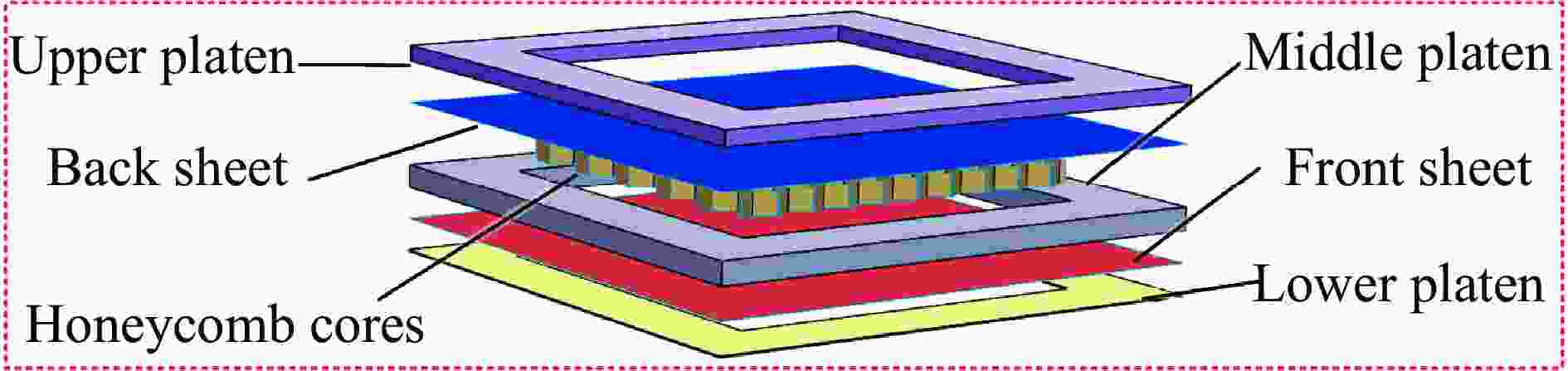

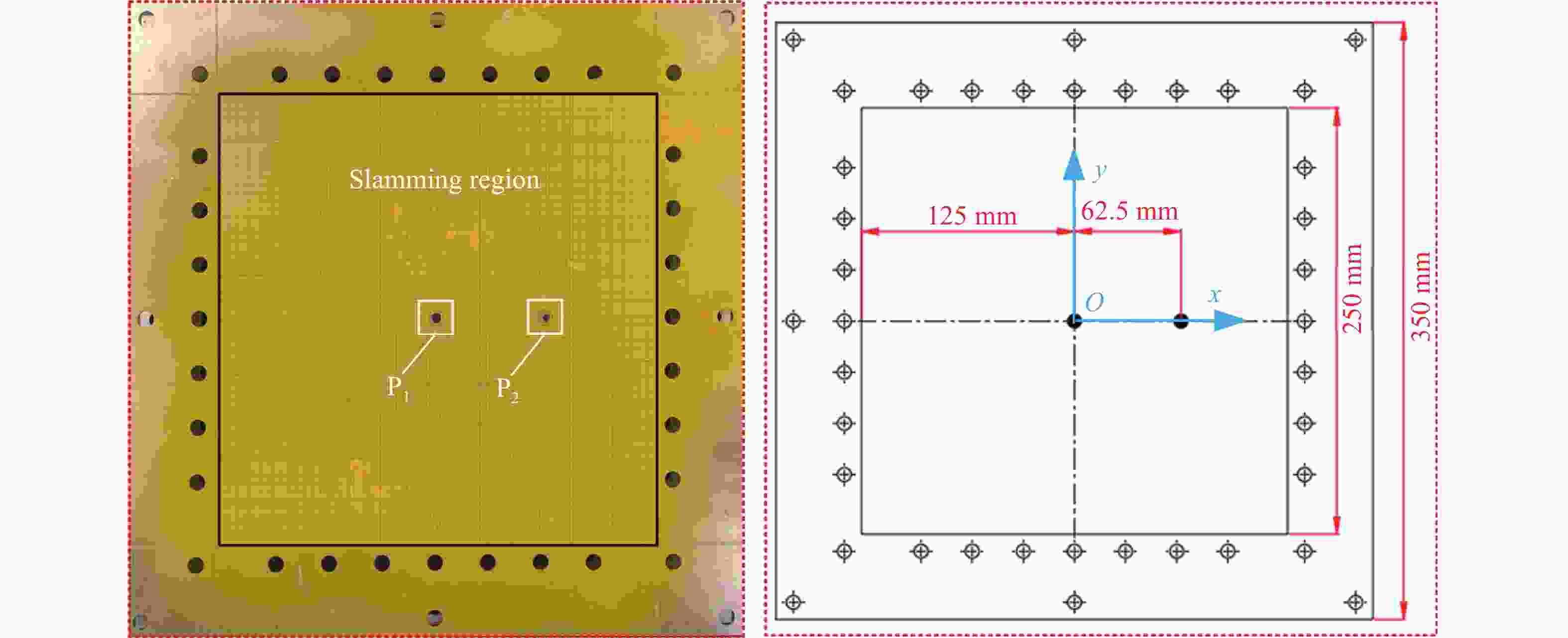

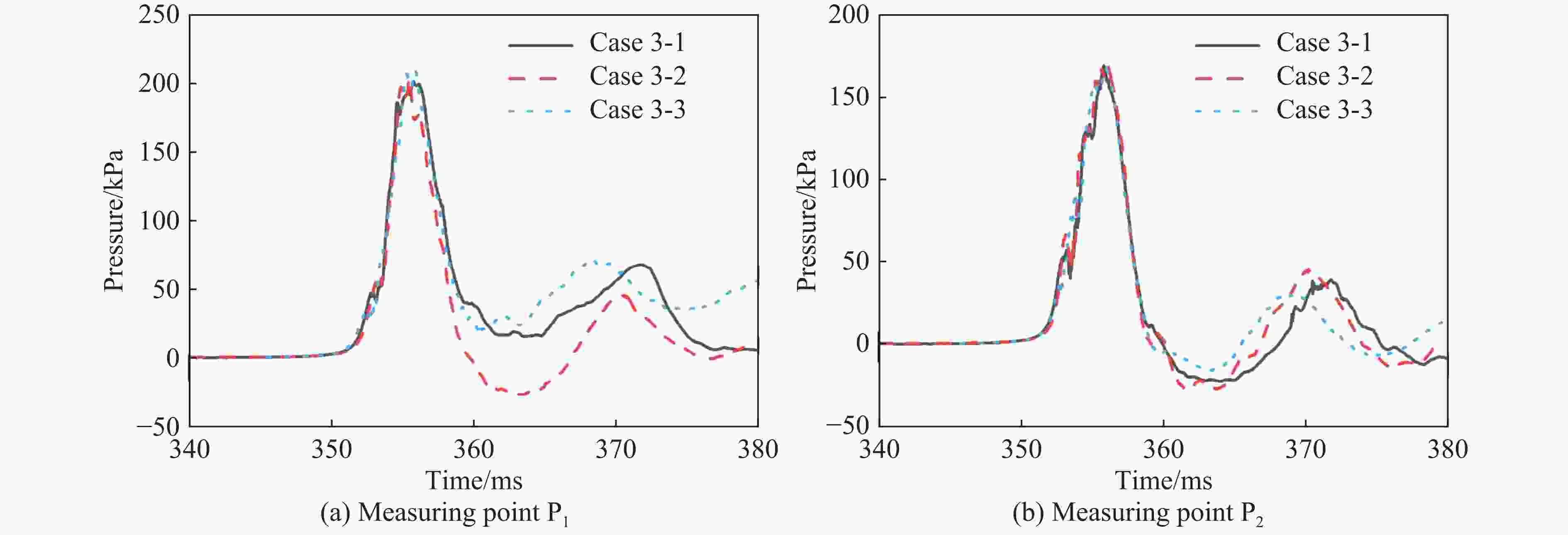

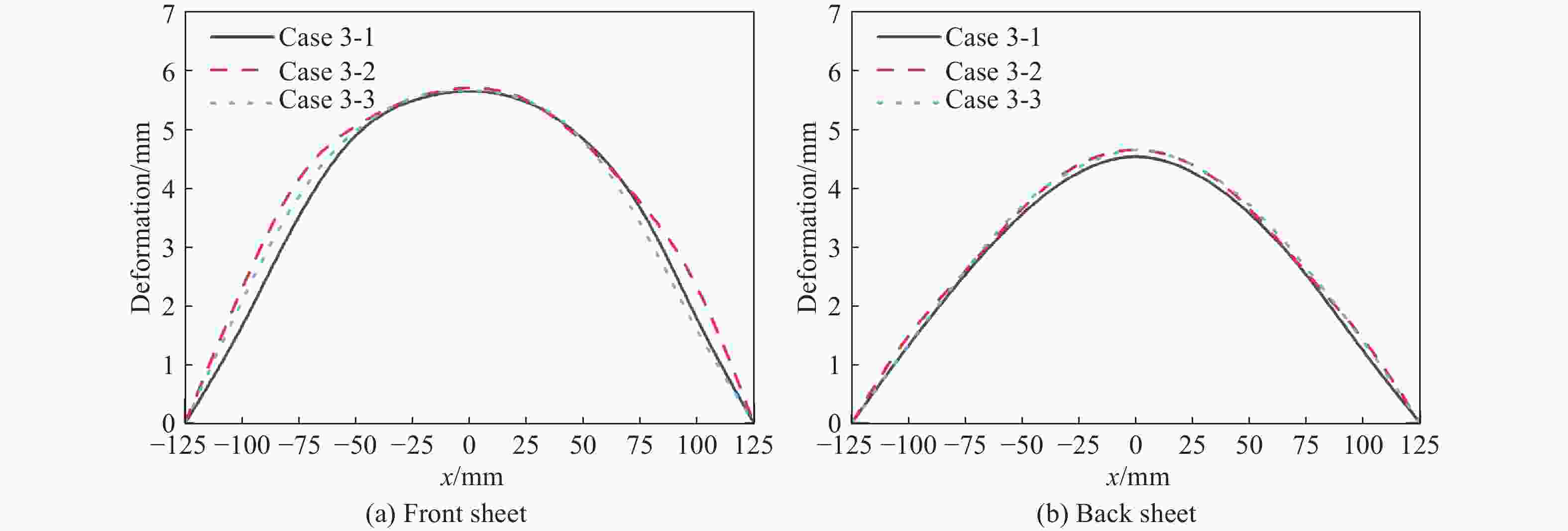

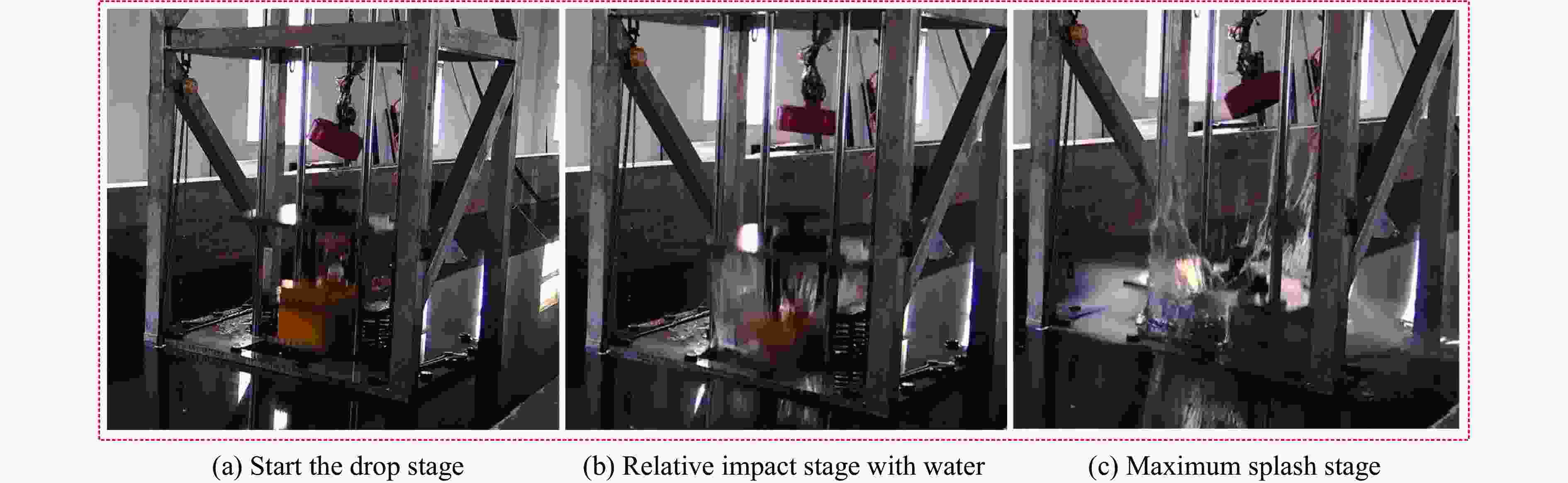

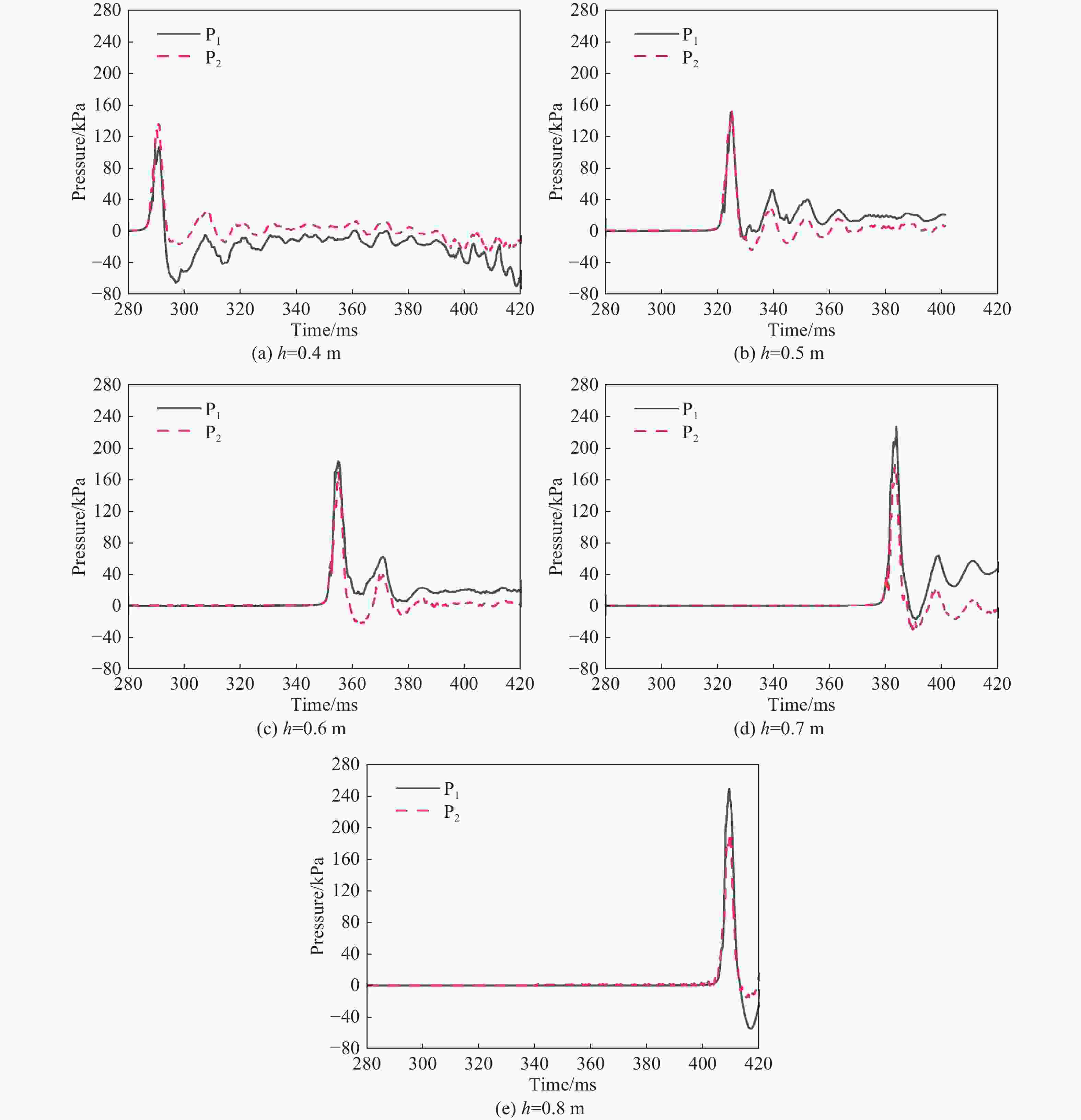

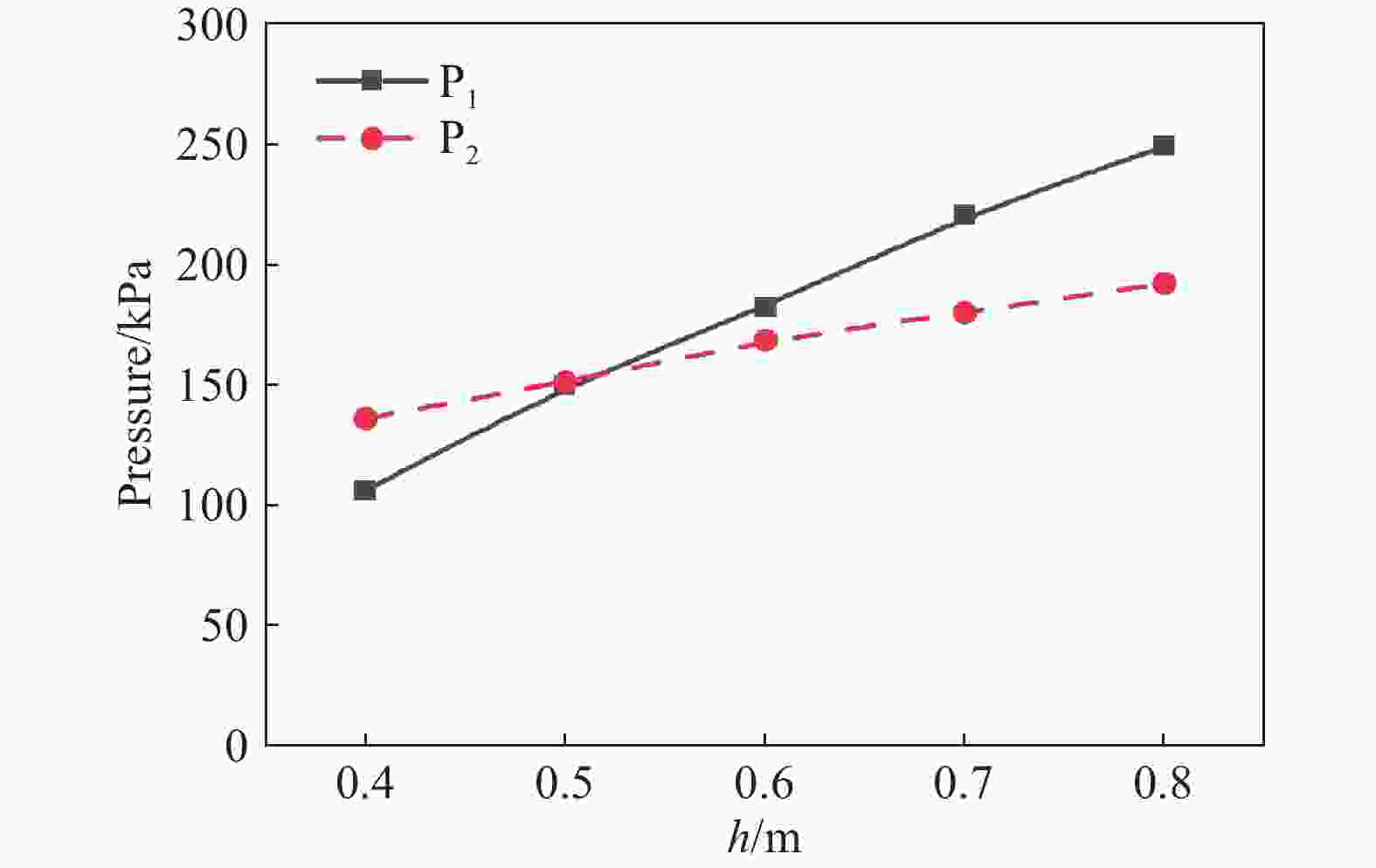

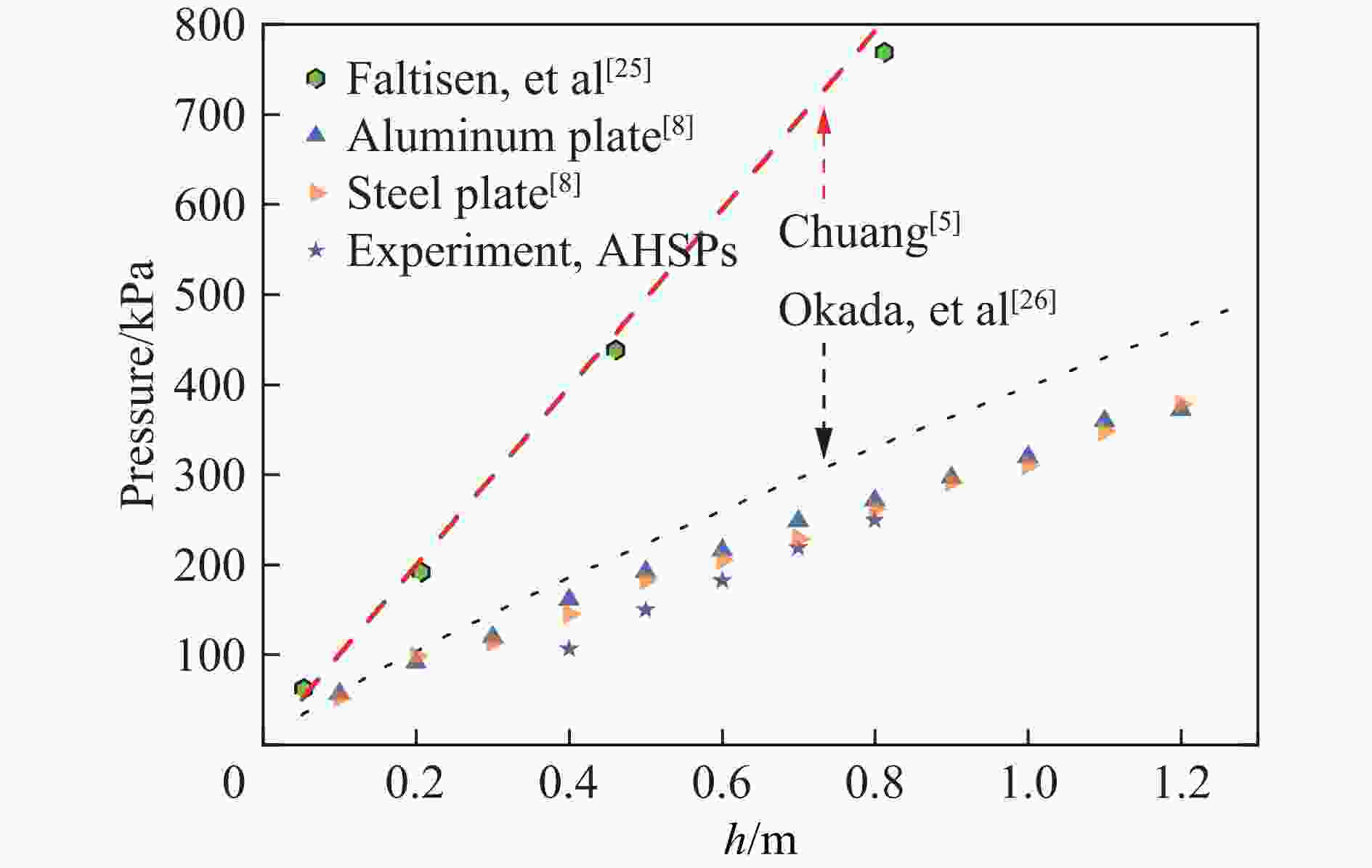

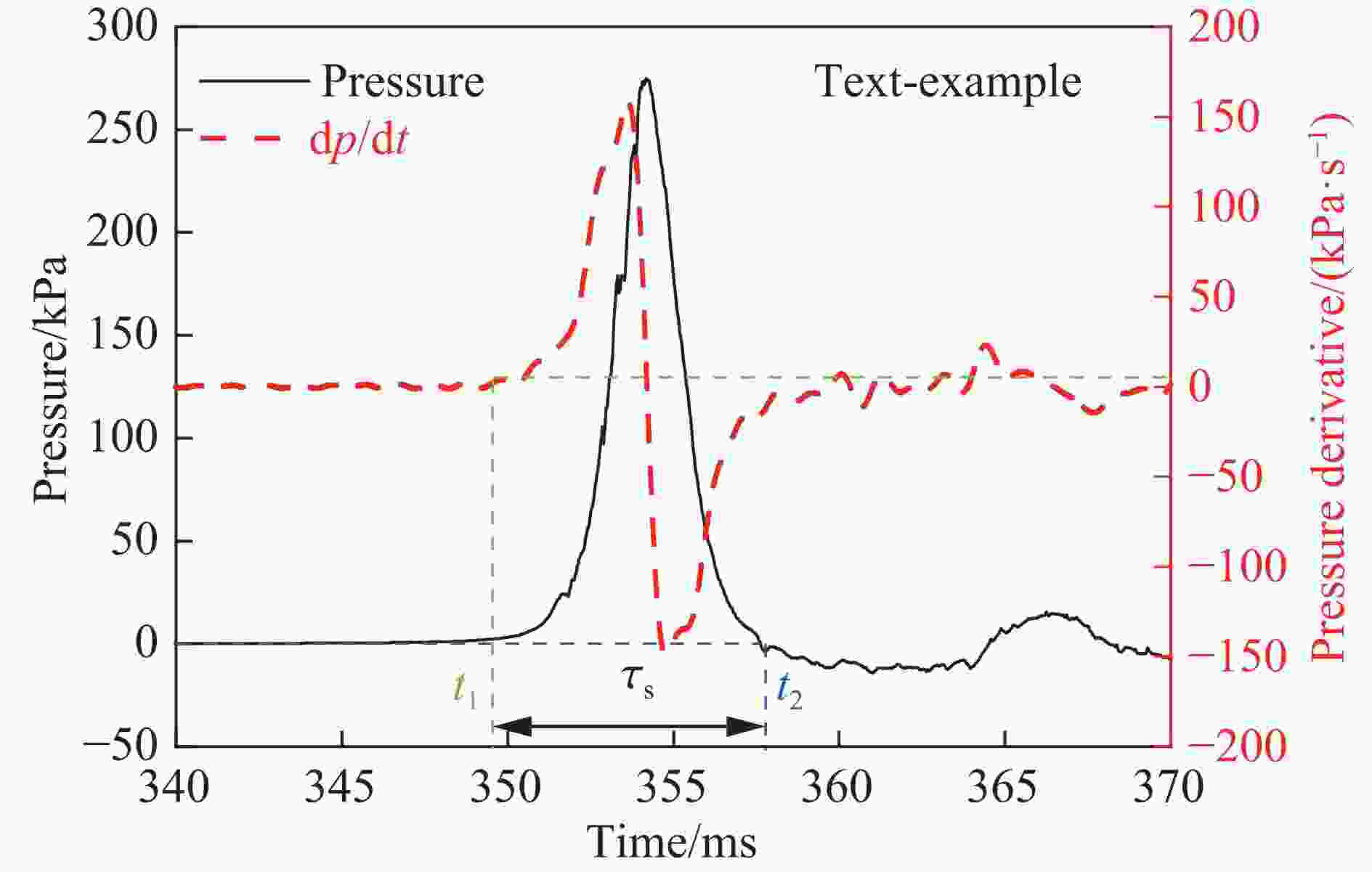

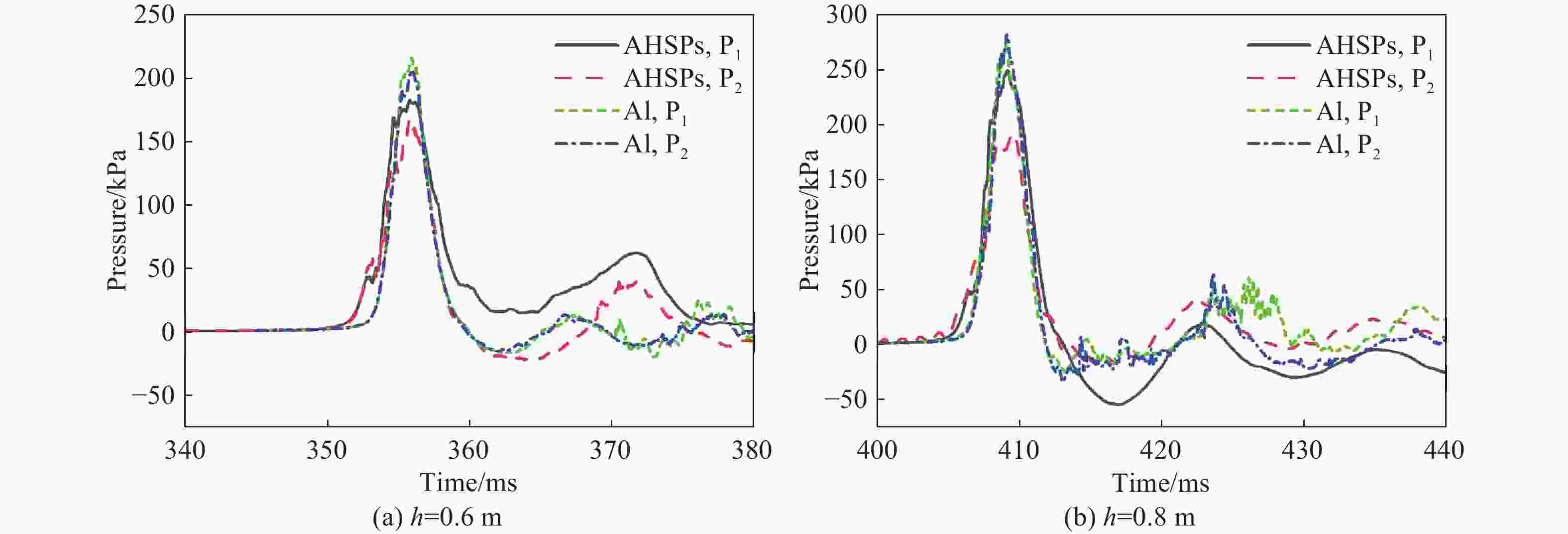

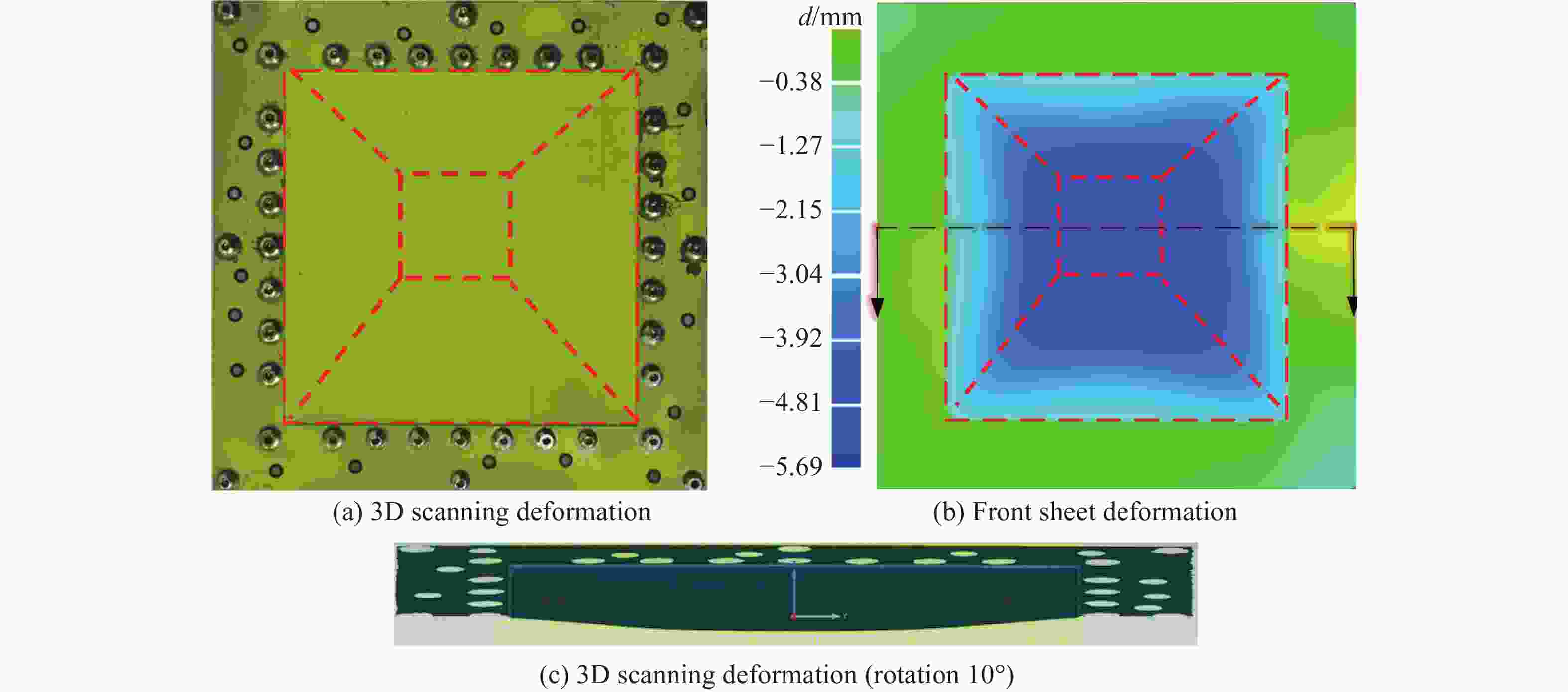

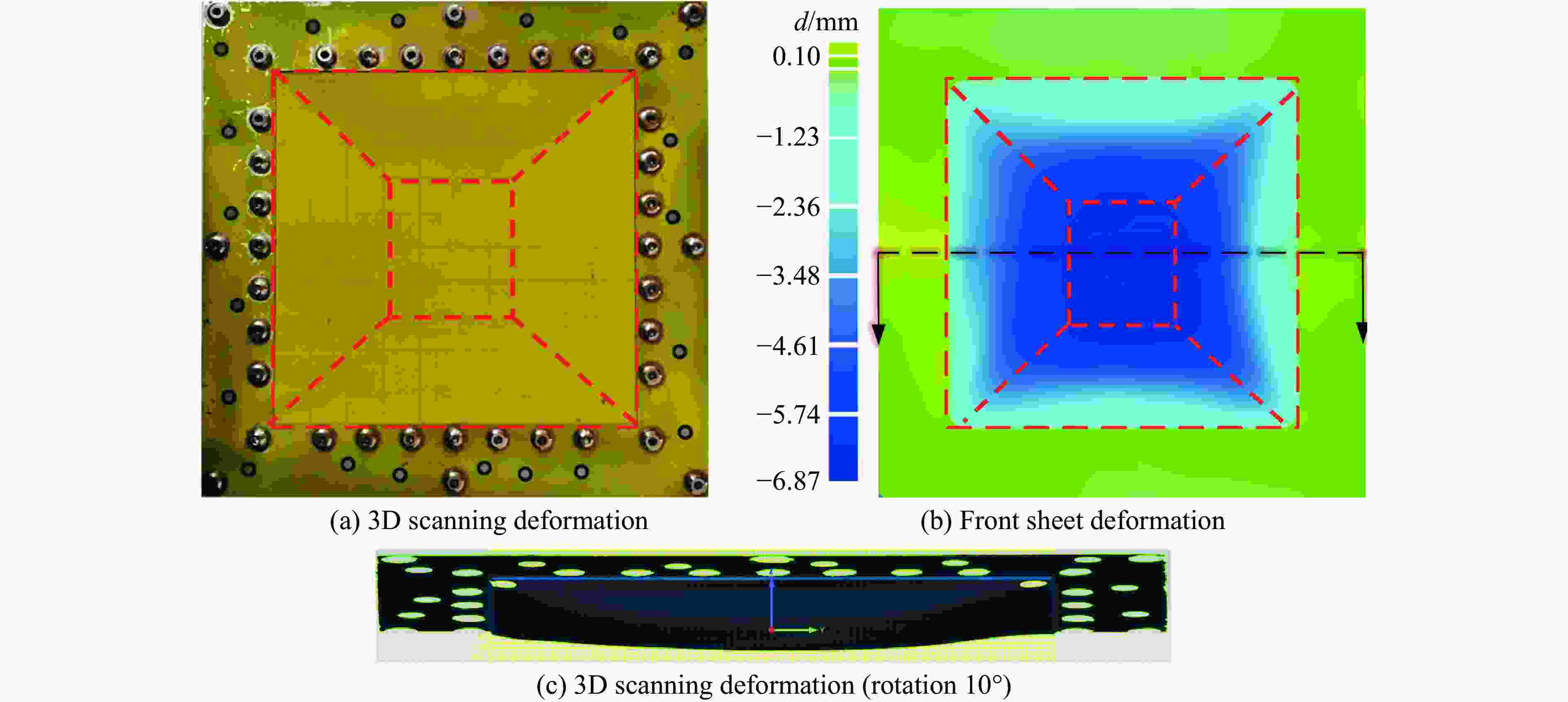

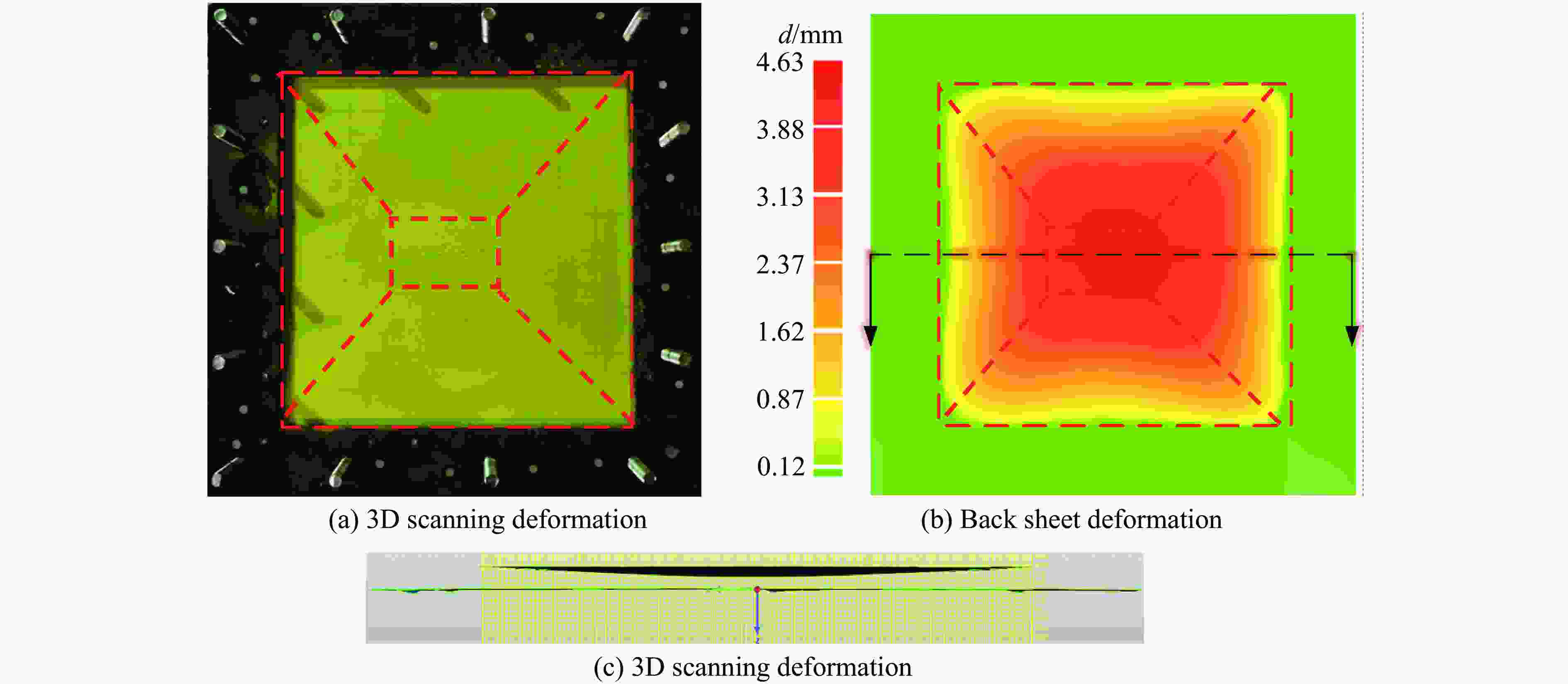

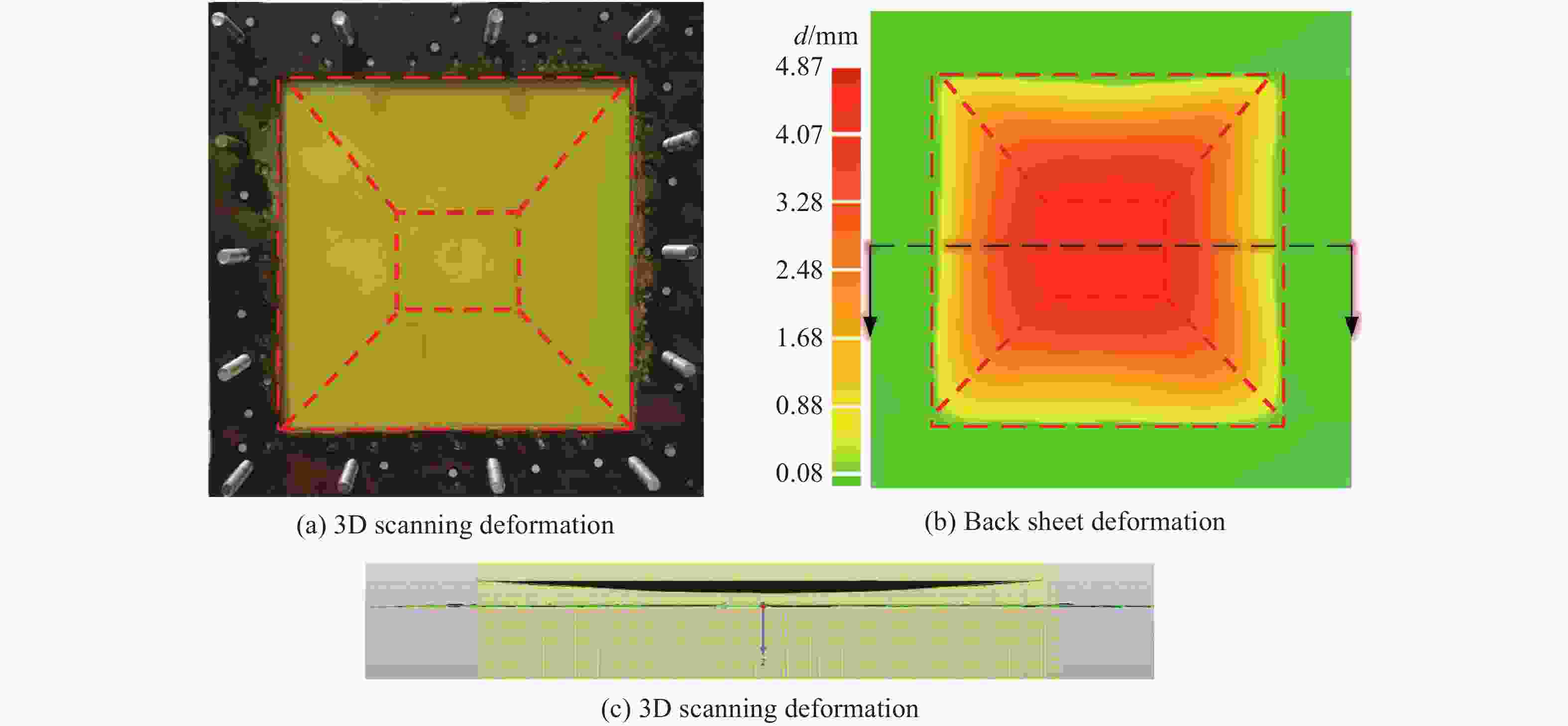

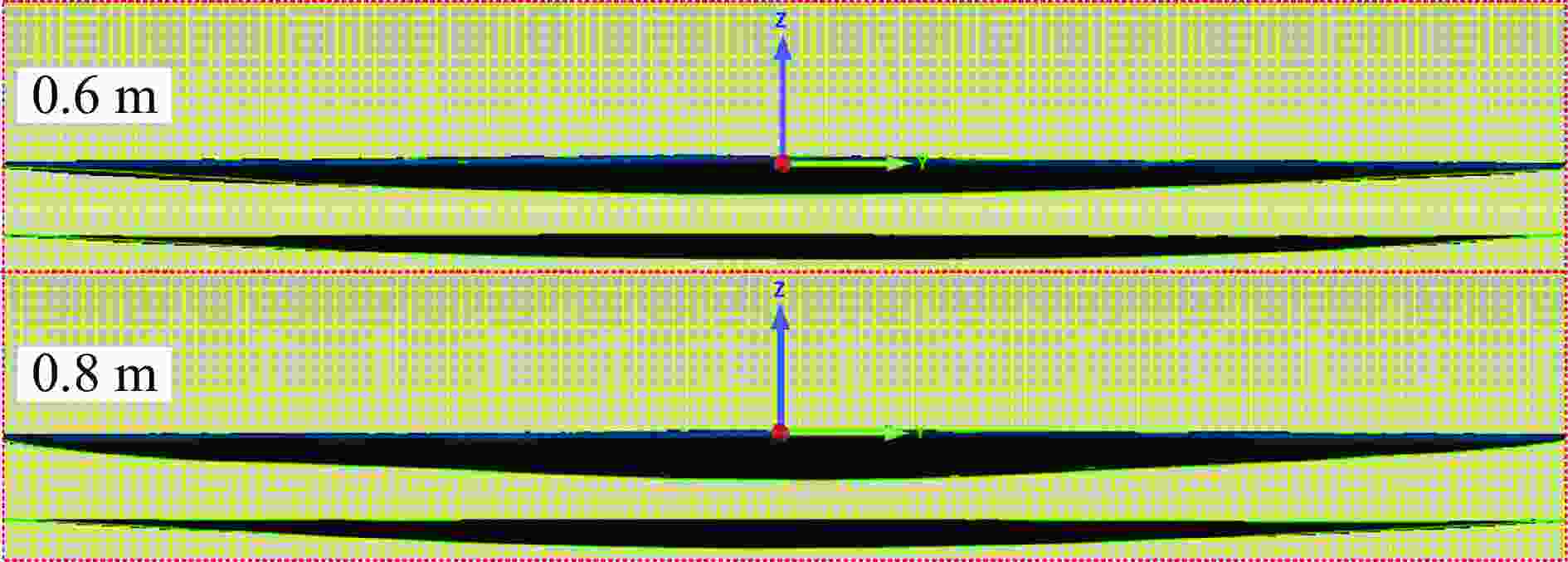

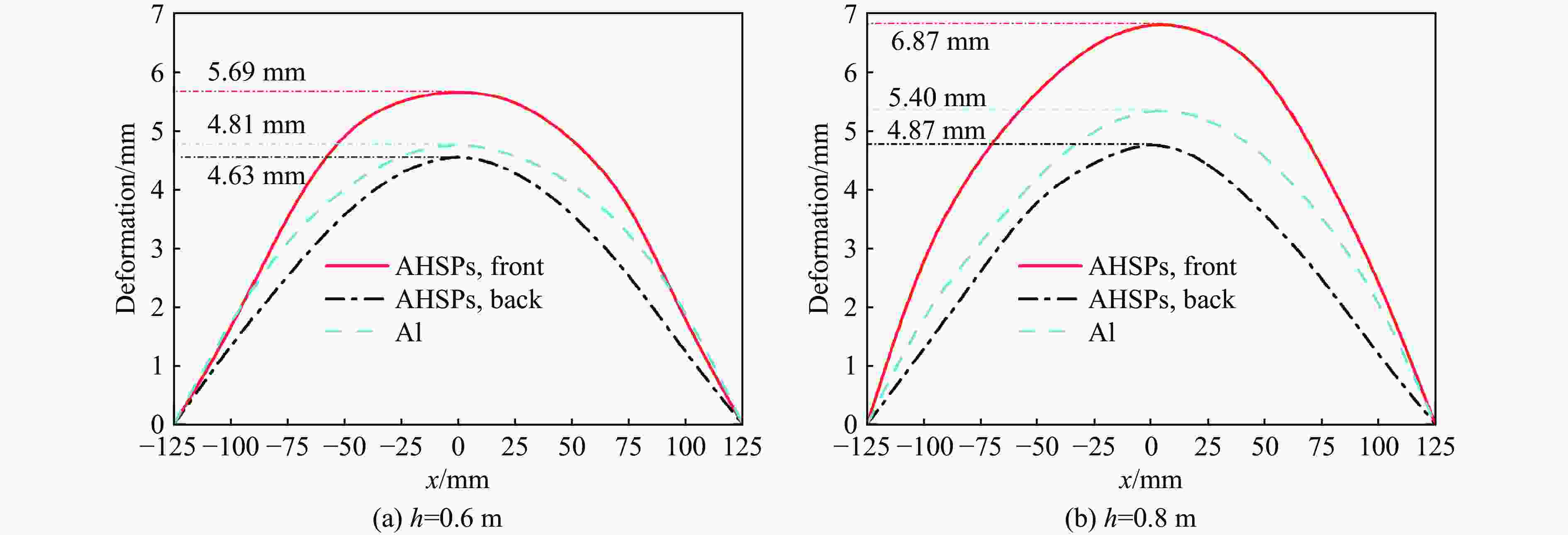

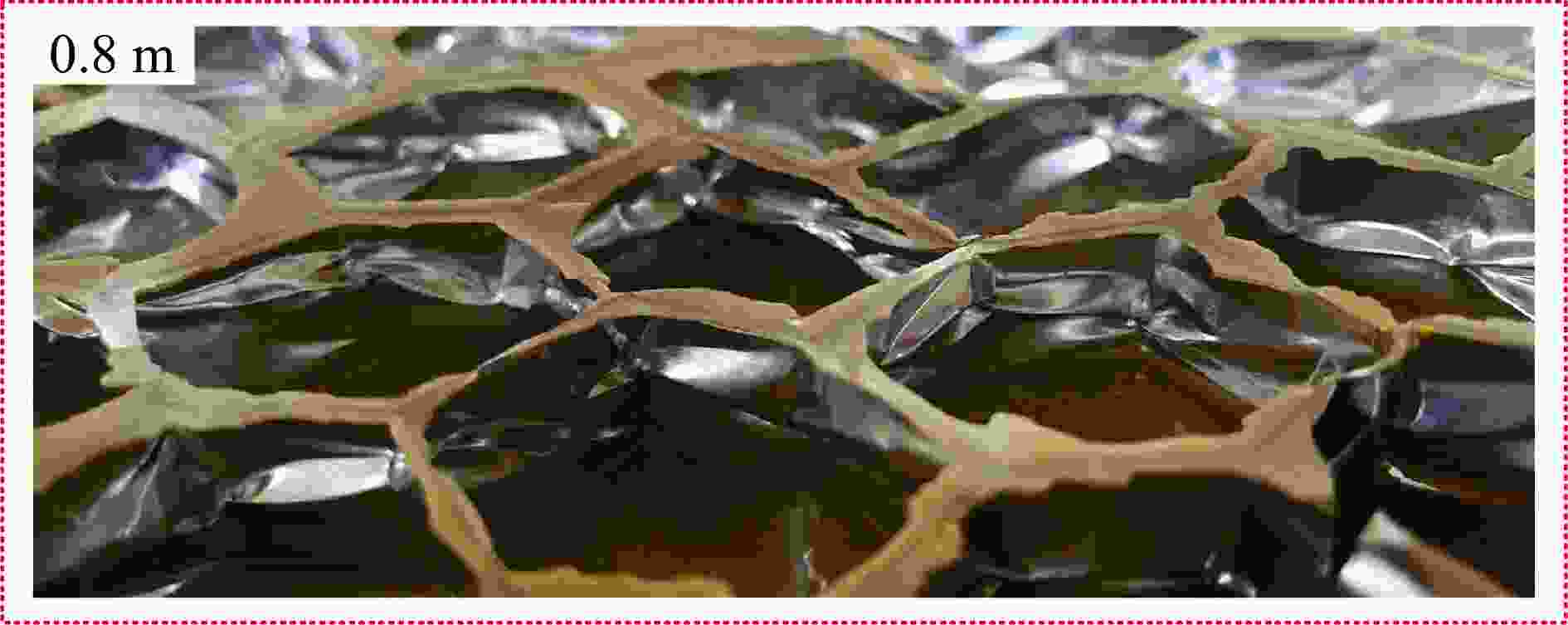

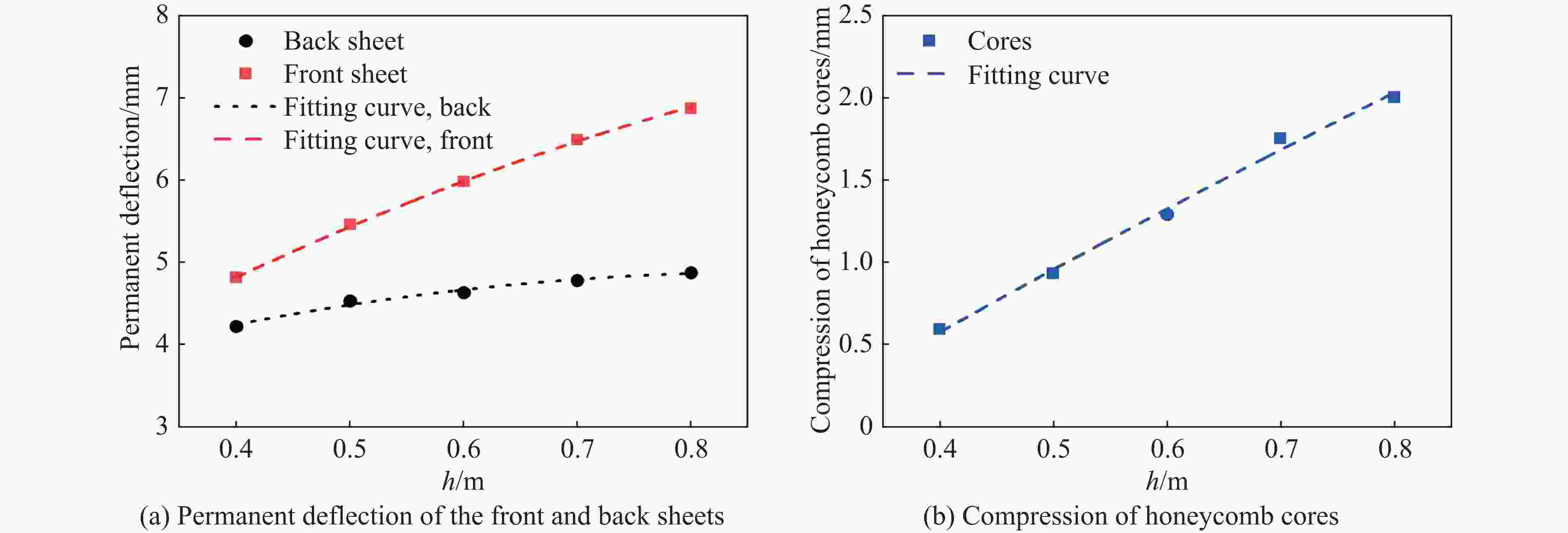

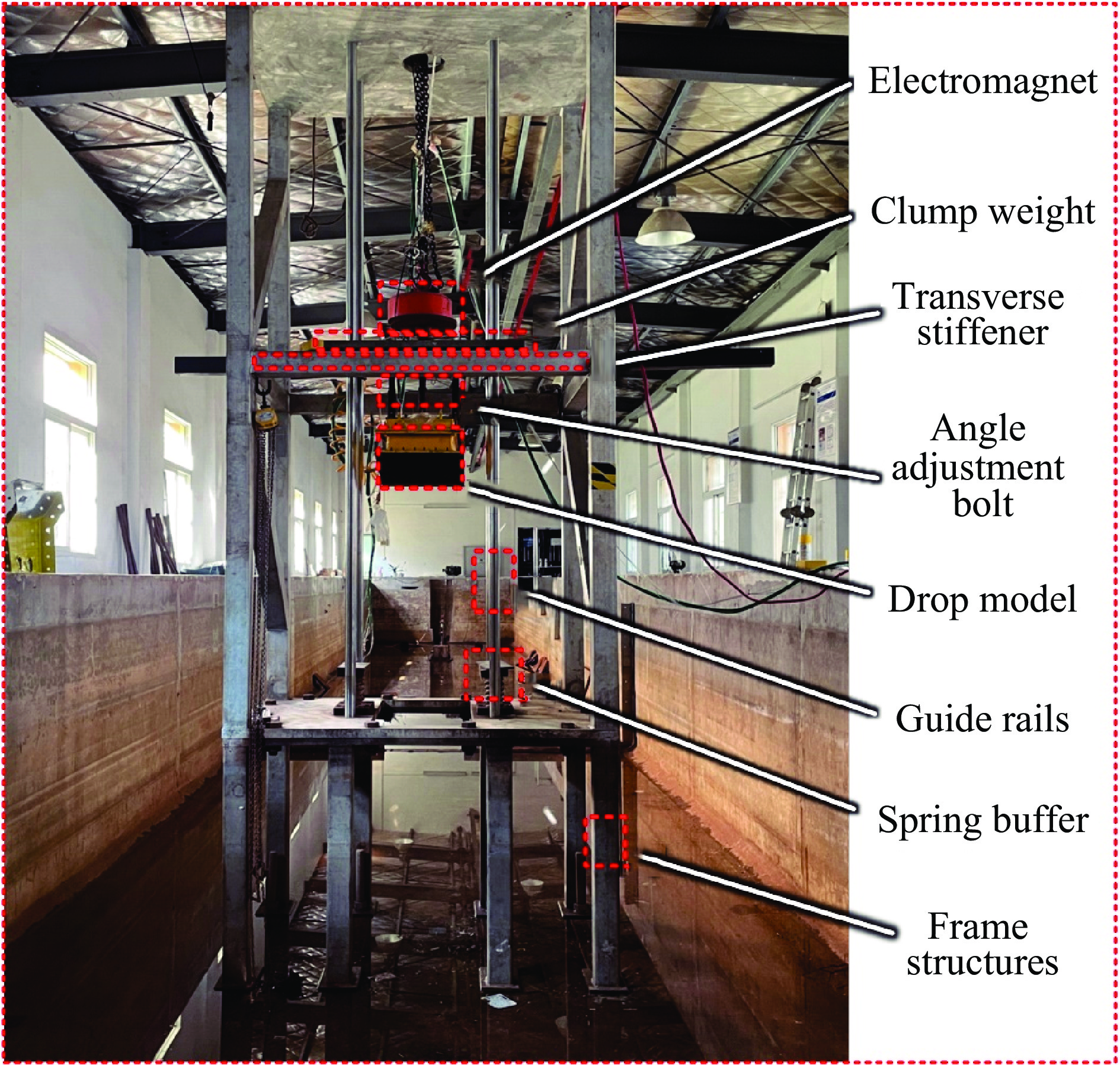

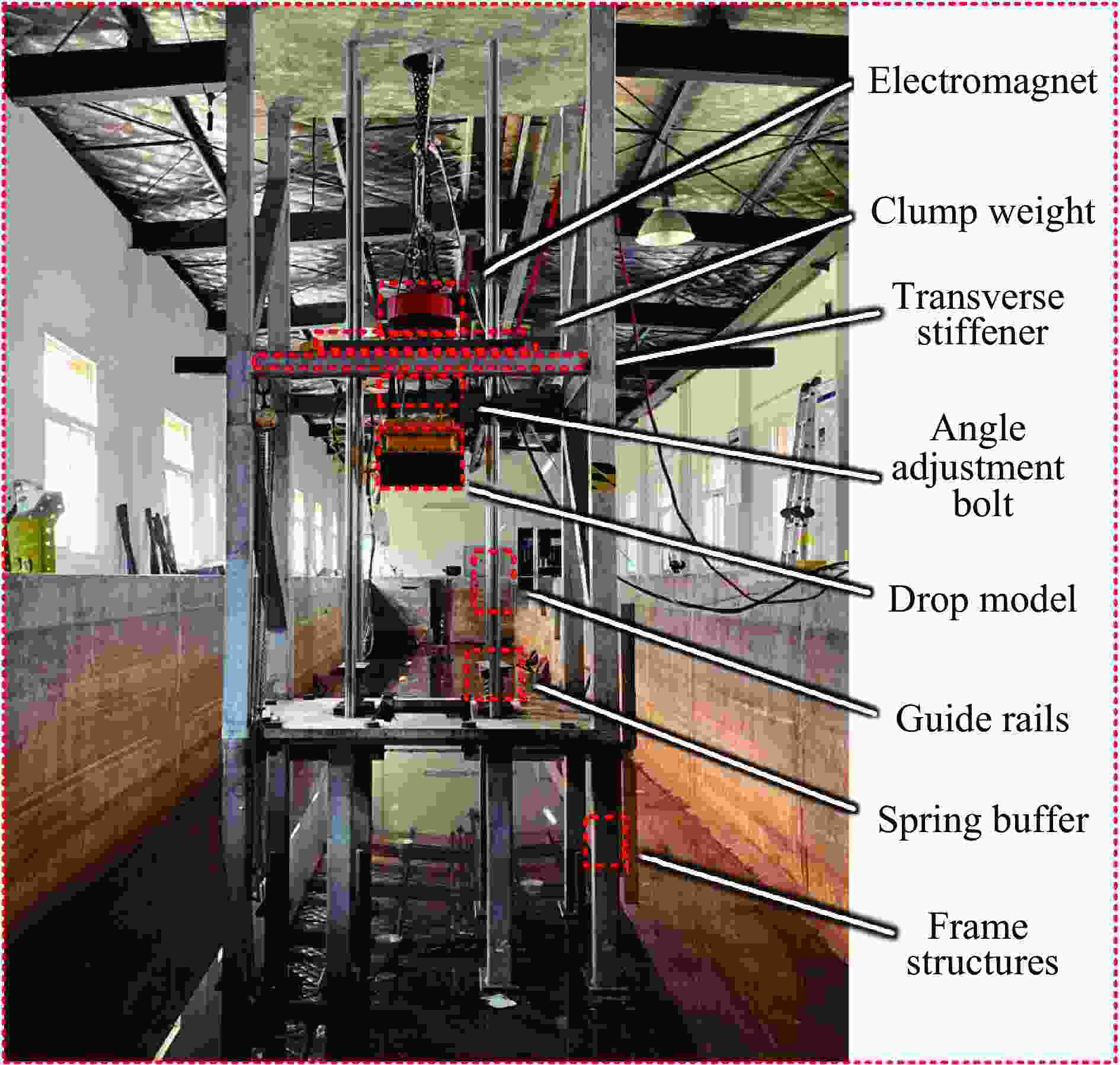

摘要: 通过实验方法研究了铝蜂窝夹芯板在入水冲击载荷作用下的压力载荷特性和结构变形机理。首先,搭建了蜂窝夹芯板入水冲击实验平台,开展了不同落体高度下的蜂窝夹芯板入水冲击实验,通过三维扫描仪得到了面板的变形结果,并监测了不同测点的入水冲击压力时程,同时验证了实验的可重复性。在此基础上,研究了蜂窝夹芯板入水冲击过程中的压力载荷特性,并与不同结构的入水冲击压力进行了对比。此外,分析了蜂窝夹芯板的变形模式、最终挠度等特性,给出了面板最终挠度和芯层压缩量的拟合公式。研究结果表明,蜂窝夹芯板表面的入水冲击压力分布不均匀,但在一定落体高度范围内,其压力峰值均与落体高度近似呈线性变化。与刚性平板入水冲击相比,蜂窝夹芯板的入水冲击压力峰值较小。相比同质量的等效铝板而言,蜂窝夹芯板的入水冲击压力峰值更小,压力持续时间更长。不同落体高度下,蜂窝夹芯板的面板变形模式基本一致。随着落体高度的增加,蜂窝夹芯板前面板和后面板中点处的最终挠度近似呈斜率减小的二次抛物线增长。在入水冲击载荷作用下,蜂窝夹芯板后面板的变形明显小于等效铝板的变形,表明蜂窝夹芯板具有更好的抗冲击性能。Abstract: The pressure characteristics and structural deformation mechanism of aluminum honeycomb sandwich plates (AHSPs) under water-entry impact were investigated through experimental methods. A self-designed drop experimental platform in the water tank was established, and the water-entry impact experiments of AHSPs at different drop heights were carried out. Meanwhile, the deformation of the face sheets was measured by a 3D scanner, and the time history of water impact pressure at different measuring points was monitored. Furthermore, the repeatability of the experiment was verified. On this basis, the water impact load characteristics of AHSPs during the process of water entry were studied and compared with those of other structures in published papers. In addition, the deformation modes and permanent deflection characteristics of AHSPs were analyzed, and the fitting formulas of the permanent deflection of the face sheets and the compression of the core were proposed. Results show that the distribution of the water impact pressure on the front sheet of AHSPs is uneven. However, within the range of drop heights studied, the peak value of the water impact pressure is approximately linear with the drop height. Additionally, compared to the water entry of rigid plates, the peak value of the water impact pressure of AHSPs is smaller. Compared with the mass equivalent aluminum plates, the peak value of the water impact pressure of AHSPs is much smaller, while the pressure duration of AHSPs is longer. The deformation modes of the face sheets of AHSPs at different drop heights are almost the same. Besides, with the increase of the drop height, the permanent deflections of the front and back faces of AHSPs increase approximately in the form of a quadratic parabola with decreasing slope. Suffering from water entry impact loadings, the permanent deflections of the back sheet of AHSPs are smaller than those of the equivalent aluminum plates, indicating that the AHSPs have better impact resistance compared with the equivalent aluminum plates.

-

表 1 蜂窝夹芯板材料及尺寸

Table 1. Material properties and dimensions of AHSPs

蜂窝夹芯板 材料类型 总体尺寸/mm 有效尺寸/mm 厚度/mm l/mm δsingle/mm δdouble/mm 前面板 Al 1060 350×350 250×250 0.5 芯层 Al 3003 250×250 250×250 15.0 15 0.04 0.08 后面板 Al 1060 350×350 250×250 0.5 表 2 数据测量与采集系统

Table 2. Data measurement and acquisition system

测量设备 用途 M+P动态采集分析系统 测点P1和P2的压力时程 三维激光扫描仪 前面板和后面板的变形 高速摄影机 入水冲击箱体的实测入水速度 LED灯 实验场景补光 表 3 入水冲击实验工况

Table 3. Cases for water-entry impact experiments

工况 h/m 1 0.4 2 0.5 3 0.6 4 0.7 5 0.8 表 4 不同落体高度下对应的入水速度

Table 4. Water-entry velocity under different drop heights

h/m vb/(m·s−1) va/(m·s−1) 相对误差/% 0.4 2.80 2.76 1.43 0.5 3.13 3.08 1.60 0.6 3.43 3.39 1.17 0.7 3.70 3.65 1.35 0.8 3.96 3.90 1.52 表 5 重复入水冲击实验结果

Table 5. Results of the repeated water-entry impact experiments

实验编号 压力峰值/kPa 中点最终挠度/mm 测点P1 测点P2 前面板 后面板 Case 3-1 200.86 169.05 5.69 4.63 Case 3-2 204.36 168.70 5.76 4.72 Case 3-3 208.51 167.06 5.69 4.75 η/% 1.87 0.63 0.71 1.33 表 6 蜂窝夹芯板在不同落体高度下测点P1和P2的压力持续时间

Table 6. Pressure duration time at monitoring points P1 and P2 of AHSPs under different drop heights

h/m 测点P1压力持续时间/ms 测点P2压力持续时间/ms 0.4 8.93 10.32 0.5 10.55 9.11 0.6 13.36 11.20 0.7 12.15 11.63 0.8 10.86 11.68 表 7 蜂窝夹芯板最终挠度曲线拟合相关性指标

Table 7. Correlation index of permanent deflection curve fitting of AHSPs

曲线类型 拟合方式 R2 前面板 二次多项式拟合 0.996 73 后面板 二次多项式拟合 0.983 53 蜂窝芯层 二次多项式拟合 0.994 40 -

[1] 王永虎, 石秀华. 入水冲击问题研究的现状与进展 [J]. 爆炸与冲击, 2008, 28(3): 276–282. DOI: 10.11883/1001-1455(2008)03-0276-07.WANG Y H, SHI X H. Review on research and development of water-entry impact problem [J]. Explosion and Shock Waves, 2008, 28(3): 276–282. DOI: 10.11883/1001-1455(2008)03-0276-07. [2] 张伟, 郭子涛, 肖新科, 等. 弹体高速入水特性实验研究 [J]. 爆炸与冲击, 2011, 31(6): 579–584. DOI: 10.11883/1001-1455(2011)06-0579-06.ZHANG W, GUO Z T, XIAO X K, et al. Experimental investigations on behaviors of projectile high-speed water entry [J]. Explosion and Shock Waves, 2011, 31(6): 579–584. DOI: 10.11883/1001-1455(2011)06-0579-06. [3] 潘光, 杨悝. 空投鱼雷入水载荷 [J]. 爆炸与冲击, 2014, 34(5): 521–526. DOI: 10.11883/1001-1455(2014)05-0521-06.PAN G, YANG K. Impact force encountered by water-entry airborne torpedo [J]. Explosion and Shock Waves, 2014, 34(5): 521–526. DOI: 10.11883/1001-1455(2014)05-0521-06. [4] CHUANG S L. Experiments on flat-bottom slamming [J]. Journal of Ship Research, 1966, 10(1): 10–17. DOI: 10.5957/jsr.1966.10.1.10. [5] CHUANG S L. Investigation of impact of rigid and elastic bodies with water: NSRDC-3284 [R]. Bethesda: Naval Ship Research and Development Center, 1970. [6] SHIN H, SEO B, CHO S R. Experimental investigation of slamming impact acted on flat bottom bodies and cumulative damage [J]. International Journal of Naval Architecture and Ocean Engineering, 2018, 10(3): 294–306. DOI: 10.1016/j.ijnaoe.2017.06.004. [7] TALIOUA A, BERKANE B, MARTIN M B, et al. Flat plate pressure impact on a still water surface: the effect of surrounding ambient pressure and plate size [J]. Ocean Engineering, 2022, 263: 111926. DOI: 10.1016/j.oceaneng.2022.111926. [8] ZHU L, ZHU Z K, YU T X, et al. An experimental study of the saturated impulse for metal plates under slamming [J]. International Journal of Impact Engineering, 2023, 178: 104601. DOI: 10.1016/j.ijimpeng.2023.104601. [9] VON KARMAN T. The impact on seaplane floats during landing: NACA-TN-321 [R]. Washington: National Advisory Committee for Aeronautics, 1929. [10] WAGNER H. Über stoß- und gleitvorgänge an der oberfläche von flüssigkeiten [J]. Zeitschrift fuer Angewandte Mathematik und Mechanik, 1932, 12(4): 193–215. DOI: 10.1002/zamm.19320120402. [11] 陈小平, 李军伟, 王辉, 等. 大尺度楔形体板架钢模落体试验和仿真研究 [J]. 船舶力学, 2012, 16(10): 1152–1163. DOI: 10.3969/j.issn.1007-7294.2012.10.007.CHEN X P, LI J W, WANG H, et al. Experiments and numerical investigation of water entry of large-scale steel wedge models [J]. Journal of Ship Mechanics, 2012, 16(10): 1152–1163. DOI: 10.3969/j.issn.1007-7294.2012.10.007. [12] 王明振, 褚林塘, 吴彬, 等. 水陆两栖飞机典型横截面入水撞击实验研究 [J]. 爆炸与冲击, 2016, 36(3): 313–318. DOI: 10.11883/1001-1455(2016)03-0313-06.WANG M Z, CHU L T, WU B, et al. Experimental study on the water impact of a typical cross section for amphibious seaplane [J]. Explosion and Shock Waves, 2016, 36(3): 313–318. DOI: 10.11883/1001-1455(2016)03-0313-06. [13] ZHU L, DUAN L L, CHEN M S, et al. Equivalent design pressure for ship plates subjected to moving slamming impact loads [J]. Marine Structures, 2020, 71: 102741. DOI: 10.1016/j.marstruc.2020.102741. [14] DUAN L L, ZHU L, CHEN M S, et al. Experimental study on the propagation characteristics of the slamming pressures [J]. Ocean Engineering, 2020, 217: 107868. DOI: 10.1016/j.oceaneng.2020.107868. [15] PARK I C, SEO B C, LEE S H, et al. A study on slamming impact load characteristics of energy storage system case for ships [J]. Journal of Marine Science and Engineering, 2023, 11(1): 44. DOI: 10.3390/jmse11010044. [16] 骆寒冰, 刘鑫, 董德龙, 等. 铝制加筋板楔形体入水砰击模型实验研究 [J]. 水动力学研究与进展A辑, 2014, 29(4): 460–468. DOI: 10.3969/j.issn1000-4874.2014.04.011.LUO H B, LIU X, DONG D L, et al. Experimental investigation of water impact of one free-drop wedge with stiffened aluminum panels [J]. Chinese Journal of Hydrodynamics, 2014, 29(4): 460–468. DOI: 10.3969/j.issn1000-4874.2014.04.011. [17] CRUPI V, EPASTO G, GUGLIELMINO E. Comparison of aluminium sandwiches for lightweight ship structures: honeycomb vs. foam [J]. Marine Structures, 2013, 30: 74–96. DOI: 10.1016/j.marstruc.2012.11.002. [18] PALOMBA G, EPASTO G, SUTHERLAND L, et al. Aluminium honeycomb sandwich as a design alternative for lightweight marine structures [J]. Ships and Offshore Structures, 2022, 17(10): 2355–2366. DOI: 10.1080/17445302.2021.1996109. [19] DAS K, BATRA R C. Local water slamming impact on sandwich composite hulls [J]. Journal of Fluids and Structures, 2011, 27(4): 523–551. DOI: 10.1016/j.jfluidstructs.2011.02.001. [20] XIE H, REN H L, QU S, et al. Numerical and experimental study on hydroelasticity in water-entry problem of a composite ship-hull structure [J]. Composite Structures, 2018, 201: 942–957. DOI: 10.1016/j.compstruct.2018.06.030. [21] HASSOON O H, TARFAOUI M, EL MOUMEN A, et al. Mechanical performance evaluation of sandwich panels exposed to slamming impacts: comparison between experimental and SPH results [J]. Composite Structures, 2019, 220: 776–783. DOI: 10.1016/j.compstruct.2019.04.051. [22] 赵飞, 程远胜, 刘均, 等. 入水砰击下金字塔点阵夹层板塑性动力响应分析 [J]. 船海工程, 2013, 42(3): 13–16. DOI: 10.3963/j.issn.1671-7953.2013.03.003.ZHAO F, CHENG Y S, LIU J, et al. Dynamic plastic responses of light weight pyramidal sandwich plate structures subjected to water-entry impact [J]. Ship & Ocean Engineering, 2013, 42(3): 13–16. DOI: 10.3963/j.issn.1671-7953.2013.03.003. [23] HE W T, CUI X F, WANG C Z, et al. Coupled Eulerian-Lagrangian (CEL) characterization of slamming response and failure mechanism on corrugated sandwich structures [J]. Applied Ocean Research, 2021, 116: 102862. DOI: 10.1016/j.apor.2021.102862. [24] WANG H, CHENG Y S, LIU J, et al. Hydroelastic behaviours of laser-welded lightweight corrugated sandwich panels subjected to water impact: experiments and simulations [J]. Thin-Walled Structures, 2020, 146: 106452. DOI: 10.1016/j.tws.2019.106452. [25] FALTINSEN O M, KVÅLSVOLD J, AARSNES J V. Wave impact on a horizontal elastic plate [J]. Journal of Marine Science and Technology, 1997, 2(2): 87–100. DOI: 10.1007/BF02491523. [26] OKADA S, SUMI Y. Experimental study on the maximum pressure and the duration time of the horizontal water impact of flat plate [J]. Journal of the Society of Naval Architects of Japan, 1995, 1995(178): 381–389. DOI: 10.2534/jjasnaoe1968.1995.178_381. -

下载:

下载: