Mechanism analysis and deformation prediction of steel-concrete-steel composite walls under coupled fire exposure and explosion

-

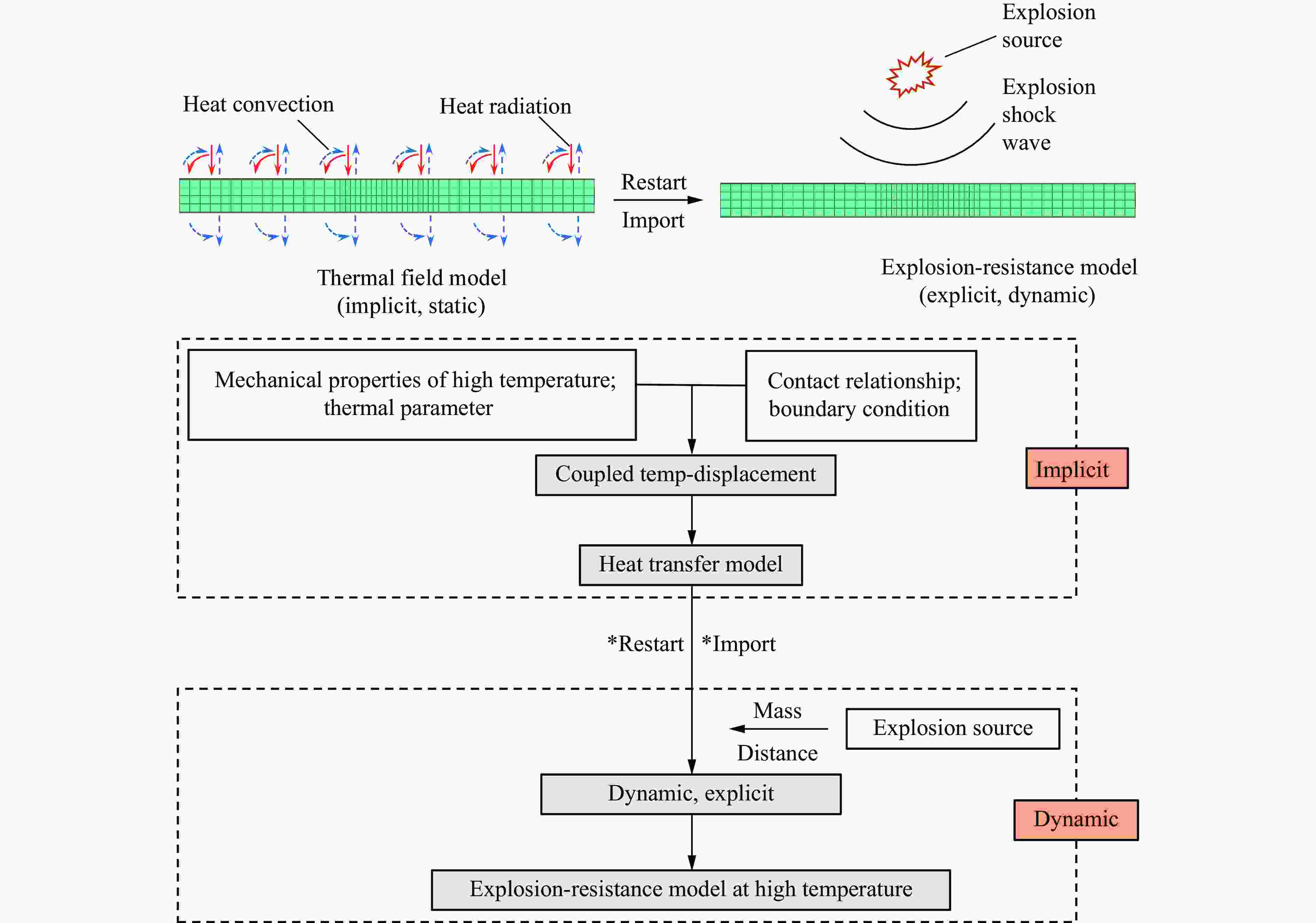

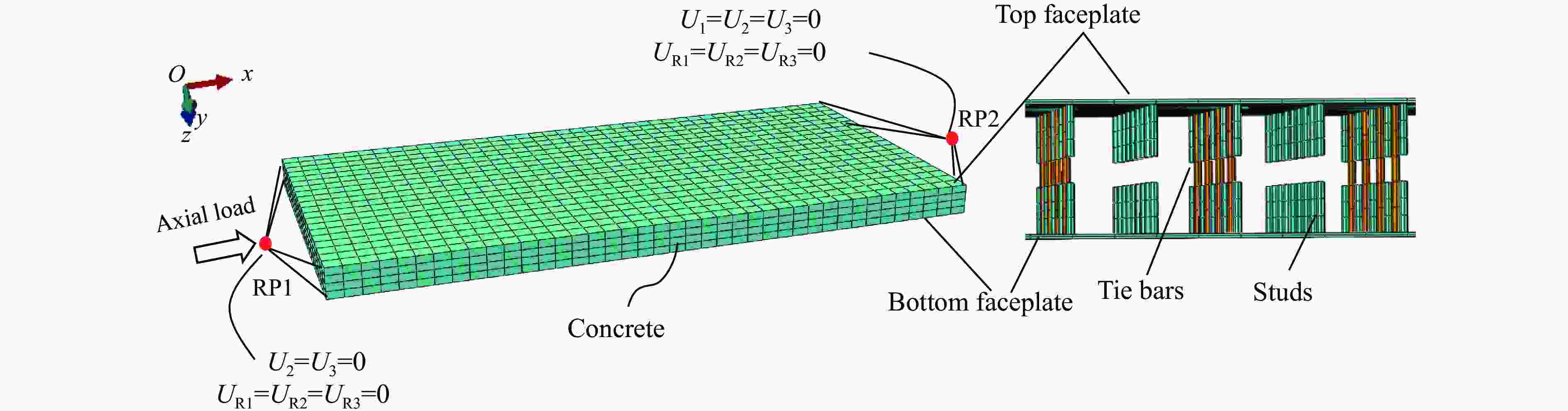

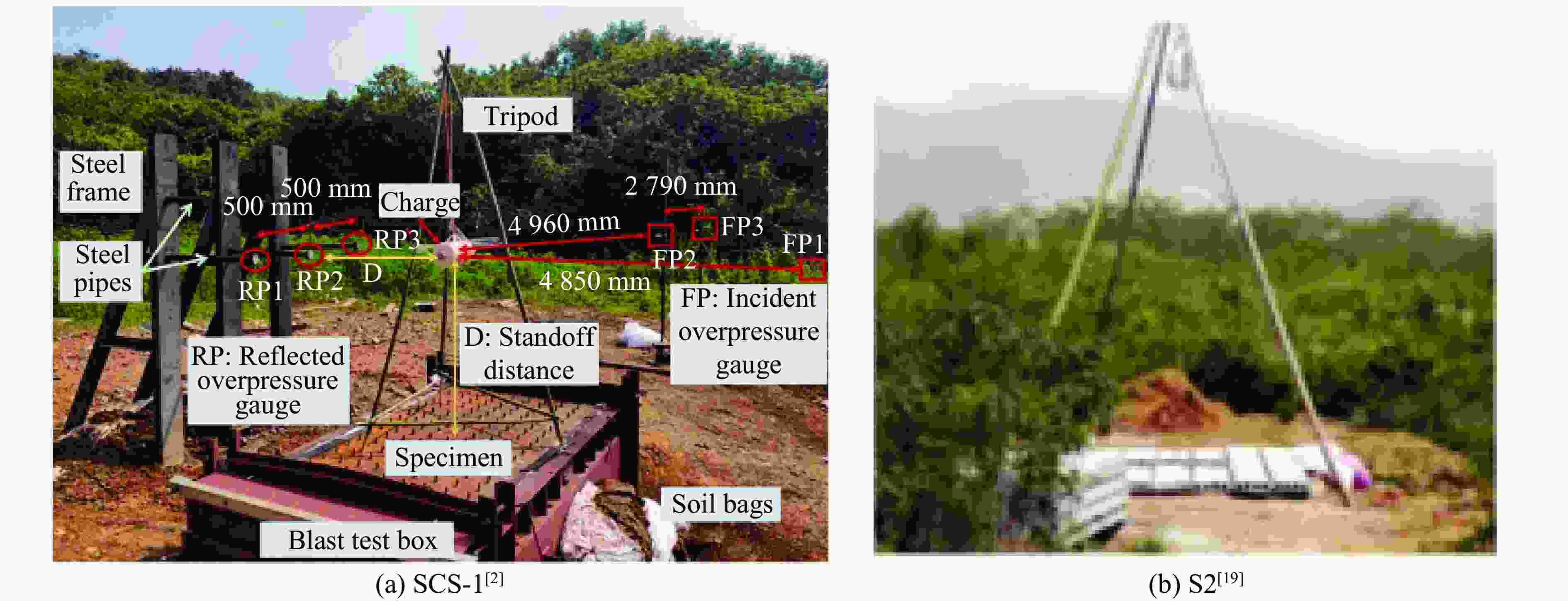

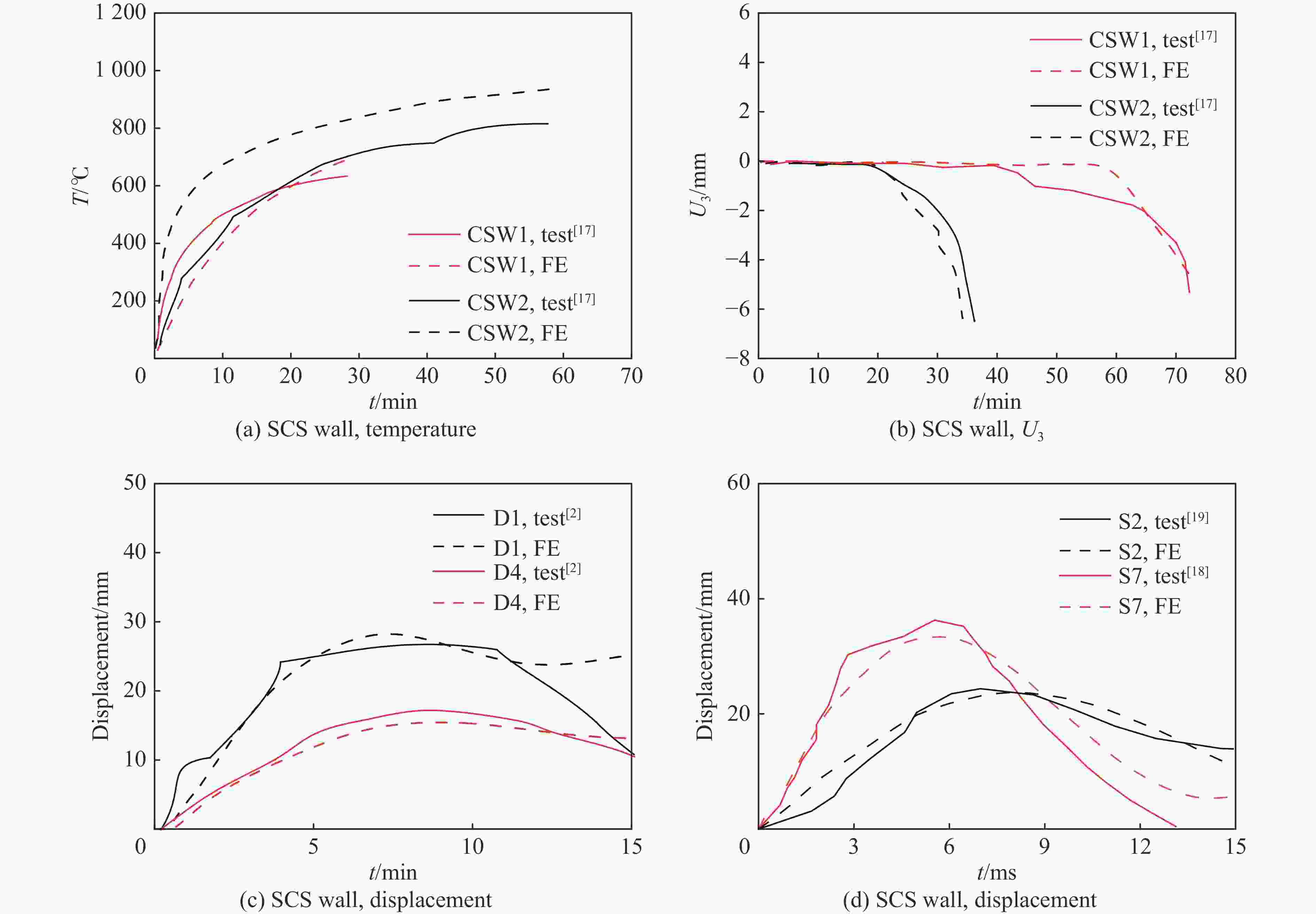

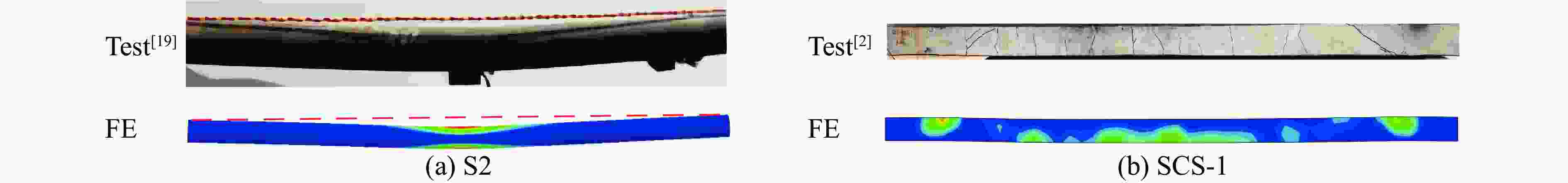

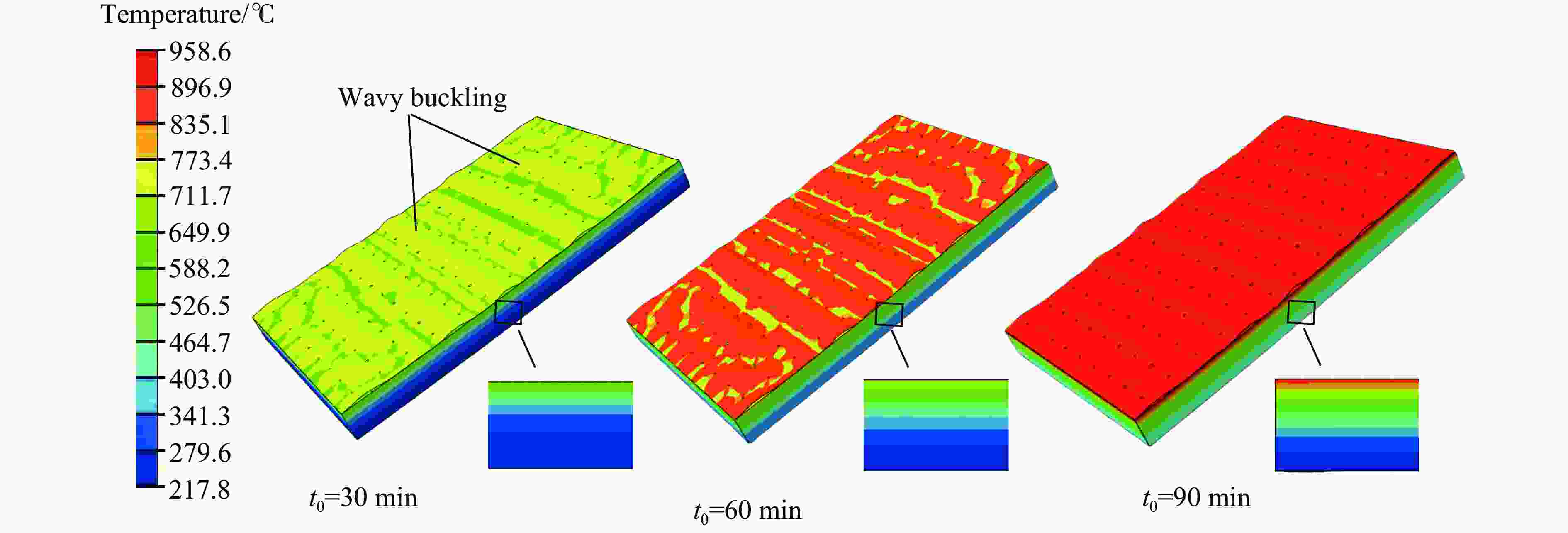

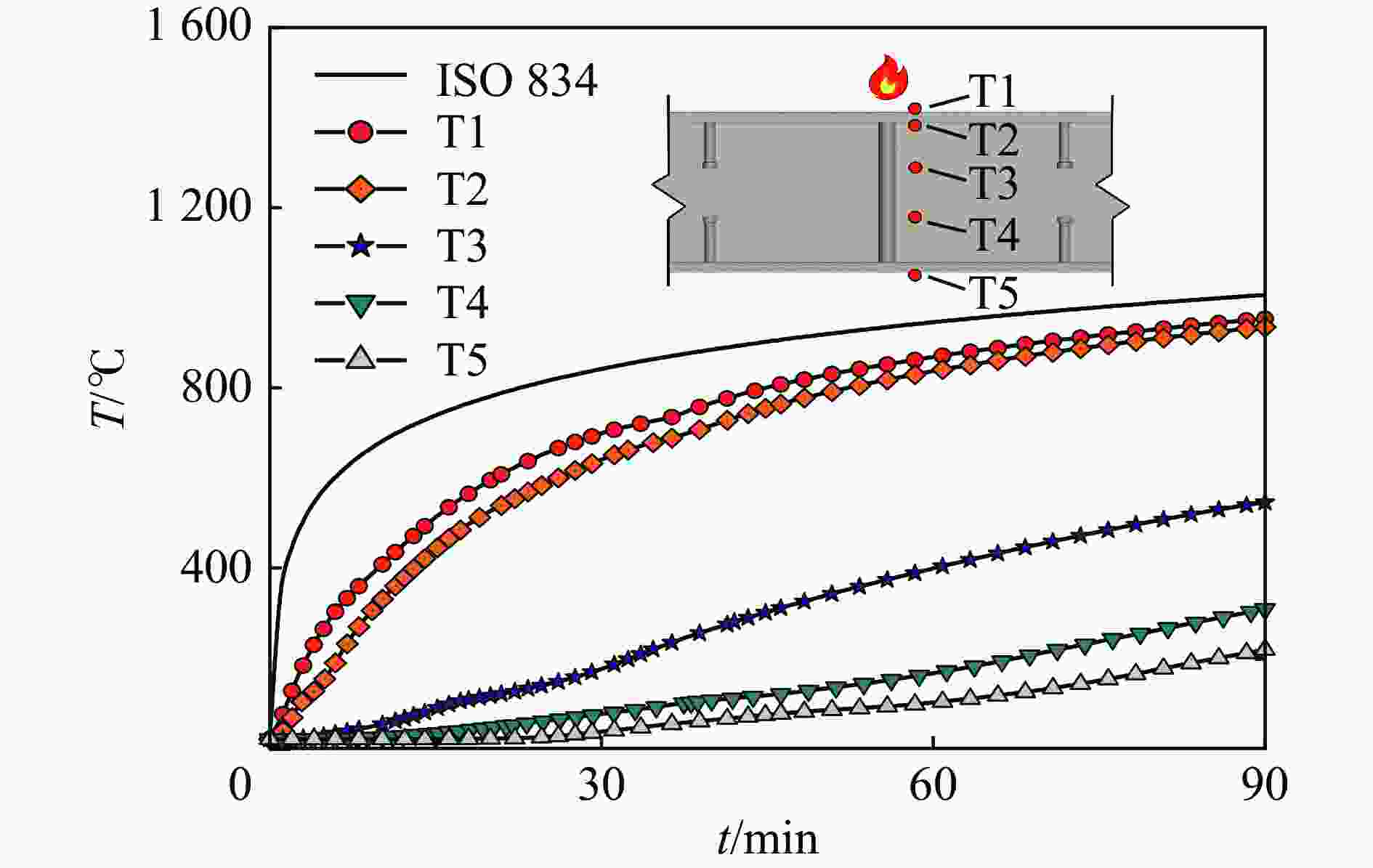

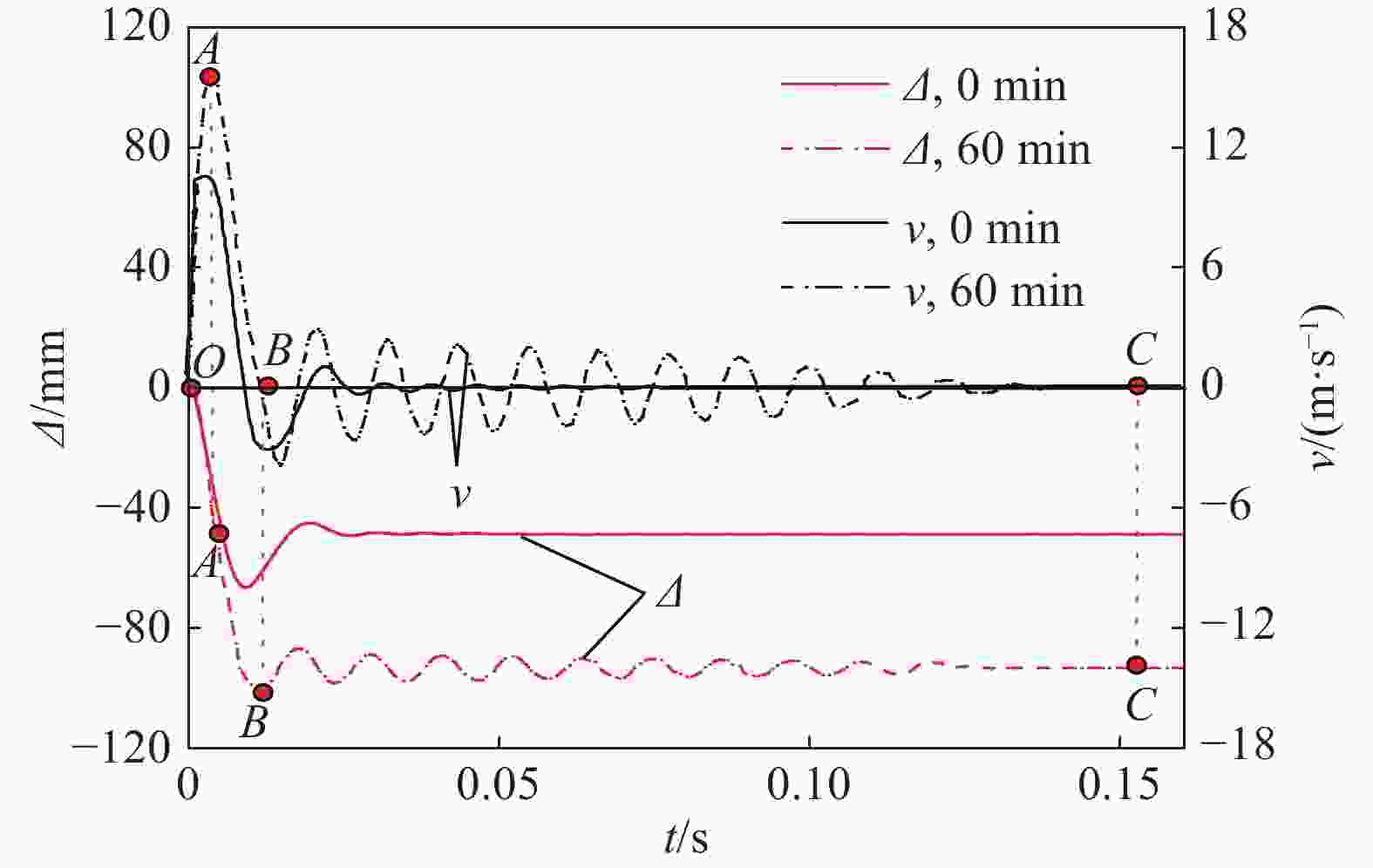

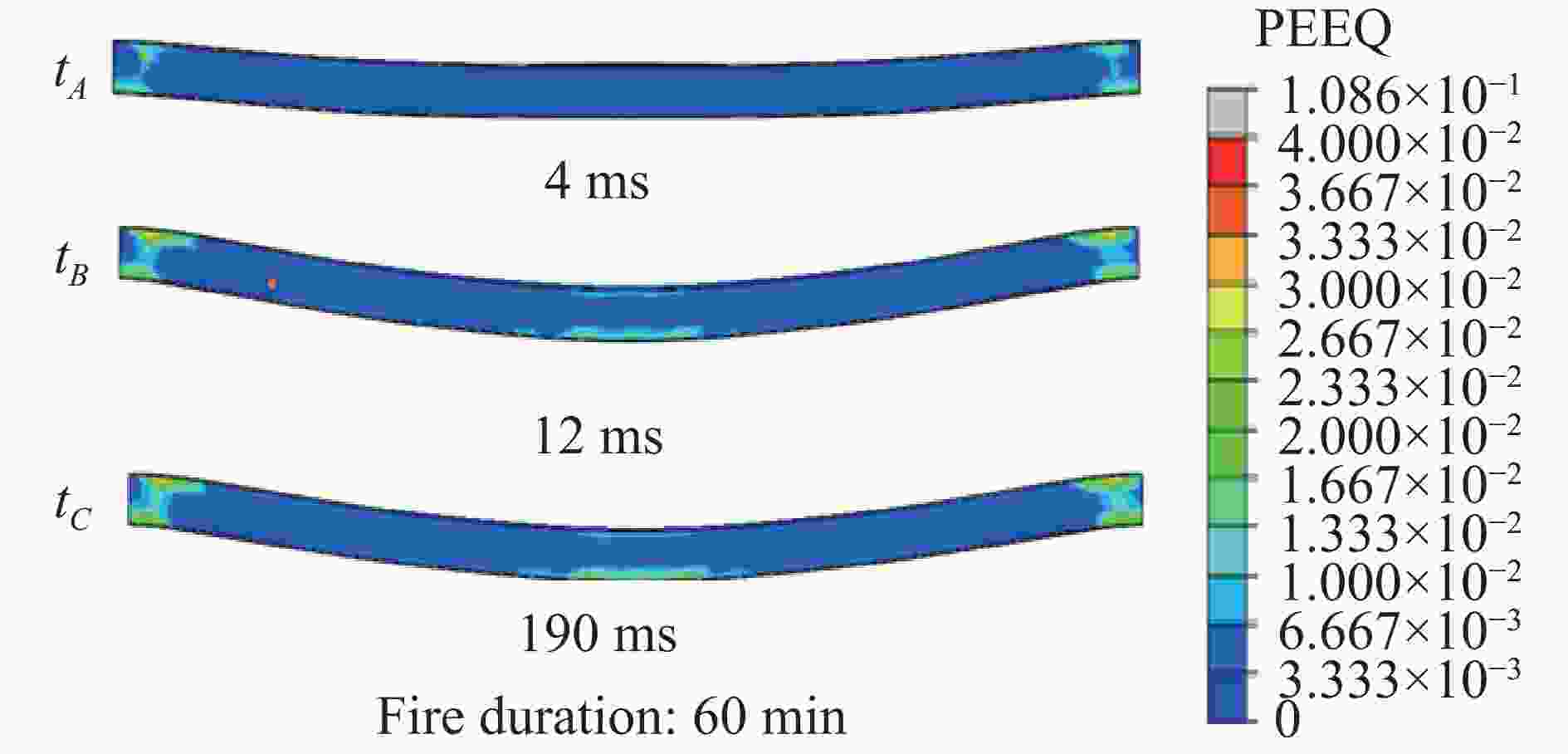

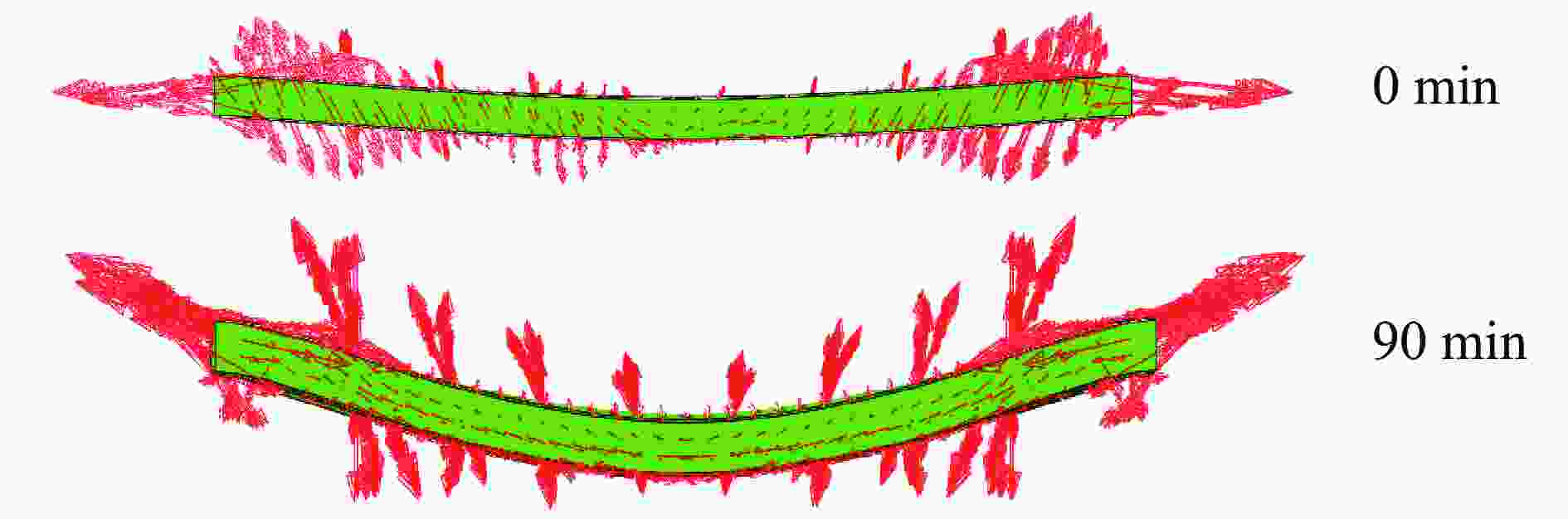

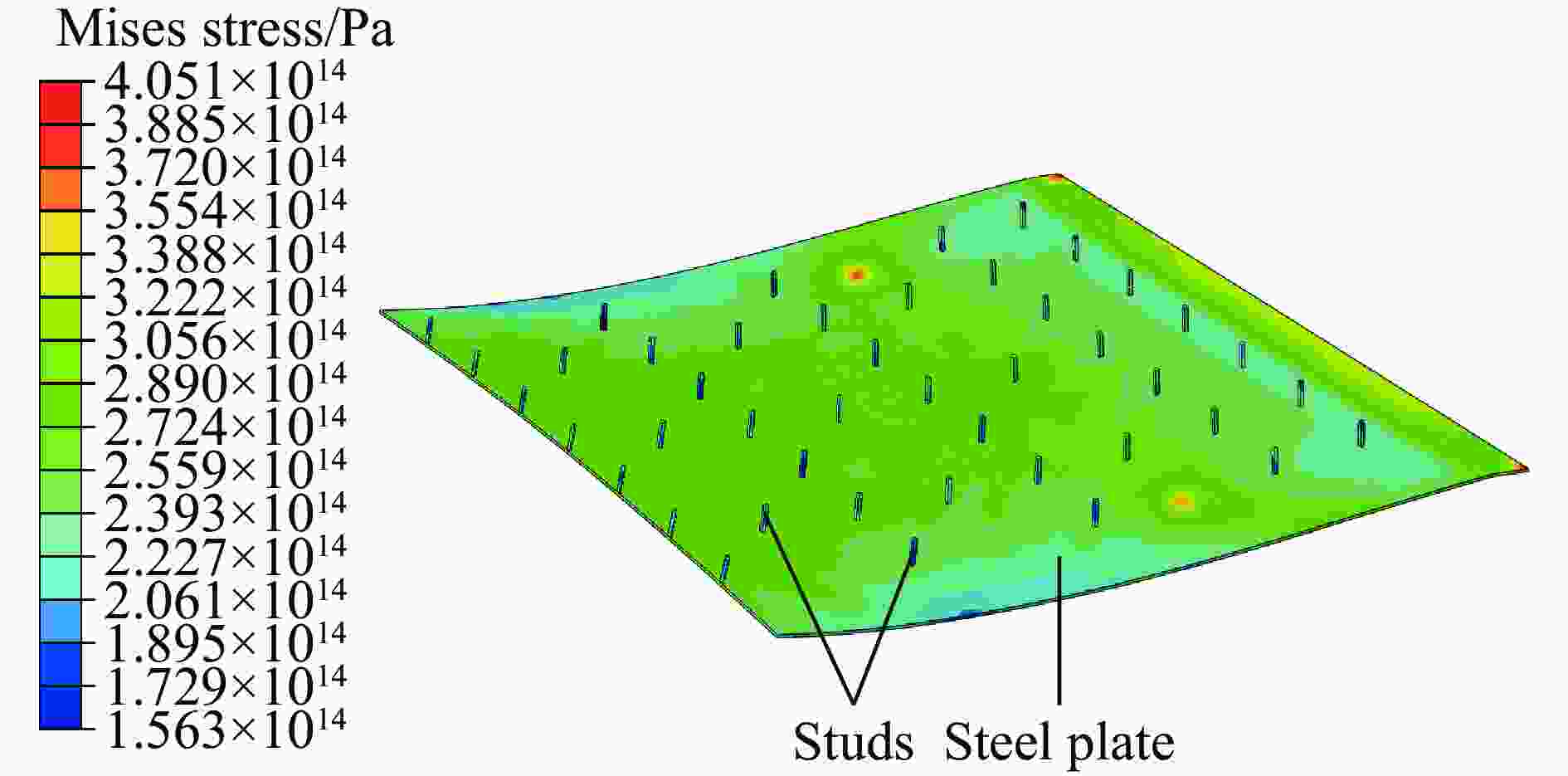

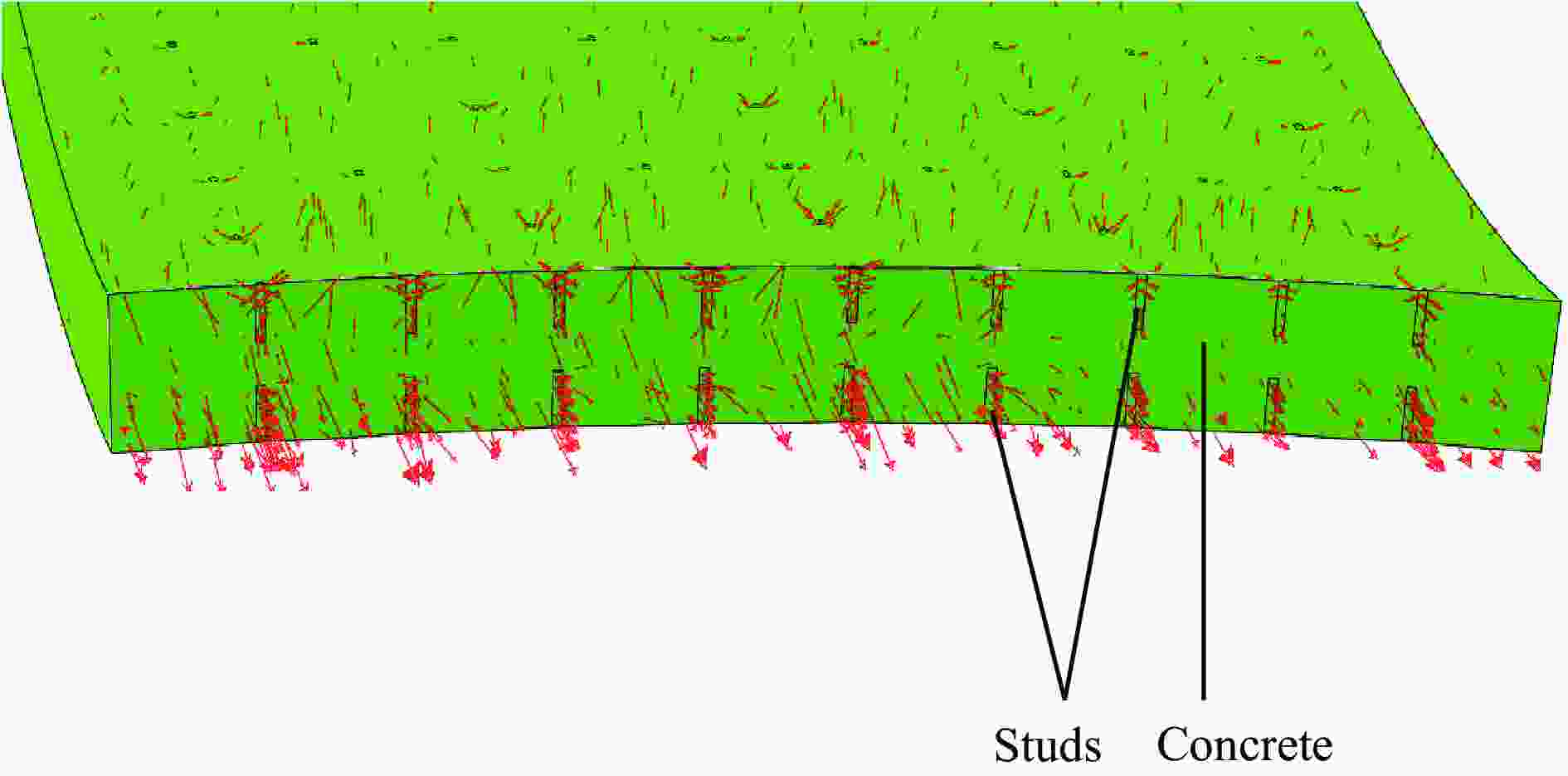

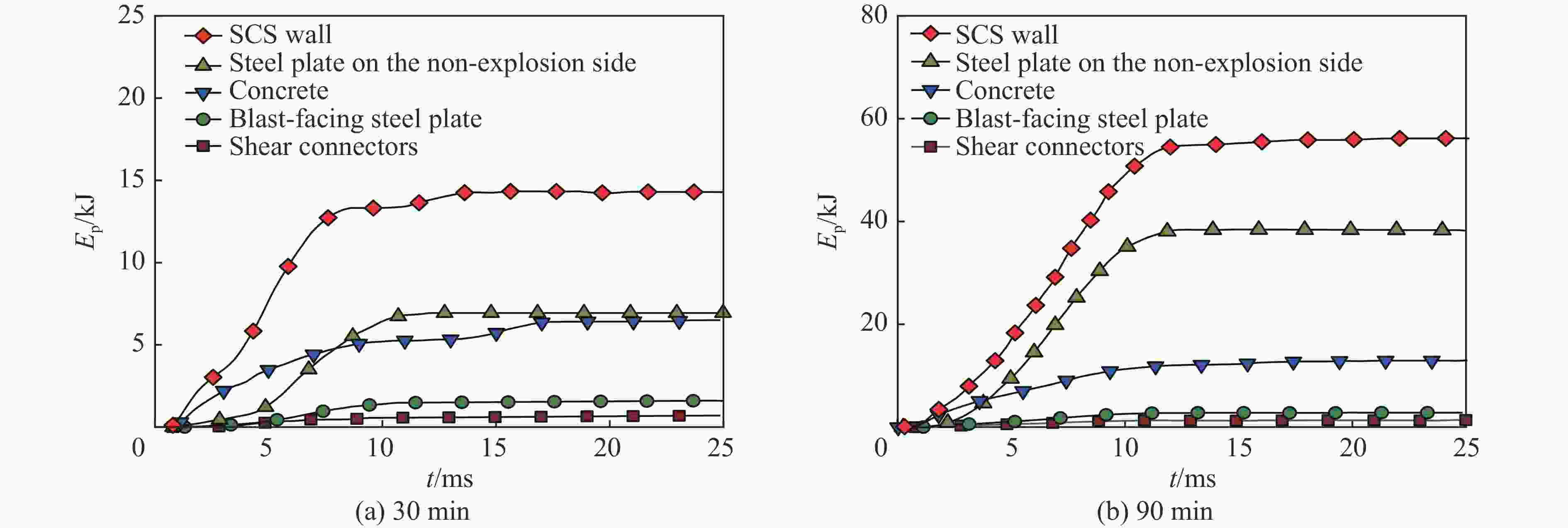

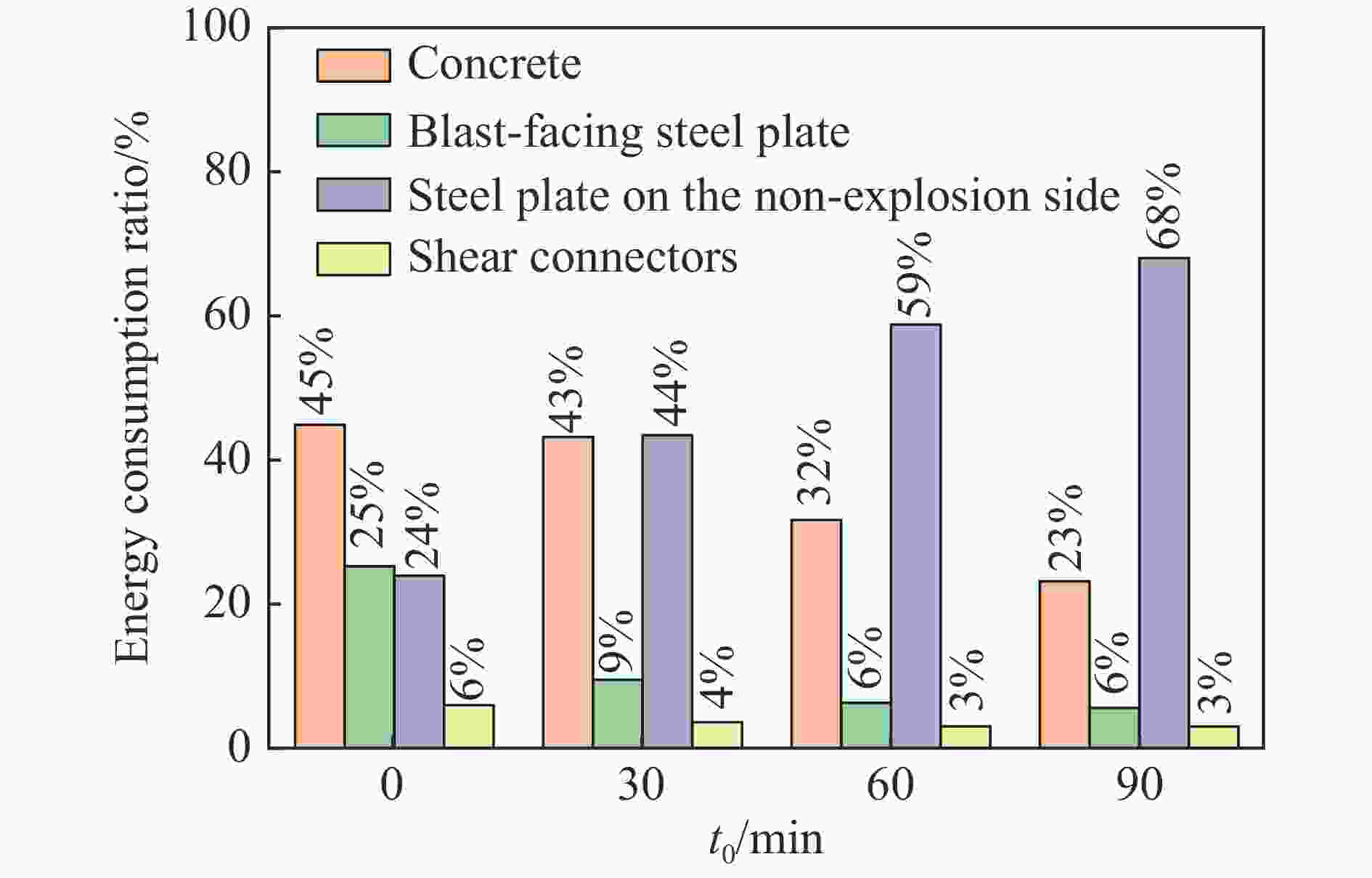

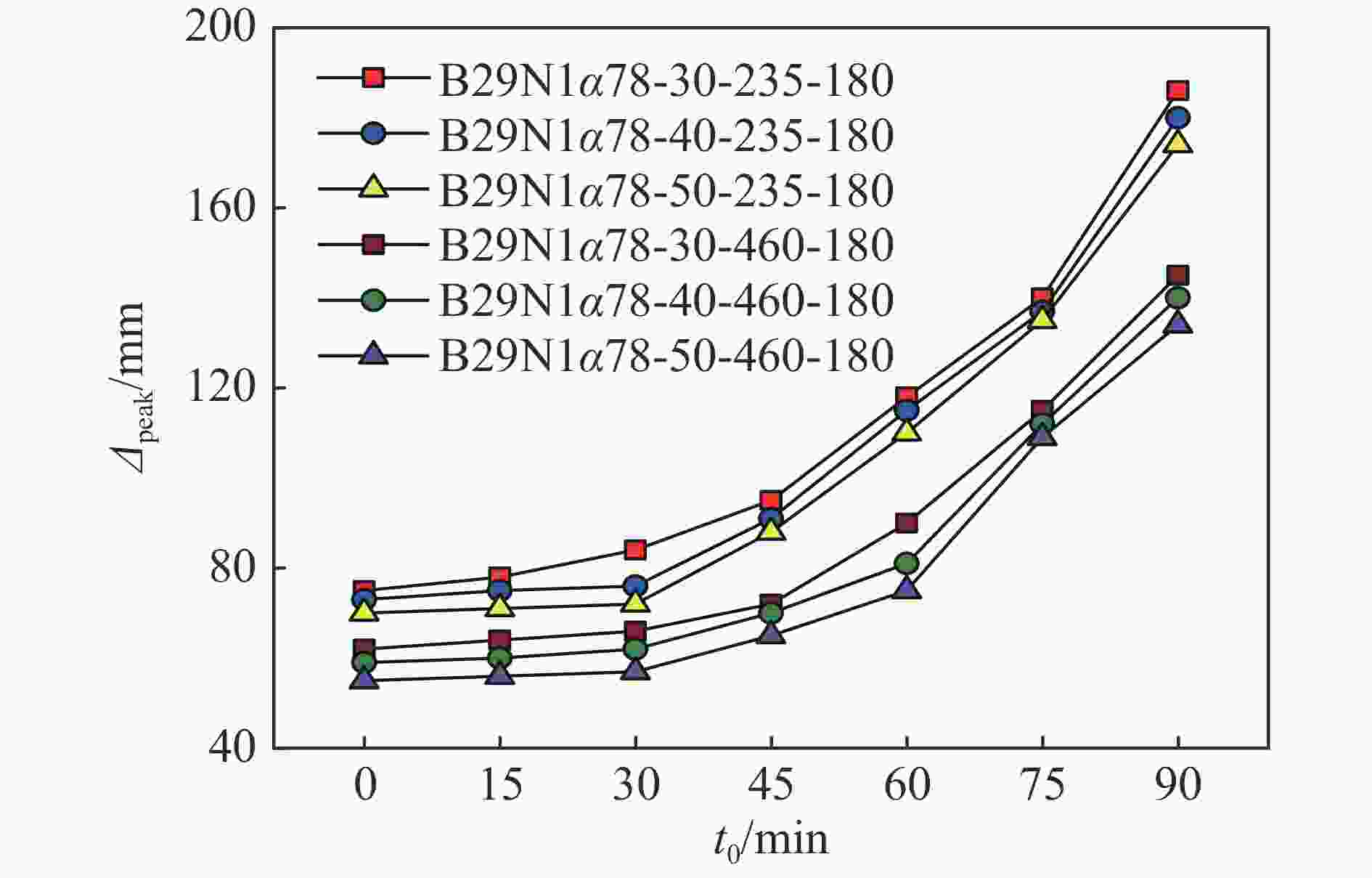

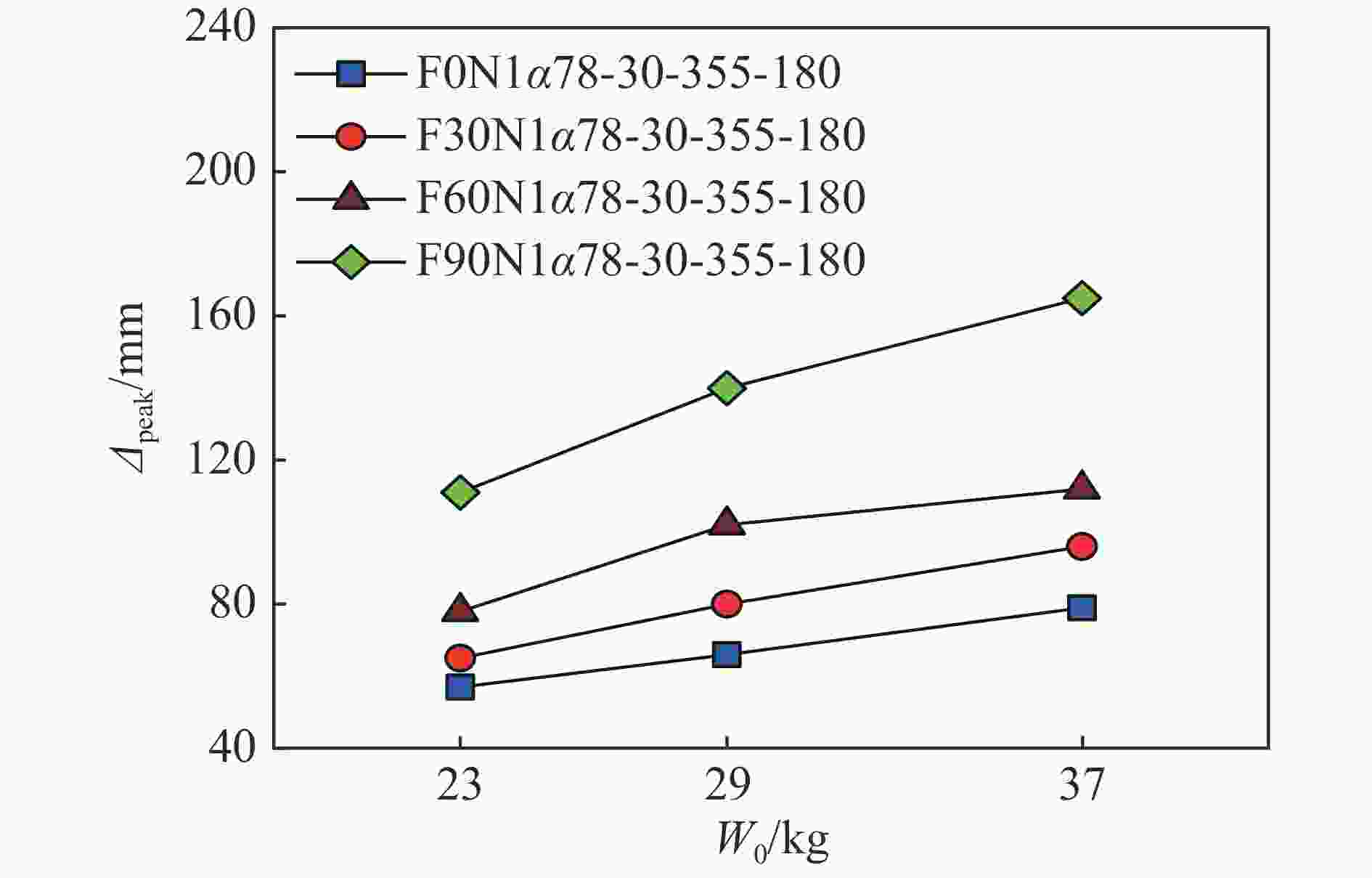

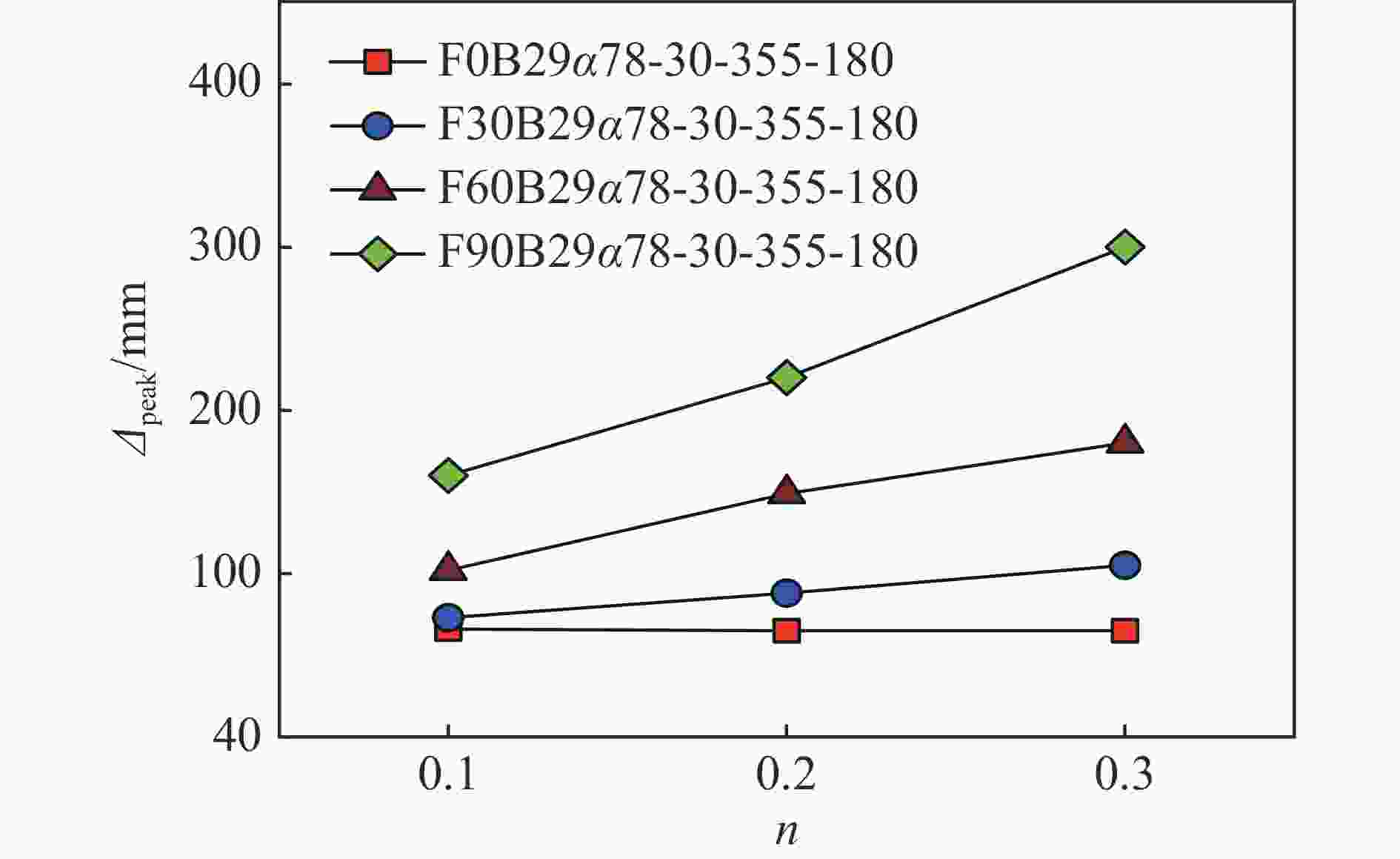

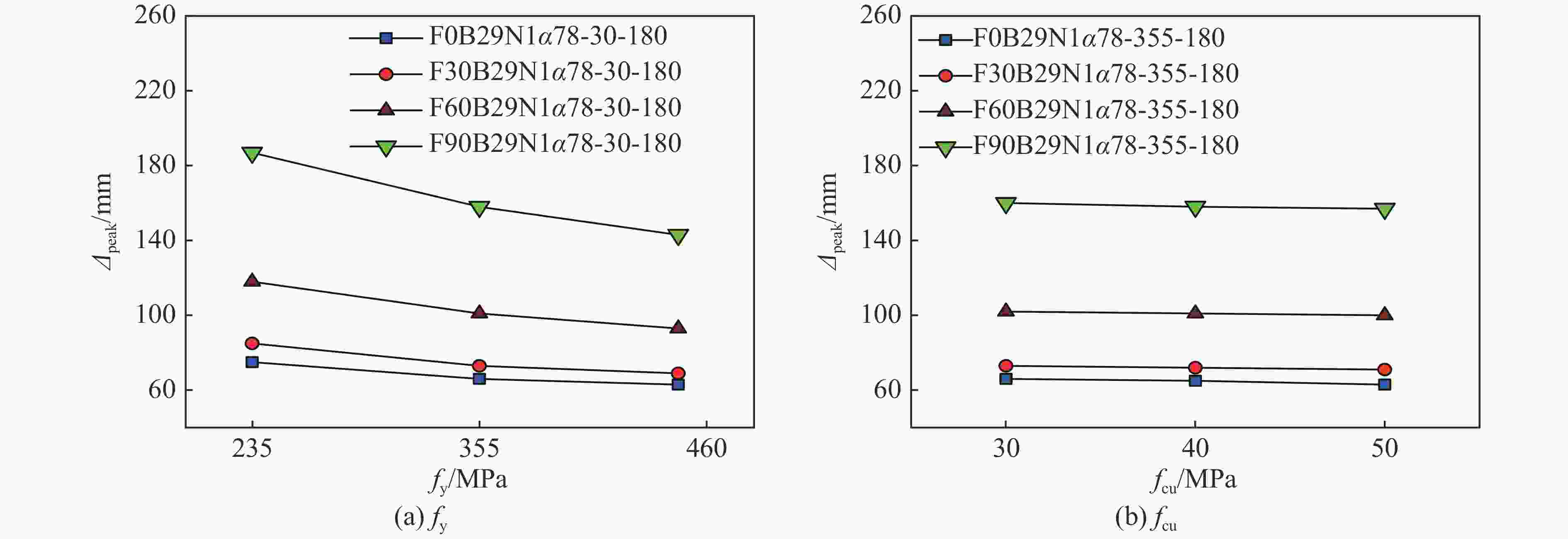

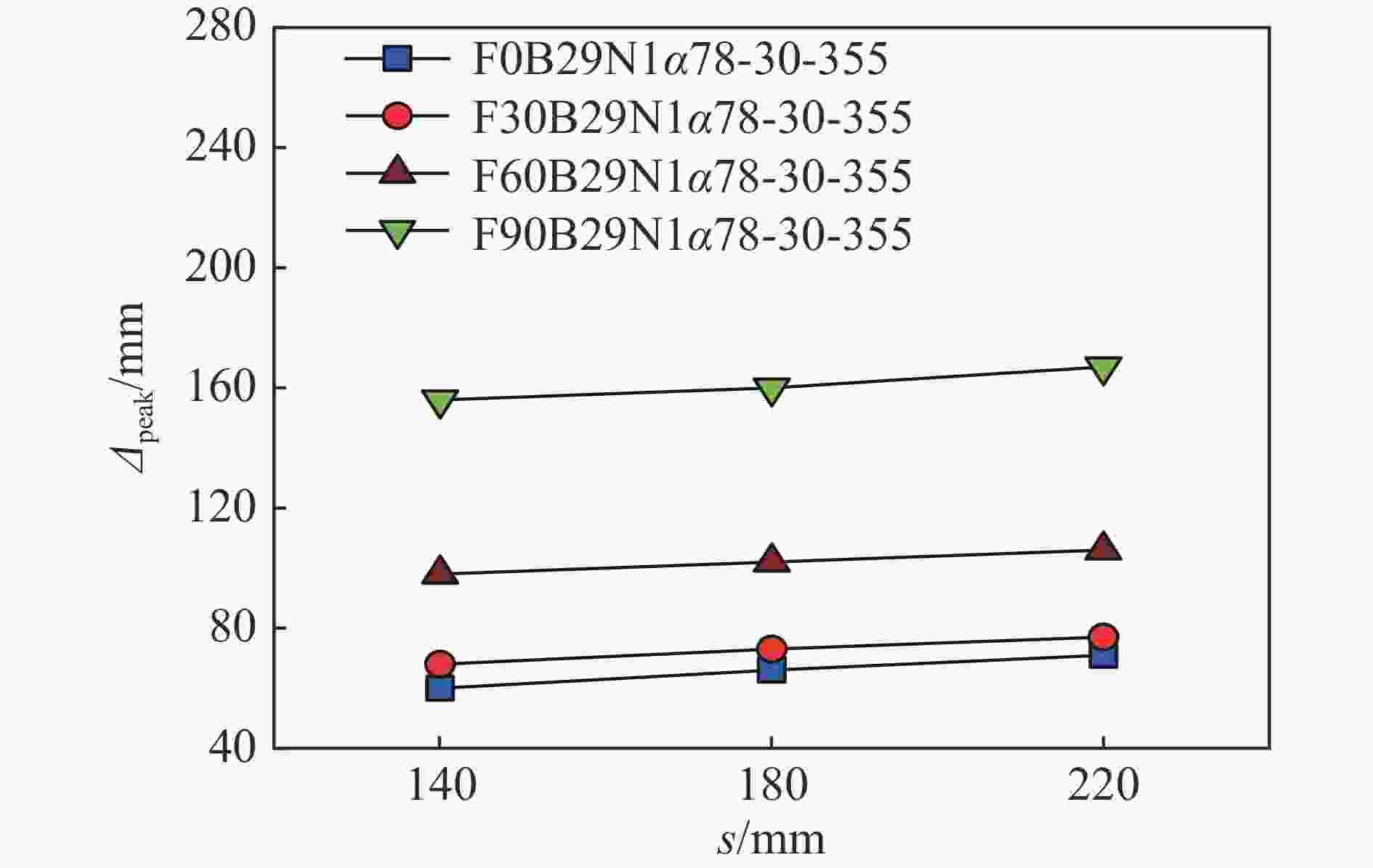

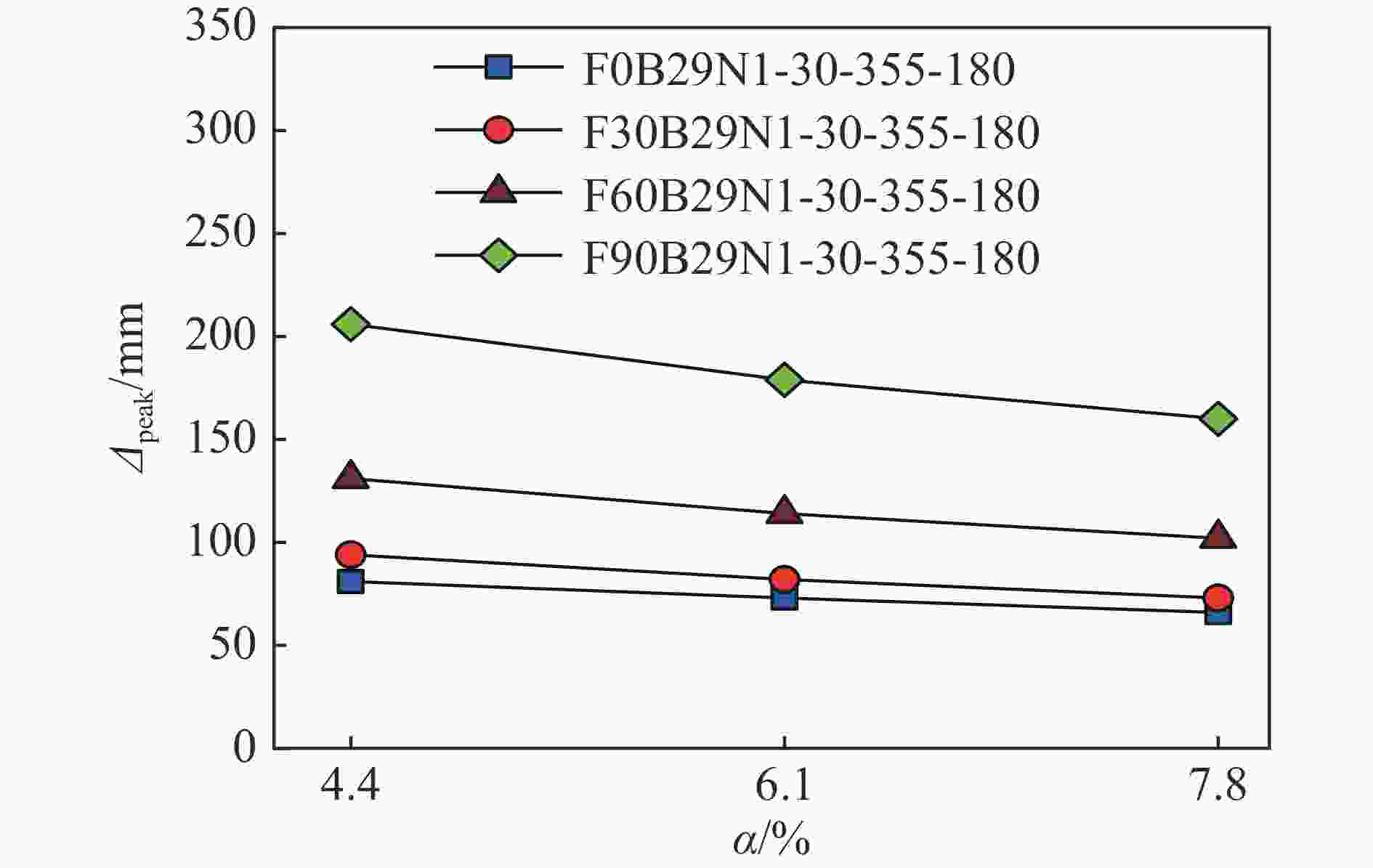

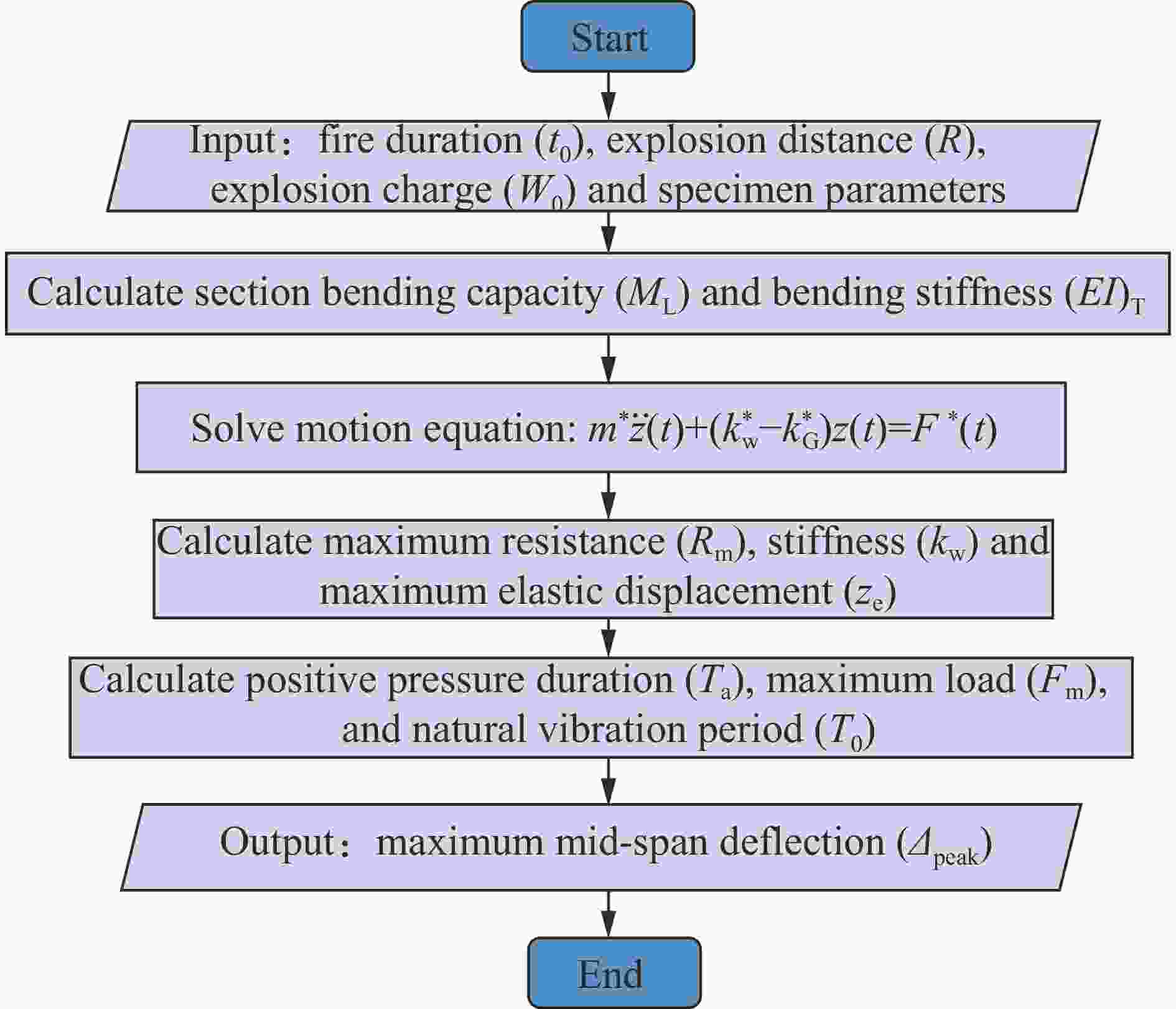

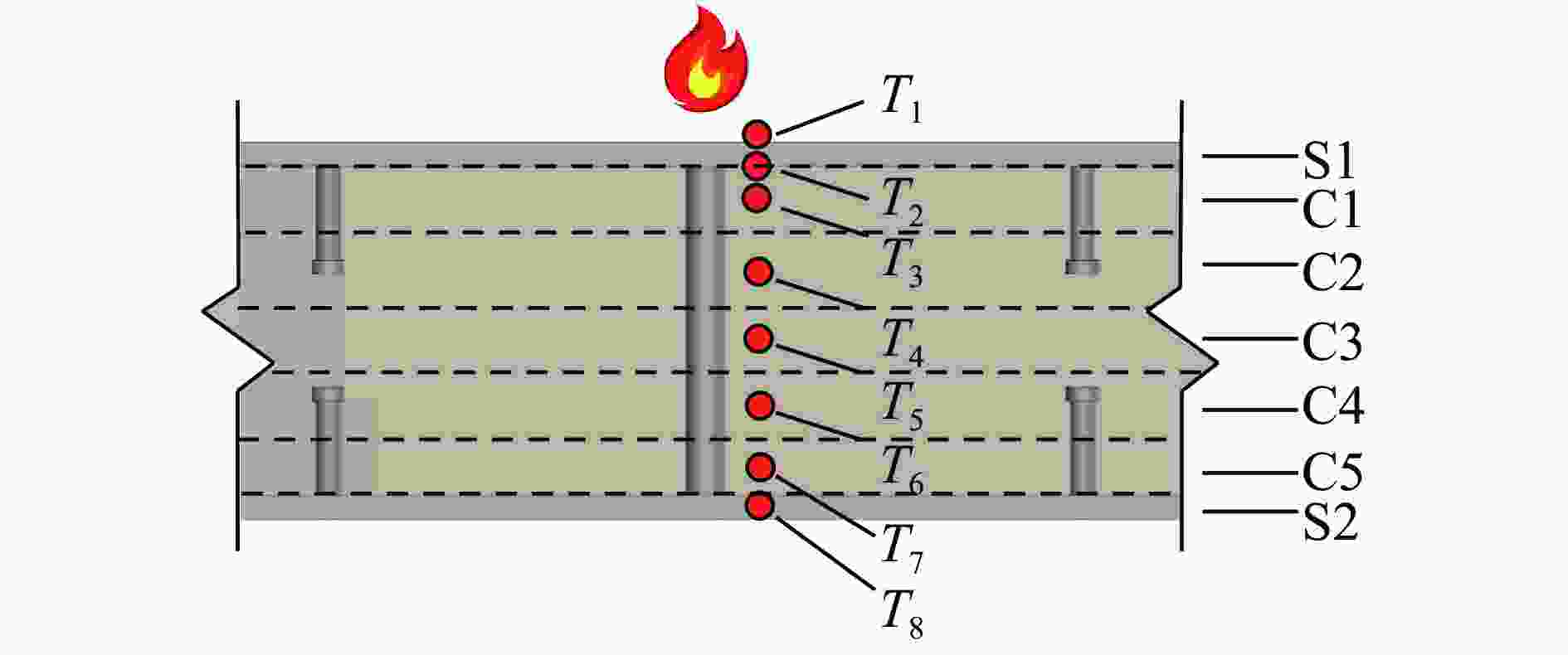

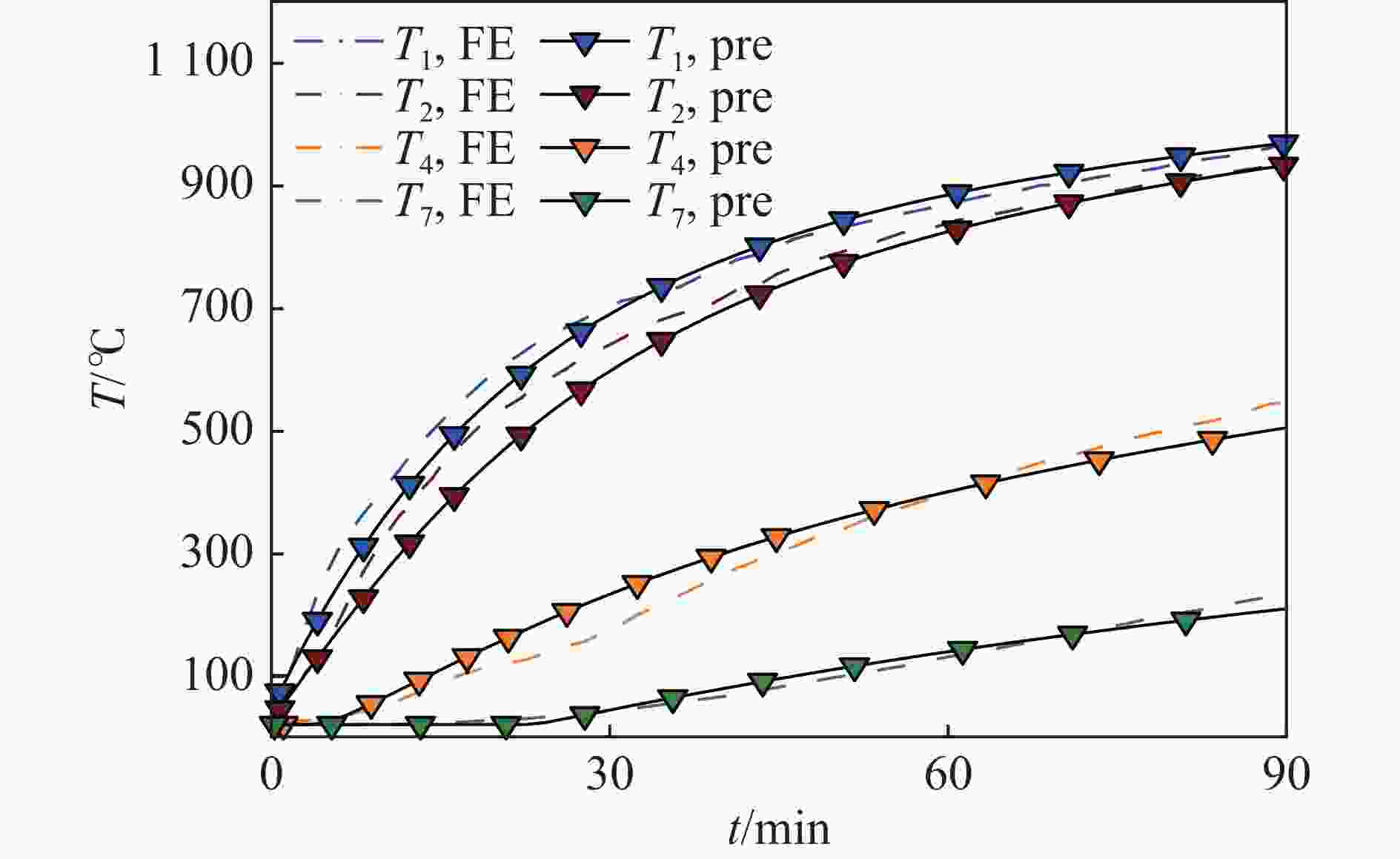

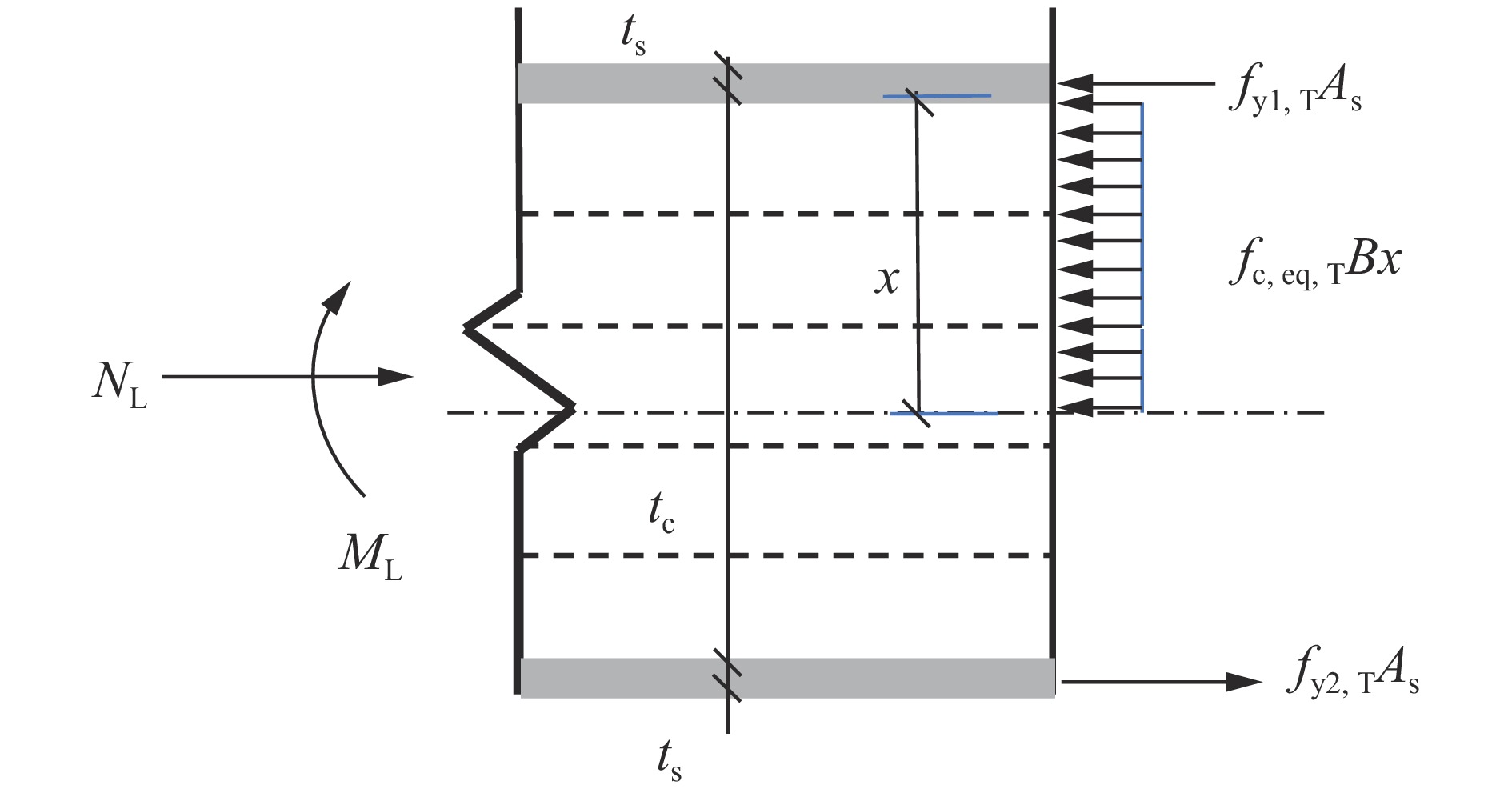

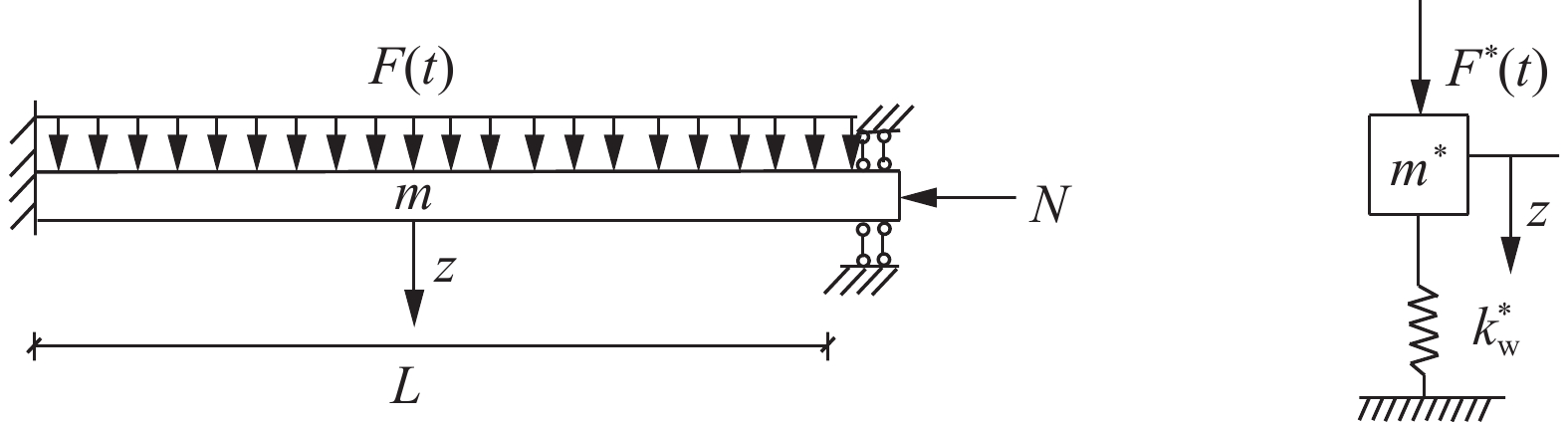

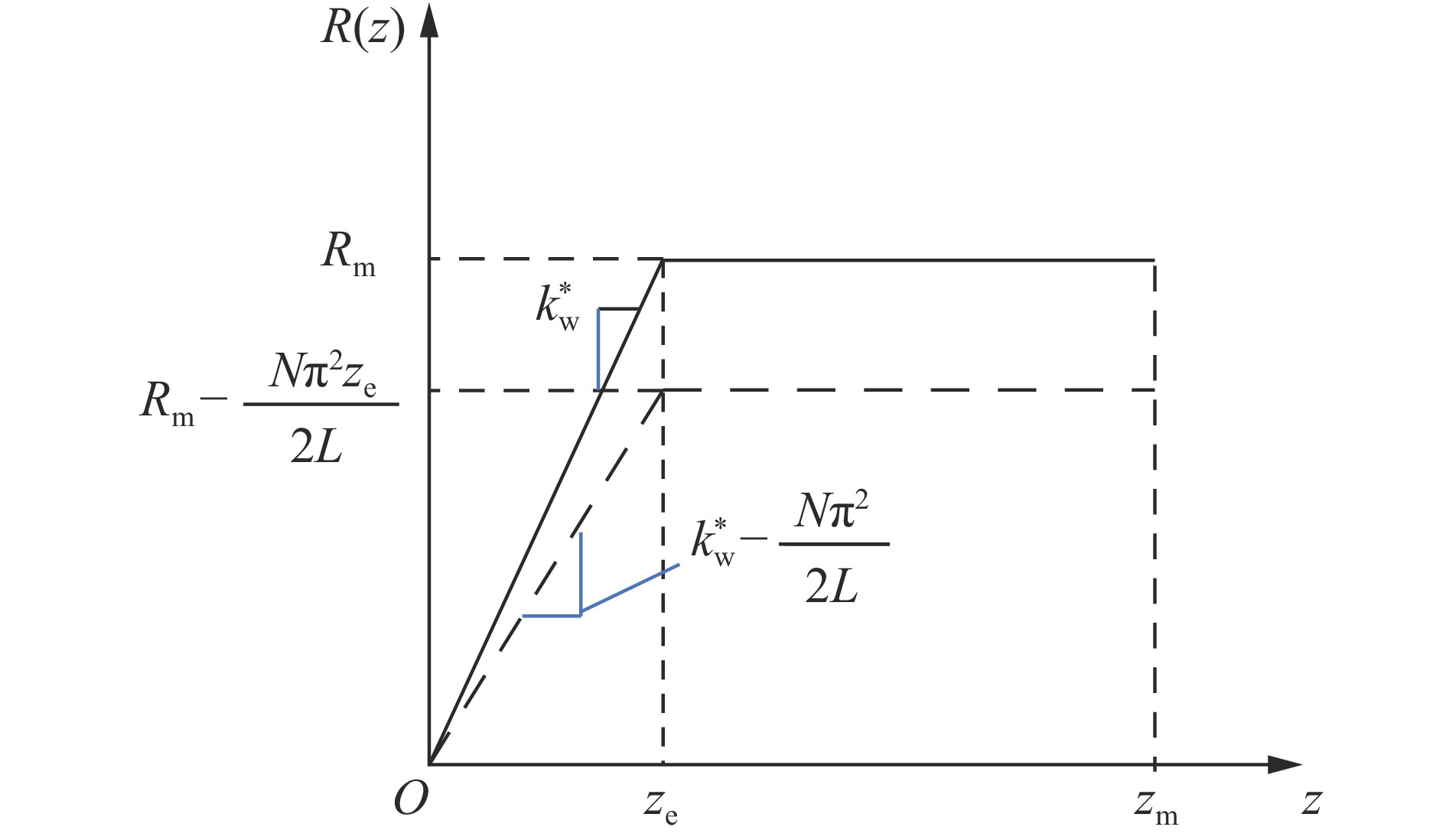

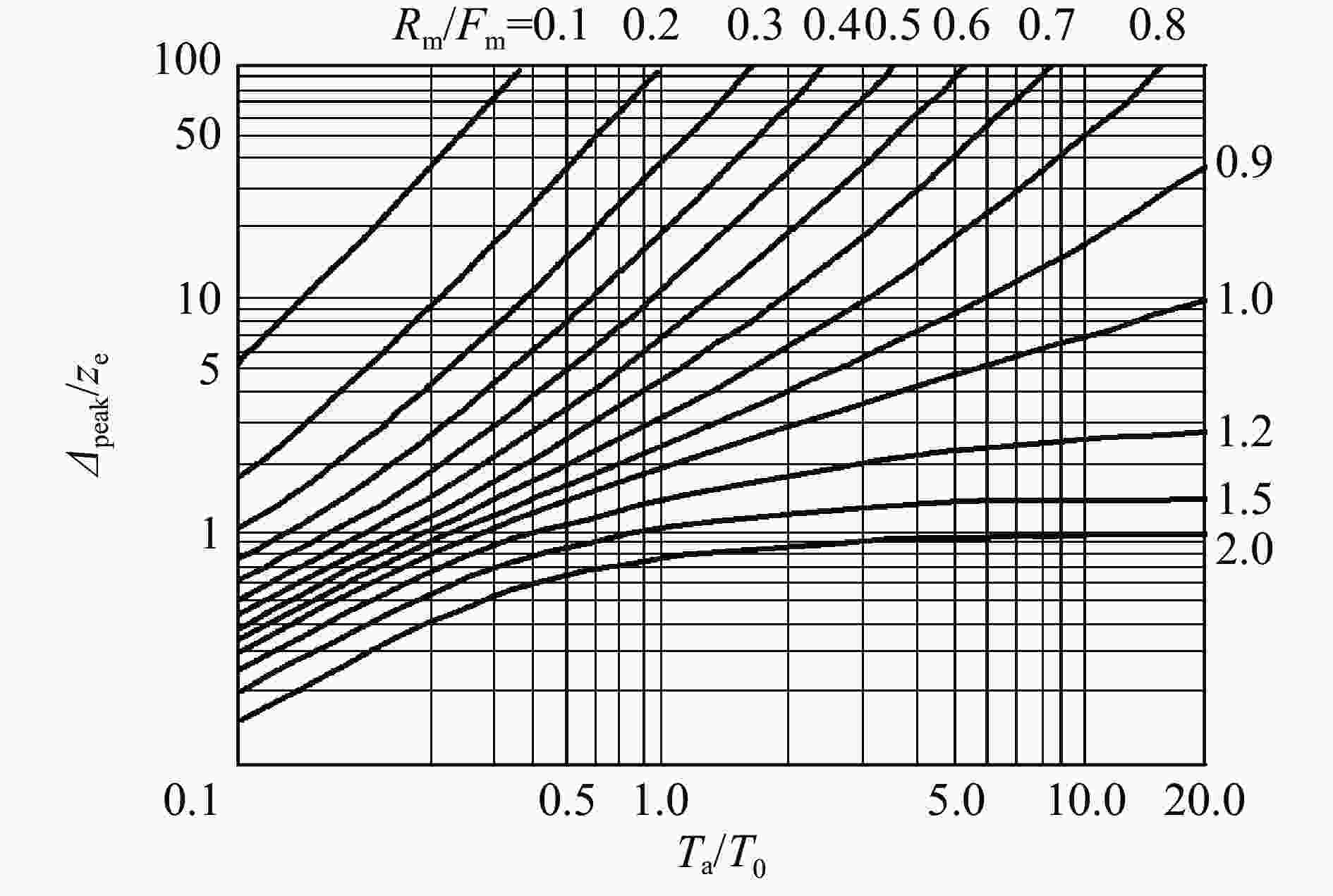

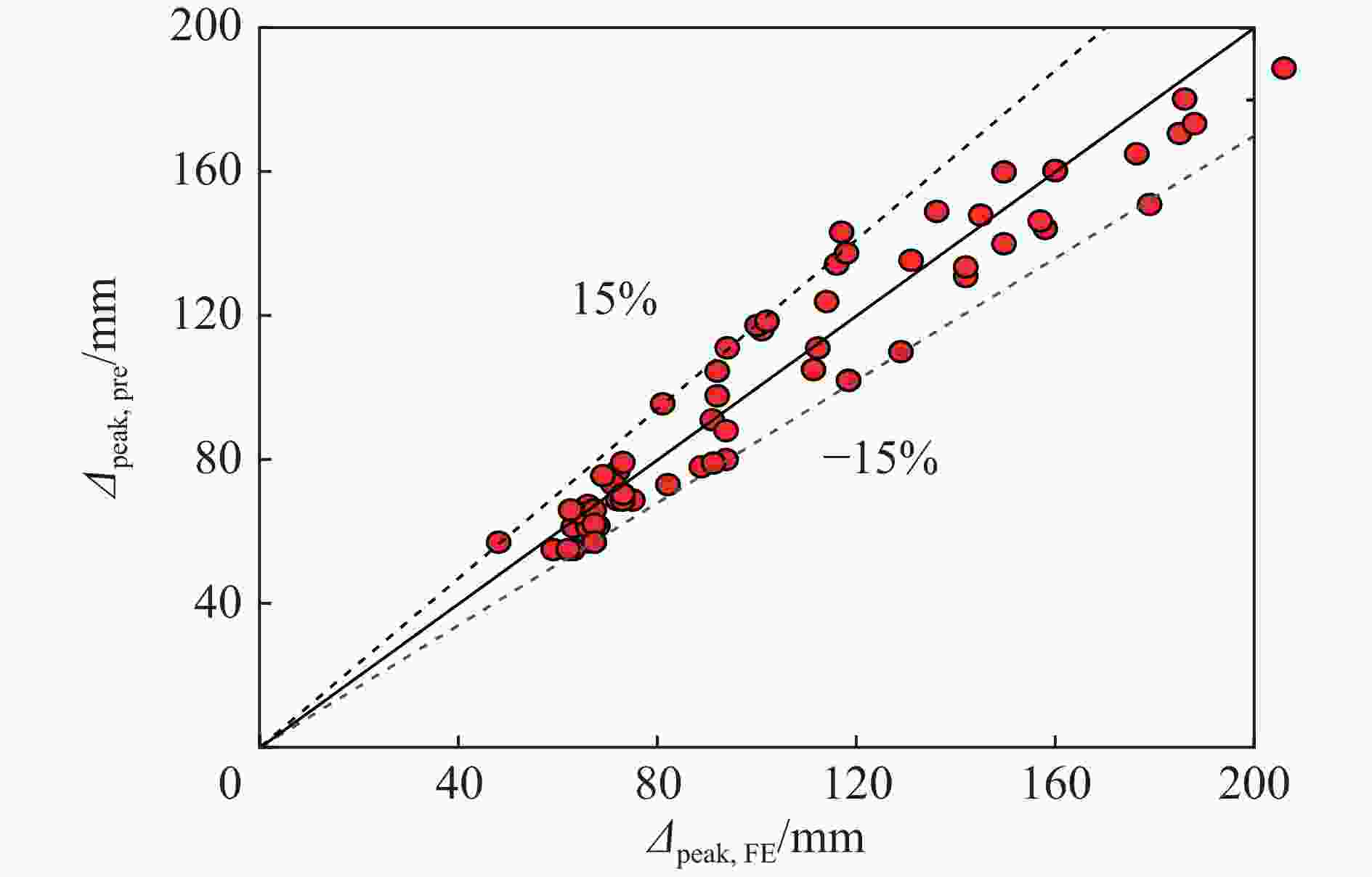

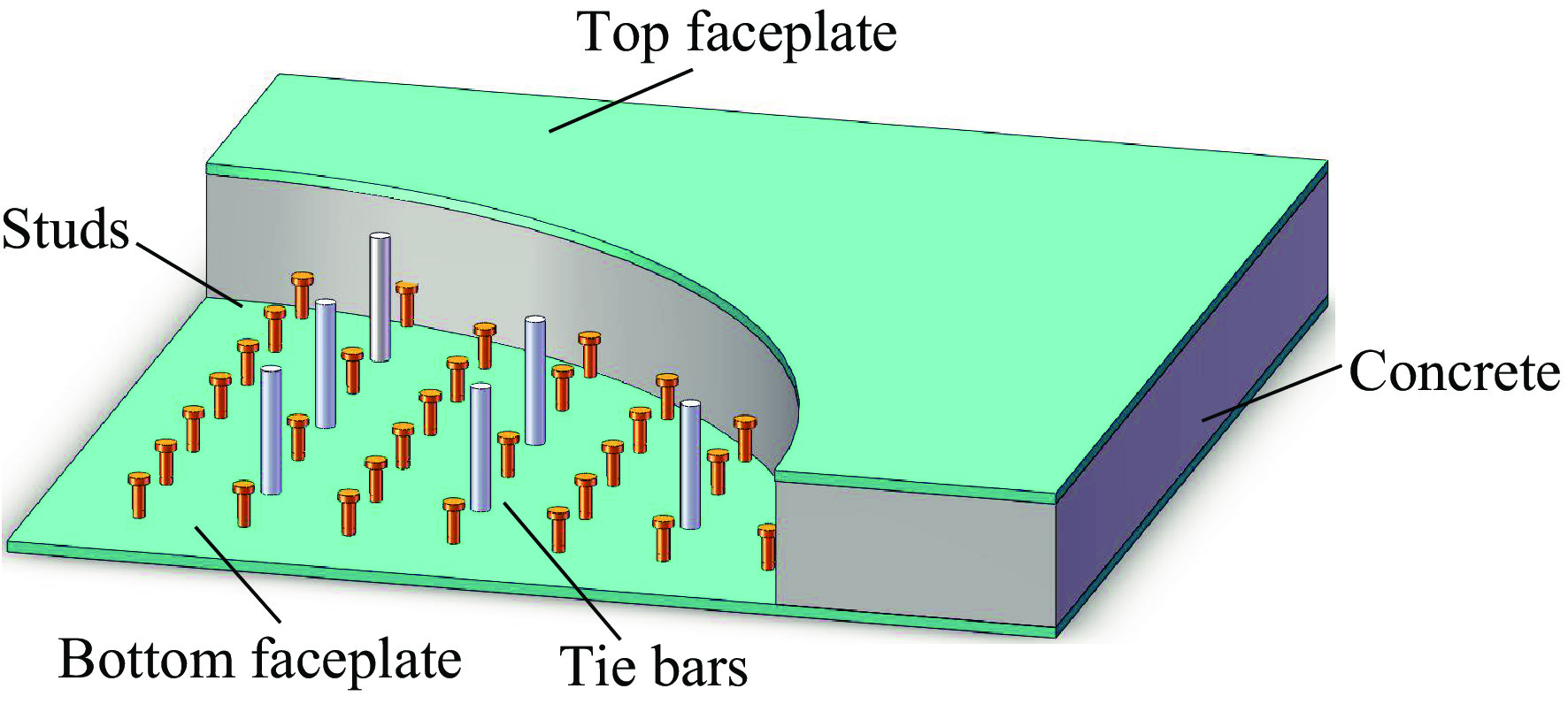

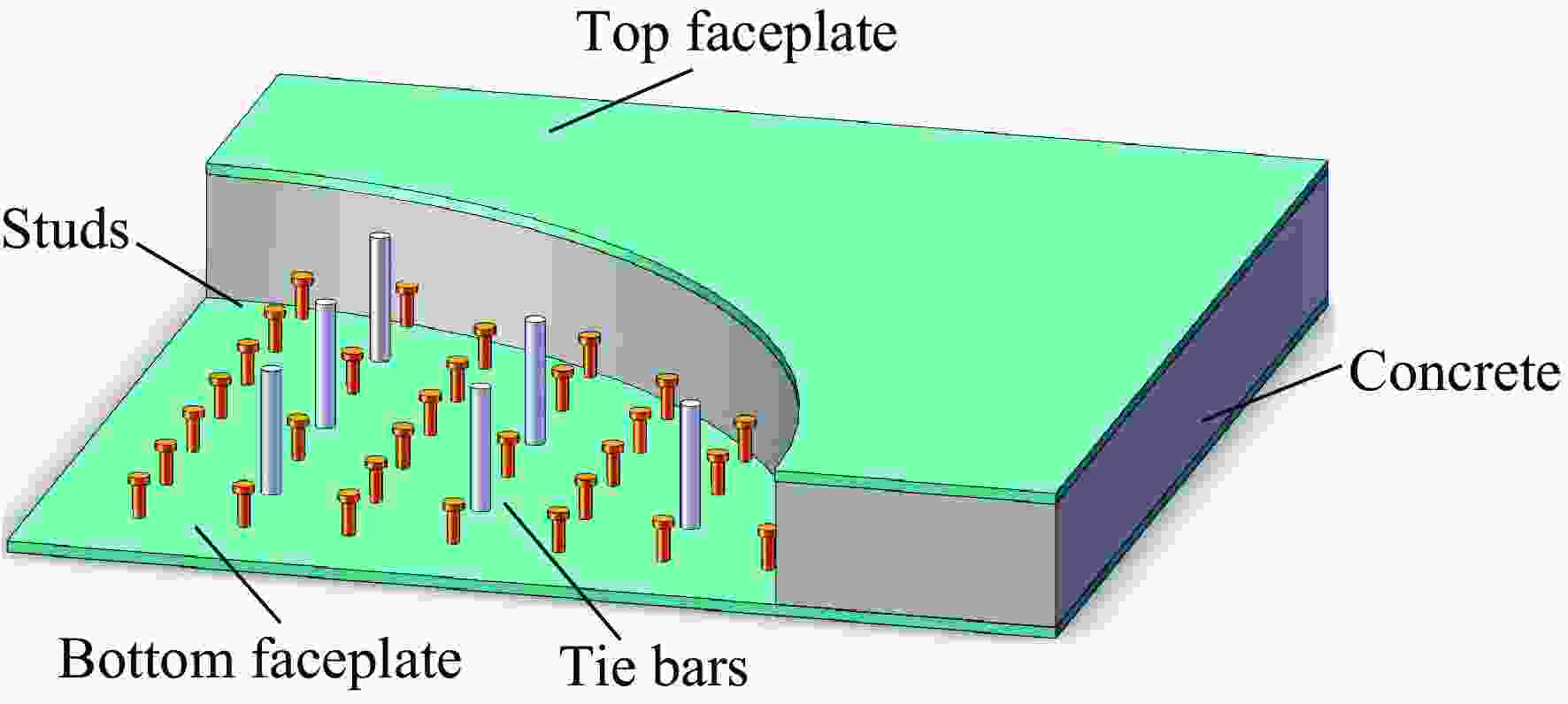

摘要: 双钢板-混凝土组合墙(steel-concrete-steel composite wall,SCS墙)已在超高层建筑、核电站等重要工程中得到应用,火灾与爆炸通常同时发生,而高温会显著降低钢材和混凝土的力学性能,从而导致结构构件的抗爆性能严重退化。为此,采用ABAQUS有限元软件,建立了120个火灾-爆炸耦合作用下SCS墙分析模型。首先,基于已有的火灾下耐火极限试验和常温下爆炸试验对有限元模型进行了验证;其次,分析了火灾-爆炸耦合作用下SCS墙的工作机理,重点研究了受火时间、爆炸当量、含钢率、材料强度、钢筋连接间距与轴压比对抗爆性能的影响;最后,基于等效单自由度模型提出了火灾-爆炸耦合作用下SCS墙跨中最大挠度的预测公式。结果表明:SCS墙在火灾与爆炸耦合作用下主要表现为整体受弯破坏;随着受火时间的增长,受火面钢板耗能占比降低,背火面钢板的塑性变形逐渐成为墙体的主要耗能机制;受火时间、爆炸当量和钢材强度对火灾下SCS墙的抗爆性能影响明显,而混凝土强度影响较小;基于等效单自由度模型提出的计算公式可较好预测火灾与爆炸耦合作用下SCS墙的跨中最大挠度。Abstract: Steel-concrete-steel composite (SCS) wall has been applied in high-rise buildings and nuclear power plants. Its performance under accidental and extreme loads during the whole life cycle deserves attention. Considering that fires and explosions often occur simultaneously, and that the mechanical properties of steel and concrete are deteriorated significantly at high temperatures, this leads to serious degradation of blast resistance of structural members. In this context, a total of 120 finite element (FE) models of SCS walls under combined fire and explosion were established using ABAQUS software. First, the FE models were verified based on existing fire resistance tests and explosion tests at room temperature on SCS walls. Then, the blast resistance mechanism of SCS walls was analyzed, and the influences of key parameters, including fire duration, explosion charge, steel plate ratio, material strength, tie bars spacing and axial compression ratio, on the explosion resistance were investigated. Finally, based on the single-degree of freedom method, the formulas were proposed to predict the maximum deformation of SCS walls under combined fire exposure and explosion. The results show that SCS walls primarily exhibit overall bending failure under coupled fire exposure and explosion. With the increase of fire duration, the contribution of the steel plate on the fire-exposed side to the energy dissipation decreases, and the plastic deformation of the steel plate on the non-fire-exposed side gradually becomes the main energy dissipation component. Fire duration, explosion charge and steel strength significantly affect the blast resistance of SCS walls under fire conditions. When exposed to fire for 90 minutes, the maximum mid-span deformation decreases by approximately 22%, as the steel yield strength increases from 235 to 460 MPa. However, the influence of the concrete strength is minor. The maximum deformation of SCS walls can be reasonably predicted by the proposed formulas based on the single-degree of freedom method under coupled fire exposure and explosion.

-

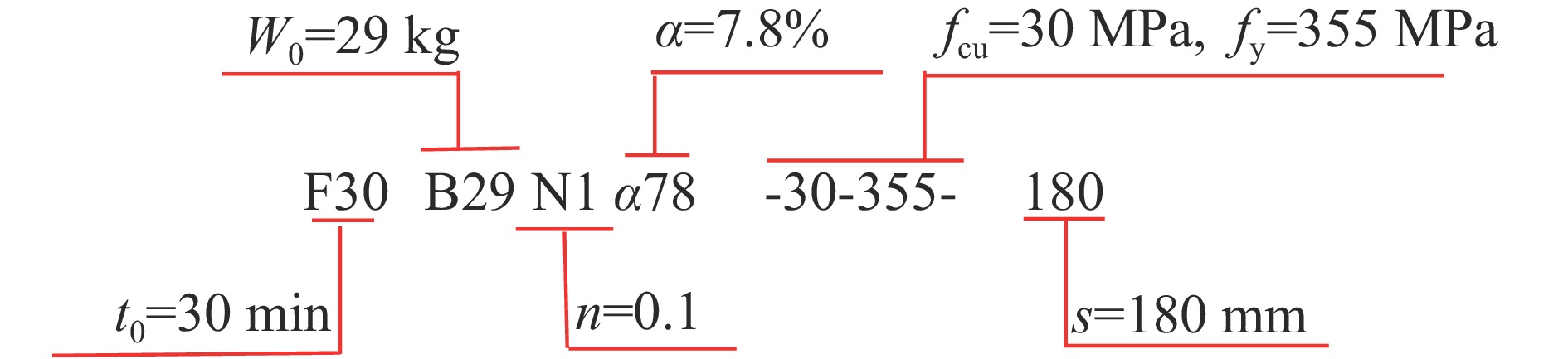

表 1 SCS墙参数

Table 1. SCS walls parameters

研究内容 t0/min W0/kg R/m Z/(m·kg−1/3) n α/% 钢板厚度/mm fy/MPa fcu/MPa s/mm 机理分析 0/30/60/90 29 2 0.65 0.1 7.8 3.5 355 30 180 受火时间 0/15/30/45/60/75/90 29 2 0.65 0.1 7.8 3.5 235/460 30/40/50 180 爆炸当量 0/30/60/90 23/29/37 2 0.70/0.65/0.60 0.1 7.8 3.5 355 30 180 轴压比 0/30/60/90 29 2 0.65 0.1/0.2/0.3 7.8 3.5 355 30 180 材料强度 0/30/60/90 29 2 0.65 0.1 7.8 3.5 235/355/460 30/40/50 180 含钢率 0/30/60/90 29 2 0.65 0.1 4.4/6.7/7.8 2.0/3.0/3.5 355 30 180 对拉钢筋间距 0/30/60/90 29 2 0.65 0.1 7.8 3.5 355 30 140/180/220 -

[1] 赵唯以, 王琳, 郭全全, 等. 双钢板混凝土组合结构抗冲击性能的研究进展 [J]. 钢结构(中英文), 2020, 35(3): 26–36. DOI: 10.13206/j.gjgS19121501.ZHAO W Y, WANG L, GUO Q Q, et al. Research advances of impact resistance of steel-concrete composite structures [J]. Steel Construction, 2020, 35(3): 26–36. DOI: 10.13206/j.gjgS19121501. [2] YU J, LIANG S L, REN Z P, et al. Structural behavior of steel-concrete-steel and steel-ultra-high-performance-concrete-steel composite panels subjected to near-field blast load [J]. Journal of Constructional Steel Research, 2023, 210: 108108. DOI: 10.1016/j.jcsr.2023.108108. [3] 赵春风, 张利, 李晓杰. 近场爆炸下波纹双钢板混凝土组合墙板的损伤破坏及抗爆性能 [J]. 高压物理学报, 2024, 38(1): 014102. DOI: 10.11858/gywlxb.20230727.ZHAO C F, ZHANG L, LI X J. Damage failure and anti-blast performance of concrete-infilled double steel corrugated-plate wall under near field explosion [J]. Chinese Journal of High Pressure Physics, 2024, 38(1): 014102. DOI: 10.11858/gywlxb.20230727. [4] WEI F, FANG C, WU B. Fire resistance of concrete-filled steel plate composite (CFSPC) walls [J]. Fire Safety Journal, 2017, 88: 26–39. DOI: 10.1016/j.firesaf.2016.12.008. [5] RUAN Z, CHEN L, FANG Q. Numerical investigation into dynamic responses of RC columns subjected for fire and blast [J]. Journal of Loss Prevention in the Process Industries, 2015, 34: 10–21. DOI: 10.1016/j.jlp.2015.01.009. [6] 胡文伟, 王蕊, 赵晖, 等. 考虑高温影响的钢管混凝土柱抗爆性能研究 [J]. 爆炸与冲击, 2021, 41(11): 113102. DOI: 10.11883/bzycj-2020-0444.HU W W, WANG R, ZHAO H, et al. Study on explosion-resistance performance of concrete-filled steel tubular columns considering the influence of elevated temperatures [J]. Explosion and Shock Waves, 2021, 41(11): 113102. DOI: 10.11883/bzycj-2020-0444. [7] 中华人民共和国住房和城乡建设部. 钢板剪力墙技术规程: JGJ/T 380–2015 [S]. 北京: 中国建筑工业出版社, 2015.Ministry of Housing and Urban-Rural Development of the People’s Republic of China. Technical specification for steel plate shear walls: JGJ/T 380–2015 [S]. Beijing: China Architecture & Building Press, 2015. [8] 中华人民共和国住房和城乡建设部, 国家市场监督管理总局. 核电站钢板混凝土结构技术标准: GB/T 51340–2018 [S]. 北京: 中国计划出版社, 2018.Ministry of Housing and Urban-Rural Development of the People's Republic of China, State Administration for Market Regulation. Technical standard for steel plate concrete structures of nuclear power plants: GB/T 51340–2018 [S]. Beijing: China Planning Press, 2018. [9] 张帝, 杨军, 曾丹, 等. 钢筋混凝土排架结构的抗爆破坏等级 [J]. 爆炸与冲击, 2020, 40(12): 121405. DOI: 10.11883/bzycj-2020-0012.ZHANG D, YANG J, ZENG D, et al. Damage grades of reinforced concrete bent structures against blast [J]. Explosion and Shock Waves, 2020, 40(12): 121405. DOI: 10.11883/bzycj-2020-0012. [10] LIE T T, KODUR V K R. Fire resistance of steel columns filled with bar-reinforced concrete [J]. Journal of Structural Engineering, 1996, 122(1): 30–36. DOI: 10.1061/(ASCE)0733-9445(1996)122:1(30). [11] Design of steel structures: Part 1-2: General rules-structural fire design: EN 1993-1-2: 2005 [S]. Brussels: European Committee for Standardization, 2004. [12] HONG S, VARMA A H. Analytical modeling of the standard fire behavior of loaded CFT columns [J]. Journal of Constructional Steel Research, 2009, 65(1): 54–69. DOI: 10.1016/j.jcsr.2008.04.008. [13] CHEN H, LIEW J Y. Explosion and fire analysis of steel frames using mixed element approach [J]. Journal of Engineering Mechanics, 2005, 131(6): 606–616. DOI: 10.1061/(ASCE)0733-9399(2005)131:6(606). [14] CHEN L, FANG Q, JIANG X Q, et al. Combined effects of high temperature and high strain rate on normal weight concrete [J]. International Journal of Impact Engineering, 2015, 86: 40–56. DOI: 10.1016/j.ijimpeng.2015.07.002. [15] 王泽芳. 双钢板-超高性能混凝土组合板冲切性能研究 [D]. 哈尔滨: 哈尔滨工业大学, 2019.WANG Z F. Punching shear performance of steel-ultra-high performance concrete-steel sandwich slabs [D]. Harbin: Harbin Institute of Technology, 2019. [16] 韩林海. 钢管混凝土结构理论与实践[M]. 北京: 科学出版社, 2016.HAN L H. Concrete filled steel tubular structures theory and practice [M]. Beijing: Science Press, 2016. [17] 韦芳芳, 杜金娥, 胡雪峰, 等. 单面受火双钢板-混凝土组合剪力墙的耐火性能试验研究 [J]. 东南大学学报(自然科学版), 2016, 46(3): 518–522. DOI: 10.3969/j.issn.1001-0505.2016.03.011.WEI F F, DU J E, HU X F, et al. Experimental research on fire performance of concrete filled double-steel-plate composite wall exposed to one-side fire [J]. Journal of Southeast University (Natural Science Edition), 2016, 46(3): 518–522. DOI: 10.3969/j.issn.1001-0505.2016.03.011. [18] WANG H W, WU C Q, ZHANG F R, et al. Experimental study of large-sized concrete filled steel tube columns under blast load [J]. Construction and Building Materials, 2017, 134: 131–141. DOI: 10.1016/j.conbuildmat.2016.12.096. [19] 李国强, 瞿海雁, 杨涛春, 等. 钢管混凝土柱抗爆性能试验研究 [J]. 建筑结构学报, 2013, 34(12): 69–76. DOI: 10.14006/j.jzjgxb.2013.12.010.LI G Q, QU H Y, YANG T C, et al. Experimental study of concrete-filled steel tubular columns under blast loading [J]. Journal of Building Structures, 2013, 34(12): 69–76. DOI: 10.14006/j.jzjgxb.2013.12.010. [20] 段泊池, 杨冬冬, 刘发起, 等. 带有防火保护的圆钢管约束钢筋混凝土柱抗火性能分析与设计 [J]. 工程力学, 2024, 41(6): 118–129. DOI: 10.6052/j.issn.1000-4750.2022.05.0470.DUAN B C, YANG D D, LIU F Q, et al. Analysis and design on fire performance of circular steel tube confined reinforced concrete columns with fire protection [J]. Engineering Mechanics, 2024, 41(6): 118–129. DOI: 10.6052/j.issn.1000-4750.2022.05.0470. [21] 师燕超, 张浩, 李忠献. 钢筋混凝土梁式构件抗爆分析的改进等效单自由度方法 [J]. 建筑结构学报, 2019, 40(10): 8–16. DOI: 10.14006/j.jzjgxb.2019.0096.SHI Y C, ZHANG H, LI Z X. Improved equivalent single degree of freedom method for blast analysis of RC beams [J]. Journal of Building Structures, 2019, 40(10): 8–16. DOI: 10.14006/j.jzjgxb.2019.0096. [22] BIGGS J M. Introduction to structural dynamics [M]. New York: McGraw-Hill, 1964. [23] HENRYCH J. The dynamics of explosion and its use [M]. Amsterdam: Elsevier Scientific Publishing Company, 1979. -

下载:

下载: