| [1] |

于潇, 陈力, 方秦. 珊瑚砂中应力波衰减规律的实验研究 [J]. 岩石力学与工程学报, 2018, 37(6): 1520–1529. DOI: 10.13722/j.cnki.jrme.2018.0147.YU X, CHEN L, FANG Q. Experimental study on the attenuation of stress wave in coral sand [J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(6): 1520–1529. DOI: 10.13722/j.cnki.jrme.2018.0147.

|

| [2] |

杨阳, 张春会, 崔恩杰, 等. 单颗粒与单粒径钙质砂破碎特性及其关联关系研究 [J]. 岩石力学与工程学报, 2022, 41(S2): 3410–3418. DOI: 10.13722/j.cnki.jrme.2021.1148.YANG Y, ZHANG C H, CUI E J, et al. The crushing characteristics of single particle and uniformly-graded sample of carbonate sand and their association relationship [J]. Chinese Journal of Rock Mechanics and Engineering, 2022, 41(S2): 3410–3418. DOI: 10.13722/j.cnki.jrme.2021.1148.

|

| [3] |

周辉, 任辉启, 吴祥云, 等. 成层式防护结构中分散层研究综述 [J]. 爆炸与冲击, 2022, 42(11): 111101. DOI: 10.11883/bzycj-2022-0280.ZHOU H, REN H Q, WU X Y, et al. A review of sacrificial claddings in multilayer protective structure [J]. Explosion and Shock Waves, 2022, 42(11): 111101. DOI: 10.11883/bzycj-2022-0280.

|

| [4] |

ZHAO D B, YI W J, KUNNATH S K. Numerical simulation and shear resistance of reinforced concrete beams under impact [J]. Engineering Structures, 2018, 166: 387–401. DOI: 10.1016/j.engstruct.2018.03.072.

|

| [5] |

LIN Y, YAO W, JAFARI M, et al. Quantification of the dynamic compressive response of two Ottawa sands [J]. Experimental Mechanics, 2017, 57(9): 1371–1382. DOI: 10.1007/s11340-017-0304-0.

|

| [6] |

SONG B, CHEN W N, LUK V. Impact compressive response of dry sand [J]. Mechanics of Materials, 2009, 41(6): 777–785. DOI: 10.1016/j.mechmat.2009.01.003.

|

| [7] |

吴建利, 胡卸文, 梅雪峰, 等. 落石冲击混凝土板与缓冲层组合结构的动力响应 [J]. 水文地质工程地质, 2021, 48(1): 78–87. DOI: 10.16030/j.cnki.issn.1000-3665.202004029.WU J L, HU X W, MEI X F, et al. Dynamic response of RC slab with cushion layer composed of sandy soil to rockfall impact [J]. Hydrogeology & Engineering Geology, 2021, 48(1): 78–87. DOI: 10.16030/j.cnki.issn.1000-3665.202004029.

|

| [8] |

吕华, 王仲琦. 密实填充砂墙对冲击波消波吸能的试验研究 [J]. 中国安全科学学报, 2016, 26(10): 64–69. DOI: 10.16265/j.cnki.issn1003-3033.2016.10.012.LYU H, WANG Z Q. Experimental study of shock attenuation by dense packed sand wall [J]. China Safety Science Journal, 2016, 26(10): 64–69. DOI: 10.16265/j.cnki.issn1003-3033.2016.10.012.

|

| [9] |

蔡改贫, 郭进山, 夏刘洋. 基于Weibull分布的Bond冲击破碎粒度分布特征 [J]. 金属矿山, 2016, 45(4): 118–121. DOI: 10.3969/j.issn.1001-1250.2016.04.024.CAI G P, GUO J S, XIA L Y. Particle size distribution characteristics of Bond impact based on Weibull distribution [J]. Metal Mine, 2016, 45(4): 118–121. DOI: 10.3969/j.issn.1001-1250.2016.04.024.

|

| [10] |

潘亚豪, 宗周红, 钱海敏, 等. 钙质砂介质中爆炸波传播规律的试验研究 [J]. 爆炸与冲击, 2023, 43(5): 053201. DOI: 10.11883/bzycj-2022-0117.PAN Y H, ZONG Z H, QIAN H M, et al. Experimental study on blast wave propagation in calcareous sand [J]. Explosion and Shock Waves, 2023, 43(5): 053201. DOI: 10.11883/bzycj-2022-0117.

|

| [11] |

YU X, CHEN L, FANG Q, et al. Determination of attenuation effects of coral sand on the propagation of impact-induced stress wave [J]. International Journal of Impact Engineering, 2019, 125: 63–82. DOI: 10.1016/j.ijimpeng.2018.11.004.

|

| [12] |

董凯, 任辉启, 阮文俊, 等. 爆炸冲击下珊瑚砂动态本构模型 [J]. 爆炸与冲击, 2021, 41(4): 043101. DOI: 10.11883/bzycj-2020-0172.DONG K, REN H Q, RUAN W J, et al. Dynamic constitutive model of coral sand under blast loading [J]. Explosion and Shock Waves, 2021, 41(4): 043101. DOI: 10.11883/bzycj-2020-0172.

|

| [13] |

LUO H Y, COOPER W L, LU H B. Effects of particle size and moisture on the compressive behavior of dense Eglin sand under confinement at high strain rates [J]. International Journal of Impact Engineering, 2014, 65: 40–55. DOI: 10.1016/j.ijimpeng.2013.11.001.

|

| [14] |

OUYANG H R, DAI G L, QIN W, et al. Dynamic behaviors of calcareous sand under repeated one-dimensional impacts [J]. Soil Dynamics and Earthquake Engineering, 2021, 150: 106891. DOI: 10.1016/J.SOILDYN.2021.106891.

|

| [15] |

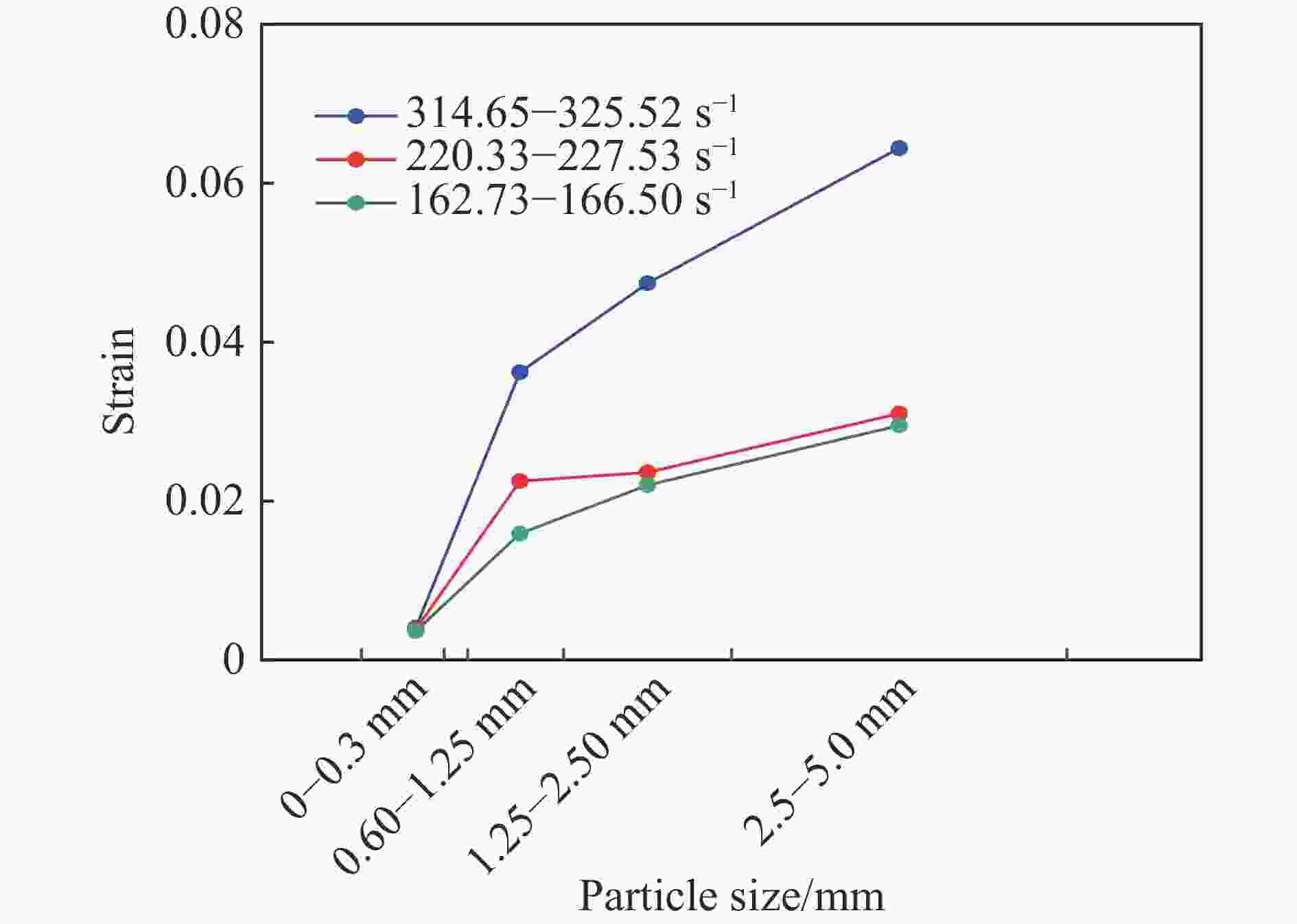

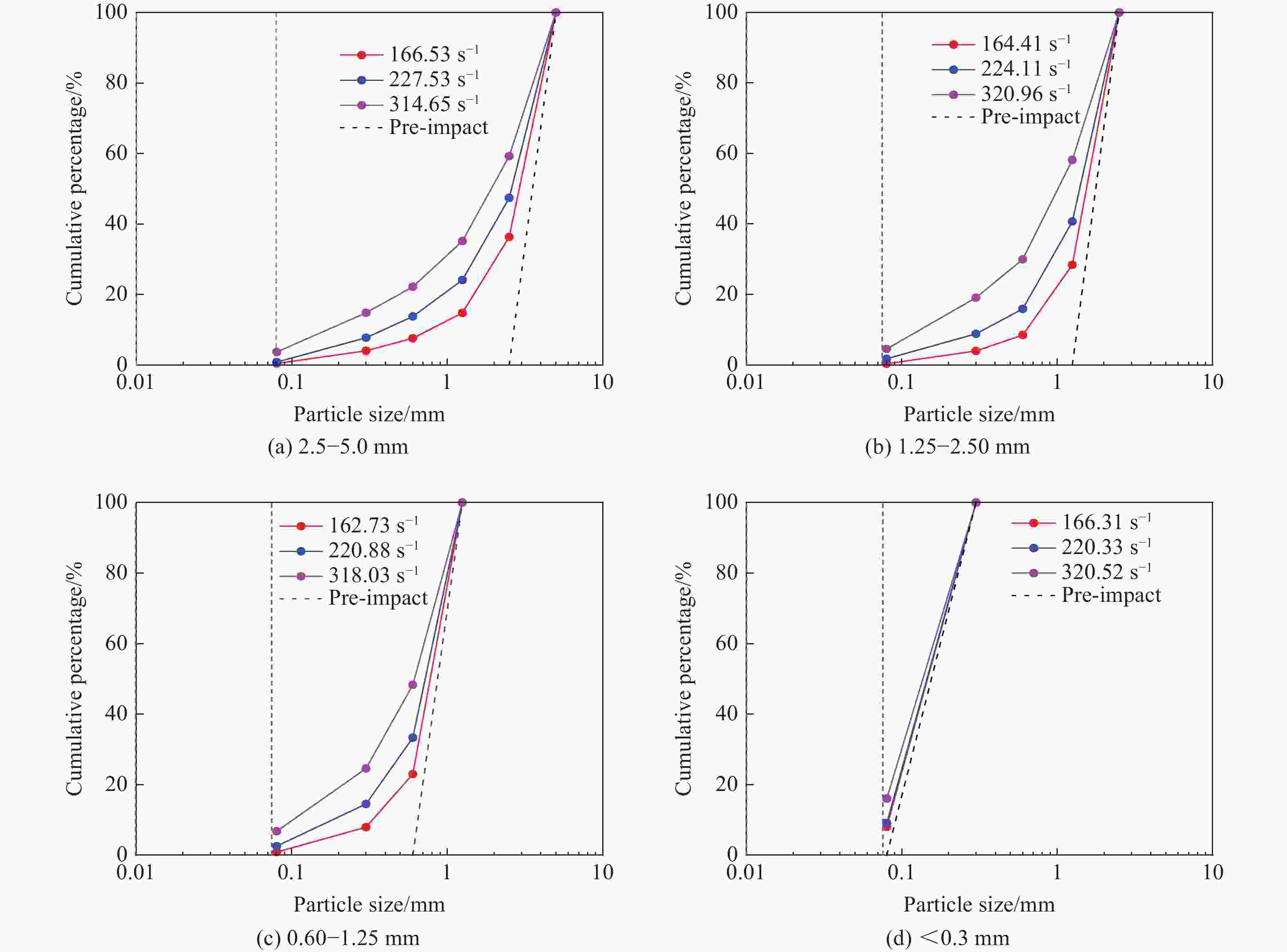

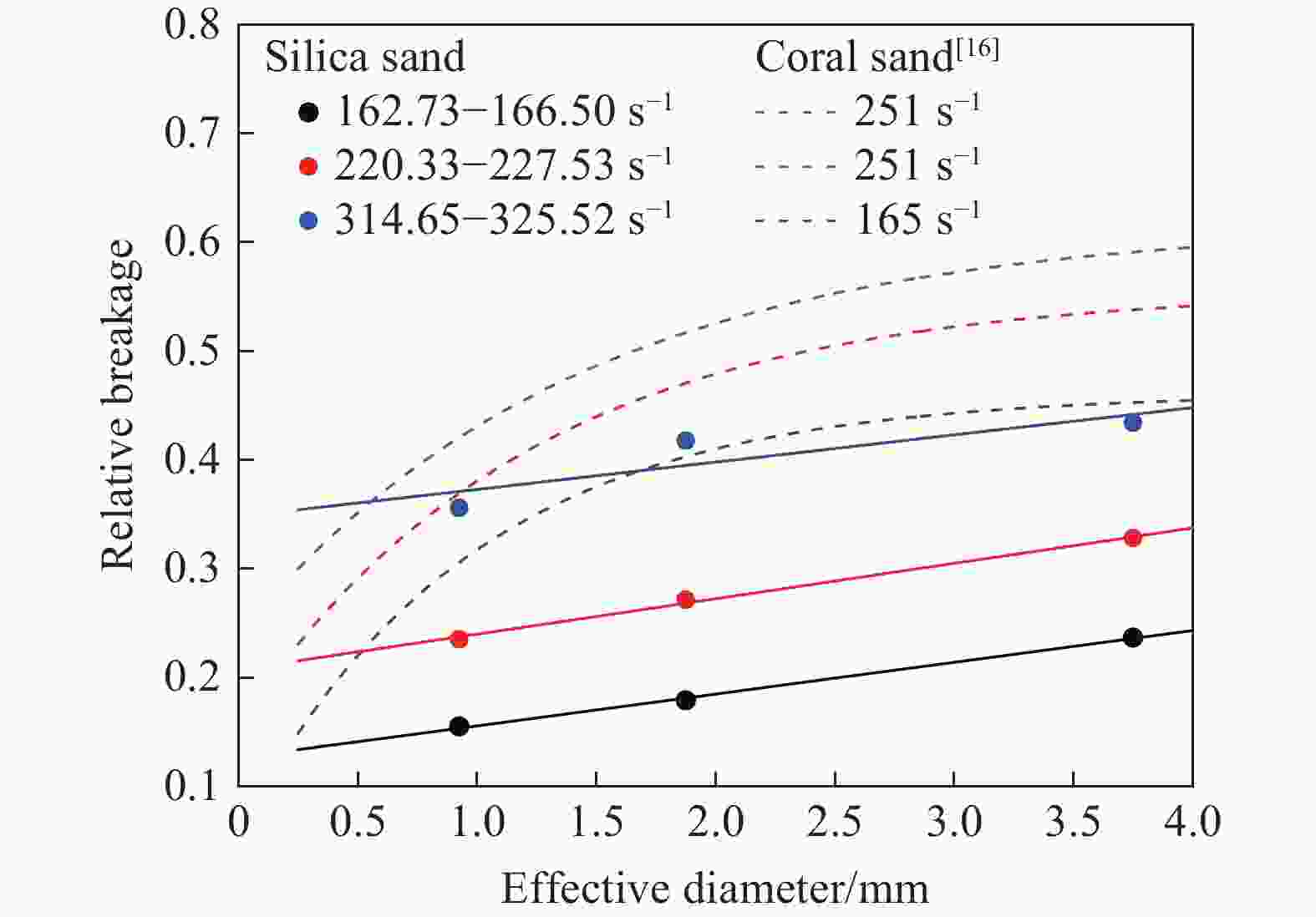

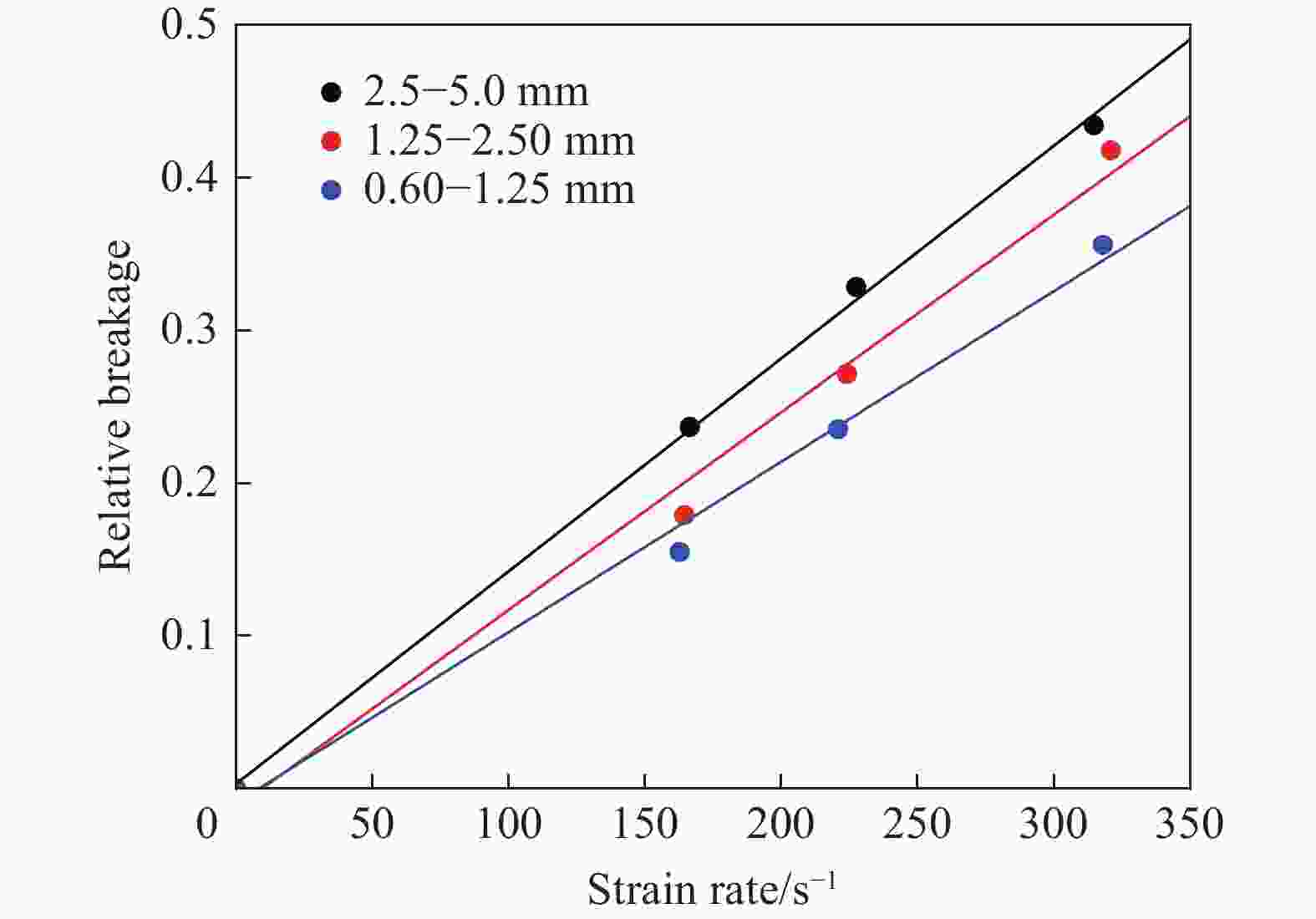

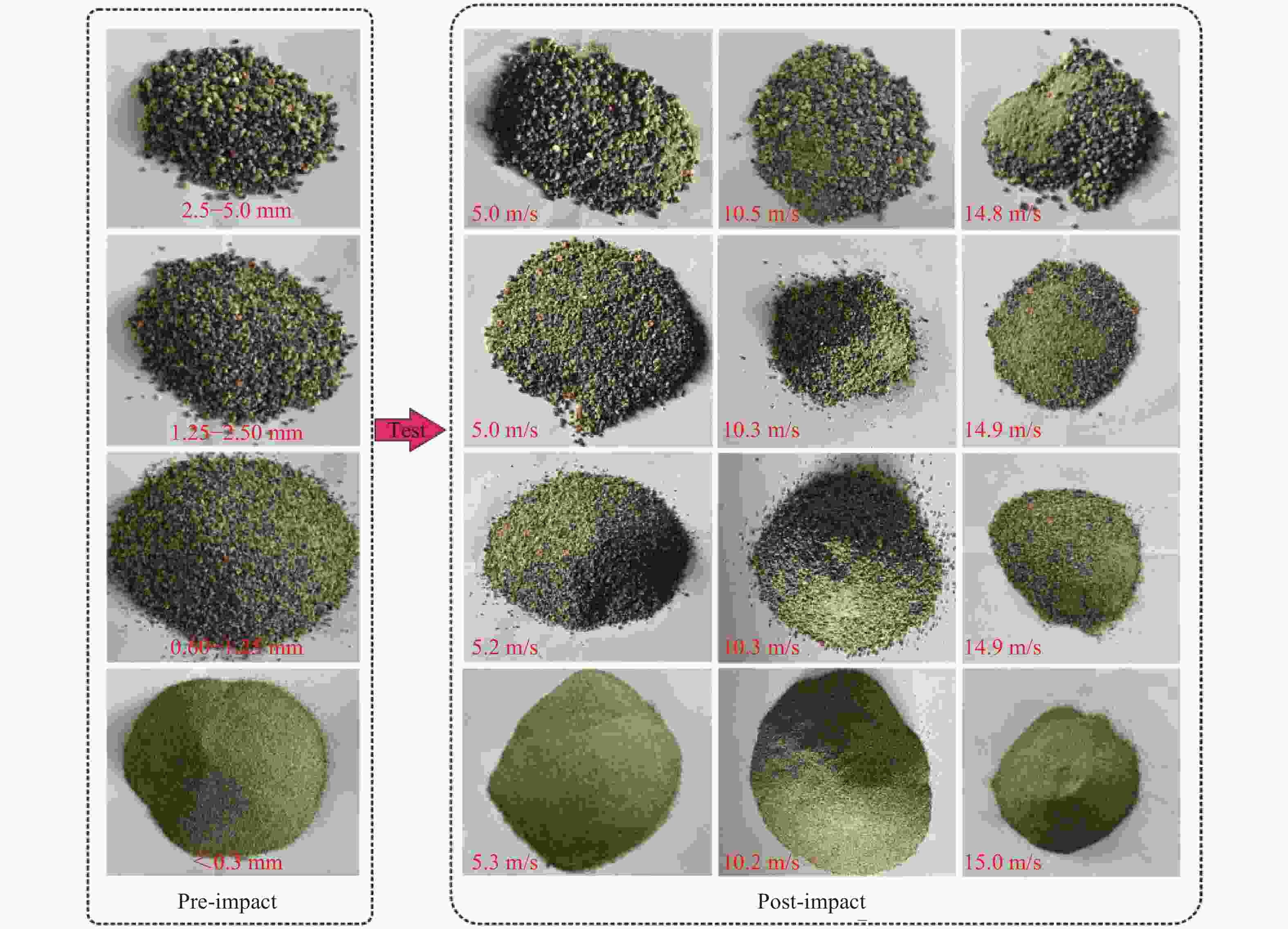

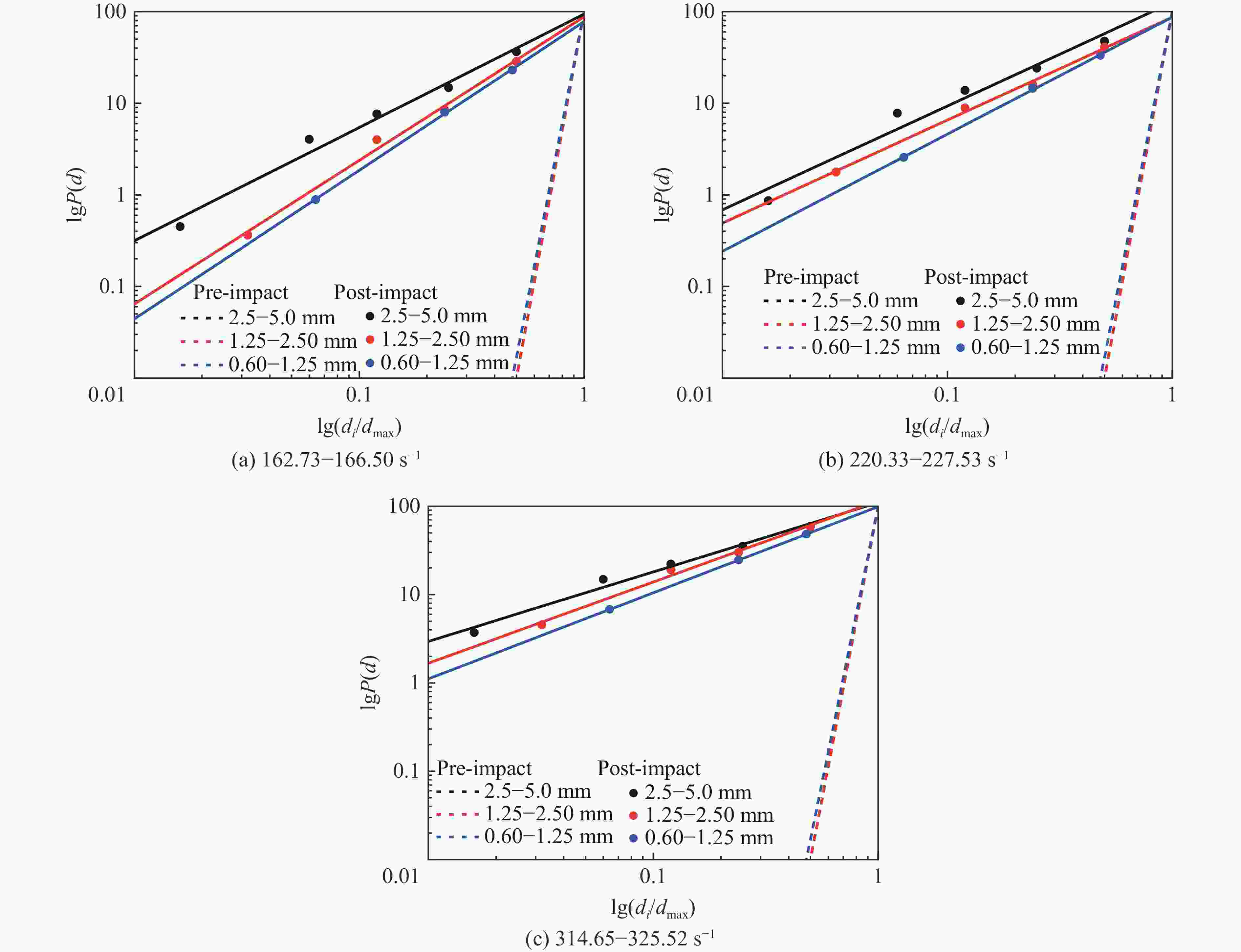

LV Y R, WANG Y, ZUO D J. Effects of particle size on dynamic constitutive relation and energy absorption of calcareous sand [J]. Powder Technology, 2019, 356: 21–30. DOI: 10.1016/j.powtec.2019.07.088.

|

| [16] |

XU D S, SHEN G, LIU Q M, et al. Dynamic mechanical response and particle breakage characteristics of calcareous sand [J]. Soil Dynamics and Earthquake Engineering, 2024, 181: 108653. DOI: 10.1016/j.soildyn.2024.108653.

|

| [17] |

XIAO Y, YUAN Z X, CHU J, et al. Particle breakage and energy dissipation of carbonate sands under quasi-static and dynamic compression [J]. Acta Geotechnica, 2019, 14(6): 1741–1755. DOI: 10.1007/s11440-019-00790-1.

|

| [18] |

吕亚茹, 吴琳, 王媛, 等. 玻璃球宏细观冲击特性的SHPB试验和耦合数值模拟研究 [J]. 工程力学, 2023, 40(6): 245–256. DOI: 10.6052/j.issn.1000-4750.2021.11.0857.LYU Y R, WU L WANG Y, et al. Macro and micro quantitative study on impact behavior of glass beadsby SHPB tests and FEM-DEM coupling analysis [J]. Engineering Mechanics, 2023, 40(6): 245–256. DOI: 10.6052/j.issn.1000-4750.2021.11.0857.

|

| [19] |

陈榕, 武智勇, 郝冬雪, 等. 高应力下石英砂三轴剪切颗粒破碎演化规律及影响 [J]. 岩土工程学报, 2023, 45(8): 1713–1722. DOI: 10.11779/CJGE20220647.CHEN R, WU Z Y, HAO D X, et al. Evolution rules and effects of particle breakage for quartz sand in triaxial shear tests under high pressures [J]. Chinese Journal of Geotechnical Engineering, 2023, 45(8): 1713–1722. DOI: 10.11779/CJGE20220647.

|

| [20] |

魏久淇, 王明洋, 邱艳宇, 等. 钙质砂动态力学特性试验研究 [J]. 振动与冲击, 2018, 37(24): 7–12. DOI: 10.13465/j.cnki.jvs.2018.24.002.WEI J Q, WANG M Y, QIU Y Y, et al. Impact compressive response of calcareous sand [J]. Journal of Vibration and Shock, 2018, 37(24): 7–12. DOI: 10.13465/j.cnki.jvs.2018.24.002.

|

| [21] |

王博, 吕果, 李江. 考虑粒径对砂土宏细观剪切性质的试验研究 [J]. 岩土工程技术, 2023, 37(5): 618–622. DOI: 10.3969/j.issn.1007-2993.2023.05.017.WANG B, LV G, LI J. Experimental study on micro-macro shear properties of sand considering particle size [J]. Geotechnical Engineering Technique, 2023, 37(5): 618–622. DOI: 10.3969/j.issn.1007-2993.2023.05.017.

|

| [22] |

孟敏强, 袁正鑫, 蒋翔. 钙质砂-石英砂单颗粒破碎-强度-尺寸效应试验研究 [J]. 中国科学: 技术科学, 2022, 52(7): 1035–1047. DOI: 10.1360/SST-2021-0241.MENG M Q, YUAN Z X, JIANG X. Experimental study of the single-particle crushing-strength-size effect of calcareous sand-quartz sand [J]. Scientia Sinica Technologica, 2022, 52(7): 1035–1047. DOI: 10.1360/SST-2021-0241.

|

| [23] |

张季如, 陈敬鑫, 王磊, 等. 三轴剪切过程中排水条件对钙质砂颗粒破碎、变形和强度特性的影响 [J]. 岩土力学, 2024, 45(2): 375–384. DOI: 10.16285/j.rsm.2023.0243.ZHANG J R, CHEN J X, WANG L, et al. Effect of drainage conditions during triaxial shearing on particle breakage, deformation, and strength properties of calcareous sand [J]. Rock and Soil Mechanics, 2024, 45(2): 375–384. DOI: 10.16285/j.rsm.2023.0243.

|

| [24] |

YU X, REN W J, ZHOU B K, et al. Experimental study on the mechanical behavior and energy absorption capacity of coral sand at high strain rates [J]. Ocean Engineering, 2024, 291: 116343. DOI: 10.1016/j.oceaneng.2023.116343.

|

| [25] |

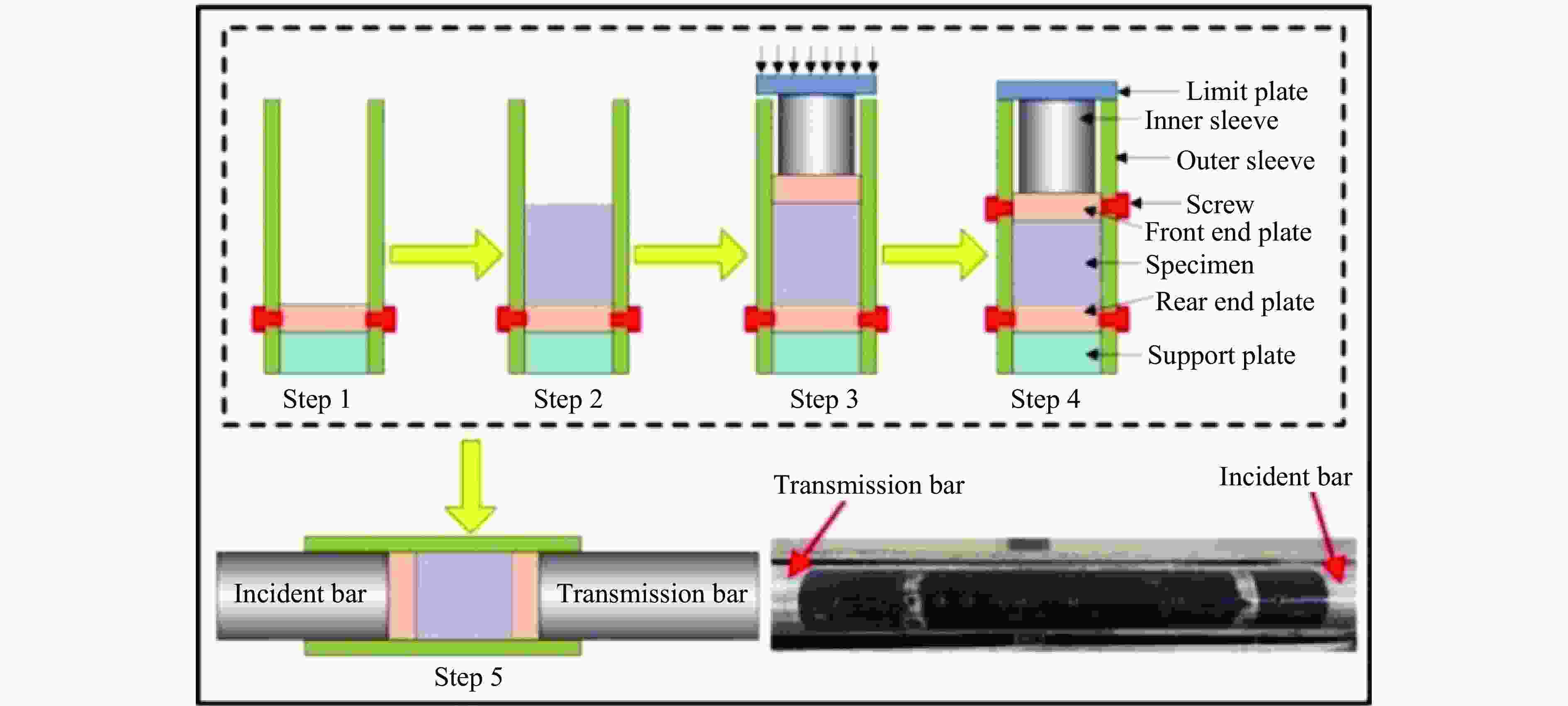

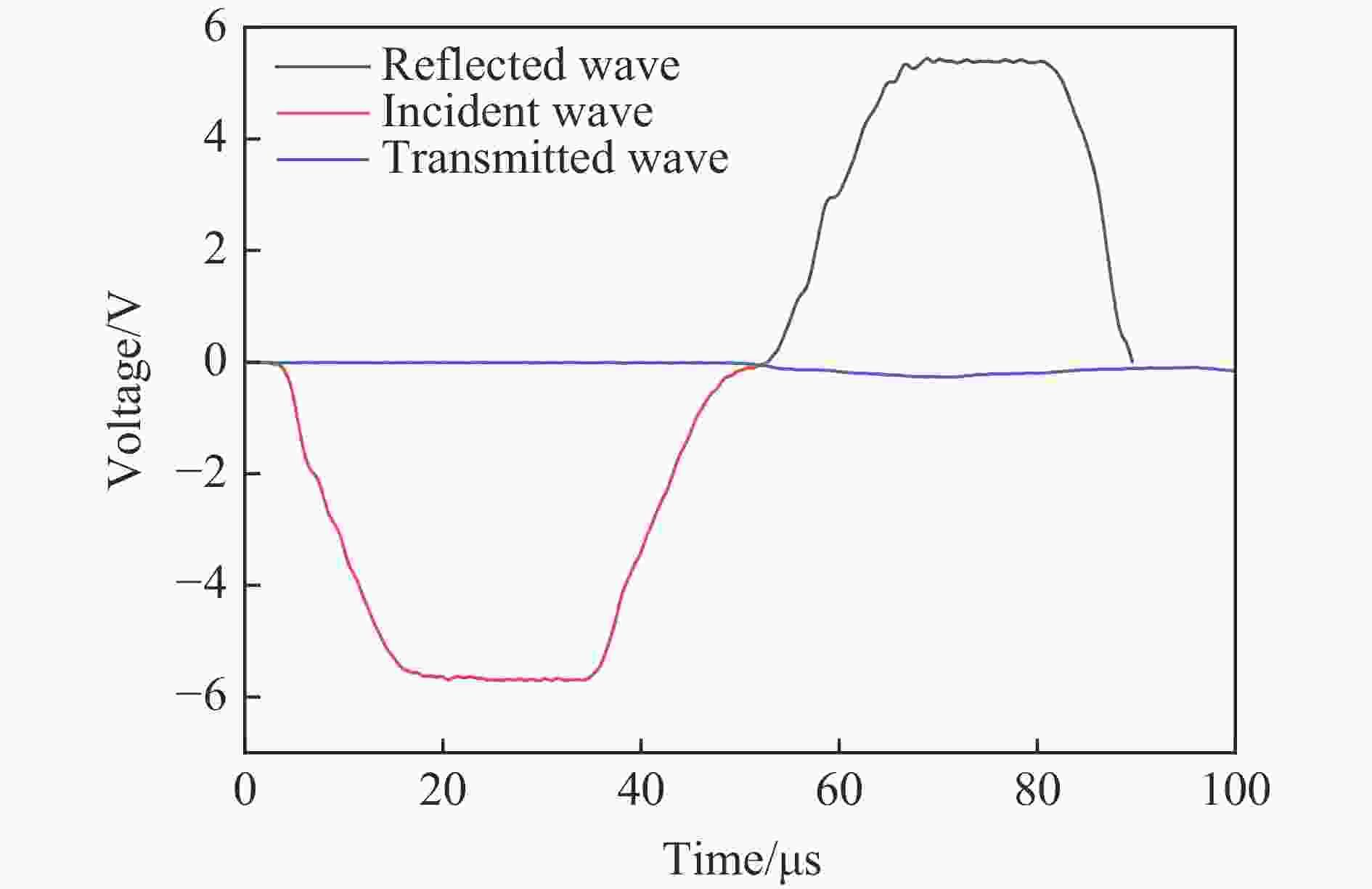

卢芳云, 陈荣, 林玉亮, 等. 霍普金森杆实验技术 [M]. 北京: 科学出版社, 2013.LU F Y, CHEN R, LIN Y L, et al. Hopkinson bar techniques [M]. Beijing: Science Press, 2013.

|

| [26] |

李胜林, 刘殿书, 李祥龙, 等. $\varnothing $ 75mm分离式霍普金森压杆试件长度效应的试验研究 [J]. 中国矿业大学学报, 2010, 39(1): 93–97.LI S L, LIU D S, LI X L, et al. The effect of specimen length in $\varnothing $ 75mm分离式霍普金森压杆试件长度效应的试验研究 [J]. 中国矿业大学学报, 2010, 39(1): 93–97.LI S L, LIU D S, LI X L, et al. The effect of specimen length in $\varnothing $ 75 mm split Hopkinson pressure bar experiment [J]. Journal of China University of Mining & Technology, 2010, 39(1): 93–97. 75 mm split Hopkinson pressure bar experiment [J]. Journal of China University of Mining & Technology, 2010, 39(1): 93–97.

|

| [27] |

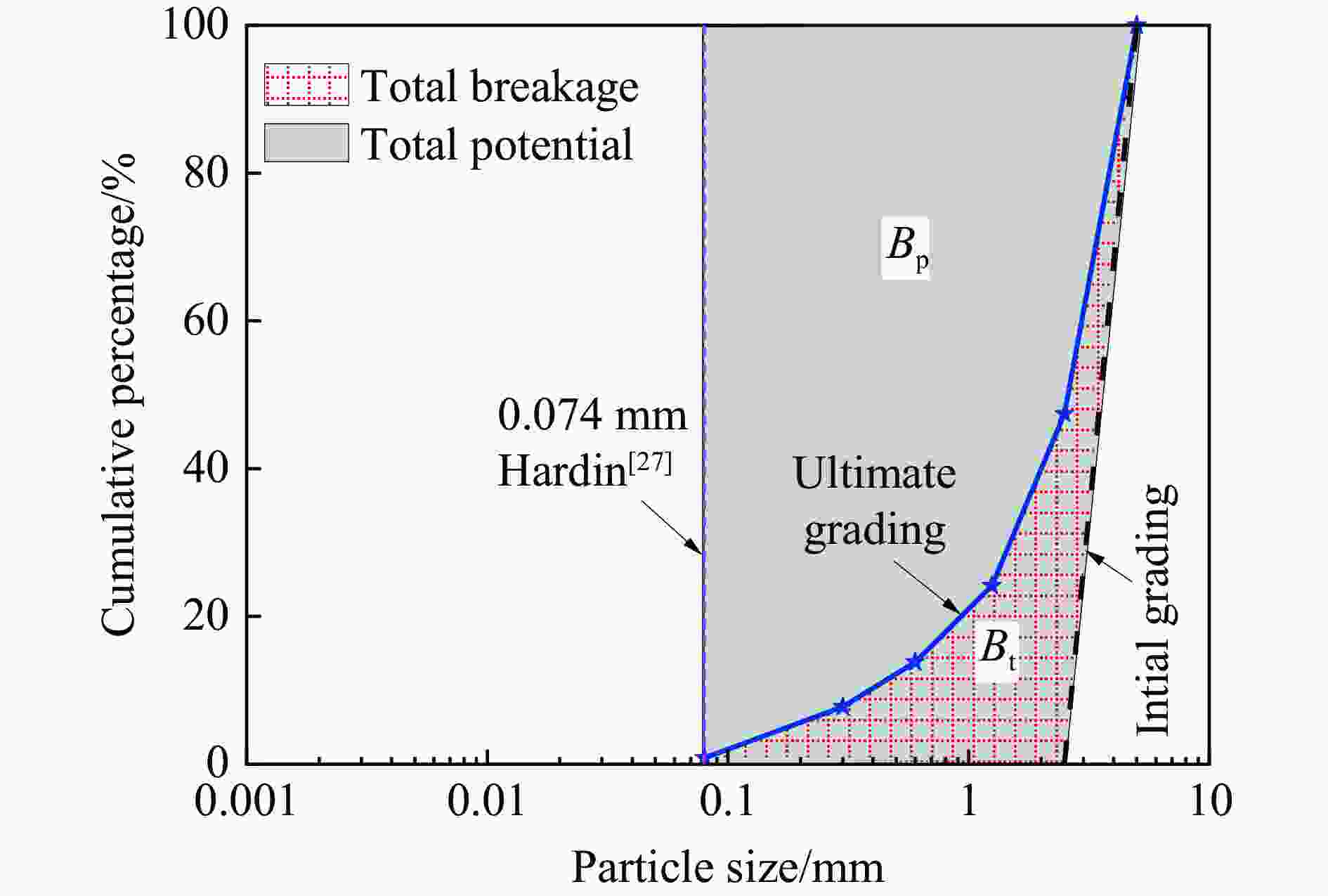

HARDIN B O. Crushing of soil particles [J]. Journal of Geotechnical Engineering, 1985, 111(10): 1177–1192. DOI: 10.1061/(ASCE)0733-9410(1985)111:10(1177.

|

| [28] |

ZHANG J M, DUAN M D, WANG D L, et al. Particle strength of calcareous sand in Nansha islands, south China sea [J]. Advances in Civil Engineering Materials, 2019, 8(1): 355–364. DOI: 10.1520/ACEM20180145.

|

| [29] |

KUANG D M, LONG Z L, GUO R Q, et al. Experimental and numerical investigation on size effect on crushing behaviors of single calcareous sand particles [J]. Marine Georesources & Geotechnology, 2021, 39(5): 543–553. DOI: 10.1080/1064119X.2020.1725194.

|

| [30] |

YANG J, LIU X. Shear wave velocity and stiffness of sand: the role of non-plastic fines [J]. Géotechnique, 2016, 66(6): 500–514. DOI: 10.1680/jgeot.15.p.205.

|

| [31] |

SHARMA S S, FAHEY M. Deformation characteristics of two cemented calcareous soils [J]. Canadian Geotechnical Journal, 2004, 41(6): 1139–1151. DOI: 10.1139/T04-066.

|

| [32] |

彭宇, 丁选明, 肖杨, 等. 基于染色标定与图像颗粒分割的钙质砂颗粒破碎特性研究 [J]. 岩土力学, 2019, 40(7): 2663–2672. DOI: 10.16285/j.rsm.2018.0689.PENG Y, DING X M, XIAO Y, et al. Study of particle breakage behaviour of calcareous sand by dyeing tracking and particle image segmentation method [J]. Rock and Soil Mechanics, 2019, 40(7): 2663–2672. DOI: 10.16285/j.rsm.2018.0689.

|

| [33] |

EINAV I. Breakage mechanics: Part Ⅰ: theory [J]. Journal of the Mechanics and Physics of Solids, 2007, 55(6): 1274–1297. DOI: 10.1016/j.jmps.2006.11.003.

|

| [34] |

PETERS J F, MUTHUSWAMY M, WIBOWO J, et al. Characterization of force chains in granular material [J]. Physical Review E, 2005, 72(4): 041307. DOI: 10.1103/PhysRevE.72.041307.

|

| [35] |

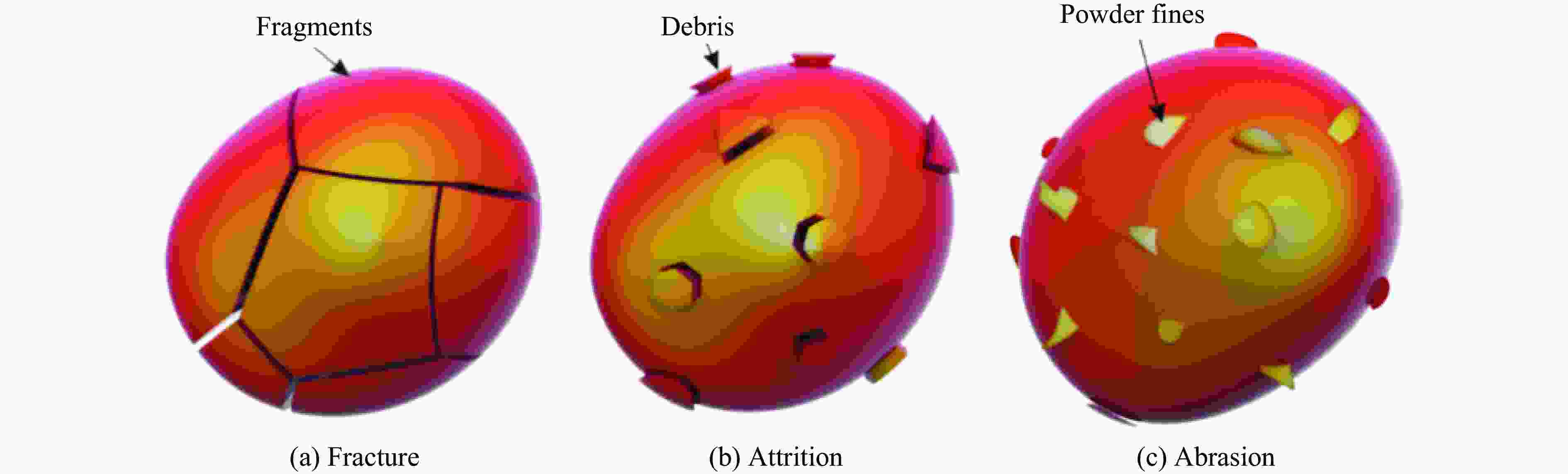

SADREKARIMI A, OLSON S M. Particle damage observed in ring shear tests on sands [J]. Canadian Geotechnical Journal, 2010, 47(5): 497–515. DOI: 10.1139/T09-117.

|

| [36] |

谢磊, 李庆华, 徐世烺. 超高韧性水泥基复合材料多次冲击压缩性能及本构关系 [J]. 工程力学, 2021, 38(12): 158–171. DOI: 10.6052/j.issn.1000-4750.2020.11.0860.XIE L, LI Q H, XU S L. Multiple impact compressive properties and constitutive model of ultra-high toughness cementitious composites [J]. Engineering Mechanics, 2021, 38(12): 158–171. DOI: 10.6052/j.issn.1000-4750.2020.11.0860.

|

| [37] |

MILTZ J, RAMON O. Energy absorption characteristics of polymeric foams used as cushioning materials [J]. Polymer Engineering and Science, 1990, 30(2): 129–133. DOI: 10.1002/pen.760300210.

|

下载:

下载: