| [1] |

BECKSTEAD M W, PUDUPPAKKAM K, THAKRE P, et al. Modeling of combustion and ignition of solid-propellant ingredients [J]. Progress in Energy and Combustion Science, 2007, 33(6): 497–551. DOI: 10.1016/j.pecs.2007.02.003.

|

| [2] |

余家泉, 许进升, 陈雄, 等. 推进剂/包覆层界面脱粘率相关特性研究 [J]. 航空学报, 2015, 36(12): 3861–3867. DOI: 10.7527/S1000-6893.2015.0089.YU J Q, XU J S, CHEN X, et al. Rate-dependent property of propellant and inhibitor interface debonding [J]. Acta Aeronautica et Astronautica Sinica, 2015, 36(12): 3861–3867. DOI: 10.7527/S1000-6893.2015.0089.

|

| [3] |

陈雄, 许进升, 郑健. 固体推进剂黏弹性力学 [M]. 北京: 北京理工大学出版社, 2016: 142–179.CHEN X, XU J S, ZHENG J. Viscoelastic mechanics of solid propellants [M]. Beijing: Beijing Institute of Technology Press, 2016: 142–179.

|

| [4] |

侯晓, 张旭, 刘向阳, 等. 固体火箭发动机药柱结构完整性研究进展 [J]. 宇航学报, 2023, 44(4): 566–579. DOI: 10.3873/j.issn.1000-1328.2023.04.011.HOU X, ZHANG X, LIU X Y, et al. Research progress on structural integrity of solid rocket motor grain [J]. Journal of Astronautics, 2023, 44(4): 566–579. DOI: 10.3873/j.issn.1000-1328.2023.04.011.

|

| [5] |

赵伯华, 辛振河, 沈月萍. 固体推进剂的体积模量与体积蠕变 [J]. 兵工学报, 1993, 14(1): 87–91.ZHAO B H, XIN Z H, SHEN Y P. Bulk modulus and bulk creep of solid propellants [J]. Acta Armamentarii, 1993, 14(1): 87–91.

|

| [6] |

JANA M K, RENGANATHAN K, RAO G V. A method of non-linear viscoelastic analysis of solid propellant grains for pressure load [J]. Computers & Structures, 1994, 52(1): 61–67. DOI: 10.1016/0045-7949(94)90256-9.

|

| [7] |

TUSSIWAND G S, SAOUMA V E, TERZENBACH R, et al. Fracture mechanics of composite solid rocket propellant grains: material testing [J]. Journal of Propulsion and Power, 2009, 25(1): 60–73. DOI: 10.2514/1.34227.

|

| [8] |

XU F, ARAVAS N, SOFRONIS P. Constitutive modeling of solid propellant materials with evolving microstructural damage [J]. Journal of the Mechanics and Physics of Solids, 2008, 56(5): 2050–2073. DOI: 10.1016/j.jmps.2007.10.013.

|

| [9] |

RAE P J, PALMER S J P, GOLDREIN H T, et al. Quasi-static studies of the deformation and failure of PBX 9501 [J]. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences, 2002, 458(2025): 2227–2242. DOI: 10.1098/rspa.2002.0967.

|

| [10] |

ZHOU Z B, CHEN P W, HUANG F L, et al. Experimental study on the micromechanical behavior of a PBX simulant using SEM and digital image correlation method [J]. Optics and Lasers in Engineering, 2011, 49(3): 366–370. DOI: 10.1016/j.optlaseng.2010.11.001.

|

| [11] |

MILLER T C. Damage and dilatometry for solid propellants with digital image correlation [J]. Propellants, Explosives, Pyrotechnics, 2019, 44(2): 234–245. DOI: 10.1002/prep.201800283.

|

| [12] |

杨秋秋, 徐胜良, 强福智, 等. 固体推进剂SEM图像分形维数研究 [J]. 化学推进剂与高分子材料, 2021, 19(1): 63–67. DOI: 10.16572/j.issn1672-2191.202109010.YANG Q Q, XU S L, QIANG F Z, et al. Study on fractal dimension of SEM images of solid propellant [J]. Chemical Propellants & Polymeric Materials, 2021, 19(1): 63–67. DOI: 10.16572/j.issn1672-2191.202109010.

|

| [13] |

BUFFIERE J Y, MAIRE E, ADRIEN J, et al. In situ experiments with X ray tomography: an attractive tool for experimental mechanics [J]. Experimental Mechanics, 2010, 50(3): 289–305. DOI: 10.1007/s11340-010-9333-7.

|

| [14] |

吴圣川, 吴正凯, 胡雅楠, 等. 同步辐射光源四维原位成像助力材料微结构损伤高分辨表征 [J]. 机械工程材料, 2020, 44(6): 72–76. DOI: 10.11973/jxgccl202006016.WU S C, WU Z K, HU Y N, et al. High-resolution characterization of microstructural damage in materials by synchrotron radiation source 4D in-situ tomography [J]. Materials for Mechanical Engineering, 2020, 44(6): 72–76. DOI: 10.11973/jxgccl202006016.

|

| [15] |

WEN H D, CHERUKARA M J, HOLT M V. Time-resolved X-ray microscopy for materials science [J]. Annual Review of Materials Research, 2019, 49: 389–415. DOI: 10.1146/annurev-matsci-070616-124014.

|

| [16] |

KERSCHEN N E, SORENSEN C J, GUO Z R, et al. X-ray phase contrast imaging of the impact of a single HMX particle in a polymeric matrix [J]. Propellants, Explosives, Pyrotechnics, 2019, 44(4): 447–454. DOI: 10.1002/prep.201800002.

|

| [17] |

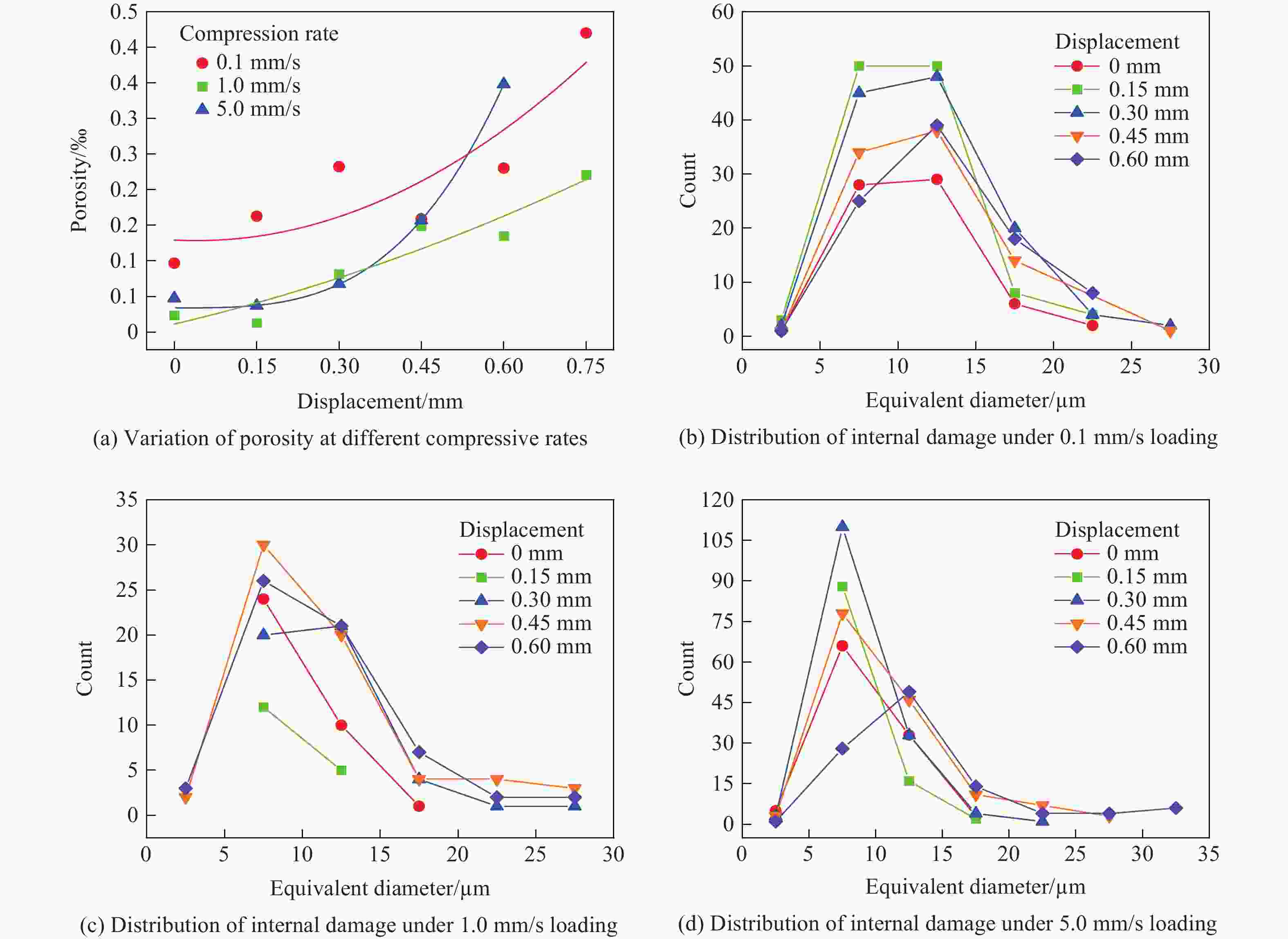

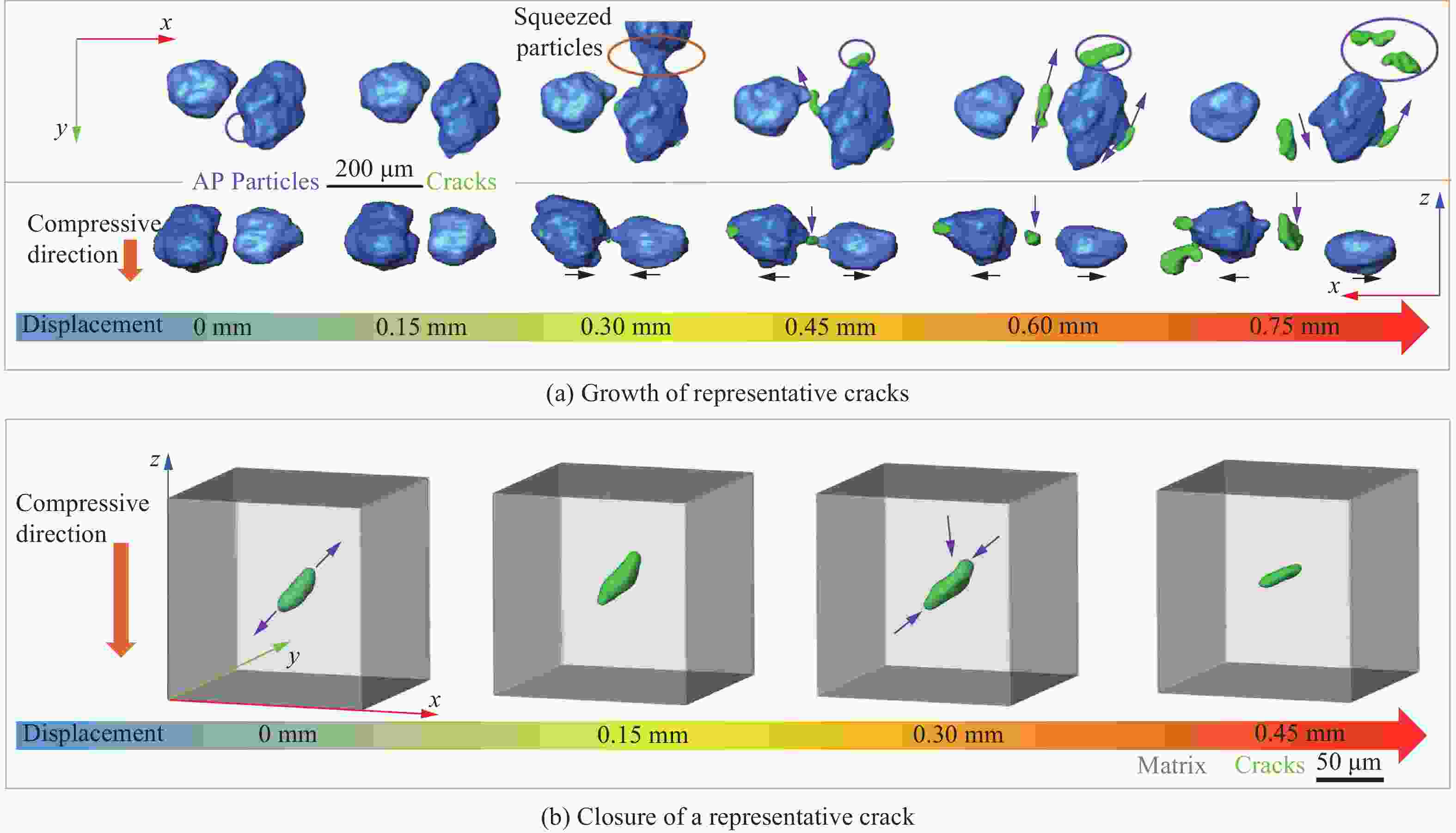

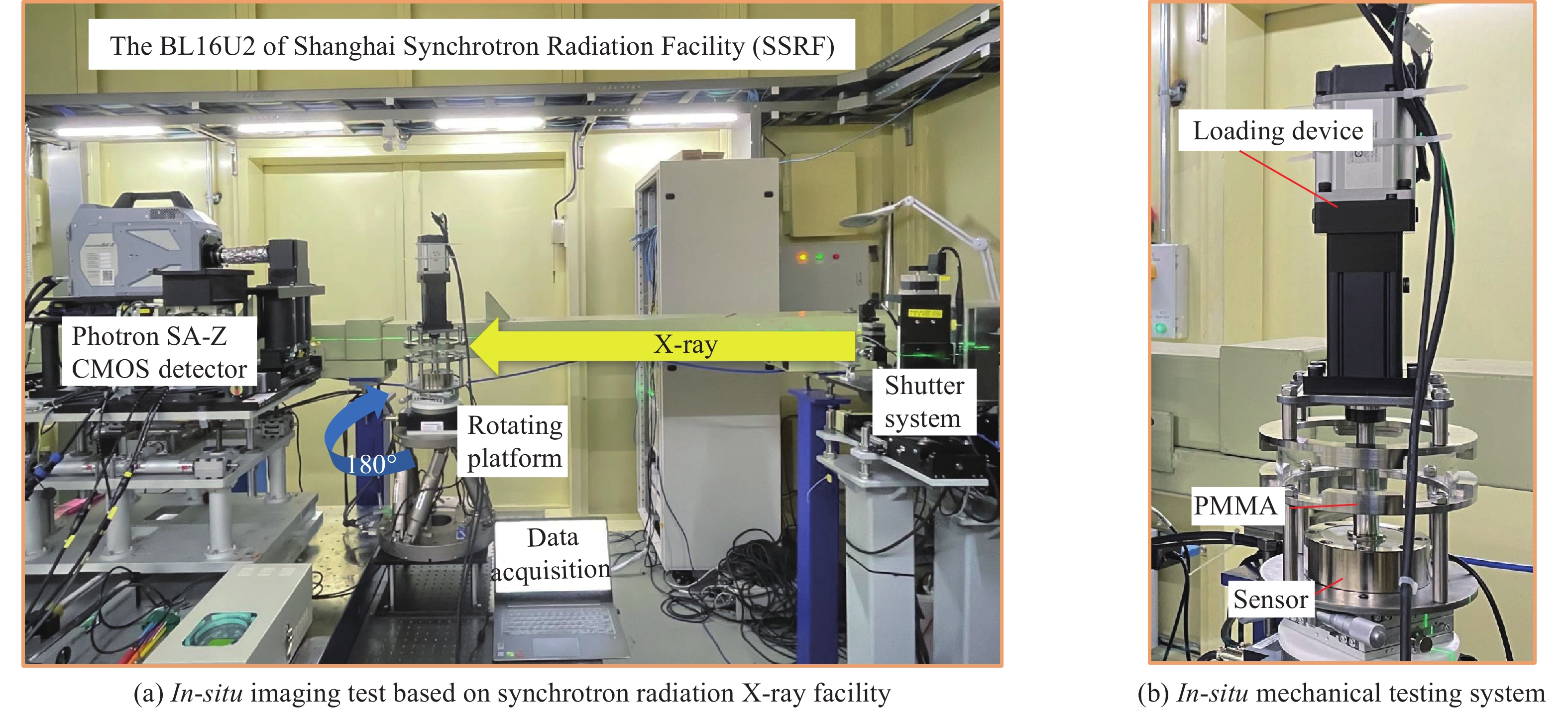

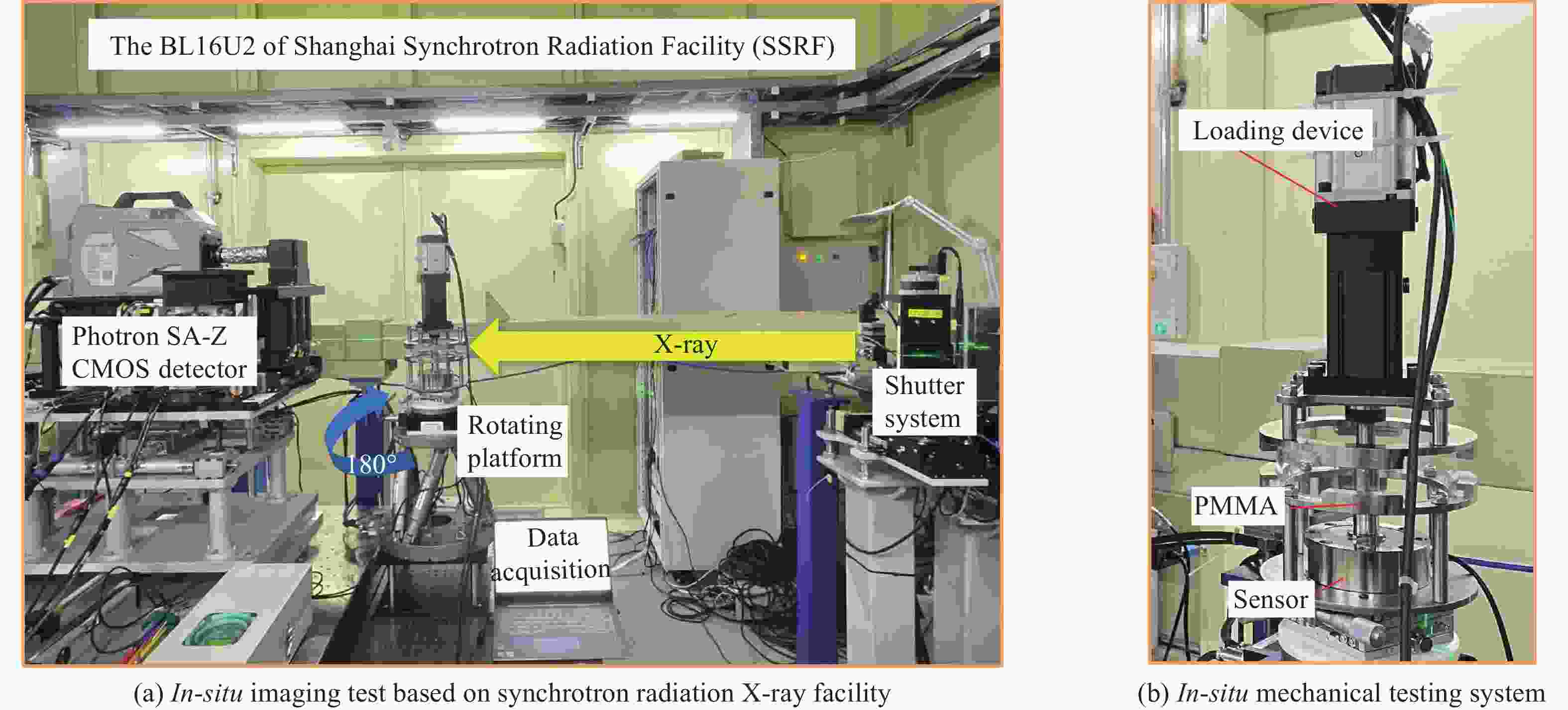

王龙, 刘岳勋, 吴圣川, 等. 基于原位X射线成像的推进剂损伤演化表征 [J]. 航空学报, 2023, 44(7): 427022. DOI: 10.7527/S1000-6893.2022.27022.WANG L, LIU Y X, WU S C, et al. In-situ X-ray tomography based characterization of propellant damage evolution [J]. Acta Aeronautica et Astronautica Sinica, 2023, 44(7): 427022. DOI: 10.7527/S1000-6893.2022.27022.

|

| [18] |

魏晋芳, 赖国栋, 柴海伟, 等. 准静态拉伸下固体推进剂三维结构变形损伤失效机理研究 [J]. 固体火箭技术, 2023, 46(2): 186–194. DOI: 10.7673/j.issn.1006-2793.2023.02.003.WEI J F, LAI G D, CHAI H W, et al. Research on three-dimensional structural deformation failure mechanism of solid propellant under quasi-static tension [J]. Journal of Solid Rocket Technology, 2023, 46(2): 186–194. DOI: 10.7673/j.issn.1006-2793.2023.02.003.

|

| [19] |

LIU Y X, QIAN W J, WANG L, et al. In situ X-ray tomography study on internal damage evolution of solid propellant for carrier rockets [J]. Materials Science and Engineering: A, 2023, 882: 145451. DOI: 10.1016/j.msea.2023.145451.

|

| [20] |

张泰华, 白以龙, 王世英, 等. 准静态压缩对高能固体推进剂燃烧行为的影响 [J]. 兵工学报, 2000, 21(4): 365–367. DOI: 10.3321/j.issn:1000-1093.2000.04.020.ZHANG T H, BAI Y L, WANG S Y, et al. Quasi-static compression of high-energy solid propellants and their combustion [J]. Acta Armamentarii, 2000, 21(4): 365–367. DOI: 10.3321/j.issn:1000-1093.2000.04.020.

|

| [21] |

吴会民, 卢芳云, 卢力, 等. 压缩加载下三种含能材料细观破坏特征观察 [J]. 高压物理学报, 2005, 19(3): 213–218. DOI: 10.11858/gywlxb.2005.03.004.WU H M, LU F Y, LU L, et al. Microstructure fractural characteristics of energetic materials under compressive loading [J]. Chinese Journal of High Pressure Physics, 2005, 19(3): 213–218. DOI: 10.11858/gywlxb.2005.03.004.

|

| [22] |

王冉, 武毅, 白龙, 等. 宽温域宽应变率下丁羟四组元HTPB推进剂单轴压缩力学行为 [J]. 含能材料, 2024, 32(2): 183–192. DOI: 10.11943/CJEM2023119.WANG R, WU Y, BAI L, et al. Uniaxial compressive mechanical behavior of four-component HTPB propellant under wide temperature and strain rate range [J]. Chinese Journal of Energetic Materials, 2024, 32(2): 183–192. DOI: 10.11943/CJEM2023119.

|

| [23] |

HO S Y. High strain-rate impact studies of predamaged rocket propellants. Ⅰ. characterization of damage using a cumulative damage failure criterion [J]. Combustion and Flame, 1996, 104(4): 524–534. DOI: 10.1016/0010-2180(95)00166-2.

|

| [24] |

WANG Z J, QIANG H F, WANG T J, et al. A thermovisco-hyperelastic constitutive model of HTPB propellant with damage at intermediate strain rates [J]. Mechanics of Time-Dependent Materials, 2018, 22(3): 291–314. DOI: 10.1007/s11043-017-9357-9.

|

| [25] |

VISHAL V, CHANDRA D. Mechanical response and strain localization in coal under uniaxial loading, using digital volume correlation on X-ray tomography images [J]. International Journal of Rock Mechanics and Mining Sciences, 2022, 154: 105103. DOI: 10.1016/j.ijrmms.2022.105103.

|

| [26] |

QIAN W J, WU S C, LEI L M, et al. Time lapse in situ X-ray imaging of failure in structural materials under cyclic loads and extreme environments [J]. Journal of Materials Science & Technology, 2024, 175: 80–103. DOI: 10.1016/j.jmst.2023.07.041.

|

| [27] |

WITHERS P J, PREUSS M. Fatigue and damage in structural materials studied by X-ray tomography [J]. Annual Review of Materials Research, 2012, 42: 81–103. DOI: 10.1146/annurev-matsci-070511-155111.

|

下载:

下载: