Effects of impact mass on dynamic mechanical responses and failure modes of square lithium-ion batteries under impact loading

-

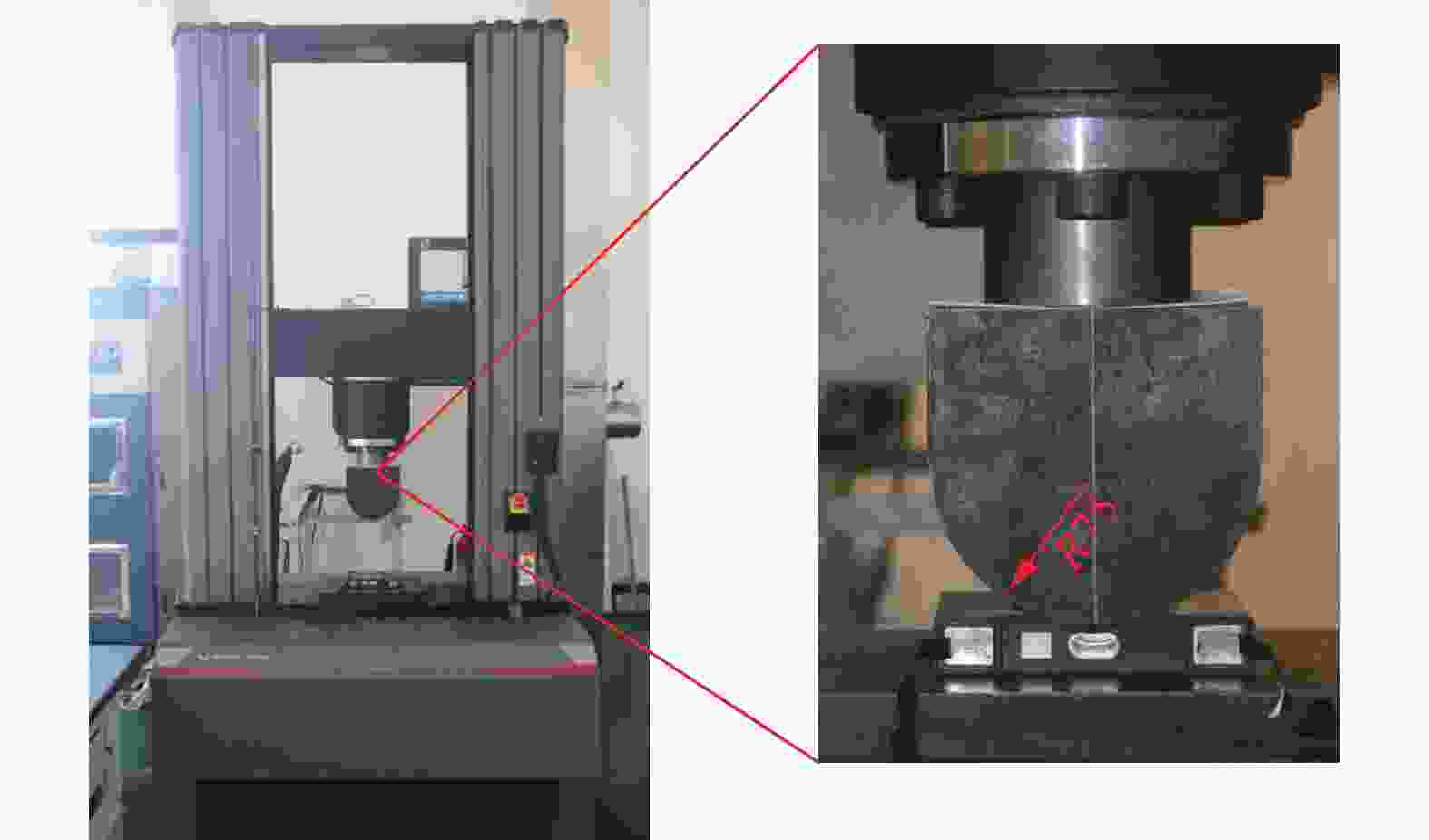

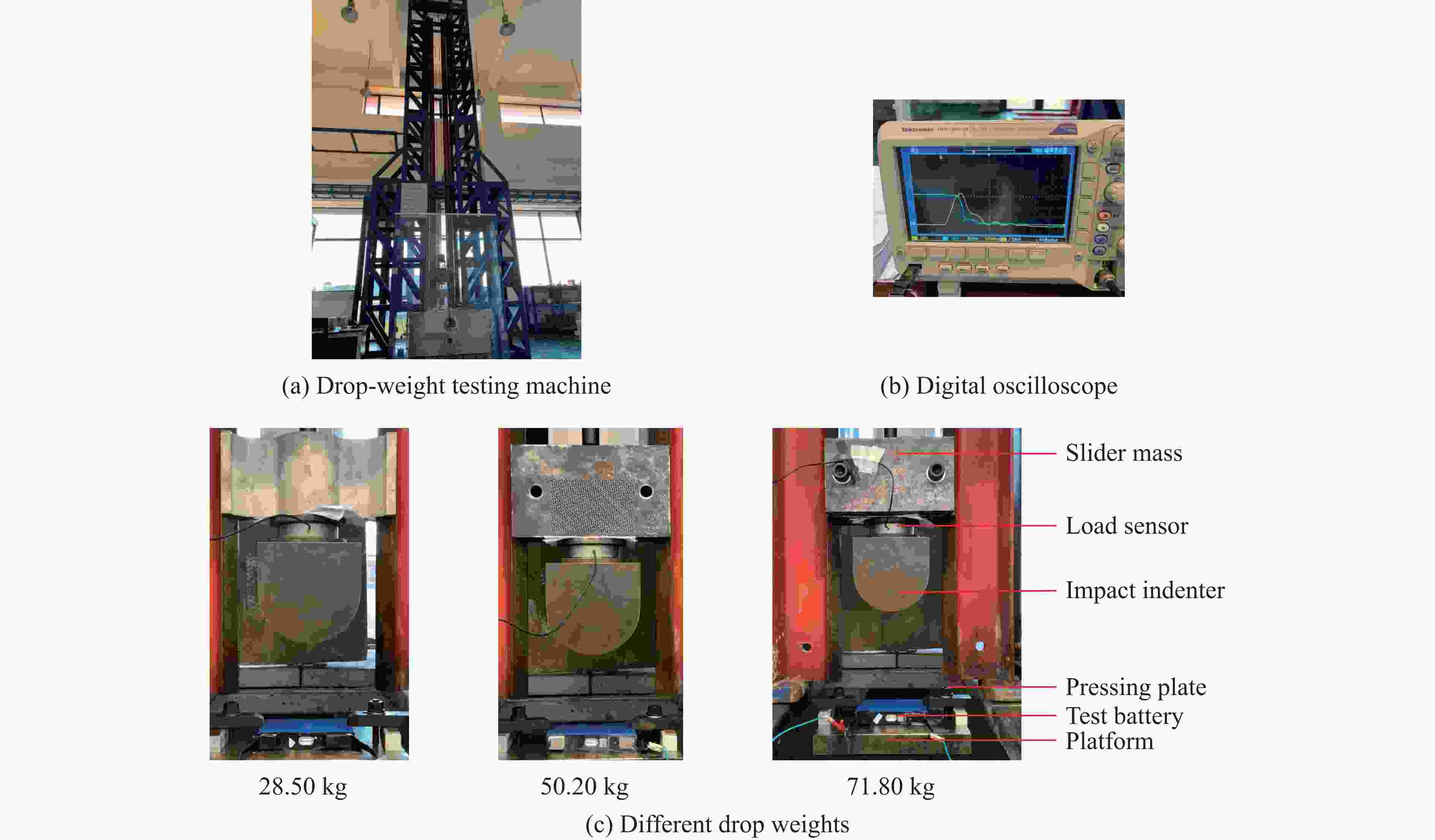

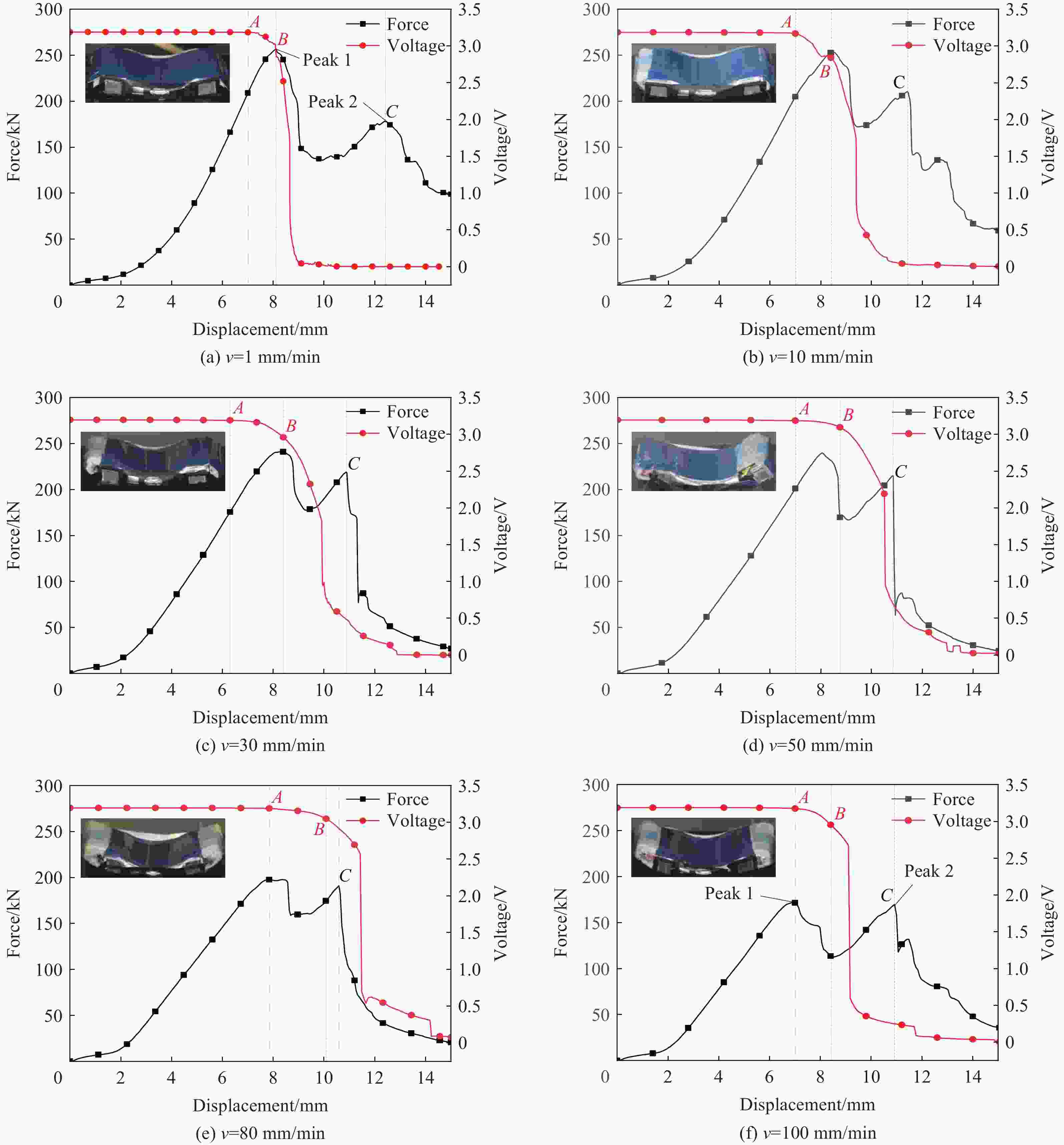

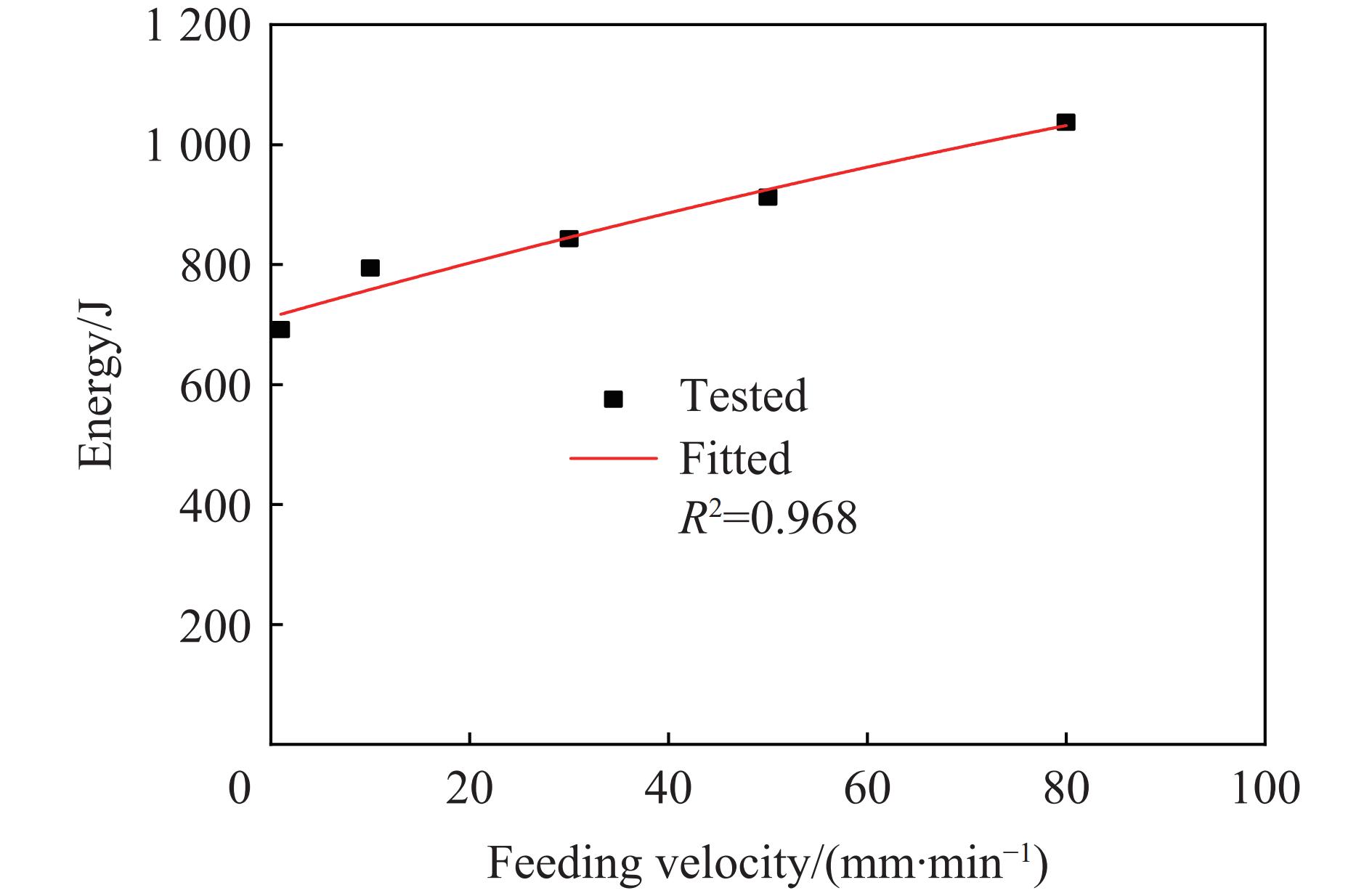

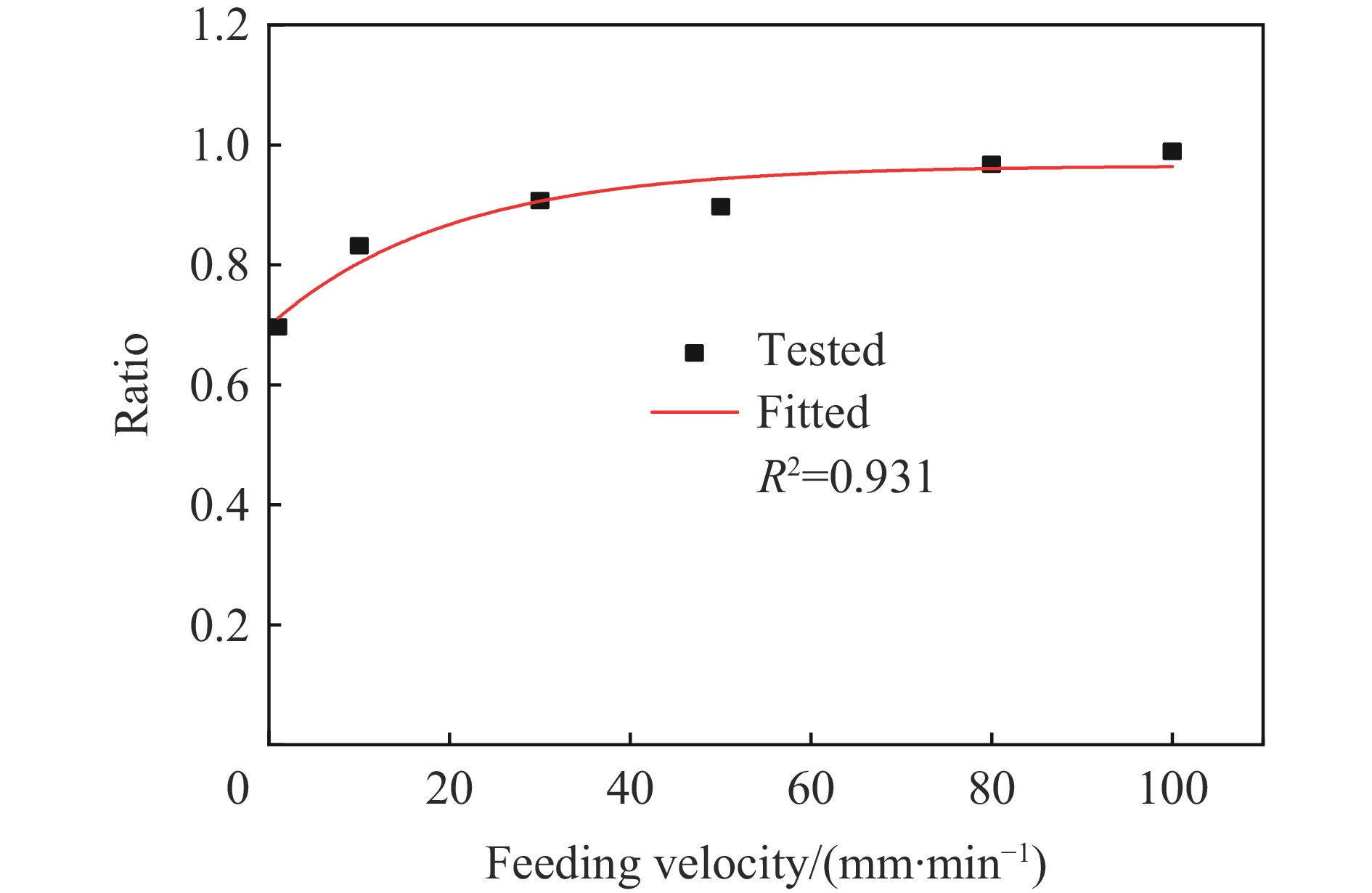

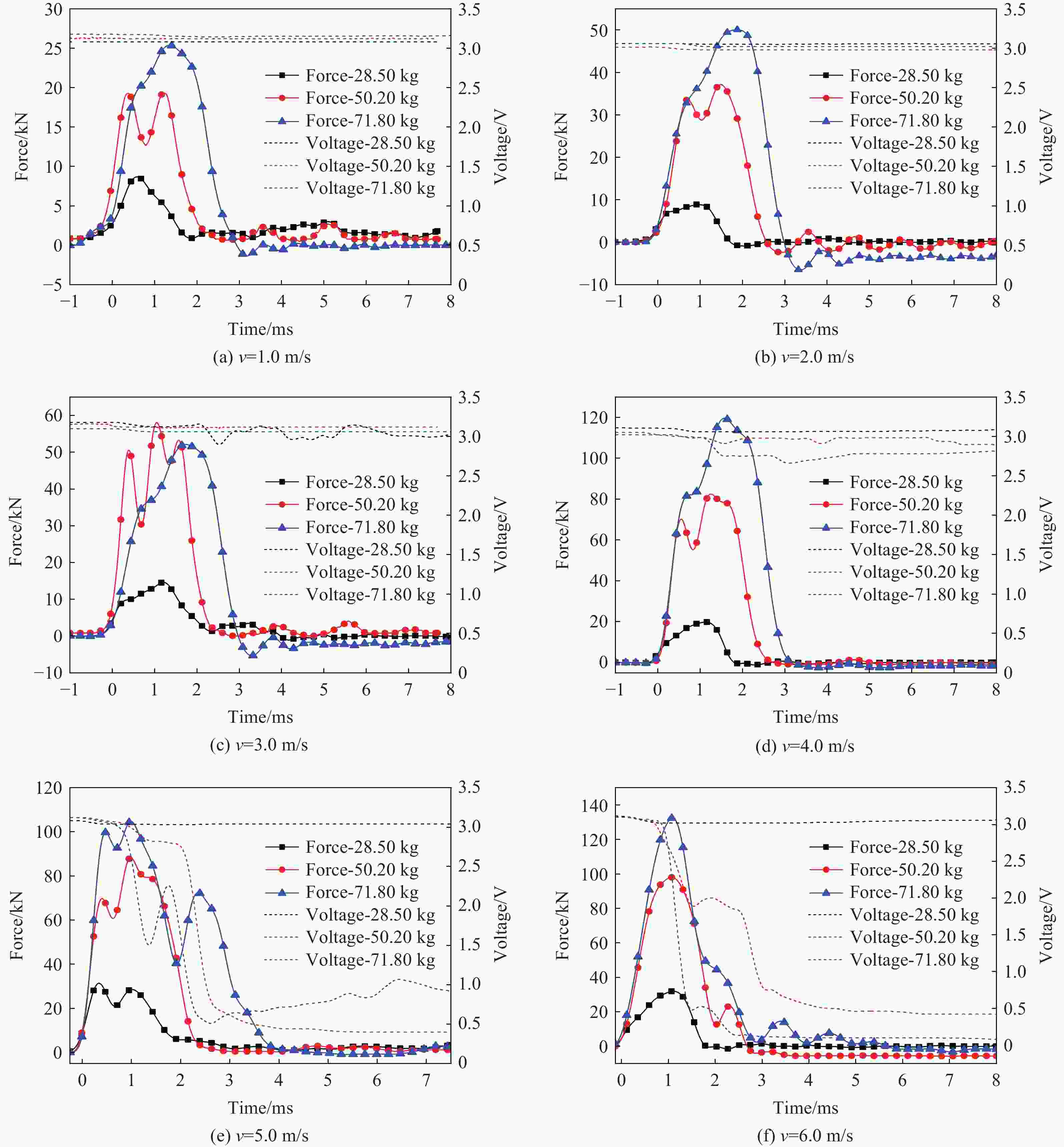

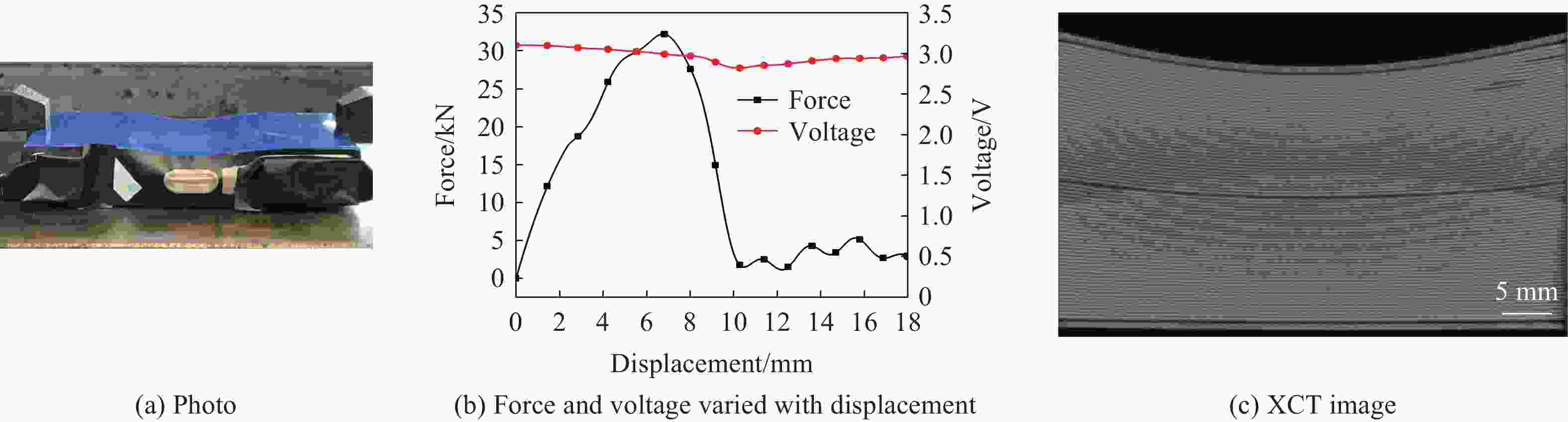

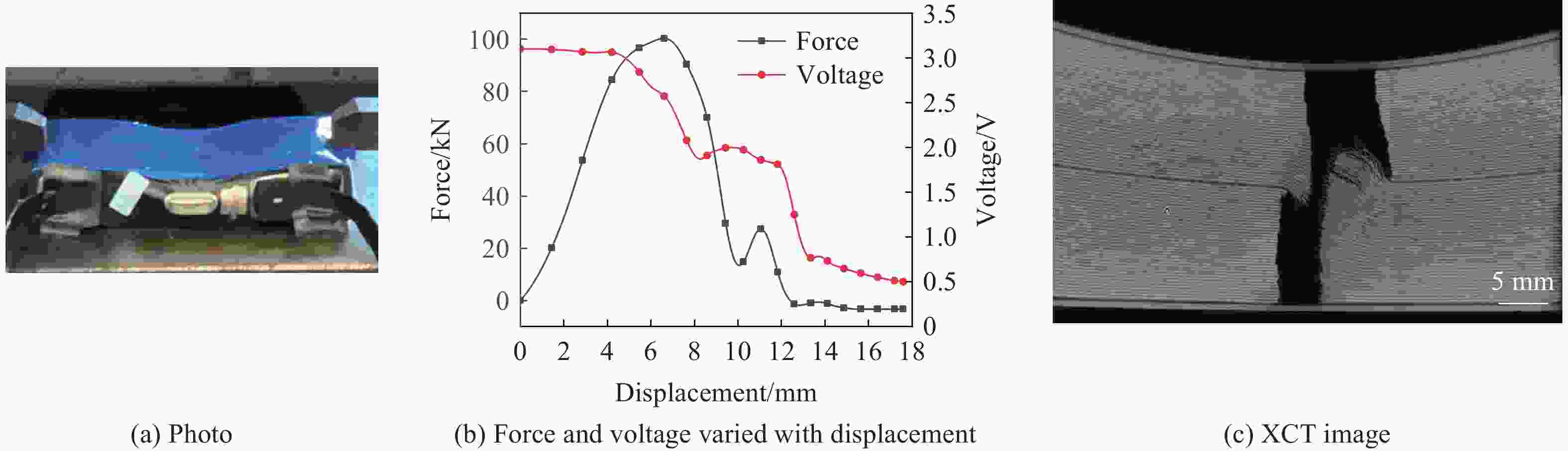

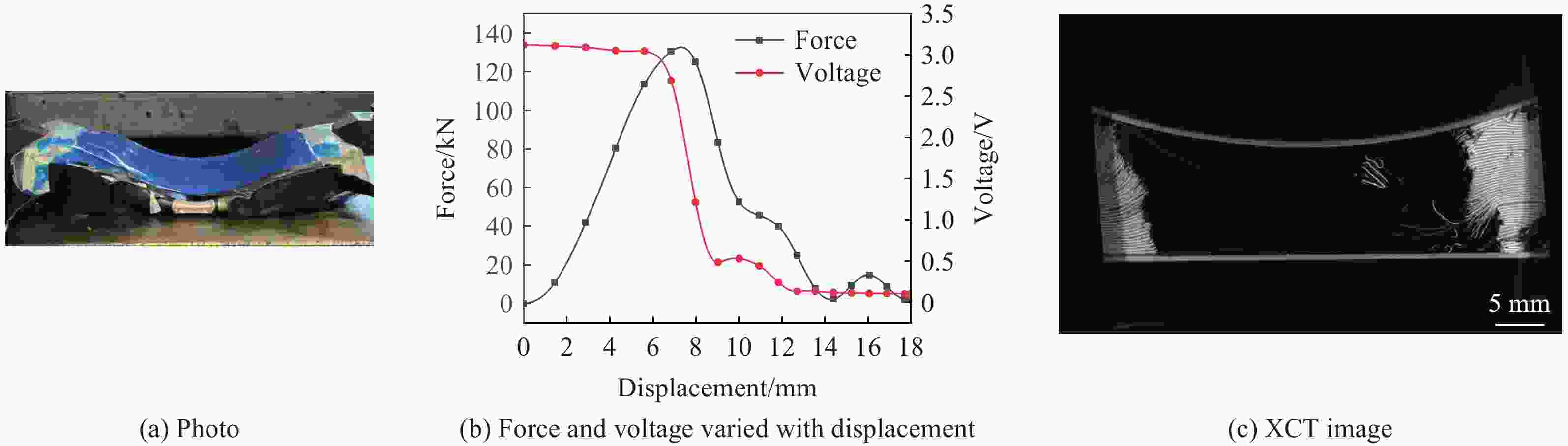

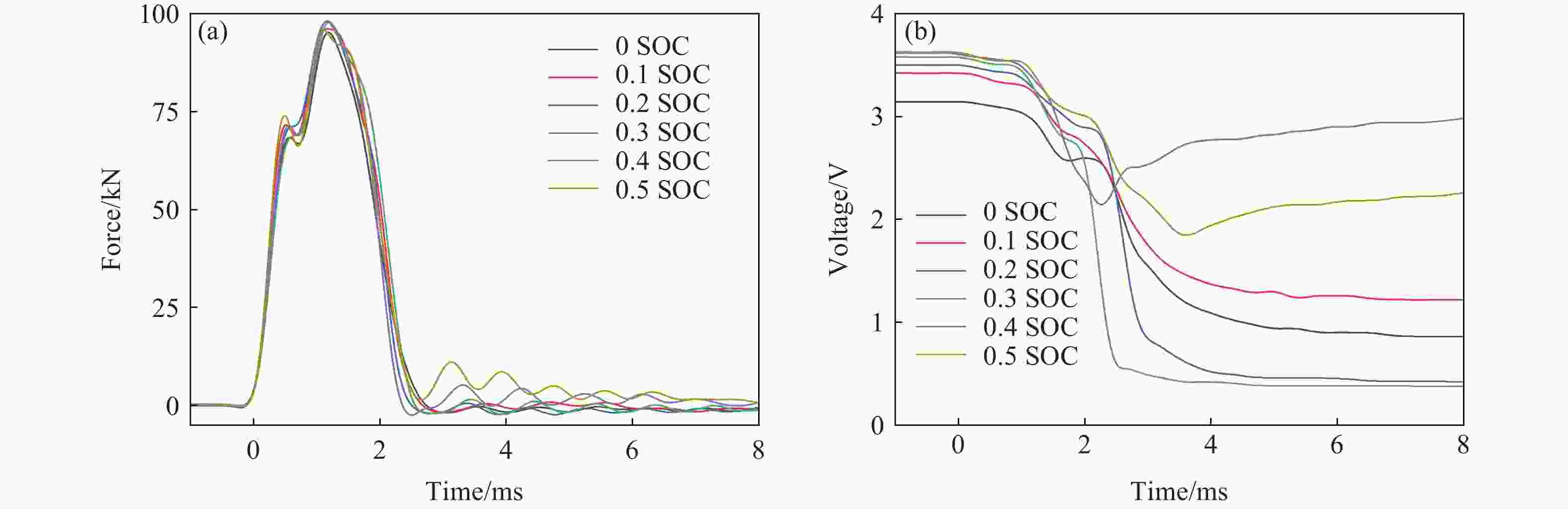

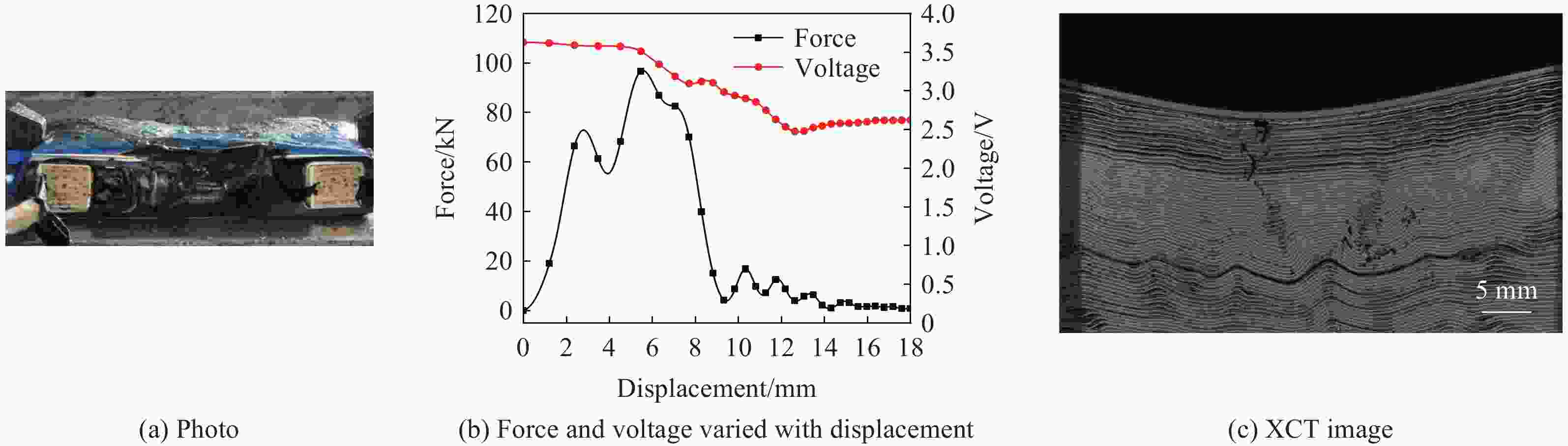

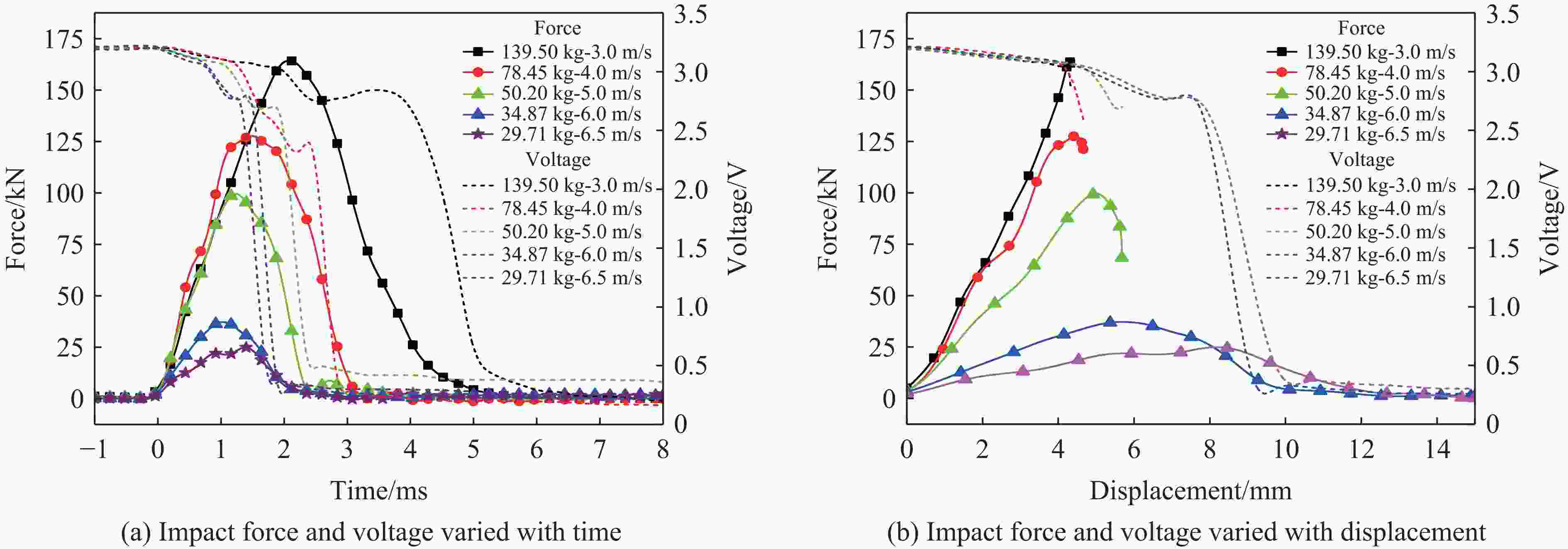

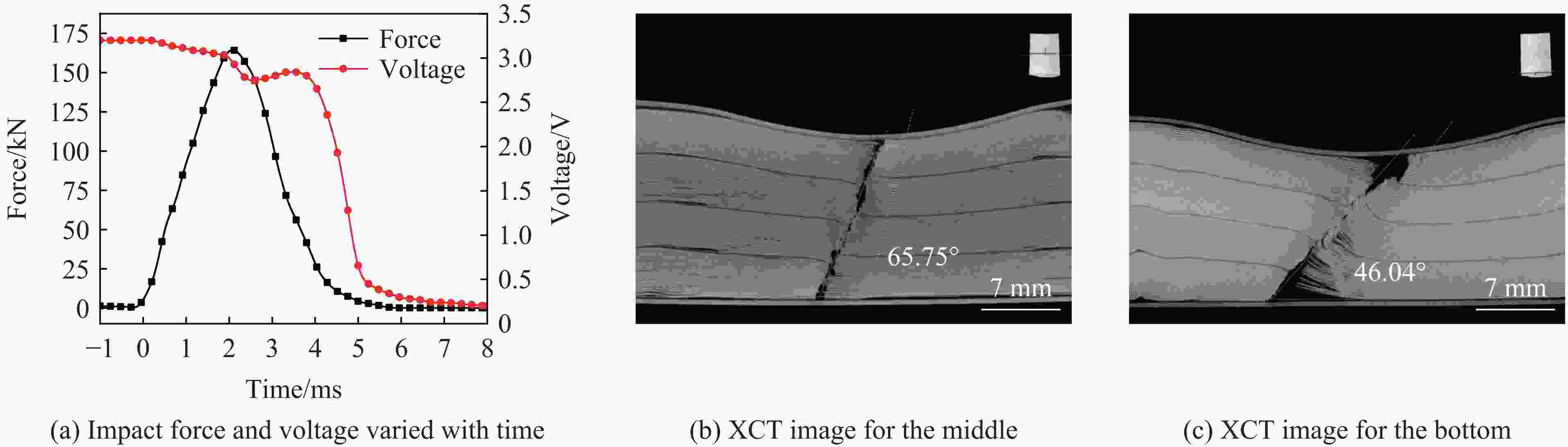

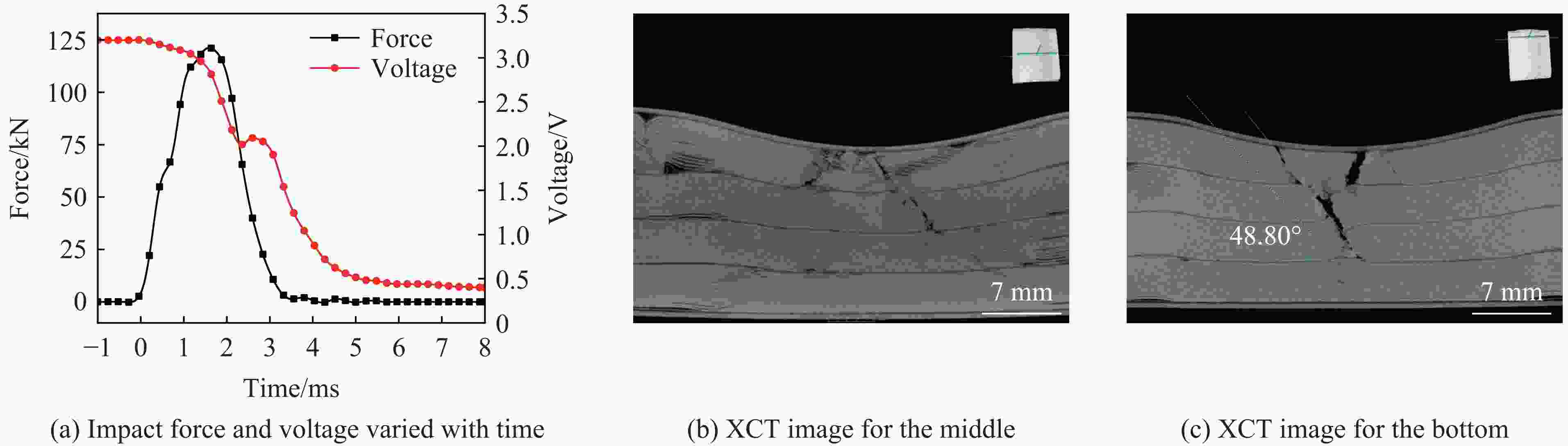

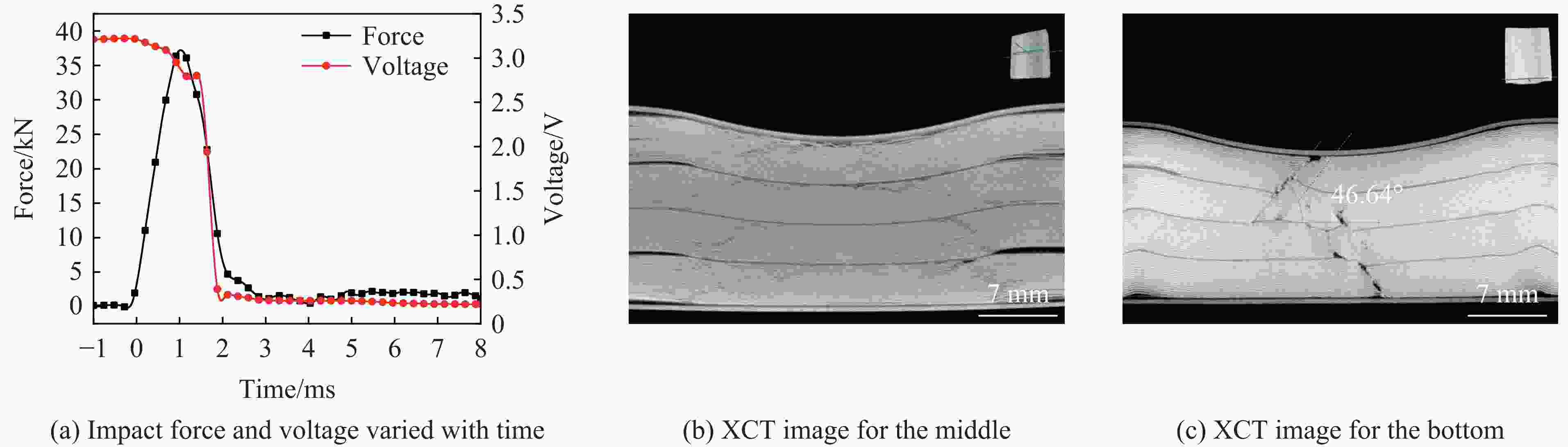

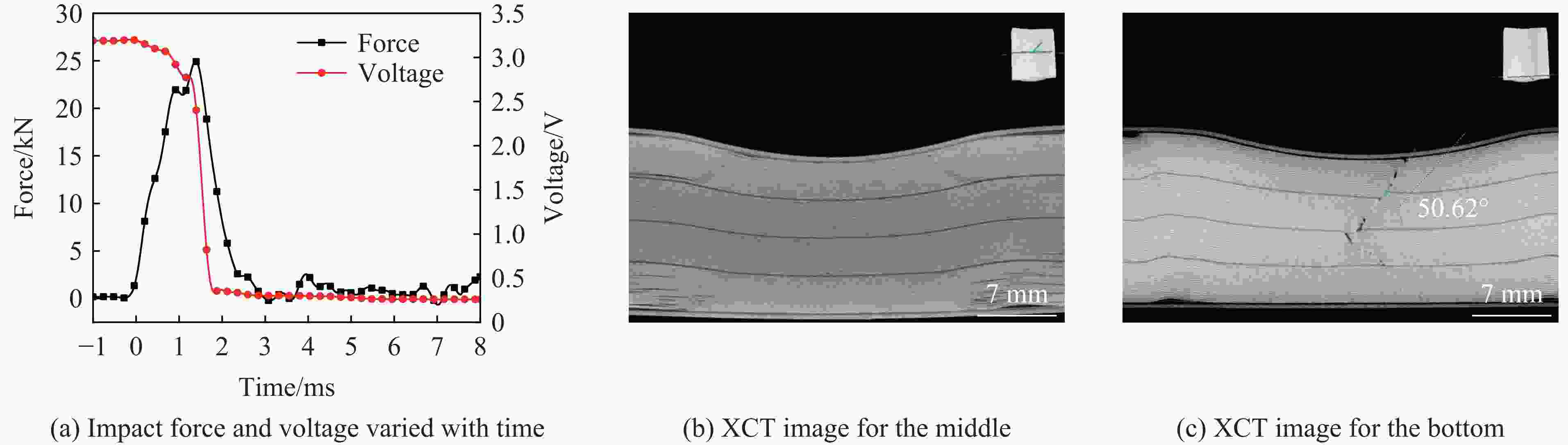

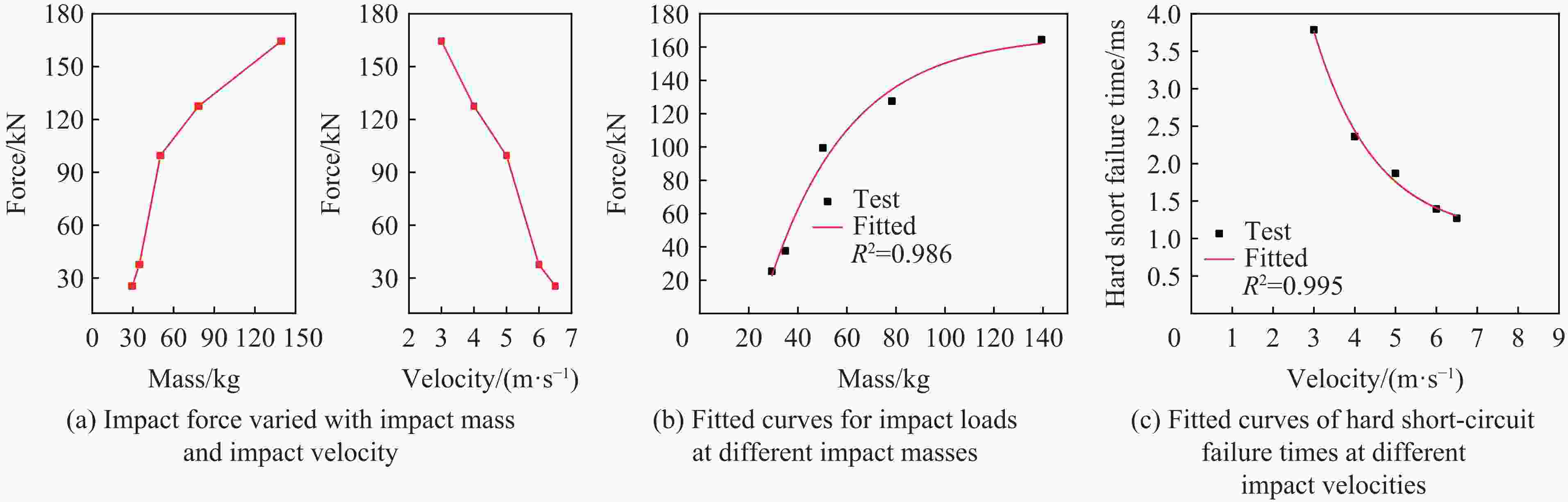

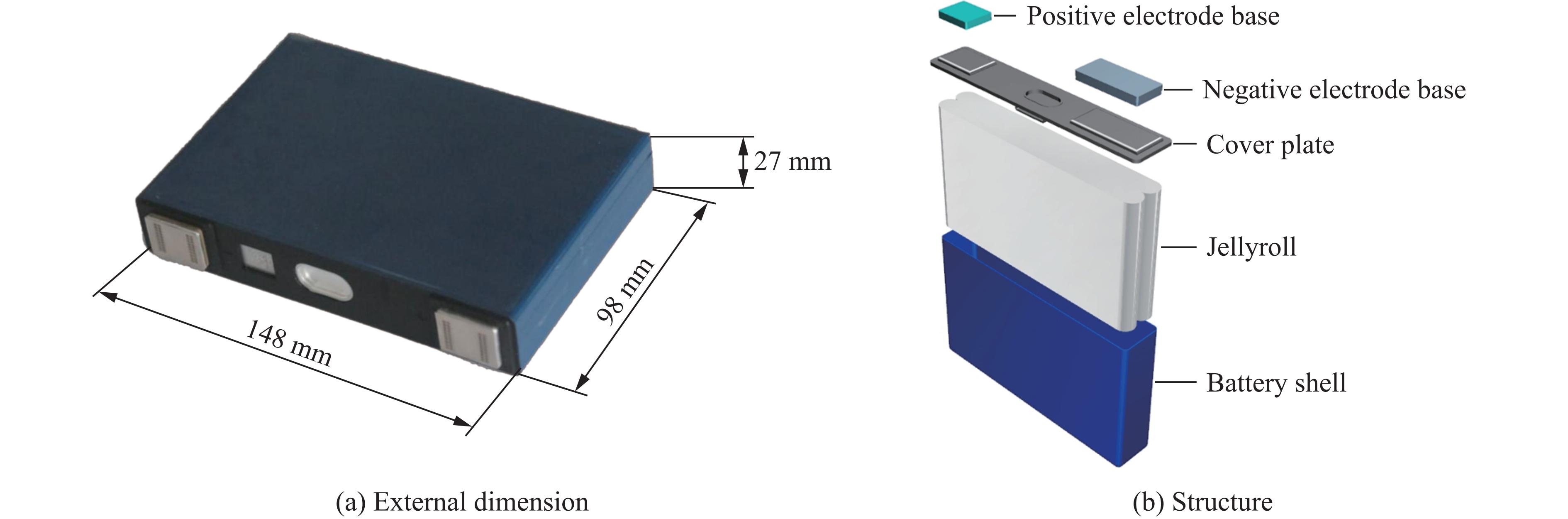

摘要: 电动汽车在运行过程中容易发生碰撞事故,动力锂离子电池不可避免会受到冲击作用,导致电池不同程度的损伤,而损伤程度的判断对电池的安全使用至关重要。基于上述背景,开展了不同冲击质量对方形锂离子电池动态冲击响应和失效行为影响的研究。首先,开展了准静态压缩试验,采用6种不同的进给速度对锂离子电池进行了挤压测试。试验结果显示,随着进给速度的递增,锂离子电池达到硬短路失效所需的峰值载荷持续减小。这表明,准静态条件下,锂离子电池的短路失效载荷主要由挤压速度决定。然后,开展了落锤冲击试验,通过调控冲头的质量和冲击速度,系统模拟了锂离子电池可能遭遇的多种冲击工况。研究结果表明,冲击质量和冲击速度是决定锂离子电池动态失效行为的关键因素。在冲击能量恒定的条件下,相较于高速、小质量的冲击条件,低速、大质量的冲头冲击对电芯内部造成的损伤更明显;当冲头质量不变时,提高冲击速度则会提前触发锂离子电池的内短路。Abstract: Electric vehicles are prone to collision accidents during operation, and power lithium-ion batteries are inevitably subjected to impact, which leads to varying degrees of damage to the battery, and assessing the extent of this damage is crucial for the safe use of the battery. Based on the above background, the study was conducted on the influence of different impact masses on the dynamic impact response and failure behavior of square lithium-ion batteries. Firstly, in the quasi-static compression test, six different feed rates were used to test the extrusion of lithium-ion batteries. The test results show that the peak load required for lithium-ion batteries to reach hard short-circuit failure continues to decrease with the increment of feed rate. This indicates that the short-circuit failure load of lithium-ion batteries under quasi-static conditions is mainly determined by the feed rate. Then the hammer impact test, through the regulation of the quality of the punch and impact speed, the system simulates the lithium-ion battery may encounter a variety of impact conditions. Impact quality is an important factor in determining the degree of damage to lithium-ion batteries. Under the same impact energy, the damage of low-speed large mass impact on lithium-ion battery is significantly higher than that of high-speed low mass impact. At a constant impact energy, mass is the dominant factor in determining the degree of battery damage. If the impact mass is heavier, it will produce a larger impact load, which will cause more serious damage to the internal structure of the lithium-ion battery, leading to its functional damage or even failure. Conversely, if the impact mass is lighter, the impact force generated is relatively small, and the damage to the battery structure is correspondingly reduced. Therefore, the size of the impact mass directly affects the degree of damage to the lithium-ion battery, which is a key indicator for evaluating its safety performance and durability. The impact speed has a significant impact on the voltage drop of lithium-ion batteries after damage. Especially accelerating the occurrence of hard short circuits, further exacerbating the sharp drop in voltage. This characteristic makes the impact velocity as an important consideration for evaluating the voltage stability and overall safety performance of lithium-ion batteries after damage.

-

Key words:

- square lithium-ion battery /

- impact mass /

- impact velocity /

- impact energy /

- dynamic failure

-

表 1 由冲击速度和落锤质量不同组合确定的冲击能量

Table 1. Impact energies determined by different combinations of impact velocity and hammer mass

冲击速度/(m∙s−1) 下落高度/mm 冲击能量/J 28.50 kg 50.20 kg 71.80 kg 1.0 51 14.25 25.10 35.90 2.0 204 57.00 100.40 143.60 3.0 459 128.25 225.90 323.10 4.0 817 228.00 401.60 574.40 5.0 1276 356.25 627.50 897.50 6.0 1838 513.00 903.60 1292.40 表 2 硬短路失效点的能量

Table 2. Energies at hard short circuit failure points

进给速度/(mm∙min−1) 位移/mm 载荷/kN 失效点能量/J 1 8.06 256.24 691.61 10 8.40 252.49 794.16 30 8.40 241.06 842.76 50 8.76 169.57 912.06 80 10.08 174.55 1036.69 100 8.40 113.61 692.85 表 3 恒定冲击能量下的不同冲击速度、落锤初始高度和冲击质量

Table 3. Different impact velocities, initial drop height and impact masses at constant impact energy

冲击能量/J 冲击速度/(m∙s−1) 落锤初始高度/mm 冲击质量/kg 627.75 3.0 459 139.50 627.60 4.0 817 78.45 627.50 5.0 1276 50.20 627.66 6.0 1838 34.87 627.62 6.5 2179 29.71 表 4 恒定冲击能量下冲击试验的峰值载荷和硬短路失效时间点

Table 4. Peak loads and hard short-circuit failure time points for impact tests at constant impact energy

冲击速度/(m∙s−1) 冲击质量/kg 峰值载荷/kN 硬短路失效时间/ms 3.0 139.50 164.43 3.79 4.0 78.45 127.60 2.36 5.0 50.20 99.46 1.87 6.0 34.87 37.60 1.39 6.5 29.71 25.40 1.27 -

[1] LIU B H, JIA Y K, YUAN C H, et al. Safety issues and mechanisms of lithium-ion battery cell upon mechanical abusive loading: a review [J]. Energy Storage Materials, 2020, 24: 85–112. DOI: 10.1016/j.ensm.2019.06.036. [2] XIA Y, WIERZBICKI T, SAHRAEI E, et al. Damage of cells and battery packs due to ground impact [J]. Journal of Power Sources, 2014, 267: 78–97. DOI: 10.1016/j.jpowsour.2014.05.078. [3] XU J, LIU B H, WANG X Y, et al. Computational model of 18650 lithium-ion battery with coupled strain rate and SOC dependencies [J]. Applied Energy, 2016, 172: 180–189. DOI: 10.1016/j.apenergy.2016.03.108. [4] XU J, LIU B H, WANG L B, et al. Dynamic mechanical integrity of cylindrical lithium-ion battery cell upon crushing [J]. Engineering Failure Analysis, 2015, 53: 97–110. DOI: 10.1016/j.engfailanal.2015.03.025. [5] JIA Y K, YIN S, LIU B H, et al. Unlocking the coupling mechanical-electrochemical behavior of lithium-ion battery upon dynamic mechanical loading [J]. Energy, 2019, 166: 951–960. DOI: 10.1016/j.energy.2018.10.142. [6] KISTERS T, SAHRAEI E, WIERZBICKI T. Dynamic impact tests on lithium-ion cells [J]. International Journal of Impact Engineering, 2017, 108: 205–216. DOI: 10.1016/j.ijimpeng.2017.04.025. [7] KISTERS T, GILAKI M, NAU S, et al. Modeling of dynamic mechanical response of Li-ion cells with homogenized electrolyte-solid interactions [J]. Journal of Energy Storage, 2022, 49: 104069. DOI: 10.1016/j.est.2022.104069. [8] RATNER A, BEAUMONT R, MASTERS I. Dynamic mechanical compression impulse of lithium-ion pouch cells [J]. Energies, 2020, 13(8): 2105. DOI: 10.3390/en13082105. [9] CHEN X P, WANG T, ZHANG Y, et al. Dynamic behavior and modeling of prismatic lithium-ion battery [J]. International Journal of Energy Research, 2020, 44(4): 2984–2997. DOI: 10.1002/er.5126. [10] CHEN X P, WANG T, ZHANG Y, et al. Dynamic mechanical behavior of prismatic lithium-ion battery upon impact [J]. International Journal of Energy Research, 2019, 43: 7421–7432. DOI: 10.1002/er.4774. [11] KOTTER P, KISTERS T, SCHLEICHER A. Dynamic impact tests to characterize the crashworthiness of large-format lithium-ion cells [J]. Journal of Energy Storage, 2019, 26: 100948. DOI: 10.1016/j.est.2019.100948. [12] HU L L, ZHANG Z W, ZHOU M Z, et al. Crushing behaviors and failure of packed batteries [J]. International Journal of Impact Engineering, 2020, 143: 103618. DOI: 10.1016/j.ijimpeng.2020.103618. [13] SAHRAEI E, KAHN M, MEIER J, et al. Modelling of cracks developed in lithium-ion cells under mechanical loading [J]. RSC Advances, 2015, 5(98): 80369–80380. DOI: 10.1039/c5ra17865g. [14] WANG H, SIMUNOVIC S, MALEKI H, et al. Internal configuration of prismatic lithium-ion cells at the onset of mechanically induced short circuit [J]. Journal of Power Sources, 2016, 306: 424–430. DOI: 10.1016/j.jpowsour.2015.12.026. [15] CHUNG S H, TANCOGNE-DEJEAN T, ZHU J E, et al. Failure in lithium-ion batteries under transverse indentation loading [J]. Journal of Power Sources, 2018, 389: 148–159. DOI: 10.1016/j.jpowsour.2018.04.003. [16] ZHU X Q, WANG H, WANG X, et al. Internal short circuit and failure mechanisms of lithium-ion pouch cells under mechanical indentation abuse conditions: an experimental study [J]. Journal of Power Sources, 2020, 455: 227939. DOI: 10.1016/j.jpowsour.2020.227939. [17] ZHU F, ZHOU R Z, SYPECK D, et al. Failure behavior of prismatic Li-ion battery cells under abuse loading condition: a combined experimental and computational study [J]. Journal of Energy Storage, 2022, 48: 103969. DOI: 10.1016/j.est.2022.103969. [18] LI W, XING B B, WATKINS T R, et al. Damage of prismatic lithium-ion cells subject to bending: test, model, and detection [J]. EcoMat, 2022, 4(6): e12257. DOI: 10.1002/eom2.12257. [19] XING B B, XIAO F Y, KOROGI Y, et al. Direction-dependent mechanical-electrical-thermal responses of large-format prismatic Li-ion battery under mechanical abuse [J]. Journal of Energy Storage, 2021, 43: 103270. DOI: 10.1016/j.est.2021.103270. [20] WANG L B, CHEN J Y, LI J P, et al. A novel anisotropic model for multi-stage failure threshold of lithium-ion battery subjected to impact loading [J]. International Journal of Mechanical Sciences, 2022, 236: 107757. DOI: 10.1016/j.ijmecsci.2022.107757. [21] KISTERS T, KUDER J, TÖPEL A, et al. Strain-rate dependence of the failure behavior of lithium-ion pouch cells under impact loading [J]. Journal of Energy Storage, 2021, 41: 102901. DOI: 10.1016/j.est.2021.102901. [22] LIU Y J, XIA Y, XING B B, et al. Mechanical-electrical-thermal responses of lithium-ion pouch cells under dynamic loading: a comparative study between fresh cells and aged ones [J]. International Journal of Impact Engineering, 2022, 166: 104237. DOI: 10.1016/j.ijimpeng.2022.104237. [23] LI W, ZHU J E, XIA Y, et al. Data-driven safety envelope of lithium-ion batteries for electric vehicles [J]. Joule, 2019, 3(11): 2703–2715. DOI: 10.1016/j.joule.2019.07.026. [24] CHEN X P, YUAN Q, WANG T, et al. Experimental study on the dynamic behavior of prismatic lithium-ion battery upon repeated impact [J]. Engineering Failure Analysis, 2020, 115: 104667. DOI: 10.1016/j.engfailanal.2020.104667. [25] ZHANG H J, ZHOU M Z, HU L L, et al. Mechanism of the dynamic behaviors and failure analysis of lithium-ion batteries under crushing based on stress wave theory [J]. Engineering Failure Analysis, 2020, 108: 104290. DOI: 10.1016/j.engfailanal.2019.104290. [26] KALNAUS S, WANG H, WATKINS T R, et al. Features of mechanical behavior of EV battery modules under high deformation rate [J]. Extreme Mechanics Letters, 2019, 32: 100550. DOI: 10.1016/j.eml.2019.100550. [27] 李志杰. 新能源汽车方形锂离子电池内部芯层载荷变形失效试验与仿真分析 [D]. 广州: 华南理工大学, 2021. DOI: 10.27151/d.cnki.ghnlu.2021.001195.LI Z J. Load deformation failure test and simulation analysis for internal configuration of prismatic lithium-ion batteries on new energy vehicle [D]. Guangzhou: South China University of Technology, 2021. DOI: 10.27151/d.cnki.ghnlu.2021.001195. -

下载:

下载: