Dynamic response characteristics of soft-pack lithium batteries for light-weight consumer drones under mechanical strong impact loads

-

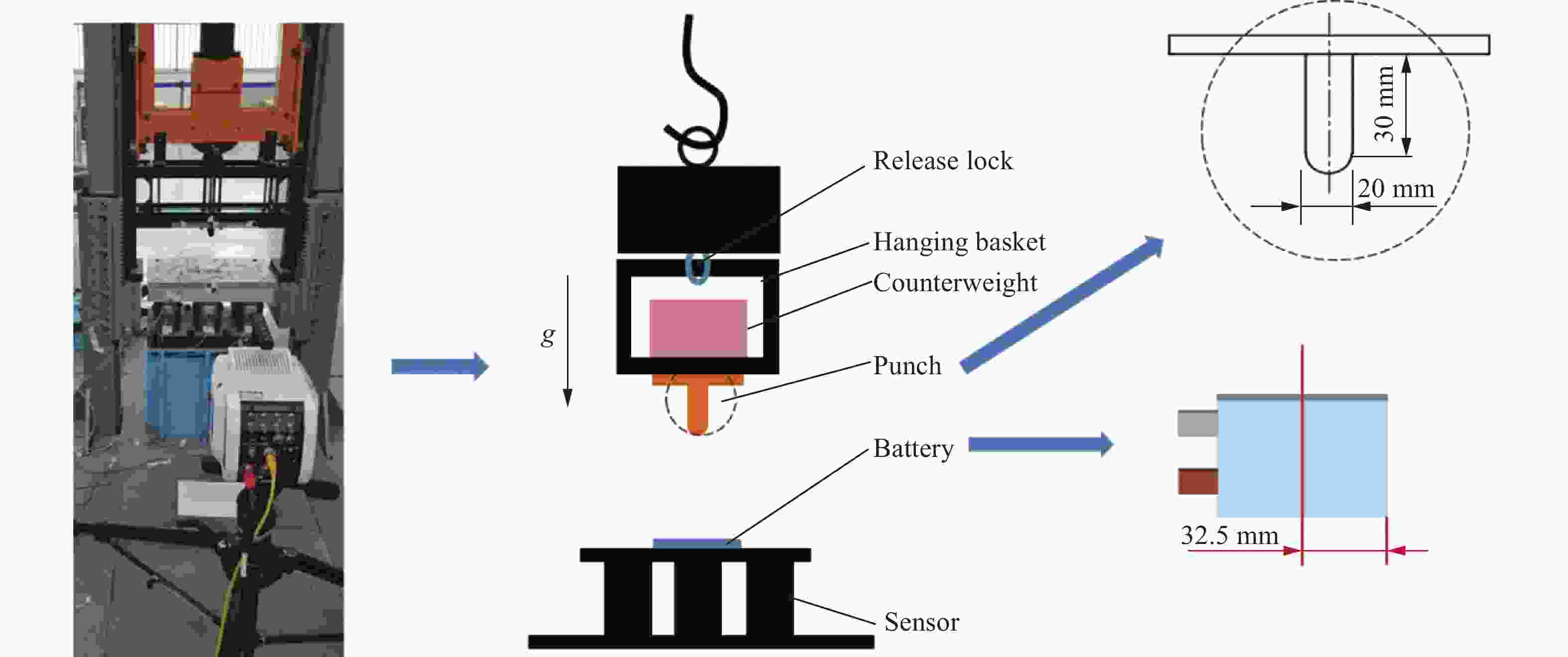

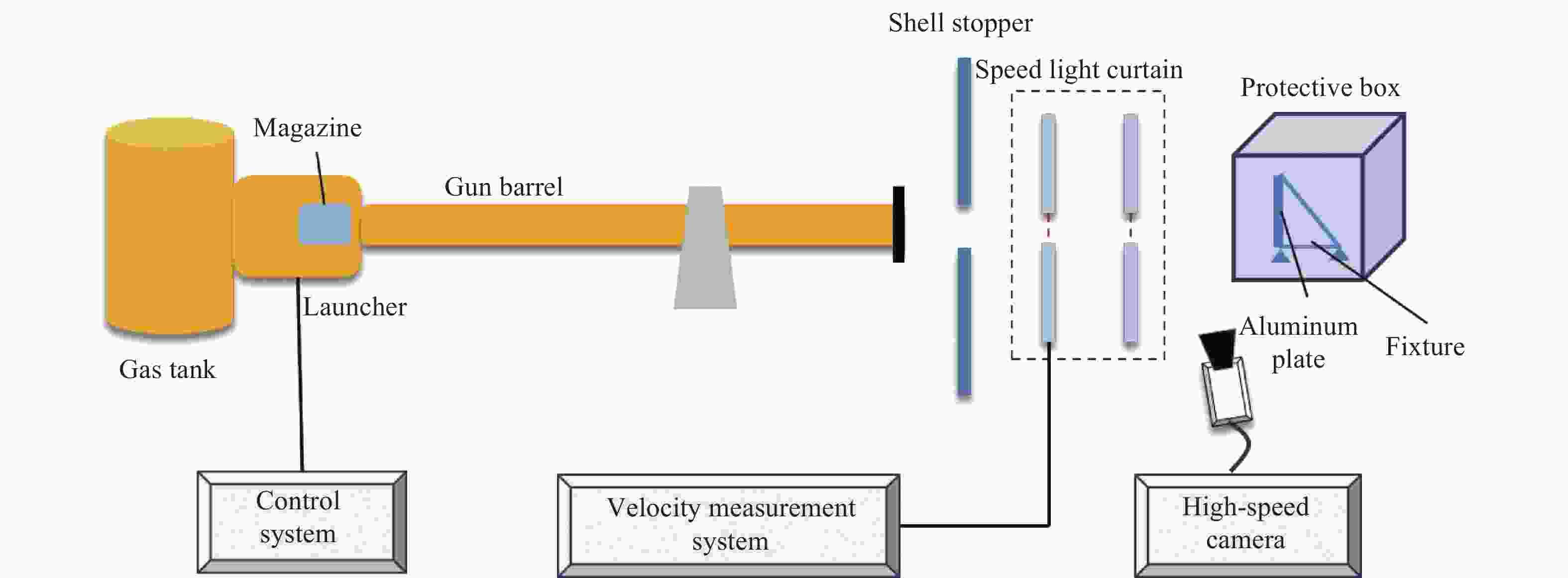

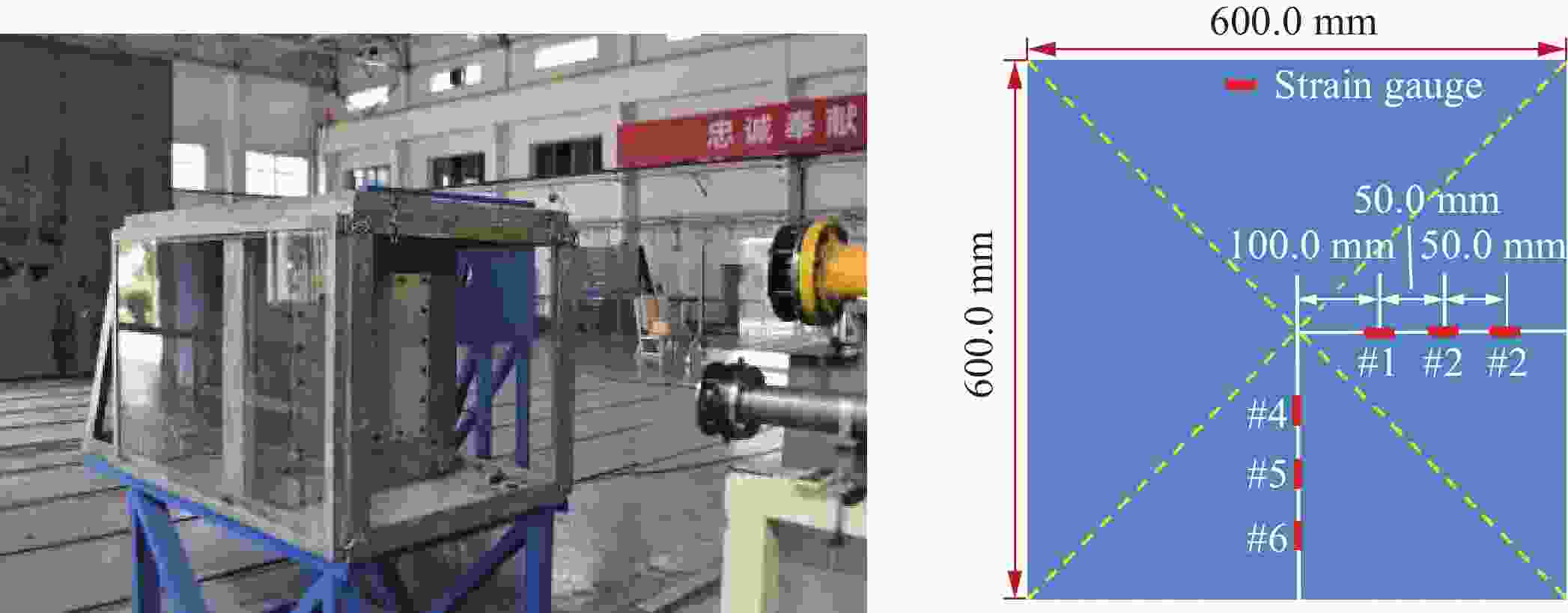

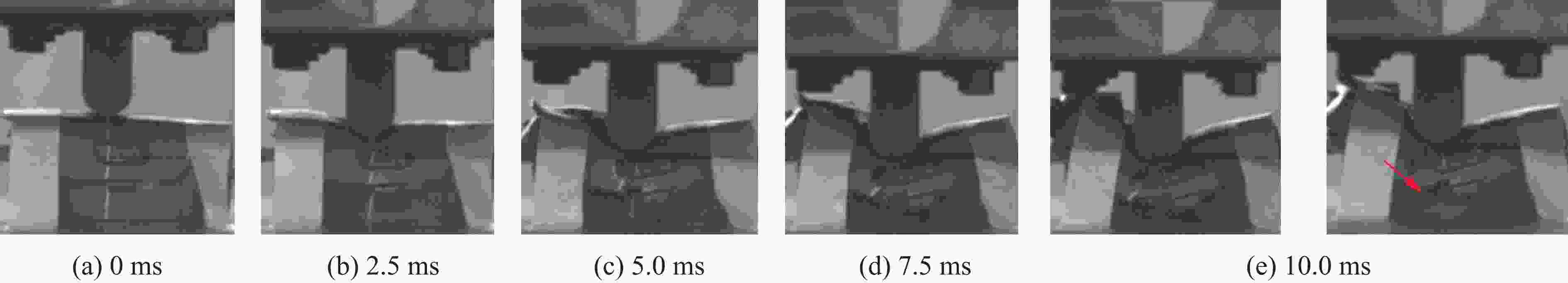

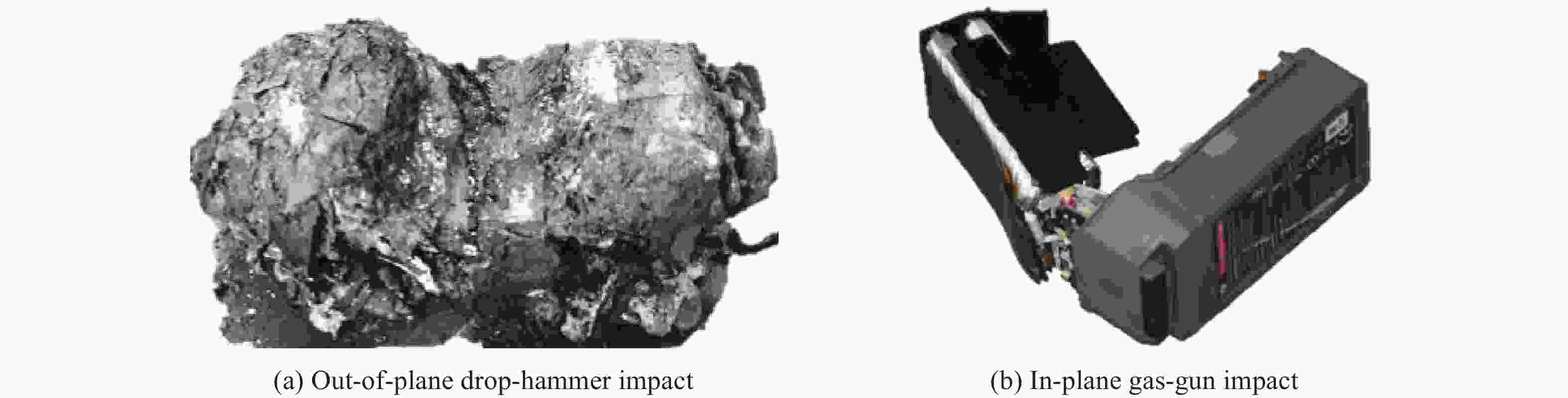

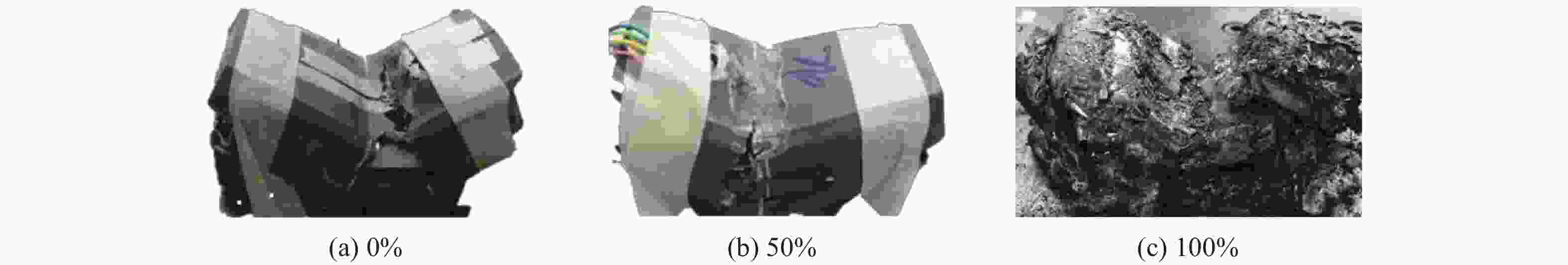

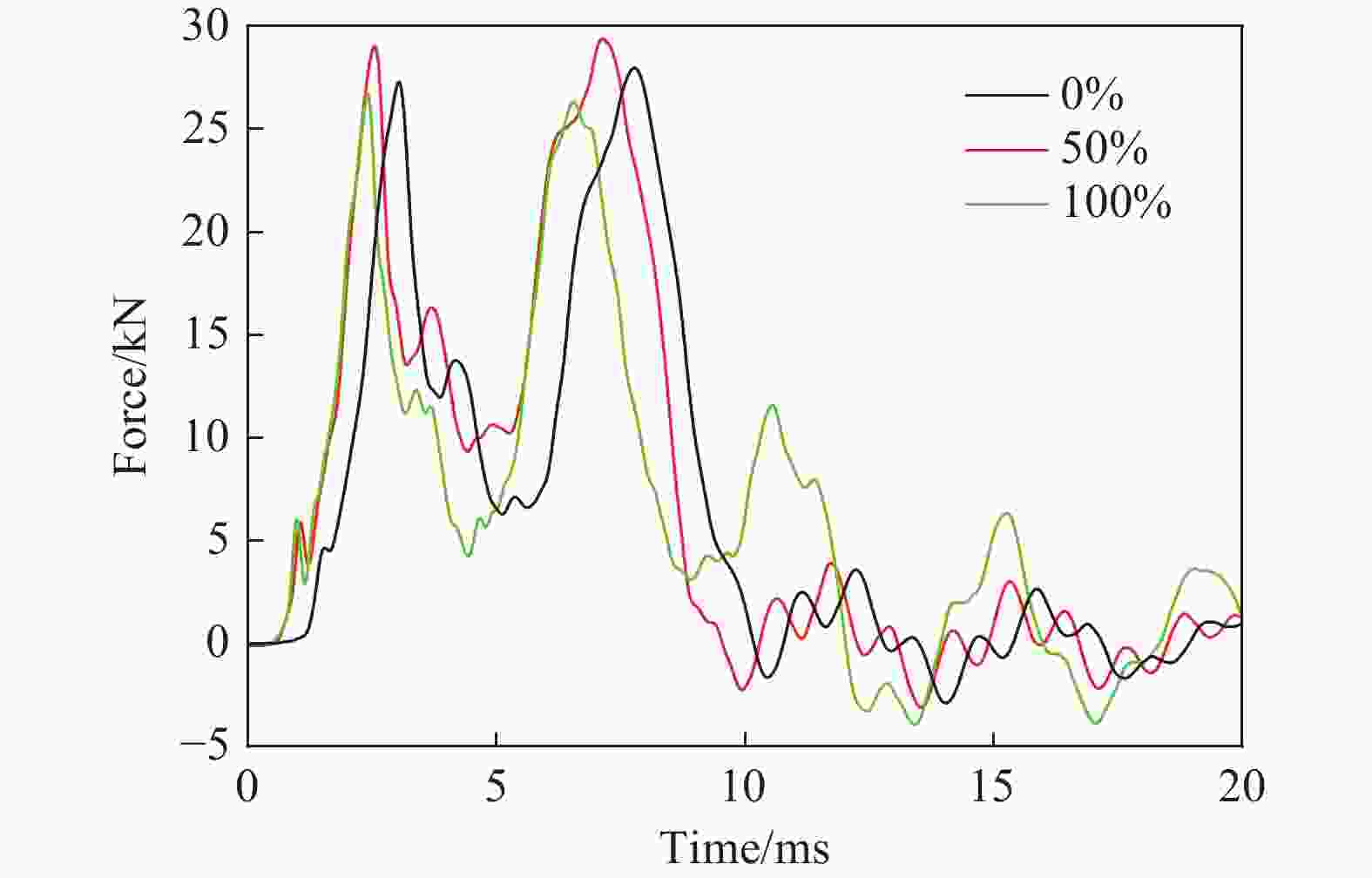

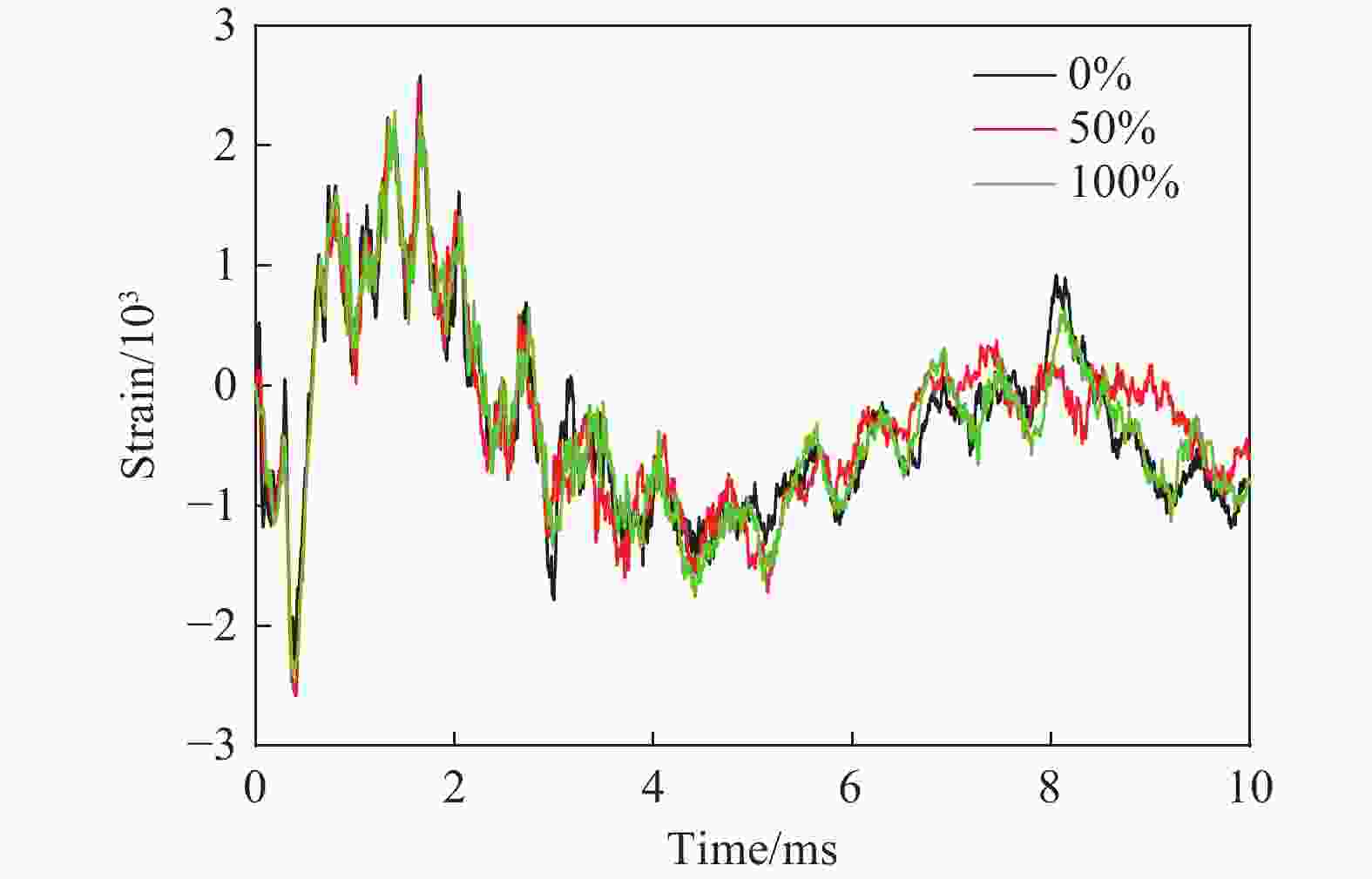

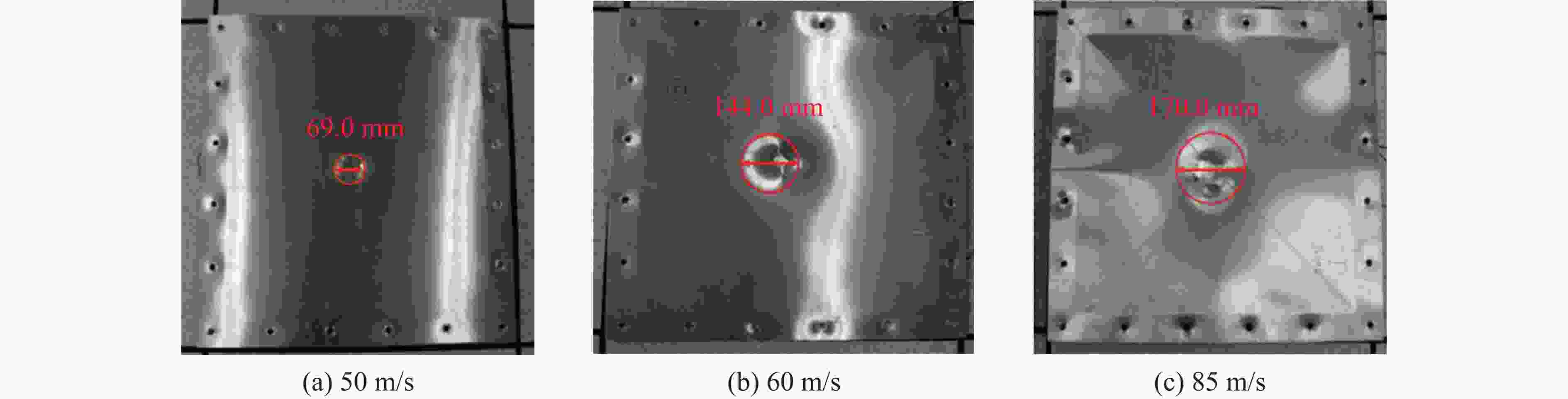

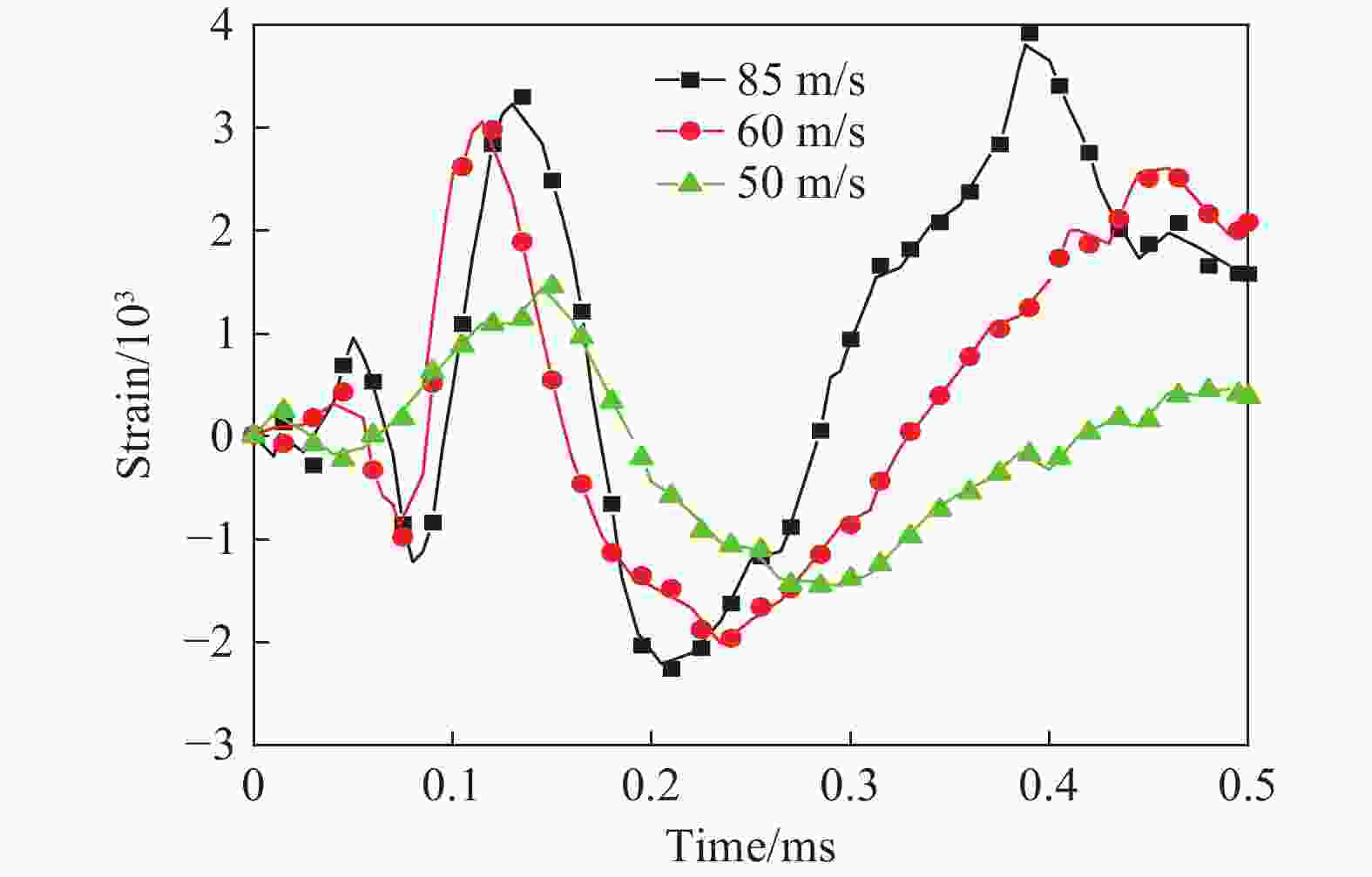

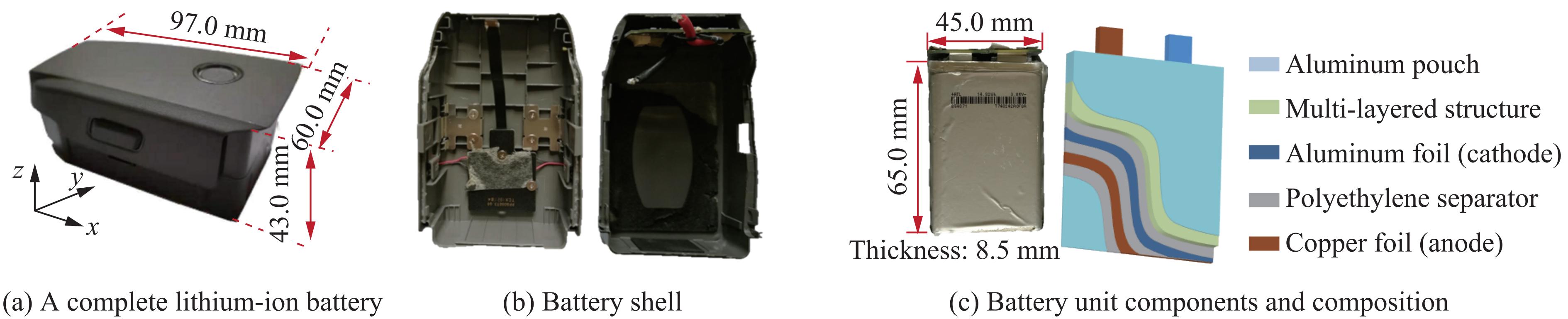

摘要: 为研究轻型消费级无人机锂离子电池在高能量冲击下的动响应模式及爆炸着火特性,评估锂离子电池在动态冲击时的安全性能,以某轻型消费级无人机软包锂离子电池为研究对象,采用落锤冲击及气炮冲击实验方法,结合轻型无人机实际应用场景,分别开展了软包电池组落锤冲击及电池高速冲击铝板测试实验,探讨了不同电池电量的软包电池组在受冲击后的变形模式及着火情况,结合电池的机械变形响应及其着火演化特性分析了软包锂离子电池的冲击安全性。研究结果表明,轻型消费级无人机软包锂离子电池在常规电池外壳防护条件下受面外方向载荷冲击后的着火风险高于面内方向载荷冲击后的着火风险;锂离子电池着火风险与电池电量、冲击速度等具有明显相关性,锂离子电池本身的力学响应主要受自身材料及结构的影响,电池电量并不会影响电池的机械力学碰撞响应;本研究中所采用的锂离子电池样品在电池电量为 100% 时以 50 m/s 的速度撞击铝板,以及电池电量为 50% 以下时以 85 m/s 的速度撞击铝板后的燃烧风险均相对较低。Abstract: This paper takes the soft-package lithium-ion batteries as the research objects to study the dynamic response modes and explosion ignition characteristics of lithium-ion batteries used in light-weight and small consumer unmanned aerial vehicles (UAVs) under high-energy impact and evaluate the safety performances of lithium batteries under dynamic impact. The drop hammer and gas gun were used to carry out the drop-hammer impact of the soft-package battery pack and the high-speed impact of the battery on the aluminum plate. The deformation modes and ignition characteristics of the soft-package lithium-ion batteries under different battery powers after impact were studied. Based on the mechanical deformation response and ignition characteristics of the batteries, the impact safety of small soft-package lithium-ion batteries was analyzed. The results show that the ignition risk of small soft-package lithium-ion batteries under conventional battery shell protection after being impacted by loads in the out-of-plane direction is much higher than that impacted in the in-plane direction. The ignition risk of lithium-ion batteries is related to battery power and impact velocity. The thickness of the impacted aluminum plate has little effect on the ignition risk of lithium-ion batteries. The lithium-ion battery samples used in this study all have a relatively low risk of combustion after impacting the aluminum plate at the velocity of 50 m/s with the state of charge of 100%, and at the velocity of 85 m/s with the states of charge of less than 50%, respectively.

-

表 1 实验用锂离子电池参数

Table 1. Parameters of lithium-ion batteries used in experiments

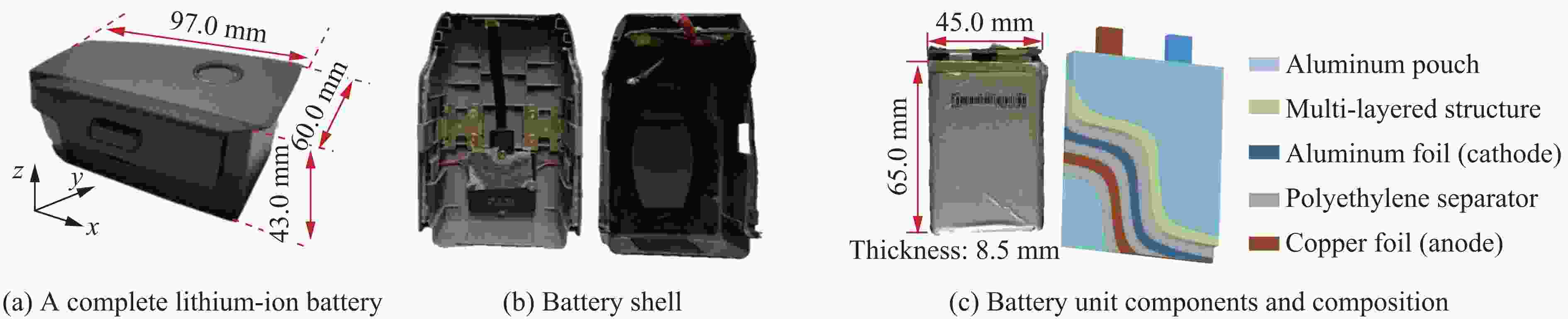

电池类型 标称电压/V 充电限制电压/V 尺寸 质量/g 电池单体 3.85 4.40 65.0 mm×45.0 mm×8.5 mm 61.5 整颗电池 15.40 17.60 97.0 mm×60.0 mm×43.0 mm 294.0 表 2 面外落锤冲击实验工况

Table 2. Conditions for out-of-plane drop-weight impact experiments

试件 电池充电状态/% 冲击能量/J 整颗电池D1 0 200 整颗电池D2 50 200 整颗电池D3 100 200 表 3 面内气炮冲击实验工况

Table 3. Conditions for in-plane gas gun impact experiments

试件 充电状态/% 铝板厚度/mm 冲击能量/J 冲击速度/(m∙s−1) 整颗电池D4 0 5.0 1 062 85 整颗电池D5 50 5.0 1 062 85 整颗电池D6 100 5.0 1 062 85 整颗电池D7 100 2.0 201 37 整颗电池D8 100 2.0 368 50 整颗电池D9 100 2.0 529 60 整颗电池D10 100 2.0 1 062 85 -

[1] CHEN X, ZOU Q, BAI J, et al. An information integration technology for safety assessment on civil airborne system [J]. Aerospace, 2024, 11(6): 459. DOI: 10.3390/AEROSPACE11060459. [2] ZHANG H H, TIAN T, FENG O G, et al. Research on public air route network planning of urban low-altitude logistics unmanned aerial vehicles [J]. Sustainability, 2023, 15(15): 12021. DOI: 10.3390/SU151512021. [3] FAN J J, FAN L L, NI Q H, et al. Perception and planning of intelligent vehicles based on BEV in extreme off-road scenarios [J]. IEEE Transactions on Intelligent Vehicles, 2024, 9(4): 4568–4572. DOI: 10.1109/TIV.2024.3392753. [4] 余莎莎, 陈艺君, 张学军. 城市低空场景下无人机运行对地风险量化评估 [J]. 北京航空航天大学学报, DOI: 10.13700/j.bh.1001-5965.2024.0244.YU S S, CHEN Y J, ZHANG X J. Urban low scenario drone operation of quantitative risk assessment [J]. Journal of Beijing University of Aeronautics and Astronautics, DOI: 10.13700/j.bh.1001-5965.2024.0244. [5] 韩鹏, 赵嶷飞, 刘宏. 无人机地面撞击风险评估体系构建及趋势展望 [J]. 中国民航大学学报, 2021, 39(1): 40–47. DOI: 10.3969/j.issn.1674-5590.2021.01.008.HAN P, ZHAO Y F, LIU H. Assessment system construction and trend foresight of UAV ground impact risk [J]. Journal of Civil Aviation University of China, 2021, 39(1): 40–47. DOI: 10.3969/j.issn.1674-5590.2021.01.008. [6] XIA C Y, YANG C R, XUE K, et al. A conflict risk analysis of MAV\UAV flight in shared airspace [J]. International Journal of Aerospace Engineering, 2021, 2021(1): 1692896. DOI: 10.1155/2021/1692896. [7] 郭亚周, 刘小川, 郭军, 等. 微型无人机和鸟体撞击飞机风挡玻璃对比实验 [J]. 实验力学, 2020, 35(1): 167–173. DOI: 10.7520/1001-4888-18-111.GUO Y Z, LIU X C, GUO J, et al. Comparative experiment of aircraft windshield glass subjected to micro-UAV and bird body impact [J]. Journal of Experimental Mechanics, 2020, 35(1): 167–173. DOI: 10.7520/1001-4888-18-111. [8] MEIER J D. Material characterization of high-voltage lithium-ion battery models for crashworthiness analysis [D]. Cambridge: Massachusetts Institute of Technology, 2013. [9] ZHANG X W, SAHRAEI E, WANG K. Deformation and failure characteristics of four types of lithium-ion battery separators [J]. Journal of Power Sources, 2016, 327: 693–701. DOI: 10.1016/j.jpowsour.2016.07.078. [10] 朱瑞卿, 胡玲玲, 周名哲. 锂离子电池多次冲击下的失效模式及损伤机制 [J]. 固体力学学报, 2023, 44(6): 795–804. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2023.032.ZHU R Q, HU L L, ZHOU M Z. Failure modes and damage mechanisms of lithium-ion batteries under repeated impacts [J]. Chinese Journal of Solid Mechanics, 2023, 44(6): 795–804. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2023.032. [11] JIA Y K, YIN S, LIU B H, et al. Unlocking the coupling mechanical-electrochemical behavior of lithium-ion battery upon dynamic mechanical loading [J]. Energy, 2019, 166: 951–960. DOI: 10.1016/j.energy.2018.10.142. [12] ZHU J E, KOCH M M, LIAN J H, et al. Mechanical deformation of lithium-ion pouch cells under in-plane loads: part Ⅰ: experimental investigation [J]. Journal of the Electrochemical Society, 2020, 167(9): 090533. DOI: 10.1149/1945-7111/ab8e83. [13] PAN Z X, LI W, XIA Y. Experiments and 3D detailed modeling for a pouch battery cell under impact loading [J]. Journal of Energy Storage, 2020, 27: 101016. DOI: 10.1016/j.est.2019.101016. [14] ZHU J E, LI W, WIERZBICKI T, et al. Deformation and failure of lithium-ion batteries treated as a discrete layered structure [J]. International Journal of Plasticity, 2019, 121: 293–311. DOI: 10.1016/j.ijplas.2019.06.011. [15] CHEN X P, WANG T, ZHANG Y, et al. Dynamic mechanical behavior of prismatic lithium-ion battery upon impact [J]. International Journal of Energy Research, 2019, 43(13): 7421–7432. DOI: 10.1002/er.4774. [16] ZHANG X W, WIERZBICKI T. Characterization of plasticity and fracture of shell casing of lithium-ion cylindrical battery [J]. Journal of Power Sources, 2015, 280: 47–56. DOI: 10.1016/j.jpowsour.2015.01.077. [17] WIERZBICKI T, SAHRAEI E. Homogenized mechanical properties for the jellyroll of cylindrical lithium-ion cells [J]. Journal of Power Sources, 2013, 241: 467–476. DOI: 10.1016/j.jpowsour.2013.04.135. [18] SAHRAEI E, KAHN M, MEIER J, et al. Modelling of cracks developed in lithium-ion cells under mechanical loading [J]. RSC Advances, 2015, 5(98): 80369–80380. DOI: 10.1039/C5RA17865G. [19] LI H G, GU J H, PAN Y J, et al. On the strain rate-dependent mechanical behavior of PE separator for lithium-ion batteries [J]. International Journal of Impact Engineering, 2024, 194: 105079. DOI: 10.1016/j.ijimpeng.2024.105079. [20] LI H G, GU J H, ZHOU D, et al. Rate-dependent damage and failure behavior of lithium-ion battery electrodes [J]. Engineering Fracture Mechanics, 2024, 303: 110143. DOI: 10.1016/j.engfracmech.2024.110143. [21] LI H G, ZHOU D, ZHANG M H, et al. Multi-field interpretation of internal short circuit and thermal runaway behavior for lithium-ion batteries under mechanical abuse [J]. Energy, 2023, 263: 126027. DOI: 10.1016/j.energy.2022.126027. [22] ZHOU D, LI H G, LI Z H, et al. Toward the performance evolution of lithium-ion battery upon impact loading [J]. Electrochimica Acta, 2022, 432: 141192. DOI: 10.1016/j.electacta.2022.141192. [23] OLIVARES G. FAA sUAS COE task A3 UAS airborne collision hazard severity evaluation [R]. Washington: FAA, 2017. DOI: 10.13140/RG.2.2.30840.08968. [24] 郭亚周, 刘小川, 白春玉, 等. 轻小型无人机锂离子电池在冲击载荷下机械/电化学耦合失效特性试验 [J]. 科学技术与工程, 2022, 22(31): 14002–14010. DOI: 10.3969/j.issn.1671-1815.2022.31.049.GUO Y Z, LIU X C, BAI C Y, et al. Mechanical/electrochemical coupling failure characteristics tests of light and small UAVs lithium battery under impact load [J]. Science Technology and Engineering, 2022, 22(31): 14002–14010. DOI: 10.3969/j.issn.1671-1815.2022.31.049. [25] MENG X H, SUN Y J, YU J Y, et al. Dynamic response of the horizontal stabilizer during UAS airborne collision [J]. International Journal of Impact Engineering, 2019, 126: 50–61. DOI: 10.1016/j.ijimpeng.2018.11.015. [26] 刘新华, 郭斌, 何瑢, 等. 轻型无人机电池动态冲击性能研究 [J]. 机械工程学报, 2023, 59(2): 177–186. DOI: 10.3901/JME.2023.02.177.LIU X H, GUO B, HE R, et al. Research on dynamic impact performance of light-UAV battery [J]. Journal of Mechanical Engineering, 2023, 59(2): 177–186. DOI: 10.3901/JME.2023.02.177. -

下载:

下载: