A new test method for mode I dynamic fracture toughness of ceramic materials

-

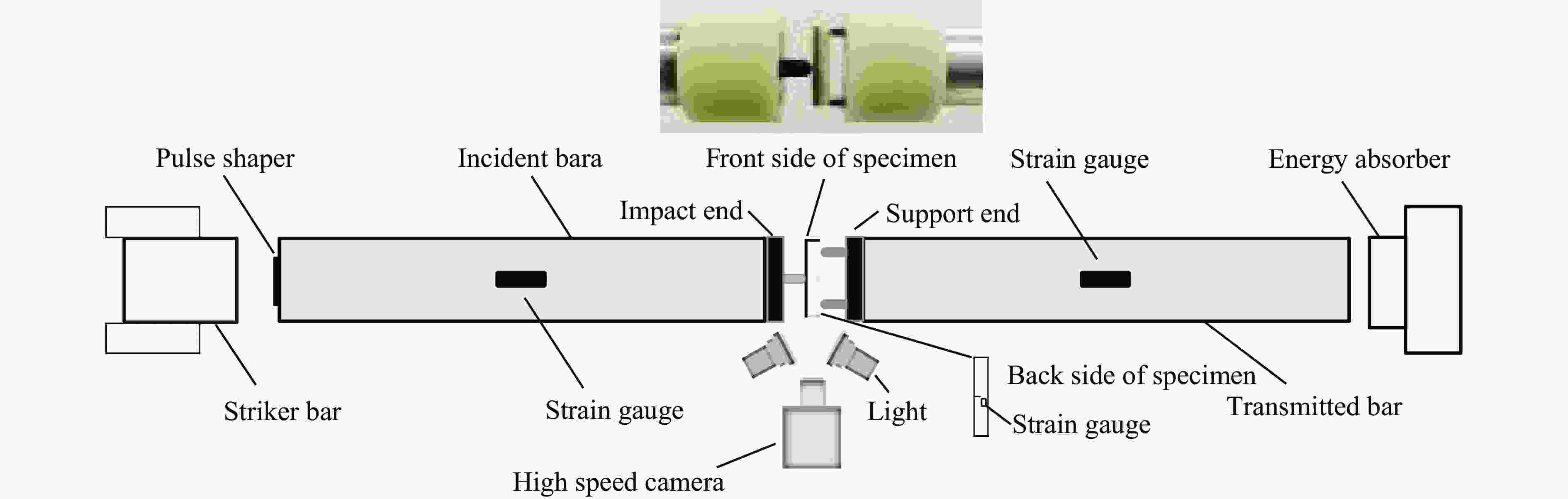

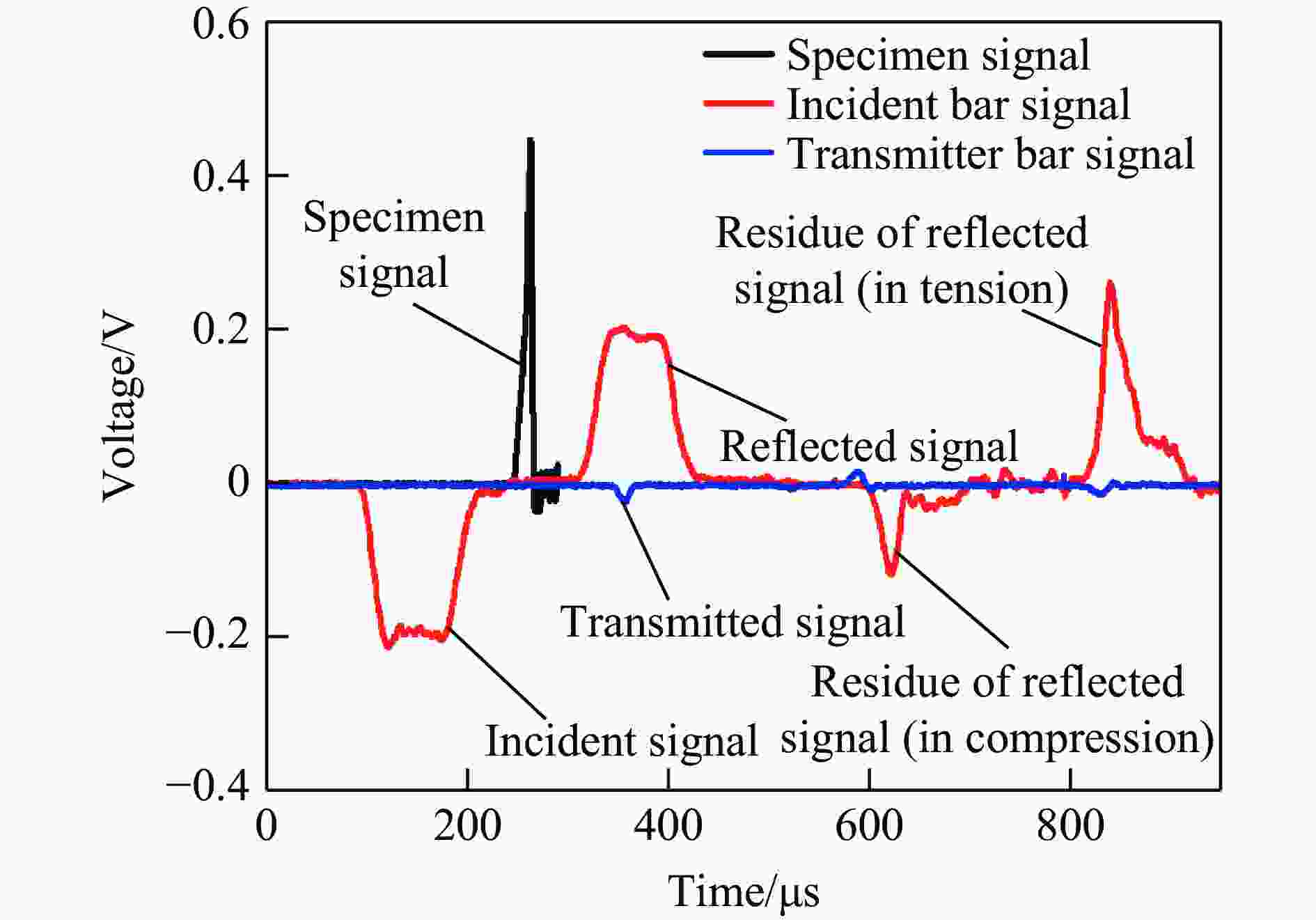

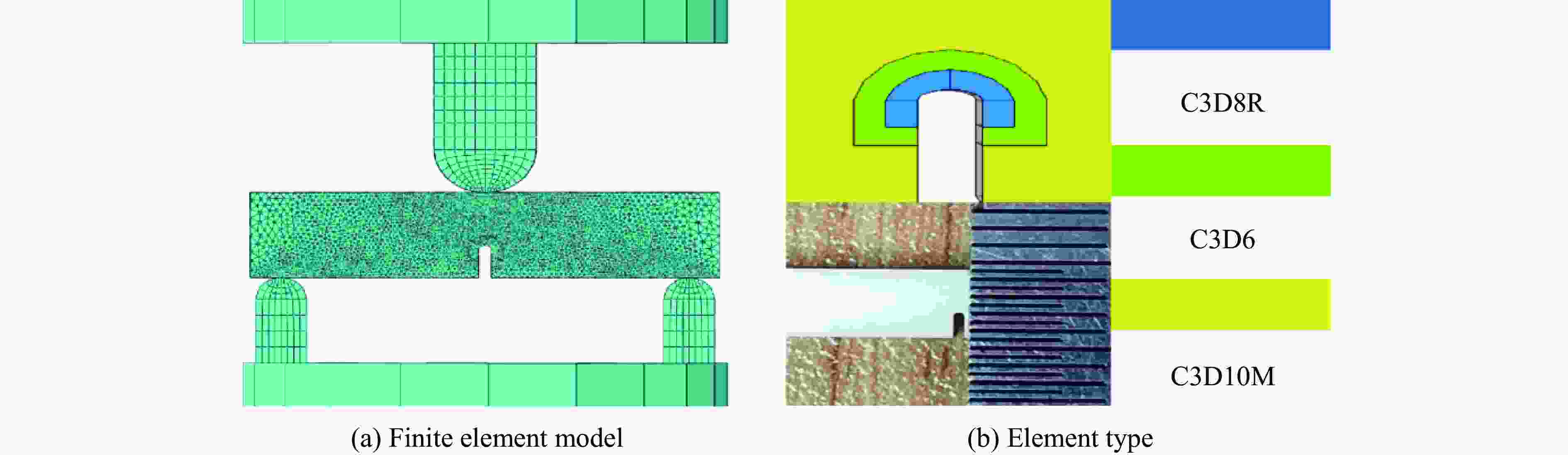

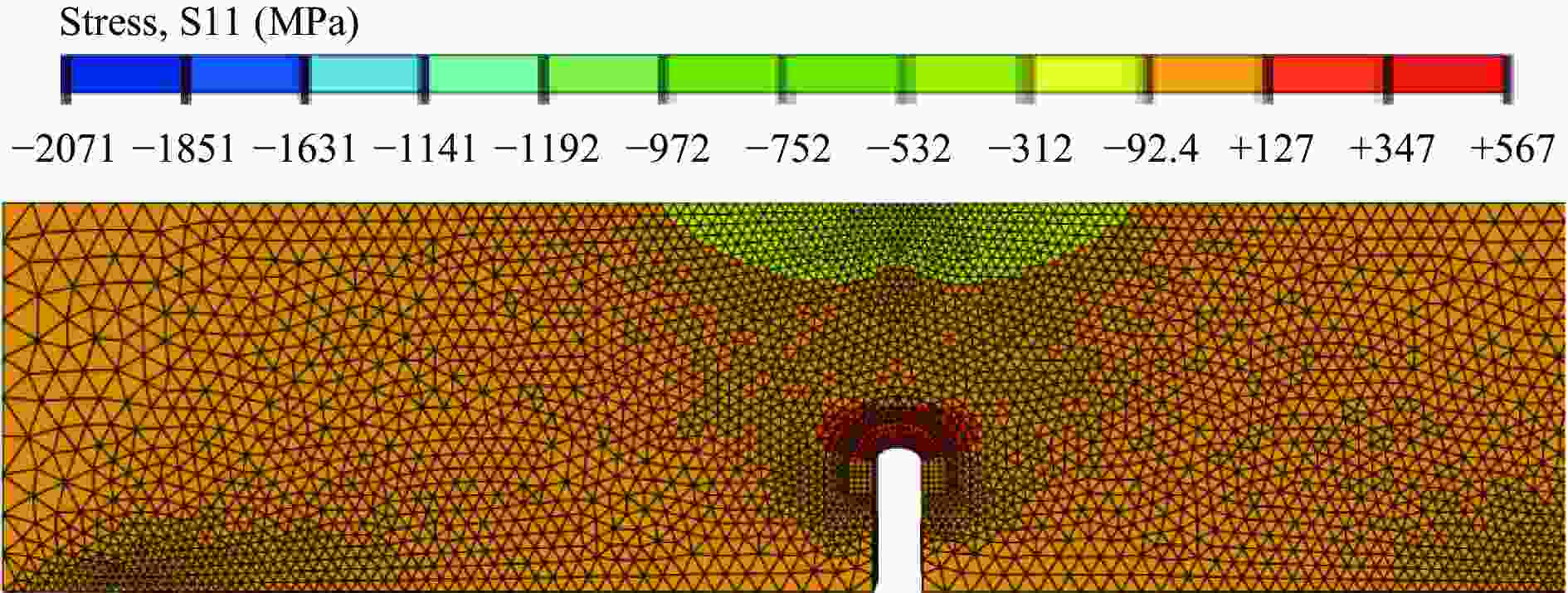

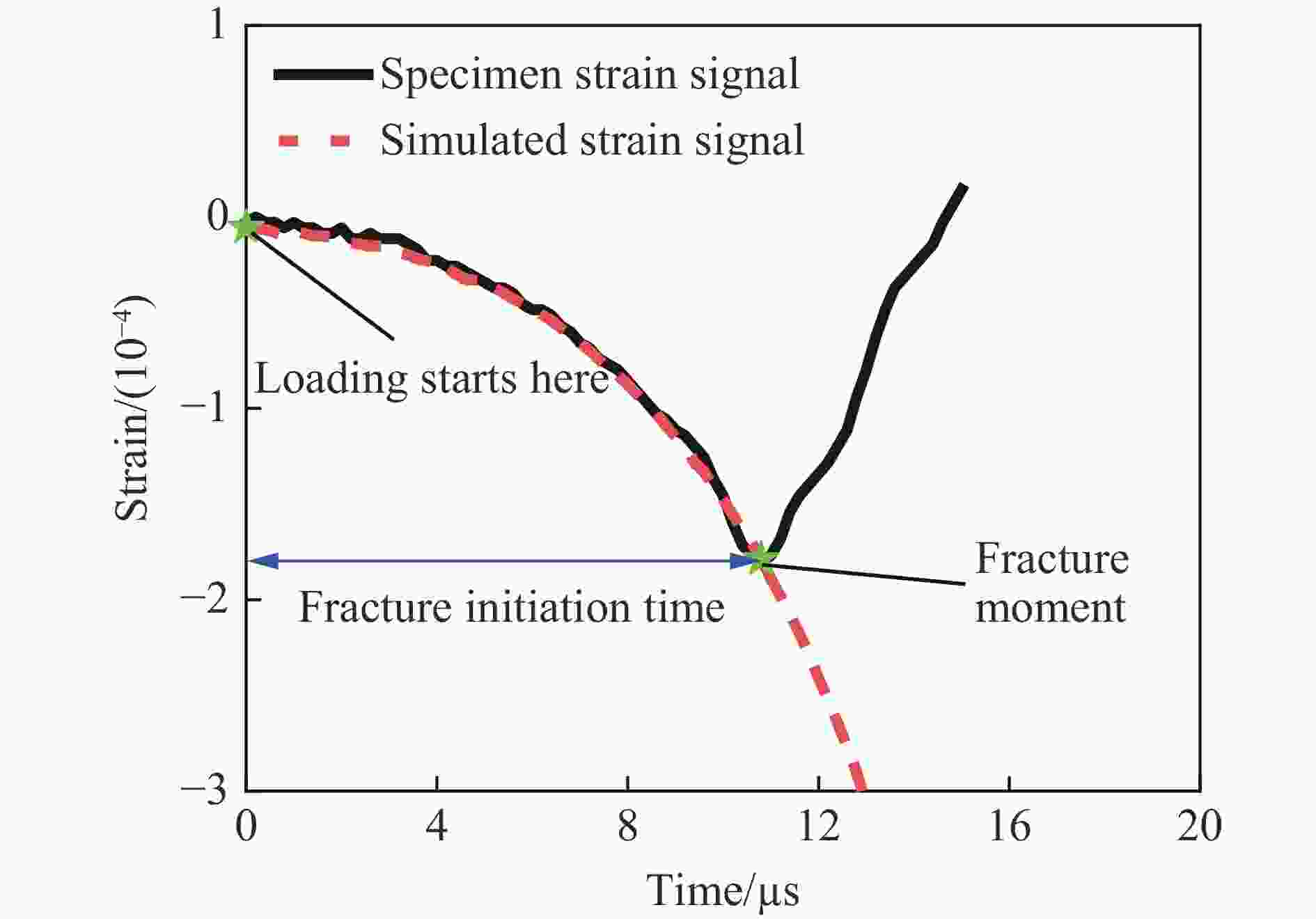

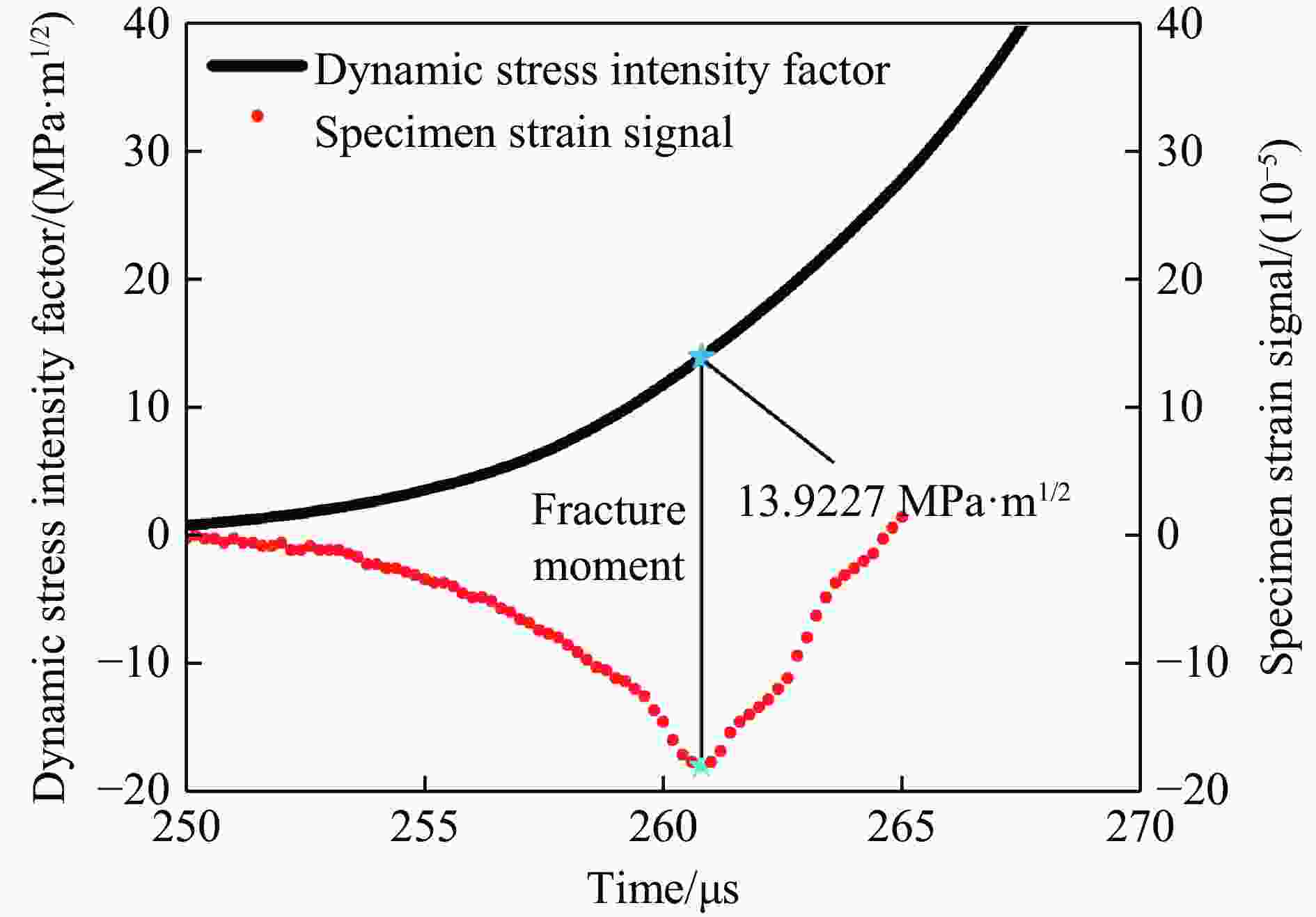

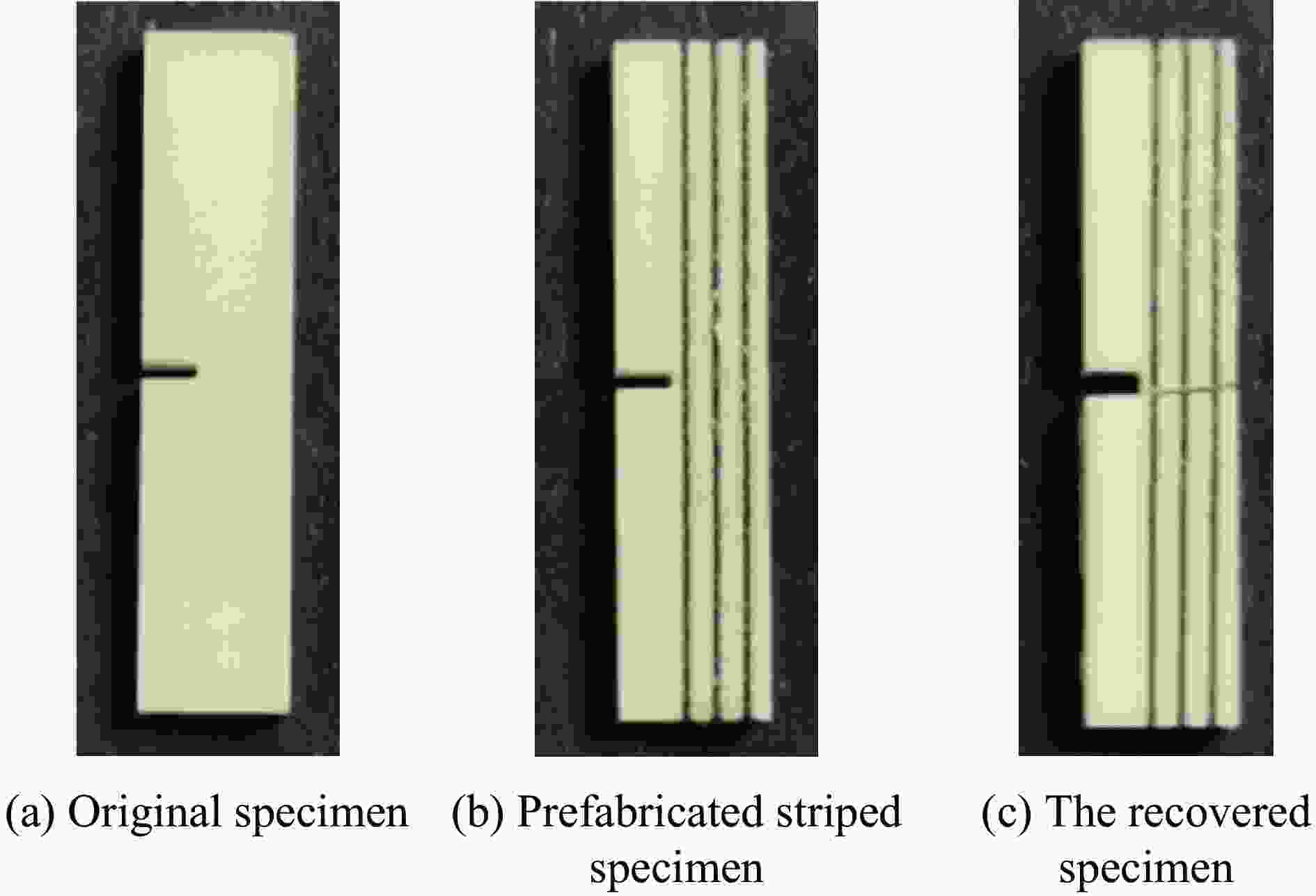

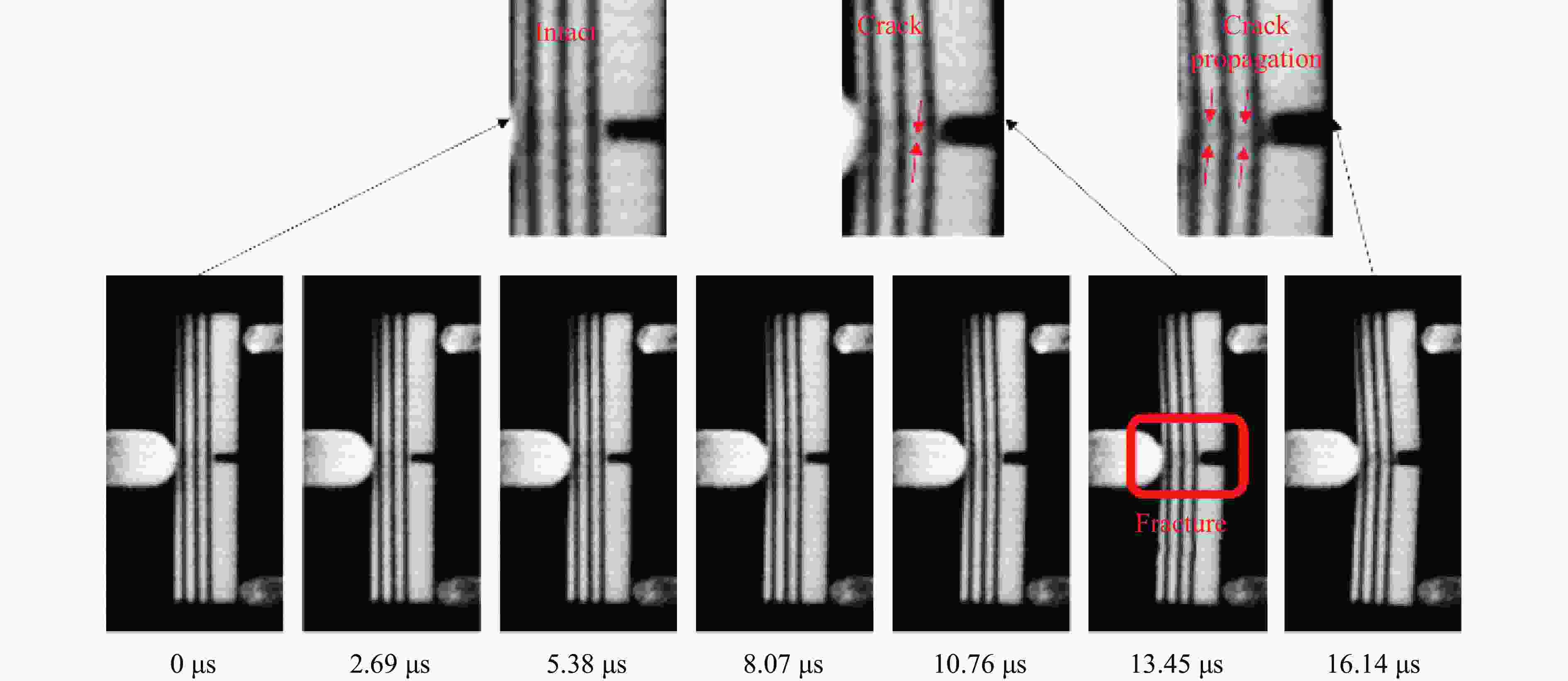

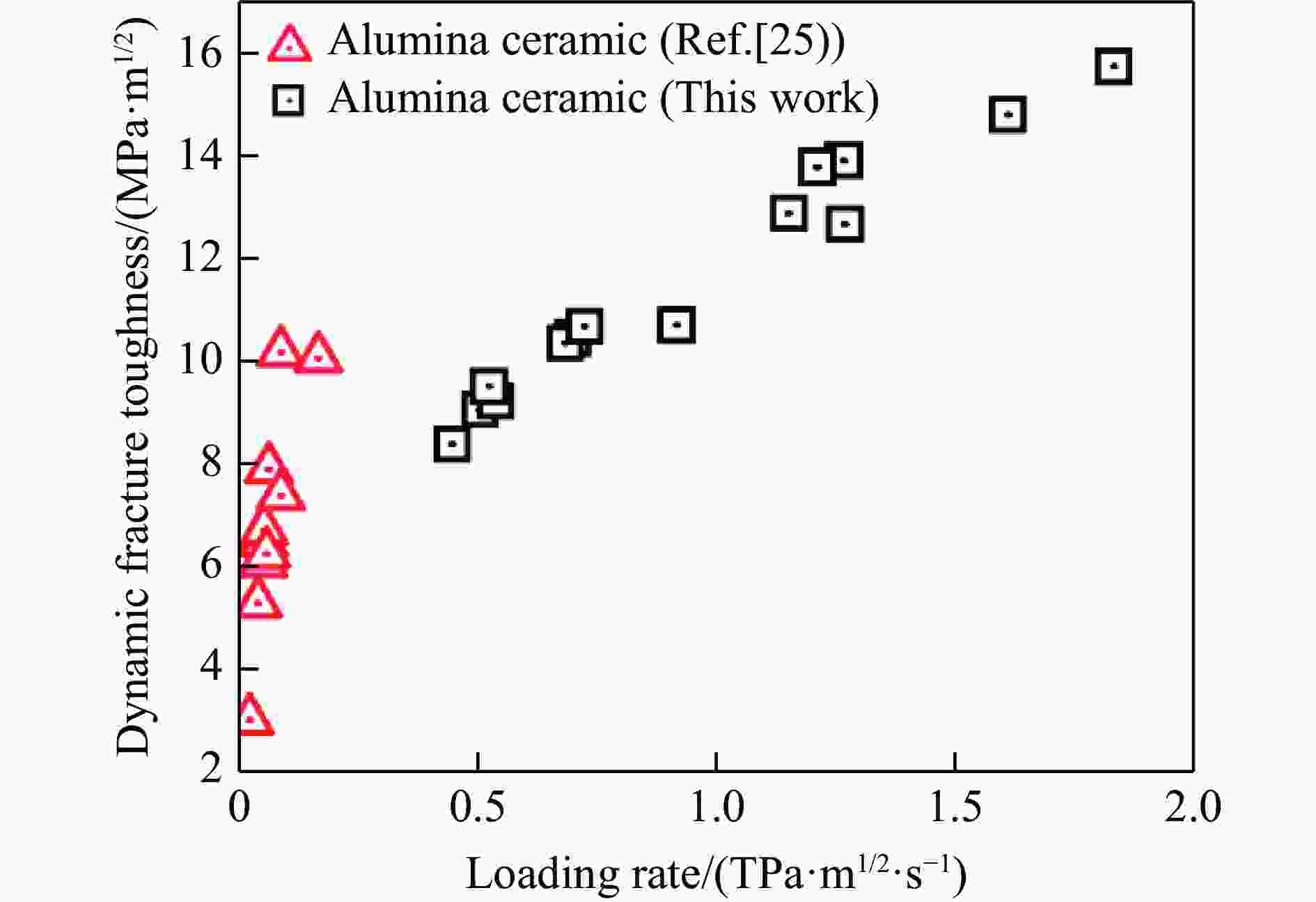

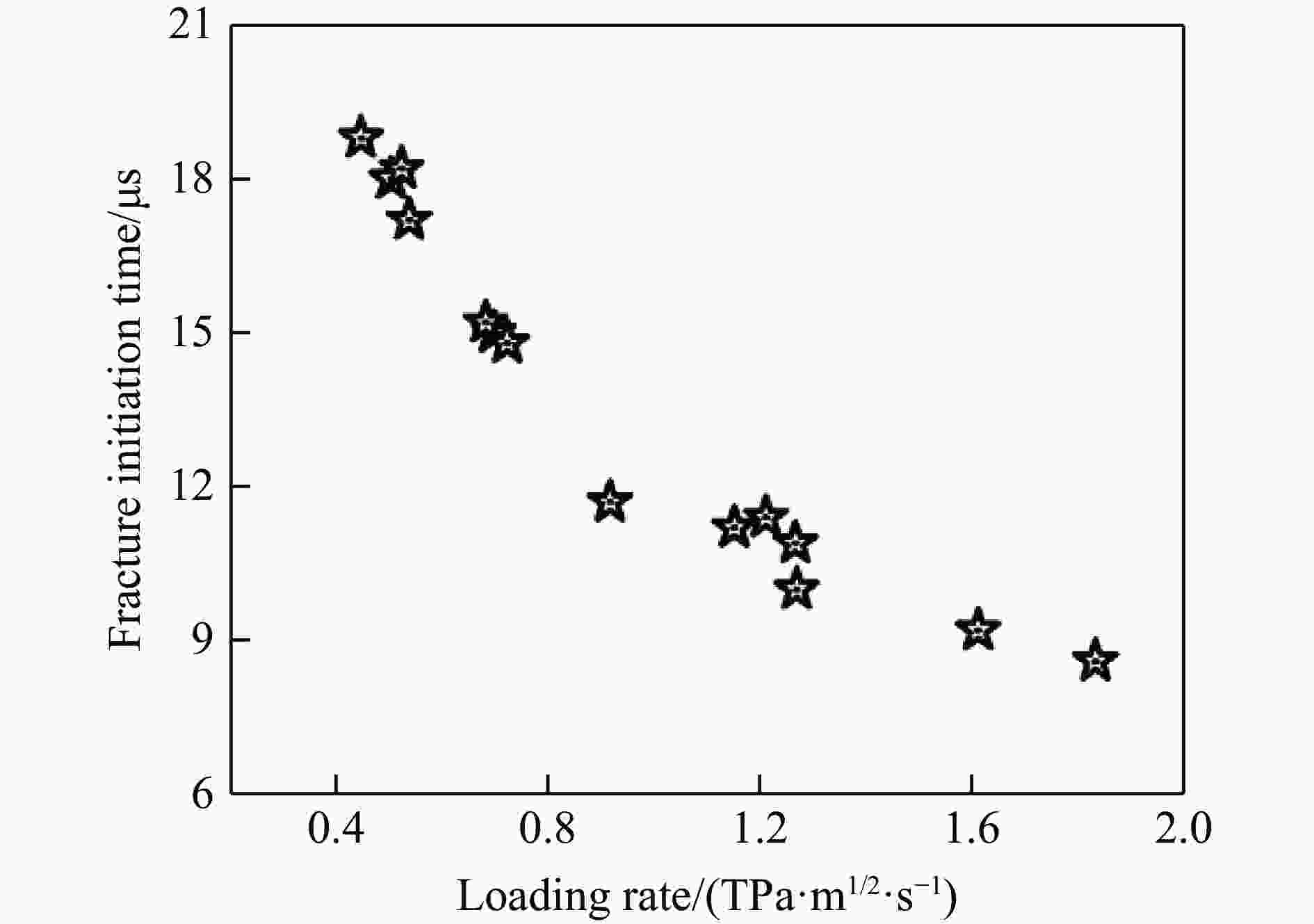

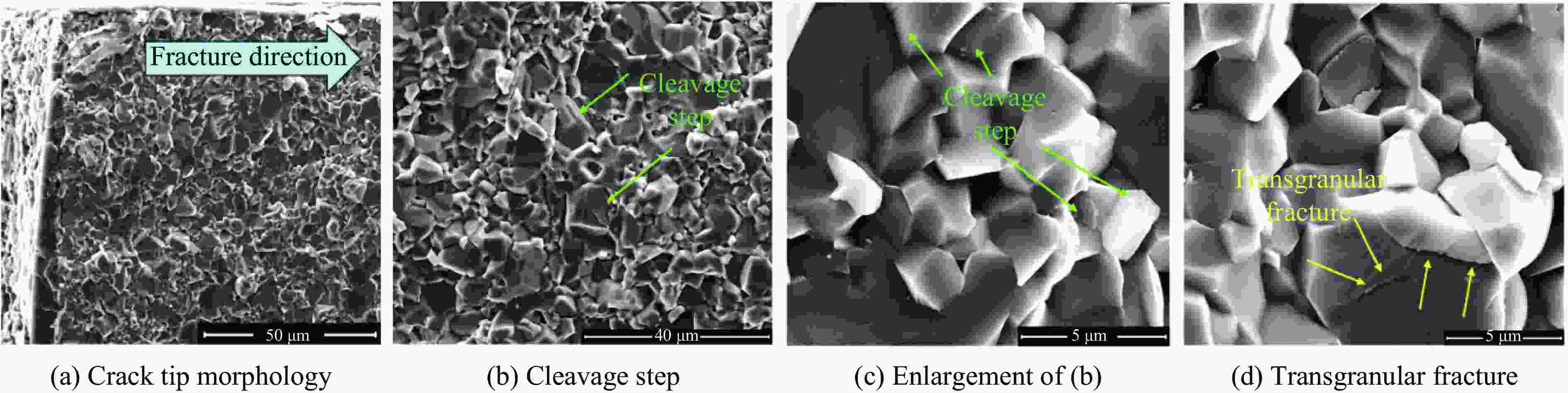

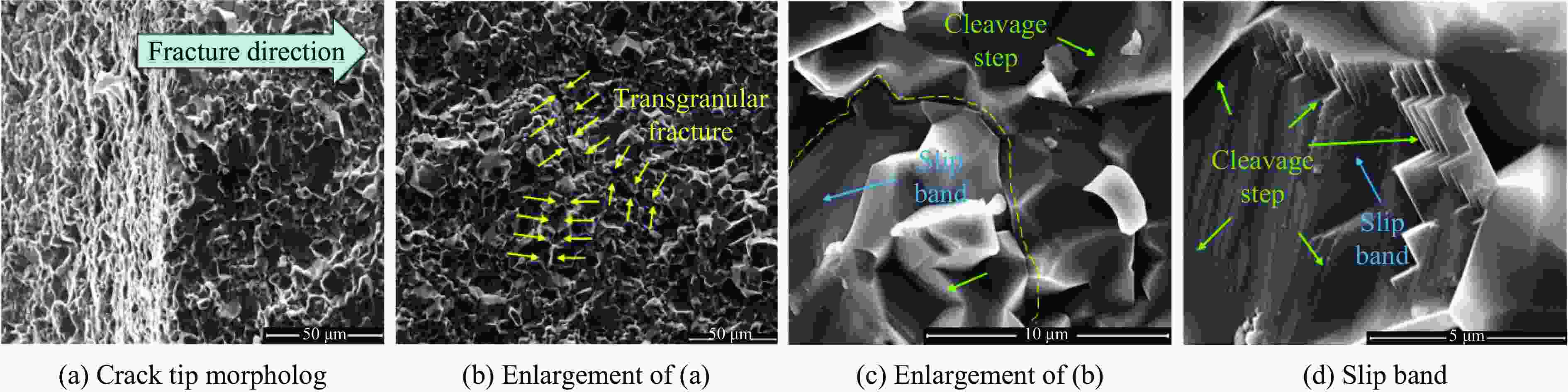

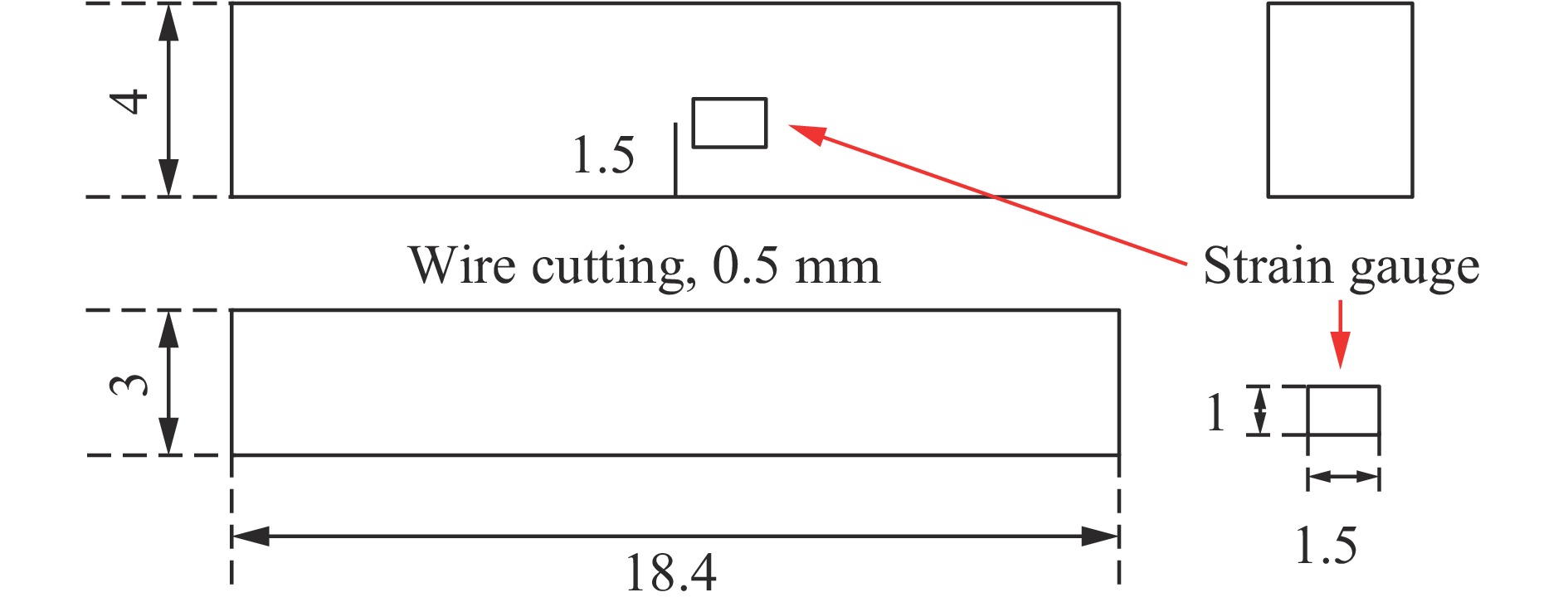

摘要: 基于霍普金森压杆技术,采用新设计的微型纯Ⅰ型断裂试样和配套夹具,提出了一种针对陶瓷材料的新型动态断裂测试方法,试样的起裂时间由应变片法测得;对氧化铝陶瓷开展了不同加载速率下的动态断裂实验,采用实验-数值方法得到了材料的Ⅰ型动态应力强度因子曲线及动态断裂韧性。结果显示:随着加载速率从0.45 TPa·m1/2·s−1提高到1.83 TPa·m1/2·s−1,氧化铝陶瓷的Ⅰ型动态断裂韧性值由8.39 MPa·m1/2增加至15.76 MPa·m1/2,而起裂时间则随着加载速率的增加而不断提前。由断口分析可知,随着加载速率的增加,氧化铝陶瓷由沿晶断裂占主导的失效模式逐步转变为以穿晶-沿晶相混合的断裂模式。这期间,更多的微缺陷被激活并扩展形成微裂纹,从而导致混合型断裂模式的发生。材料失效模式的转变将引起更多的能量耗散,这是断裂韧性升高的根本原因。Abstract: To address the longstanding challenge of accurately evaluating the dynamic fracture toughness of ceramic materials, a new mode I dynamic fracture testing method was developed based on the conventional split-Hopkinson pressure bar (SHPB) technique. This approach introduced a miniature fracture specimen specifically designed to ensure pure mode I loading, along with a custom fixture system that enabled stable and repeatable dynamic fracture experiments on alumina ceramics with varying loading rates. The combined experimental-numerical method was used to obtain the variation of the mode I dynamic stress intensity factor at the crack tip under different loading rates. Fracture initiation time was obtained with high precision using the strain gauge method, allowing for the determination of mode I dynamic fracture toughness. To further validate the accuracy of the measured fracture initiation time, high-speed photography was employed to capture the entire failure process in real time and corroborate the onset of fracture of the tested specimens. The results show that as the applied loading rate increases from 0.45 TPa·m1/2·s−1 to 1.83 TPa·m1/2·s−1, the dynamic fracture toughness of alumina ceramics rises significantly from 8.39 MPa·m1/2 to 15.76 MPa·m1/2, indicating a pronounced strengthening effect induced by higher loading rates. Meanwhile, the crack initiation time decreases notably with increasing loading rate. Fractographic analysis using scanning electron microscopy reveals a clear fracture mode transition behavior. Under lower loading rates, the fracture of alumina ceramics predominantly exhibits intergranular fracture features. Under higher loading rates, the fracture shows a mixed-mode fracture involving both intergranular and transgranular features. This transition is attributed to the activation and propagation of more micro-defects under higher rates, resulting in increased microcracking. The emergence of this mixed fracture mode is associated with greater energy dissipation, which fundamentally contributes to the increase in mode I dynamic fracture toughness. The proposed method offers a robust framework for accurately assessing the mode I dynamic fracture properties of ceramic materials.

-

表 1 氧化铝陶瓷的元素成分及质量分数

Table 1. Composition and mass fraction of alumina ceramic %

Al2O3 SiO2 Fe2O3 Na2O CaO MgO ≥99 0~2.8 0~0.025 0~0.06 0~1.5 0~0.05 表 2 氧化铝陶瓷的力学性能参数

Table 2. Mechanical properties of alumina ceramic

ρ/(g·cm−3) E/GPa μ σb/MPa 3.5~3.6 300 0.2 300 表 3 部的材料及力学性能

Table 3. Mechanical properties of materials

部件 材料 ρ/(kg·m−3) E/GPa μ 入射杆/透射杆 18Ni马氏体钢 8000 190 0.3 夹具 高强钢40Cr 7820 199 0.3 试样 氧化铝陶瓷 3550 350 0.2 -

[1] 余毅磊, 蒋招绣, 王晓东, 等. 轻型陶瓷/金属复合装甲抗垂直侵彻过程中陶瓷碎裂行为研究 [J]. 爆炸与冲击, 2021, 41(11): 113301. DOI: 10.11883/bzycj-2021-0134.YU Y L, JIANG Z X, WANG X D, et al. Research on ceramic fragmentation behavior of lightweight ceramic/metal composite armor during vertical penetration [J]. Explosion and Shock Waves, 2021, 41(11): 113301. DOI: 10.11883/bzycj-2021-0134. [2] 余毅磊, 王晓东, 任文科, 等. 三层组合陶瓷复合装甲的抗侵彻性能及其损伤机制 [J]. 兵工学报, 2024, 45(1): 44–57. DOI: 10.12382/bgxb.2022.0319.YU Y L, WANG X D, REN W K, et al. Anti-penetration performance and damage mechanism of three-layer composite ceramic armor [J]. Acta Armamentarii, 2024, 45(1): 44–57. DOI: 10.12382/bgxb.2022.0319. [3] 武一丁, 王晓东, 余毅磊, 等. 纤维背板结构对B4C陶瓷复合装甲抗侵彻破碎特性的影响 [J]. 爆炸与冲击, 2023, 43(9): 091411. DOI: 10.11883/bzycj-2023-0133.WU Y D, WANG X D, YU Y L, et al. Affection of fiber backboard structure on the penetration and crushing resistance of B4C ceramic composite armor [J]. Explosion and Shock Waves, 2023, 43(9): 091411. DOI: 10.11883/bzycj-2023-0133. [4] COMMINS T, GRAHAM A, SIVIOUR C R. Influence of surface preparation and polymer backing properties on the quasi-static and impact response of ceramic faced 1D armour systems [J]. International Journal of Impact Engineering, 2023, 180: 104708. DOI: 10.1016/j.ijimpeng.2023.104708. [5] 马铭辉, 武一丁, 王晓东, 等. 多孔钛合金夹芯层陶瓷/UHMWPE复合结构的抗侵彻性能 [J]. 爆炸与冲击, 2024, 44(4): 041001. DOI: 10.11883/bzycj-2023-0375.MA M H, WU Y D, WANG X D, et al. Penetration resistance of ceramic/UHMWPE composite structures with porous titanium alloy sandwich layer [J]. Explosion and Shock Waves, 2024, 44(4): 041001. DOI: 10.11883/bzycj-2023-0375. [6] 谢雨珊, 陆建华, 徐松林, 等. Mo-ZrC梯度金属陶瓷的冲击响应行为 [J]. 爆炸与冲击, 2023, 43(3): 033101. DOI: 10.11883/bzycj-2022-0374.XIE Y S, LU J H, XU S L, et al. On impact properties of Mo-ZrC gradient metal ceramics [J]. Explosion and Shock Waves, 2023, 43(3): 033101. DOI: 10.11883/bzycj-2022-0374. [7] HUANG C Y, CHEN Y L. Effect of mechanical properties on the ballistic resistance capability of Al2O3-ZrO2 functionally graded materials [J]. Ceramics International, 2016, 42(11): 12946–12955. DOI: 10.1016/j.ceramint.2016.05.067. [8] 牛欢欢, 闫晓鹏, 罗浩舜, 等. 不同应变率下蓝宝石透明陶瓷玻璃的力学响应 [J]. 爆炸与冲击, 2022, 42(7): 073105. DOI: 10.11883/bzycj-2021-0434.NIU H H, YAN X P, LUO H S, et al. Mechanical response of sapphire transparent ceramic glass at different strain rates [J]. Explosion and Shock Waves, 2022, 42(7): 073105. DOI: 10.11883/bzycj-2021-0434. [9] 党泉勇, 葛彦鑫, 高玉波. 冲击加载下Al2O3/SiC复合陶瓷的动态力学行为 [J]. 兵工学报, 2022, 43(1): 175–180. DOI: 10.3969/j.issn.1000-1093.2022.01.019.DANG Q Y, GE Y X, GAO Y B. Dynamic mechanical properties of Al2O3/SiC composite ceramic subjected to impact loading [J]. Acta Armamentarii, 2022, 43(1): 175–180. DOI: 10.3969/j.issn.1000-1093.2022.01.019. [10] AKELLA K. Studies for improved damage tolerance of ceramics against ballistic impact using layers [J]. Procedia Engineering, 2017, 173: 244–250. DOI: 10.1016/j.proeng.2016.12.006. [11] BAO J W, WANG Y W, CHENG X W, et al. Ballistic properties of silicon carbide ceramic under weak support conditions [J]. Journal of Materials Research and Technology, 2024, 28: 1764–1773. DOI: 10.1016/j.jmrt.2023.12.035. [12] 何泽夏, 路民旭, 郑修麟, 等. 陶瓷材料裂纹制备及其在KIC测试中的应用 [J]. 兵器材料科学与工程, 1993, 16(2): 57–60. DOI: 10.14024/j.cnki.1004-244x.1993.02.014. [13] 王学成, 金志浩, 李光新, 等. 双扭法及其在脆性材料力学性能评定中的应用 [J]. 材料科学进展, 1989, 3(5): 436–441.WANG X C, JIN Z H, LI G X, et al. Double torsion method and its use for mechanical properties evaluation of brittle materials [J]. Chinese Journal of Materials Research, 1989, 3(5): 436–441. [14] KASAEIAN-NAEINI M, SEDIGHI M, HASHEMI R, et al. Microstructure, mechanical properties and fracture toughness of ECAPed magnesium matrix composite reinforced with hydroxyapatite ceramic particulates for bioabsorbable implants [J]. Ceramics International, 2023, 49(11): 17074–17090. DOI: 10.1016/j.ceramint.2023.02.069. [15] SUN N J, CHENG Y, ZHU T B, et al. Mechanical properties of binderless tungsten carbide enhanced via the addition of ZrO2-20 wt% Al2O3 composite powder and graphene nanosheets [J]. Ceramics International, 2023, 49(14): 22853–22860. DOI: 10.1016/j.ceramint.2023.04.109. [16] SUN N J, ZHU T B, LIANG X, et al. Improved comprehensive mechanical properties of oscillatory pressure sintered WC–ZrO2–Al2O3 ceramics with VC/Cr3C2 addition [J]. Ceramics International, 2023, 49(7): 11494–11503. DOI: 10.1016/j.ceramint.2022.11.349. [17] 吴昊龙, 曹大可, 李俊峰, 等. 莫来石涂层对氧化铝基体力学性能的影响 [J]. 硅酸盐学报, 2023, 51(3): 750–756. DOI: 10.14062/j.issn.0454-5648.20221008.WU H L, CAO D K, LI J F, et al. Effects of mullite coating on mechanical properties of alumina component [J]. Journal of the Chinese Ceramic Society, 2023, 51(3): 750–756. DOI: 10.14062/j.issn.0454-5648.20221008. [18] KONG D K, GUO A F, WU H L, et al. Method for preparing biomimetic ceramic structures with high strength and high toughness [J]. Ceramics International, 2023, 49(24): 40284–40296. DOI: 10.1016/j.ceramint.2023.10.001. [19] CHAI J L, ZHU Y B, SHEN T L, et al. Assessing fracture toughness in sintered Al2O3–ZrO2(3Y)–SiC ceramic composites through indentation technique [J]. Ceramics International, 2020, 46(17): 27143–27149. DOI: 10.1016/j.ceramint.2020.07.194. [20] JI M, LI H Y, ZHENG J, et al. An experimental study on the strain-rate-dependent compressive and tensile response of an alumina ceramic [J]. Ceramics International, 2022, 48(19): 28121–28134. DOI: 10.1016/j.ceramint.2022.06.117. [21] ZAIEMYEKEH Z, LI H Y, ROMANYK D L, et al. Strain-rate-dependent behavior of additively manufactured alumina ceramics: Characterization and mechanical testing [J]. Journal of Materials Research and Technology, 2024, 28: 3794–3804. DOI: 10.1016/j.jmrt.2023.12.274. [22] MA Y Y, WANG Z Y, QIN Y Q. Impact of characteristic length and loading rate upon dynamic constitutive behavior and fracture process in alumina ceramics [J]. Ceramics International, 2023, 49(3): 4775–4784. DOI: 10.1016/j.ceramint.2022.09.367. [23] TONG S H, TIAN D Q, MA Q W, et al. Static and dynamic fracture toughness of graphite materials with varying grain sizes [J]. Journal of Nuclear Materials, 2024, 599: 155221. DOI: 10.1016/j.jnucmat.2024.155221. [24] PANDOURIA A K, KUMAR S, TIWARI V. Determination of static and dynamic fracture initiation toughness and numerical simulation of dynamic 3-point bend experiments of Al6063-T6 [J]. Mechanics Research Communications, 2023, 128: 104070. DOI: 10.1016/j.mechrescom.2023.104070. [25] 陈静静. 基于高速DIC方法的脆性材料动态力学性能研究 [D]. 北京: 北京理工大学, 2014: 43–44.CHEN J J. Study on the dynamic mechanical properties of brittle materials by high-speed DIC [D]. Beijing: Beijing Institute of Technology, 2014: 43–44. [26] LIU K W, GUO T F, YANG J C, et al. Static and dynamic fracture behavior of rock-concrete bi-material disc with different interface crack inclinations [J]. Theoretical and Applied Fracture Mechanics, 2023, 123: 103659. DOI: 10.1016/j.tafmec.2022.103659. [27] LIAN H H, SUN X J, YU Z P, et al. Study on the dynamic fracture properties and size effect of concrete based on DIC technology [J]. Engineering Fracture Mechanics, 2022, 274: 108789. DOI: 10.1016/j.engfracmech.2022.108789. [28] LI Z Y, WANG Z. Effect of interlayer carbon nanotube films on the quasi-static and dynamic mode Ⅰ fracture behavior of laminated composites – An experimental and numerical investigation [J]. Theoretical and Applied Fracture Mechanics, 2023, 125: 103932. DOI: 10.1016/j.tafmec.2023.103932. [29] FENG W H, TANG Y C, HE W M, et al. Mode Ⅰ dynamic fracture toughness of rubberised concrete using a drop hammer device and split Hopkinson pressure bar [J]. Journal of Building Engineering, 2022, 48: 103995. DOI: 10.1016/j.jobe.2022.103995. [30] YANG Z Q, WANG Z J, QIN N. Experimental and numerical investigation of model I dynamic fracture toughness of 95W-3.5Ni-1.5Fe alloy using the semi-circular bend specimens [J]. Engineering Fracture Mechanics, 2021, 258: 108053. DOI: 10.1016/j.engfracmech.2021.108053. [31] ZHANG Z Z, MAO H T, CHEN Y L, et al. Dynamic fracture toughness and damage mechanism of 38CrMoAl steel under salt spray corrosion [J]. Theoretical and Applied Fracture Mechanics, 2022, 119: 103382. DOI: 10.1016/j.tafmec.2022.103382. [32] 赵亚溥. 裂纹动态起始问题的研究进展 [J]. 力学进展, 1996, 26(3): 362–378.ZHAO Y P. The advances of studies on the dynamic initiation of cracks [J]. Advances in Mechanics, 1996, 26(3): 362–378. [33] FAN C Z, XU Z J, HAN Y, et al. Study on mode I dynamic fracture characteristics with a mini three-point bending specimen for the split Hopkinson bar technique [J]. International Journal of Impact Engineering, 2023, 179: 104635. DOI: 10.1016/j.ijimpeng.2023.104635. [34] FAN C Z, XU Z J, HAN Y, et al. Effects of notch width and loading rate on the dynamic mode II fracture toughness of Ti-6Al-4V [J]. Engineering Fracture Mechanics, 2024, 304: 110173. DOI: 10.1016/j.engfracmech.2024.110173. [35] FAN C Z, XU Z J, HAN Y, et al. Loading rate effect and failure mechanisms of ultra-high-strength steel under mode Ⅱ fracture [J]. International Journal of Impact Engineering, 2023, 171: 104374. DOI: 10.1016/j.ijimpeng.2022.104374. [36] 范昌增, 许泽建, 何晓东, 等. 加载速率对40Cr钢Ⅱ型动态断裂特性的影响 [J]. 爆炸与冲击, 2021, 41(8): 083101. DOI: 10.11883/bzycj-2021-0029.FAN C Z, XU Z J, HE X D, et al. Effect of loading rate on the mode Ⅱ dynamic fracture characteristics of 40Cr steel [J]. Explosion and Shock Waves, 2021, 41(8): 083101. DOI: 10.11883/bzycj-2021-0029. [37] 张永新, 范昌增, 许泽建, 等. 球墨铸铁在低温及冲击载荷下的韧脆转变行为 [J]. 爆炸与冲击, 2025, 45(8): 083103. DOI: 10.11883/bzycj-2024-0002.ZHANG Y X, FAN C Z, XU Z J, et al. Ductile-brittle transition behaviors of nodular cast iron under low temperature and impact loading [J]. Explosion and Shock Waves, 2025, 45(8): 083103. DOI: 10.11883/bzycj-2024-0002. [38] 蔡治城, 许泽建, 郭保桥, 等. 氧化锆陶瓷的动态弯曲断裂行为 [J]. 兵工学报, 2025, 46(4): 270–278. DOI: 10.12382/bgxb.2024.0020.CAI Z C, XU Z J, GUO B Q, et al. Dynamic bending fracture behavior of zirconia ceramic [J]. Acta Armamentarii, 2025, 46(4): 270–278. DOI: 10.12382/bgxb.2024.0020. -

下载:

下载: