| [1] |

CHEN Y Q, KANG Y Q, ZHAO Y, et al. A review of lithium-ion battery safety concerns: the issues, strategies, and testing standards [J]. Journal of Energy Chemistry, 2021, 59: 83–99. DOI: 10.1016/j.jechem.2020.10.017.

|

| [2] |

陈文博, 颜健, 孟凌杰, 等. 电动汽车动力锂电池火灾危险性的研究进展 [J]. 电源技术, 2021, 45(2): 270–273. DOI: 10.3969/j.issn.1002-087X.2021.02.030.CHEN W B, YAN J, MENG L J, et al. Analysis of current situation of fire hazard of power lithium ion batteries for electric vehicles [J]. Chinese Journal of Power Sources, 2021, 45(2): 270–273. DOI: 10.3969/j.issn.1002-087X.2021.02.030.

|

| [3] |

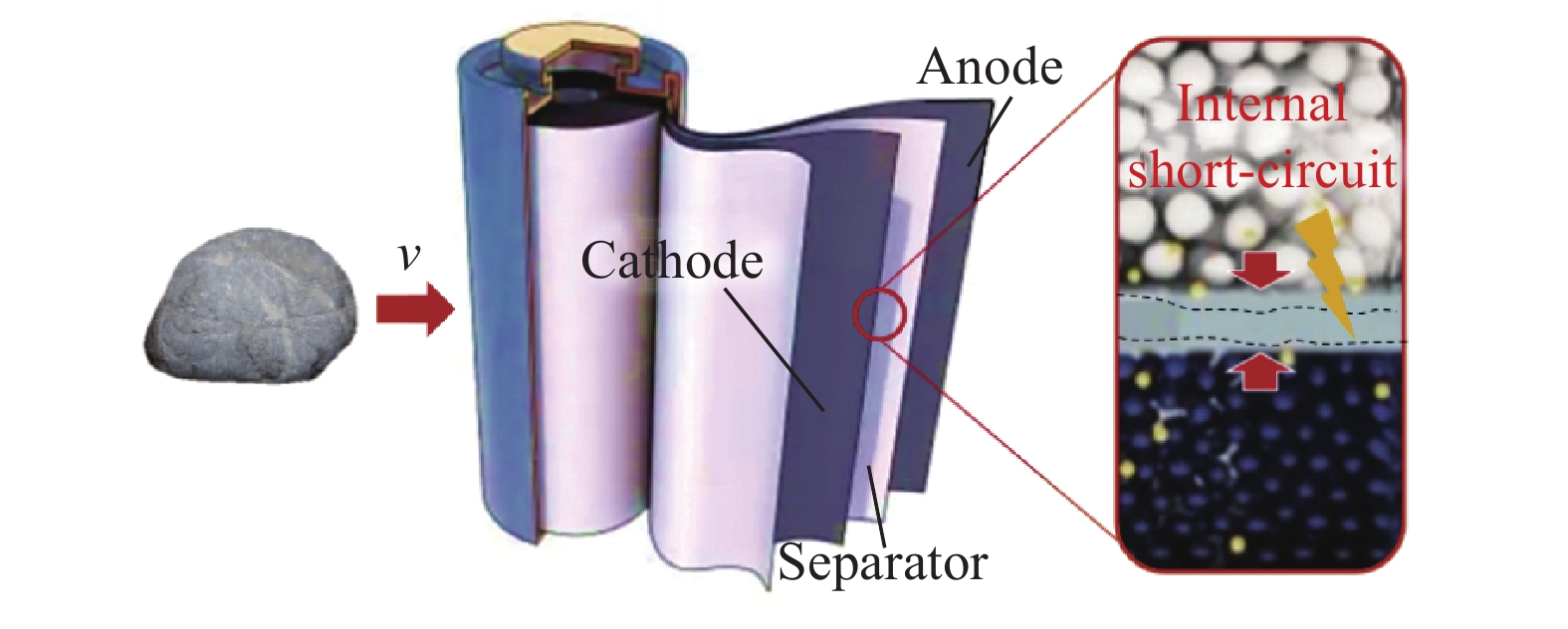

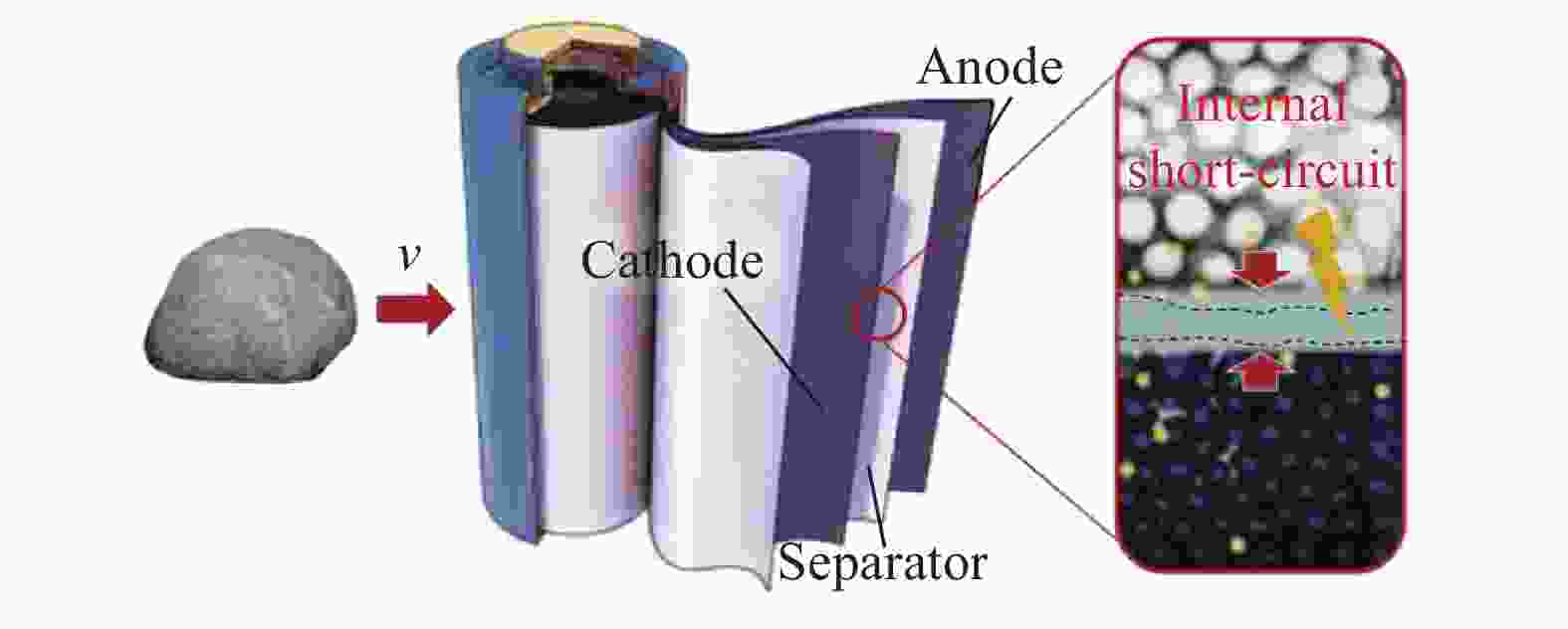

LIU B H, JIA Y K, YUAN C H, et al. Safety issues and mechanisms of lithium-ion battery cell upon mechanical abusive loading: a review [J]. Energy Storage Materials, 2020, 24: 85–112. DOI: 10.1016/j.ensm.2019.06.036.

|

| [4] |

XIA Y, WIERZBICKI T, SAHRAEI E, et al. Damage of cells and battery packs due to ground impact [J]. Journal of Power Sources, 2014, 267: 78–97. DOI: 10.1016/j.jpowsour.2014.05.078.

|

| [5] |

GREVE L, FEHRENBACH C. Mechanical testing and macro-mechanical finite element simulation of the deformation, fracture, and short circuit initiation of cylindrical lithium ion battery cells [J]. Journal of Power Sources, 2012, 214: 377–385. DOI: 10.1016/j.jpowsour.2012.04.055.

|

| [6] |

SAHRAEI E, MEIER J, WIERZBICKI T. Characterizing and modeling mechanical properties and onset of short circuit for three types of lithium-ion pouch cells [J]. Journal of Power Sources, 2014, 247: 503–516. DOI: 10.1016/j.jpowsour.2013.08.056.

|

| [7] |

AVDEEV I, GILAKI M. Structural analysis and experimental characterization of cylindrical lithium-ion battery cells subject to lateral impact [J]. Journal of Power Sources, 2014, 271: 382–391. DOI: 10.1016/j.jpowsour.2014.08.014.

|

| [8] |

ZHU X Q, WANG H, WANG X, et al. Internal short circuit and failure mechanisms of lithium-ion pouch cells under mechanical indentation abuse conditions: an experimental study [J]. Journal of Power Sources, 2020, 455: 227939. DOI: 10.1016/j.jpowsour.2020.227939.

|

| [9] |

ZHANG X W, SAHRAEI E, WANG K. Li-ion battery separators, mechanical integrity and failure mechanisms leading to soft and hard internal shorts [J]. Scientific Reports, 2016, 6: 32578. DOI: 10.1038/srep32578.

|

| [10] |

WIERZBICKI T, SAHRAEI E. Homogenized mechanical properties for the jellyroll of cylindrical lithium-ion cells [J]. Journal of Power Sources, 2013, 241: 467–476. DOI: 10.1016/j.jpowsour.2013.04.135.

|

| [11] |

XU J, LIU B H, WANG X Y, et al. Computational model of 18650 lithium-ion battery with coupled strain rate and SOC dependencies [J]. Applied Energy, 2016, 172: 180–189. DOI: 10.1016/j.apenergy.2016.03.108.

|

| [12] |

WANG L B, YIN S, XU J. A detailed computational model for cylindrical lithium-ion batteries under mechanical loading: From cell deformation to short-circuit onset [J]. Journal of Power Sources, 2019, 413: 284–292. DOI: 10.1016/j.jpowsour.2018.12.059.

|

| [13] |

SAHRAEI E, HILL R, WIERZBICKI T. Calibration and finite element simulation of pouch lithium-ion batteries for mechanical integrity [J]. Journal of Power Sources, 2012, 201: 307–321. DOI: 10.1016/j.jpowsour.2011.10.094.

|

| [14] |

XU J, LIU B H, WANG L B, et al. Dynamic mechanical integrity of cylindrical lithium-ion battery cell upon crushing [J]. Engineering Failure Analysis, 2015, 53: 97–110. DOI: 10.1016/j.engfailanal.2015.03.025.

|

| [15] |

YUAN C H, WANG L B, YIN S, et al. Generalized separator failure criteria for internal short circuit of lithium-ion battery [J]. Journal of Power Sources, 2020, 467: 228360. DOI: 10.1016/j.jpowsour.2020.228360.

|

| [16] |

FRANCIS C F J, KYRATZIS I L, BEST A S. Lithium-ion battery separators for ionic-liquid electrolytes: A review [J]. Advanced Materials, 2020, 32(18): 1904205. DOI: 10.1002/adma.201904205.

|

| [17] |

LAGADEC M F, ZAHN R, WOOD V. Characterization and performance evaluation of lithium-ion battery separators [J]. Nature Energy, 2019, 4(1): 16–25. DOI: 10.1038/s41560-018-0295-9.

|

| [18] |

ZHAO W, LUO G, WANG C Y. Modeling internal shorting process in large-format Li-ion cells [J]. Journal of the Electrochemical Society, 2015, 162(7): A1352–A1364. DOI: 10.1149/2.1031507jes.

|

| [19] |

WANG M, LE A V, NOELLE D J, et al. Internal-short-mitigating current collector for lithium-ion battery [J]. Journal of Power Sources, 2017, 349: 84–93. DOI: 10.1016/j.jpowsour.2017.03.004.

|

| [20] |

WU Q, YANG L, LI N, et al. In-situ thermography revealing the evolution of internal short circuit of lithium-ion batteries [J]. Journal of Power Sources, 2022, 540: 231602. DOI: 10.1016/j.jpowsour.2022.231602.

|

| [21] |

KIM J, MALLARAPU A, SANTHANAGOPALAN S. Transport processes in a Li-ion cell during an internal short-circuit [J]. Journal of the Electrochemical Society, 2020, 167(9): 090554. DOI: 10.1149/1945-7111/ab995d.

|

| [22] |

ZHANG M X, LIU L S, STEFANOPOULOU A, et al. Fusing phenomenon of lithium-ion battery internal short circuit [J]. Journal of the Electrochemical Society, 2017, 164(12): A2738–A2745. DOI: 10.1149/2.1721712jes.

|

| [23] |

WANG Q S, PING P, ZHAO X J, et al. Thermal runaway caused fire and explosion of lithium ion battery [J]. Journal of Power Sources, 2012, 208: 210–224. DOI: 10.1016/j.jpowsour.2012.02.038.

|

| [24] |

FENG X N, FANG M, HE X M, et al. Thermal runaway features of large format prismatic lithium ion battery using extended volume accelerating rate calorimetry [J]. Journal of Power Sources, 2014, 255: 294–301. DOI: 10.1016/j.jpowsour.2014.01.005.

|

| [25] |

LUO Y G, FENG G X, WAN S, et al. Charging scheduling strategy for different electric vehicles with optimization for convenience of drivers, performance of transport system and distribution network [J]. Energy, 2020, 194: 116807. DOI: 10.1016/j.energy.2019.116807.

|

| [26] |

COMAN P T, RAYMAN S, WHITE R E. A lumped model of venting during thermal runaway in a cylindrical Lithium Cobalt Oxide lithium-ion cell [J]. Journal of Power Sources, 2016, 307: 56–62. DOI: 10.1016/j.jpowsour.2015.12.088.

|

| [27] |

LEE C, SAID A O, STOLIAROV S I. Impact of state of charge and cell arrangement on thermal runaway propagation in lithium ion battery cell arrays [J]. Transportation Research Record, 2019, 2673(8): 408–417. DOI: 10.1177/0361198119845654.

|

| [28] |

LI H G, ZHOU D, ZHANG M H, et al. Multi-field interpretation of internal short circuit and thermal runaway behavior for lithium-ion batteries under mechanical abuse [J]. Energy, 2023, 263: 126027. DOI: 10.1016/j.energy.2022.126027.

|

| [29] |

LIU B H, DUAN X D, YUAN C H, et al. Quantifying and modeling of stress-driven short-circuits in lithium-ion batteries in electrified vehicles [J]. Journal of Materials Chemistry A, 2021, 9(11): 7102–7113. DOI: 10.1039/d0ta12082k.

|

| [30] |

WANG L B, JIA Y K, XU J. Mechanistic understanding of the electrochemo-dependent mechanical behaviors of battery anodes [J]. Journal of Power Sources, 2021, 510: 230428. DOI: 10.1016/j.jpowsour.2021.230428.

|

| [31] |

HWANG I, LEE C W, KIM J C, et al. Particle size effect of Ni-rich cathode materials on lithium ion battery performance [J]. Materials Research Bulletin, 2012, 47(1): 73–78. DOI: 10.1016/J.MATERRESBULL.2011.10.002.

|

| [32] |

LIU J H, CHEN H Y, XIE J N, et al. Electrochemical performance studies of Li-rich cathode materials with different primary particle sizes [J]. Journal of Power Sources, 2014, 251: 208–214. DOI: 10.1016/j.jpowsour.2013.11.055.

|

| [33] |

SCHREINER D, LINDENBLATT J, DAUB R, et al. Simulation of the calendering process of NMC-622 cathodes for lithium-ion batteries [J]. Energy Technology, 2023, 11(5): 2200442. DOI: 10.1002/ente.202200442.

|

| [34] |

DUAN X D, WANG H C, JIA Y K, et al. A multiphysics understanding of internal short circuit mechanisms in lithium-ion batteries upon mechanical stress abuse [J]. Energy Storage Materials, 2022, 45: 667–679. DOI: 10.1016/j.ensm.2021.12.018.

|

| [35] |

KALNAUS S, WANG Y L, LI J L, et al. Temperature and strain rate dependent behavior of polymer separator for Li-ion batteries [J]. Extreme Mechanics Letters, 2018, 20: 73–80. DOI: 10.1016/j.eml.2018.01.006.

|

下载:

下载: