Influence of length-diameter ratio and volume on hydrocarbon explosion overpressure characteristics in a closed square pipeline

-

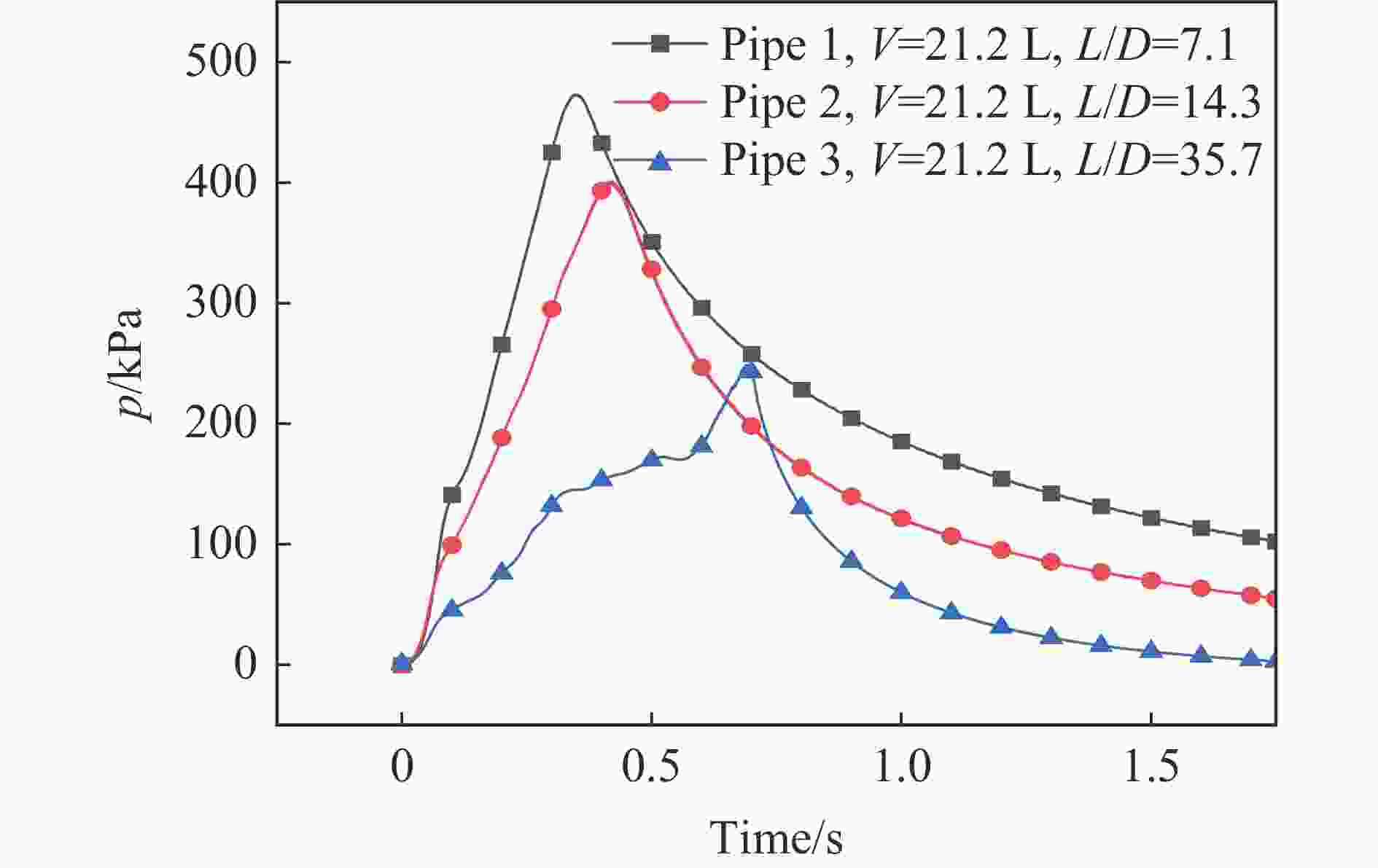

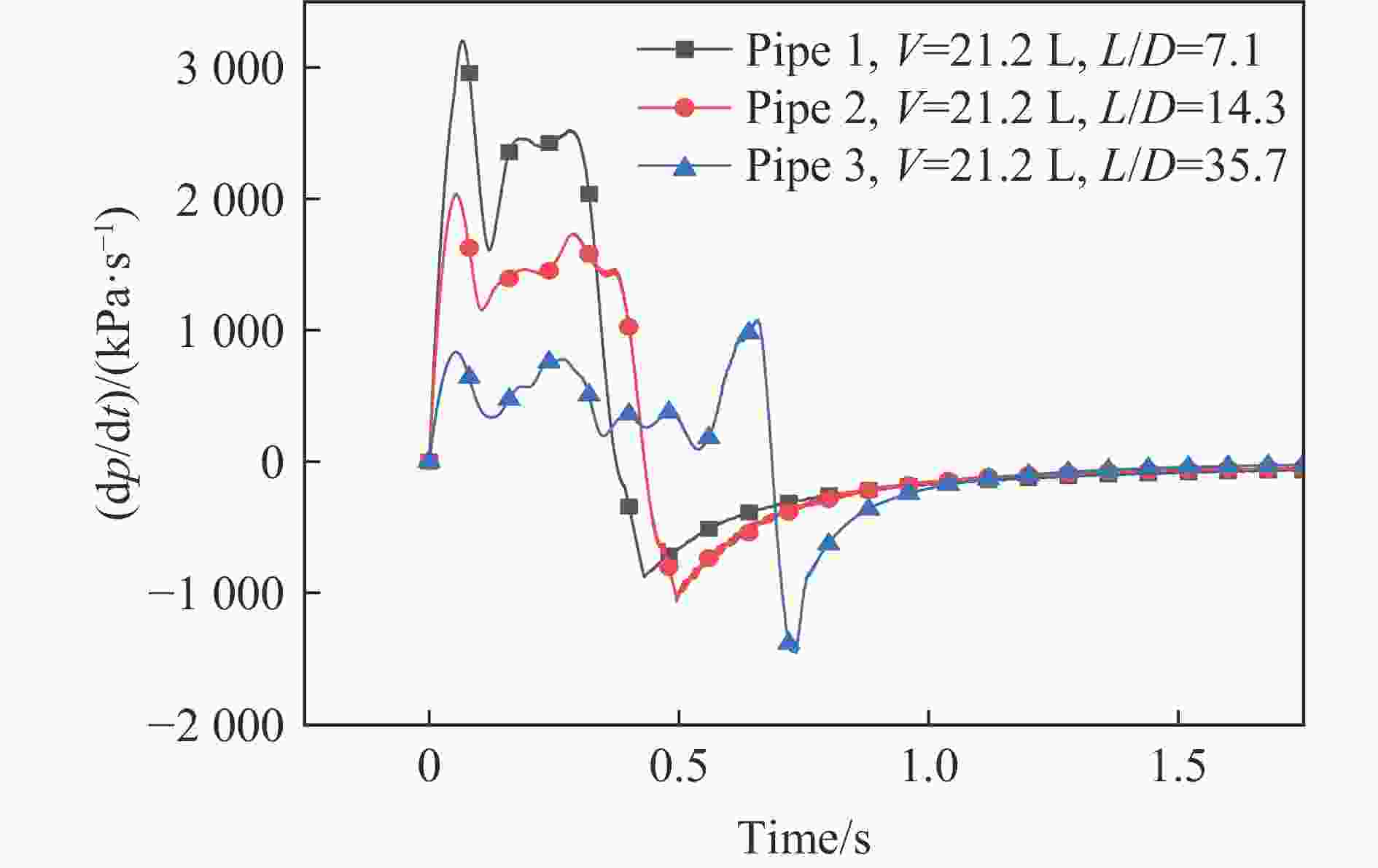

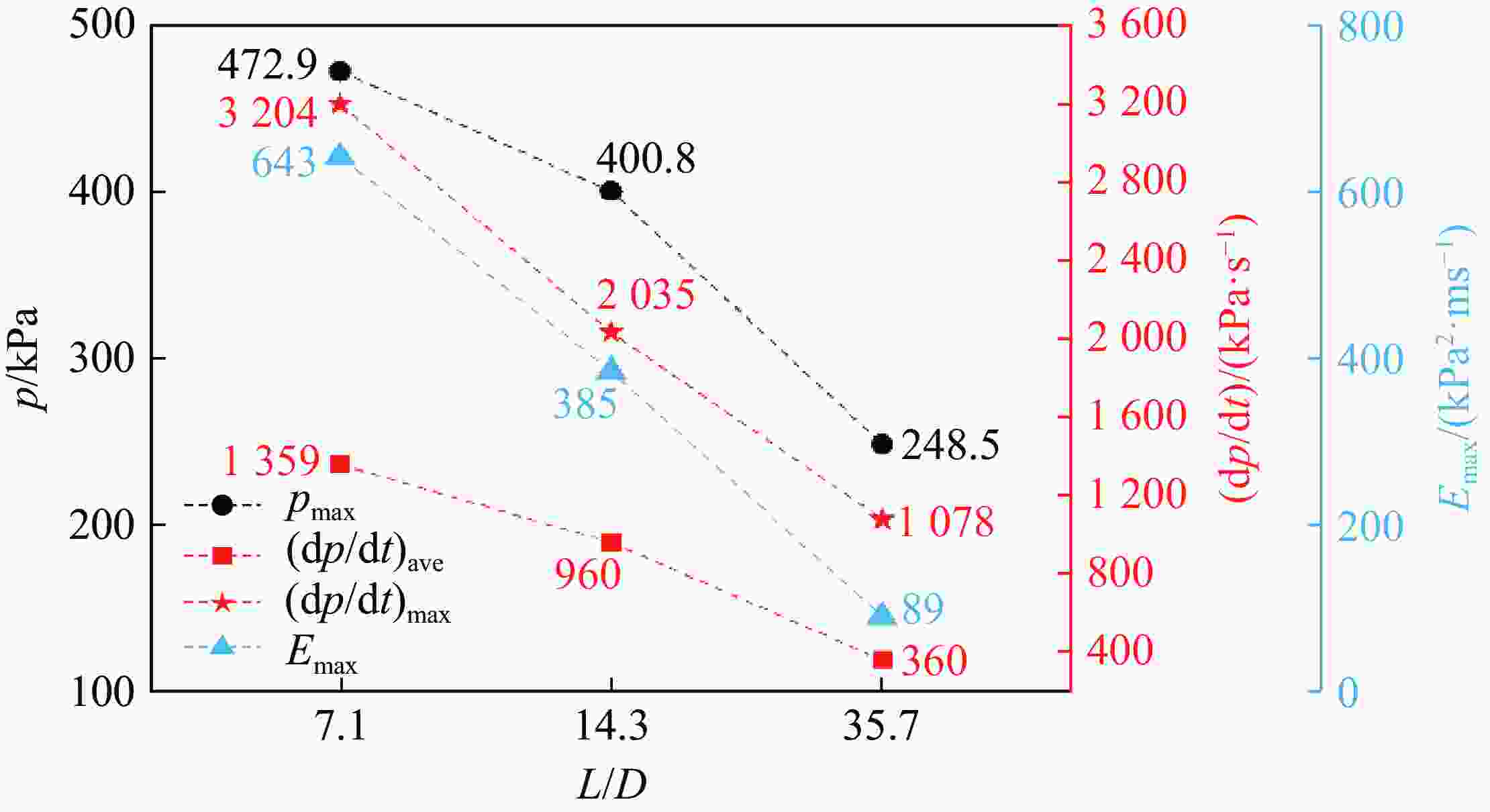

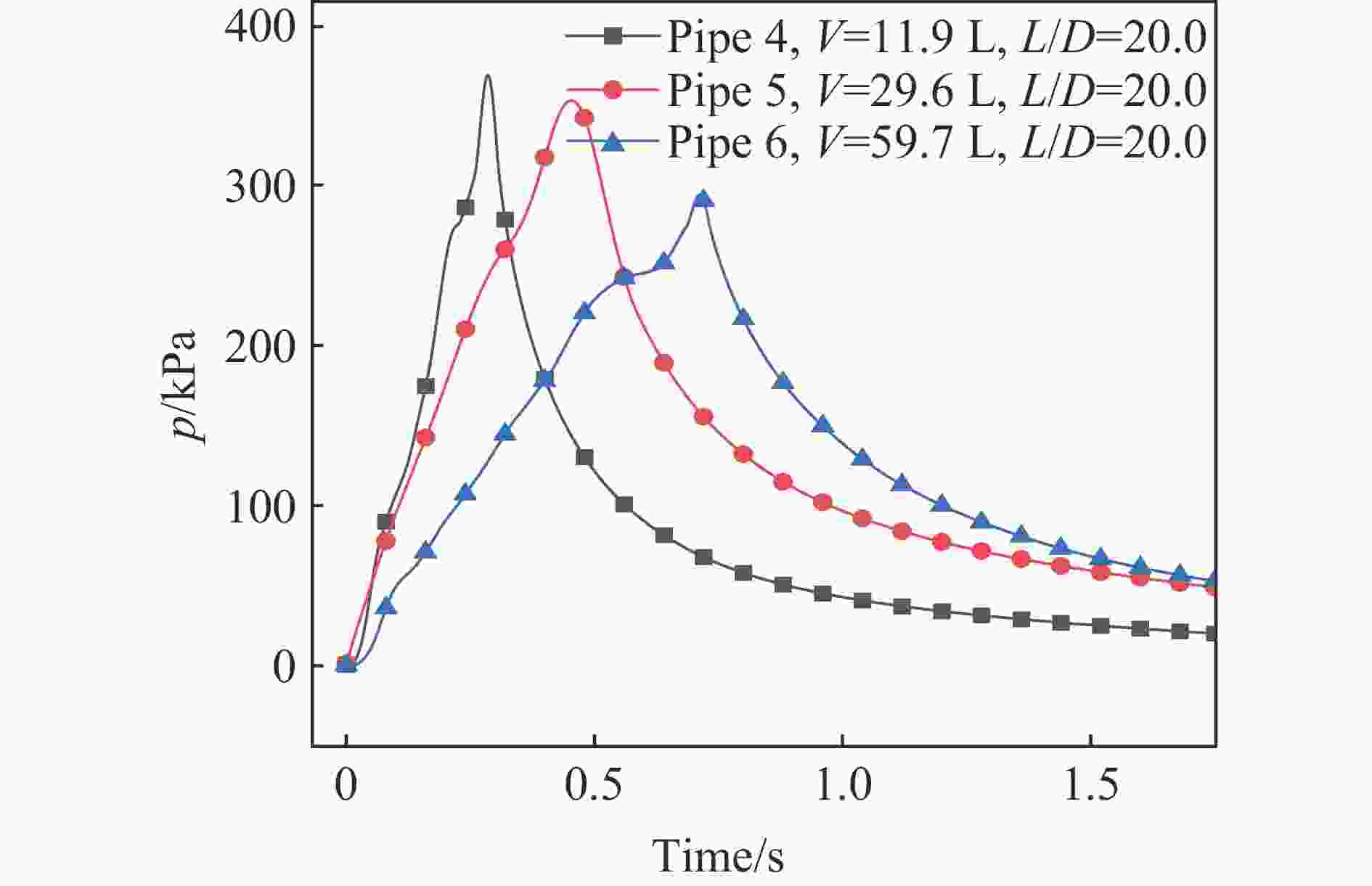

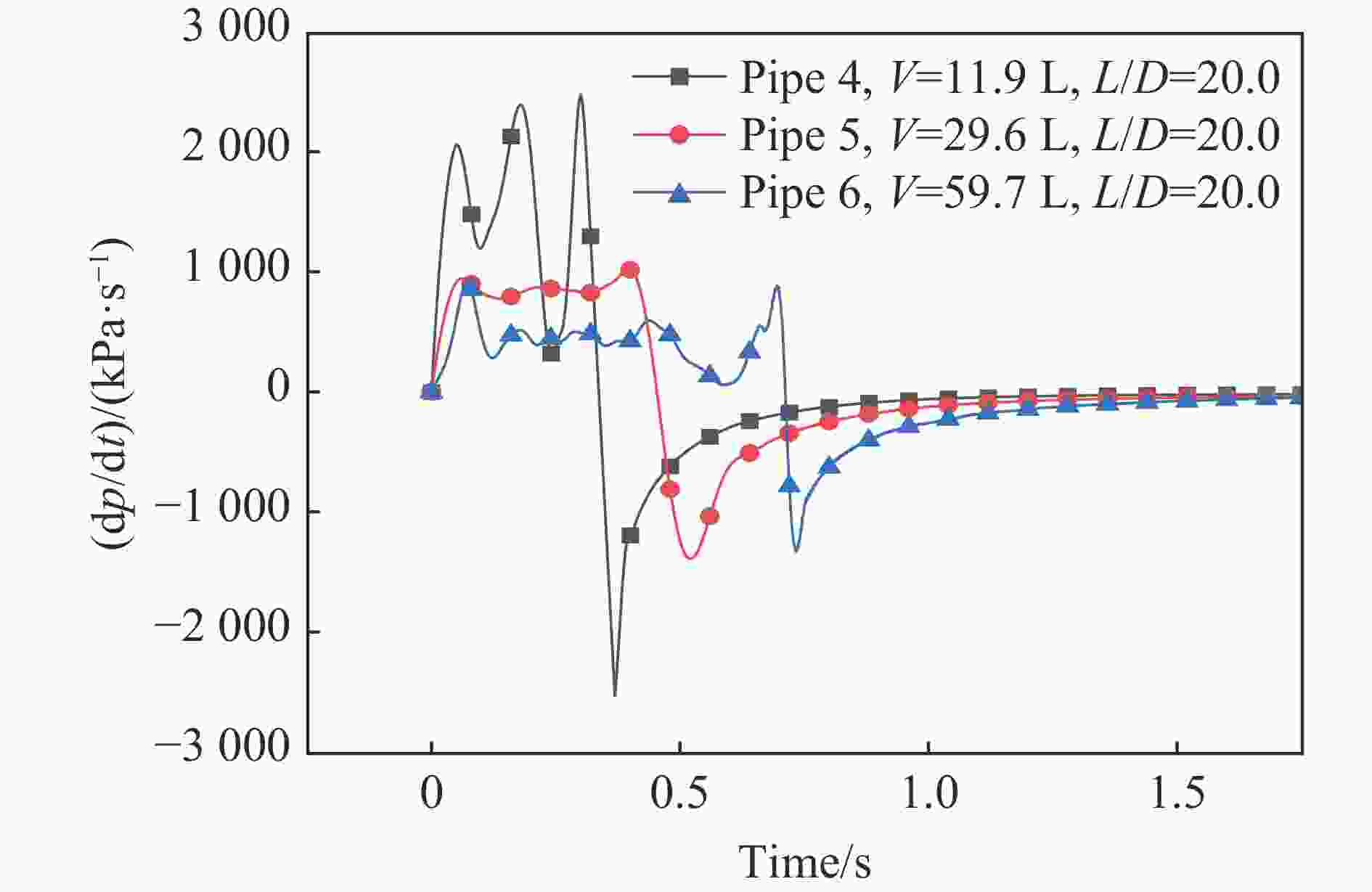

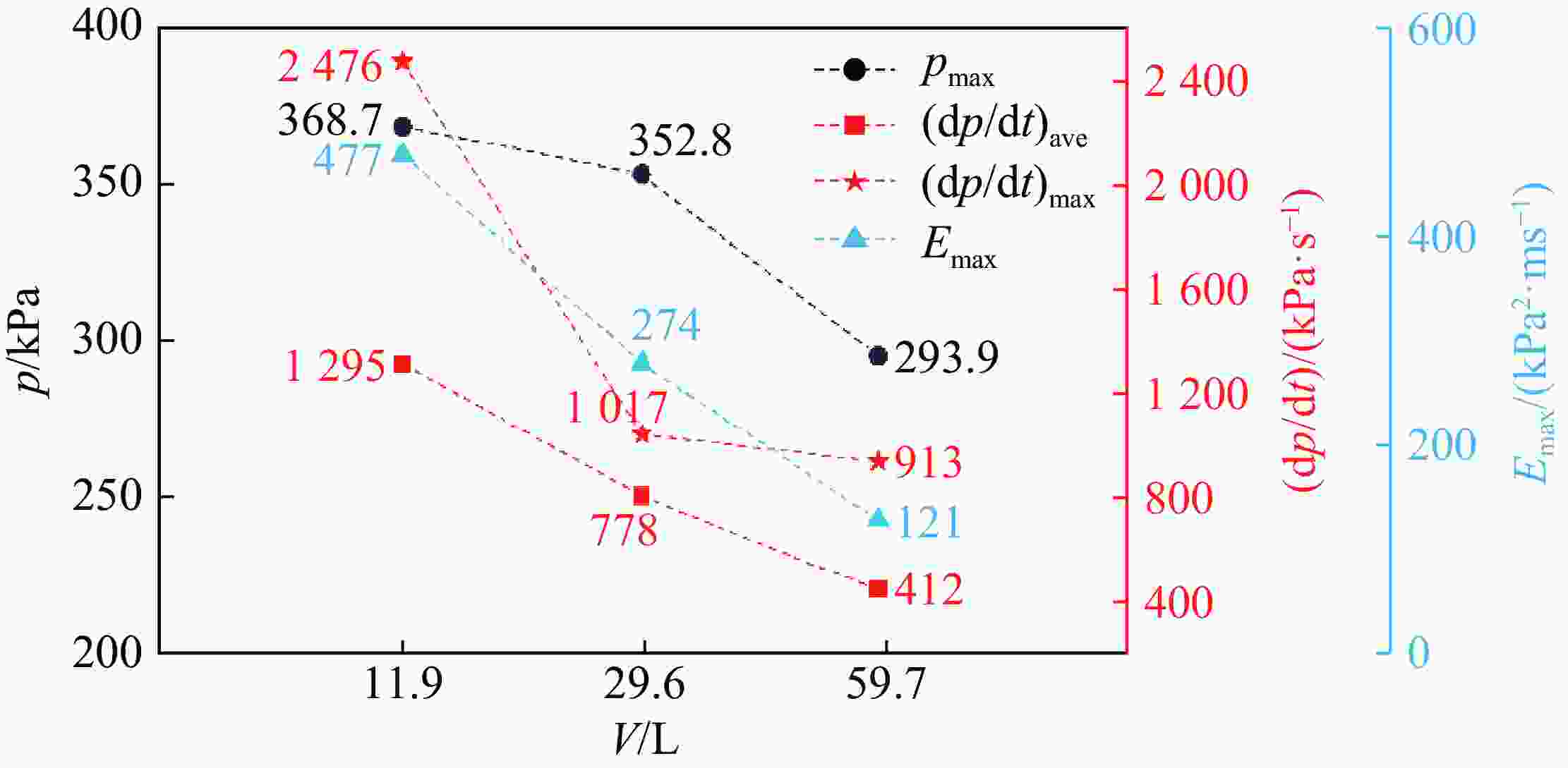

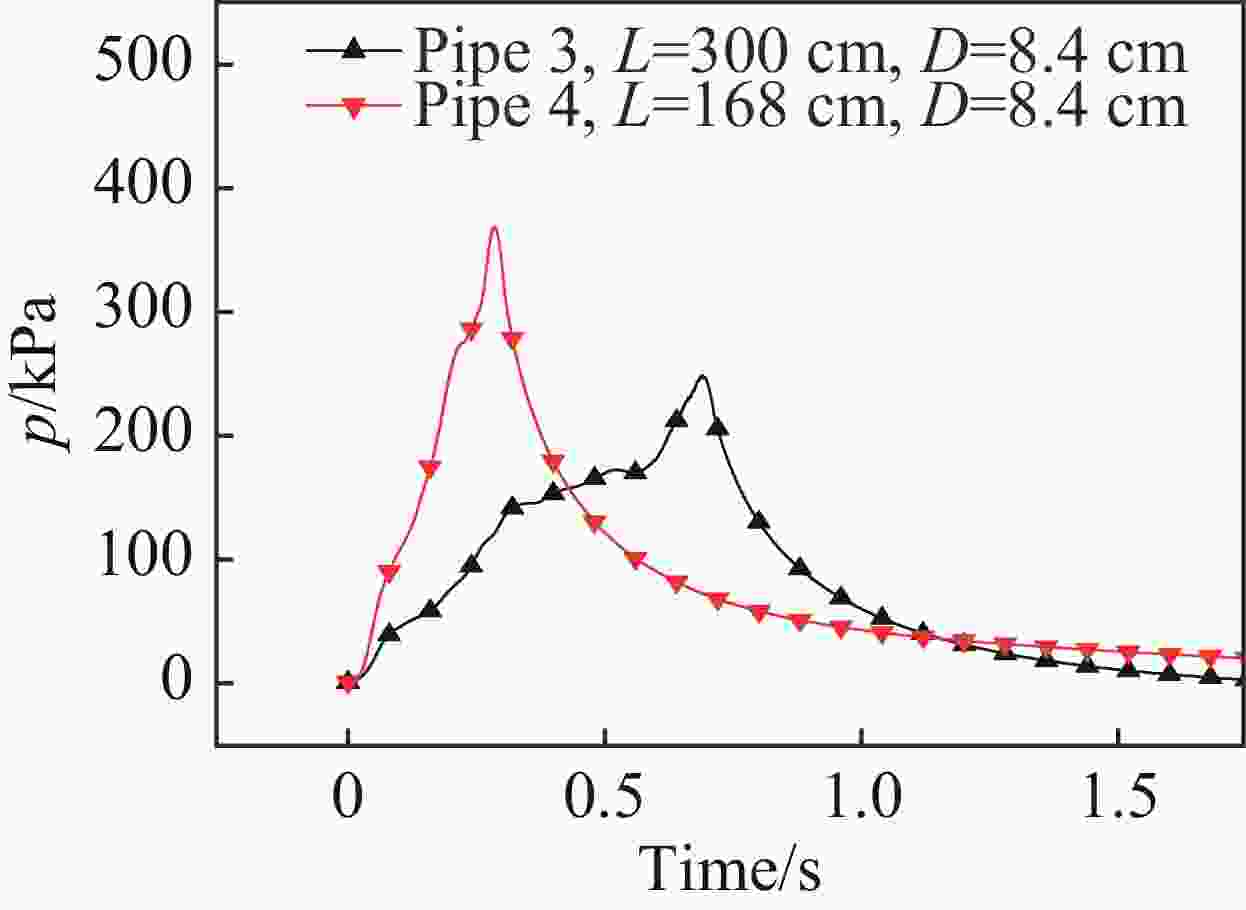

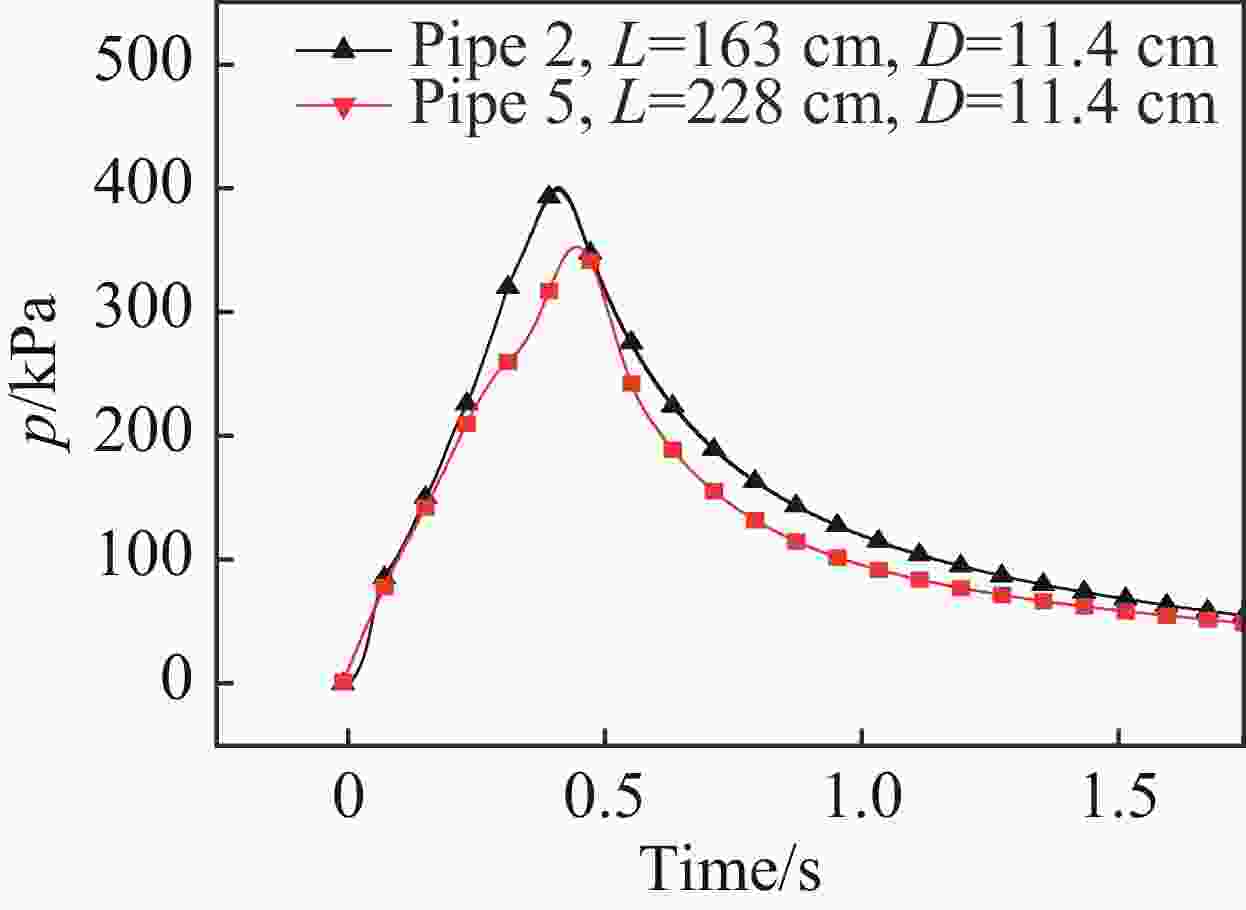

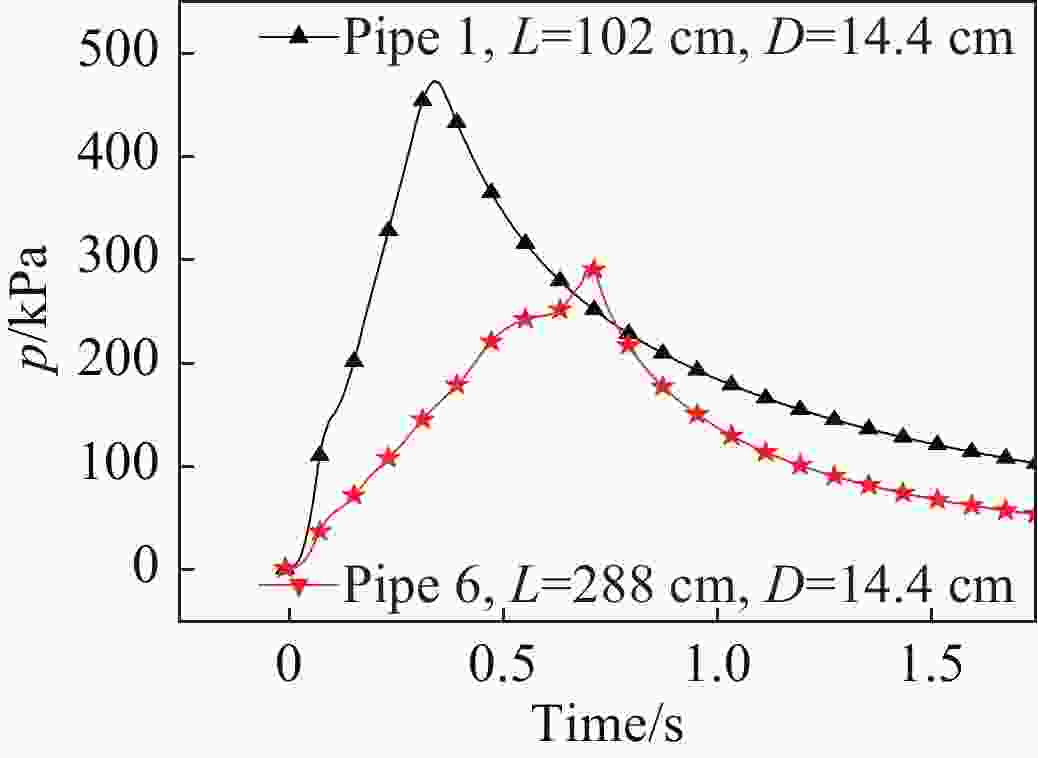

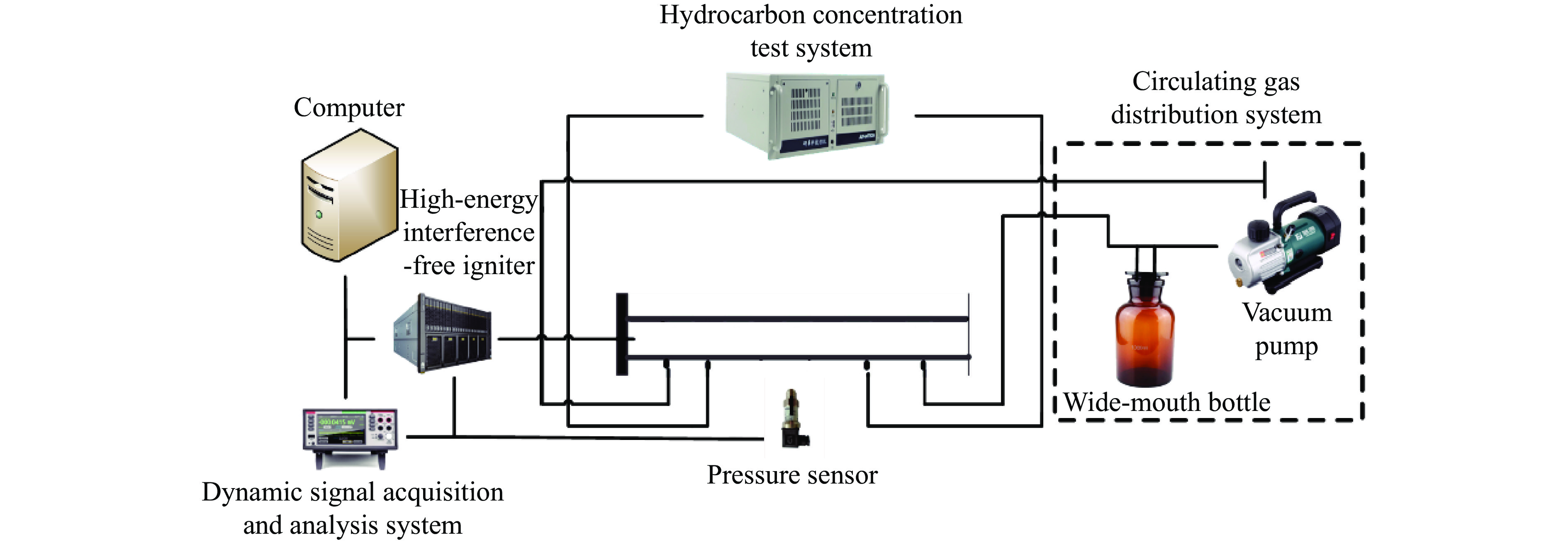

摘要: 为了有效预测和控制封闭空间内油气爆炸的后果,减少事故导致的人员伤亡和财产损失,对油气爆炸的超压特性与爆炸发生空间尺度的关系进行了研究。在控制初始油气体积分数、点火位置和点火能量不变的情况下,开展了不同长径比和体积的密闭方形管道条件下油气的爆炸超压特性实验。实验结果显示,在爆炸过程中,超压上升的速率经历急剧增长期、持续振荡期和衰减终止期3个阶段;管口面积的减小和内表面积的增加会导致最大超压、平均超压上升速率、最大超压上升速率和爆炸威力下降。进一步分析实验结果发现,管口面积变化会直接影响火焰前锋面积和反应速率,对最大超压的影响更为直接和显著,而内表面积变化对最大超压的影响相对间接,是通过调节能量传递和热损失发挥作用。此外,管道长度是影响到达最大超压时间的关键因素,延长管道不仅增加了热损失,还使反射波与入射波的叠加时间点延后,并且反射波的能量会相对较多地衰减。Abstract: In order to effectively predict and control the consequences of fuel-air mixture explosions in enclosed spaces and thereby reduce the casualties and property losses caused by accidents, the relationship between the explosive overpressure characteristics of fuel-air mixtures and the spatial scale of explosions was investigated. Closed square pipes with varying length-diameter ratios, volumes, and lengths were used to examine the impact of fuel-air mixture explosion overpressure characteristics by keeping the initial oil and gas concentration, ignition position, and ignition energy constant. The experimental results show that the rate of overpressure rise goes through three stages: a rapid increase period, a continuous oscillation period, and an attenuation termination period, which reveals the dynamic relationship between reaction rate and heat loss. The reduce of the nozzle area and the increase of the internal surface area of the pipeline can both lead to the decrease of the maximum overpressure, the average overpressure rise rate, the maximum overpressure rise rate, and the explosion power. The further analysis of the experimental results reveals that the change in the nozzle area will directly affect the flame front area and reaction rate, with a more direct and significant impact on the maximum overpressure. The changes in the inner surface area have a relatively indirect effect on the maximum overpressure by regulating energy transfer and heat loss. Additionally, pipeline length is a crucial factor affecting the time to reach the maximum overpressure. The increase of the pipeline length not only increases the heat loss but also delays the superposition time point of the reflected wave and the incident wave, with the energy of the reflected wave undergoing relative attenuation.

-

表 1 密闭管道的尺寸

Table 1. Size of closed pipes

管道 L/cm D/cm V/L L/D 管道 L/cm D/cm V/L L/D 管道 L/cm D/cm V/L L/D 1 102 14.4 21.2 7.1 3 300 8.4 21.2 35.7 5 228 11.4 29.6 20.0 2 163 11.4 21.2 14.3 4 168 8.4 11.9 20.0 6 288 14.4 59.7 20.0 表 2 内表面积和管口面积对最大超压的影响

Table 2. The influence of internal surface area and nozzle area on the peak overpressure

管道 L/cm D/cm 内表面积/cm2 管口面积/cm2 pmax/kPa 2 163 11.4 769 130 400.8 3 300 8.4 1022 71 248.5 4 168 8.4 579 71 368.7 5 228 11.4 1066 130 352.8 -

[1] MA G W, HUANG Y M, LI J D. Risk analysis of vapour cloud explosions for oil and gas facilities [M]. Singapore: Springer, 2019. DOI: 10.1007/978-981-13-7948-2. [2] 魏树旺, 蒋新生, 徐建楠, 等. 狭长受限空间油气爆炸抑制实验研究 [J]. 振动与冲击, 2017, 36(10): 51–56,62. DOI: 10.13465/j.cnki.jvs.2017.10.009.WEI S W, JIANG X S, XU J N, et al. Experiment study on the gasoline-air mixture explosion suppression in a long-narrow confined space [J]. Journal of Vibration and Shock, 2017, 36(10): 51–56,62. DOI: 10.13465/j.cnki.jvs.2017.10.009. [3] LI T, WANG L Q, MA H H, et al. Explosion characteristics of H2/CH4/N2O at fuel-lean and stoichiometric conditions [J]. Combustion Science and Technology, 2022, 194(8): 1631–1642. DOI: 10.1080/00102202.2020.1825400. [4] MITU M, BRANDES E. Influence of pressure, temperature and vessel volume on explosion characteristics of ethanol/air mixtures in closed spherical vessels [J]. Fuel, 2017, 203: 460–468. DOI: 10.1016/j.fuel.2017.04.124. [5] CHENG F M, CHANG Z C, LUO Z M, et al. Large eddy simulation and experimental study of the effect of wire mesh on flame behaviours of methane/air explosions in a semi-confined pipe [J]. Journal of Loss Prevention in the Process Industries, 2020, 68: 104258. DOI: 10.1016/j.jlp.2020.104258. [6] 杜扬, 李国庆, 吴松林, 等. T型分支管道对油气爆炸强度的影响 [J]. 爆炸与冲击, 2015, 35(5): 729–734. DOI: 10.11883/1001-1455(2015)05-0729-06.DU Y, LI G Q, WU S L, et al. Explosion intensity of gasoline-air mixture in the pipeline containing a T-shaped branch pipe [J]. Explosion and Shock Waves, 2015, 35(5): 729–734. DOI: 10.11883/1001-1455(2015)05-0729-06. [7] SALVADO F C, TAVARES A J, TEIXEIRA-DIAS F, et al. Confined explosions: the effect of compartment geometry [J]. Journal of Loss Prevention in the Process Industries, 2017, 48: 126–144. DOI: 10.1016/j.jlp.2017.04.013. [8] MITTAL M. Explosion pressure measurement of methane-air mixtures in different sizes of confinement [J]. Journal of Loss Prevention in the Process Industries, 2017, 46: 200–208. DOI: 10.1016/j.jlp.2017.02.022. [9] HUANG L J, WANG Y, ZHANG L, et al. Influence of pressure on the flammability limits and explosion pressure of ethane/propane-air mixtures in a cylinder vessel [J]. Journal of Loss Prevention in the Process Industries, 2022, 74: 104638. DOI: 10.1016/j.jlp.2021.104638. [10] 李静野, 蒋新生, 李进, 等. 长径比对管道油气爆炸特性与火焰传播规律影响研究[J]. 中国安全生产科学技术, 2020, 16(8): 88-94. DOI: 10.11731/jissn.1673-193x.2020.08.014.LI J Y, JIANG X S, LI J, et al. Study on influence of length-diameter ratio on explosion characteristics and flame propagation laws of gasoline-air mixture in pipeline [J]. Journal of Safety Science and Technology, DOI: 10.11731/jissn.1673-193x.2020.08.014. [11] 赵祥迪, 张广文, 郑毅, 等. 狭长通道内部丙烷气体爆炸冲击实验与模拟分析 [J]. 中国安全生产科学技术, 2024, 20(3): 40–45. DOI: 10.11731/j.issn.1673-193x.2024.03.006.ZHAO X D, ZHANG G W, ZHENG Y, et al. Experimental and numerical analysis on propane gas explosion in narrow and long channel [J]. Journal of Safety Science and Technology, 2024, 20(3): 40–45. DOI: 10.11731/j.issn.1673-193x.2024.03.006. [12] 李重情, 穆朝民, 许登科, 等. 空腔长度对瓦斯爆炸冲击波传播影响研究 [J]. 采矿与安全工程学报, 2018, 35(6): 1293–1300. DOI: 10.13545/j.cnki.jmse.2018.06.028.LI Z Q, MU C M, XU D K, et al. Influence of cavity length on shock wave propagation of gas explosion [J]. Journal of Mining & Safety Engineering, 2018, 35(6): 1293–1300. DOI: 10.13545/j.cnki.jmse.2018.06.028. [13] 王波, 杜扬, 李国庆, 等. 细长密闭管道内油气爆炸特性研究 [J]. 振动与冲击, 2017, 36(9): 80–85, 145. DOI: 10.13465/j.cnki.jvs.2017.09.013.WANG B, DU Y, LI G Q, et al. Tests for explosion characteristics of gasoline-air mixture in an elongated closed tube [J]. Journal of Vibration and Shock, 2017, 36(9): 80–85, 145. DOI: 10.13465/j.cnki.jvs.2017.09.013. [14] 冯路阳. 管道结构对瓦斯爆炸压力及温度的影响研究 [D]. 阜新: 辽宁工程技术大学, 2017. [15] 蒋新生, 魏树旺, 袁广强, 等. 狭长管道油气爆炸流场分布特征规律及分析 [J]. 中国安全生产科学技术, 2016, 12(8): 130–134. DOI: 10.11731/j.issn.1673-193x.2016.08.022.JIANG X S, WEI S W, YUAN G Q, et al. Characteristic rules and analysis of flow field distribution for gasoline-air mixture explosion in narrow and long pipeline [J]. Journal of Safety Science and Technology, 2016, 12(8): 130–134. DOI: 10.11731/j.issn.1673-193x.2016.08.022. [16] 李国庆, 张笈玮, 武军, 等. 方管内汽油-空气混合气体密闭爆炸和泄爆特性研究 [J]. 爆炸与冲击, 2020, 40(10): 102101. DOI: 10.11883/bzycj-2019-0416.LI G Q, ZHANG J W, WU J, et al. Characteristics of closed and vented explosions of gasoline-air mixture in a square tube [J]. Explosion and Shock Waves, 2020, 40(10): 102101. DOI: 10.11883/bzycj-2019-0416. [17] BI M S, DONG C J, ZHOU Y H. Numerical simulation of premixed methane–air deflagration in large L/D closed pipes [J]. Applied Thermal Engineering, 2012, 40: 337–342. DOI: 10.1016/j.applthermaleng.2012.01.065. [18] RAZUS D, BRINZEA V, MITU M, et al. Temperature and pressure influence on explosion pressures of closed vessel propane–air deflagrations [J]. Journal of Hazardous Materials, 2010, 174(1/2/3): 548–555. DOI: 10.1016/j.jhazmat.2009.09.086. [19] 刘冲, 杜扬, 李国庆, 等. 狭长密闭空间内油气爆炸火焰特性大涡模拟 [J]. 化工学报, 2018, 69(12): 5348–5358. DOI: 10.11949/j.issn.0438-1157.20180614.LIU C, DU Y, LI G Q et al. Large eddy simulation of gasoline-air mixture explosion in closed narrow-long space [J]. CIESC Journal, 2018, 69(12): 5348–5358. DOI: 10.11949/j.issn.0438-1157.20180614. [20] CAMMAROTA F, BENEDETTO A D, RUSSO P, et al. Experimental analysis of gas explosions at non-atmospheric initial conditions in cylindrical vessel [J]. Process Safety and Environmental Protection, 2010, 88(5): 341–349. DOI: 10.1016/j.psep.2010.05.001. [21] METGHALCHI M, KECK J C. Burning velocities of mixtures of air with methanol, isooctane, and indolene at high pressure and temperature [J]. Combustion and Flame, 1982, 48: 191–210. DOI: 10.1016/0010-2180(82)90127-4. -

下载:

下载: