Effect of loading rate on the shear performance of ACC structures

-

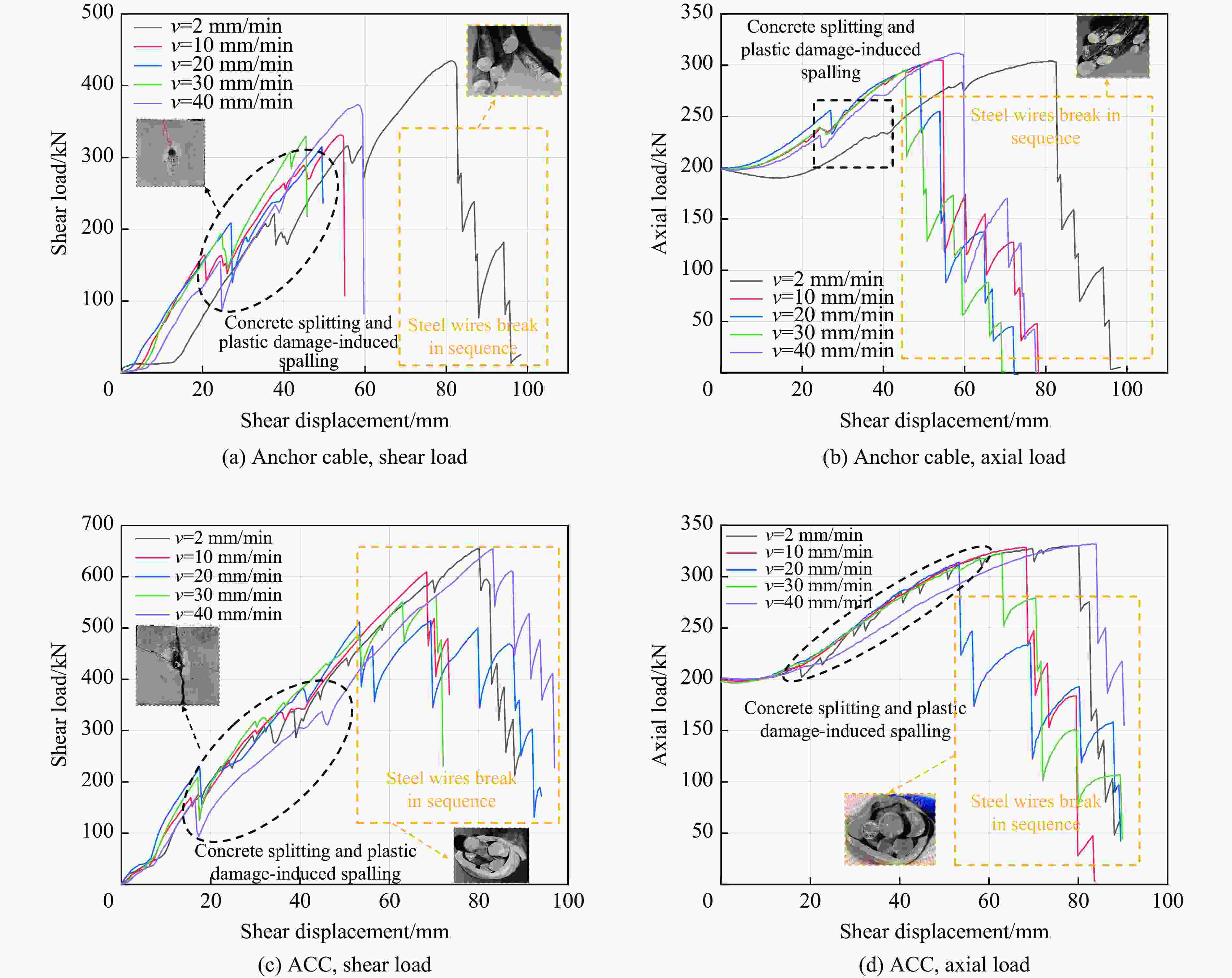

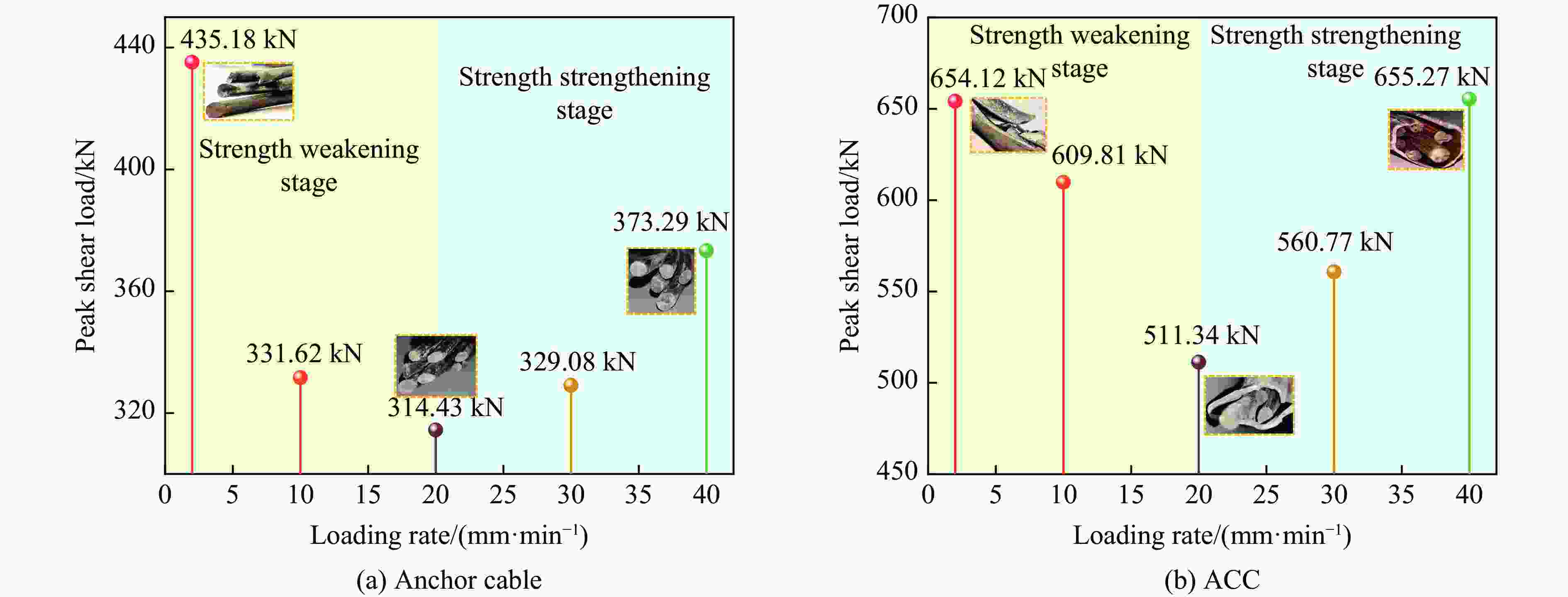

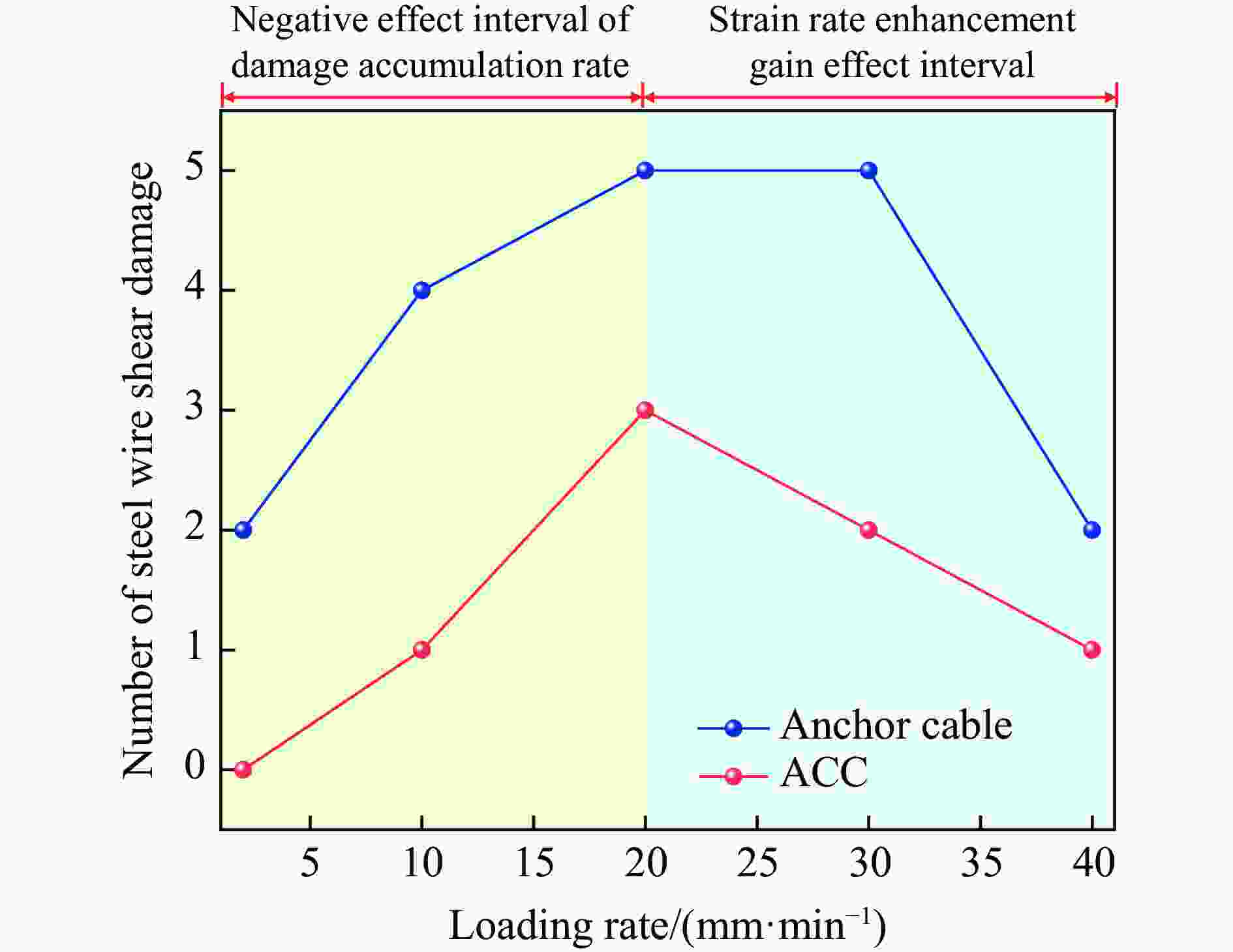

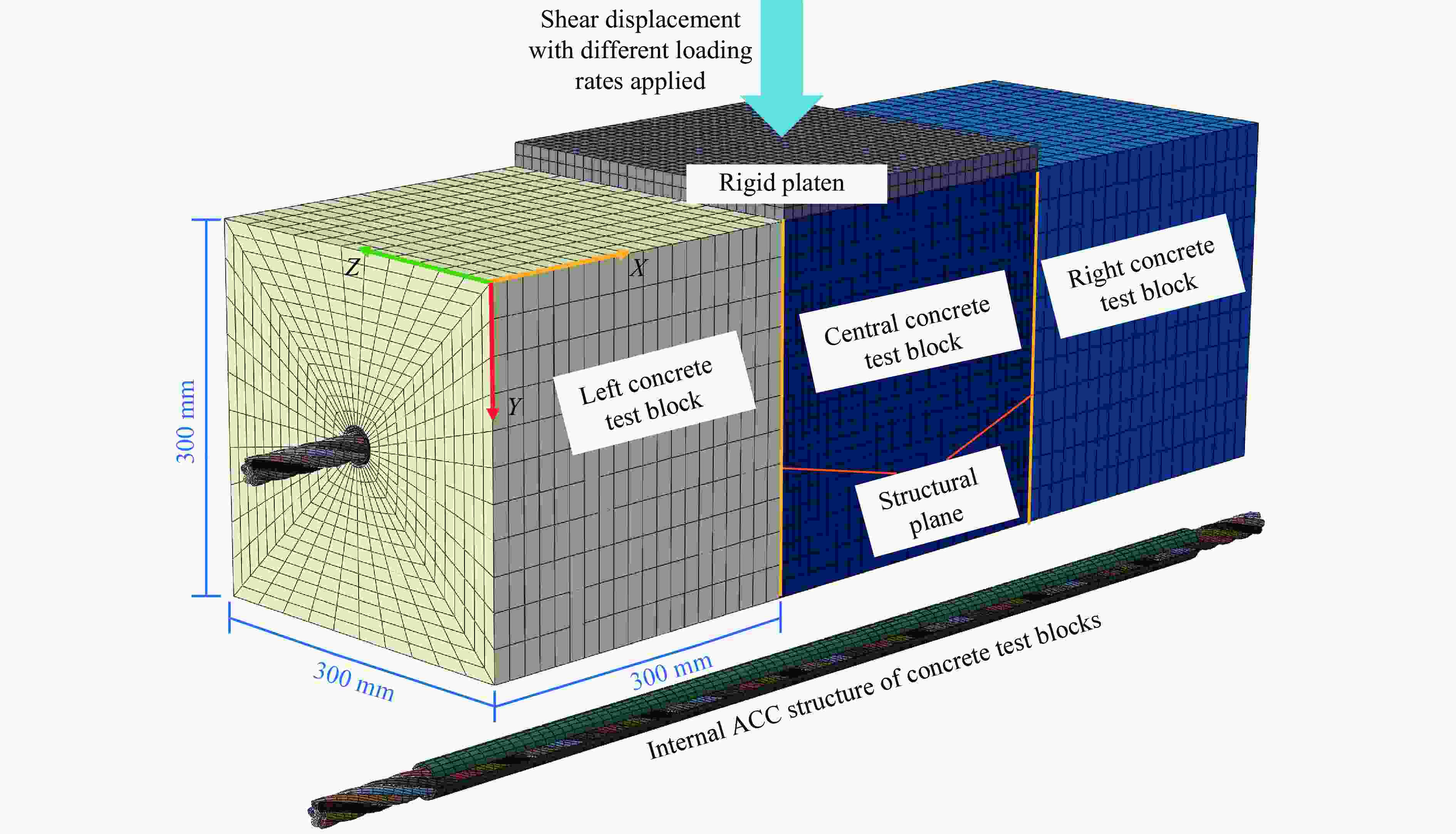

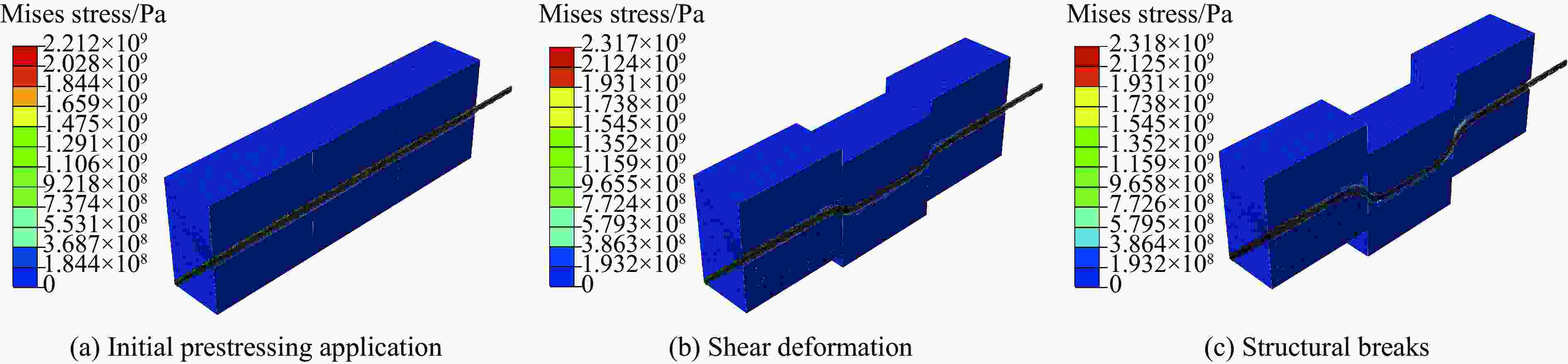

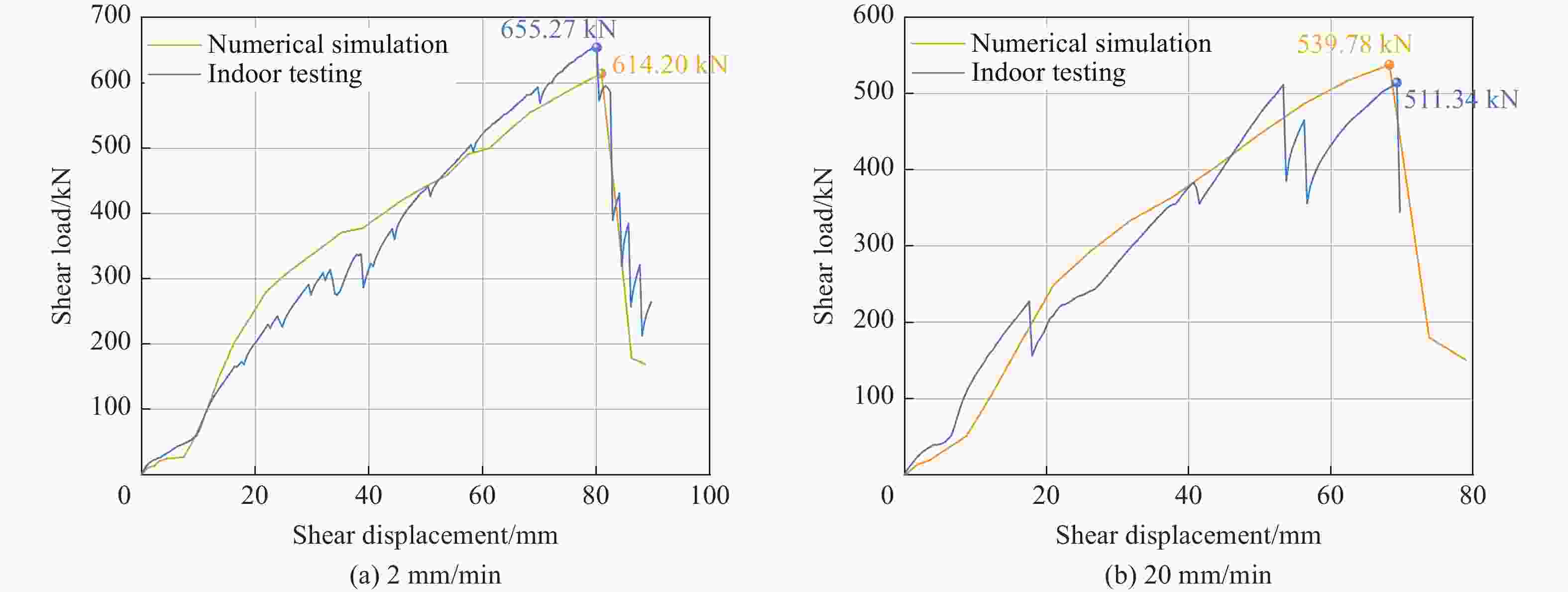

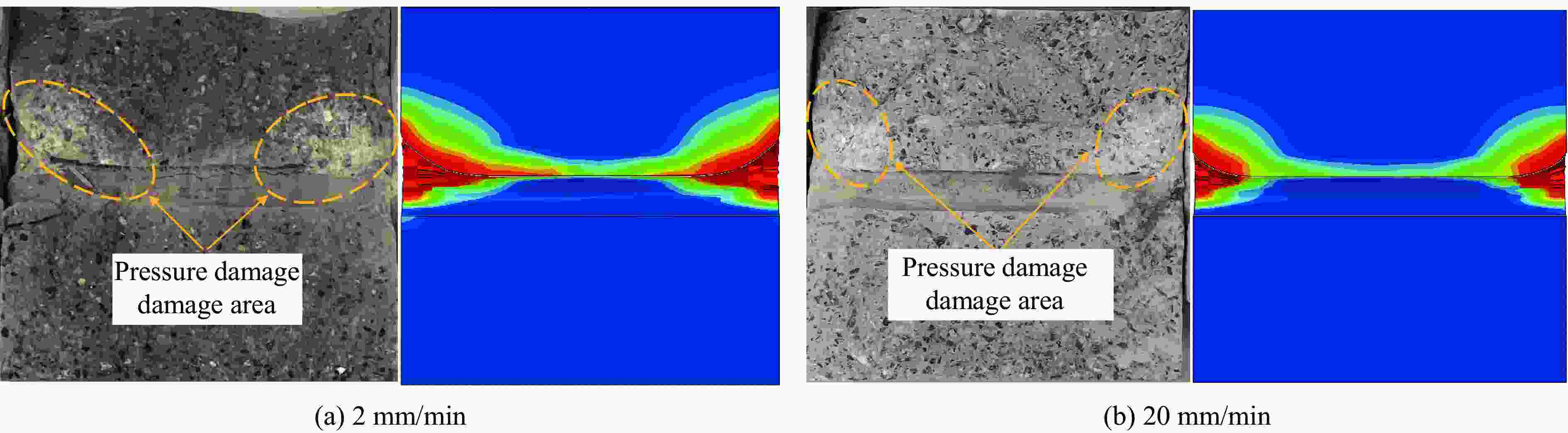

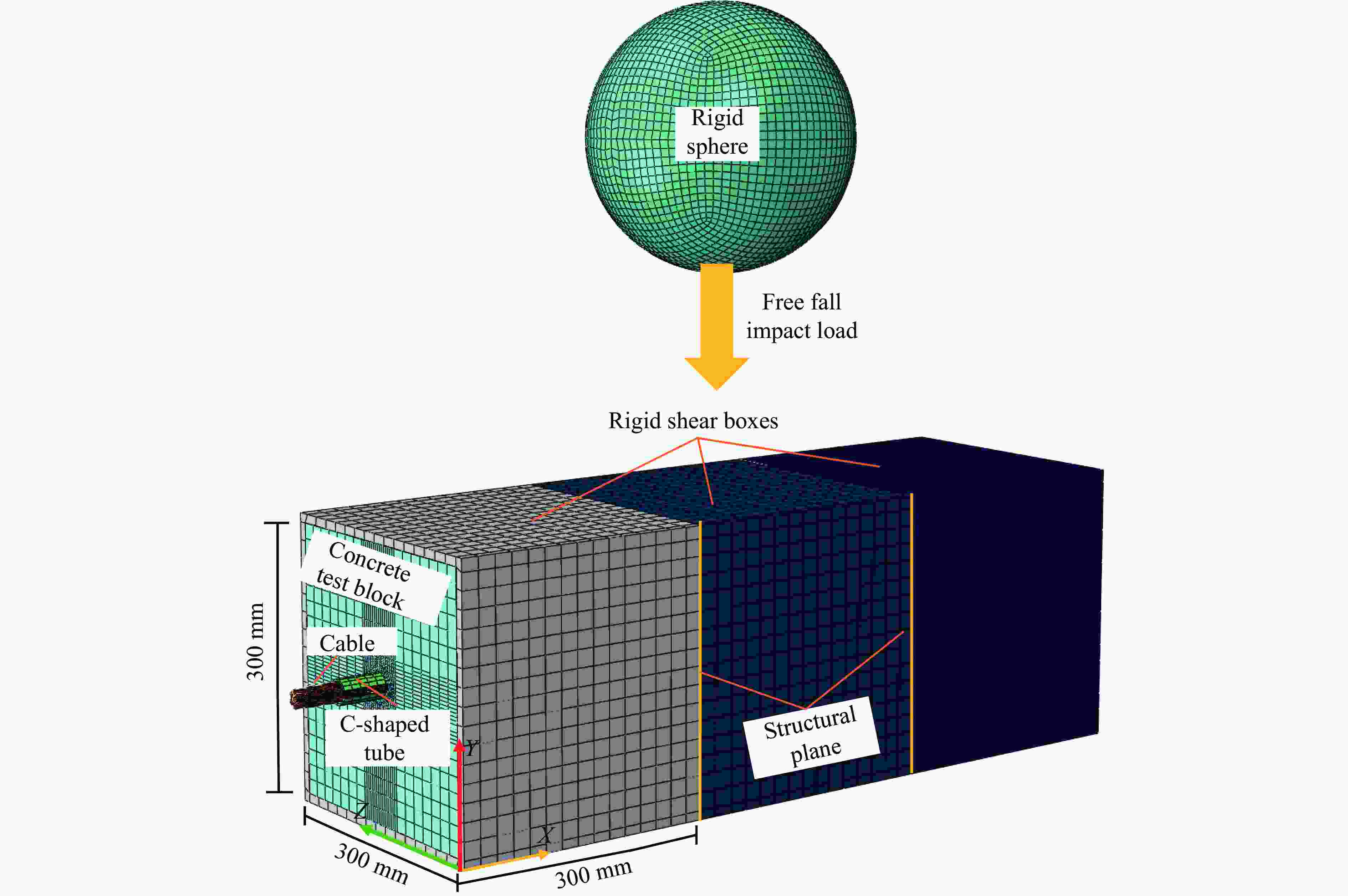

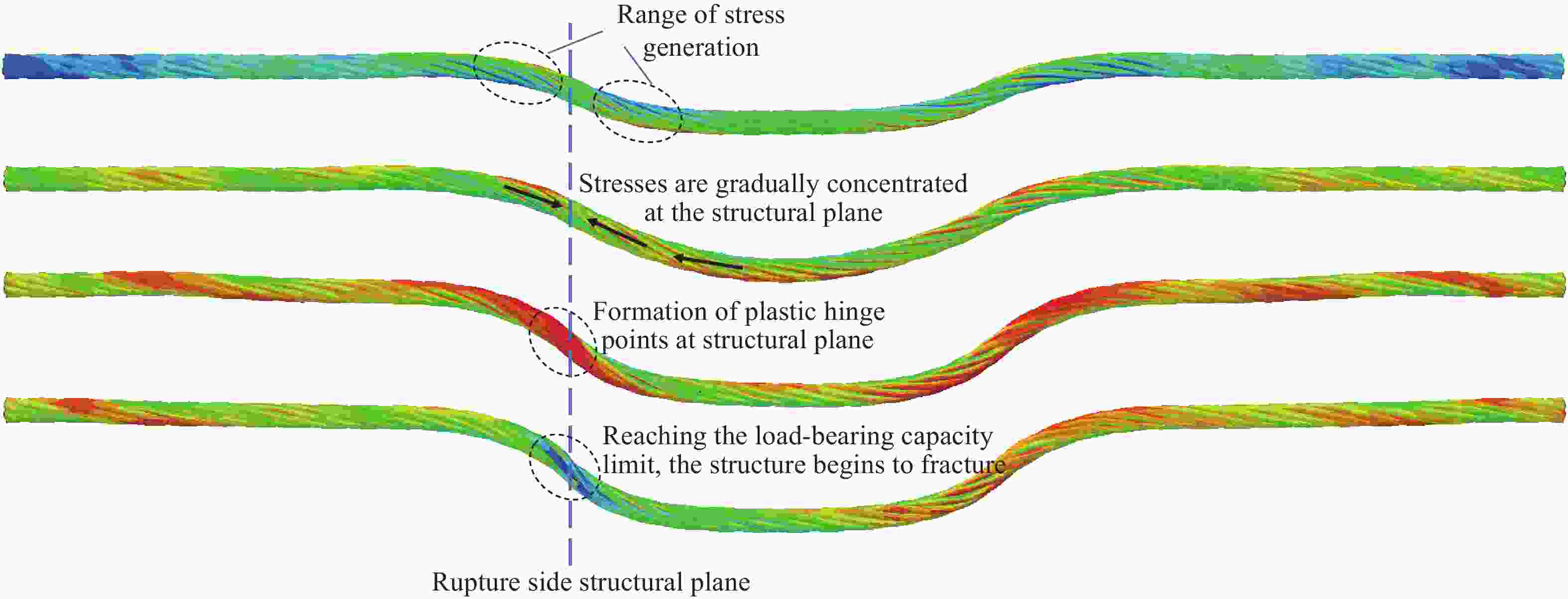

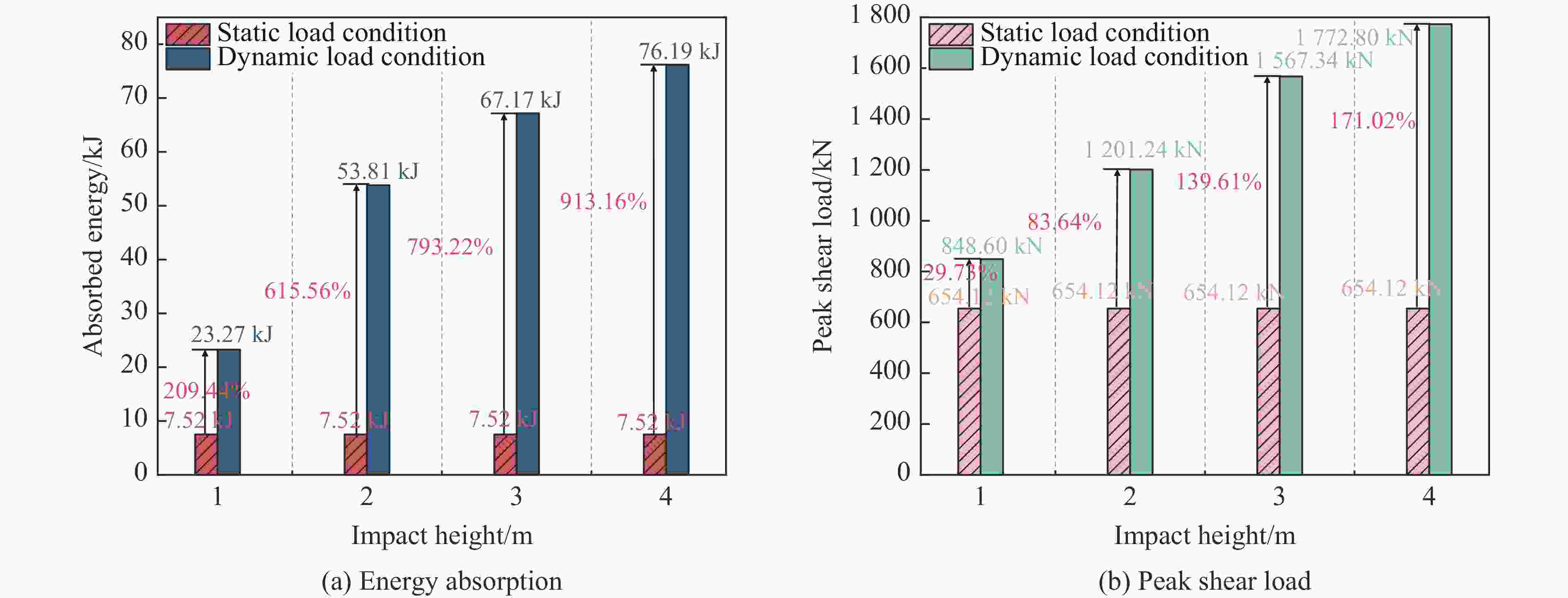

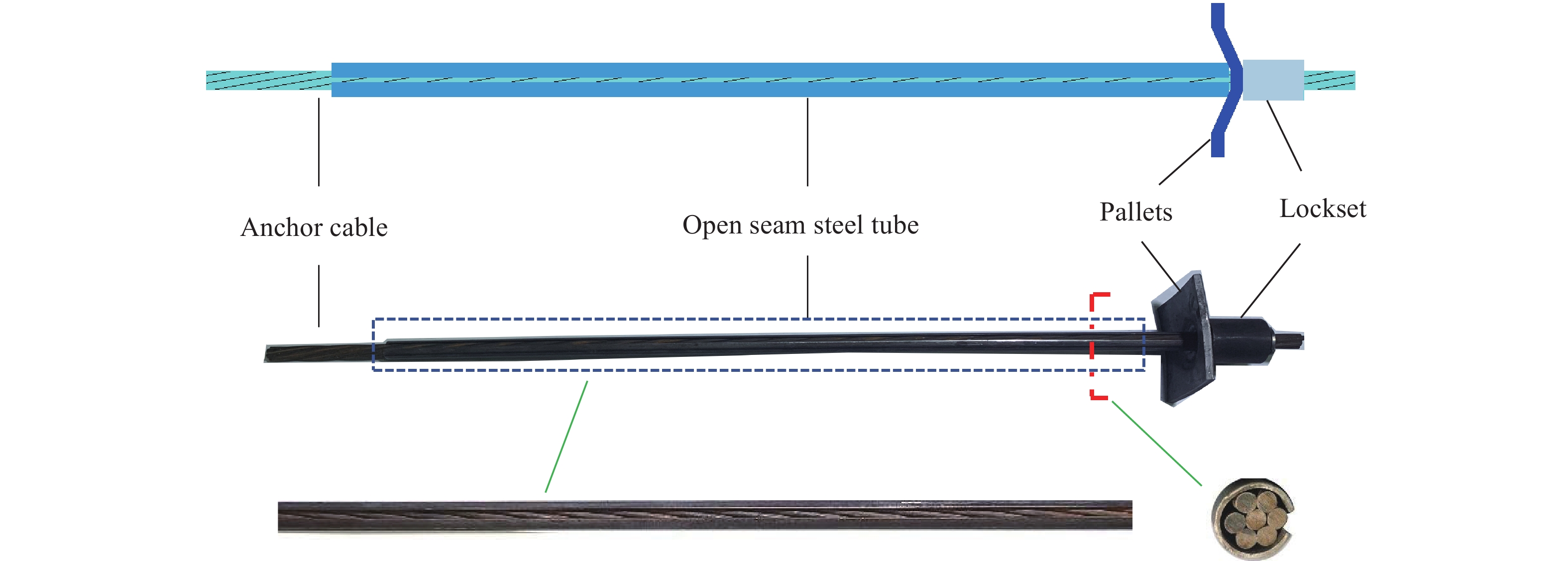

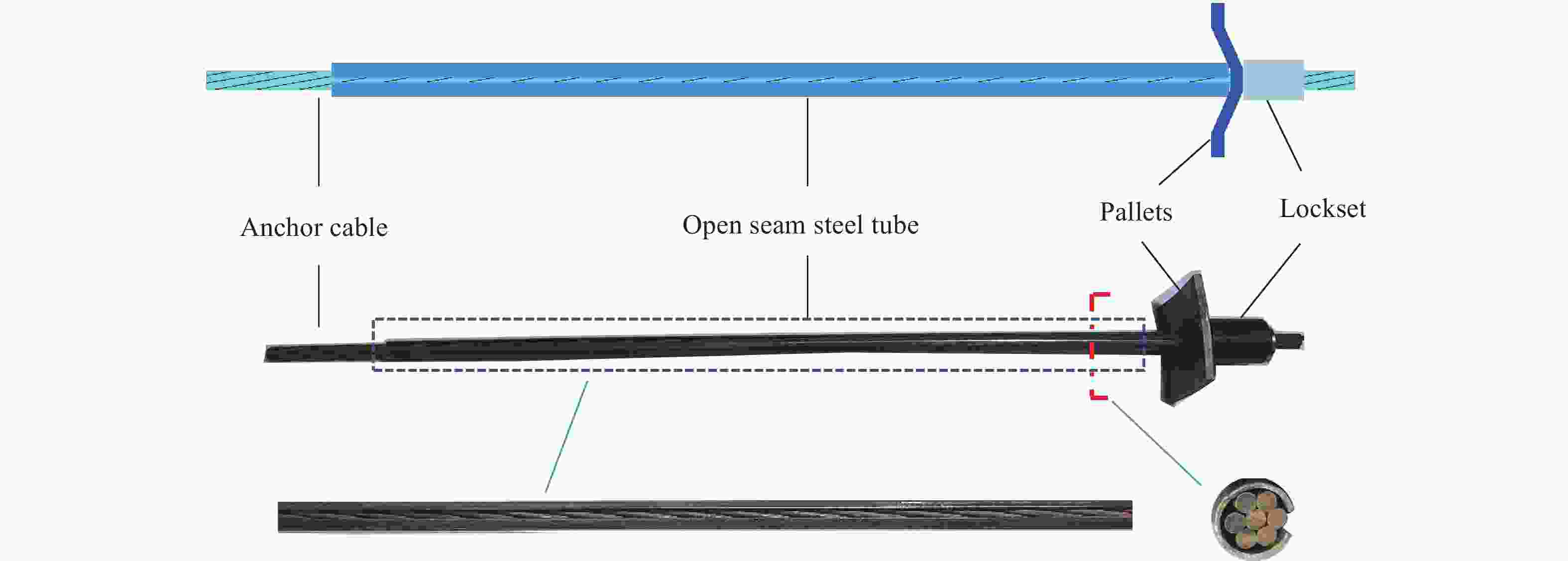

摘要: 通过试验和数值模拟分析,研究了锚索和新型管索组合结构(anchor cable with C-shaped tube,ACC)在不同加载速率下的双结构面剪切力学特性和变形破坏机制。在混凝土试块强度为55 MPa、预应力为200 kN的条件下,分别以2、10、20、30、40 mm/min的剪切位移加载速率进行双结构面剪切试验。试验以剪切变形曲线、结构峰值剪切荷载、钢丝破坏形态和结构面抗剪强度贡献为主要参数。结果表明:加载速率对结构的抗剪性能有显著的影响,在一定的加载速率区间内,受损伤累积速度和应变率强化效应的影响,结构分别表现出强度弱化和强度强化的特性,抗剪承载能力出现较大的变化。在结构面附近,支护结构表现出拉剪组合破坏现象,但由于ACC结构中C形管的存在,应力集中效应降低,试验曲线波动减弱,内部钢丝受剪切作用破坏的情况与锚索相比明显减弱。同时,以试验结果为基础构建的ACC结构双剪试验数值模型的准确性较高,动荷载试验的数值模拟结果表明,ACC结构形成的锚固系统具备良好的吸能效果,冲击能量越大,吸能效果越明显;且ACC结构在高速冲击作用下,表现出明显的应变率强化效应,冲击速度越高,抗剪承载能力越强。Abstract: The shear mechanical properties and deformation damage mechanism of the double structural planes of traditional anchor cables and new anchor cables with C-shaped tube structures (abbreviated as ACC) under different loading rate conditions were investigated through experimental and numerical simulation analyses. Dual structural face shear tests were conducted at shear displacement loading rates of 2, 10, 20, 30, and 40 mm/min under 55 MPa concrete specimen strength and 200 kN preload, with shear deformation curves, peak structural shear loads, steel wire damage patterns, and structural plane shear strength contributions as the main parameters considered. The results show that the loading rate significantly affects the shear performance of the structure. Within a certain loading rate interval, influenced by the damage accumulation rate and the strain rate strengthening effect, the structure exhibits characteristics of strength weakening and strengthening, respectively, with a large variation interval in shear load-carrying capacity. Near the structural plane, the support structure shows a combination of tensile and shear damage. However, the ACC structure, due to the presence of the C-shaped tube, exhibits lower stress concentration effects, reduced fluctuation in the test curve, and significantly weakened internal steel wire damage compared to traditional anchor cables. Meanwhile, the numerical model of the double shear test of the ACC structure, constructed based on the test results, exhibits high accuracy. Numerical simulations of dynamic loading tests demonstrate that the anchoring system formed by the ACC structure has a good energy absorption effect, which becomes more pronounced with increasing impact energy. Under high-speed impact, the ACC structure is significantly affected by the strain rate reinforcement effect, with higher shear load capacity at greater impact velocities.

-

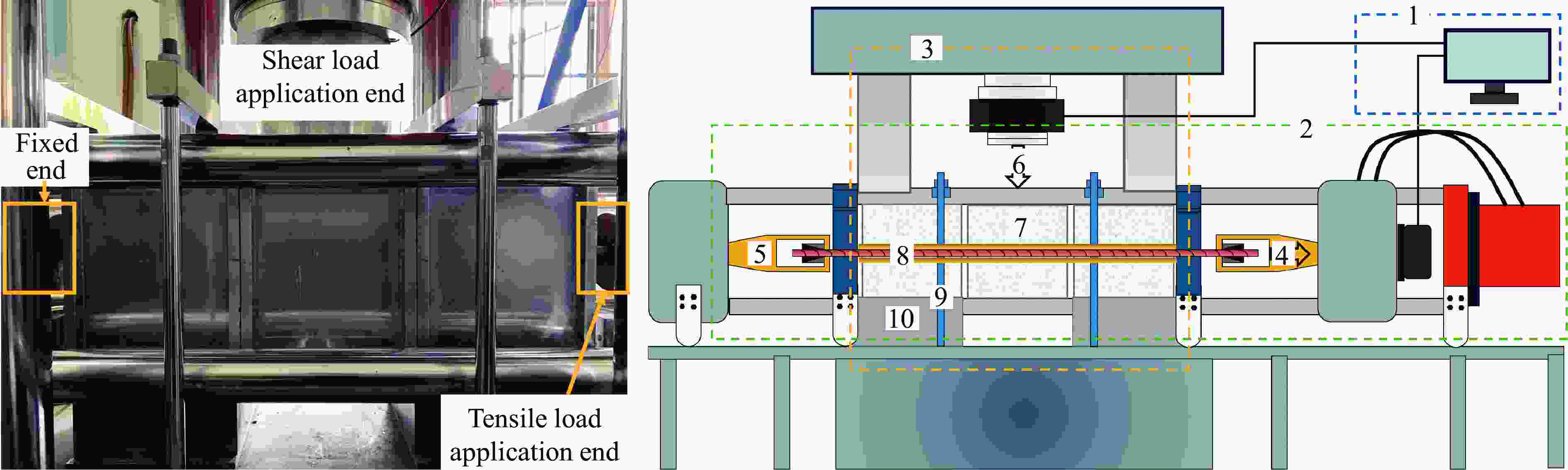

图 2 试验系统图

Figure 2. Schematic diagram of test system

1. Computer-controlled module;2. Tensile-testing module;3. Shear-testing module;4. Tensile load application end;5. Anchored termination of support member;6. Shear load application end;7. Shear box and concrete specimen;8. Test support member;9. Bracing beam and fixed column;10. Shear-testing support pedestal

表 1 混凝土试块参数

Table 1. Parameters of concrete specimens

密度/

(kg·m−3)弹性模量/

GPa泊松比 剪胀角/(°) 内聚力/

MPa抗压强度/

MPa2400 38.5 0.2 38 1.0 55 表 2 加载速率剪切试验方案

Table 2. Shear testing protocol under different loading rates

结构类型 加载速率/(mm·min−1) 预应力/kN 索径/mm 长度/mm 锚索 2~40 200 17.8 1400 ACC 2~40 200 17.8 1400 表 3 锚索与ACC结构在5种不同加载速率条件下的峰值荷载与破断位移

Table 3. Peak load and failure displacement of anchor cables and ACC structures under five loading rate conditions

加载速率/(mm·min−1) 结构类型 峰值剪切荷载/kN 峰值轴向荷载/kN 破断位移/mm 2 锚索 435.18 304.19 83.21 ACC 654.12 330.21 81.71 10 锚索 331.62 305.36 53.79 ACC 609.81 328.33 68.36 20 锚索 314.43 300.12 49.35 ACC 511.34 313.92 68.87 30 锚索 329.08 295.61 45.46 ACC 560.77 322.66 70.10 40 锚索 373.29 311.52 58.73 ACC 655.27 332.06 83.19 表 4 锚索和ACC结构的抗剪性能相关参数

Table 4. Comparative parameters of shear performance between anchor cables and ACC structures

加载速率/(mm·min−1) 结构类型 $ {T}_{\max}^{*} $ $ P $/% $ {\eta }_{{\mathrm{c}}} $/% 2 锚索 0.60 50.31 33.47 ACC 0.89 10 锚索 0.45 83.89 45.62 ACC 0.84 20 锚索 0.43 62.62 38.51 ACC 0.70 30 锚索 0.45 70.41 41.32 ACC 0.77 40 锚索 0.51 75.54 43.03 ACC 0.90 表 5 锚索参数

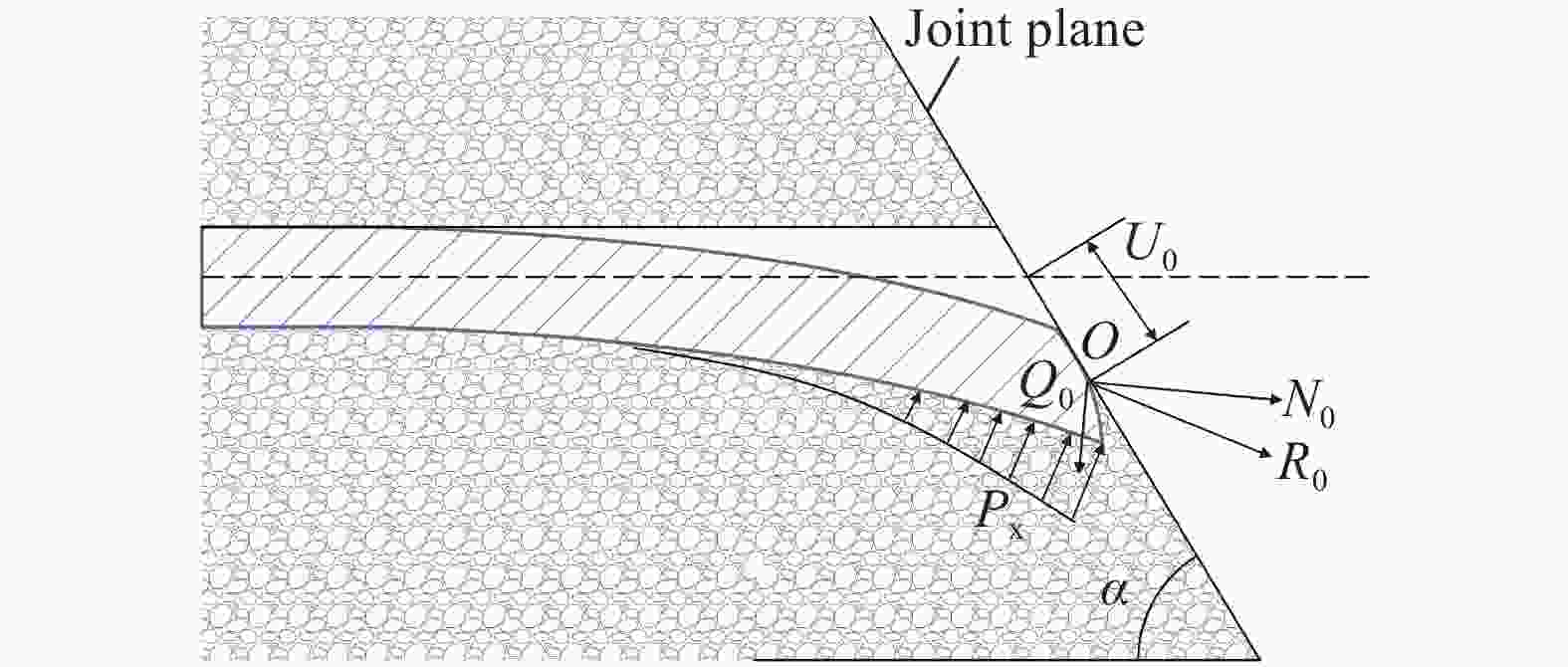

Table 5. Parameters of the anchor cable

密度/

(kg·m−3)弹性模量/

GPa屈服应力/

MPa泊松比 截面积/

mm2直径/

mm7800 208.4 1662 0.31 193.98 17.8 表 6 C形管参数

Table 6. Parameters of C-shaped tube

密度/

(kg·m−3)弹性模量/

GPa屈服应力/

MPa泊松比 外径/

mm内径/

mm7850 210 345 0.3 28 24 -

[1] 陈昊祥, 王明洋, 李杰. 深部岩体变形破坏的特征能量因子与应用 [J]. 爆炸与冲击, 2019, 39(8): 081103. DOI: 10.11883/bzycj-2019-0191.CHEN H X, WANG M Y, LI J. A characteristic energy factor for deformation and failure of deep rock masses and its application [J]. Explosion and Shock Waves, 2019, 39(8): 081103. DOI: 10.11883/bzycj-2019-0191. [2] 王明洋, 徐天涵, 邓树新, 等. 深部硐室长期稳定性的两个力学问题 [J]. 爆炸与冲击, 2021, 41(7): 071101. DOI: 10.11883/bzycj-2021-0023.WANG M Y, XU T H, DENG S X, et al. Mechanical problems for the long-term stability of rocks surrounding deep level underground tunnels [J]. Explosion and Shock Waves, 2021, 41(7): 071101. DOI: 10.11883/bzycj-2021-0023. [3] MENG X, REN Q Y, XIAO S Q, et al. Numerical simulation of mechanical characteristics and tension-torsion coupling effect of tension-type anchor cable [J]. Engineering Computations, 2023, 40(9/10): 2730–2753. DOI: 10.1108/EC-08-2023-0440. [4] 丁瑜, 王全才, 何思明. 拉力分散型锚索锚固段荷载传递机制 [J]. 岩土力学, 2010, 31(2): 599–603. DOI: 10.16285/j.rsm.2010.02.026.DING Y, WANG Q C, HE S M. Loading transfer mechanism of dispersion-type tensile cables along anchoring section [J]. Rock and Soil Mechanics, 2010, 31(2): 599–603. DOI: 10.16285/j.rsm.2010.02.026. [5] 沈俊, 顾金才, 张向阳, 等. 拉力型和压力型自由式锚索现场拉拔试验研究 [J]. 岩石力学与工程学报, 2012, 31(S1): 3291–3297. DOI: 10.3969/j.issn.1000-6915.2012.z1.094.SHEN J, GU J C, ZHANG X Y, et al. Field pull-out test research on tension and pressrue unbonded anchor cables [J]. Chinese Journal of Rock Mechanics and Engineering, 2012, 31(S1): 3291–3297. DOI: 10.3969/j.issn.1000-6915.2012.z1.094. [6] JALALIFAR H, AZIZ N, HADI M. The effect of surface profile, rock strength and pretension load on bending behaviour of fully grouted bolts [J]. Geotechnical & Geological Engineering, 2006, 24(5): 1203–1227. DOI: 10.1007/s10706-005-1340-6. [7] AZIZ N, HOSSEIN J, HADI M S N. The effect of resin thickness on bolt-grout-concrete interaction in shear [C]//Coal 2005: Coal Operators’ Conference. Brisbane, Australia, 2005. [8] FERRERO A M. The shear strength of reinforced rock joints [J]. International Journal of Rock Mechanics and Mining Sciences & Geomechanics Abstracts, 1995, 32(6): 595–605. DOI: 10.1016/0148-9062(95)00002-X. [9] GORIS J M, MARTIN L A, CURTIN R P. Shear behaviour of cable bolt supports in horizontal bedded deposits [J]. Cim Bulletin, 1996, 89: 124–128. [10] GRASSELLI G. 3D Behaviour of bolted rock joints: experimental and numerical study [J]. International Journal of Rock Mechanics and Mining Sciences, 2005, 42(1): 13–24. DOI: 10.1016/j.ijrmms.2004.06.003. [11] JALALIFAR H, AZIZ N. Experimental and 3D numerical simulation of reinforced shear joints [J]. Rock Mechanics and Rock Engineering, 2010, 43(1): 95–103. DOI: 10.1007/s00603-009-0031-7. [12] 单仁亮, 陶宇, 孔祥松, 等. 能承担横向剪切力的锚管索支护结构: CN201410206614.5 [P]. 2016-03-02.SHAN R L, TAO Y, KONG X S, et al. Composite support method of longitudinal beam in coal roadway: CN201410206614.5 [P]. 2016-03-02. [13] 单仁亮, 仝潇, 黄鹏程, 等. 管索组合结构及其力学性能研究 [J]. 岩土力学, 2022, 43(3): 602–614. DOI: 10.16285/j.rsm.2021.0764.SHAN R L, TONG X, HUANG P C, et al. Research on the anchor cable combined with the C-shaped tube and the mechanical properties [J]. Rock and Soil Mechanics, 2022, 43(3): 602–614. DOI: 10.16285/j.rsm.2021.0764. [14] SHAN R L, XIAO S C, LIANG J Q, et al. Study on the double-sided shear test and three-dimensional numerical simulation of anchor cable with C-shaped tube [J]. Structures, 2024, 61: 106065. DOI: 10.1016/j.istruc.2024.106065. [15] 单仁亮, 仝潇, 代卫林, 等. 管索组合结构支护新技术及其在深部大变形巷道应用研究 [J]. 矿业科学学报, 2023, 8(1): 39–49. DOI: 10.19606/j.cnki.jmst.2023.01.004.SHAN R L, TONG X, DAI W L, et al. Research on the new technology of anchor cable with C-shaped tube support and its application in deep large deformation roadway [J]. Journal of Mining Science and Technology, 2023, 8(1): 39–49. DOI: 10.19606/j.cnki.jmst.2023.01.004. [16] 刘海峰, 宁建国. 冲击荷载作用下混凝土材料的细观本构模型 [J]. 爆炸与冲击, 2009, 29(3): 261–267. DOI: 10.11883/1001-1455(2009)03-0261-07.LIU H F, NING J G. A meso-mechanical constitutive model of concrete subjected to impact loading [J]. Explosion and Shock Waves, 2009, 29(3): 261–267. DOI: 10.11883/1001-1455(2009)03-0261-07. [17] 张永杰, 陈力, 谢普初, 等. ABAQUS混凝土损伤塑性模型中损伤因子的率相关性及实现方法 [J]. 爆炸与冲击, 2022, 42(10): 103103. DOI: 10.11883/bzycj-2021-0464.ZHANG Y J, CHEN L, XIE P C, et al. Rate correlation of the ABAQUS damage parameter in the concrete damage plasticity model and its realization method [J]. Explosion and Shock Waves, 2022, 42(10): 103103. DOI: 10.11883/bzycj-2021-0464. [18] 赵武超, 钱江, 张文娜. 冲击荷载下钢筋混凝土梁的性能及损伤评估 [J]. 爆炸与冲击, 2019, 39(1): 015102. DOI: 10.11883/bzycj-2017-0288.ZHAO W C, QIAN J, ZHANG W N. Performance and damage evaluation of RC beams under impact loading [J]. Explosion and Shock Waves, 2019, 39(1): 015102. DOI: 10.11883/bzycj-2017-0288. [19] 张书鹏. 深部穿层巷道管索组合结构支护理论与技术研究 [D]. 北京: 中国矿业大学(北京), 2022: 54–56. DOI: 10.27624/d.cnki.gzkbu.2022.000132.ZHANG S P. Study on the theory and technology of Anchor Cable with C-shaped tube structure support in deep roadway [D]. Beijing: China University of Mining & Technology (Beijing), 2022: 54–56. DOI: 10.27624/d.cnki.gzkbu.2022.000132. [20] PELLET F, EGGER P. Analytical model for the mechanical behaviour of bolted rock joints subjected to shearing [J]. Rock Mechanics and Rock Engineering, 1996, 29(2): 73–97. DOI: 10.1007/BF01079755. -

下载:

下载: