Investigation on combustion reaction evolution model of charge with mass inertia constraint via non-shock ignition

-

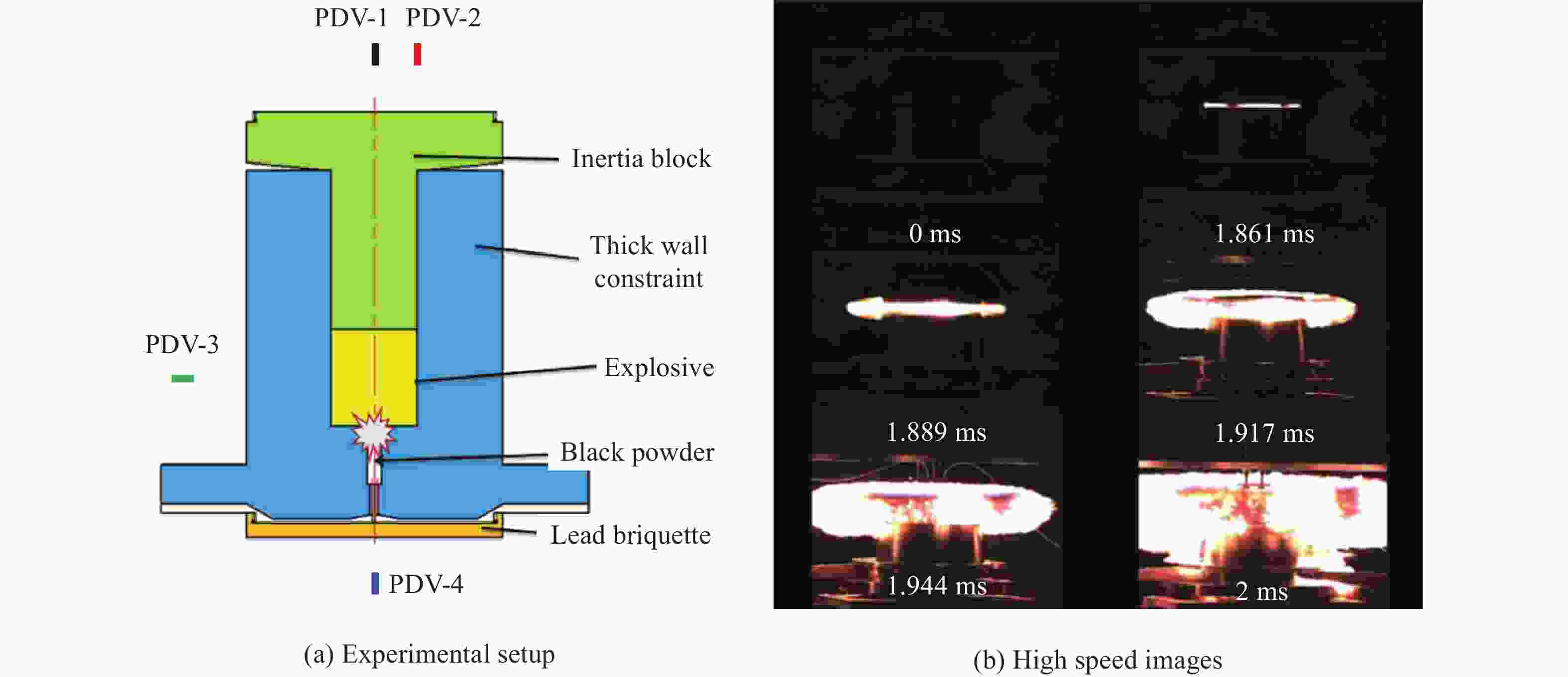

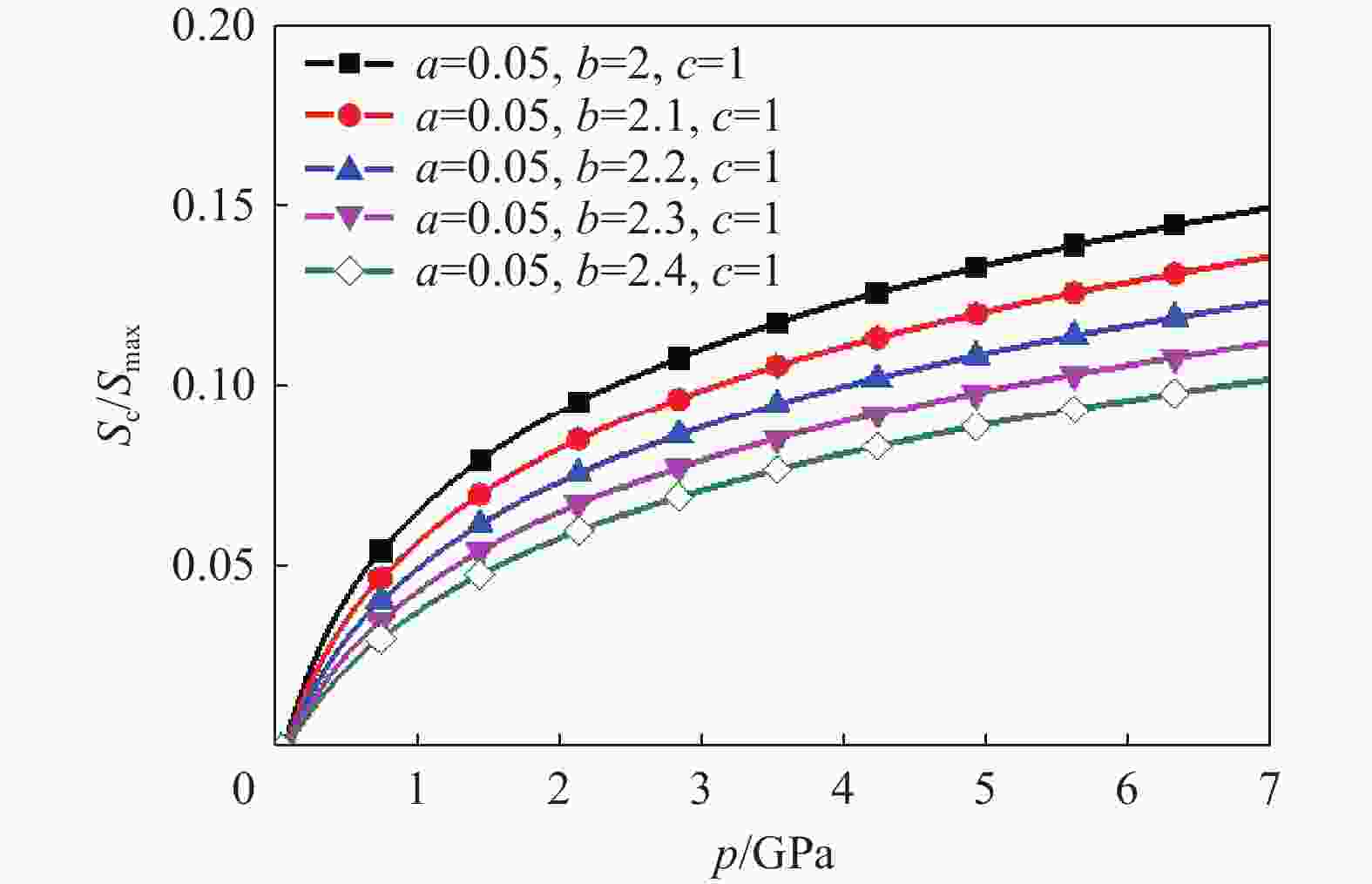

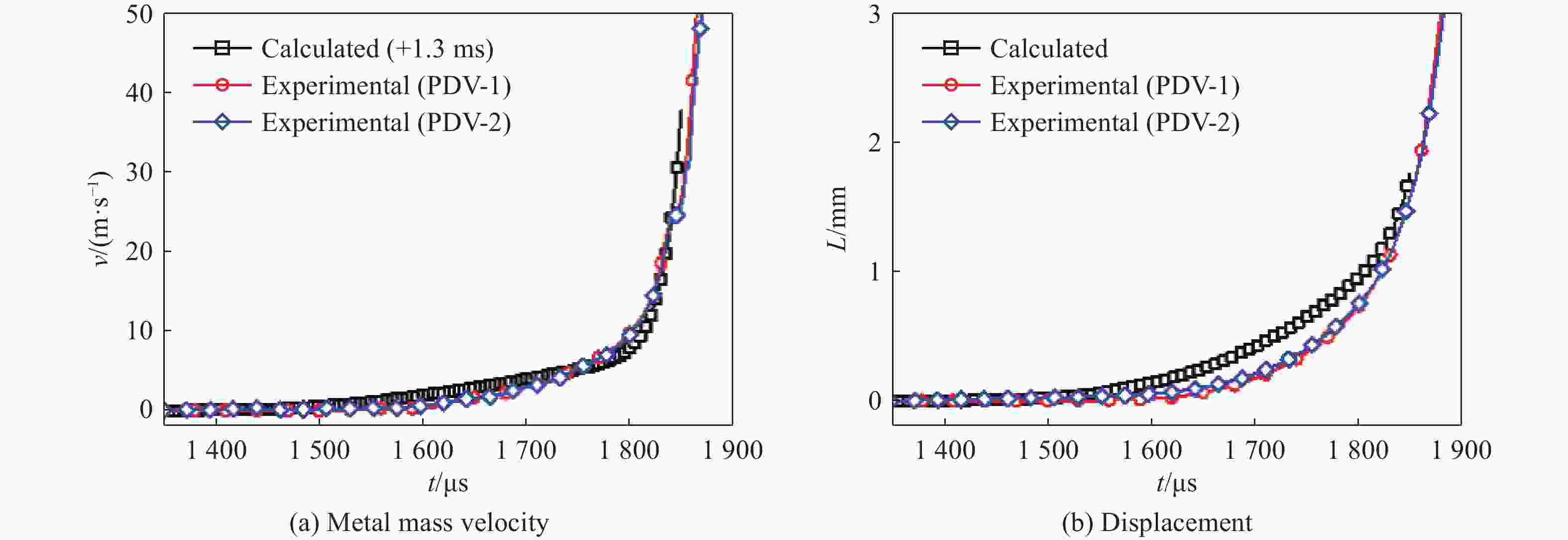

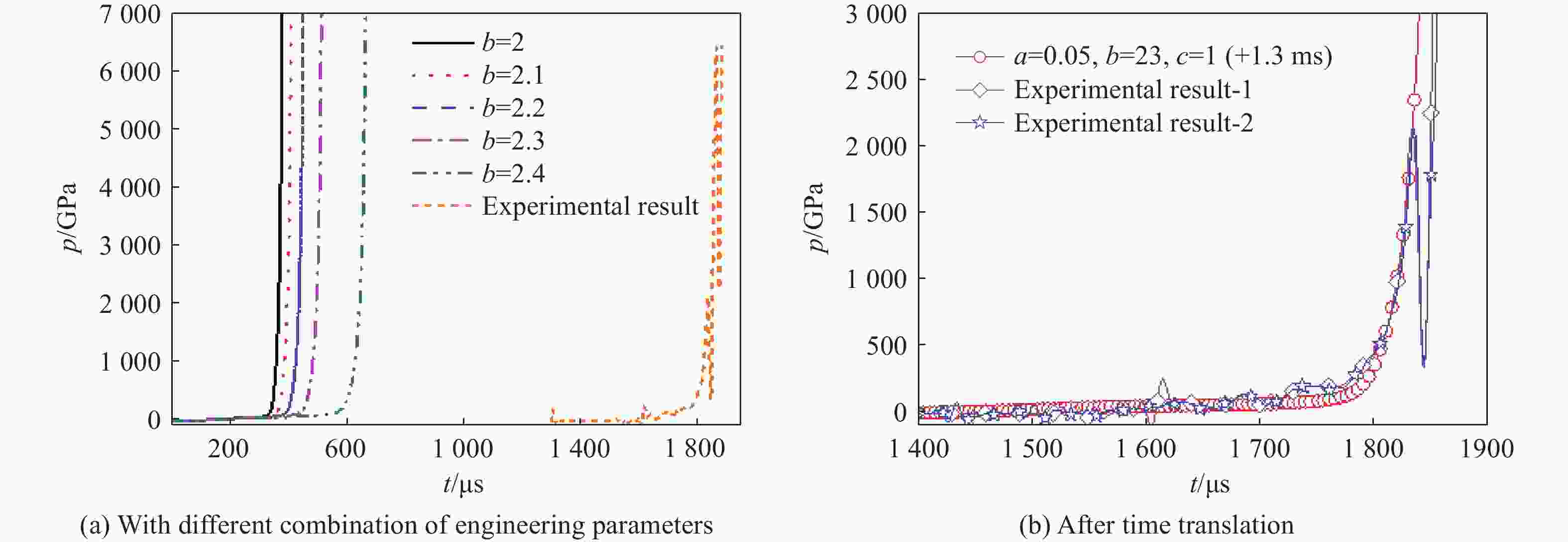

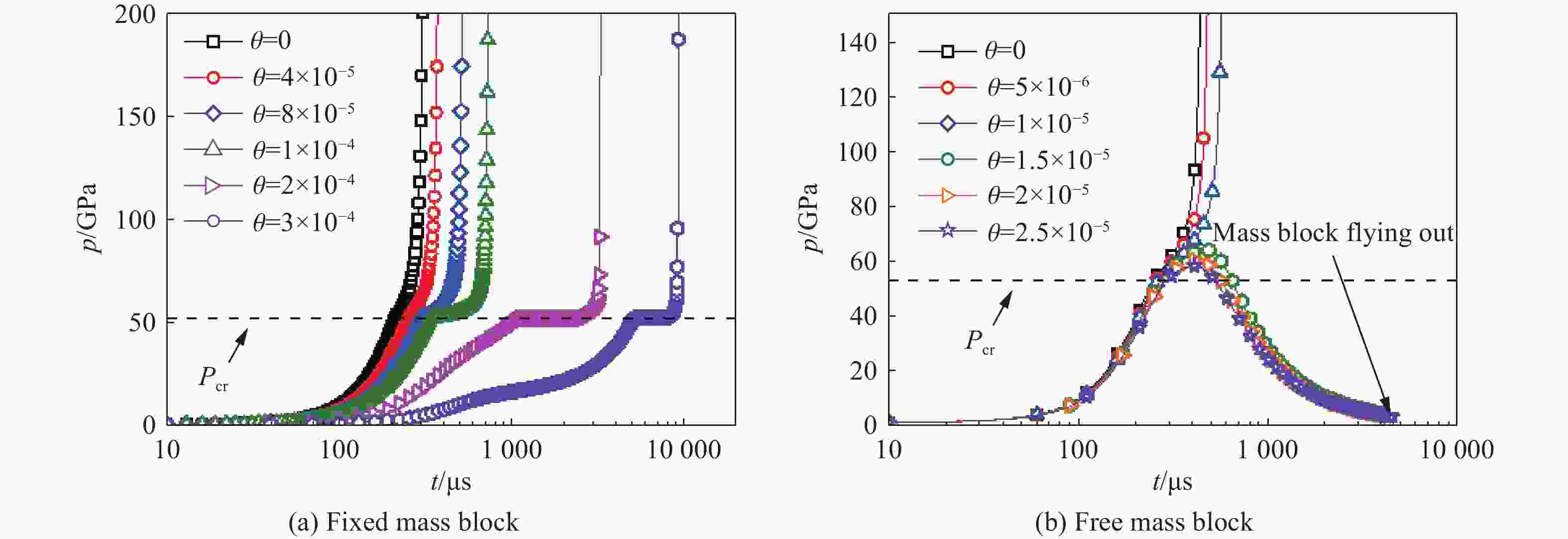

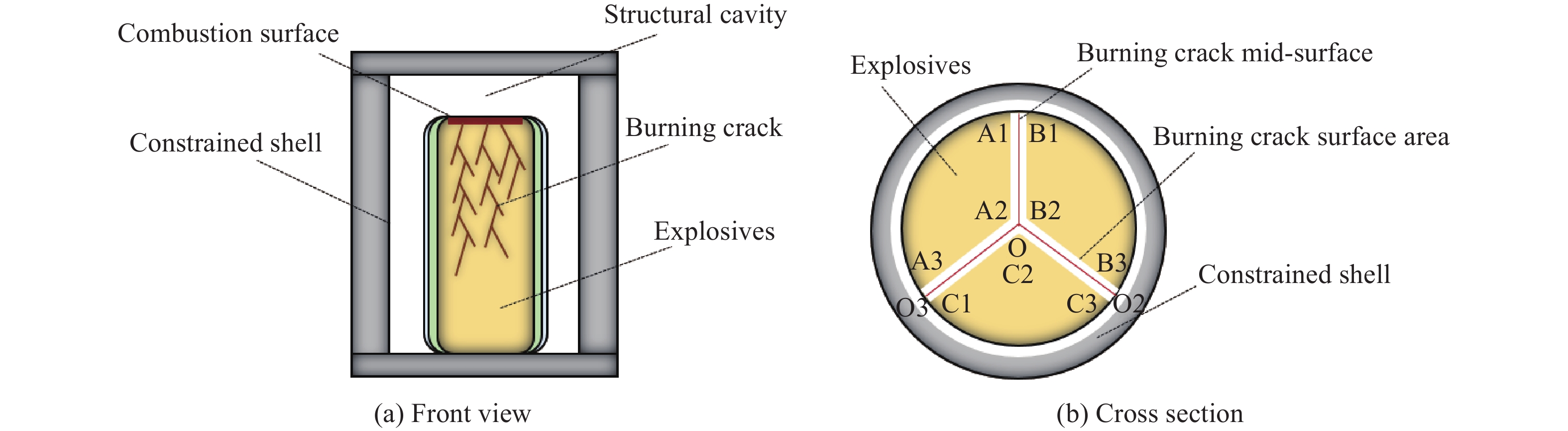

摘要: 为了发展基于结构装药非冲击点火反应演化的物理机制的工程模型、描述反应演化过程并量化表征反应烈度,本文基于装药反应裂纹扩展的主控机制,考虑了空腔膨胀体积,以断裂韧性与反应压力为主要参量,构建了约束装药燃烧反应演化模型,可描述装药燃烧过程中燃烧气体产物增压和壳体结构约束强度的变化过程。利用质量惯性约束作用下的PBX-3炸药燃烧反应演化实验,验证了约束装药反应燃烧演化模型的可靠性。分析结果表明:模型计算获得的反应增压历程与实验中的反应压力增长趋势(通过质量块运动速度历程推算)大致吻合,考虑结构泄压效应的模型能够反映压力增长历程中燃烧产气增压与泄气释压竞争的物理机制,压力增长趋势随泄压面积系数的变化关系符合机理分析预期。Abstract: To develop an engineering model based on the physical mechanism of the non-shock initiation reaction of structural charge, which can be used to describe the reaction evolution process and quantify the reaction intensity for evaluating weapons and ammunition safety. Considering the cavity expansion volume, a constrained charge combustion reaction evolution model was established in this paper, with fracture toughness and reaction pressure as the main parameters based on the main control mechanism of charge reaction crack propagation, which can describe the combustion gaseous product pressurization and shell constraint strength during combustion evolution. Relevant details for the control model establishment process were given. The model reliability of confined charge reaction combustion evolution was verified via the experiments of PBX-3 (87% HMX) explosive combustion reaction evolution under mass inertial confinement. The mass velocity time was recorded by PDV (photonic Doppler velocimetry) transducers, the pressure-time profiles were recorded via pressure transducers, and the experimental process was captured via a high-speed camera. The experimental results were compared with calculated results from the control model proposed in this work. The results show that the reaction pressurization process calculated via the model is roughly consistent with the pressure-increasing trend in the experiment (calculated by the mass velocity). The control model considering the structural venting effect can reflect the competition mechanism between combustion gas pressurization and venting in the pressure-increasing process, and the relationship between the pressure-increasing trend and the vent coefficient is in line with the mechanism analysis expectation. The results can support deepening the understanding of the accidental explosive combustion reaction evolution mechanism.

-

表 1 约束柱壳参数数值

Table 1. Parameter values of confined cylindrical shell

R1/mm R2/mm μ E/GPa σs /MPa pe /MPa ps /MPa I/GPa 25 75 0.3 200 370 189.9 469.4 146.34 注:R1为内径,R2为外径,μ为泊松比,E为弹性模量,σs/为屈服强度,pe为弹性极限强度,ps为塑性极限强度,I为约束体积模量。 表 2 PBX-3炸药基本参数

Table 2. Parameter values of PBX-3 Explosives

B/GPa ρe0/(g·cm−3) Ve0/cm3 me0/kg Mg/(g·mol−1) ω R/(J·mol−1·K−1) T/K 10.1 1.845 98.175 0.181 27.2 1 8.314 472 4000 Rp/(m2·s−2·K−1) l0/μm KIC/(MPa·K1/2) pIG/MPa Smax/m2 η α/(mm·MPa−β·s−1) β 305.68 90 0.5 1 6.533 1 1.63 0.92 注:B为体积模量;ρe0为初始密度;Ve0为初始体积;me0为初始质量;Mg为产物气体摩尔质量;ω为气体产物转化率;R为摩尔气体常数;T为气体产物温度;l0为颗粒平均粒径;KIC为断裂韧度;pIG为初始点火压力;Smax为最大饱和燃烧面积;η为变形几何参数;α为炸药燃烧系数,通过燃速实验标定;β为燃烧指数,通过燃速实验标定。 -

[1] PICART D, BOUTON E. Non shock ignition of HMX based high explosives: thermo mechanical numerical study [C]// 14th International Detonation Symposium, 2010: 717–724. [2] ASAY B W. Shock Wave Science and Technology Reference Library [M]. Berlin, Heidelberg: Springer, 2010: 11–488. DOI: 10.1007/978-3-540-87953-4. [3] 黄辉, 黄亨建, 王杰, 等. 安全弹药的发展思路与技术途径 [J]. 含能材料, 2023, 31(10): 1079–1087. DOI: 10.11943/CJEM2023165.HUANG H, HUANG H J, WANG J, et al. Development ideas and technical approaches for safety ammunition [J]. Chinese Journal of Energetic Materials, 2023, 31(10): 1079–1087. DOI: 10.11943/CJEM2023165. [4] GRIFFITHS S K, NILSON R H. Similarity analysis of fracture growth and flame spread in deformable solid propellants [J]. Combustion and Flame, 1992, 88(3/4): 369–383. DOI: 10.1016/0010-2180(92)90040-V. [5] BELYAEV A F, BOBOLEV V K, KOROTKOV A I, et al. Transition from deflagration to detonation in condensed phases[M], translation. Orginial work published 1973, 1975. [6] JACKSON S I, HILL L G. Runaway reaction due to gas-dynamic choking in solid explosive containing a single crack [J]. Proceedings of the Combustion Institute, 2009, 32(2): 2307–2313. DOI: 10.1016/j.proci.2008.05.089. [7] 胡海波, 傅华, 李涛, 等. 压装密实炸药装药非冲击点火反应传播与烈度演化实验研究进展 [J]. 爆炸与冲击, 2020, 40(1): 1–13. DOI: 10.11883/bzycj-2019-0346.HU H B, FU H, LI T, et al. Progress in experimental studies on the evolution behaviors of non-shock initiation reaction in low porosity pressed explosive with confinement [J]. Explosion and Shock Waves, 2020, 40(1): 1–13. DOI: 10.11883/bzycj-2019-0346. [8] BERGHOUT H L, SON S F, ASAY B W. Convective burning in gaps of PBX 9501 [J]. Proceedings of the Combustion Institute, 2000, 28(1): 911–917. DOI: 10.1016/S0082-0784(00)80297-0. [9] BERGHOUT H L, SON S F, SKIDMORE C B, et al. Combustion of damaged PBX 9501 explosive [J]. Thermochimica Acta, 2002, 384(1/2): 261–277. DOI: 10.1016/S0040-6031(01)00802-4. [10] BERGHOUT H L, SON S F, HILL L G, et al. Flame spread through cracks of PBX 9501 (a composite octahydro-1, 3, 5, 7-tetranitro-1, 3, 5, 7-tetrazocine-based explosive) [J]. Journal of Applied Physics, 2006, 99(11): 114901. DOI: 10.1063/1.2196219. [11] 尚海林, 杨洁, 胡秋实, 等. 炸药裂缝中的对流燃烧现象实验研究 [J]. 兵工学报, 2019, 40(1): 99–106. DOI: 10.3969/j.issn.1000-1093.2019.01.012.SHANG H L, YANG J, HU Q S, et al. Experimental research on convective burning in explosive cracks [J]. Acta Armamentarii, 2019, 40(1): 99–106. DOI: 10.3969/j.issn.1000-1093.2019.01.012. [12] 尚海林, 杨洁, 李涛, 等. 约束HMX基PBX炸药裂缝中燃烧演化实验 [J]. 含能材料, 2019, 27(12): 1056–1061. DOI: 10.11943/CJEM2018339.SHANG H L, YANG J, LI T, et al. Experimental study on burning evolution in confined HMX-based PBX cracks [J]. Chinese Journal of Energetic Materials, 2019, 27(12): 1056–1061. DOI: 10.11943/CJEM2018339. [13] 尚海林, 马骁, 程赋, 等. 炸药燃烧产物驱动裂纹动态扩展耦合特性 [J]. 含能材料, 2019, 27(10): 819–823. DOI: 10.11943/CJEM2019136.SHANG H L, MA X, CHENG F, et al. Coupling properties of crack penetration driven by explosive burning products [J]. Chinese Journal of Energetic Materials, 2019, 27(10): 819–823. DOI: 10.11943/CJEM2019136. [14] SMILOWITZ L, HENSON B F, ROMERO J J, et al. Direct observation of the phenomenology of a solid thermal explosion using time-resolved proton radiography [J]. Physical Review Letters, 2008, 100(22): 228301. DOI: 10.1103/PhysRevLett.100.228301. [15] SMILOWITZ L, HENSON B F, ROMERO J J, et al. Thermal decomposition of energetic materials viewed via dynamic x-ray radiography [J]. Applied Physics Letters, 2014, 104(2): 024107. DOI: 10.1063/1.4858965. [16] SMILOWITZ L, HENSON B F, OSCHWALD D, et al. Internal sub-sonic burning during an explosion viewed via dynamic X-ray radiography [J]. Applied Physics Letters, 2017, 111(18): 184103. DOI: 10.1063/1.5004424. [17] SMILOWITZ L, HENSON B F, ROMERO J J, et al. The evolution of solid density within a thermal explosion. I. proton radiography of pre-ignition expansion, material motion, and chemical decomposition [J]. Journal of Applied Physics, 2012, 111(10): 103515. DOI: 10.1063/1.4711071. [18] SMILOWITZ L, HENSON B F, ROMERO J J, et al. The evolution of solid density within a thermal explosion II. dynamic proton radiography of cracking and solid consumption by burning [J]. Journal of Applied Physics, 2012, 111(10): 103516. DOI: 10.1063/1.4711072. [19] SWANSON S R. Application of Schapery's theory of viscoelastic fracture to solid propellant [J]. Journal of Spacecraft and Rockets, 1976, 13(9): 528–533. DOI: 10.2514/3.27925. [20] BENNETT J G, HABERMAN K S, JOHNSON J N, et al. A constitutive model for the non-shock ignition and mechanical response of high explosives [J]. Journal of the Mechanics and Physics of Solids, 1998, 46(12): 2303–2322. DOI: 10.1016/S0022-5096(98)00011-8. [21] HILL L G. Burning crack networks and combustion bootstrapping in cookoff explosions [J]. AIP Conference Proceedings, 2006, 845(1): 531–534. DOI: 10.1063/1.2263377. [22] 段卓平, 白志玲, 白孟璟, 等. 强约束固体炸药燃烧裂纹网络反应演化模型 [J]. 兵工学报, 2021, 42(11): 2291–2299. DOI: 10.3969/j.issn.1000-1093.2021.11.001.DUAN Z P, BAI Z L, BAI M J, et al. Burning-crack networks model for combustion reaction growth of solid explosives with strong confinement [J]. Acta Armamentarii, 2021, 42(11): 2291–2299. DOI: 10.3969/j.issn.1000-1093.2021.11.001. [23] 白志玲, 段卓平, 李治, 等. 热刺激约束DNAN基不敏感熔铸炸药装药点火后反应演化调控模型 [J]. 含能材料, 2023, 31(10): 1004–1012. DOI: 10.11943/CJEM2023160.BAI Z L, DUAN Z P, LI Z, et al. Regulation model for reaction evolution of confined DNAN-based cast explosives after ignition under thermal stimulation [J]. Chinese Journal of Energetic Materials, 2023, 31(10): 1004–1012. DOI: 10.11943/CJEM2023160. [24] GRAHAM K J. Mitigation of fuel fire threat to large rocket motors by venting [C]//Insensitive Munitions & Energetic Materials Symposium Munich. Munich: Air Force Research Laboratory, 2010. -

下载:

下载: