Study on dynamic energy dissipation mechanism and damage characteristics of high-temperature marble

-

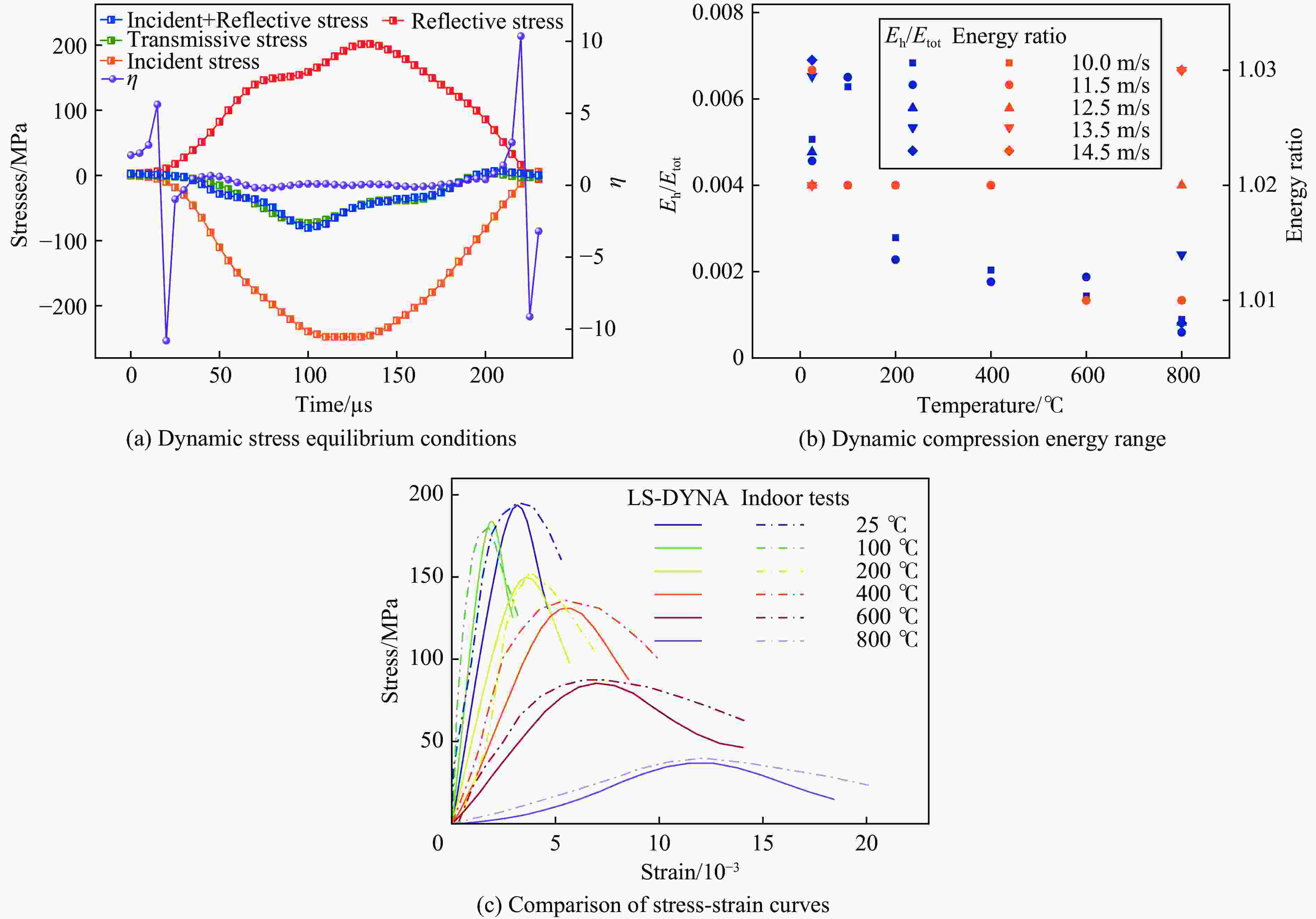

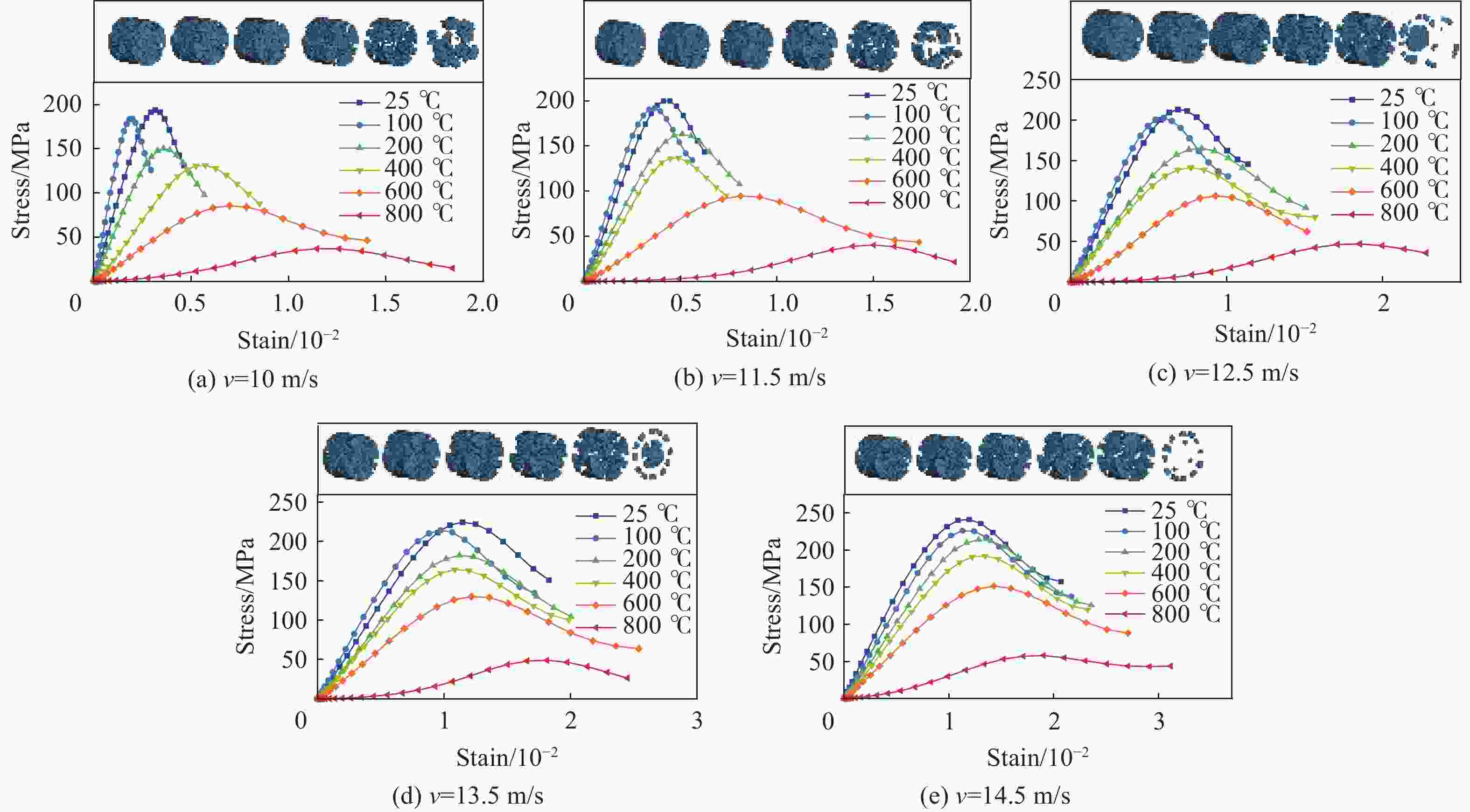

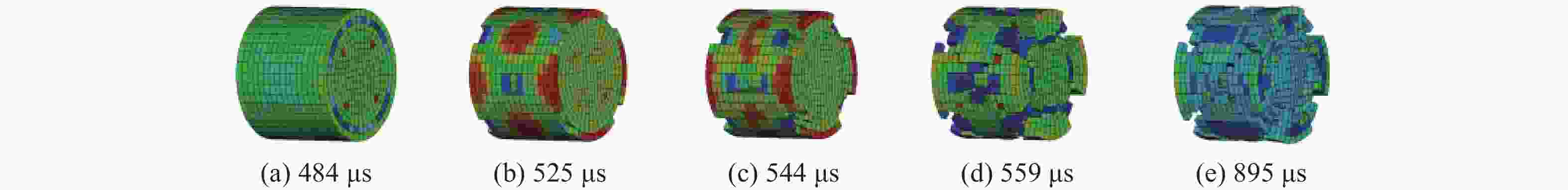

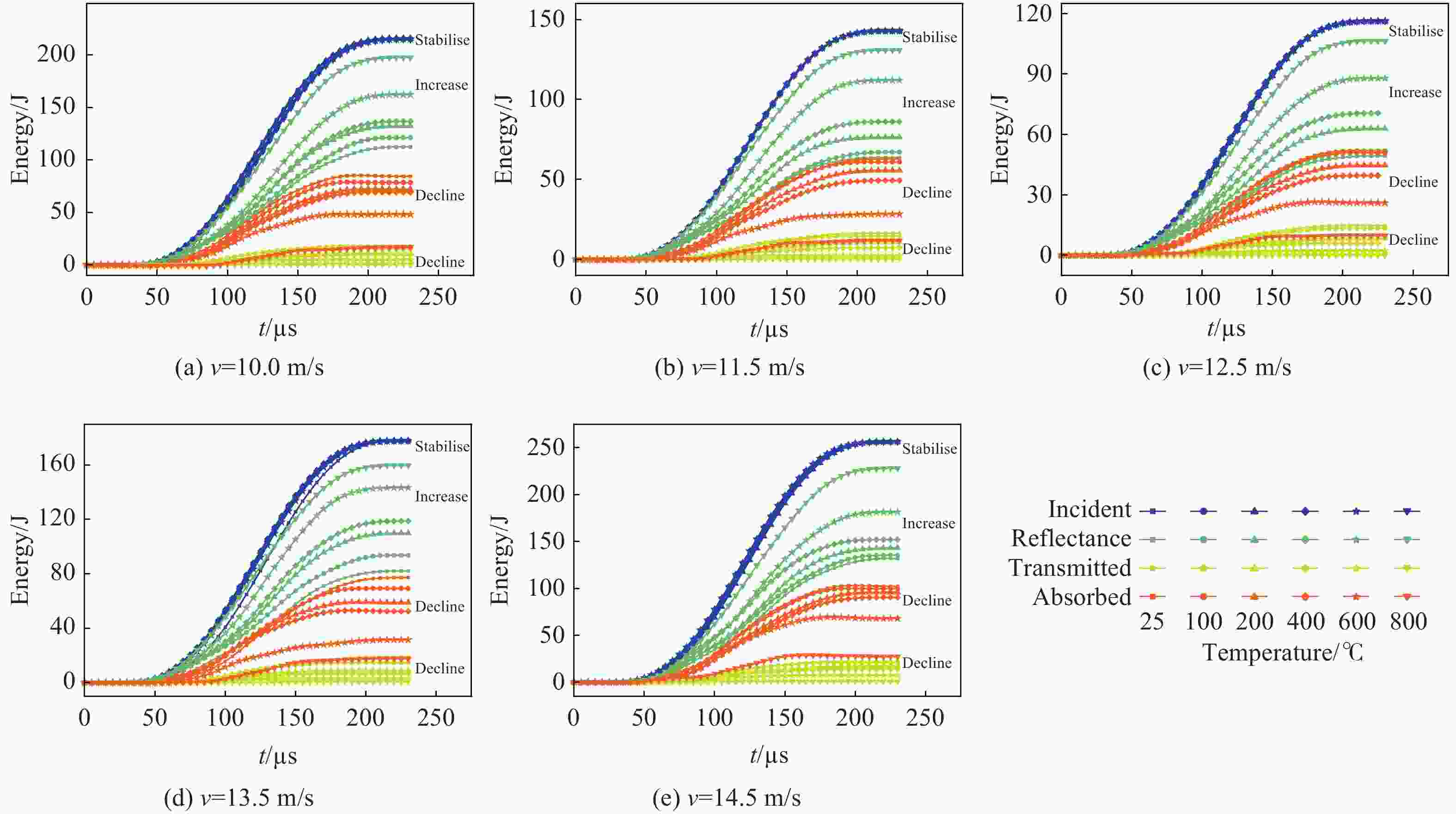

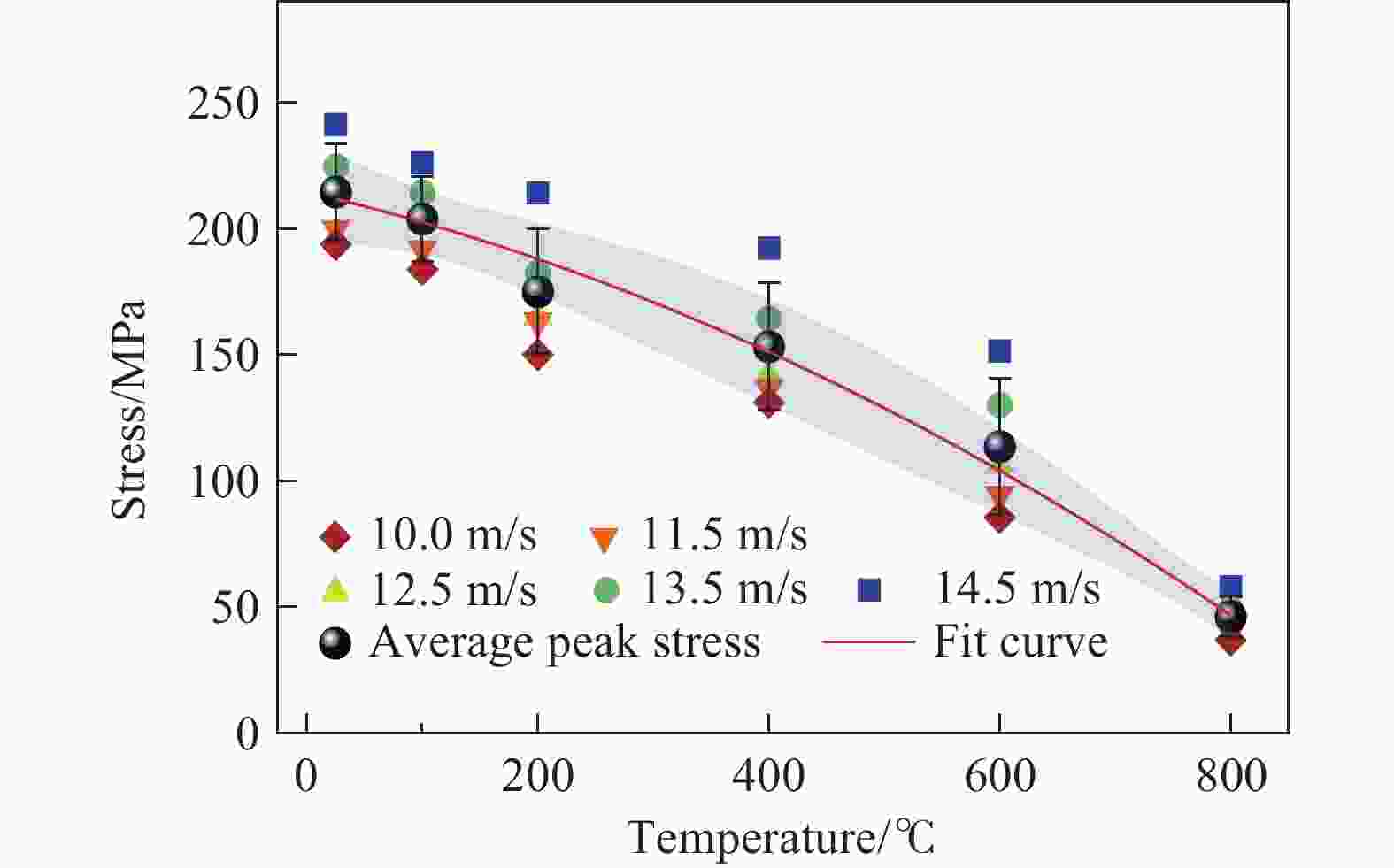

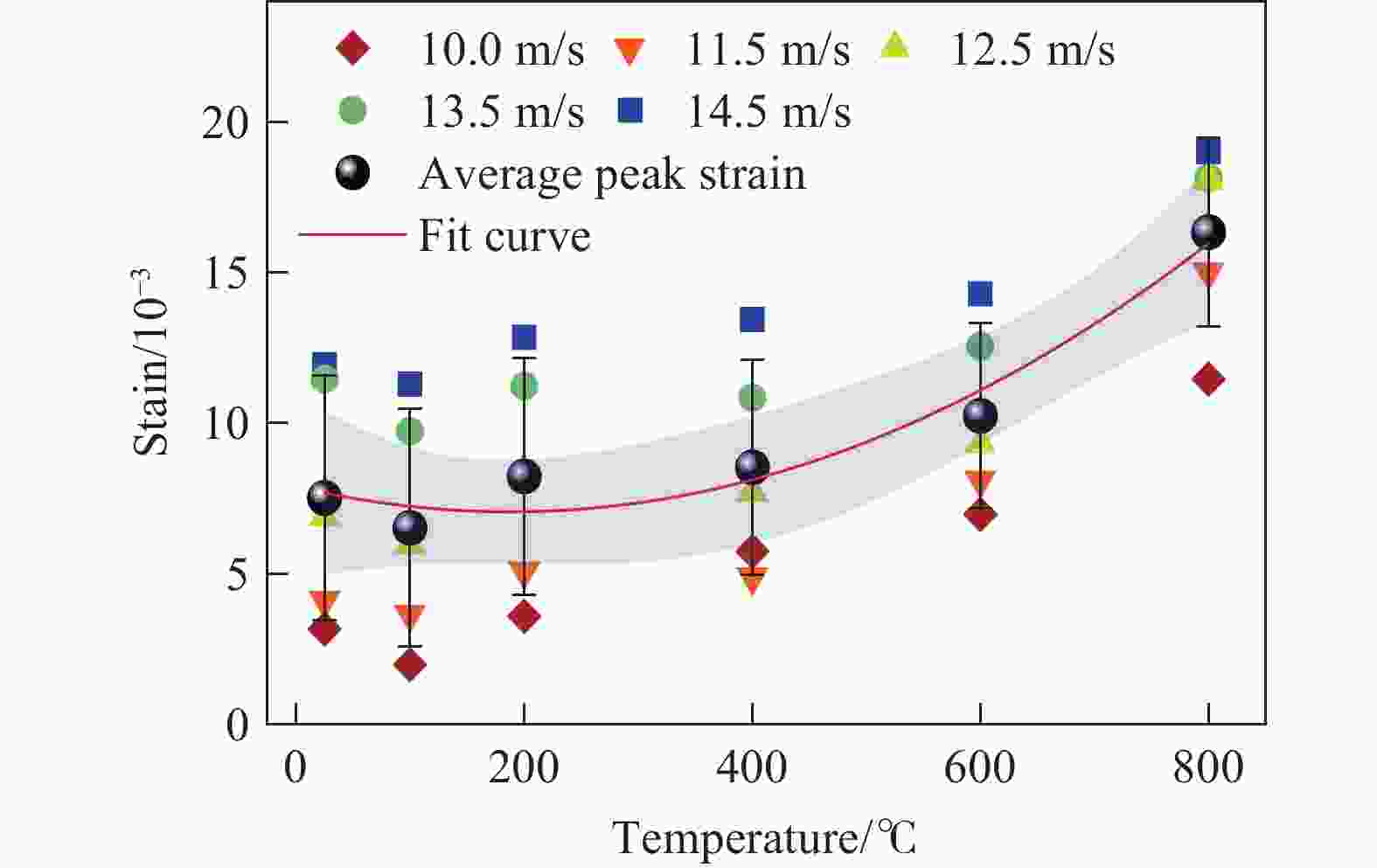

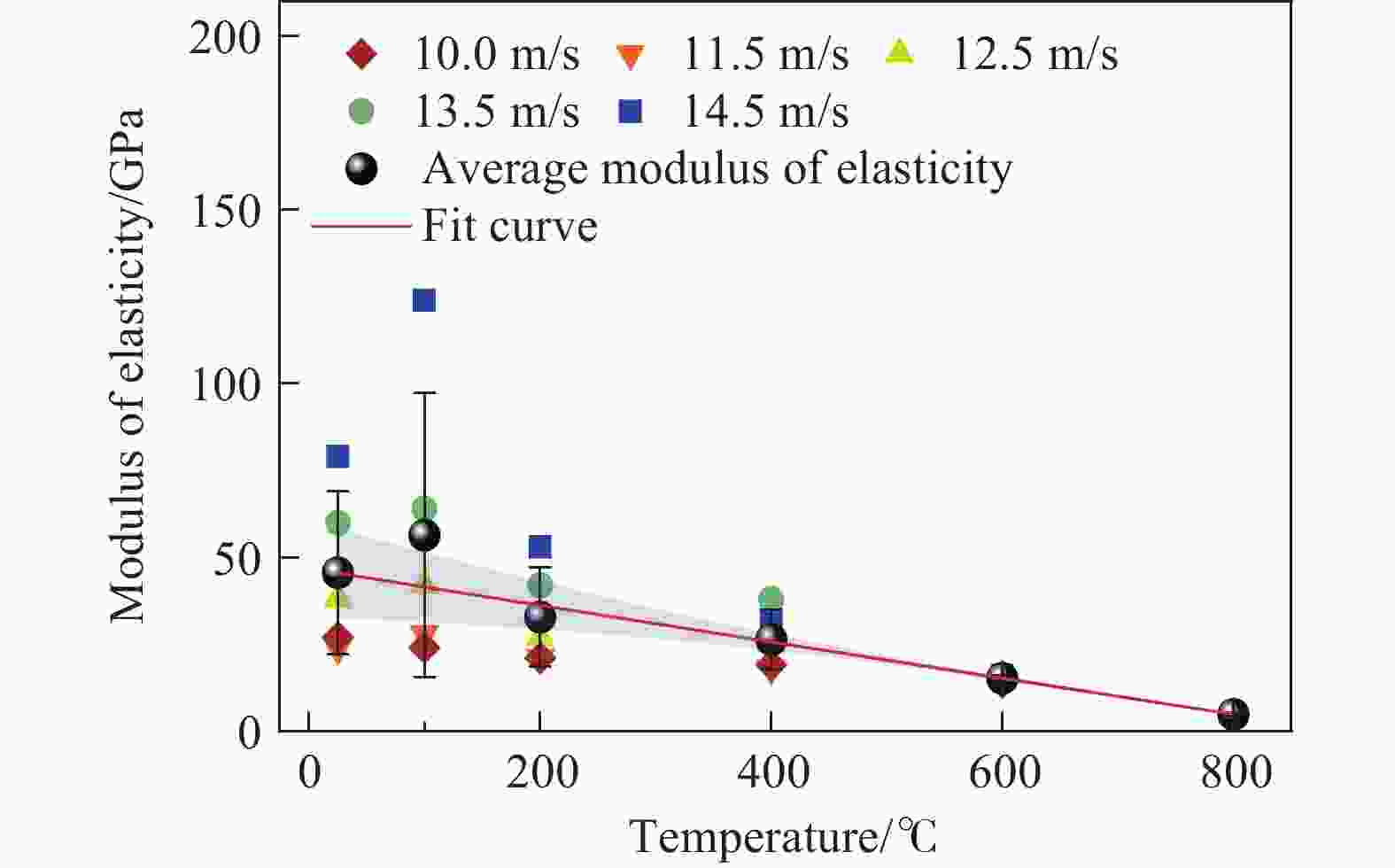

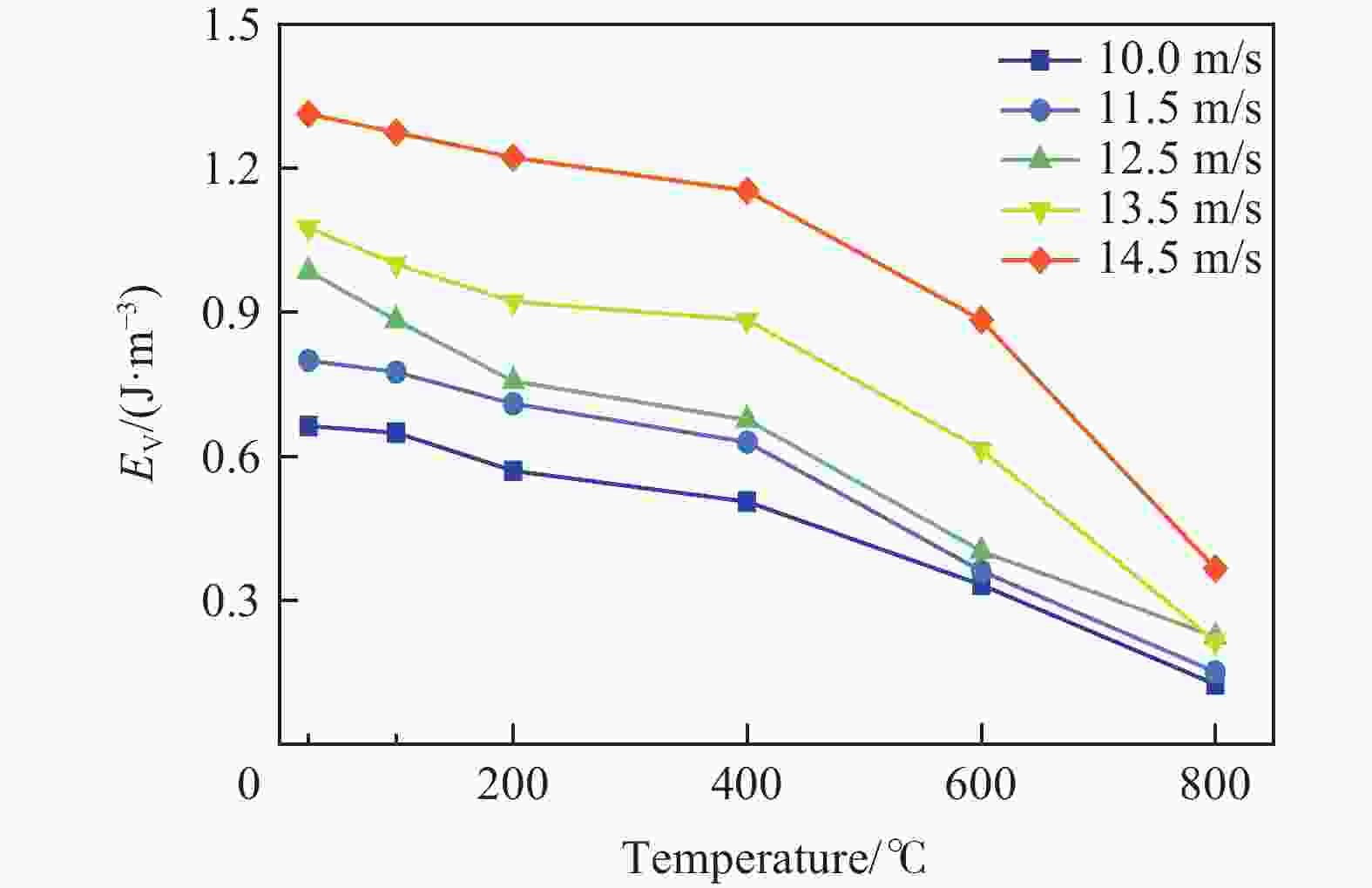

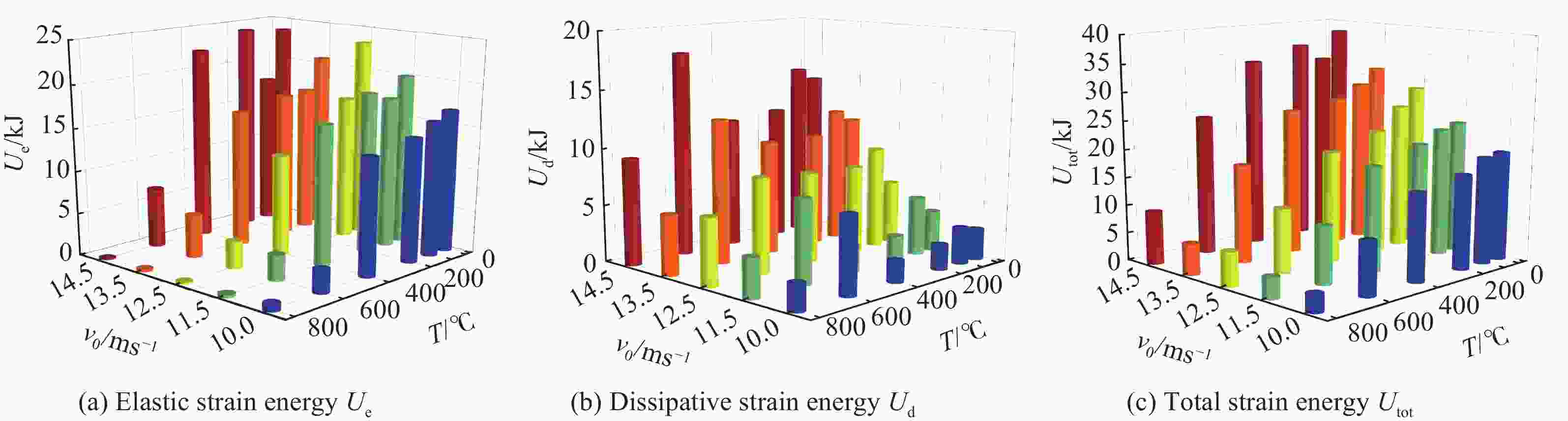

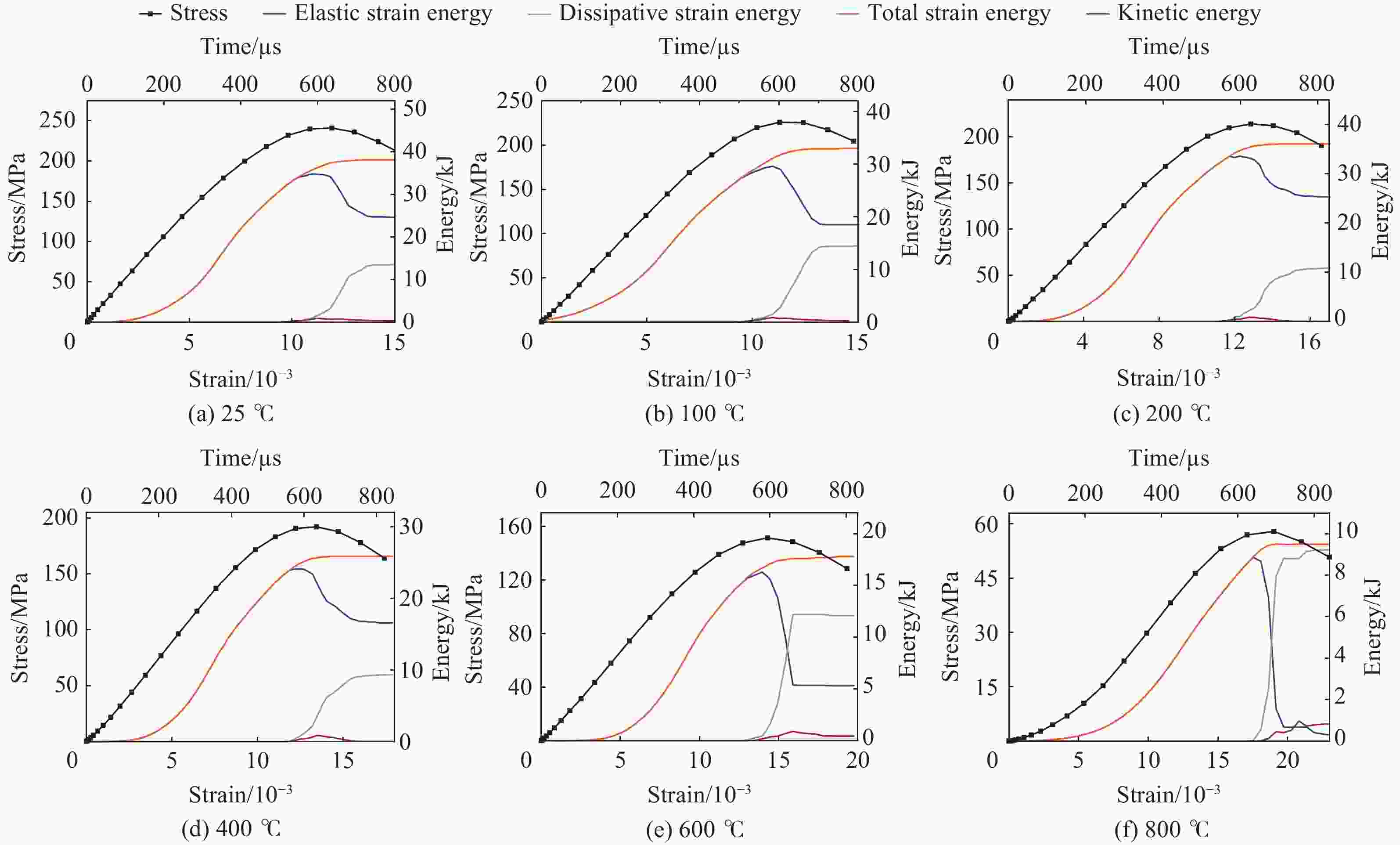

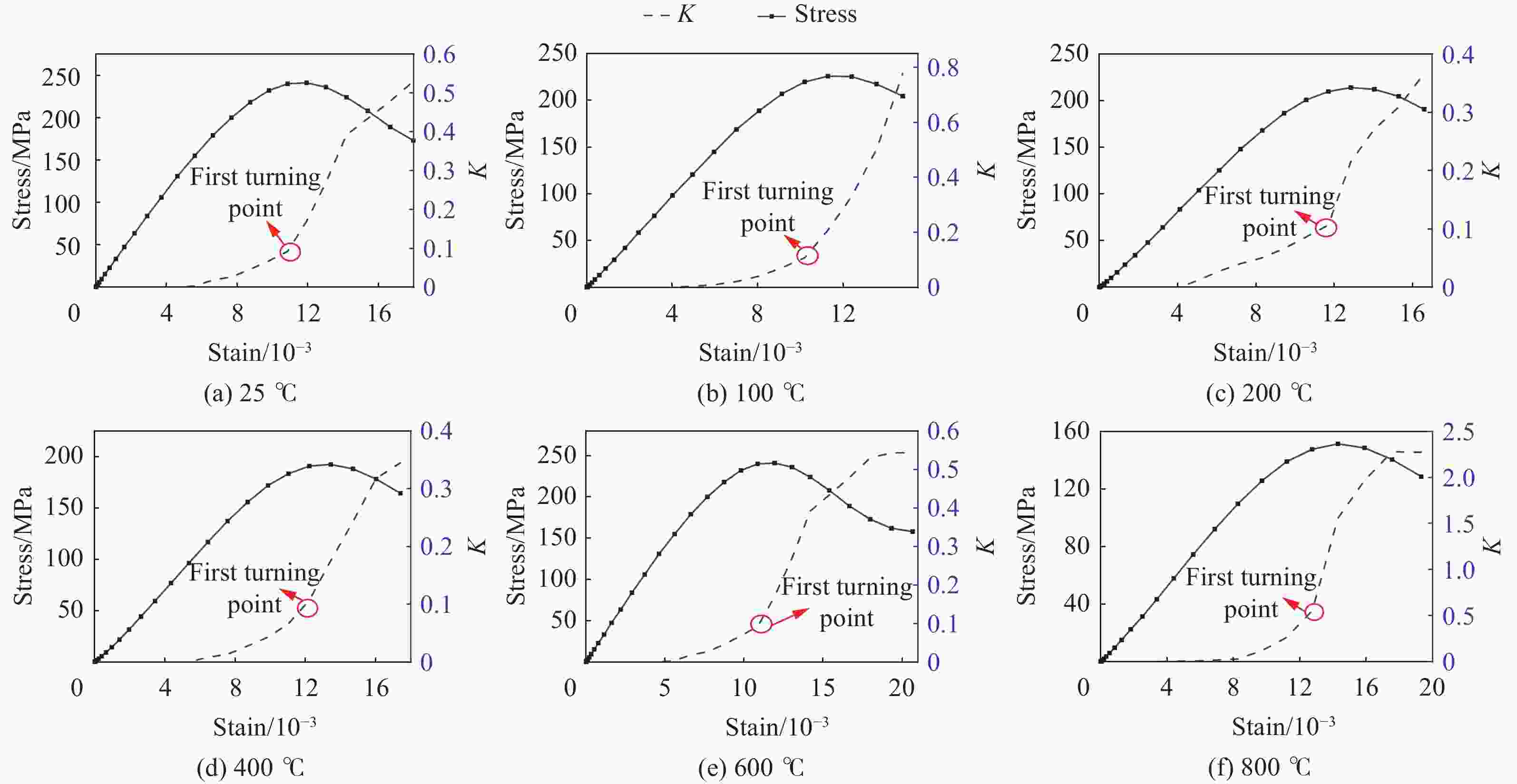

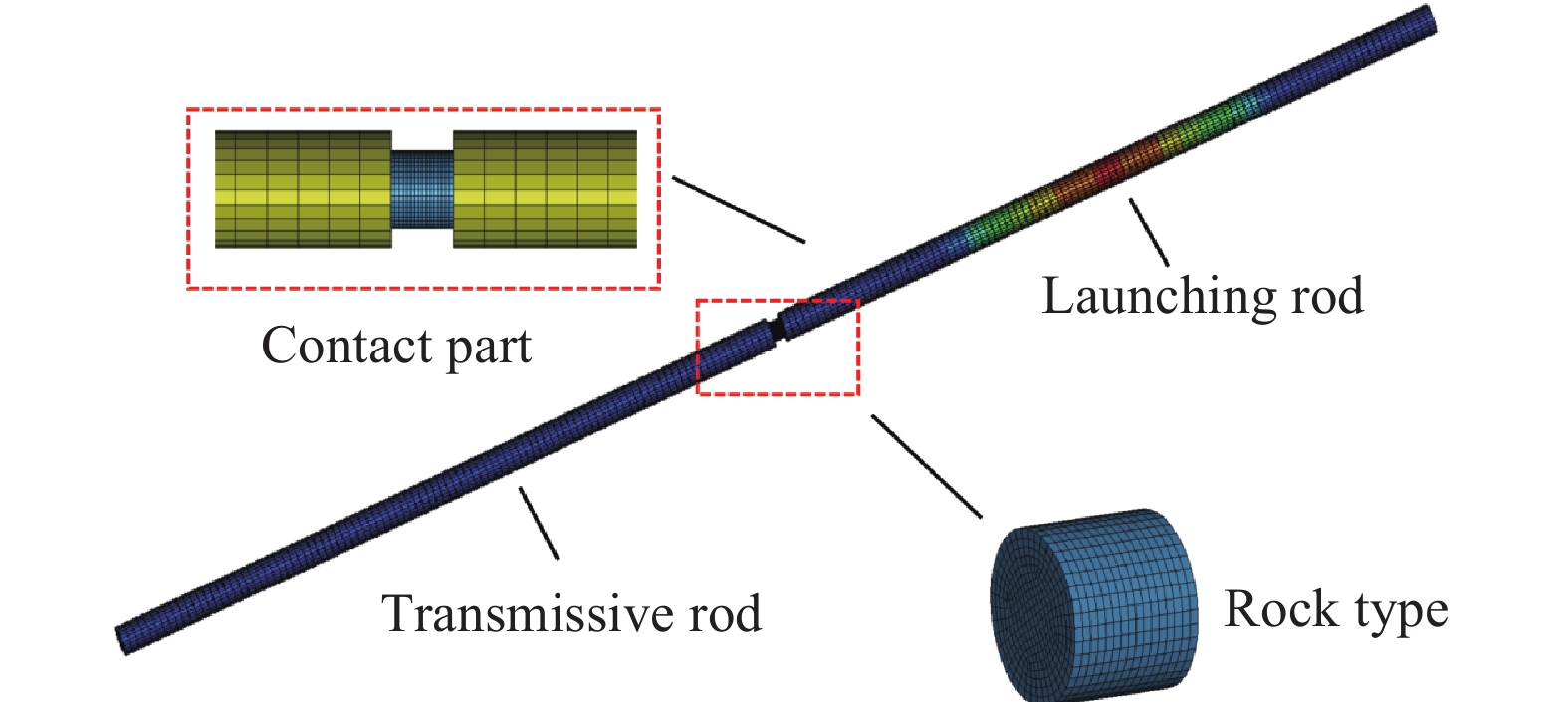

摘要: 为探究高温对大理岩能量特性的影响,利用ANSYS/LS-DYNA对大理岩开展了6级温度梯度、 5种冲击速度的动态压缩试验,分析了高温动载作用下大理岩力学特性、能量演化的温度效应,最终从能量耗散角度探讨高温大理岩强度失效的能量判据。研究结果表明:(1) HJC本构模型能够合理有效模拟不同温度下大理岩动态变化破坏过程;(2) 随着温度的增加,大理岩动态峰值强度和动弹性模量与温度呈二次函数负相关,动态峰值应变与温度呈二次函数正相关,破坏形态由“X型”共轭剪切破坏向粉碎性破坏转变,破碎细粒尺寸减小;(3) 当温度到达600 ℃时,峰值强度大幅降低,大理岩延性增加,呈现粉碎性破坏,耗散应变能达到最大值,600 ℃可作为大理岩脆延转化的阈值温度;(4) 依据能量演化过程特征,将耗散应变能陡增点视为大理岩整体失稳破坏前兆信息点,根据应力-弹性能耗比-应变关系曲线界定弹性能耗比增长速率首次出现的拐点作为大理岩的强度失效能量判据。Abstract: To investigate the effect of high temperature on the energy characteristics of marble, ANSYS/LS-DYNA was used to carry out dynamic compression simulation tests on marble with six temperature gradients at five impact velocities to analyze the mechanical properties of marble under high-temperature dynamic loading and the temperature effect on energy evolution, and to explore the energy criterion for strength failure of high-temperature marble from the perspective of energy dissipation. The results show that the Holmquist-Johnson-Cook (HJC) constitutive model can reasonably and effectively simulate the dynamic damage process of marble under different temperatures. With the increase in temperature, the dynamic peak strength and dynamic elastic modulus of marble exhibit a quadratic negative correlation with temperature, the dynamic peak strain exhibits a quadratic positive correlation with temperature, and the damage morphology is changed from X-type to conjugate shear damage. The increase in temperature reduces the energy storage capacity of the marble specimen to a certain extent, while the effect of high temperature on the energy dissipation capacity of marble is transformed from a facilitating effect to an inhibiting effect with 600 ℃ as the cut-off point. When the temperature reaches 600 ℃, the peak strength is significantly reduced, the ductility of the marble increases, crushing damage is presented, and the dissipated strain energy reaches the maximum value. 600 ℃ can be used as the threshold temperature for the brittle-delayed transformation of the marble. Based on the characteristics of the energy evolution process, the point of a steep increase in dissipated strain energy is regarded as a precursor information point of the precursor of overall instability and damage of marble. The inflection point at which the growth rate of the elastic energy consumption ratio first appears is defined according to the curve of the stress-elastic energy consumption ratio-strain relationship as the energy criterion of the strength failure of marble.

-

Key words:

- high temperature marble /

- SHPB /

- energy dissipation /

- failure criterion

-

表 1 高温大理岩温度无影响参数

Table 1. Temperature unaffected parameters of high temperature marble

A B N C plock/GPa $ \dot{{\varepsilon }_{0}} $/s−1 Smax 0.355 2.003 0.849 0.008 1.2 0.001 6.0 K1/GPa K2/GPa K3/GPa D1 D2 破坏类型 εf,min 44 39 3.8 0.04 1 2.0 0.03 注:A为归一化黏性强度系数, B为归一化压力硬化系数, N为压力硬化指数, C为应变率系数, plock为压实点静水压力, $ \dot{{\varepsilon }_{0}} $为参考应变率, Smax为归一化最大强度, K1、K2、K3为压力参数, D1、D2损伤参数, εf,min为材料断裂时最小塑性应变。 表 2 高温大理岩受温度影响参数

Table 2. Parameters of high temperature marble affected by temperature

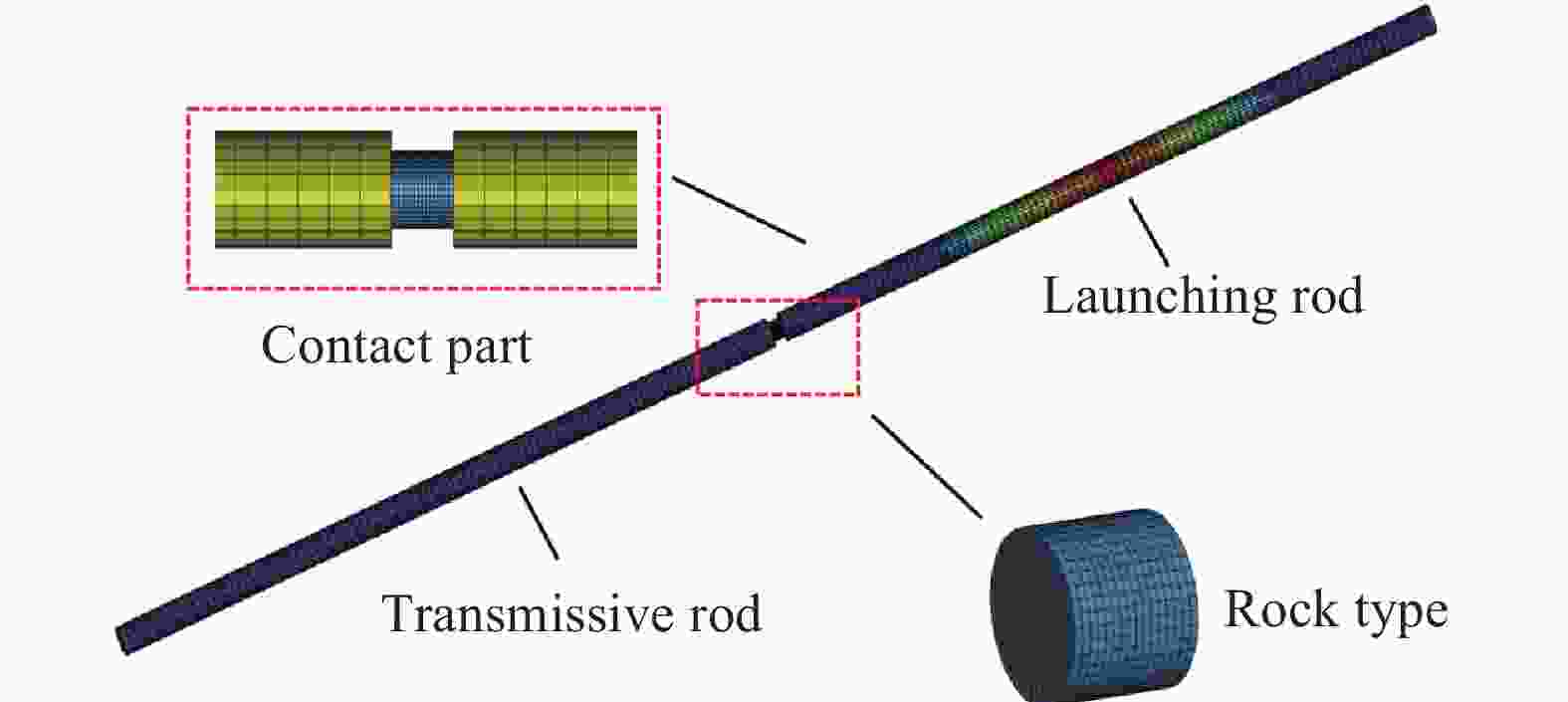

温度/℃ 密度/(g·cm−3) 抗压强度/MPa 剪切模量/GPa 抗拉强度/MPa 压溃点静水压力/MPa 压溃点体积应变/10−2 压实点体积应变/10−2 25 2.73 73.6 14.2 6.82 24.5 0.19 2.22 100 2.74 83.7 13.3 6.64 27.9 0.15 2.19 200 2.72 51.5 12.1 6.44 17.2 0.12 2.03 400 2.58 42.9 9.40 6.80 14.3 0.12 2.03 600 2.67 54.4 7.93 6.48 18.1 0.19 2.04 800 1.86 34.2 1.89 3.40 11.4 0.49 2.04 表 3 杆件有限元模型参数

Table 3. Parameters of finite element model for rods

入射杆

长度/m透射杆

长度/m直径/

mm密度/

(g·cm−3)弹性模量/

GPa泊松比 1.0 1.0 75 7.80 211 0.3 -

[1] ROCCHI V, SAMMONDS P R, KILBURN C R J. Fracturing of Etnean and Vesuvian rocks at high temperatures and low pressures [J]. Journal of Volcanology and Geothermal Research, 2004, 132(2/3): 137–157. DOI: 10.1016/S0377-0273(03)00342-1. [2] PARK J W, LEE Y K, PARK C, et al. Crack initiation and propagation thresholds of Hwangdeung granite under elevated temperature [J]. Geosciences Journal, 2022, 26(6): 715–729. DOI: 10.1007/s12303-022-0015-0. [3] KWON S, XIE L M, PARK S, et al. Correction to characterization of 4.2-km-deep fractured granodiorite cores from Pohang geothermal reservoir, Korea [J]. Rock Mechanics and Rock Engineering, 2020, 53(1): 453. DOI: 10.1007/s00603-019-01925-2. [4] HAJPÁL M. Changes in sandstones of historical monuments exposed to fire or high temperature [J]. Fire Technology, 2002, 38(4): 373–382. DOI: 10.1023/A:1020174500861. [5] 谢和平, 鞠杨, 黎立云. 基于能量耗散与释放原理的岩石强度与整体破坏准则 [J]. 岩石力学与工程学报, 2005, 24(17): 3003–3010. DOI: 10.3321/j.issn:1000-6915.2005.17.001.XIE H P, JU Y, LI L Y. Criteria for strength and structural failure of rocks based on energy dissipation and energy release principles [J]. Chinese Journal of Rock Mechanics and Engineering, 2005, 24(17): 3003–3010. DOI: 10.3321/j.issn:1000-6915.2005.17.001. [6] 谢和平, 鞠杨, 黎立云, 等. 岩体变形破坏过程的能量机制 [J]. 岩石力学与工程学报, 2008, 27(9): 1729–1740. DOI: 10.3321/j.issn:1000-6915.2008.09.001.XIE H P, JU Y, LI L Y, et al. Energy mechanism of deformation and failure of rock masses [J]. Chinese Journal of Rock Mechanics and Engineering, 2008, 27(9): 1729–1740. DOI: 10.3321/j.issn:1000-6915.2008.09.001. [7] WANG Z L, SHI H, WANG J G. Mechanical behavior and damage constitutive model of granite under coupling of temperature and dynamic loading [J]. Rock Mechanics and Rock Engineering, 2018, 51(10): 3045–3059. DOI: 10.1007/s00603-018-1523-0. [8] 蔚立元, 武东阳, 张涛, 等. 高温–水冷却花岗岩动态压缩力学特性的应变率效应研究 [J]. 岩石力学与工程学报, 2022, 41(S1): 2615–2625. DOI: 10.13722/j.cnki.jrme.2021.0316.WEI L Y, WU D Y, ZHANG T, et al. Study on strain rate effect of dynamic compression mechanical properties of high-temperature granite after cooling with water [J]. Chinese Journal of Rock Mechanics and Engineering, 2022, 41(S1): 2615–2625. DOI: 10.13722/j.cnki.jrme.2021.0316. [9] PING Q, ZHANG C L, SUN H J, et al. Dynamic mechanical properties and energy dissipation analysis of sandstone after high temperature cycling [J]. Shock and Vibration, 2020(5): 8848595. DOI: 10.1155/2020/8848595. [10] 平琦, 吴明静, 袁璞, 等. 冲击载荷作用下高温砂岩动态力学性能试验研究 [J]. 岩石力学与工程学报, 2019, 38(4): 782–792. DOI: 10.13722/j.cnki.jrme.2018.1299.PING Q, WU M J, YUAN P, et al. Experimental study on dynamic mechanical properties of high temperature sandstone under impact loads [J]. Chinese Journal of Rock Mechanics and Engineering, 2019, 38(4): 782–792. DOI: 10.13722/j.cnki.jrme.2018.1299. [11] 田文岭, 杨圣奇, 黄彦华, 等. 花岗岩高温高压损伤破裂细观机制模拟研究 [J]. 岩石力学与工程学报, 2022, 41(9): 1810–1819. DOI: 10.13722/j.cnki.jrme.2021.1260.TIAN W L, YANG S Q, HUANG Y H, et al. Meso-fracture mechanism of granite specimens under high temperature and confining pressure by numerical simulation [J]. Chinese Journal of Rock Mechanics and Engineering, 2022, 41(9): 1810–1819. DOI: 10.13722/j.cnki.jrme.2021.1260. [12] 吴顺川, 郭沛, 张诗淮, 等. 基于巴西劈裂试验的花岗岩热损伤研究 [J]. 岩石力学与工程学报, 2018, 37(S2): 3805–3816.WU S C, GUO P, ZHANG S H, et al. Study on ther-maldamage of granite based on Brazilian splitting test [J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(S2): 3805–3816. [13] 夏开文, 蔡英鹏, 徐颖, 等. 静水压下热损伤大理岩动态拉伸特性研究 [J]. 天津大学学报(自然科学与工程技术版), 2020, 53(11): 1136–1145. DOI: 10.11784/tdxbz202001002.XIA K W, CAI Y P, XU Y, et al. Experimental study of dynamic tensile failure of thermally damaged Fangshan marble subjected to hydrostatic confinement [J]. Journal of Tianjin University (Science and Technology), 2020, 53(11): 1136–1145. DOI: 10.11784/tdxbz202001002. [14] 张平, 任松, 张闯, 等. 循环扰动和高温作用下砂岩的岩爆倾向性及破坏特征研究 [J]. 岩土力学, 2023, 44(3): 771–783. DOI: 10.16285/j.rsm.2022.0448.ZHANG P, REN S, ZHANG C, et al. Rockburst tendency and failure characteristics of sandstone under cyclic disturbance and high temperature [J]. Rock and Soil Mechanics, 2023, 44(3): 771–783. DOI: 10.16285/j.rsm.2022.0448. [15] LI P F, SUN Q, GAO Q, et al. Size effect of failure mode of thermally damaged torus granite [J]. International Journal of Rock Mechanics and Mining Sciences, 2023, 163: 105331. DOI: 10.1016/j.ijrmms.2023.105331. [16] 刘锦, 李峰辉, 刘秀秀. 基于HJC模型的煤岩冲击损伤特性研究 [J]. 工程爆破, 2021, 27(2): 35–42, 65. DOI: 10.19931/j.EB.20200159.LIU J, LI F H, LIU X X. Study on impact damage characteristics of coal-rock based on HJC model [J]. Engineering Blasting, 2021, 27(2): 35–42, 65. DOI: 10.19931/j.EB.20200159. [17] 李睿, 刘磊, 张志华, 等. 基于HJC模型高温后大理岩SHPB实验数值模拟研究 [J]. 工程爆破, 2022, 28(1): 37–44. DOI: 10.19931/j.EB.20210138.LI R, LIU L, ZHANG Z H, et al. Numerical simulation of marble damaged by high temperature in SHPB experiment based on HJC model [J]. Engineering Blasting, 2022, 28(1): 37–44. DOI: 10.19931/j.EB.20210138. [18] TIAN X C, TAO T J, LOU Q X, et al. Modification and application of limestone HJC constitutive model under the impact load [J]. Lithosphere, 2022, 2021(Special 7): 6443087. DOI: 10.2113/2022/6443087. [19] 赖玉彰. 热-力耦合作用下岩石力学特性及破坏机理研究 [D]. 赣州: 江西理工大学, 2023. DOI: 10.27176/d.cnki.gnfyc.2023.000655.LAI Y Z. Study on mechanical properties and failure mechanism of rock under thermal-mechanical coupling [D]. Ganzhou, Jiangxi: Jiangxi University of Science and Technology, 2023. DOI: 10.27176/d.cnki.gnfyc.2023.000655. [20] 宋帅, 杜闯, 李艳艳. 超高性能混凝土HJC本构模型参数确定及应用 [J]. 爆炸与冲击, 2023, 43(5): 053102. DOI: 10.11883/bzycj-2022-0343.SONG S, DU G, LI Y Y. Determination and application of the HJC constitutive model parameters for ultra-high performance concrete [J]. Explosion and Shock Waves, 2023, 43(5): 053102. DOI: 10.11883/bzycj-2022-0343. [21] 程树范, 叶阳, 曾亚武, 等. 基于损伤-虚拟张拉裂纹模型的地下爆炸围岩破坏规律研究 [J]. 爆炸与冲击, 2022, 42(5): 055201. DOI: 10.11883/bzycj-2021-0414.CHENG S F, YE Y, ZENG Y W, et al. Failure law of surrounding rock under underground explosion based on a new damage-virtual tensile crack model [J]. Explosion and Shock Waves, 2002, 42(5): 055201. DOI: 10.11883/bzycj-2021-0414. [22] 夏文彬. 热损伤花岗岩动态力学特性及数值模拟研究 [D]. 赣州: 江西理工大学, 2023. DOI: 10.27176/d.cnki.gnfyc.2023.000090.XIA W B. Study on dynamic characteristics and numerical simulation of thermally damaged granite [D]. Ganzhou, Jiangxi: Jiangxi University of Science and Technology, 2023. DOI: 10.27176/d.cnki.gnfyc.2023.000090. [23] 张志华. 高温条件下大理岩的动、静态力学性能研究 [D]. 昆明: 昆明理工大学, 2019. DOI: 10.27200/d.cnki.gkmlu.2019.000115. [24] JOHNSON H G R. A computational constitutive model for glass subjected to large strains, high strain rates and high pressures [J]. Journal of Applied Mechanics, 2011, 78(5): 051003. DOI: 10.1115/1.4004326. [25] 毕程程. 华山花岗岩HJC本构参数标定及爆破损伤数值模拟 [D]. 合肥: 合肥工业大学, 2018.BI C C. Calibration of HJC constitutive parameters of Huashan granite and its blasting damage numerical simulation [D]. Hefei: Hefei University of Technology, 2018. [26] 李夕兵, 李地元, 郭雷, 等. 动力扰动下深部高应力矿柱力学响应研究 [J]. 岩石力学与工程学报, 2007, 26(5): 922–928. DOI: 10.3321/j.issn:1000-6915.2007.05.008.LI X B, LI D Y, GUO L, et al. Study on mechanical response of highly-stressed pillars in deep mining under dynamic disturbance [J]. Chinese Journal of Rock Mechanics and Engineering, 2007, 26(5): 922–928. DOI: 10.3321/j.issn:1000-6915.2007.05.008. [27] 余同希, 邱信明. 冲击动力学 [M]. 北京: 清华大学出版社, 2011. [28] 邱薛, 刘晓辉, 胡安奎, 等. 煤岩动态RHT本构模型数值模拟研究 [J]. 煤炭学报, 2024, 49(S1): 261–273. DOI: 10.13225/j.cnki.jccs.2023.0540.QIU X, LIU X H, HU A K, et al. Research on numerical simulation of coal dynamic RHT constitutive model [J]. Journal of China Coal Society, 2024, 49(S1): 261–273. DOI: 10.13225/j.cnki.jccs.2023.0540. [29] LI D Y, HAN Z Y, ZHU Q Q, et al. Stress wave propagation and dynamic behavior of red sandstone with single bonded planar joint at various angles [J]. International Journal of Rock Mechanics and Mining Sciences, 2019, 117: 162–170. DOI: 10.1016/j.ijrmms.2019.03.011. -

下载:

下载: