Preparation of NiP@Fe-SBA-15 suppressant and its inhibition mechanism on polypropylene dust deflagration flames

-

摘要: 抑爆剂在防止粉尘爆炸事故中起着至关重要的作用。通过原位合成方法制备了一种新型的NiP@Fe-SBA-15抑爆剂,采用哈特曼管道爆炸测试系统,对爆燃火焰的传播行为进行了实验研究,测定了NiP@Fe-SBA-15抑爆剂对聚丙烯(polypropylene,PP)爆炸火焰的抑制作用,以及添加不同比例的NiP@Fe-SBA-15抑爆剂对PP爆炸火焰的抑制效果。实验结果表明:NiP@Fe-SBA-15抑爆剂能够显著降低PP粉尘爆燃火焰的温度和燃烧速度,当添加质量分数为70%的NiP@Fe-SBA-15时,基本实现了对PP爆燃火焰的高效抑制。此外,结合爆炸产物的实验分析结果,提出了NiP@Fe-SBA-15对PP粉尘爆燃的物理和化学抑制机制。

-

关键词:

- 聚丙烯粉尘 /

- NiP@Fe-SBA-15 /

- 原位合成 /

- 抑爆机理

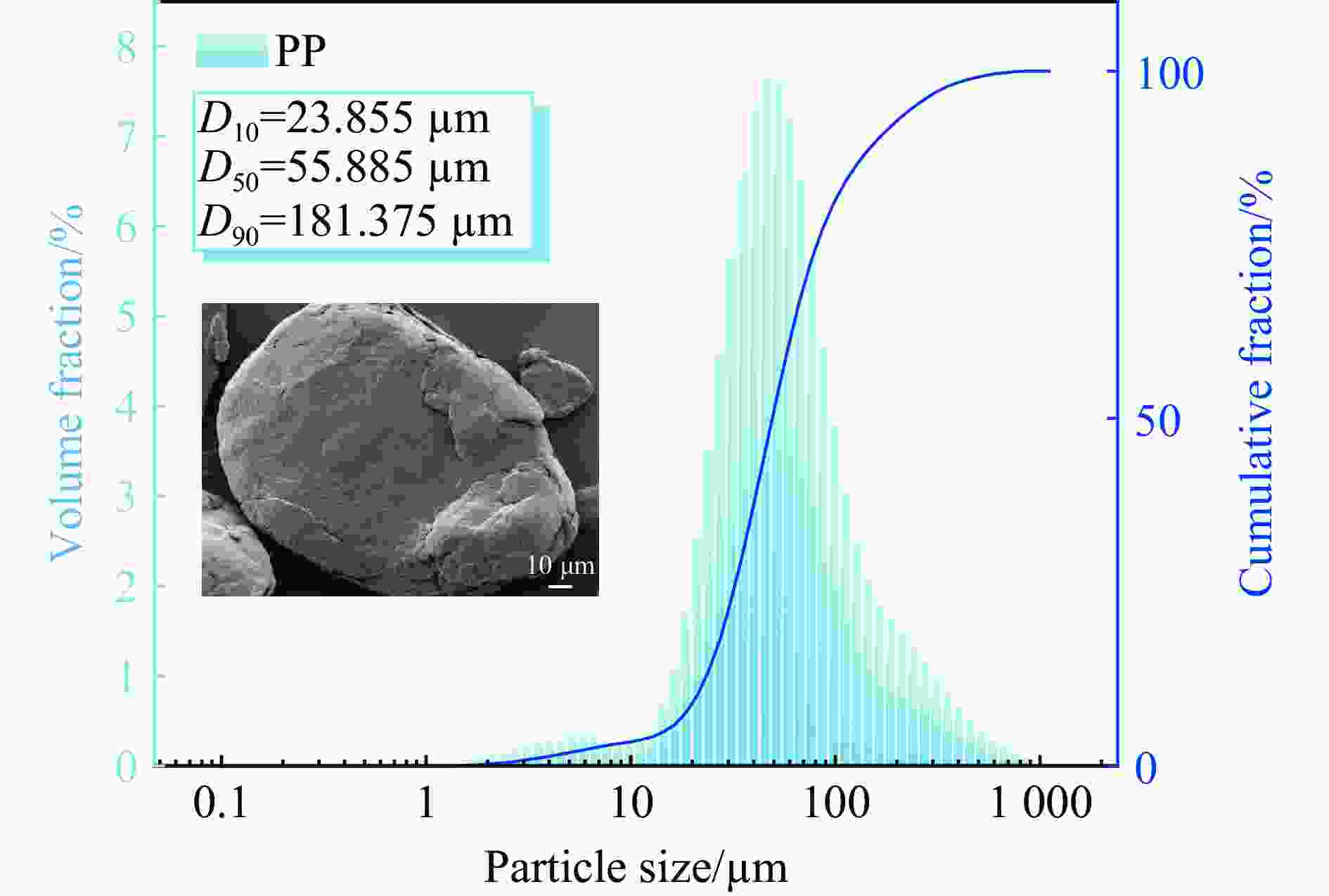

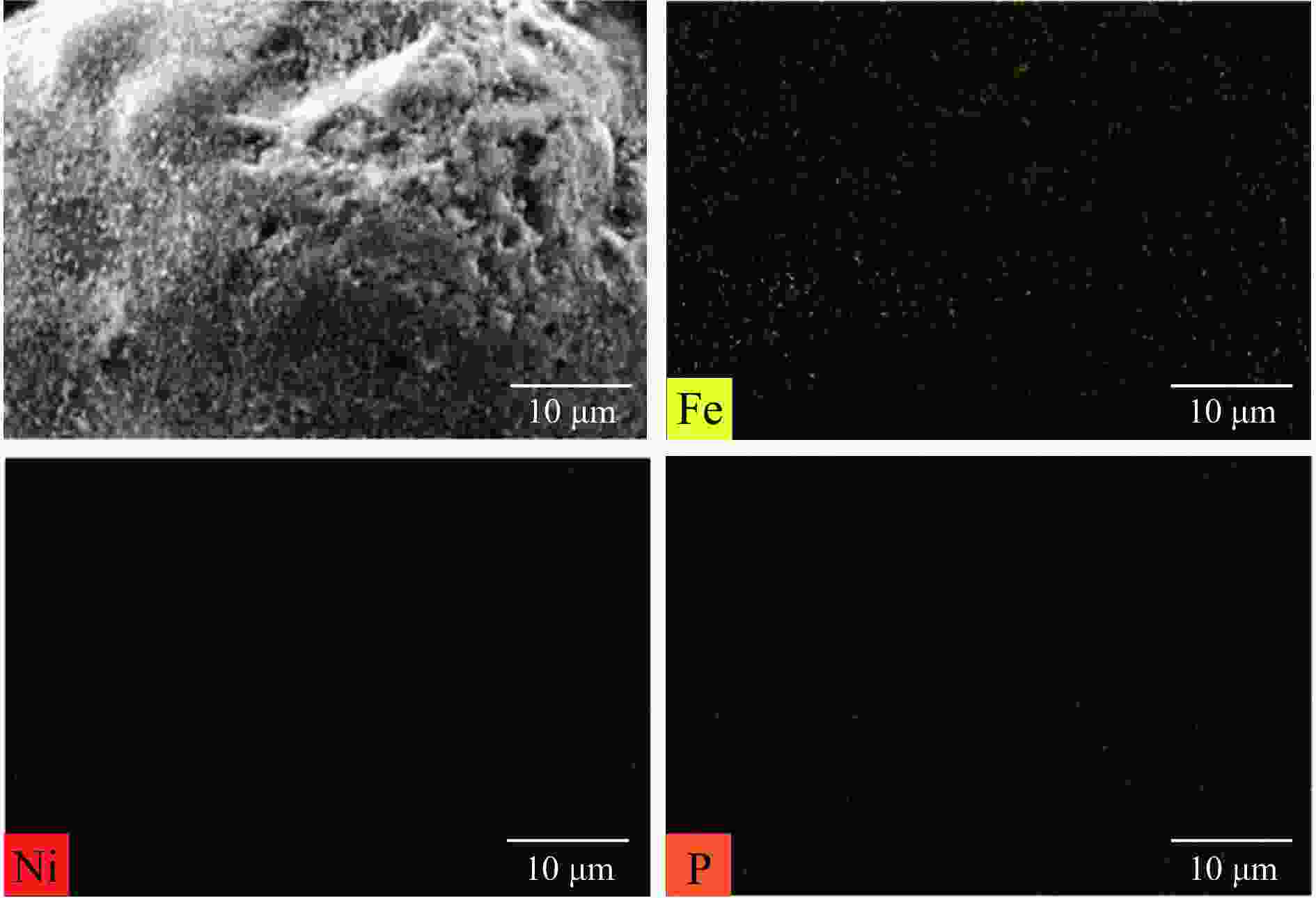

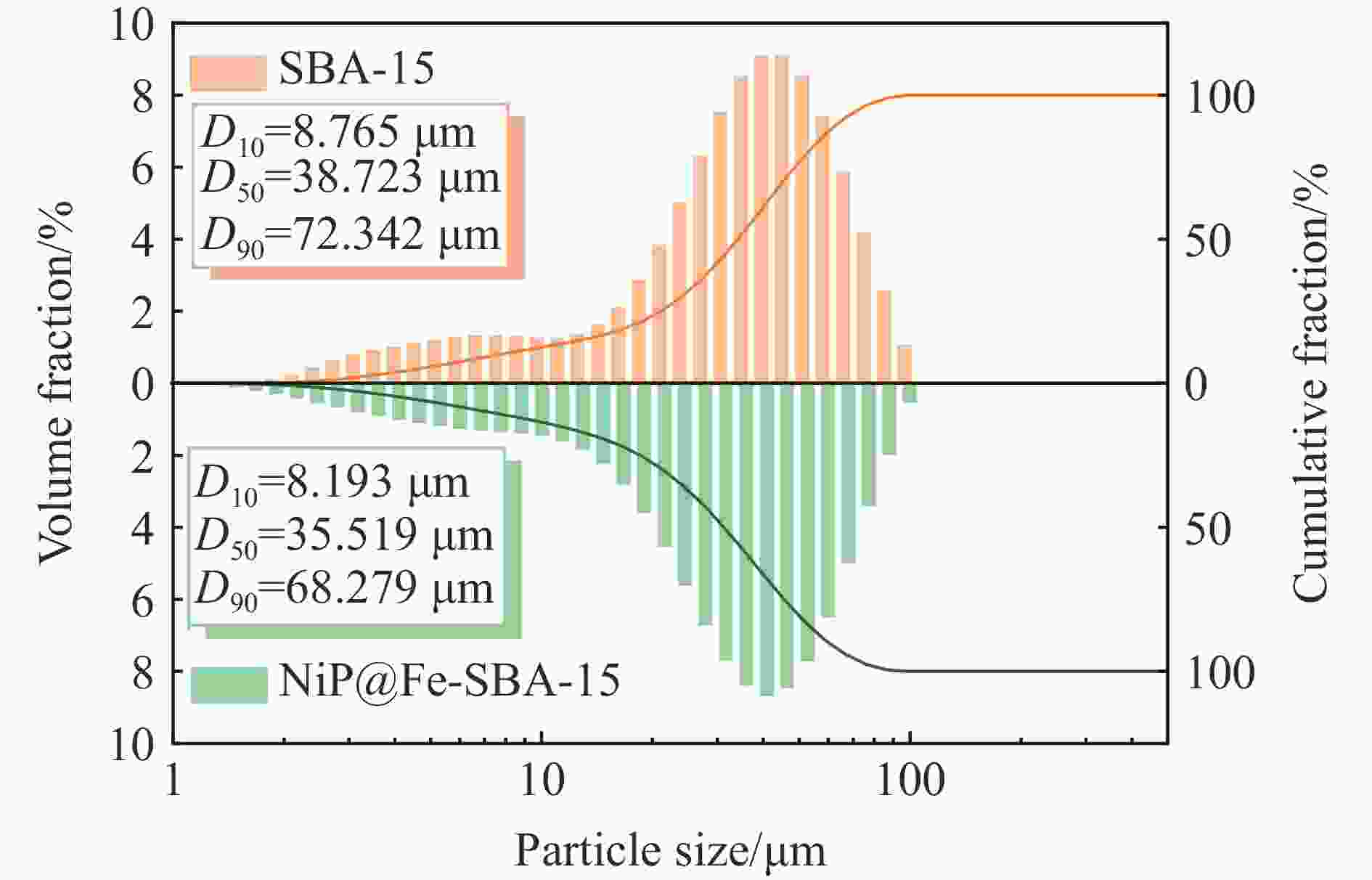

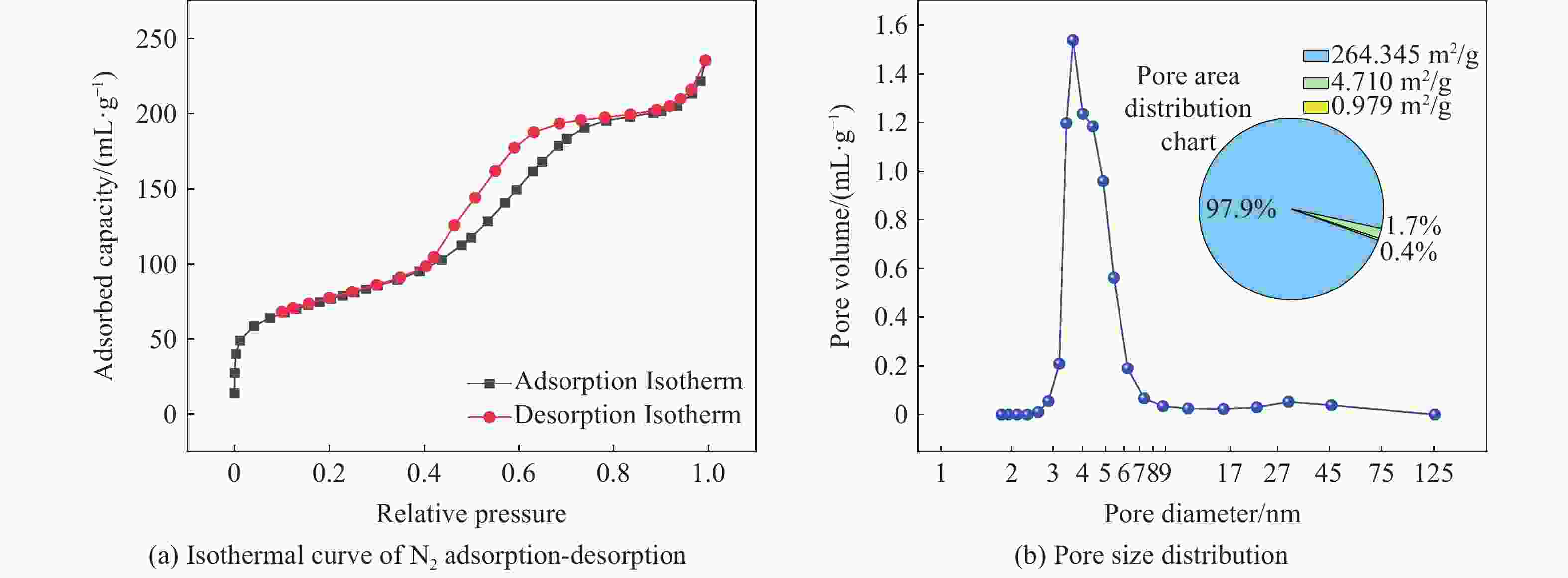

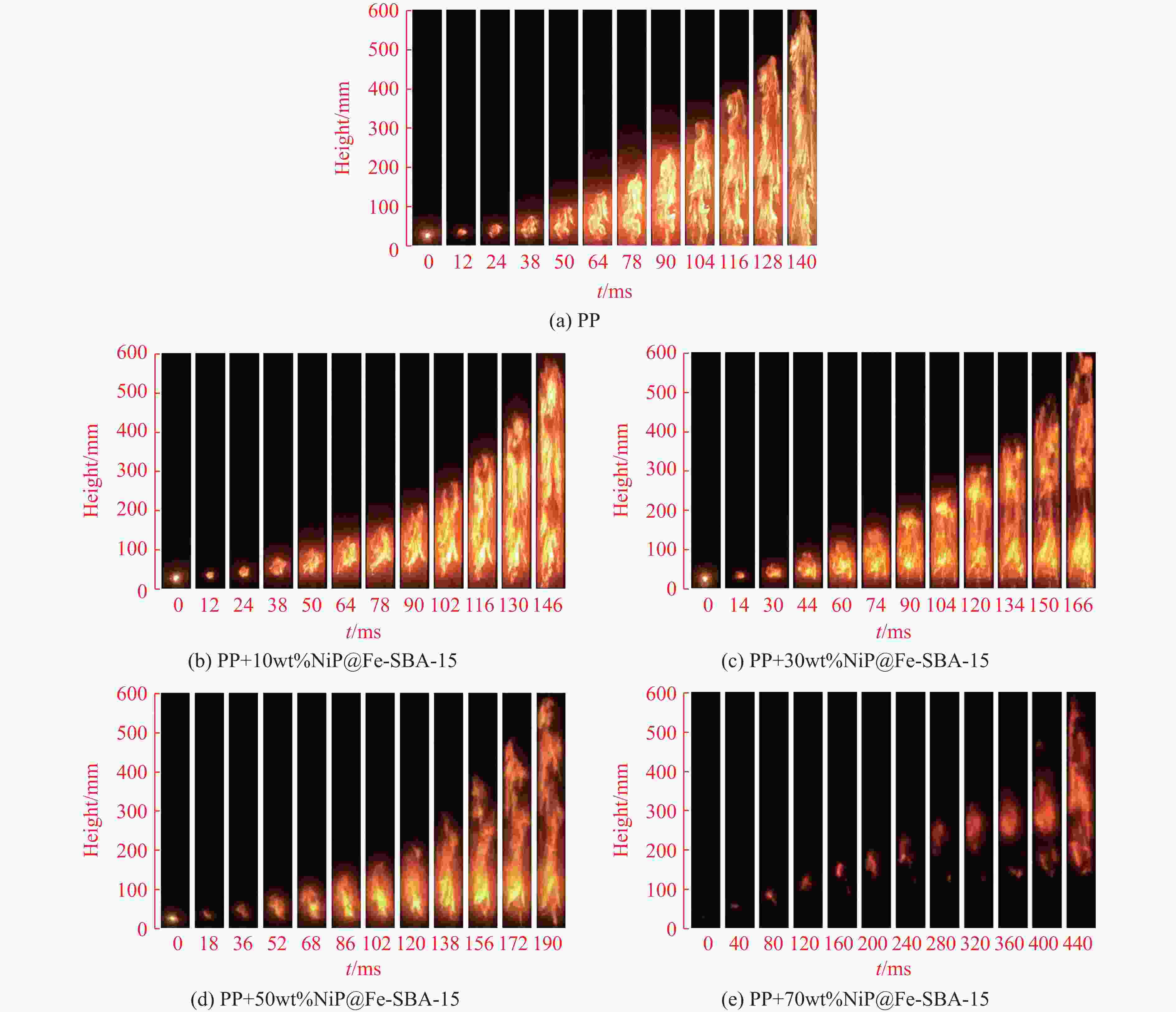

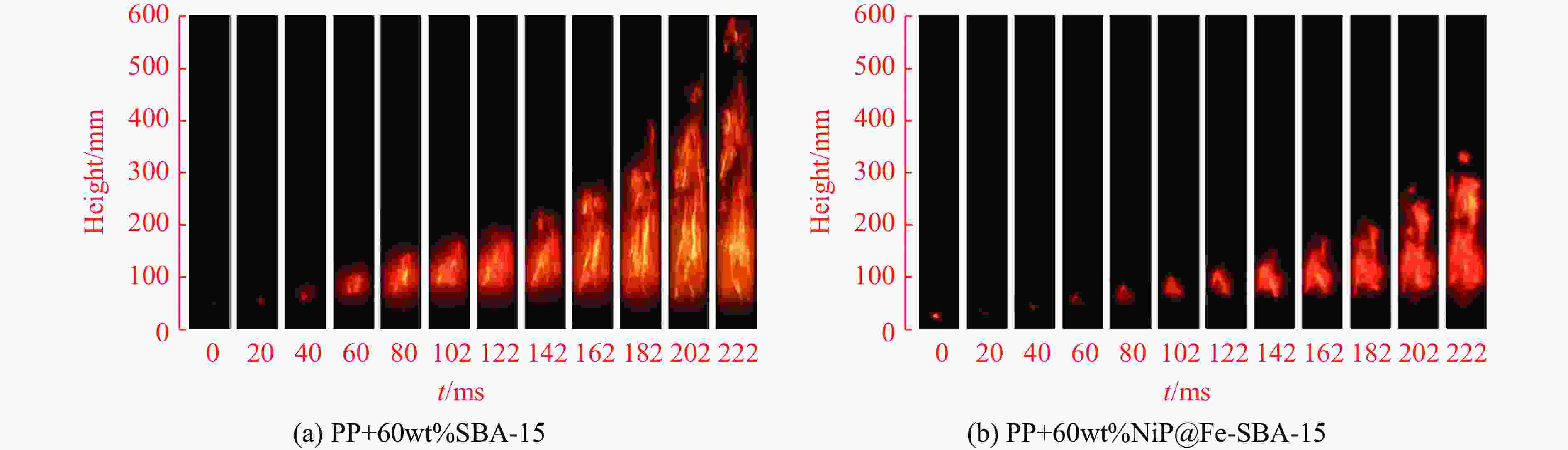

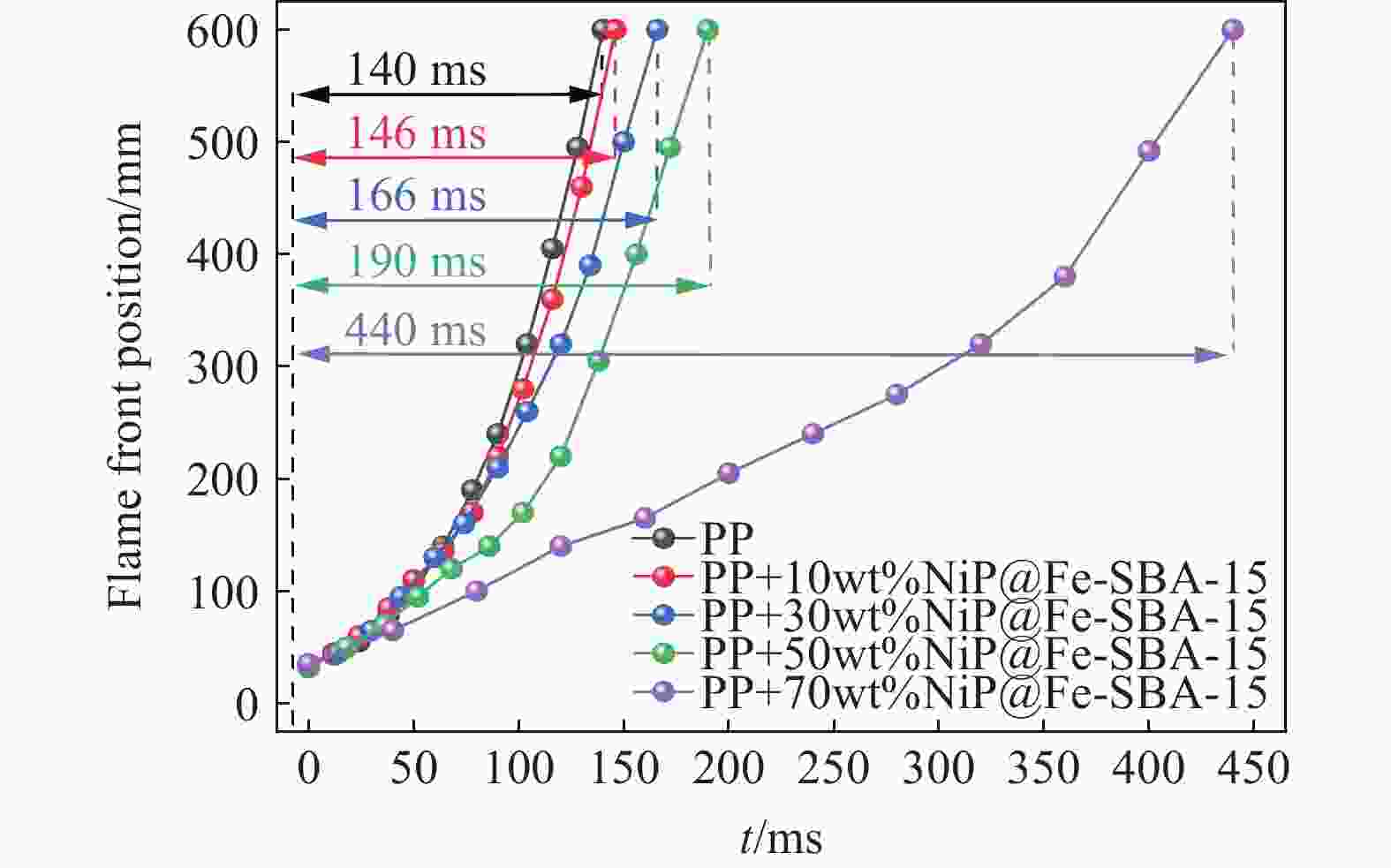

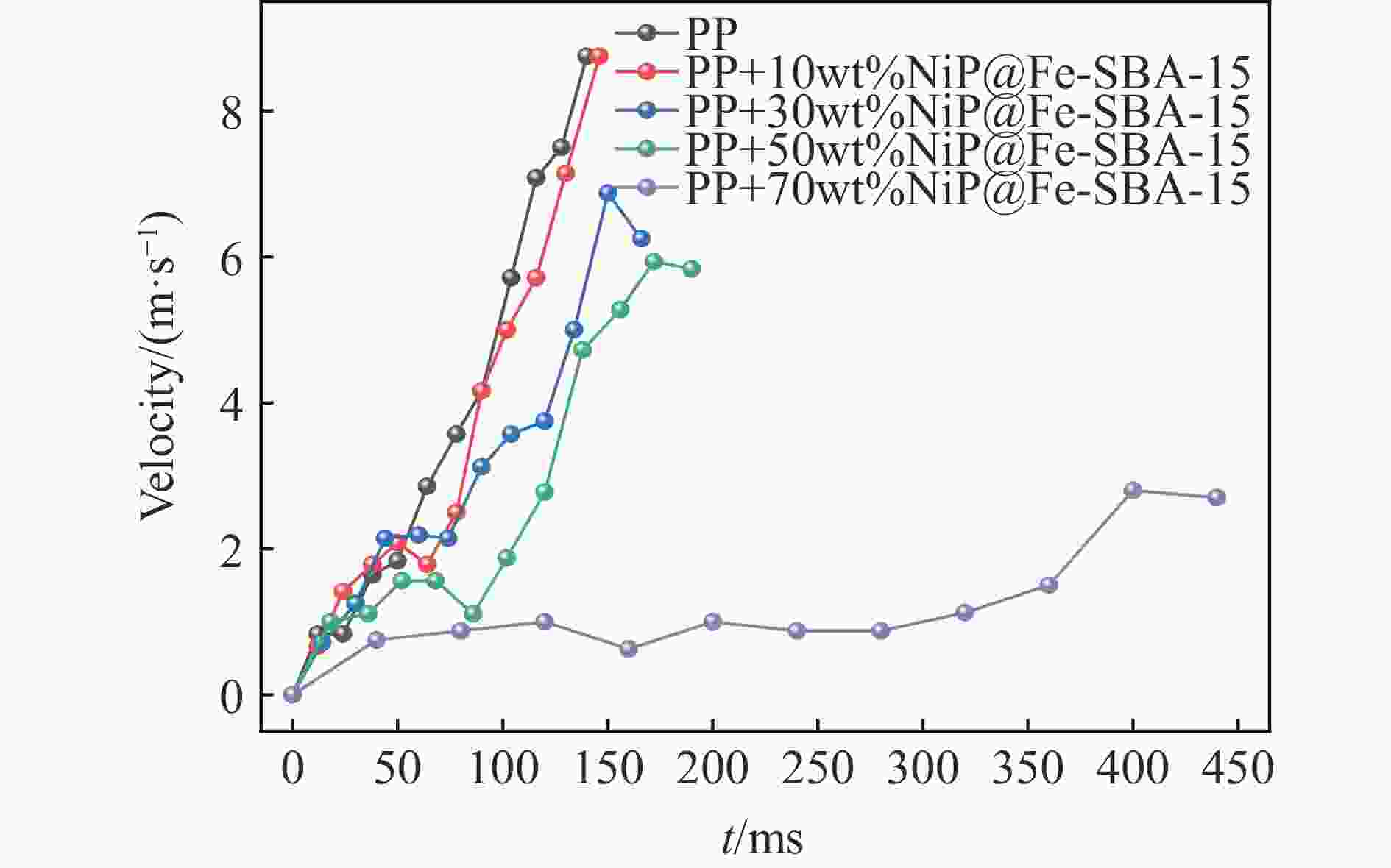

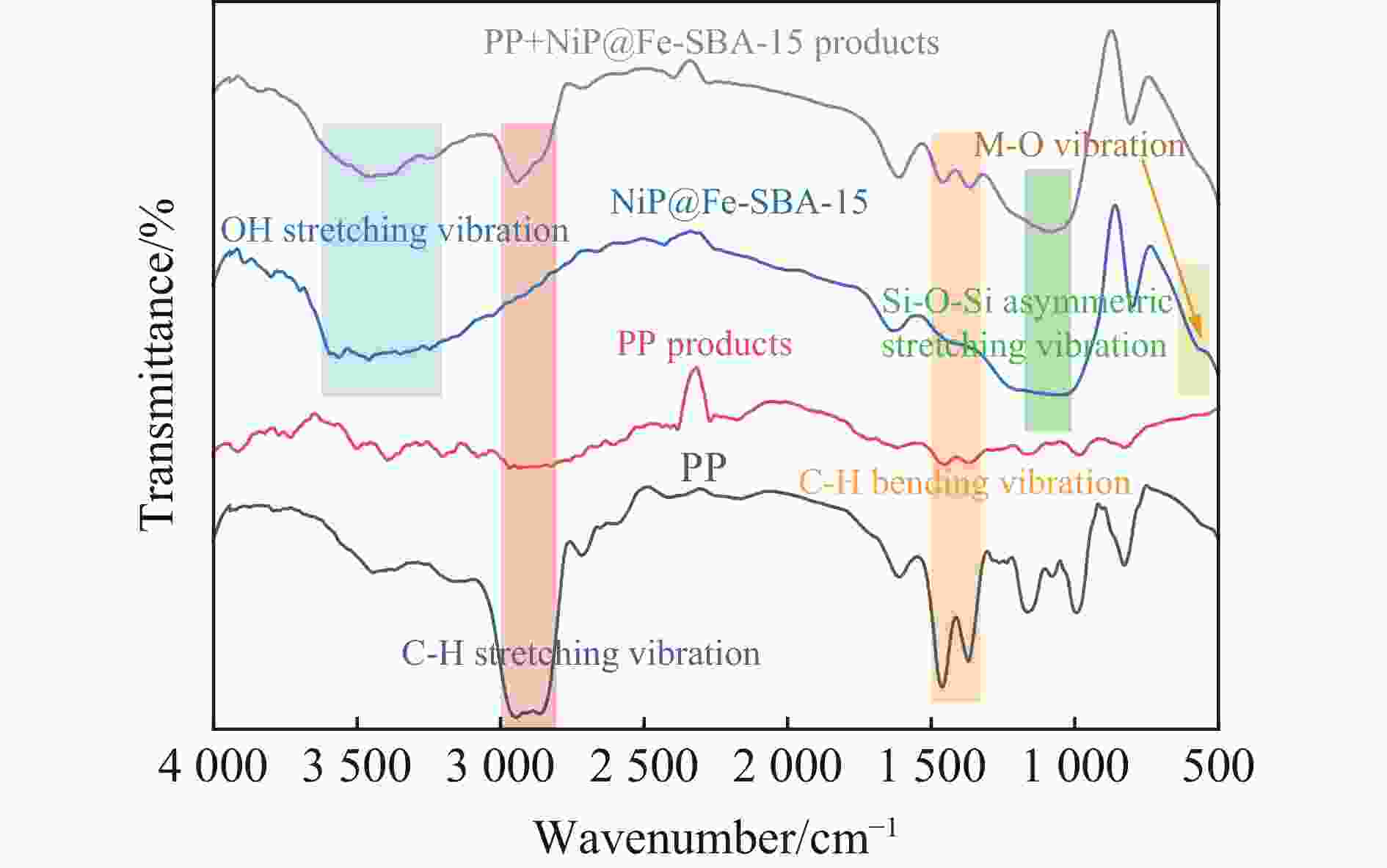

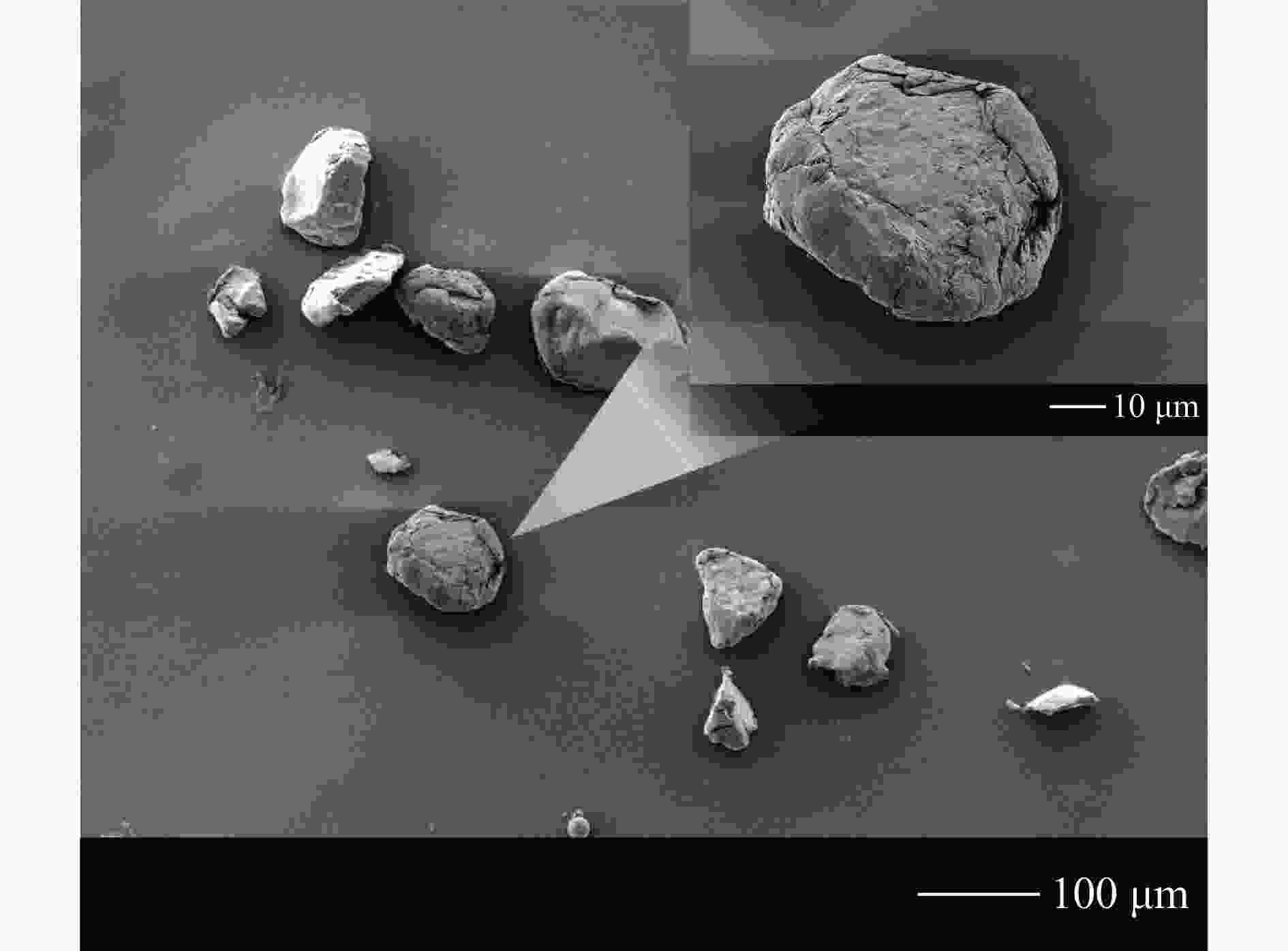

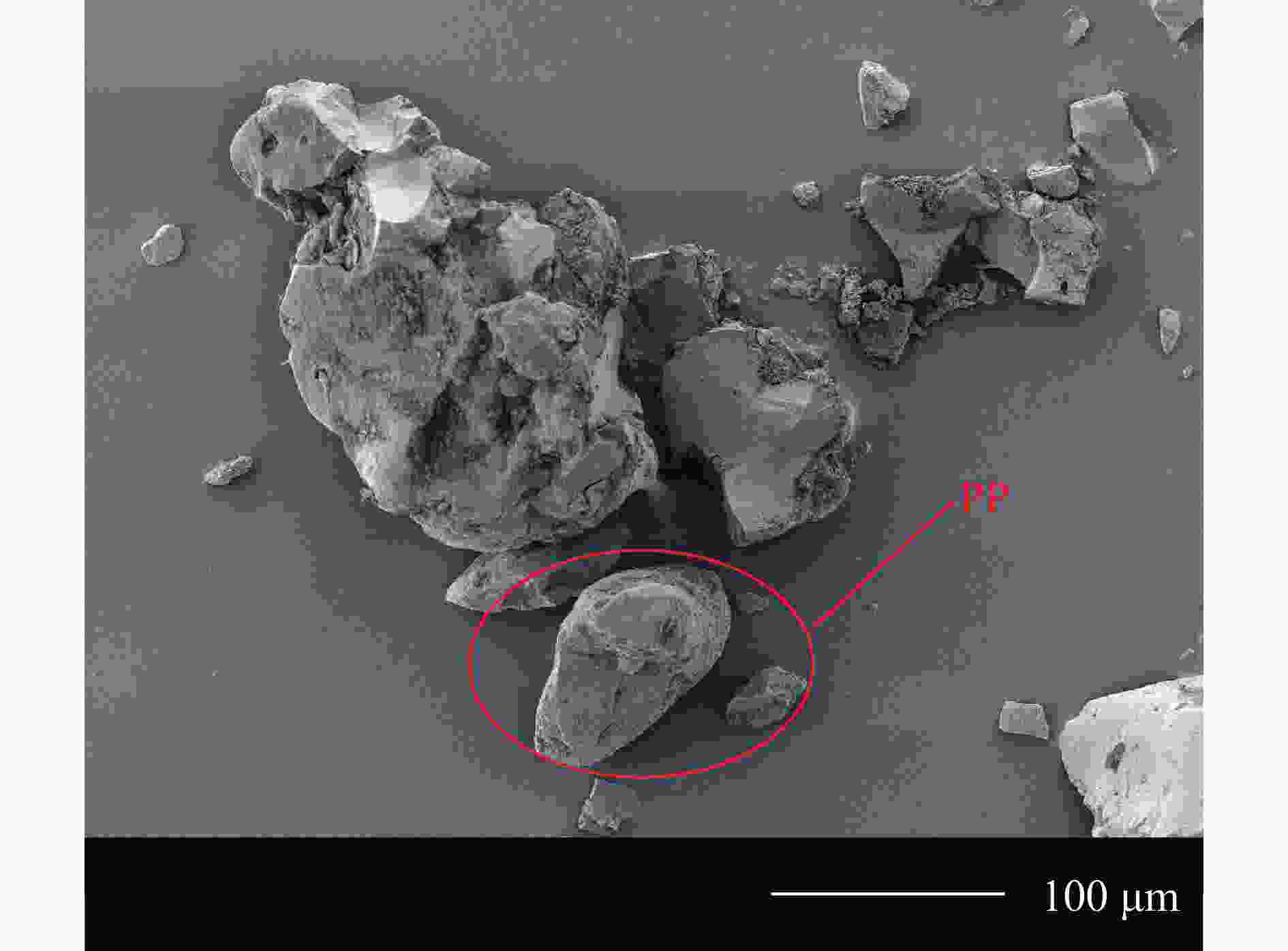

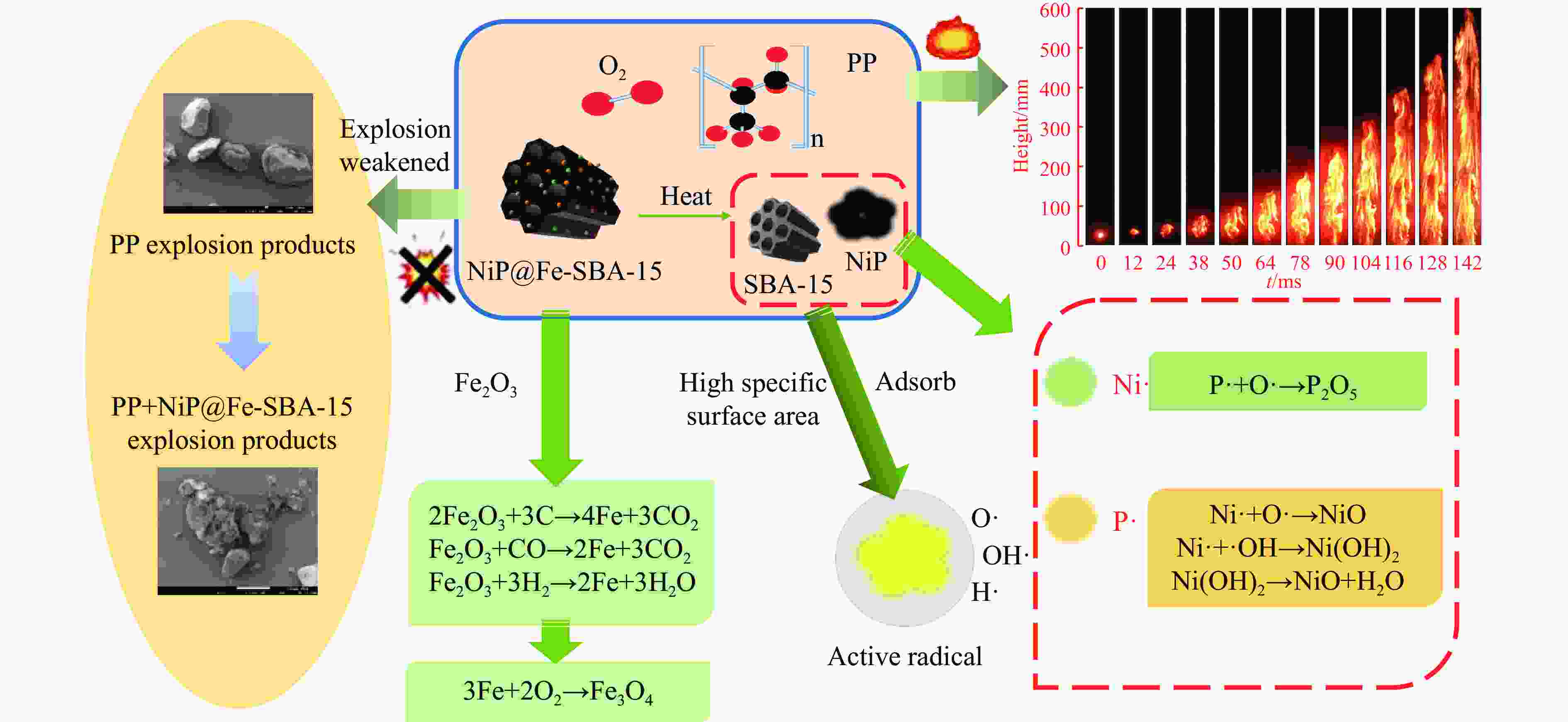

Abstract: Polypropylene (PP) is widely utilized in industrial production, yet PP dust generated during its production and transportation can form explosive dust clouds, leading to severe dust explosion accidents that threaten personnel and equipment safety. To address this issue, a novel explosion suppressant, NiP@Fe-SBA-15, was synthesized to inhibit the propagation of PP dust combustion flames. The synthesis involved modifying SBA-15 mesoporous silica with Fe ions and subsequently loading NiP, resulting in a composite powder with uniformly dispersed active components and a well-preserved mesoporous structure. Characterization via SEM-Mapping and N2 adsorption-desorption experiments revealed that NiP@Fe-SBA-15 maintains a high specific surface area, exhibits a regulated pore structure, and shows no significant particle agglomeration. The Hartman tube explosive testing system was employed to evaluate the effect of NiP@Fe-SBA-15 on PP dust deflagration. Results indicated that as the NiP@Fe-SBA-15 additive increased, the flame propagation speed, brightness, and flame length of PP deflagration decreased significantly, with flame propagation almost completely inhibited by a suppressant dosage with the mass fraction of 70 %. The dual explosion suppression mechanism of NiP@Fe-SBA-15 was analyzed. Physically, NiP@Fe-SBA-15 occupies reaction space, reducing oxygen and combustible volatile concentrations, while the SBA-15 molecular sieve, exposed by thermal decomposition of the suppressant, absorbs heat and forms a physical barrier, thereby reducing combustion intensity. Chemically, NiP decomposition releases Ni· and P· radicals that consume key free radicals (H·, O·, OH·) in combustion reactions, interrupting explosion chain reactions. Meanwhile, Fe-based species rapidly oxidize to Fe3O4, reducing oxygen availability and further weakening combustion intensity. In summary, NiP@Fe-SBA-15 was proven to be an effective explosion suppressant for PP dust explosions, reducing combustion intensity through combined physicochemical synergies. This research provides a new approach to enhancing polypropylene industry safety. Future work will focus on optimizing the industrial application of NiP@Fe-SBA-15 explosion suppressants while addressing cost, environmental sustainability, and stability issues to further advance dust explosion prevention technology.-

Key words:

- polypropylene dust /

- NiP@Fe-SBA-15 /

- in situ synthesis /

- explosion suppression mechanism

-

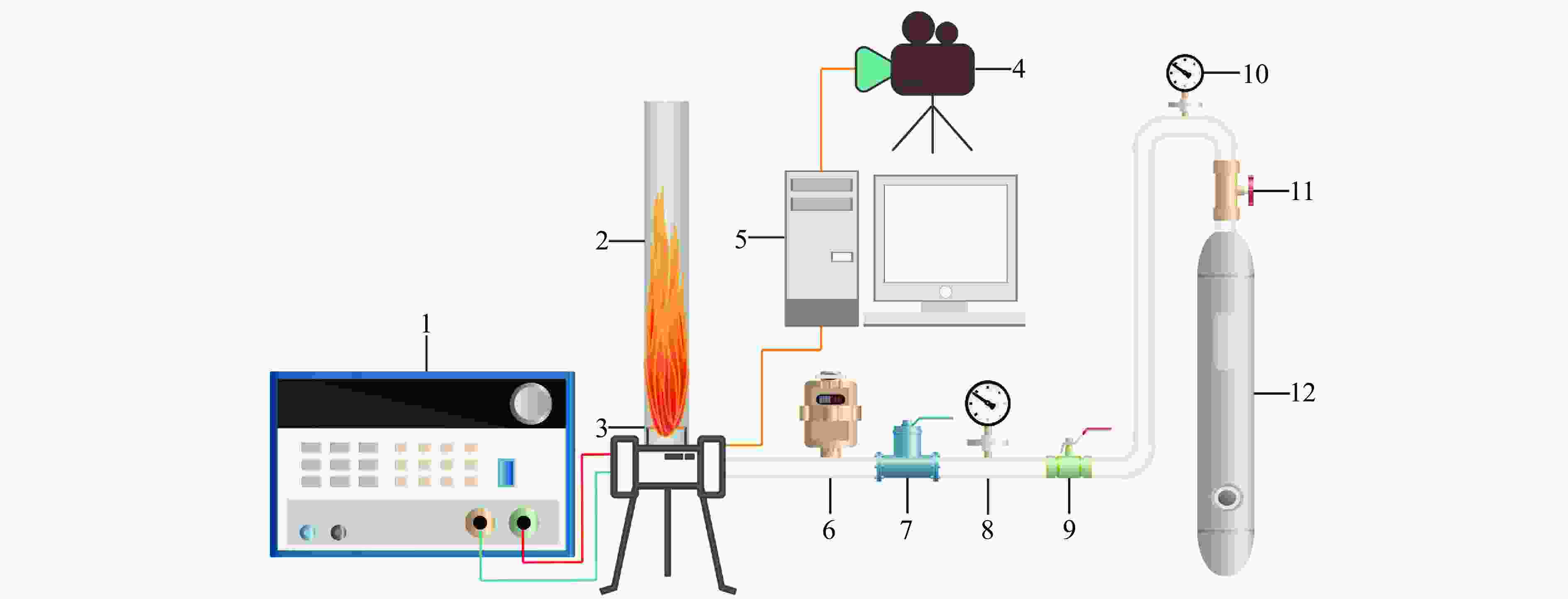

图 1 哈特曼管道爆炸测试系统示意图

Figure 1. Schematic diagram of the Hartmann tube explosion testing system

1. Control valve ignition generator; 2. Quartz glass tube; 3. Electrode; 4. High-speed camera; 5. Computer; 6. Solenoid valve; 7. Air storage chamber; 8. Barometer 1; 9. Intake valve 1; 10. Barometer 2; 11. Intake valve 2; 12. High-pressure air tank

表 1 NiP@Fe-SBA-15的结构参数

Table 1. Structural parameters of NiP@Fe-SBA-15

比表面积/(m2·g−1) 孔容/(mL·g−1) 孔径/nm 262.5751 0.3594 4.6823 -

[1] 左前明, 程卫民, 汤家轩. 粉体抑爆剂在煤矿应用研究的现状与展望 [J]. 煤炭技术, 2010, 29(11): 78–80.ZUO Q M, CHENG W M, TANG J X. Current status and prospects of application and research of powder coal mine explosion suppression agent [J]. Coal Technology, 2010, 29(11): 78–80. [2] 林晨迪. 不同抑爆粉体对聚乙烯粉尘爆炸的抑制作用研究 [D]. 河南焦作: 河南理工大学, 2020. DOI: 10.27116/d.cnki.gjzgc.2020.000223.LIN C D. Investigation into the suppression effect of different powders on explosion of polyethylene dust [D]. Jiaozuo, Henan, China: Henan Polytechnic University, 2020. DOI: 10.27116/d.cnki.gjzgc.2020.000223. [3] 敖万路, 吴书杭, 邢璐, 等. 二次回收PP无纺布条单螺杆挤出技术研究 [J]. 模具工业, 2024, 50(2): 60–63. DOI: 10.16787/j.cnki.1001-2168.dmi.2024.02.012.AO W L, WU S H, XING L, et al. Research on single screw extrusion technology for secondary recovery of PP non-woven fabric strip [J]. Die & Mould Industry, 2024, 50(2): 60–63. DOI: 10.16787/j.cnki.1001-2168.dmi.2024.02.012. [4] WANG S X, MUIRURI J K, SOO X Y D, et al. Bio-polypropylene and polypropylene-based biocomposites: solutions for a sustainable future [J]. Chemistry-An Asian Journal, 2023, 18(2): e202200972. DOI: 10.1002/asia.202200972. [5] ZHANG S L, YAN X, WEN Z, et al. Study on flame propagation characteristic and mechanism of polypropylene dust explosion [J]. Powder Technology, 2024, 440: 119794. DOI: 10.1016/j.powtec.2024.119794. [6] ABBASI M R, SHAMIRI A, HUSSAIN M A. Dynamic modeling and molecular weight distribution of ethylene copolymerization in an industrial gas-phase fluidized-bed reactor [J]. Advanced Powder Technology, 2016, 27(4): 1526–1538. DOI: 10.1016/j.apt.2016.05.014. [7] LI C, ZHANG C T, GHOLIZADEH M, et al. Different reaction behaviours of light or heavy density polyethylene during the pyrolysis with biochar as the catalyst [J]. Journal of Hazardous Materials, 2020, 399: 123075. DOI: 10.1016/j.jhazmat.2020.123075. [8] 张延松, 李南, 郭瑞, 等. 月桂酸与硬脂酸粉尘爆炸过程热解动力学与火焰传播特性关系 [J]. 爆炸与冲击, 2022, 42(7): 075402. DOI: 10.11883/bzycj-2021-0470.ZHANG Y S, LI N, GUO R, et al. Relationship between pyrolysis kinetics and flame propagation characteristics of lauric acid and stearic acid dust explosion [J]. Explosion and Shock Waves, 2022, 42(7): 075402. DOI: 10.11883/bzycj-2021-0470. [9] ZHANG C B, JIN P G, CHEN C F, et al. Flame propagation characteristics and surface functional groups changes of corn starch dust during the combustion process [J]. Powder Technology, 2023, 430: 118995. DOI: 10.1016/j.powtec.2023.118995. [10] LI Y D, MENG X B, SONG S Z M, et al. Piperazine pyrophosphate-functionalized Ni-MOF metal framework: fabrication and synergistic explosion suppression mechanisms [J]. Chemical Engineering Journal, 2024, 499: 155870. DOI: 10.1016/j.cej.2024.155870. [11] NAN F, LUO Z M, CHENG F M, et al. Research progress and development trends of hydrogen explosion suppression materials and mechanisms [J]. Process Safety and Environmental Protection, 2024, 184: 1318–1331. DOI: 10.1016/j.psep.2024.02.062. [12] VAN WINGERDEN M, SKJOLD T, ROOSENDANS D, et al. Chemical inhibition of hydrogen-air explosions: literature review, simulations and experiments [J]. Process Safety and Environmental Protection, 2023, 176: 1120–1129. DOI: 10.1016/j.psep.2023.03.042. [13] 贾海林, 项海军, 李第辉, 等. 含NaCl超细水雾对不同阻塞率管道内爆炸的抑制 [J]. 爆炸与冲击, 2020, 40(4): 34–43. DOI: 10.11883/bzycj-2019-0268.JIA H L, XIANG H J, LI D H, et al. Suppression of explosion in pipelines with different blocking ratios by ultrafine water mist containing sodium chloride [J]. Explosion and Shock Waves, 2020, 40(4): 34–43. DOI: 10.11883/bzycj-2019-0268. [14] 马冉. LDPE粉尘爆炸特性及惰化研究 [D]. 北京: 北京石油化工学院, 2018.MA R. Study on dust explosion characteristics and inertion of LDPE [D]. Beijing: Beijing Institute of Petrochemical Technology, 2018. [15] WANG Z, MENG X B, YAN K, et al. Study on the inhibition of Al-Mg alloy dust explosion by modified Mg(OH)2 [J]. Powder Technology, 2021, 384: 284–296. DOI: 10.1016/j.powtec.2021.02.037. [16] ZHANG P P, ZHOU Y H, CAO X Y, et al. Mitigation of methane/air explosion in a closed vessel by ultrafine water fog [J]. Safety Science, 2014, 62: 1–7. DOI: 10.1016/j.ssci.2013.07.027. [17] 郝峥, 许开立, 张毓媛, 等. Al(OH)3对聚丙烯腈粉火焰传播特性影响研究 [J]. 爆炸与冲击, 2022, 42(6): 147–157. DOI: 10.11883/bzycj-2021-0322.HAO Z, XU K L, ZHANG Y Y, et al. Study on the effect of Al(OH)3 on the flame propagation characteristics of polyacrylonitrile powder [J]. Explosion and Shock Waves, 2022, 42(6): 147–157. DOI: 10.11883/bzycj-2021-0322. [18] 王燕, 何佳, 杨晶晶, 等. 草酸盐和碳酸氢盐抑制聚乙烯粉尘爆炸特性 [J]. 化工学报, 2022, 73(9): 4207–4216. DOI: 10.11949/0438-1157.20220790.WANG Y, HE J, YANG J J, et al. Inhibition of polyethylene dust explosion by oxalate and bicarbonate [J]. CIESC Journal, 2022, 73(9): 4207–4216. DOI: 10.11949/0438-1157.20220790. [19] YANG J, YU Y, LI Y H, et al. Inerting effects of ammonium polyphosphate on explosion characteristics of polypropylene dust [J]. Process Safety and Environmental Protection, 2019, 130: 221–230. DOI: 10.1016/j.psep.2019.08.015. [20] 王保, 江丙友, 苏明清, 等. 三聚氰胺聚磷酸盐抑制聚丙烯粉尘爆炸研究 [J]. 消防科学与技术, 2022, 41(3): 291–295. DOI: 10.3969/j.issn.1009-0029.2022.03.001.WANG B, JIANG B Y, SU M Q, et al. Research on suppression of polypropylene dust explosion by melamine polyphosphate [J]. Fire Science and Technology, 2022, 41(3): 291–295. DOI: 10.3969/j.issn.1009-0029.2022.03.001. [21] WEI L J, SU M Q, WANG K, et al. Suppression effects of ABC powder on explosion characteristics of hybrid C2H4/polyethylene dust [J]. Fuel, 2022, 310: 122159. DOI: 10.1016/j.fuel.2021.122159. [22] ZHANG Y S, PAN Z C, YANG J J, et al. Study on the suppression mechanism of (NH4)2CO3 and SiC for polyethylene deflagration based on flame propagation and experimental analysis [J]. Powder Technology, 2022, 399: 117193. DOI: 10.1016/j.powtec.2022.117193. [23] YU Y, LI Y H, ZHANG Q W, et al. Experimental investigation of the inerting effect of crystalline Ⅱ type ammonium polyphosphate on explosion characteristics of micron-size acrylates copolymer dust [J]. Journal of Hazardous Materials, 2018, 344: 558–565. DOI: 10.1016/j.jhazmat.2017.10.060. [24] SHAH P, RAMASWAMY V. Thermal stability of mesoporous SBA-15 and Sn-SBA-15 molecular sieves: an in situ HTXRD study [J]. Microporous and Mesoporous Materials, 2008, 114(1/2/3): 270–280. DOI: 10.1016/j.micromeso.2008.01.013. [25] PARLETT C M A, ARANDIYAN H, DURNDELL L J, et al. Continuous-flow synthesis of mesoporous SBA-15 [J]. Microporous and Mesoporous Materials, 2022, 329: 111535. DOI: 10.1016/j.micromeso.2021.111535. [26] 桑净净, 赵君华, 李玲, 等. 不同制备条件对SBA-15介孔氧化硅的形貌、比表面积和孔径分布的影响 [J]. 化学工程师, 2011, 25(12): 1–5. DOI: 10.3969/j.issn.1002-1124.2011.12.001.SANG J J, ZHAO J H, LI L, et al. Effect of preparation conditions on the morphology, surface area and pore size distribution of mesoporous SBA-15 [J]. Chemical Engineer, 2011, 25(12): 1–5. DOI: 10.3969/j.issn.1002-1124.2011.12.001. [27] 牛振江, 吴廷华, 李则林. 化学镀镍-高磷合金晶化行为的现场XRD研究 [J]. 物理化学学报, 2003, 19(8): 705–708. DOI: 10.3866/PKU.WHXB20030806.NIU Z J, WU T H, LI Z L. In situ XRD investigation on the crystallization behaviors of electroless high-phosphorous Ni-P alloys [J]. Acta Physico-Chimica Sinica, 2003, 19(8): 705–708. DOI: 10.3866/PKU.WHXB20030806. [28] WANG B, HUANG X, ZHU Z B, et al. Hydrothermal synthesis of nano nickel phosphides and investigation of their thermal stability [J]. International Journal of Materials Research, 2013, 104(5): 507–510. DOI: 10.3139/146.110890. [29] MALAKAR M, SHUKLA P K. Effects of boron/nitrogen/phosphorus doping on the scavenging action of armchair single-walled carbon nanotubes (armchair-SWCNT) for OH radicals: a DFT study [J]. Carbon Letters, 2023, 33(1): 99–113. DOI: 10.1007/s42823-022-00407-w. [30] POON K C, WAN W Y, SU H B, et al. One-minute synthesis via electroless reduction of amorphous phosphorus-doped graphene for oxygen reduction reaction [J]. ACS Applied Energy Materials, 2021, 4(6): 5388–5391. DOI: 10.1021/acsaem.1c01075. [31] LIU J Y, WANG L, GAO J C, et al. Inhibition mechanism of metal barrier explosion-proof materials on ethane explosion [J]. Materials Chemistry and Physics, 2024, 312: 128652. DOI: 10.1016/j.matchemphys.2023.128652. -

下载:

下载: