Computational modeling and validation of rock-breaking radius by supercritical CO2 phase transition considering porous impacts

-

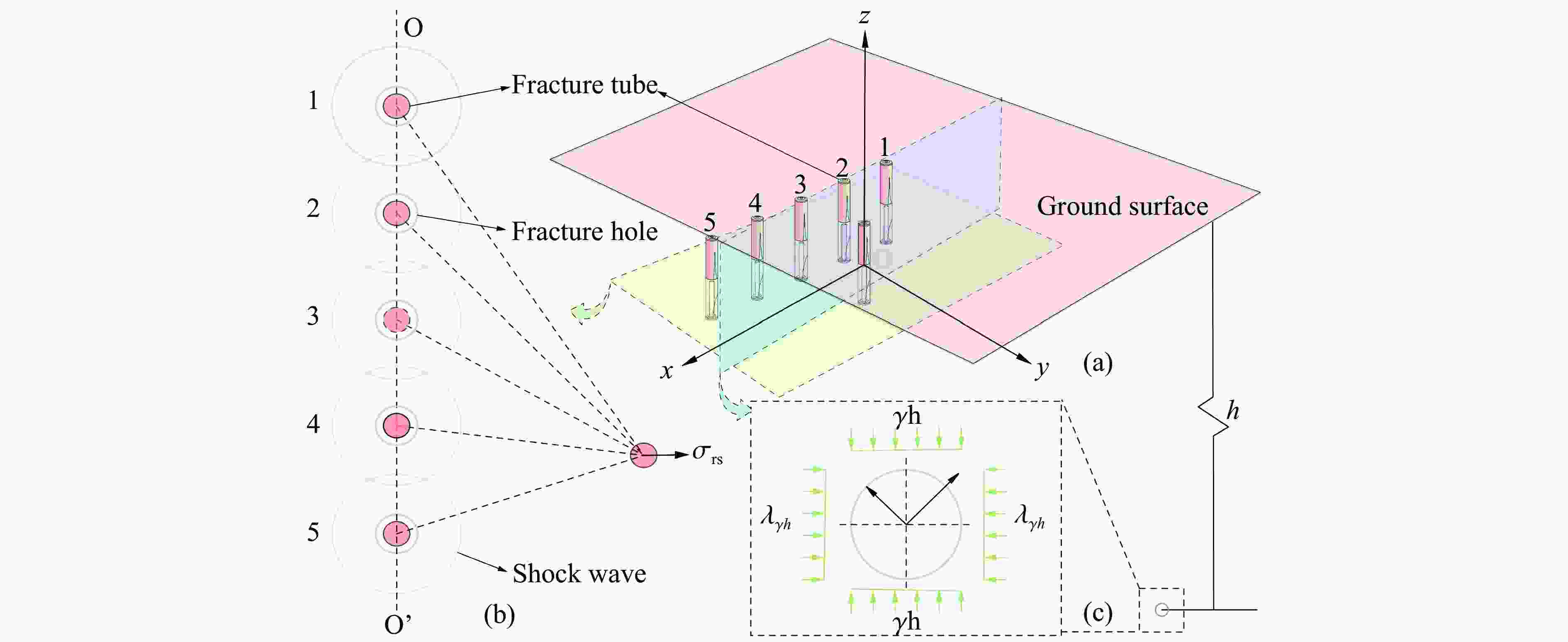

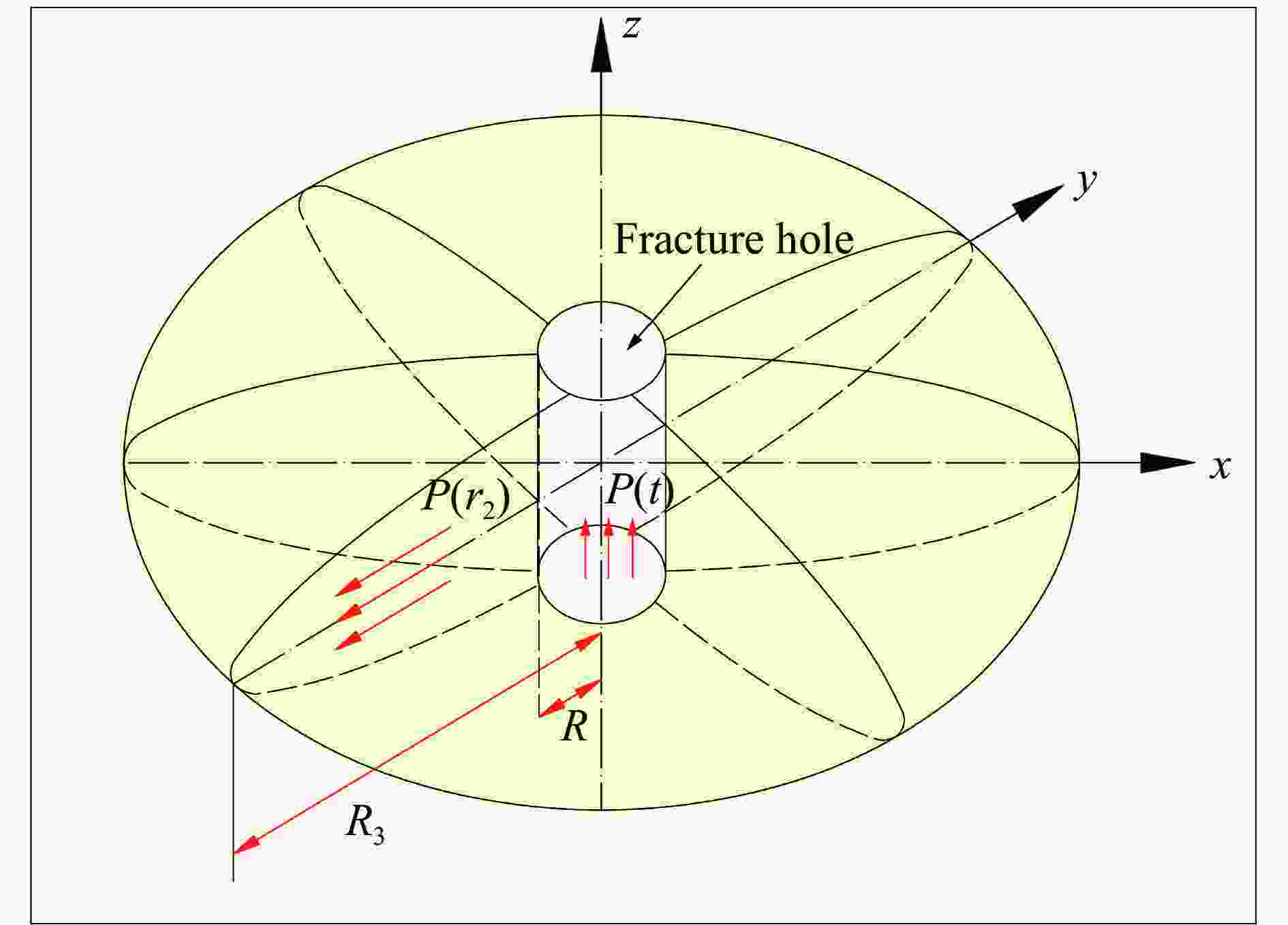

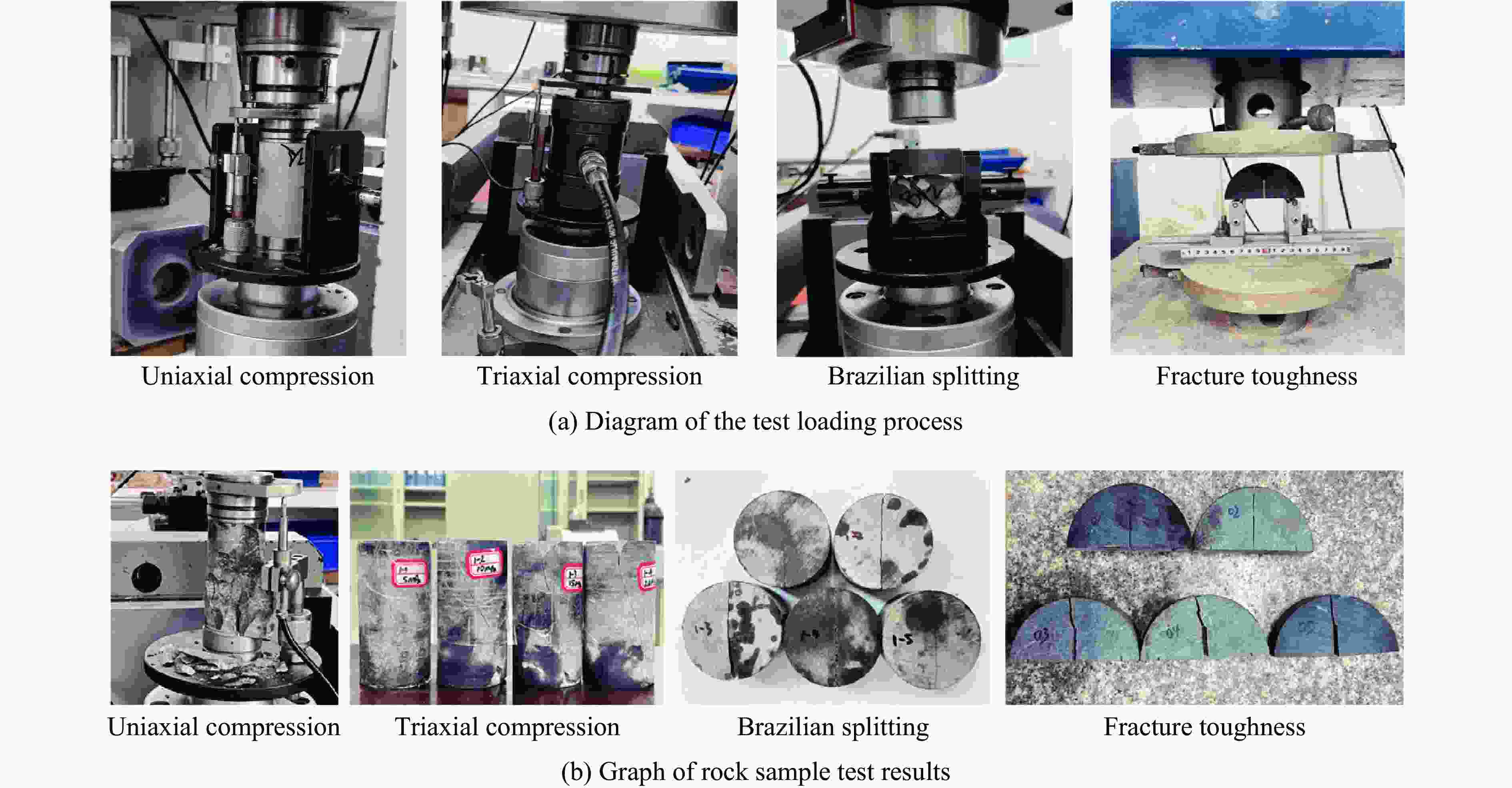

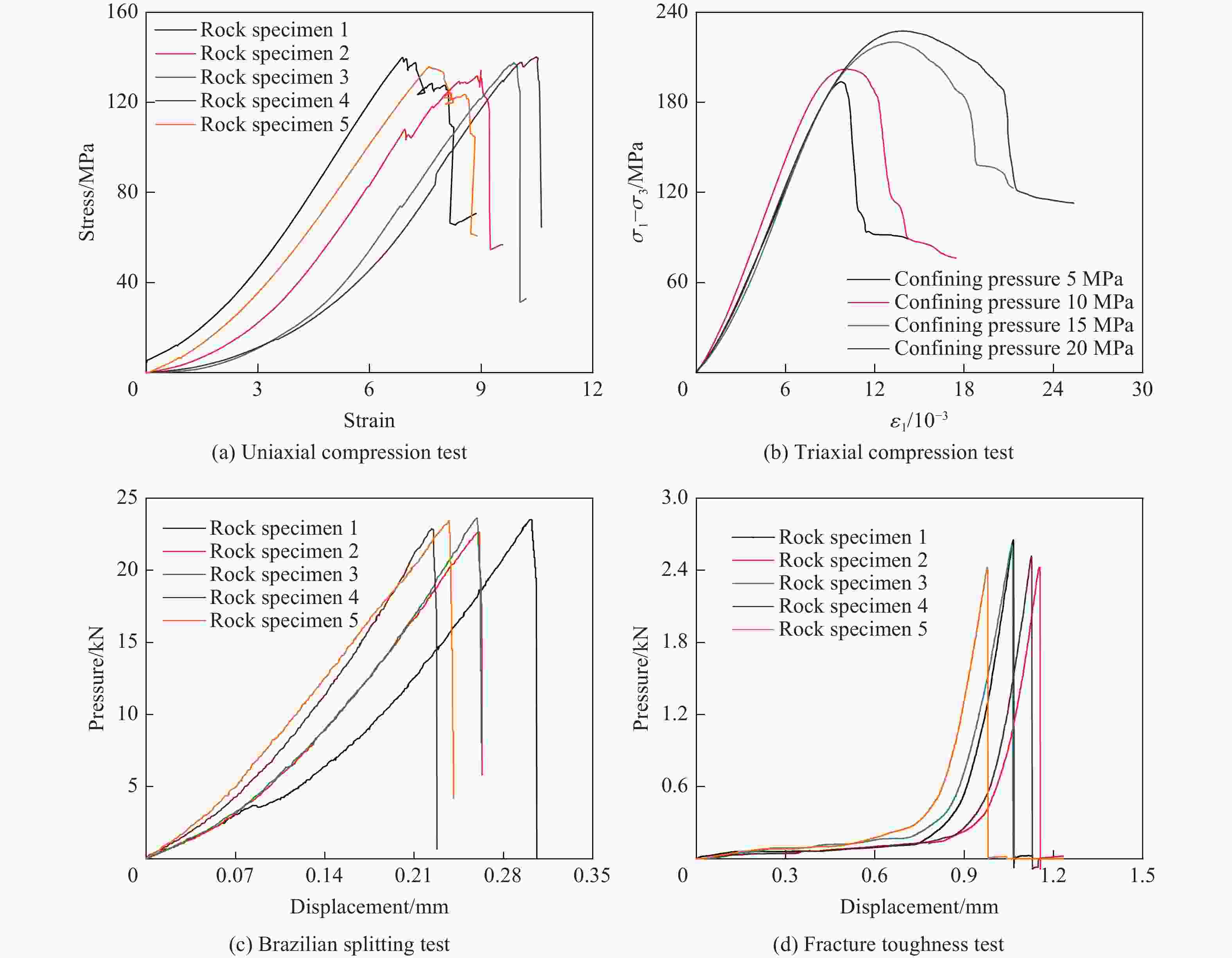

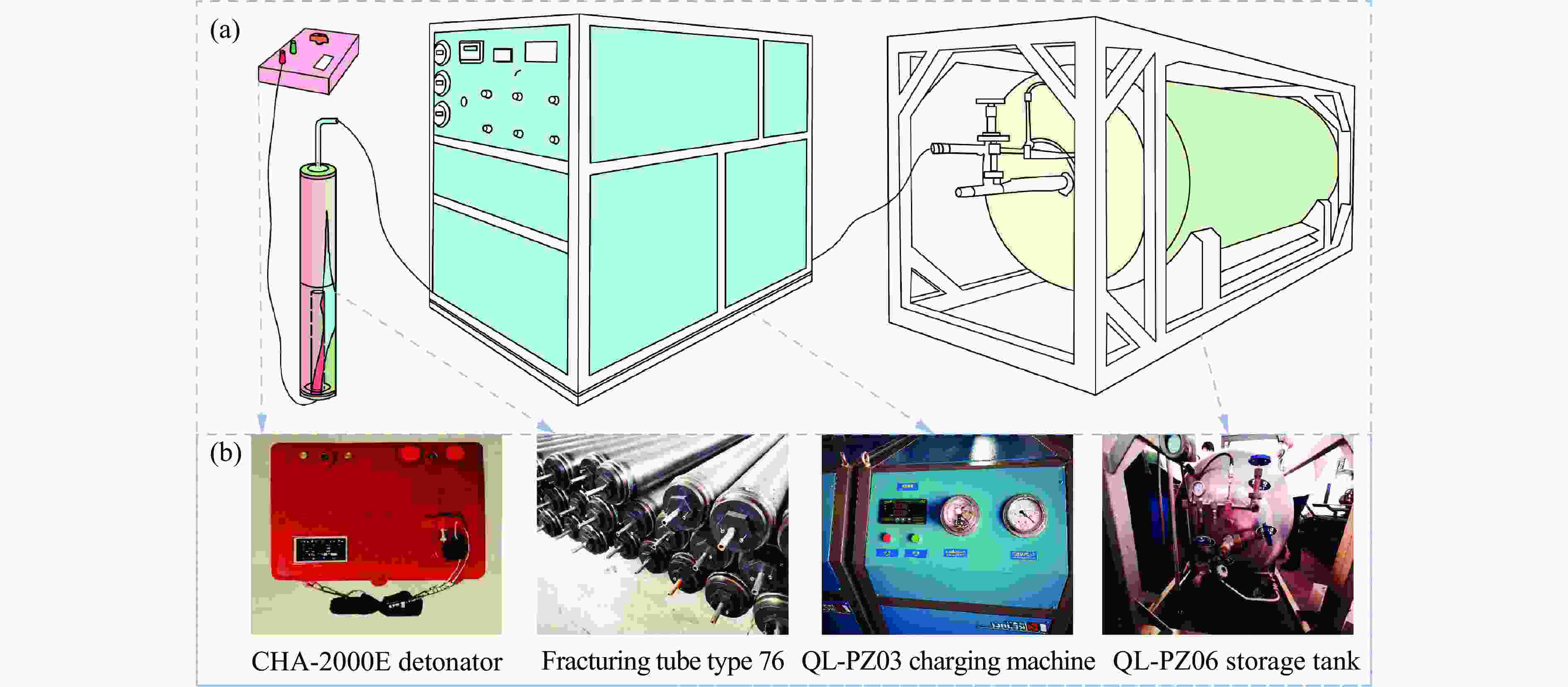

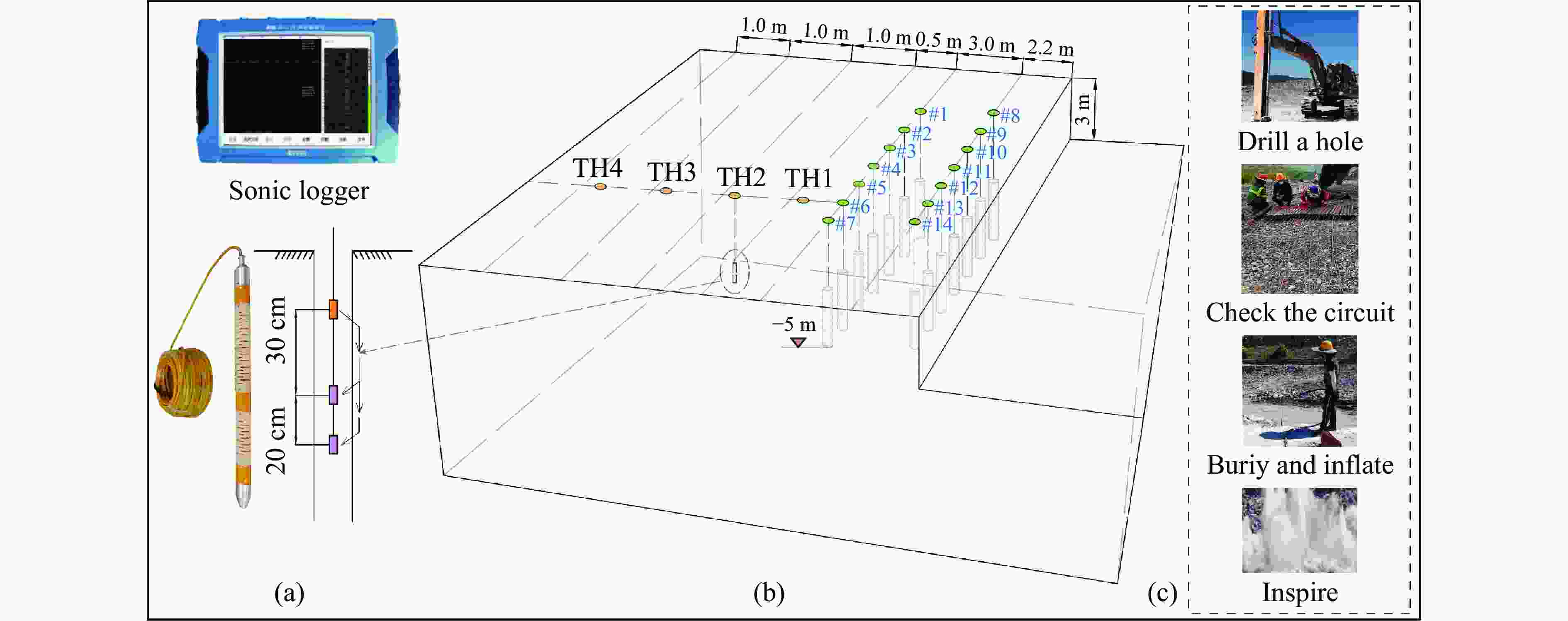

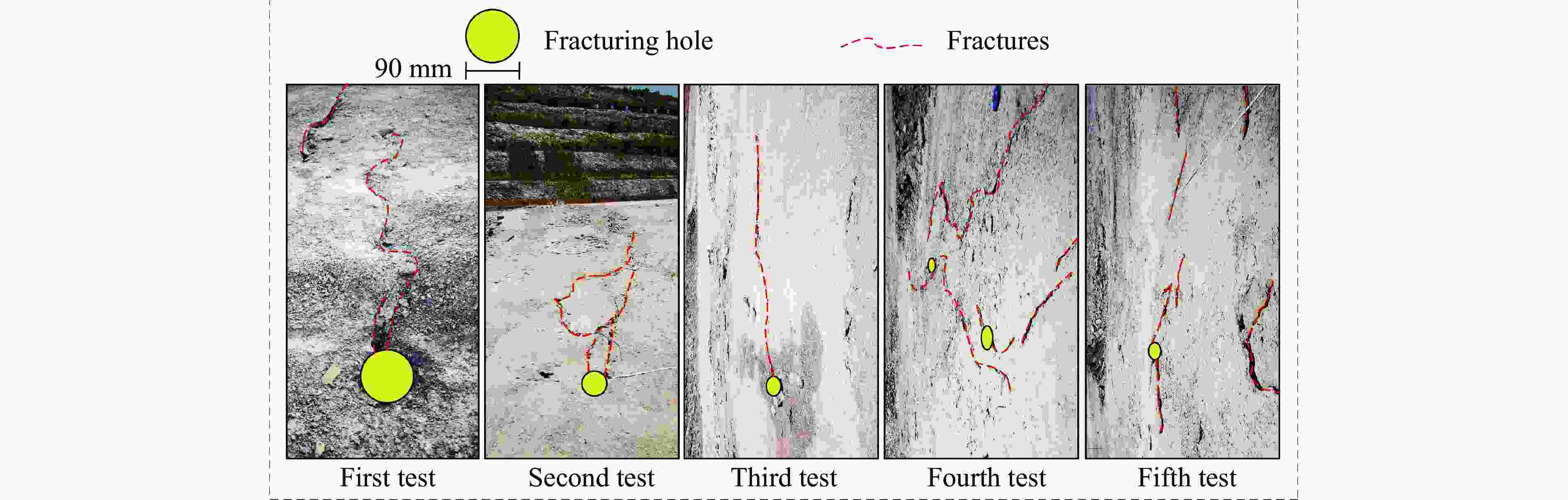

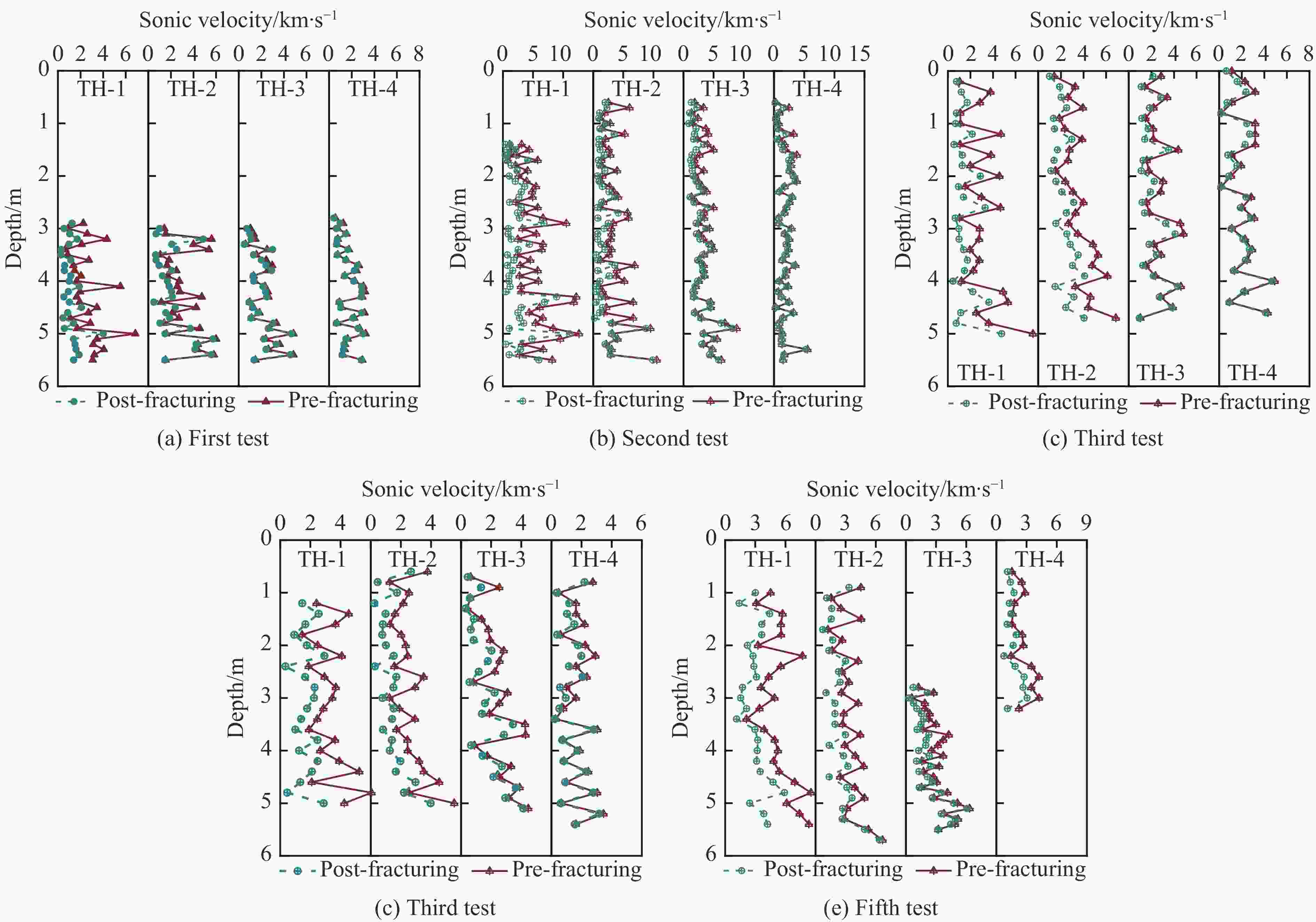

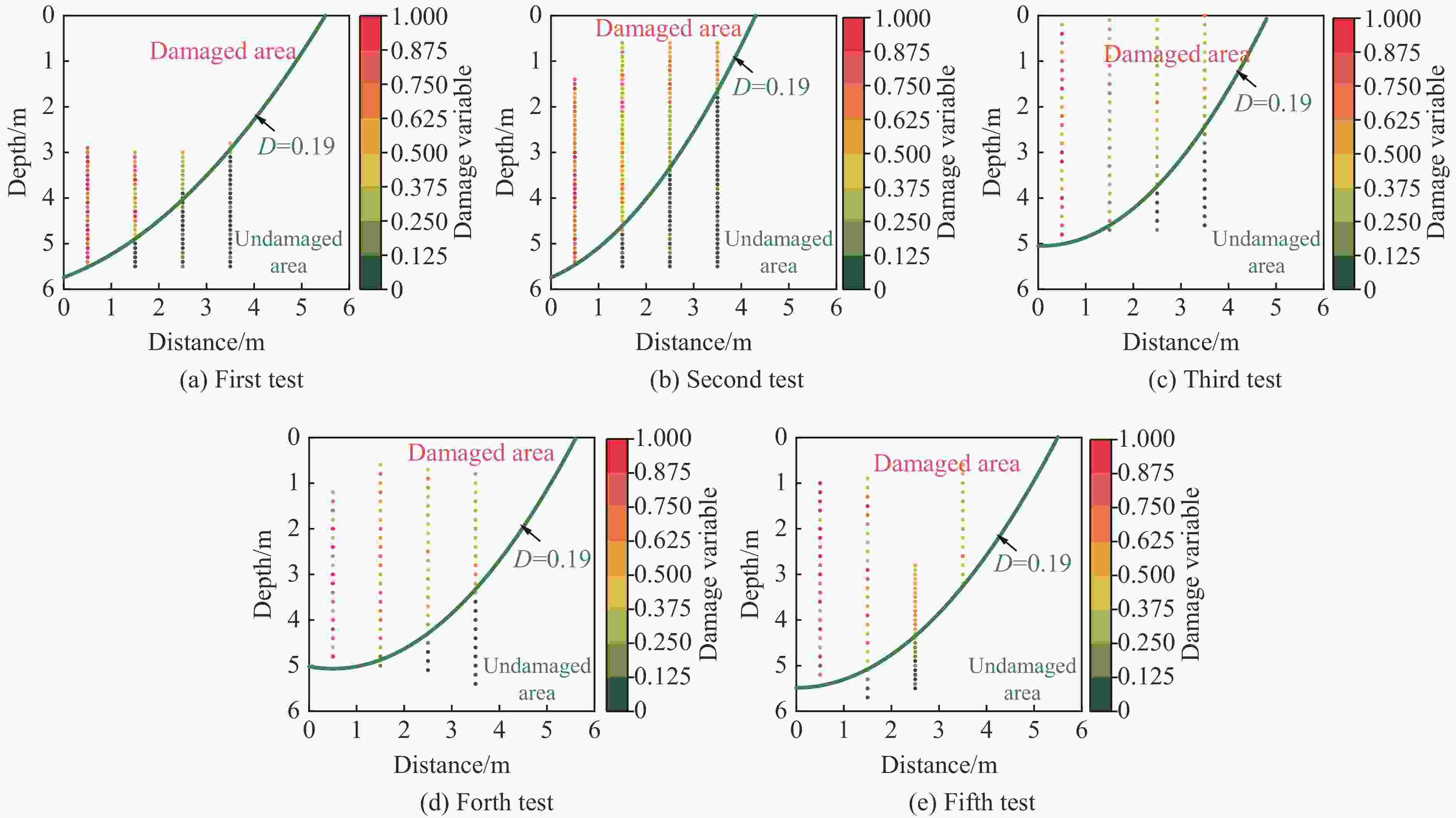

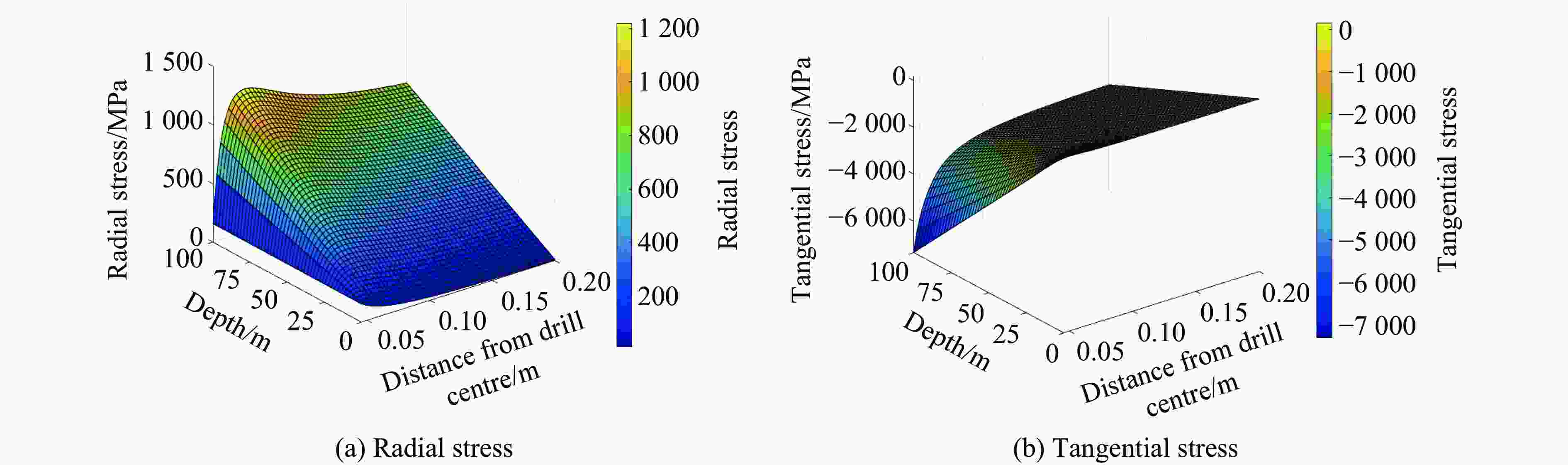

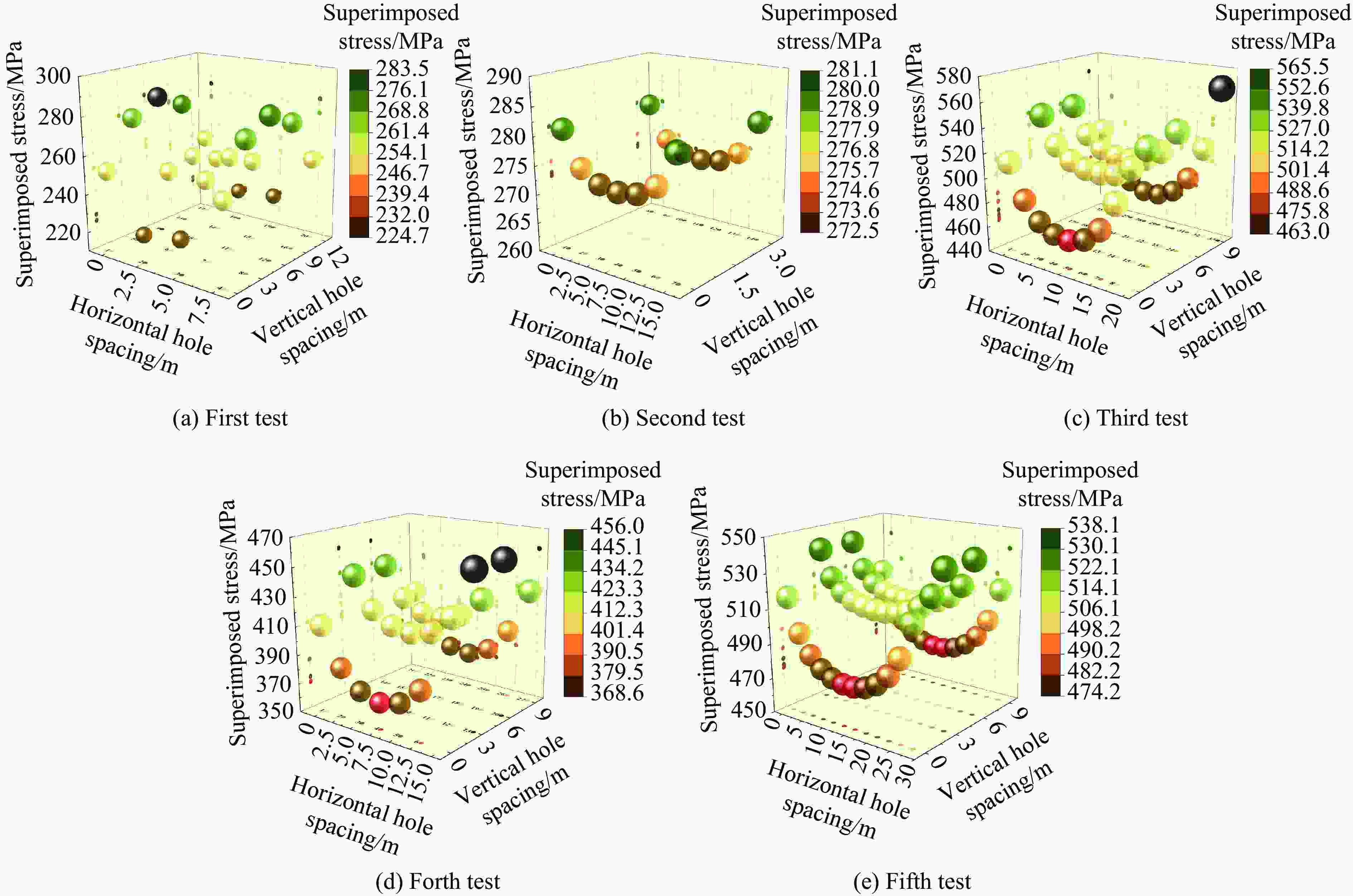

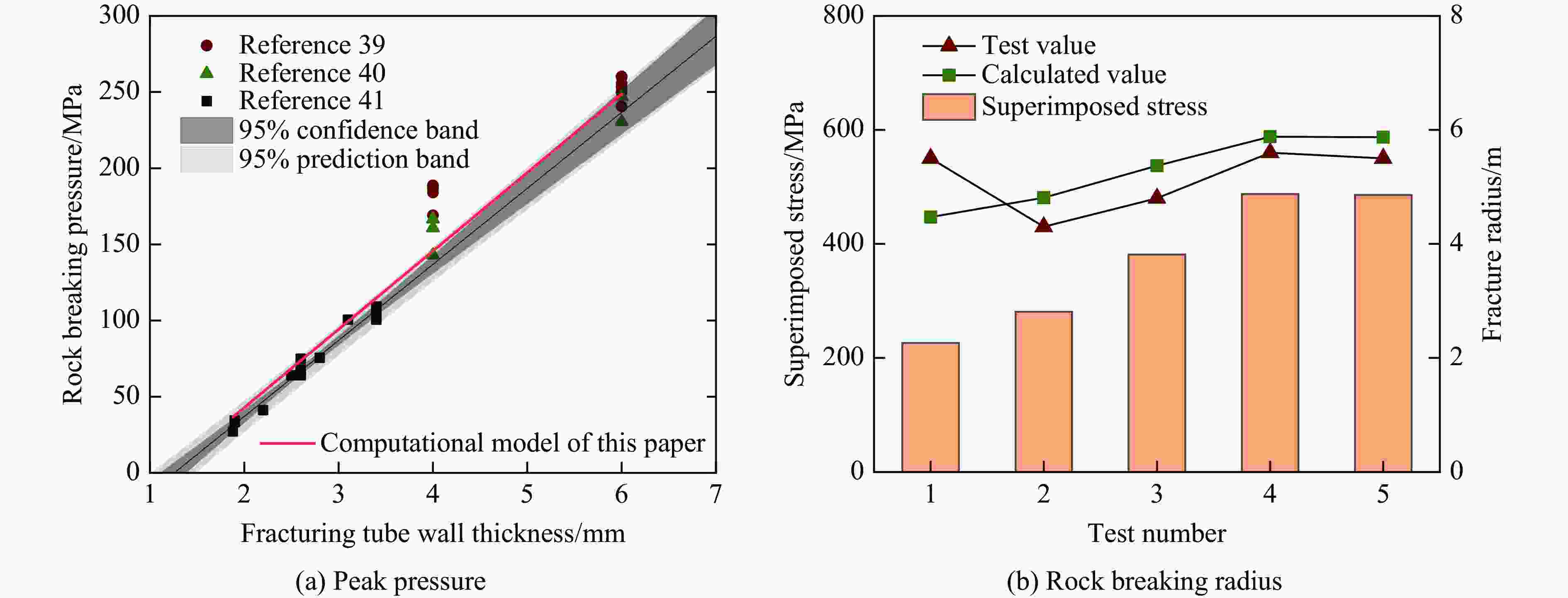

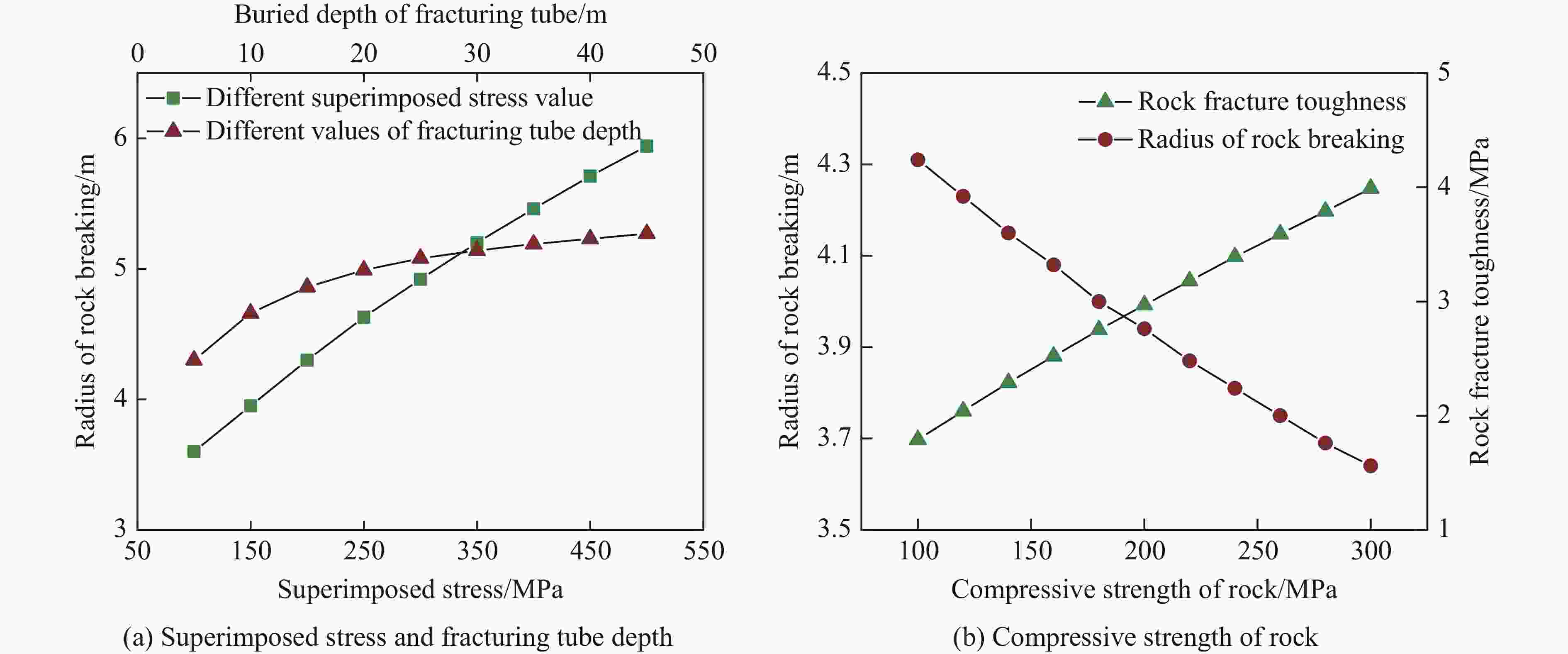

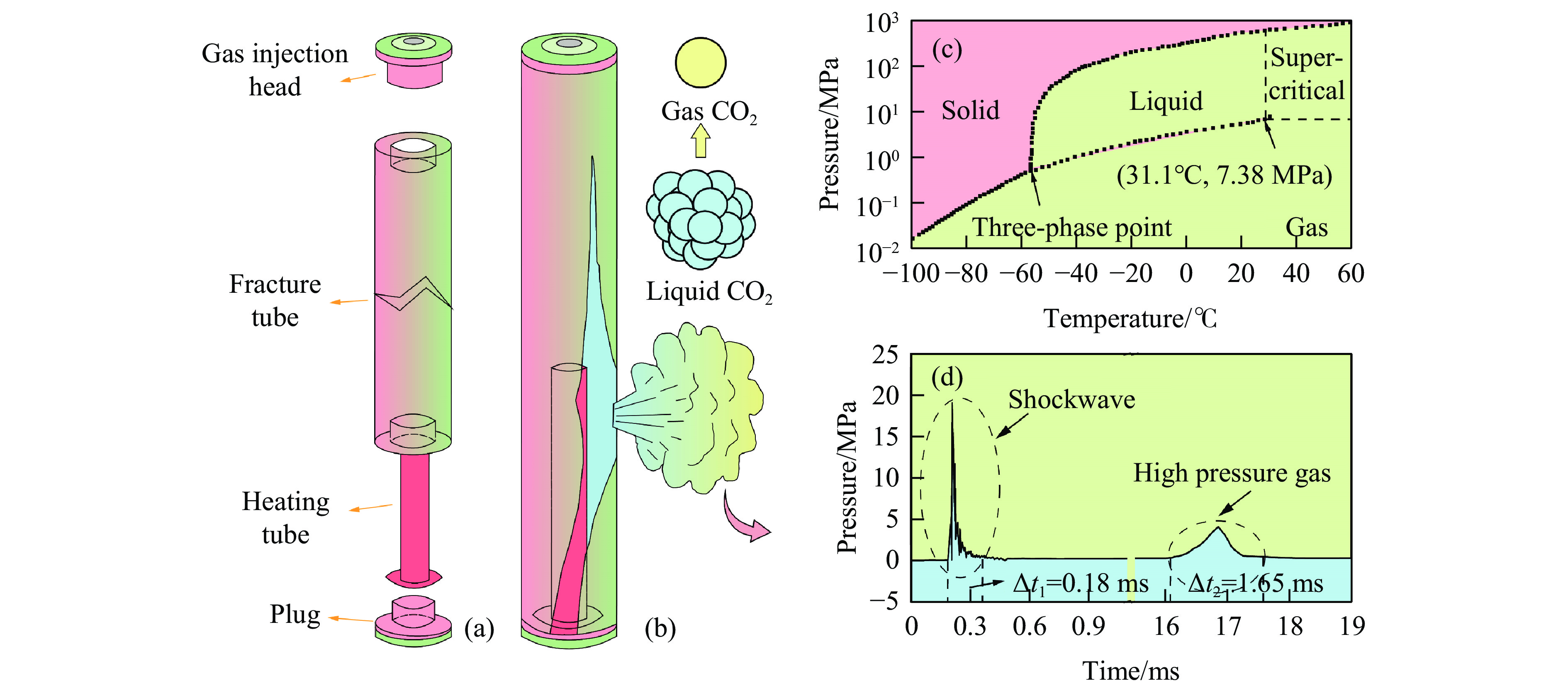

摘要: 超临界CO2相变破岩是冲击波与高压气体协同作用下的动态破坏过程。为深入探究多孔同步激发与地应力耦合条件下的超临界CO2相变破岩机制,针对CO2现场破岩实际工况,基于薄壁圆筒理论解析了单孔初始破岩压力,结合一维爆生气体膨胀理论,构建了地应力作用下多孔冲击波与高压气体联合破岩半径预测模型,并通过现场多孔CO2相变破岩试验进行了对比验证。结果表明:当致裂管埋深较浅时,地应力对岩体应力分布的影响较微弱;当单孔压力一致时,致裂孔数量越多,各孔的叠加峰值应力越大,在垂直于测试孔布置方向,各孔的峰值应力均呈U型抛物线分布,两端的致裂孔的叠加应力最大,而在平行于测试孔布置方向,各孔的峰值应力均呈倒U型抛物线分布,中部致裂孔的叠加应力最大。此外,利用声波测试得到的现场多孔冲击下岩体损伤破坏范围呈三维漏斗形状,竖向损伤破坏范围在5.05~5.73 m之间,平面损伤破坏范围在4.3~5.6 m之间,其中平面损伤破坏范围测试值与理论计算值的相对误差在5.0%~18.7%之间,计算误差多来自各致裂孔叠加应力的不均匀性。进一步分析可知:超临界CO2相变破岩半径随致裂孔叠加应力呈半抛物线式增长,随致裂孔深度呈对数式增长;当岩体抗压强度增大时,岩石断裂韧度近线性增长,对应破岩半径近线性下降。研究成果可为多孔超临界CO2相变破岩工程参数优化提供定量化设计依据。Abstract: Supercritical CO2 phase transition rock-breaking is a dynamic destruction process under the combined action of shock waves and high-pressure gas. To deeply investigate the rock-breaking mechanisms of supercritical CO2 phase transition under multi-hole synchronous initiation and in-situ stress coupling conditions, targeting the actual working conditions of CO2 field rock-breaking, the initial rock-breaking pressure of a single hole was analyzed based on the thin-walled cylinder theory. A predictive model for the joint rock-breaking radius of multi-hole shock waves and high-pressure gas under in-situ stress was developed by integrating the one-dimensional detonation gas expansion theory. Field experiments on multi-hole CO2 phase transition rock-breaking were subsequently conducted for comparative validation. The results show that when the fracturing pipe is buried shallowly, the influence of in-situ stress on the stress distribution of the rock mass is relatively weak. When the pressure of a single hole is consistent, the more fracturing holes there are, the greater the superposed peak stress of each hole. In the direction perpendicular to the layout of the test hole, the peak stress of each hole shows a U-shaped parabolic distribution. The superposed stress of the fracturing holes at both ends is the largest. In the direction parallel to the layout of the test hole, the peak stress of each hole shows an inverted U-shaped parabolic distribution, and the superposed stress of the middle fracturing hole is the largest. In addition, the rock mass damage and fracture range under multi-pore impact obtained by acoustic wave testing in the field is in the shape of a three-dimensional funnel. The vertical damage and fracture range is between 5.05 and 5.73 m, and the planar damage and fracture range is between 4.3 and 5.6 m. The error between the measured value of the planar damage and fracture range and the theoretically calculated value is between 5.0% and 18.7%. The calculation error mainly comes from the uneven superposition stress of each fracturing hole. Further analysis shows that the radius of supercritical CO2 phase transition rock-breaking increases semi-parabolically with the superposed stress of the fracturing hole and increases logarithmically with the depth of the fracturing hole. As the compressive strength of the rock mass increases, the rock fracture toughness increases nearly linearly, and the corresponding rock-breaking radius decreases nearly linearly. The research results can provide a quantitative design basis for optimizing engineering parameters in the multi-pore supercritical CO2 phase transition for rock-breaking.

-

表 1 南桐矿山灰岩物理力学参数

Table 1. Physical and mechanical parameters of Nantong mine limestone

ρ/(kg·m−3) ${\sigma }_{\text{d}}^{{'}} $/MPa ${\sigma }_{\text{c}}^{{'}} $/MPa μ KIC/(MPa·m1/2) E/GPa G/GPa ${\sigma }_{\text{td}}^{{'}} $/MPa ${\sigma }_{\text{cd}}^{{'}} $/MPa 2 738 5.86 84.01 0.26 1.33 26.34 10.45 7.21 103.35 表 2 现场致裂管布置情况

Table 2. Arrangement of fracturing tubes in the field

编号 坡高/m 管型 埋深/m 孔径/mm 管数量/根 排距/m 孔距/m 抵抗线/m 1 3 76 5 90 20 3 2.5 1.7 2 3 76 5 90 14 3 2.5 2.2 3 3 76 5 90 32+1 3 2.5 1.5 4 3 76 5 90 24+3 3 2.5 1.0 5 3 76 5 90 48 3 2.5 1.4 表 3 超临界CO2相变破岩半径影响参数计算方案

Table 3. Calculation scheme for parameters affecting the radius of supercritical CO2 phase change rock breakage

致裂孔叠加应力/MPa 致裂管埋深/m 岩体动态抗压强度/MPa 100 5 100 150 10 125 200 15 150 250 20 175 300 25 200 350 30 225 400 35 250 450 40 275 500 45 300 -

[1] CHEN Y, ZHANG H W, ZHU Z J, et al. A new shock-wave test apparatus for liquid CO2 blasting and measurement analysis [J]. Measurement and Control, 2019, 52(5/6): 399–408. DOI: 10.1177/0020294019838581. [2] CHEN Z S, YUAN Y, YAN C L, et al. A novel carbon dioxide phase transition rock breaking technology: theory and application of non-explosive blasting [J]. Processes, 2022, 10(11): 2434. DOI: 10.3390/pr10112434. [3] PU C, LIU Z J, PU G. On the factors of impact pressure in supercritical CO2 phase-transition blasting-a numerical study [J]. Energies, 2022, 15(22): 8599. DOI: 10.3390/en15228599. [4] 孙小明. 液态二氧化碳相变致裂掏槽破岩试验研究 [J]. 煤炭科学技术, 2021, 49(8): 81–87. DOI: 10.13199/j.cnki.cst.2021.08.010.SUN X M. Experimental study on cutting and rock breaking by liquid CO2 phase transition fracturing technology [J]. Coal Science and Technology, 2021, 49(8): 81–87. DOI: 10.13199/j.cnki.cst.2021.08.010. [5] 王莉, 陈杰, 李必红. 复杂环境下CO2膨胀爆破工程应用 [J]. 工程爆破, 2021, 27(1): 95–99. DOI: 10.19931/j.EB.20190189.WANG L, CHEN J, LI B H. Application of CO2 expansion blasting project in complex environment [J]. Engineering Blasting, 2021, 27(1): 95–99. DOI: 10.19931/j.EB.20190189. [6] SHANG Z, WANG H F, LI B, et al. Experimental investigation of BLEVE in liquid CO2 phase-transition blasting for enhanced coalbed methane recovery [J]. Fuel, 2021, 292: 120283. DOI: 10.1016/j.fuel.2021.120283. [7] 彭然, 霍中刚, 温良. 二氧化碳致裂器止飞技术研究 [J]. 煤炭科学技术, 2020, 48(S1): 134–139.PENG R, HUO Z G, WEN L. Study on anti-flying technology of carbon dioxide fracturer [J]. Coal Science and Technology, 2020, 48(S1): 134–139. [8] HU S B, PANG S G, YAN Z Y. A new dynamic fracturing method: deflagration fracturing technology with carbon dioxide [J]. International Journal of Fracture, 2019, 220(1): 99–111. DOI: 10.1007/s10704-019-00403-8. [9] 孙可明, 辛利伟, 吴迪. 超临界CO2气爆煤体致裂机理实验研究 [J]. 爆炸与冲击, 2018, 38(2): 302–308. DOI: 10.11883/bzycj-2016-0230.SUN K M, XIN L W, WU D. Experimental study on fracture mechanism of coal caused by supercritical CO2 explosion [J]. Explosion and Shock Waves, 2018, 38(2): 302–308. DOI: 10.11883/bzycj-2016-0230. [10] 孙可明, 辛利伟, 王婷婷, 等. 超临界CO2气爆煤体致裂规律模拟研究 [J]. 中国矿业大学学报, 2017, 46(3): 501–506. DOI: 10.13247/j.cnki.jcumt.000669.SUN K M, XIN L W, WANG T T, et al. Simulation research on law of coal fracture caused by supercritical CO2 explosion [J]. Journal of China University of Mining & Technology, 2017, 46(3): 501–506. DOI: 10.13247/j.cnki.jcumt.000669. [11] 谢晓锋, 李夕兵, 李启月, 等. 液态CO2相变破岩桩井开挖技术 [J]. 中南大学学报(自然科学版), 2018, 49(8): 2031–2038. DOI: 10.11817/j.issn.1672-7207.2018.08.025.XIE X F, LI X B, LI Q Y, et al. Liquid CO2 phase-transforming rock fracturing technology in pile-well excavation [J]. Journal of Central South University (Science and Technology), 2018, 49(8): 2031–2038. DOI: 10.11817/j.issn.1672-7207.2018.08.025. [12] 孙可明, 王金彧, 辛利伟. 超临界CO2气爆致裂爆生气体压力沿破裂面变化规律实验研究 [J]. 实验力学, 2019, 34(4): 693–699. DOI: 10.7520/1001-4888-18-001.SUN K M, WANG J Y, XIN L W. Experimental study of variation pattern of gas pressure from explosion along fracture surface in supercritical CO2 gas explosion [J]. Journal of Experimental Mechanics, 2019, 34(4): 693–699. DOI: 10.7520/1001-4888-18-001. [13] ZHOU S T, JIANG N, HE X, et al. Rock breaking and dynamic response characteristics of carbon dioxide phase transition fracturing considering the gathering energy effect [J]. Energies, 2020, 13(6): 1336. DOI: 10.3390/en13061336. [14] ZHANG Y N, DENG J R, DENG H W, et al. Peridynamics simulation of rock fracturing under liquid carbon dioxide blasting [J]. International Journal of Damage Mechanics, 2019, 28(7): 1038–1052. DOI: 10.1177/1056789518807532. [15] 周西华, 门金龙, 王鹏辉, 等. 井下液态CO2爆破增透工业试验研究 [J]. 中国安全生产科学技术, 2015, 11(9): 76–82. DOI: 10.11731/j.issn.1673-193x.2015.09.012.ZHOU X H, MEN J L, WANG P H, et al. Industry experimental research on improving permeability by underground liquid CO2 blasting [J]. Journal of Safety Science and Technology, 2015, 11(9): 76–82. DOI: 10.11731/j.issn.1673-193x.2015.09.012. [16] 孙可明, 辛利伟, 张树翠, 等. 超临界CO2气爆致裂规律实验研究 [J]. 中国安全生产科学技术, 2016, 12(7): 27–31. DOI: 10.11731/j.issn.1673-193x.2016.07.005.SUN K M, XIN L W, ZHANG S C, et al. Experimental study on laws of crack caused by gas burst of supercritical carbon dioxide [J]. Journal of Safety Science and Technology, 2016, 12(7): 27–31. DOI: 10.11731/j.issn.1673-193x.2016.07.005. [17] 田泽础. 液态二氧化碳相变致裂裂缝形态及影响因素研究 [D]. 徐州: 中国矿业大学, 2018: 28–37.TIAN Z C. Crack form and influencing factors of liquid carbon dioxide phase transition fracturing [D]. Xuzhou: University of Mining and Technology, 2018: 28–37. [18] KANG J H, ZHOU F B, QIANG Z Y, et al. Evaluation of gas drainage and coal permeability improvement with liquid CO2 gasification blasting [J]. Advances in Mechanical Engineering, 2018, 10(4): 1–15. DOI: 10.1177/1687814018768578. [19] 题正义, 陈波. 亭南煤矿液态CO2致裂巷道卸压技术的应用研究 [J]. 金属矿山, 2019(4): 48–52. DOI: 10.19614/j.cnki.jsks.201904010.TI Z Y, CHEN B. Application of pressure relief technology of liquid CO2 fracturing roadway in Tingnan coal mine [J]. Metal Mine, 2019(4): 48–52. DOI: 10.19614/j.cnki.jsks.201904010. [20] 王明宇. 液态二氧化碳相变爆破裂纹扩展规律研究及应用 [D]. 徐州: 中国矿业大学, 2018: 36–54.WANG M Y. Study on crack propagation law of liquid carbon dioxide phase transition blasting and its application [D]. Xuzhou: University of Mining and Technology, 2018: 36–54. [21] 孙可明, 辛利伟, 吴迪, 等. 初应力条件下超临界CO2气爆致裂规律模拟研究 [J]. 振动与冲击, 2018, 37(12): 232–238. DOI: 10.13465/j.cnki.jvs.2018.12.035.SUN K M, XIN L W, WU D, et al. Simulation of fracture law of supercritical CO2 explosion under initial stress condition [J]. Journal of Vibration and Shock, 2018, 37(12): 232–238. DOI: 10.13465/j.cnki.jvs.2018.12.035. [22] 孙可明, 王金彧, 辛利伟. 不同应力差条件下超临界CO2气爆煤岩体气楔作用次生裂纹扩展规律研究 [J]. 应用力学学报, 2019, 36(2): 466–472. DOI: 10.11776/cjam.36.02.B130.SUN K M, WANG J Y, XIN L W. Research on the law of secondary cracks propagation in coal and rock caused by gas wedging during supercritical CO2 explosion under different stress differences [J]. Chinese Journal of Applied Mechanics, 2019, 36(2): 466–472. DOI: 10.11776/cjam.36.02.B130. [23] 孙可明, 辛利伟, 吴迪, 等. 初应力条件下超临界CO2气爆致裂规律研究 [J]. 固体力学学报, 2017, 38(5): 473–482. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2017.05.011.SUN K M, XIN L W, WU D, et al. Mechanism of fracture caused by supercritical CO2 explosion under the impact of initial stress [J]. Chinese Journal of Solid Mechanics, 2017, 38(5): 473–482. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2017.05.011. [24] 赵博, 邵东亮, 曹先锋, 等. 水平圆管超临界二氧化碳摩阻试验研究 [J]. 科学技术与工程, 2016, 16(25): 75–78. DOI: 1671-1815 2016 025-0075-04.ZHAO B, SHAO D L, CAO X F, et al. An experimental study of supercritical carbon dioxide pressure drop in a horizontal tube [J]. Science Technology and Engineering, 2016, 16(25): 75–78. DOI: 1671-1815 2016 025-0075-04. [25] JOHLITZ M, DIERCKS N, LION A. Thermo-oxidative ageing of elastomers: a modelling approach based on a finite strain theory [J]. International Journal of Plasticity, 2014, 63: 138–151. DOI: 10.1016/j.ijplas.2014.01.012. [26] VOISIN C. Bloch’s conjecture for Catanese and Barlow surfaces [J]. Journal of Differential Geometry, 2014, 97(1): 149–175. DOI: 10.4310/jdg/1404912107. [27] CHEN Z F, LI X Y, WANG W, et al. Dynamic burst pressure analysis of cylindrical shells based on average shear stress yield criterion [J]. Thin-Walled Structures, 2020, 148: 106498. DOI: 10.1016/j.tws.2019.106498. [28] YAO Y P, HU J, ZHOU A N, et al. Unified strength criterion for soils, gravels, rocks, and concretes [J]. Acta Geotechnica, 2015, 10(6): 749–759. DOI: 10.1007/s11440-015-0404-x. [29] BAI M, ELSWORTH D. Coupled processes in subsurface deformation, flow, and transport [M]. Reston, VA: American Society of Civil Engineers, 2000. [30] 韦汉. 隧道工程聚能爆破破岩机理及参数优化研究 [D]. 南宁: 广西大学, 2021: 45–58. DOI: 10.27034/d.cnki.ggxiu.2021.000859.WEI H. Study on rock fragmentation mechanism and parameter optimization of shaped charge blasting in tunnel engineering [J]. Nanning: Guangxi University, 2021: 45–58. DOI: 10.27034/d.cnki.ggxiu.2021.000859. [31] 费鸿禄, 苏强, 蒋安俊, 等. 爆破载荷下隧道围岩破坏裂隙范围研究 [J]. 爆破器材, 2019, 48(2): 51–56. DOI: 10.3969/j.issn.1001-8352.2019.02.010.FEI H L, SU Q, JIANG A J, et al. Damage fracture range of tunnel surrounding rock under blasting load [J]. Explosive Materials, 2019, 48(2): 51–56. DOI: 10.3969/j.issn.1001-8352.2019.02.010. [32] 肖思友, 姜元俊, 刘志祥, 等. 高地应力下硬岩爆破破岩特性及能量分布研究 [J]. 振动与冲击, 2018, 37(15): 143–149. DOI: 10.13465/j.cnki.jvs.2018.15.020.XIAO S Y, JIANG Y J, LIU Z X, et al. Hard rock blasting energy distribution and fragmentation characteristics under high earth stress [J]. Journal of Vibration and Shock, 2018, 37(15): 143–149. DOI: 10.13465/j.cnki.jvs.2018.15.020. [33] 高维廷, 朱哲明, 朱伟, 等. 动荷载下岩石裂纹动态扩展行为实验研究综述 [J]. 爆炸与冲击, 2023, 43(8): 081101. DOI: 10.11883/bzycj-2022-0526.GAO W Y, ZHU Z M, ZHU W, et al. Experimental studies on crack propagation behaviors of rock materials under dynamic loads: a review [J]. Explosion and Shock Waves, 2023, 43(8): 081101. DOI: 10.11883/bzycj-2022-0526. [34] FAROTTI E, MANCINI E, LATTANZI A, et al. Effect of temperature and strain rate on the formation of shear bands in polymers under quasi-static and dynamic compressive loadings: proposed constitutive model and numerical validation [J]. Polymer, 2022, 245: 124690. DOI: 10.1016/j.polymer.2022.124690. [35] 吴飞鹏, 刘洪志, 任杨, 等. 燃爆冲击作用下岩石初始破坏区形成机制与主控因素 [J]. 爆炸与冲击, 2016, 36(5): 663–669. DOI: 10.11883/1001-1455(2016)05-0663-07.WU F P, LIU H Z, REN Y, et al. Formation mechanism and main controlling factors of rock's initial damaged zone under explosive impact effect [J]. Explosion and Shock Waves, 2016, 36(5): 663–669. DOI: 10.11883/1001-1455(2016)05-0663-07. [36] 中华人民共和国水利部. 水工建筑物岩石地基开挖施工技术规范: SL 47—2020 [S]. 北京: 中国水利水电出版社, 2021.Ministry of Water Resources of the People’s Republic of China. Technical specification for excavation construction of rock-foundation of hydraulic structures: SL 47—2020 [S]. Beijing: China Water & Power Press, 2021. [37] DING C X, YANG R S, FENG C. Stress wave superposition effect and crack initiation mechanism between two adjacent boreholes [J]. International Journal of Rock Mechanics and Mining Sciences, 2021, 138: 104622. DOI: 10.1016/j.ijrmms.2021.104622. [38] CHEN Z S, YUAN Y, QIN Z H, et al. The mechanism of crack propagation under dynamic loading stress at different rates [J]. Computational Particle Mechanics, 2024, 11(6): 2715–2726. DOI: 10.1007/s40571-024-00748-5. [39] ZENG Y Q, LI H B, XIA X, et al. Experimental study on cavity pressure of carbon dioxide fracturing tube [J]. Journal of Vibroengineering, 2021, 23(7): 1602–1620. DOI: 10.21595/JVE.2021.21967. [40] 肖诚旭. 液态二氧化碳相变致裂的试验研究 [D]. 武汉: 湖北工业大学, 2018: 16–22.XIAO C X. Experimental study of phase-transforming fracturing of liquid carbon dioxide [D]. Wuhan: Hubei University of Technology, 2018: 16–22. [41] ABI E D, ZENG Q F, FU L, et al. Characterization and modeling of supercritical CO2 pulse pressures: effects of activator mass and discharge plate thickness [J]. Rock Mechanics Bulletin, 2024, 3(3): 100126. DOI: 10.1016/j.rockmb.2024.100126. -

下载:

下载: