Influence of microstructure and loading conditions on the dynamic tensile property of Ni-based single crystal superalloys

-

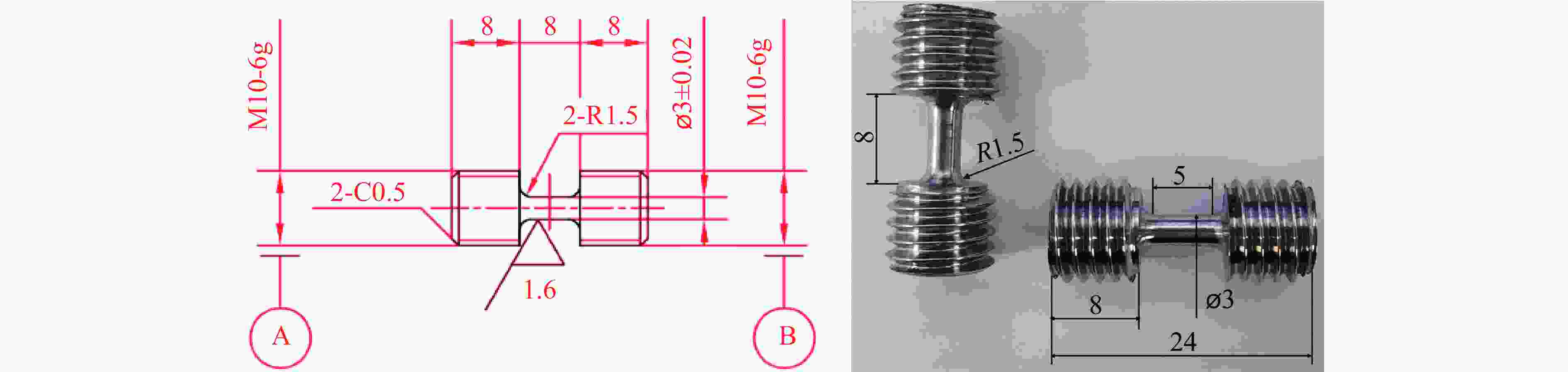

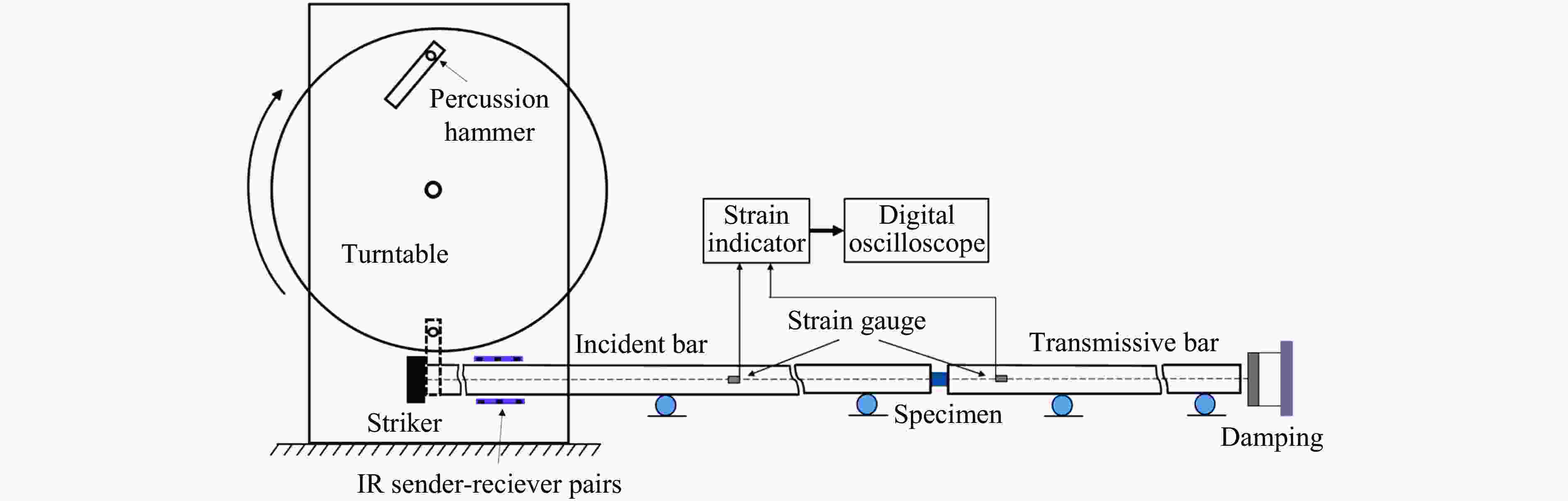

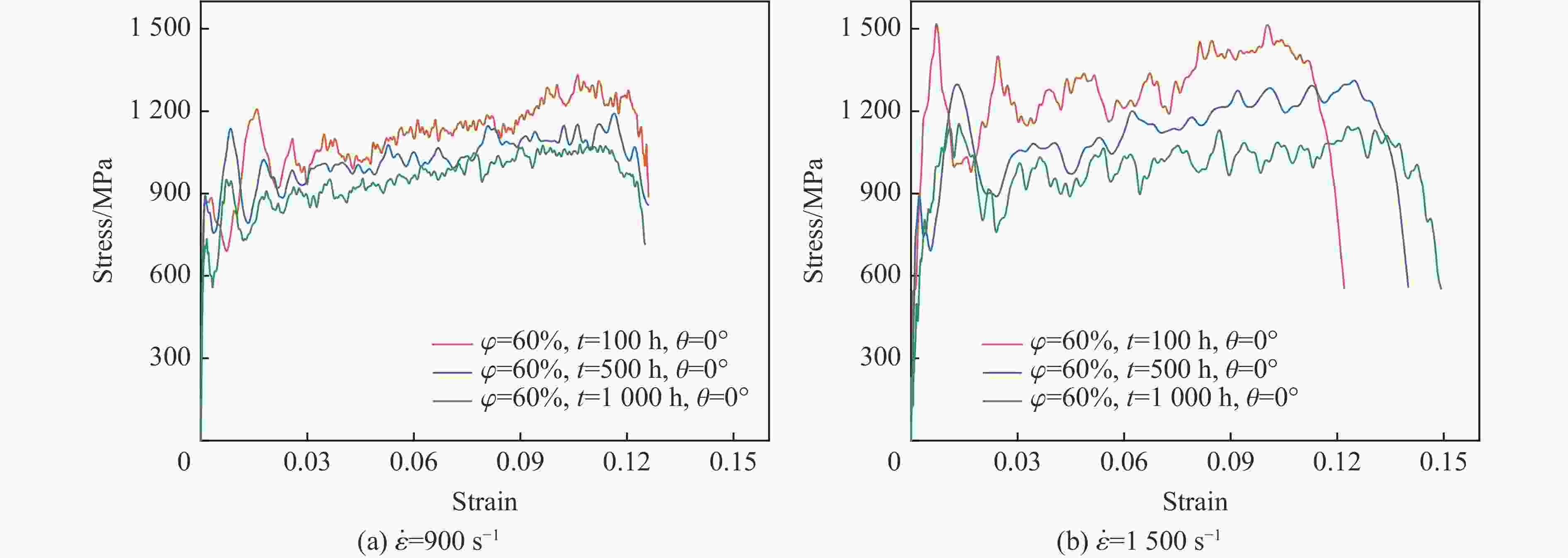

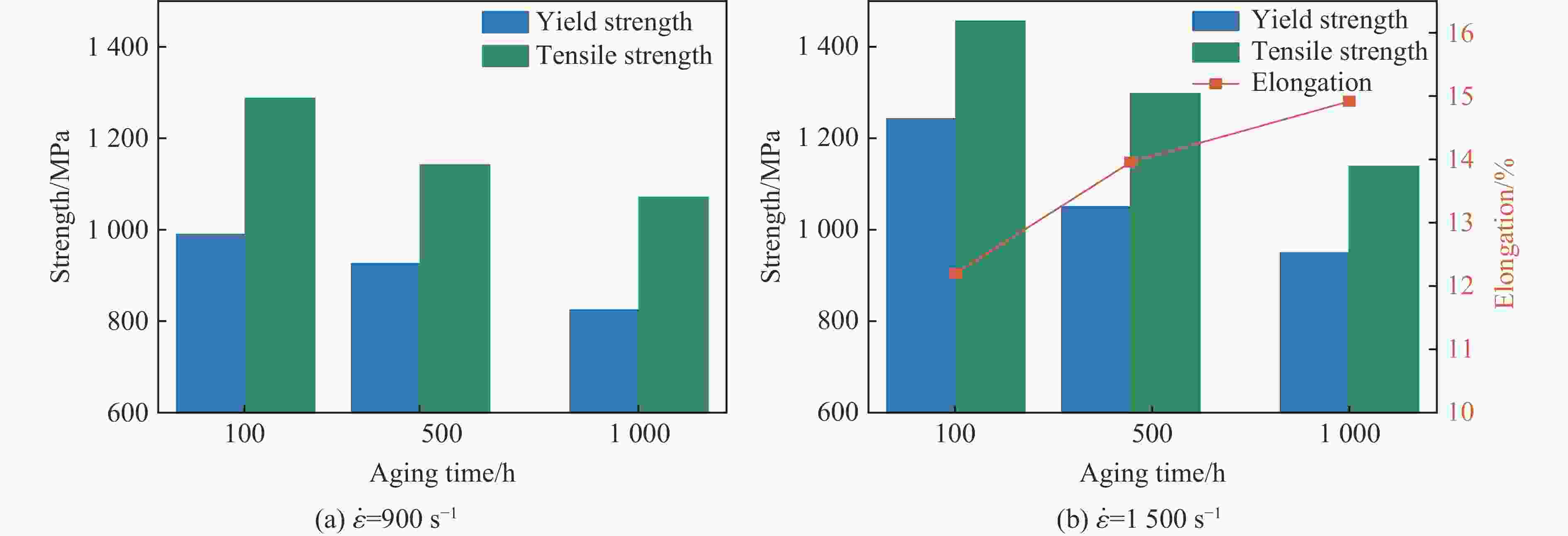

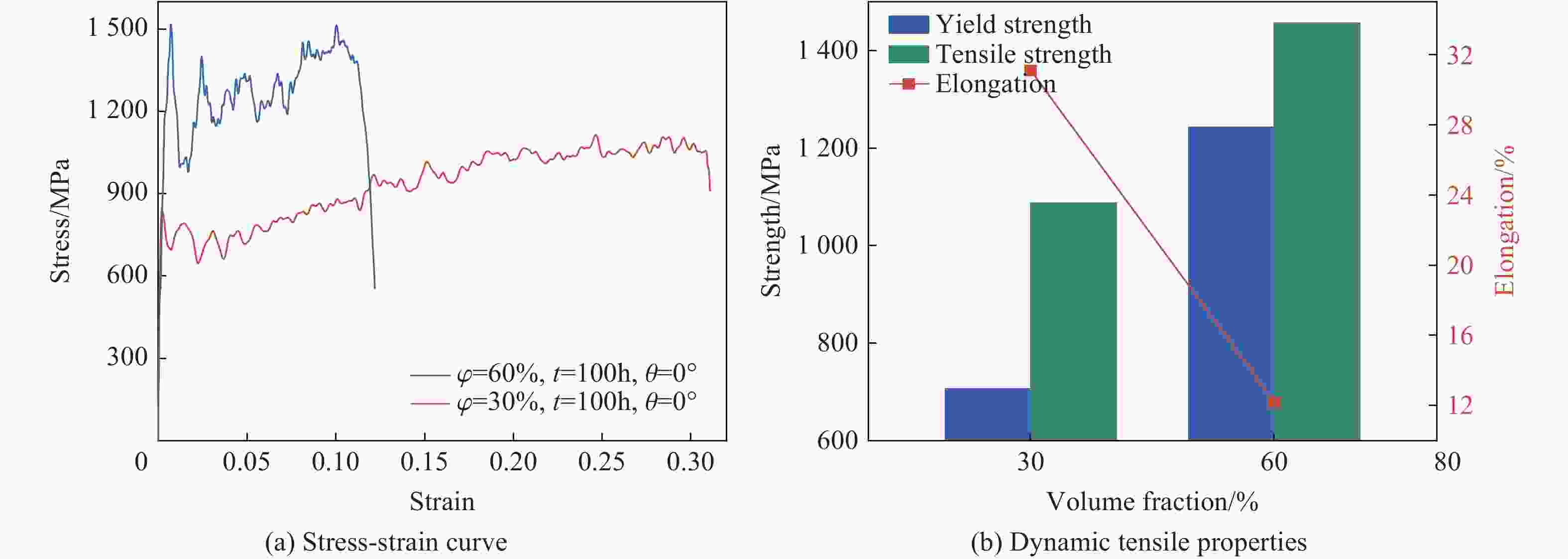

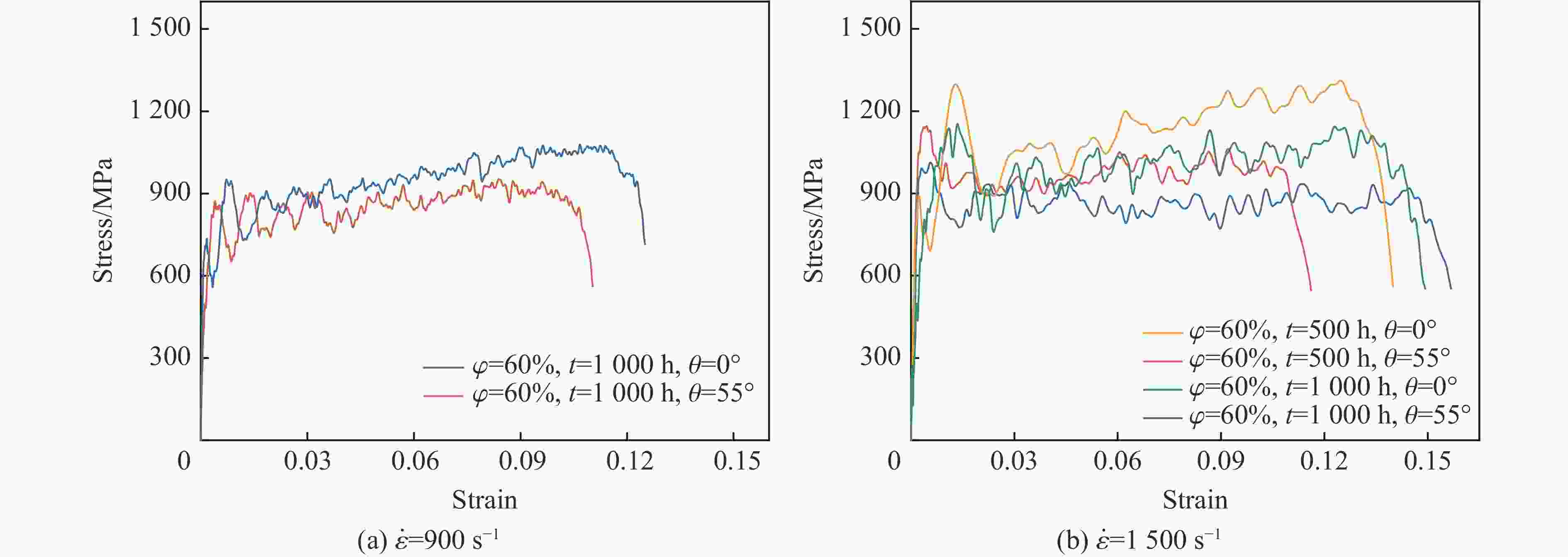

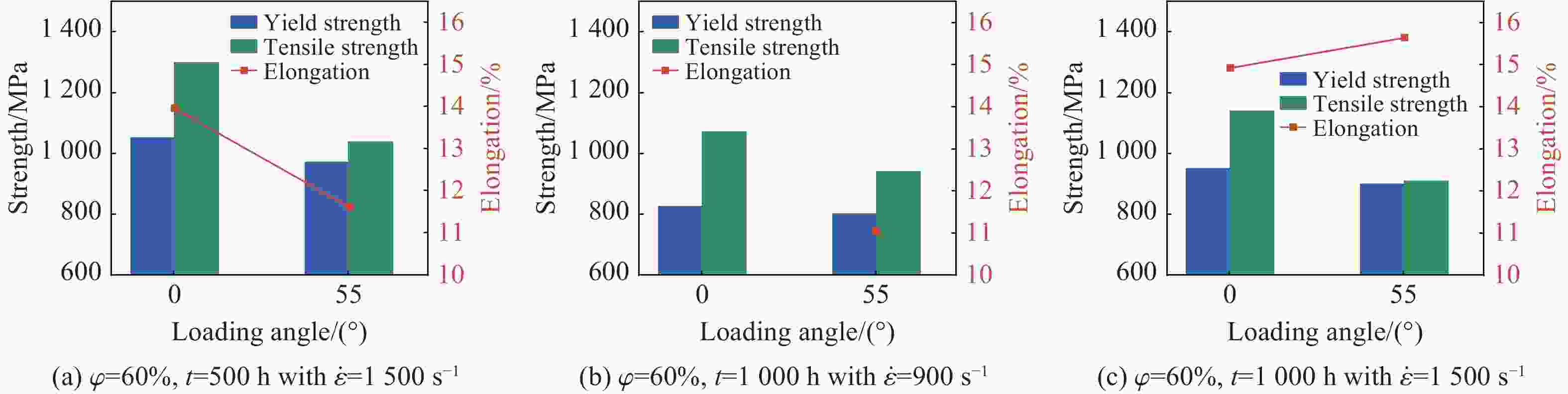

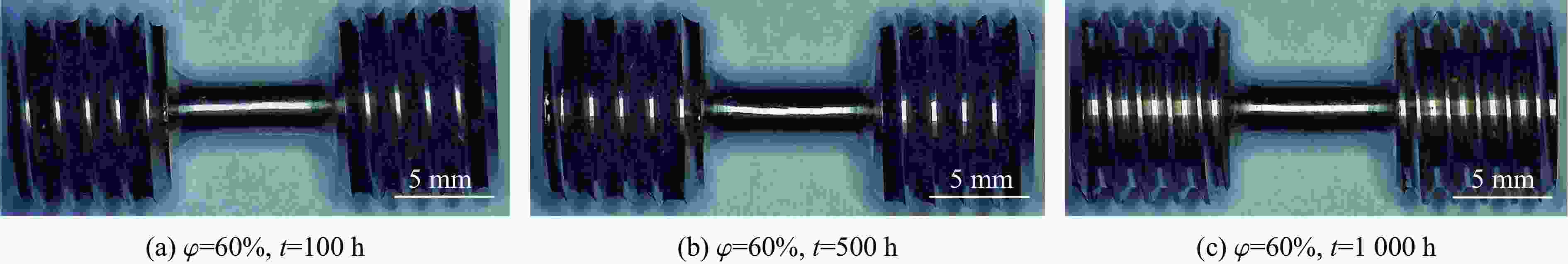

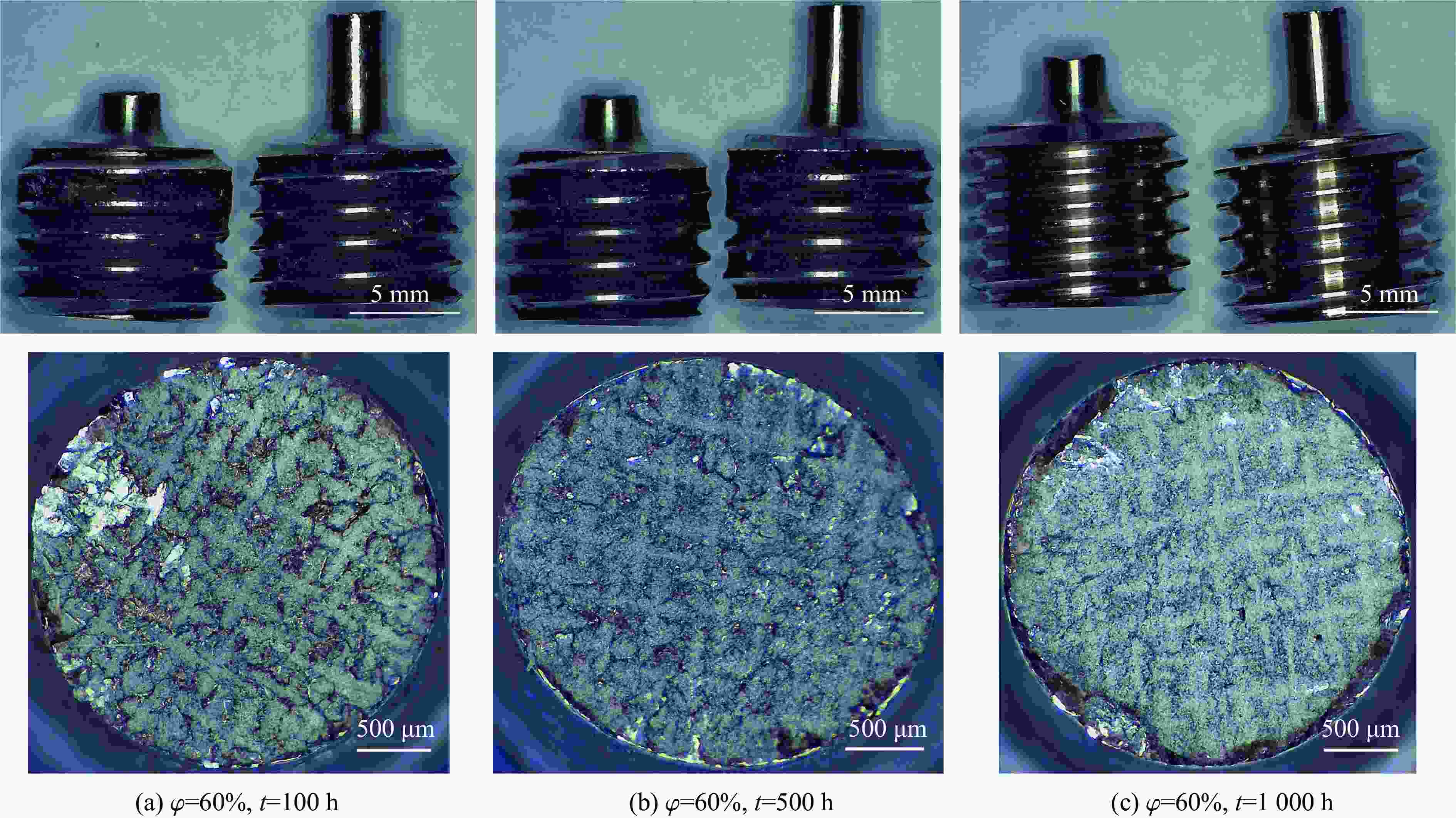

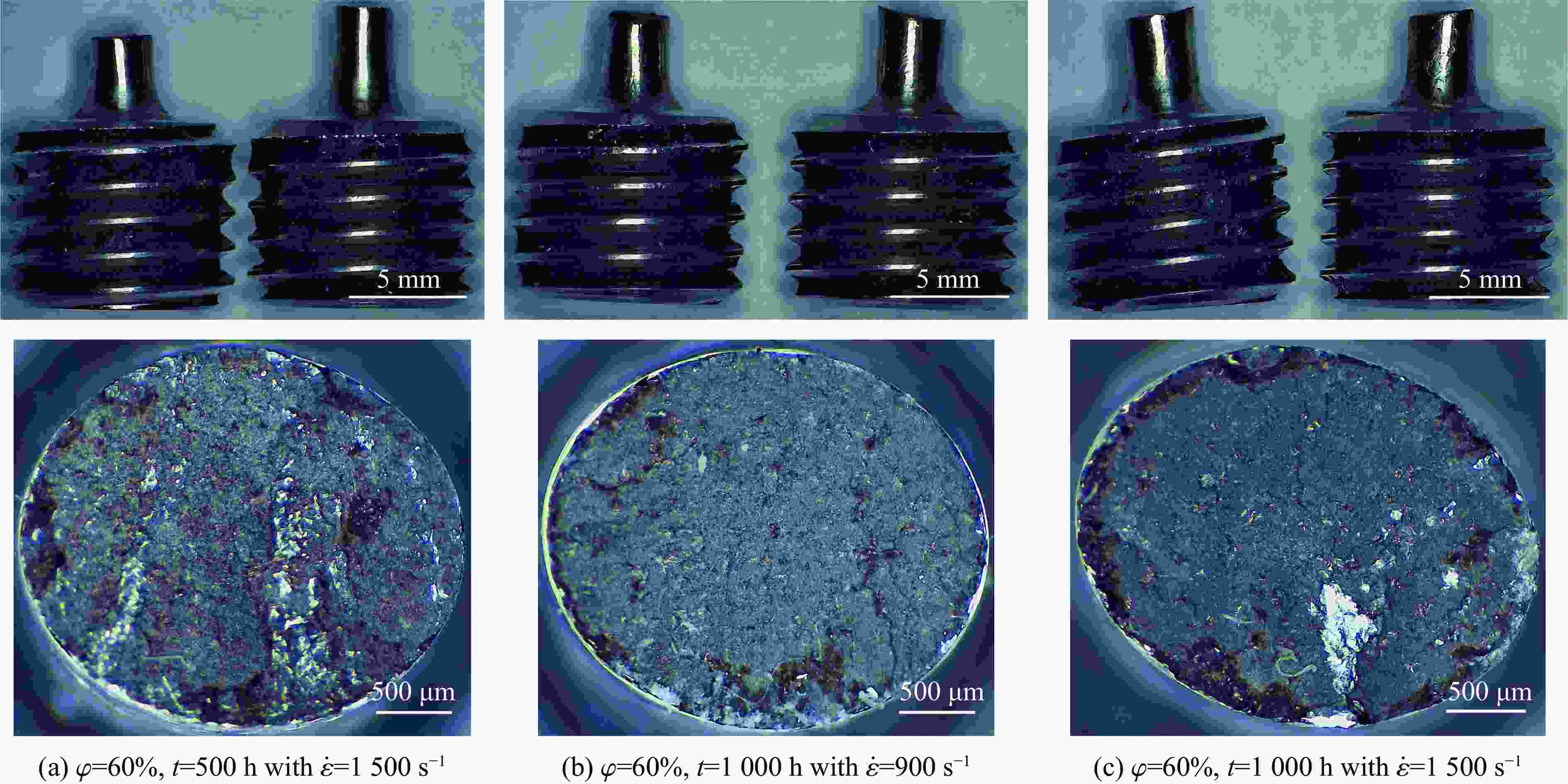

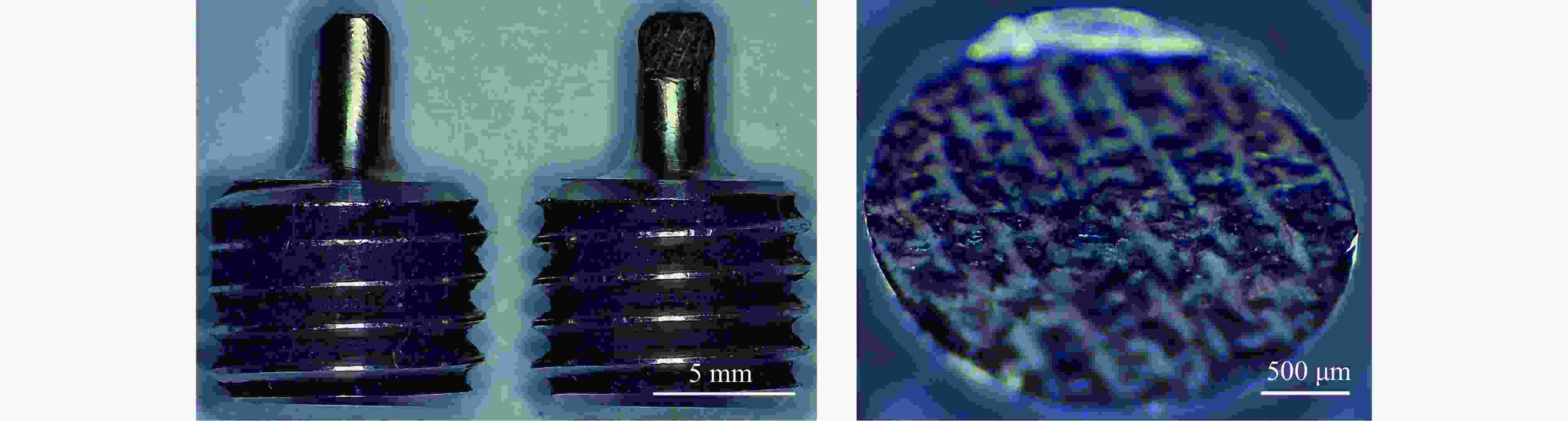

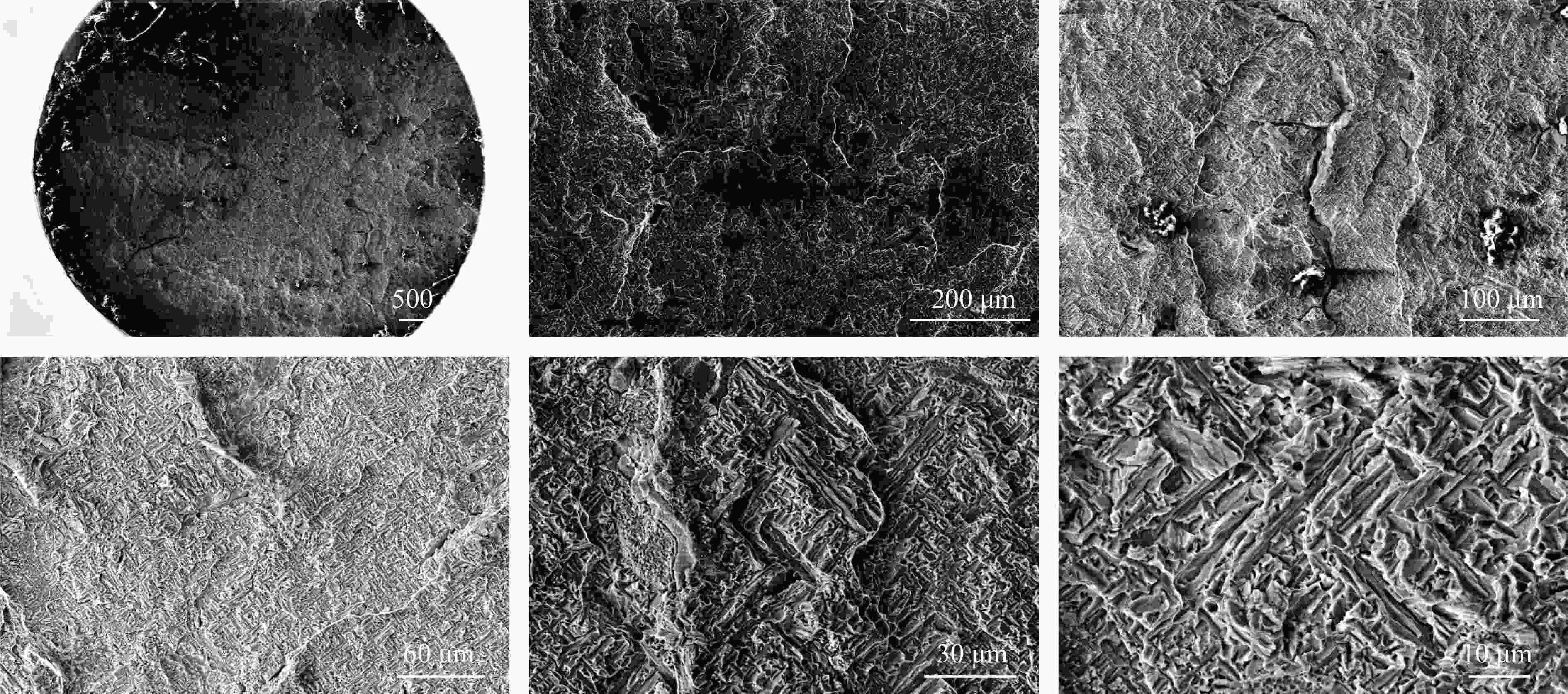

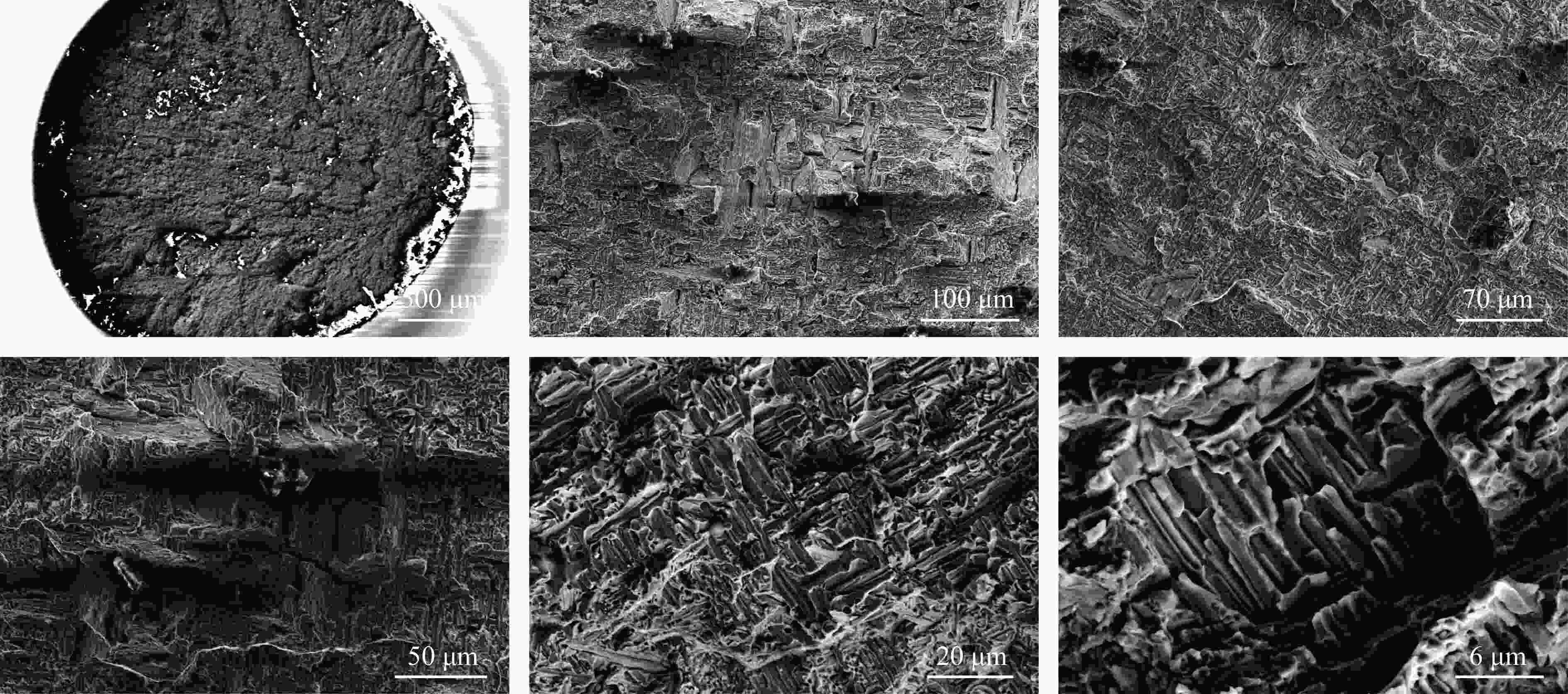

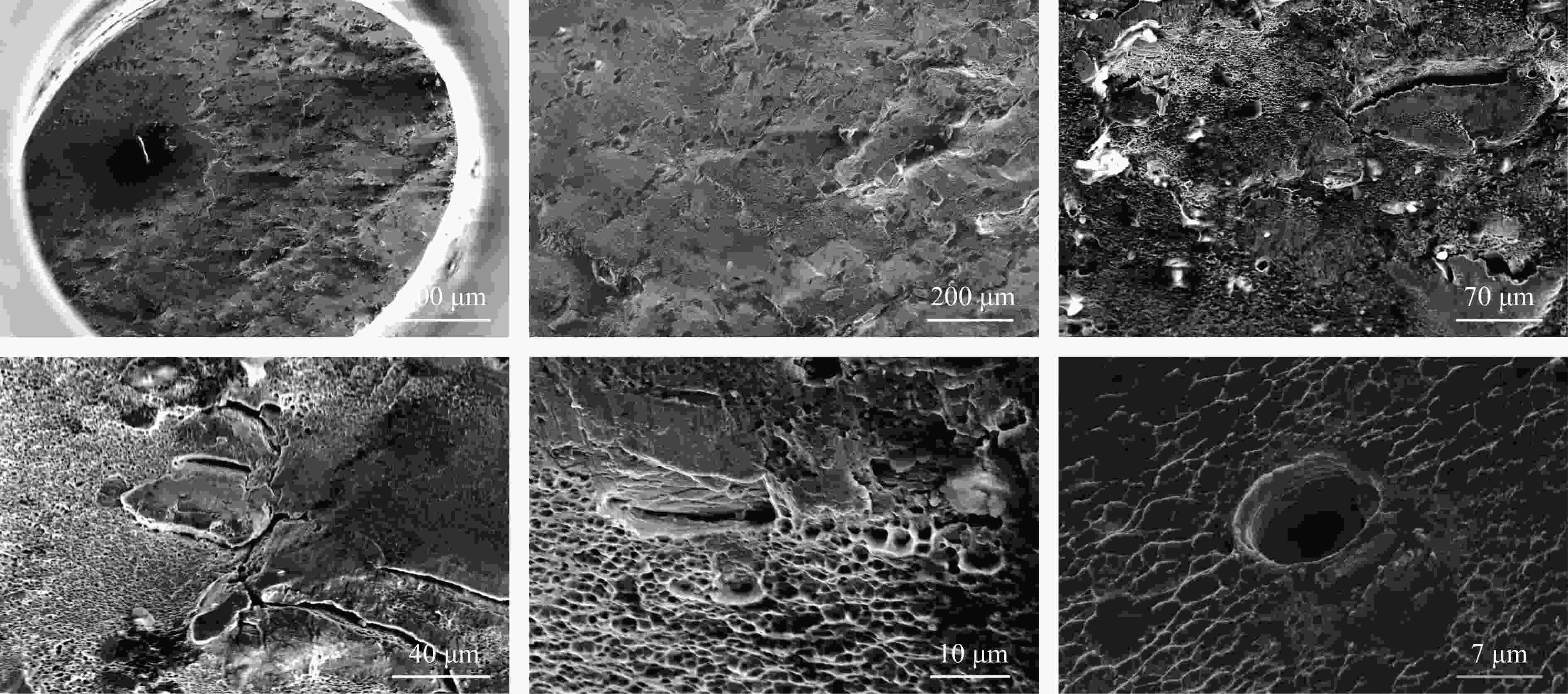

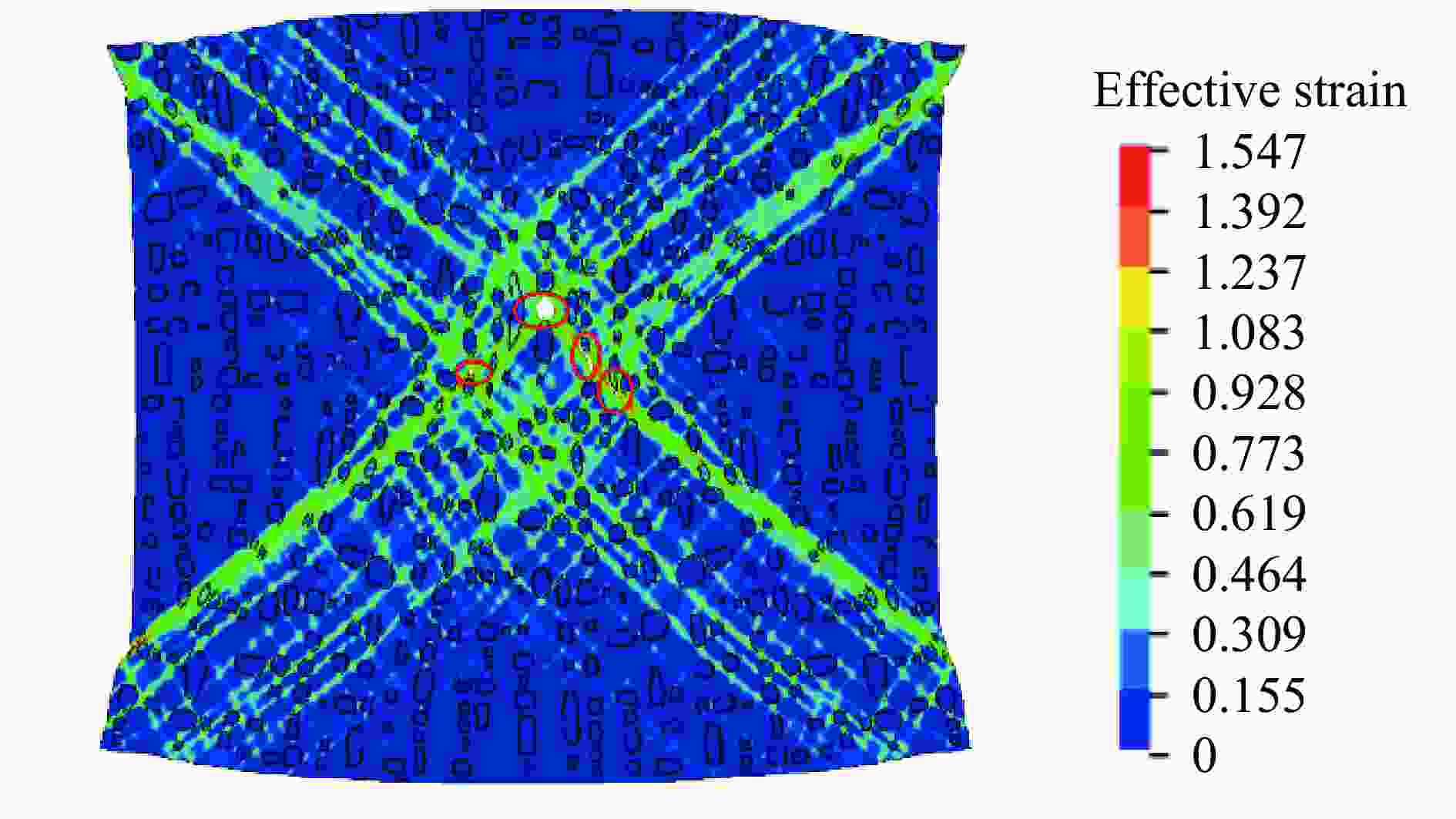

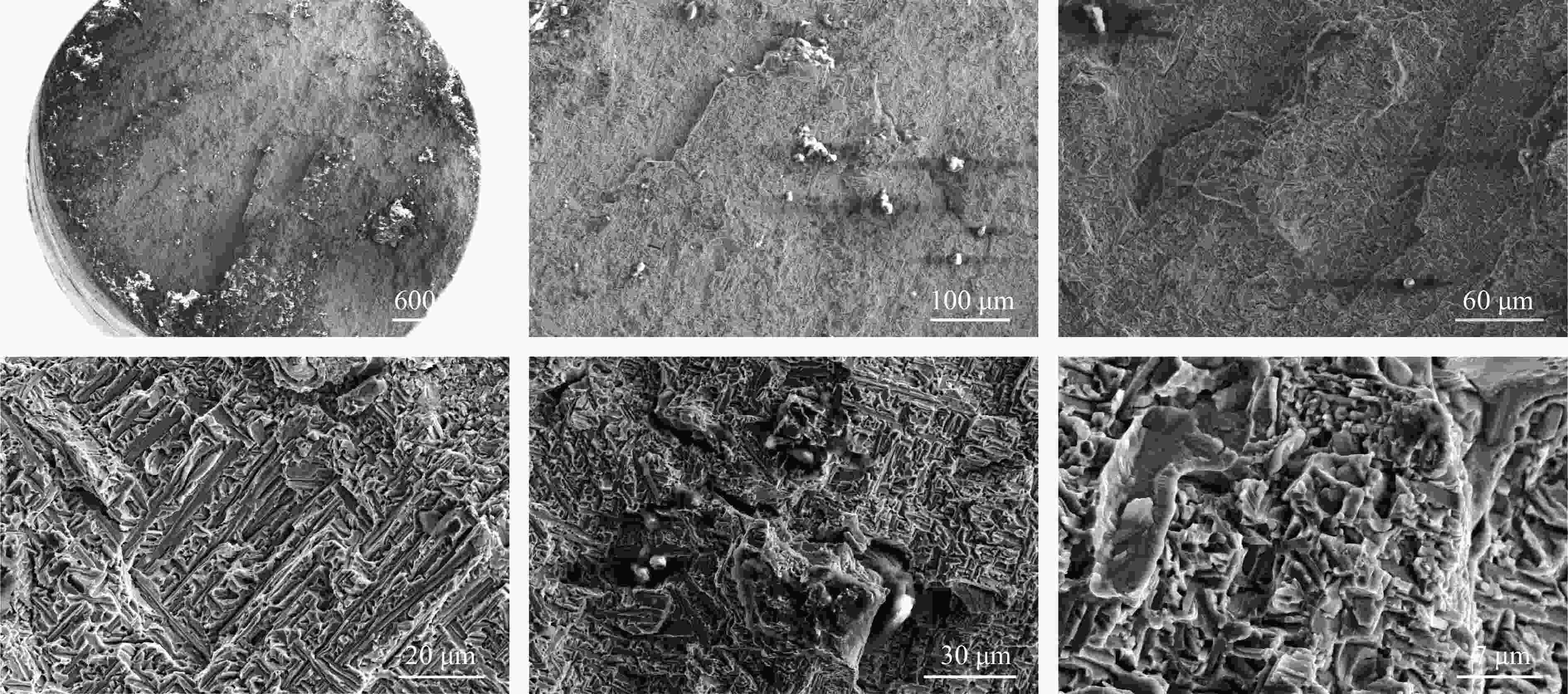

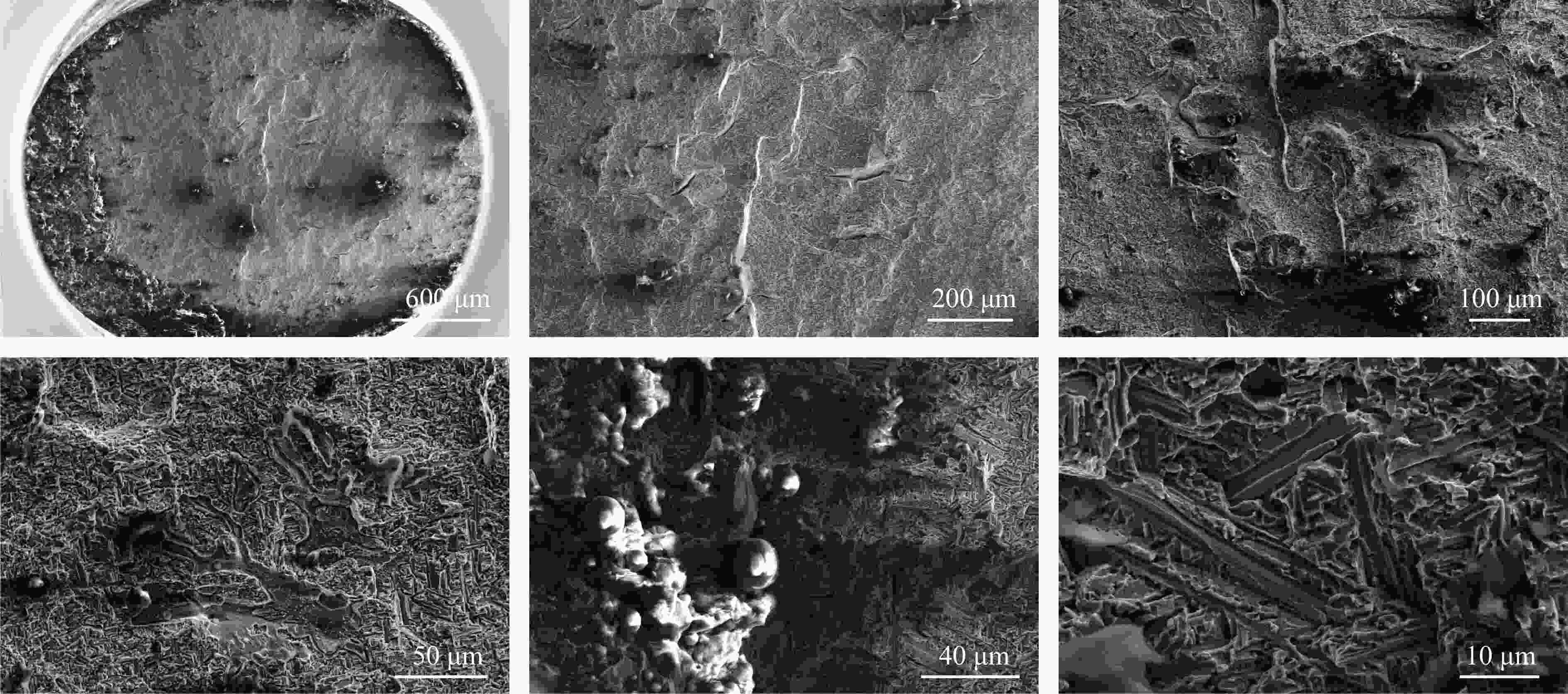

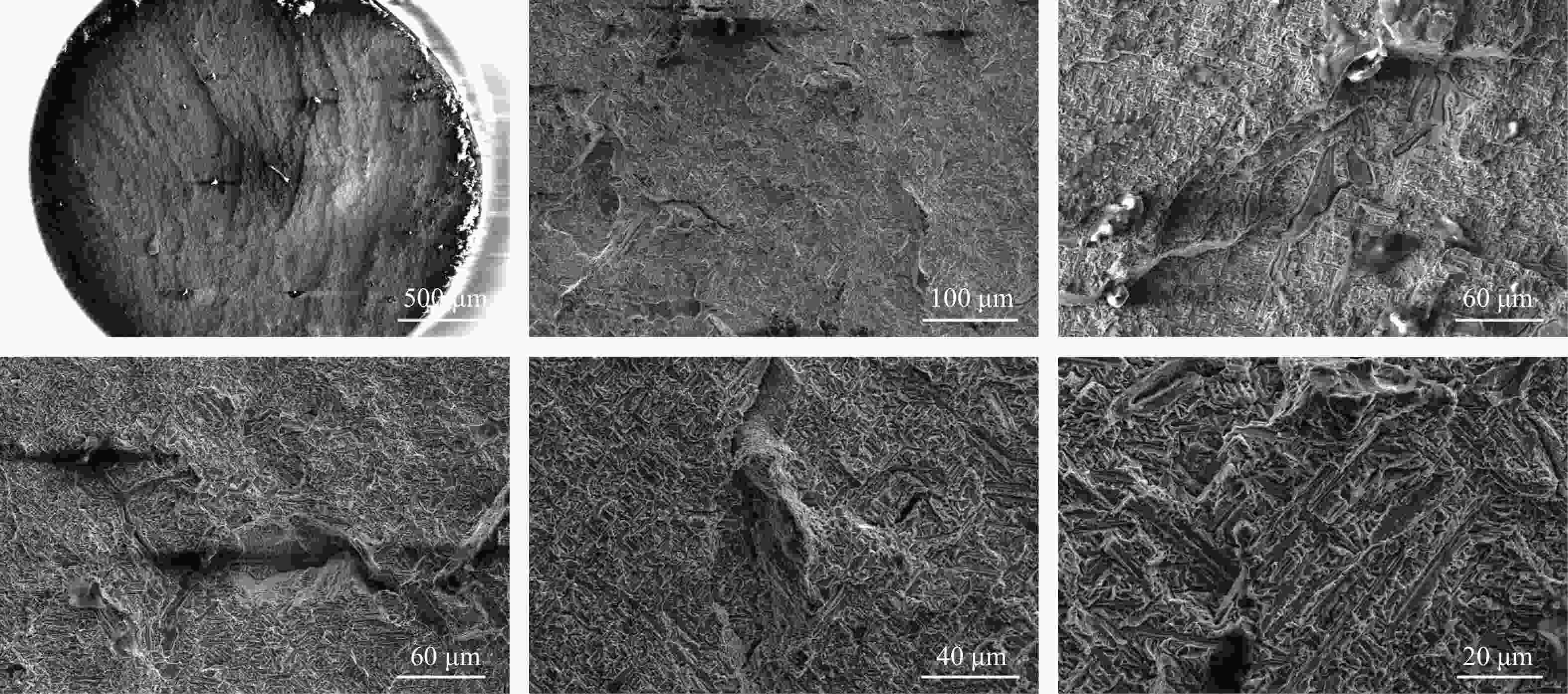

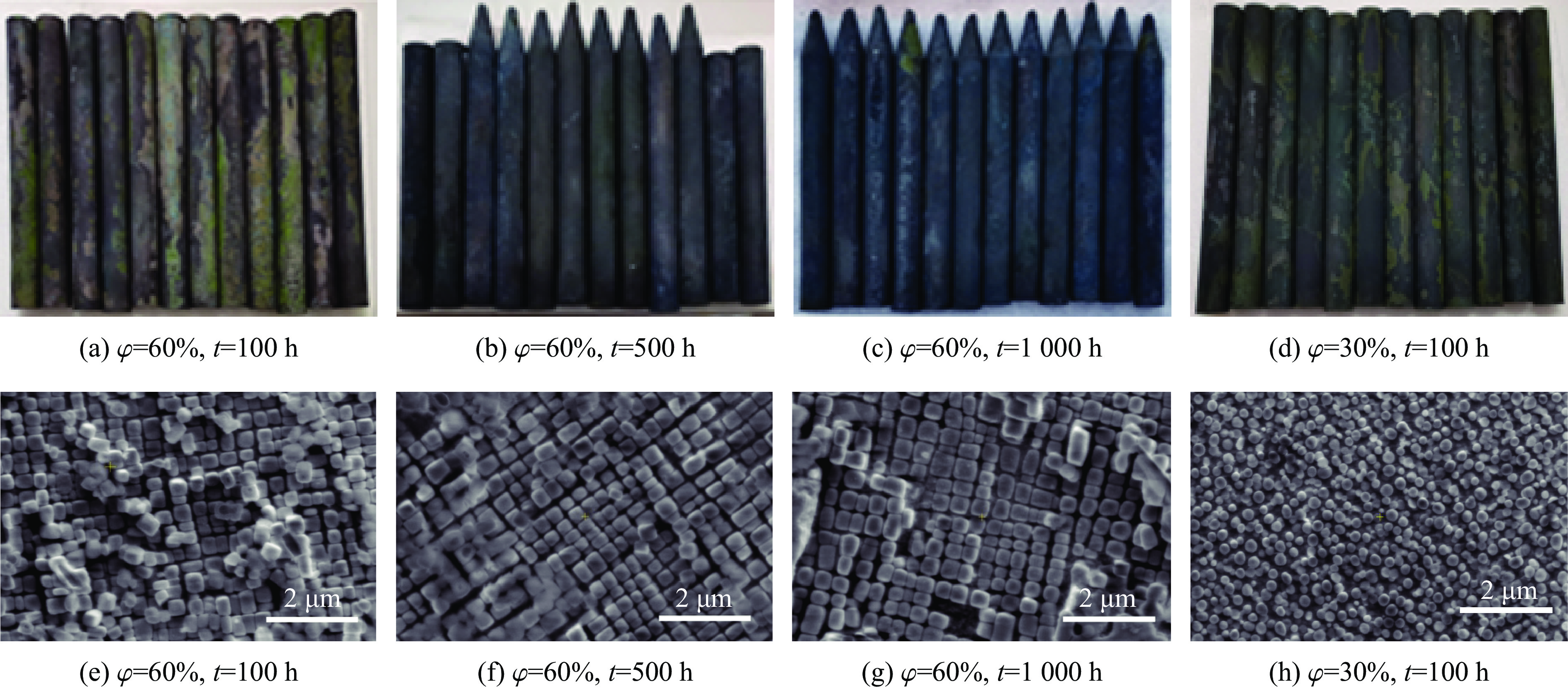

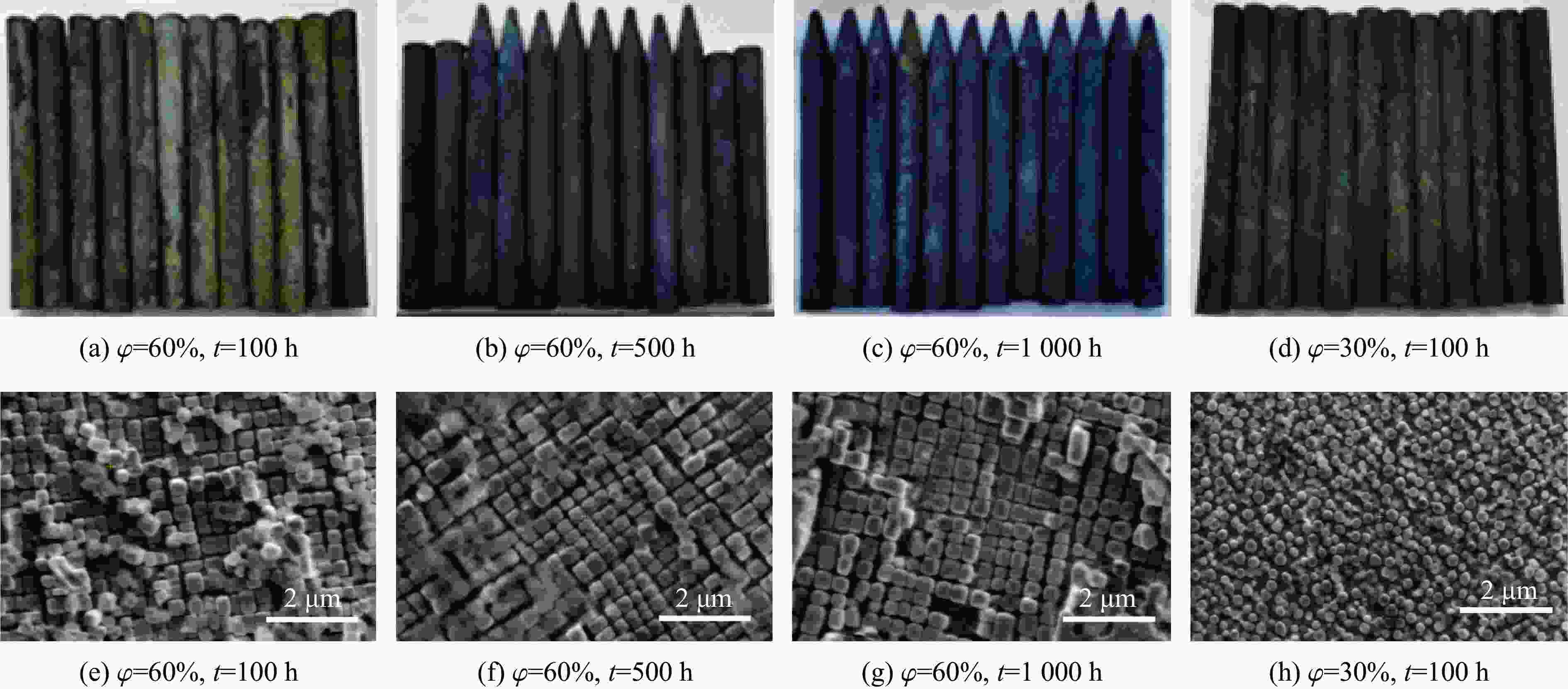

摘要: 为促进装备热端部件在动态载荷下服役性能的评估和预测,针对不同微结构特征的镍基单晶高温合金开展了一系列分离式霍普金森拉杆(split Hopkinson tensile bar,SHTB)试验和扫描电镜表征,系统研究了沉淀相体积分数、相粗化程度、应变率和加载角度等因素对合金动态拉伸性能的影响。结果表明:微结构和应变率对镍基单晶高温合金动态拉伸性能具有显著影响,且相粗化后合金动态拉伸性能呈现出复杂的各向异性特征。总体而言,合金屈服强度和抗拉强度呈正相关关系,随着沉淀颗粒体积分数或应变率的增大,试件逐渐表现出脆性断裂特征,且其屈服强度和抗拉强度逐渐增大,而极限伸长率则逐渐减小;其次,时效处理所导致的颗粒相粗化对合金强度有着明显的弱化作用,而对极限伸长率起到强化效果,即相粗化后合金试样表现出混合断裂特征,随着相粗化程度增加,其屈服强度和抗拉强度逐渐降低,而极限伸长率逐渐增大。此外,在55°加载角度时,合金强度和极限伸长率均低于0°加载角度下的情况;然而,在应变率较高时,对于体积分数和相粗化程度均较大的合金,其极限伸长率在55°加载角度时取得最大值。相关变化同断口纤维区面积和解理面特征密切相关,材料微结构和加载条件的改变将影响材料内部微裂纹形核和运动特性,进而影响合金变形特征和动态拉伸性能。研究结果可为提高镍基单晶高温合金性能和优化热端部件结构设计提供理论支持和数据支撑。Abstract: To enhance the evaluation and prediction for service performance of hot-end components in equipment under the dynamic loads, a comprehensive study was conducted on Ni-based single crystal superalloys with diverse microstructures. This study involved a series of split Hopkinson tensile bar (SHTB) tests and related scanning electron microscopy (SEM) characterization. The influences of various factors, including the volume fraction of precipitation particles, phase coarsening, loading angle and strain rate, etc., on the dynamic tensile properties of superalloys were systematically investigated. Moreover, the relationships between these factors and the fracture morphology of alloys were thoroughly discussed. The results indicated that the microstructural features and strain rate have significant effect on the dynamic tensile properties of alloys, leading to a complex anisotropic characteristic occur in their dynamic tensile behaviors after phase coarsening. In general, the yielding strength displays a positive relationship with the tensile strength. As the volume fraction of precipitation particles or the strain rate increases, the alloy specimen gradually exhibits brittle fracture characteristics, with an increase in strength and a decrease in elongation. Besides, phase coarsening derived from the aging treatment significantly weakens the strength of alloys while enhancing their elongation, i.e., the specimens progressively show mixed fracture characteristics after phase coarsening, and both yielding strength and tensile ultimate strength gradually decrease while the elongation increases with the degree of phase coarsening. Furthermore, the strength and elongation of alloys at the loading angle of 55° are lower than those at the loading angle of 0°. Comparatively, for alloys with high volume fraction of precipitation particles and high degree of phase coarsening, the elongation achieves the maximum value at the loading angle of 55°. The corresponding variation characteristics are closely related to the fibrous zone and the cleavage plane on the fracture surface. Meanwhile, the variations in microstructure of materials and loading conditions affect the microcrack nucleation and fracture mode within the specimen, leading to various dynamic tensile properties in Ni-based single crystal superalloys. The present research and related results provide theoretical guidance and experimental data support for improving the mechanical performance of Ni-based single crystal superalloys and optimizing the design of hot-end components.

-

表 1 镍基单晶高温合金的化学成分

Table 1. Chemical composition of Ni-based single crystal superalloys

φ=30% φ=60% w(C) /% w(Al)/% w(Cr)/% w(Co)/% w(Ta)/% w(W)/% w(C)/% w(Al)/% w(Cr)/% w(Co)/% w(Ta)/% w(W)/% 0.021 4.00 18.63 13.91 3.51 4.04 0.014 6.16 18.58 9.49 5.17 4.00 -

[1] PAN X Y, JIA C L, JI Z Y, et al. Microstructural evolution and dynamic recrystallization mechanism of a heavily-alloyed Ni-based superalloy during hot extrusion [J]. Journal of Materials Research and Technology, 2023, 23: 4922–4937. DOI: 10.1016/j.jmrt.2023.02.118. [2] GERANMAYEH A, MALEKAN M, FORGHANI F, et al. Microstructural and mechanical investigations on the heat treatment rejuvenation of a long-term service-exposed GTD-111 Ni-based superalloy [J]. Materials Science and Engineering: A, 2023, 862: 144381. DOI: 10.1016/j.msea.2022.144381. [3] 罗宁, 李晓杰, 孙贵磊, 等. 石墨包覆纳米镍颗粒的结构及磁性能的表征 [J]. 爆炸与冲击, 2011, 31(4): 433–438. DOI: 10.11883/1001-1455(2011)04-0433-06.LUO N, LI X J, SUN G L, et al. Synthesis, morphology and magnetic properties of graphite-encapsulated nickel nanoparticles [J]. Explosion and Shock Waves, 2011, 31(4): 433–438. DOI: 10.11883/1001-1455(2011)04-0433-06. [4] WANG K G, WANG G Q, GAMSJÄGER E, et al. A comparison of theory and simulation with microgravity experiments on phase coarsening [J]. Acta Materialia, 2021, 221: 117402. DOI: 10.1016/j.actamat.2021.117402. [5] REN P R, HUANG W Q, YANG X G, et al. A modified constitutive model considering microstructure degradation of Ni-based superalloys and its application to microstructural damage calculation [J]. Journal of Alloys and Compounds, 2021, 882: 160605. DOI: 10.1016/j.jallcom.2021.160605. [6] XIE G L, GAO Z F, YU X T, et al. Tension/compression asymmetry of quasi – Static and dynamic mechanical properties in a face centered cubic Ni-W-Co ternary alloy [J]. Journal of Materials Research and Technology, 2022, 18: 2797–2807. DOI: 10.1016/j.jmrt.2022.03.127. [7] YAN H, WANG K G, GLICKSMAN M E. Microstructural coarsening in dense binary systems [J]. Acta Materialia, 2022, 233: 117964. DOI: 10.1016/j.actamat.2022.117964. [8] WANG K G. Analytical and numerical modeling of phase coarsening in dense binary systems [J]. Acta Materialia, 2023, 260: 119301. DOI: 10.1016/j.actamat.2023.119301. [9] LIN Y C, NONG F Q, CHEN X M, et al. Microstructural evolution and constitutive models to predict hot deformation behaviors of a nickel-based superalloy [J]. Vacuum, 2017, 137: 104–114. DOI: 10.1016/j.vacuum.2016.12.022. [10] XU Y C, GONG Y D, ZHANG W J, et al. Microstructure evolution and dynamic recrystallization mechanism induced by grinding of Ni-based single crystal superalloy [J]. Journal of Materials Processing Technology, 2022, 310: 117784. DOI: 10.1016/j.jmatprotec.2022.117784. [11] MEYERS M A, CHAWLA K K. Mechanical behavior of materials [M]. 2nd ed. Cambridge: Cambridge University Press, 2008. [12] JALADURGAM N R, KABRA S, COLLIANDER M H. Macro- and micro-mechanical behaviour of a γ′ strengthened Ni-based superalloy at cryogenic temperatures [J]. Materials & Design, 2021, 209: 109954. DOI: 10.1016/j.matdes.2021.109954. [13] QU Z H, ZHANG P X, LAI Y J, et al. Influence of powder particle size on the microstructure of a hot isostatically pressed superalloy [J]. Journal of Materials Research and Technology, 2022, 16: 1283–1292. DOI: 10.1016/j.jmrt.2021.12.081. [14] DUAN J X, AN T, GU Y, et al. Effect of γ′ phase and microtwins on the microstructural evolution and mechanical properties of a novel Ni-Co base superalloy [J]. Materials Science and Engineering: A, 2023, 865: 144323. DOI: 10.1016/j.msea.2022.144323. [15] TSUKADA Y, MURATA Y, KOYAMA T, et al. Creep deformation and rafting in nickel-based superalloys simulated by the phase-field method using classical flow and creep theories [J]. Acta Materialia, 2011, 59(16): 6378–6386. DOI: 10.1016/j.actamat.2011.06.050. [16] SHISHVAN S S, MCMEEKING R M, POLLOCK T M, et al. Discrete dislocation plasticity analysis of the effect of interfacial diffusion on the creep response of Ni single-crystal superalloys [J]. Acta Materialia, 2017, 135: 188–200. DOI: 10.1016/j.actamat.2017.06.026. [17] HASAN M H, SOI C, MIRZAJAVADKHAN A, et al. Experimental study and computer simulation of fracture toughness of Ni base superalloy using CT specimen [J]. International Journal of Engineering Materials and Manufacture, 2018, 3(4): 224–236. DOI: 10.26776/ijemm.03.04.2018.07. [18] LIU H, ZHAO X B, YUAN Y, et al. Influence of thermal exposure on microstructural stability and tensile properties of a new Ni-base superalloy [J]. Journal of Materials Research and Technology, 2022, 21: 4462–4472. DOI: 10.1016/j.jmrt.2022.11.050. [19] LIU Z C, NIE Z H, NING X J, et al. Mechanical response and microstructural evolution of Ni-27 W alloys during uniaxial tension [J]. Journal of Alloys and Compounds, 2022, 891: 161972. DOI: 10.1016/j.jallcom.2021.161972. [20] PAN J, WANG C D, WANG Z X, et al. Microstructure characteristics and properties of a novel Ni-based alloy for thermal neutron and gamma ray co-shielding [J]. Materials Characterization, 2024, 210: 113840. DOI: 10.1016/j.matchar.2024.113840. [21] HUO J J, SHI Q Y, TIN S, et al. Improvement of creep resistance at 950 °C and 400 MPa in Ru-containing single-crystal superalloys with a high level of Co addition [J]. Metallurgical and Materials Transactions A, 2018, 49(11): 5298–5308. DOI: 10.1007/s11661-018-4842-6. [22] CAO P S, WANG H, RU Y, et al. Microstructure and creep properties of Ni-based single-crystal superalloys with Mo/Al addition at 760 °C/850 MPa [J]. Rare Metals, 2023, 42(11): 3806–3813. DOI: 10.1007/s12598-018-1094-y. [23] FIROZ R, BASANTIA S K, KHUTIA N, et al. Effect of microstructural constituents on mechanical properties and fracture toughness of Inconel 718 with anomalous deformation behavior at 650°C [J]. Journal of Alloys and Compounds, 2020, 845: 156276. DOI: 10.1016/j.jallcom.2020.156276. [24] JI D W, HU X M, ZHAO Z P, et al. Stress rupture life prediction method for notched specimens based on minimum average von mises equivalent stress [J]. Metals, 2022, 12(1): 68. DOI: 10.3390/met12010068. [25] WEN S M, LIU Z C, MI D, et al. Revealing the fatigue crack propagation mechanism of a Ni-based superalloy electron beam welded joint through in-situ SEM observation [J]. International Journal of Fatigue, 2022, 162: 106955. DOI: 10.1016/j.ijfatigue.2022.106955. [26] ZHANG L L, YANG Q, CHEN J Y, et al. Phase evolution in Ni-based superalloy K439B during thermal process [J]. Materials Characterization, 2024, 216: 114243. DOI: 10.1016/j.matchar.2024.114243. [27] 崔凯波, 王向东, 熊超, 等. 火炮驻退机节制环耐磨涂层组织及抗冲蚀性能 [J]. 爆炸与冲击, 2018, 38(5): 1013–1022. DOI: 10.11883/bzycj-2017-0039.CUI K B, WANG X D, XIONG C, et al. Microstructure and erosive resistance of wear-resistant coating on the throttling ring of gun recoil brake [J]. Explosion and Shock Waves, 2018, 38(5): 1013–1022. DOI: 10.11883/bzycj-2017-0039. [28] 张顺咏, 李继承. 镍基高温合金沉淀相粗化之后的硬度退化及其各向异性特征 [J]. 中国有色金属学报, 2022, 32(10): 3030–3047. DOI: 10.11817/j.ysxb.1004.0609.2021-42811.ZHANG S Y, LI J C. Degradation and anisotropy characteristics of hardness in Ni-base superalloys after precipitation phase coarsening [J]. The Chinese Journal of Nonferrous Metals, 2022, 32(10): 3030–3047. DOI: 10.11817/j.ysxb.1004.0609.2021-42811. [29] ZHANG S Y, ZHANG B, CHEN Y D, et al. Influence of microstructural and loading direction on the ductility and anisotropy of Ni-based superalloys [J]. Materials & Design, 2024, 246: 113342. DOI: 10.1016/j.matdes.2024.113342. [30] ZHANG S Y, ZHAO J F, LIANG Y X, et al. Degradation and anisotropy characteristics of fracture toughness in Ni-based superalloys after phase coarsening [J]. Materials Science and Engineering: A, 2024, 889: 145852. DOI: 10.1016/j.msea.2023.145852. [31] YU Y C, RU Y, SHANG Y, et al. Effect of applied stress on γ′-rafting behavior in a Ni-based single-crystal superalloy: experiments and finite element analysis [J]. Journal of Iron and Steel Research International, 2019, 26(3): 259–267. DOI: 10.1007/s42243-018-0076-5. [32] LIU X, LIU Z L, ZHANG L T, et al. Increased tensile strength and elongation of the Ni-Fe based polycrystalline cast superalloy via the trace addition of TiC nanoparticles [J]. Materials Science and Engineering: A, 2021, 827: 141988. DOI: 10.1016/j.msea.2021.141988. [33] YIN Q, LIAN Y D, WEN Z X, et al. Atomic simulation of the effect of orientation on tensile/compressive properties in nickel-based single crystal superalloys [J]. Journal of Alloys and Compounds, 2022, 893: 162210. DOI: 10.1016/j.jallcom.2021.162210. [34] ZHANG X Y, LIANG Y F, YI F, et al. Anisotropy in microstructure and mechanical properties of additively manufactured Ni-based GH4099 alloy [J]. Journal of Materials Research and Technology, 2023, 26: 6552–6564. DOI: 10.1016/j.jmrt.2023.09.038. [35] DONG H C, CHEN Y H, WU D Y, et al. Molecular dynamics simulation of tensile properties of nickel-based superalloy with temperature and Co [J]. Materials Chemistry and Physics, 2024, 326: 129635. DOI: 10.1016/j.matchemphys.2024.129635. [36] REN Q, CHEN J T, LU J X, et al. In-situ study of microstructure and mechanical properties of GH3536 alloy manufactured by selective laser melting at 750°C [J]. Materials Science and Engineering: A, 2024, 900: 146452. DOI: 10.1016/j.msea.2024.146452. [37] 吴宇, 陈冰清, 刘伟, 等. 增材制造镍基高温合金在航空发动机与燃气轮机中的研究应用进展 [J]. 航空材料学报, 2024, 44(1): 31–45. DOI: 10.11868/j.issn.1005-5053.2023.000211.WU Y, CHEN B Q, LIU W, et al. Progress in research and applications of additively manufactured nickel-based superalloy in aero-engines and gas turbines [J]. Journal of Aeronautical Materials, 2024, 44(1): 31–45. DOI: 10.11868/j.issn.1005-5053.2023.000211. [38] LI J C, WANG K G. Effect of phase coarsening on the mechanical properties of alloys: Ⅰ. Numerical simulations [J]. Engineering Fracture Mechanics, 2018, 201: 229–245. DOI: 10.1016/j.engfracmech.2018.06.028. [39] YUAN K B, GUO W G, LI D W, et al. Influence of heat treatments on plastic flow of laser deposited Inconel 718: Testing and microstructural based constitutive modeling [J]. International Journal of Plasticity, 2021, 136: 102865. DOI: 10.1016/j.ijplas.2020.102865. [40] 史亚辉, 杨璞, 邓志方, 等. 螺栓连接结构冲击载荷传递特性及冲击响应行为研究进展综述 [J]. 包装工程, 2024, 45(19): 1–28. DOI: 10.19554/j.cnki.1001-3563.2024.19.001.SHI Y H, YANG P, DENG Z F, et al. Research advance on impact load transfer characteristics and impact response behavior of bolted connection structures [J]. Packaging Engineering, 2024, 45(19): 1–28. DOI: 10.19554/j.cnki.1001-3563.2024.19.001. [41] ITURBE A, GIRAUD E, HORMAETXE E, et al. Mechanical characterization and modelling of Inconel 718 material behavior for machining process assessment [J]. Materials Science and Engineering: A, 2017, 682: 441–453. DOI: 10.1016/j.msea.2016.11.054. [42] ZHOU S Y, HU M H, LI C, et al. Microstructure-performance relationships in Ni-based superalloy with coprecipitation of γ' and γ'' phases [J]. Materials Science and Engineering: A, 2022, 855: 143954. DOI: 10.1016/j.msea.2022.143954. [43] JIANG W, XU P W, LI Y Y, et al. Effect of a gradient structure on the mechanical performance of Inconel 718 Ni-based superalloy at elevated temperatures [J]. Journal of Materials Research and Technology, 2023, 23: 2031–2042. DOI: 10.1016/j.jmrt.2023.01.121. -

下载:

下载: