On penetration characteristics of three typical shaped chargesinto double-layer spaced targets in water

-

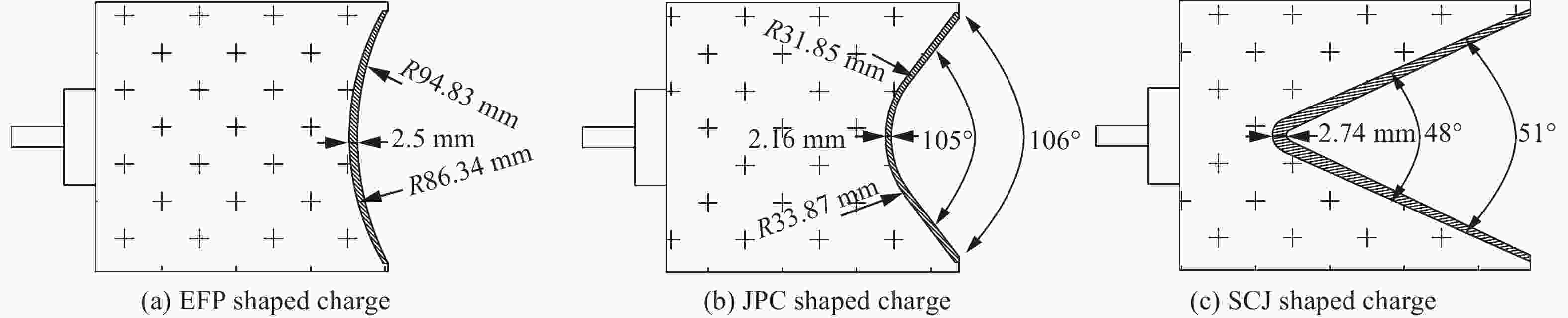

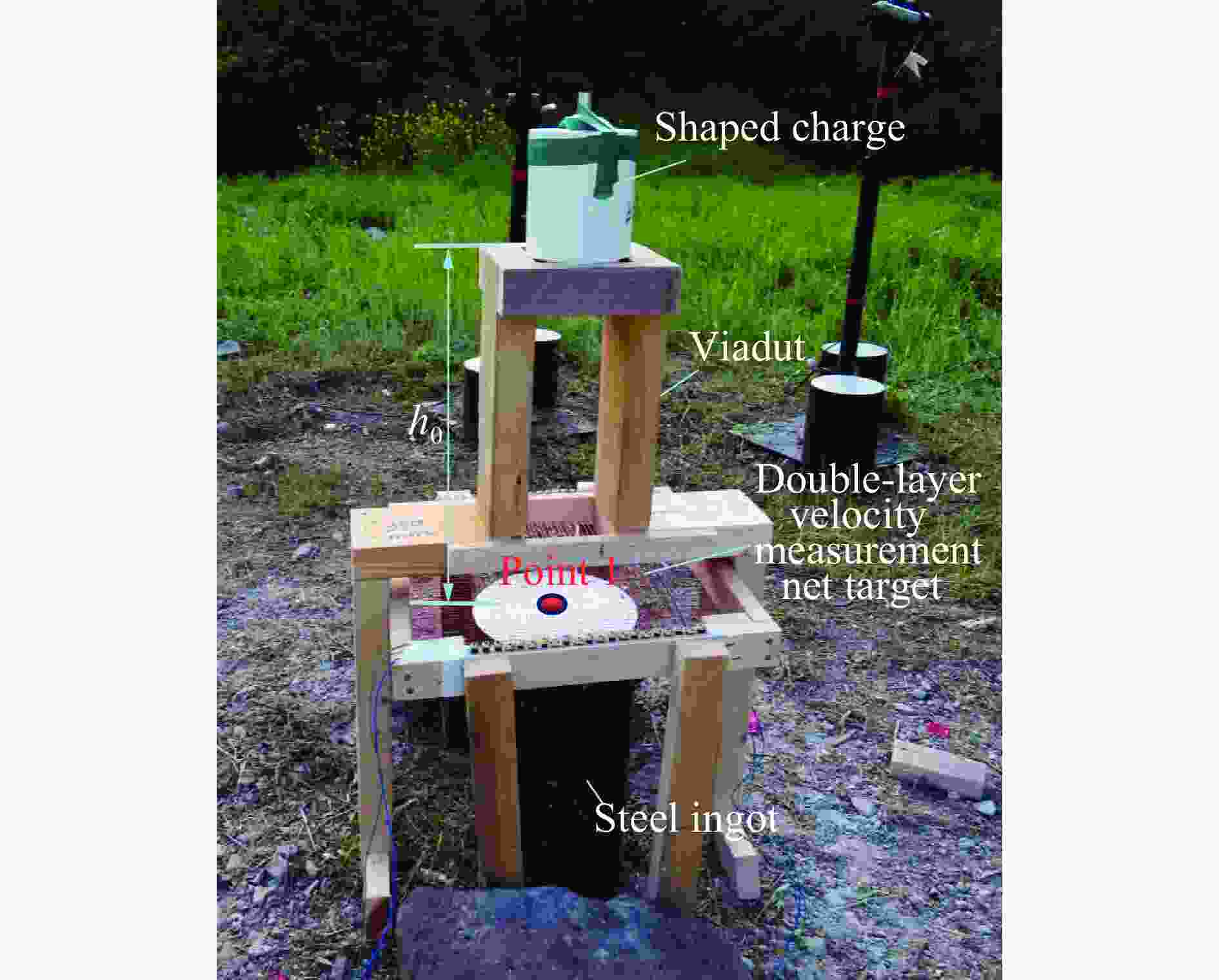

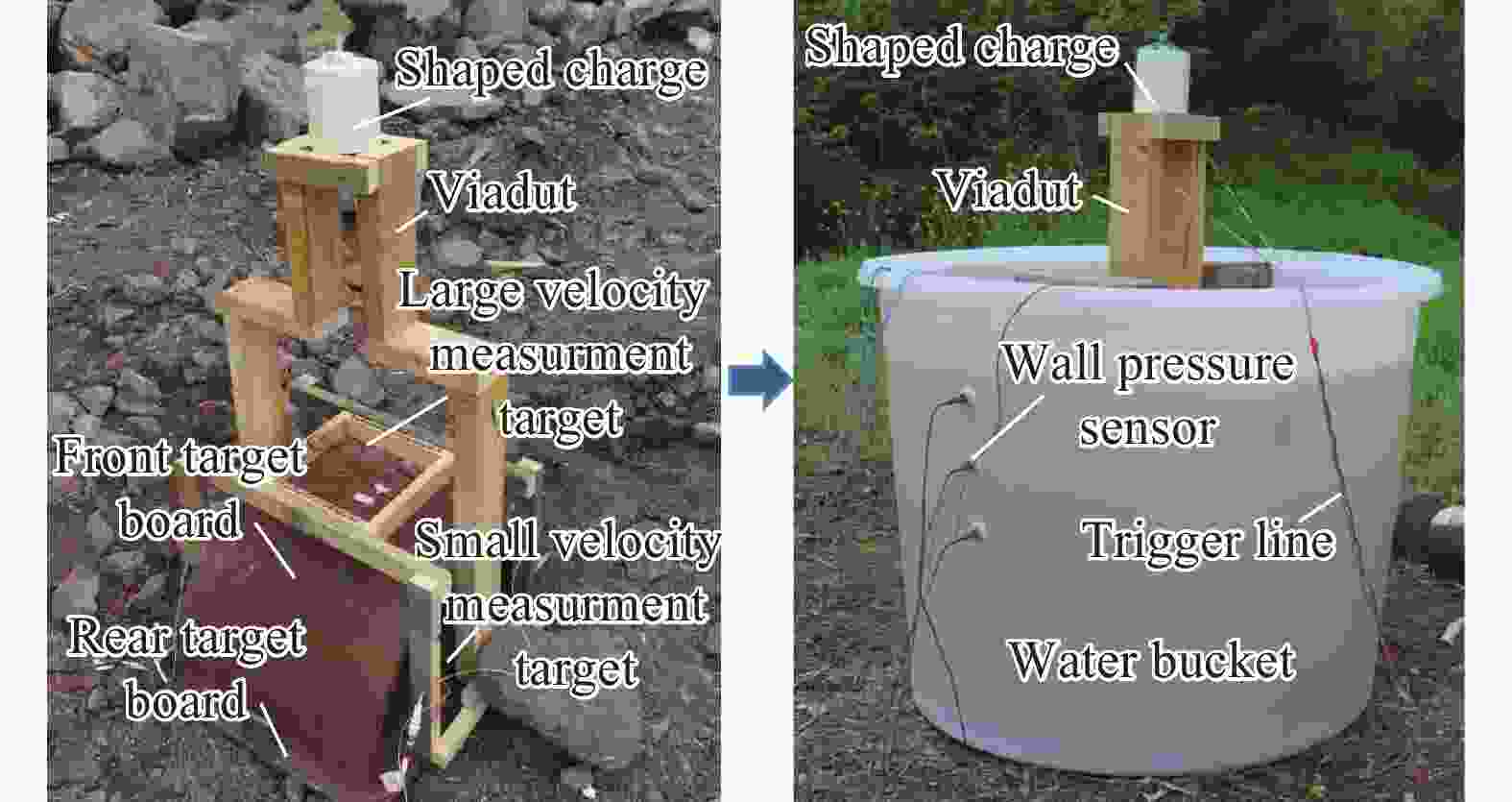

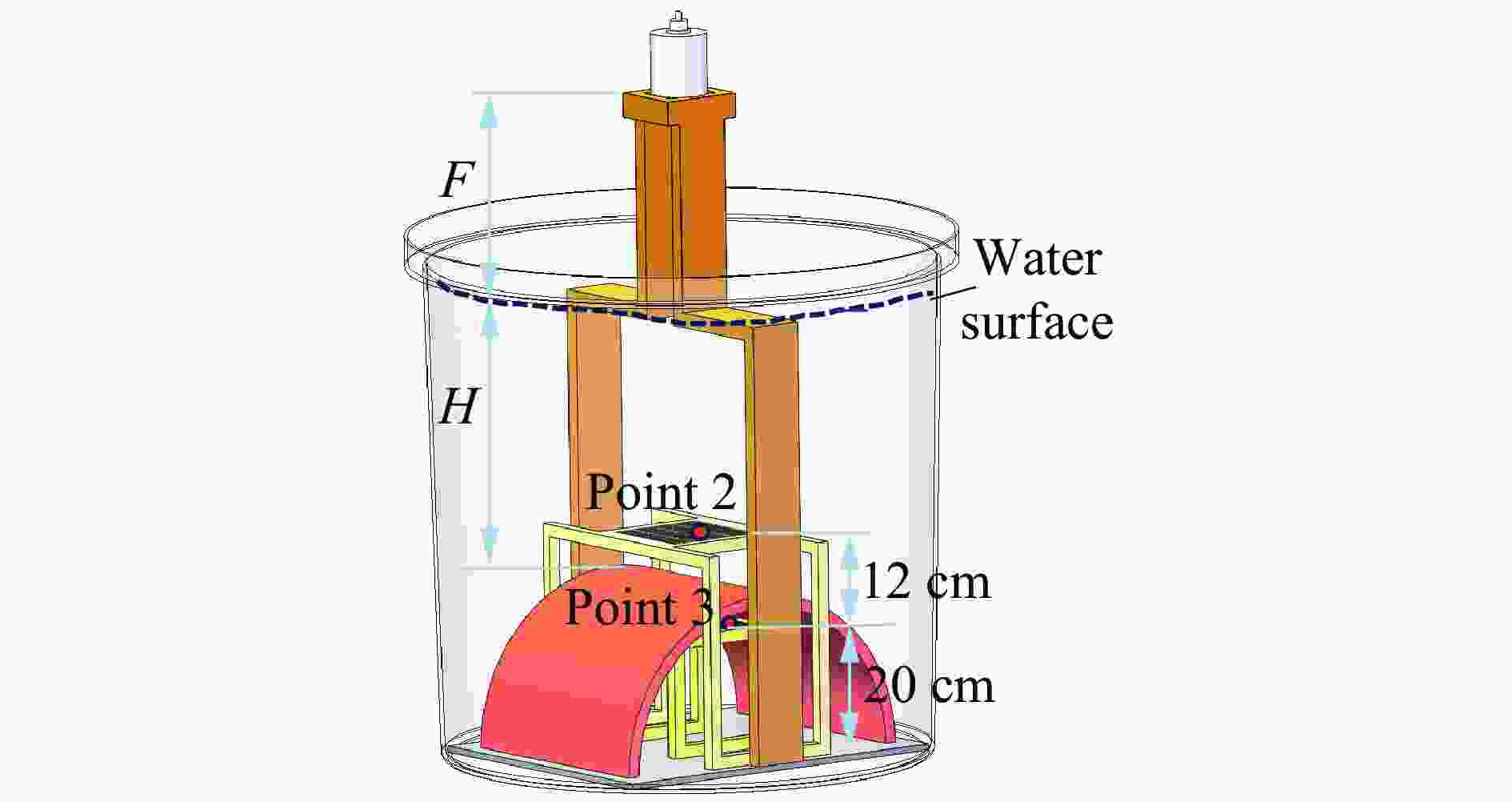

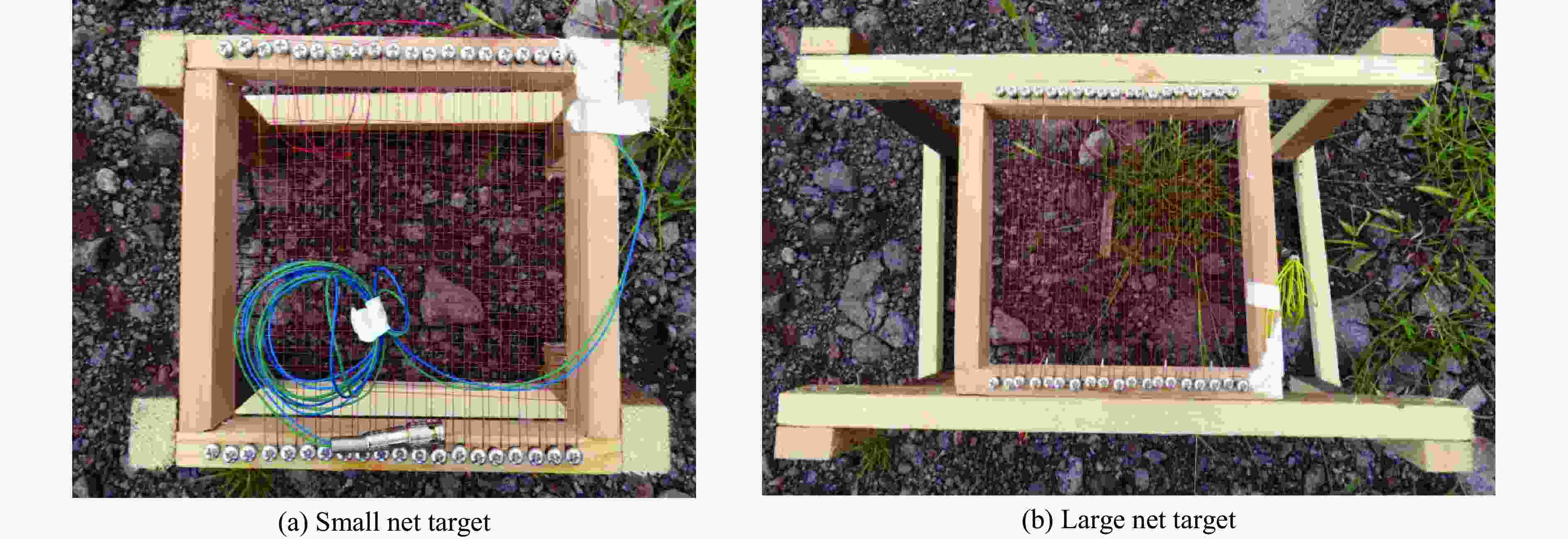

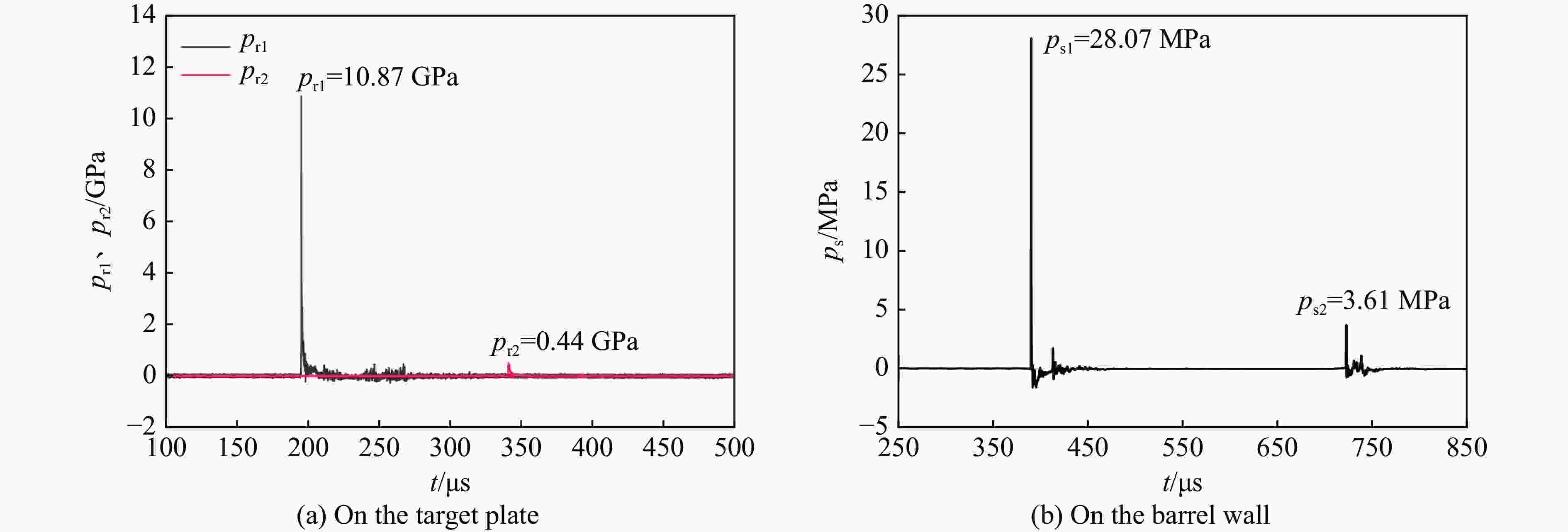

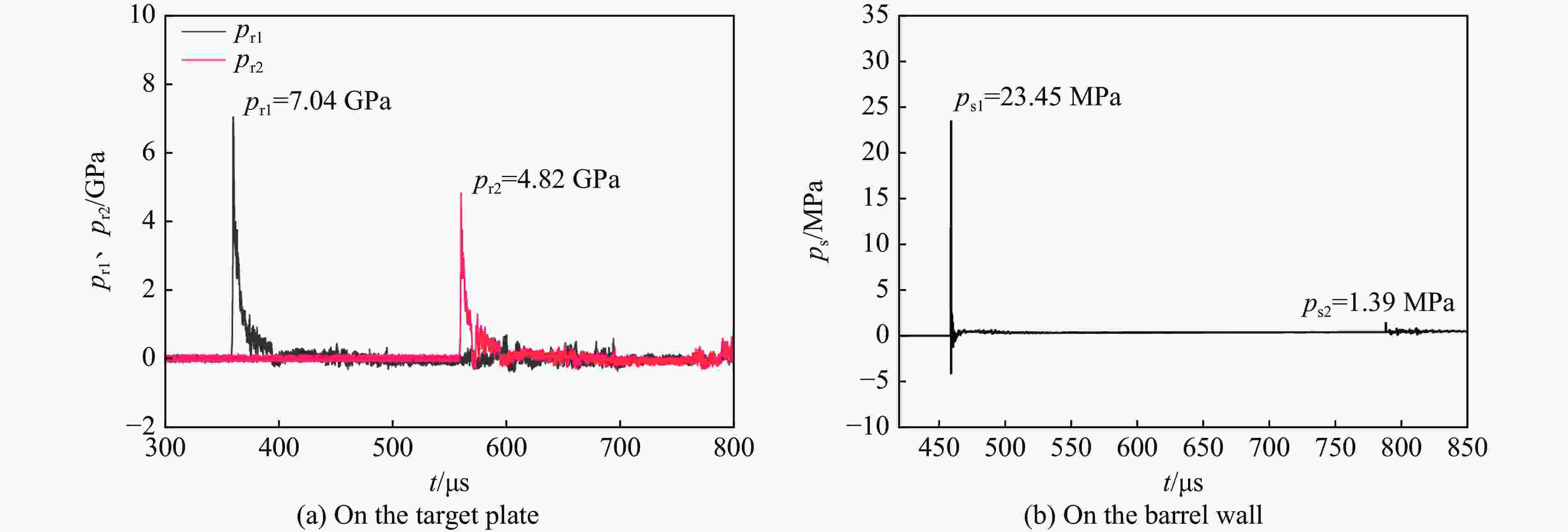

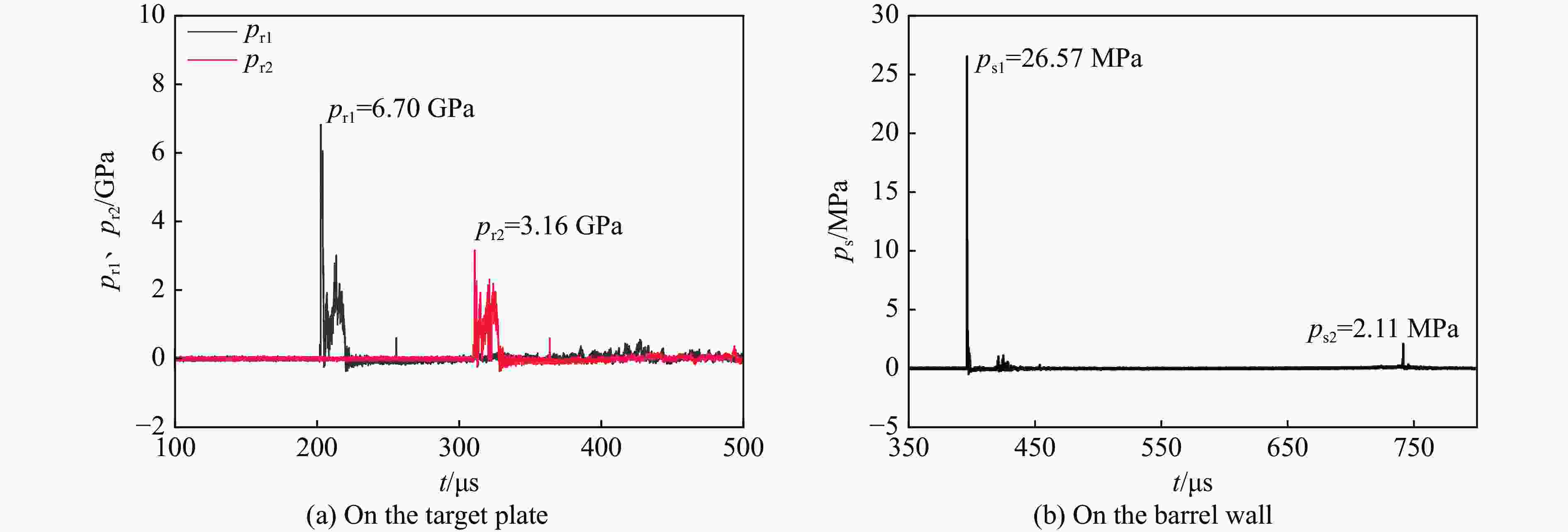

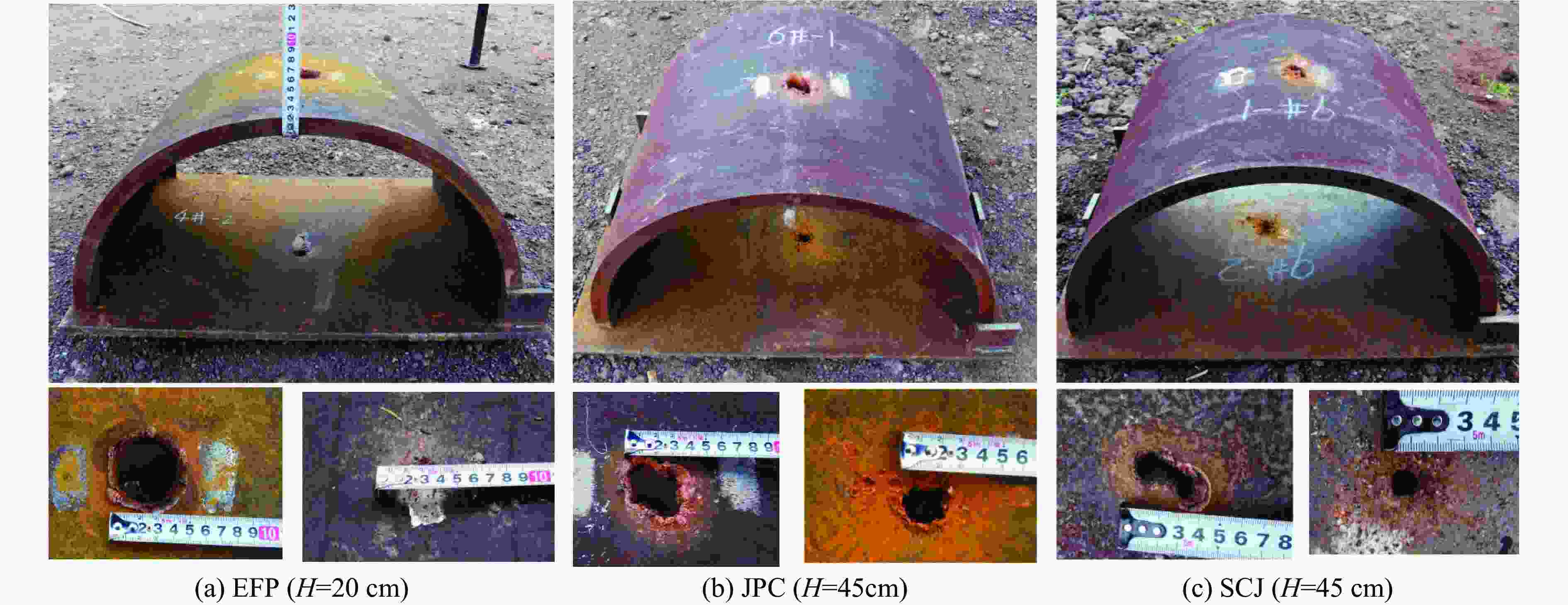

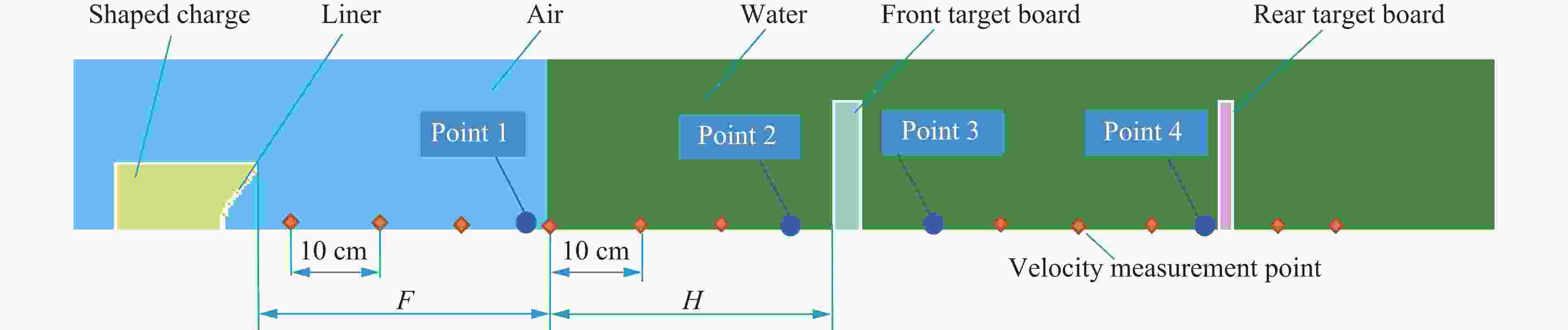

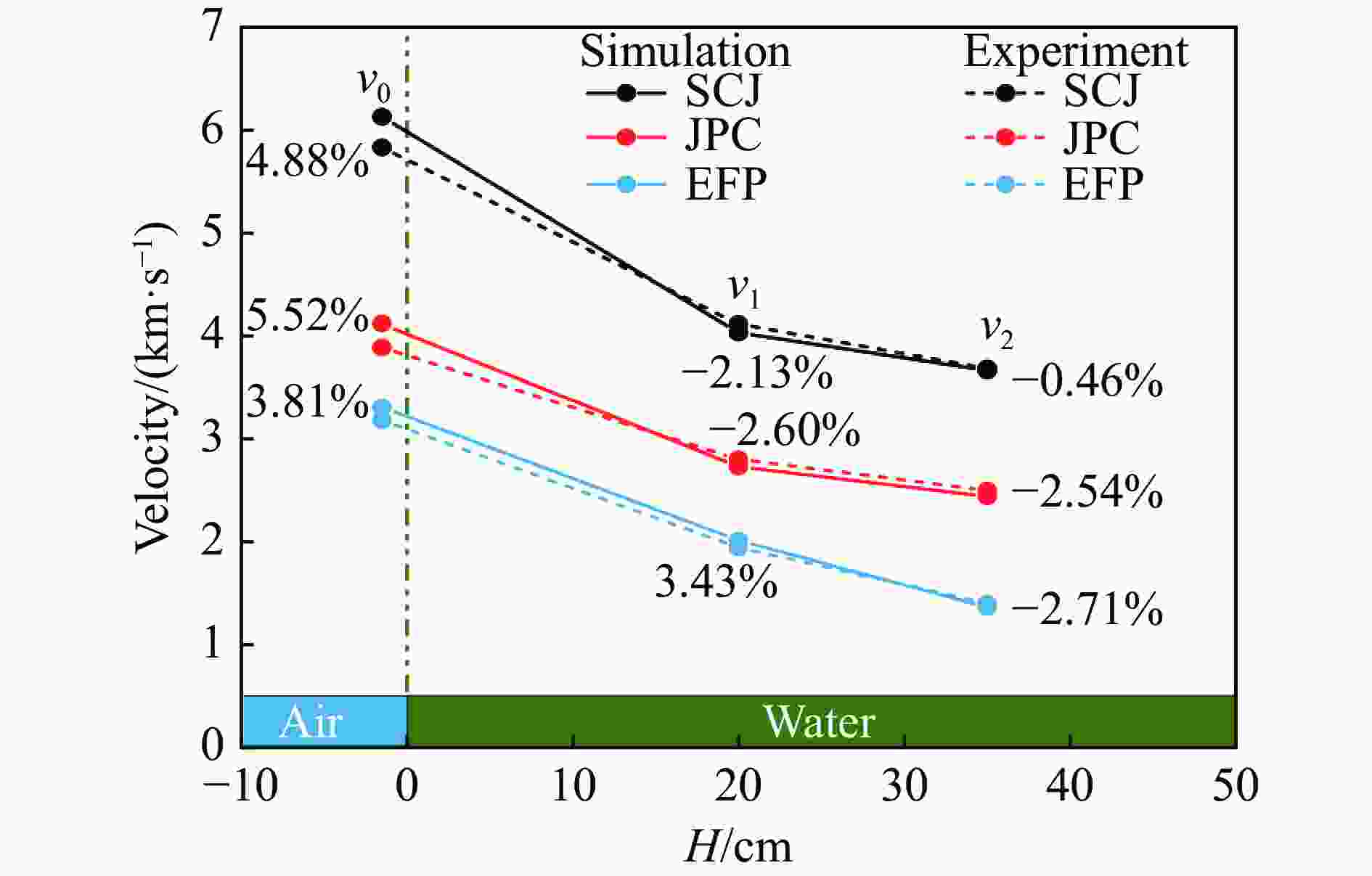

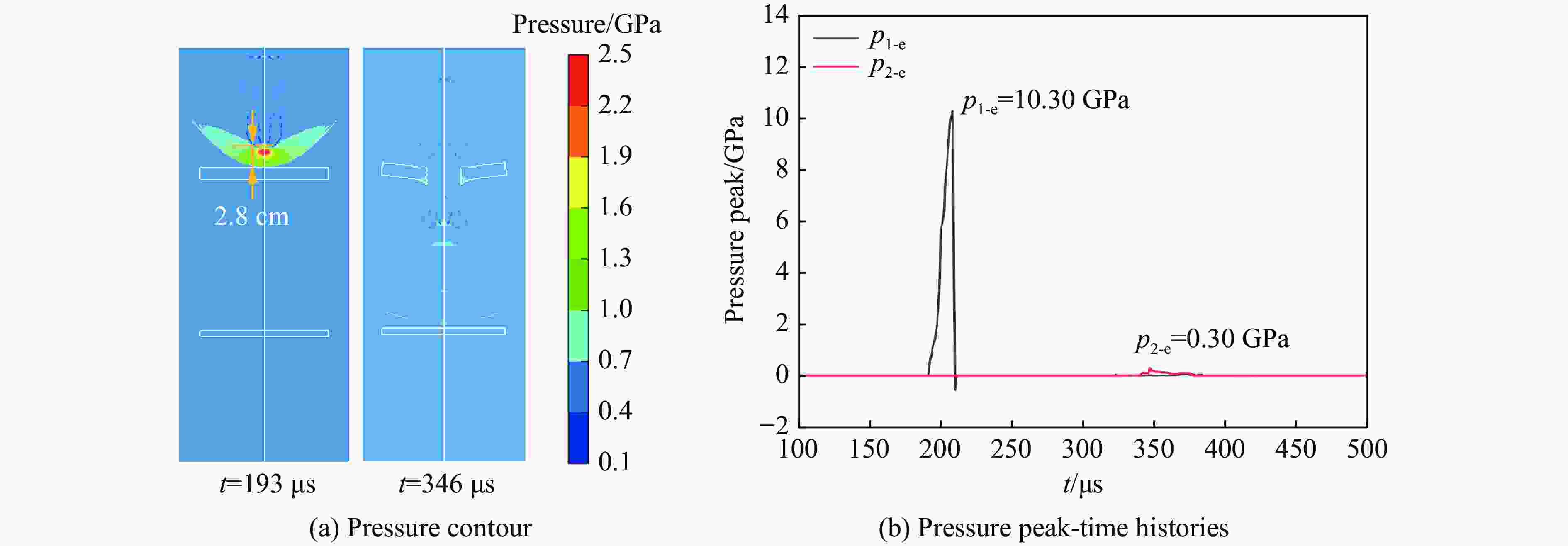

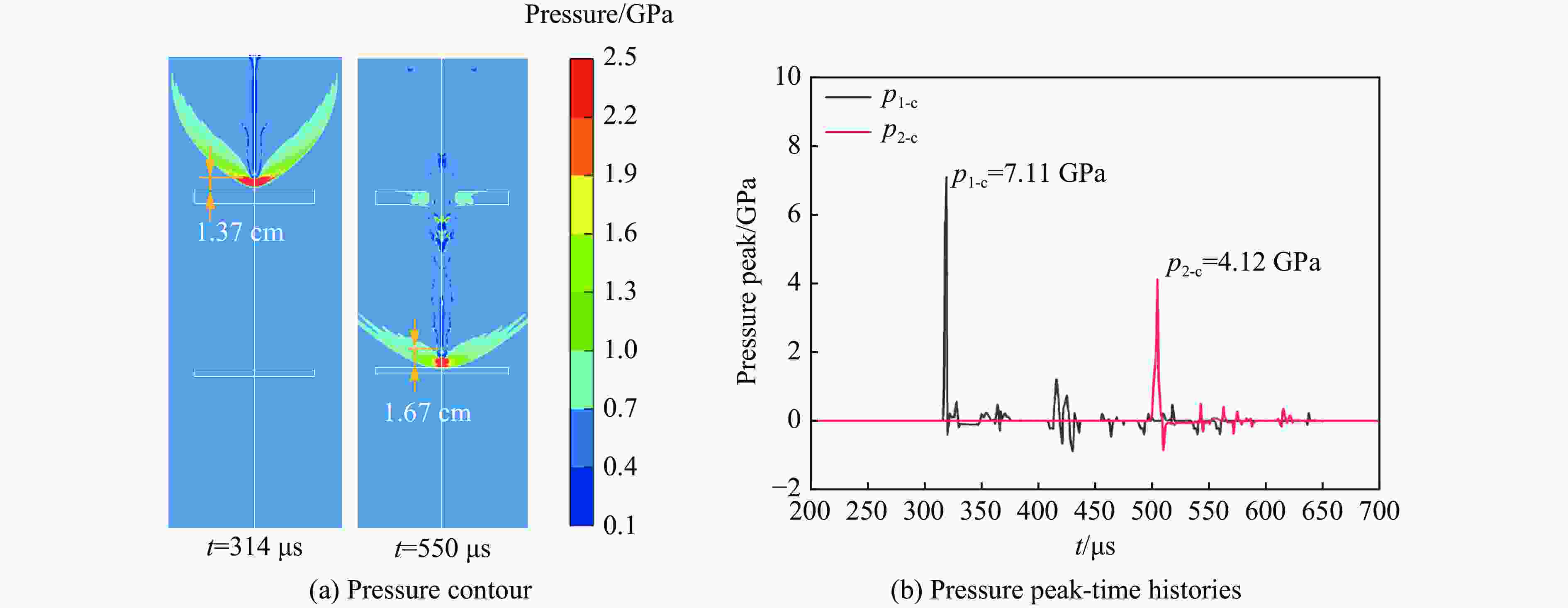

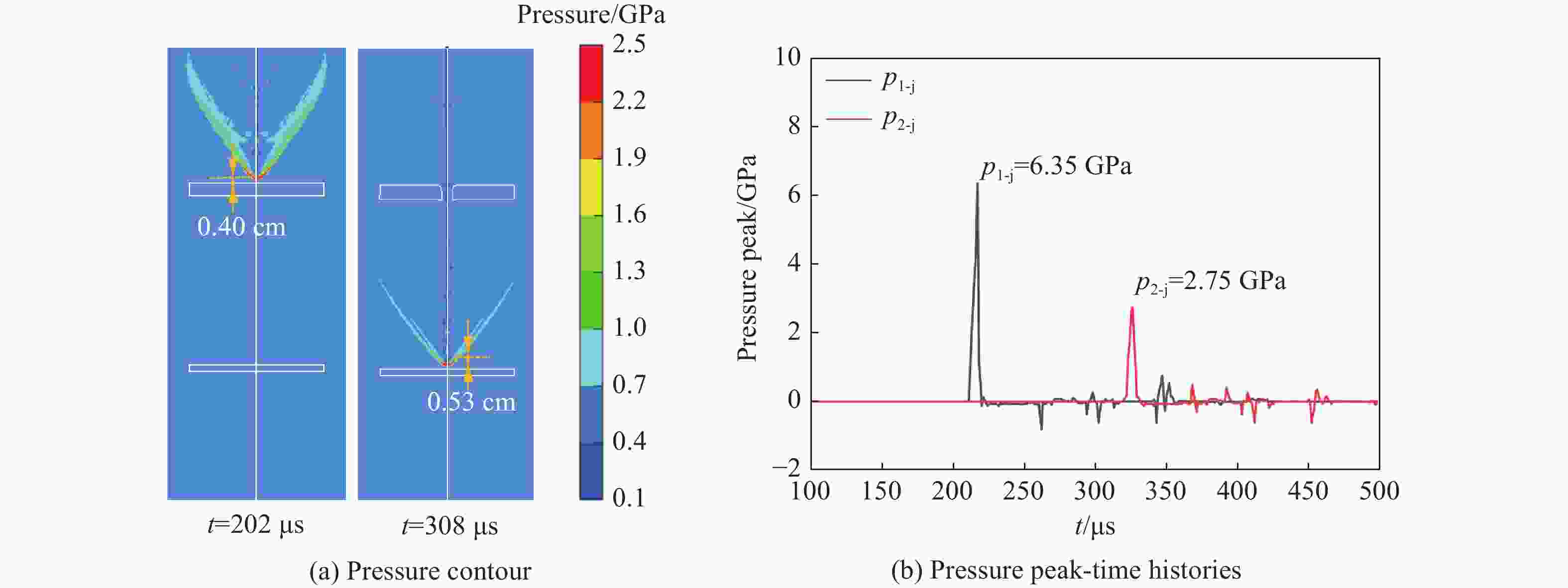

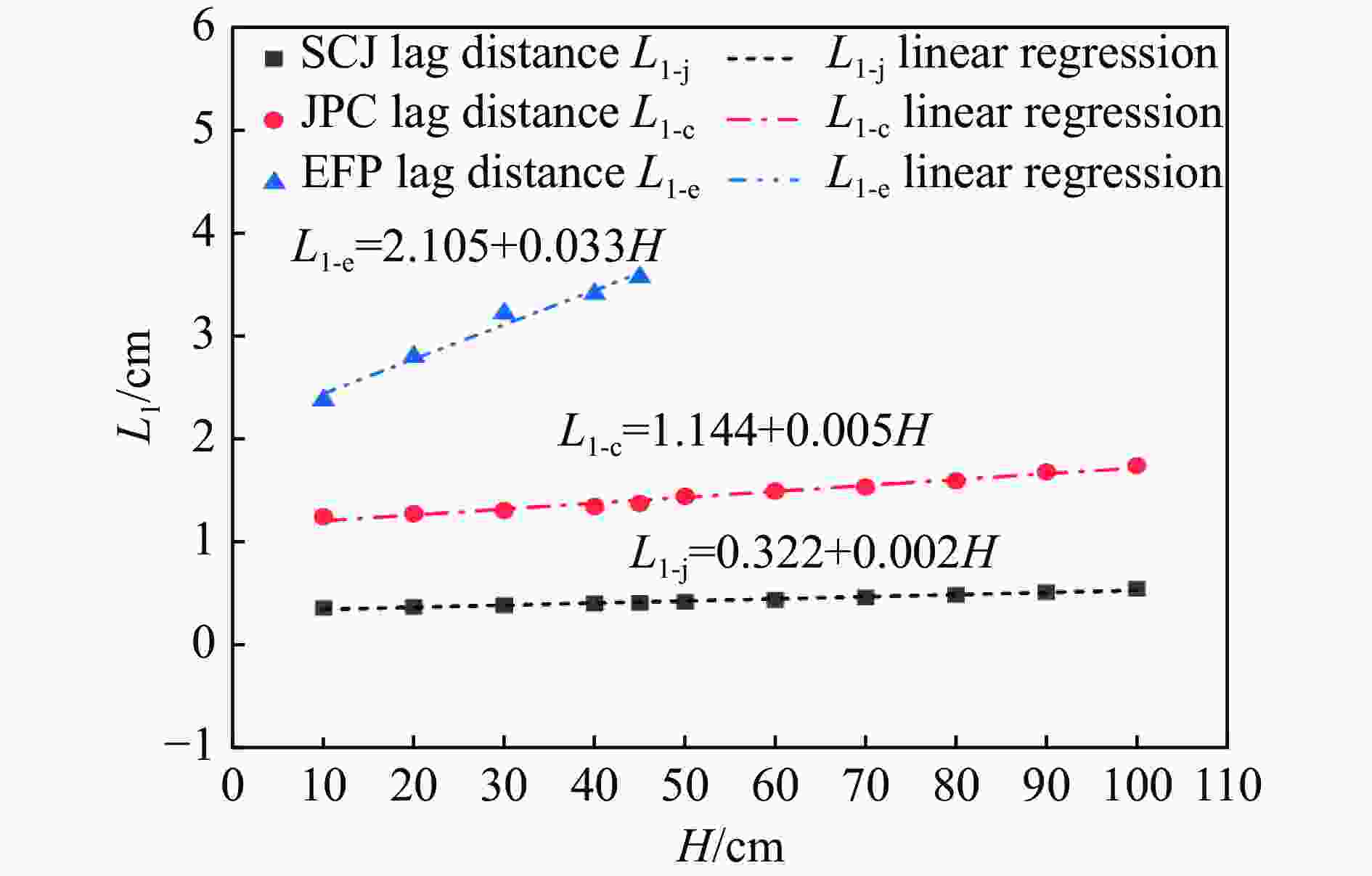

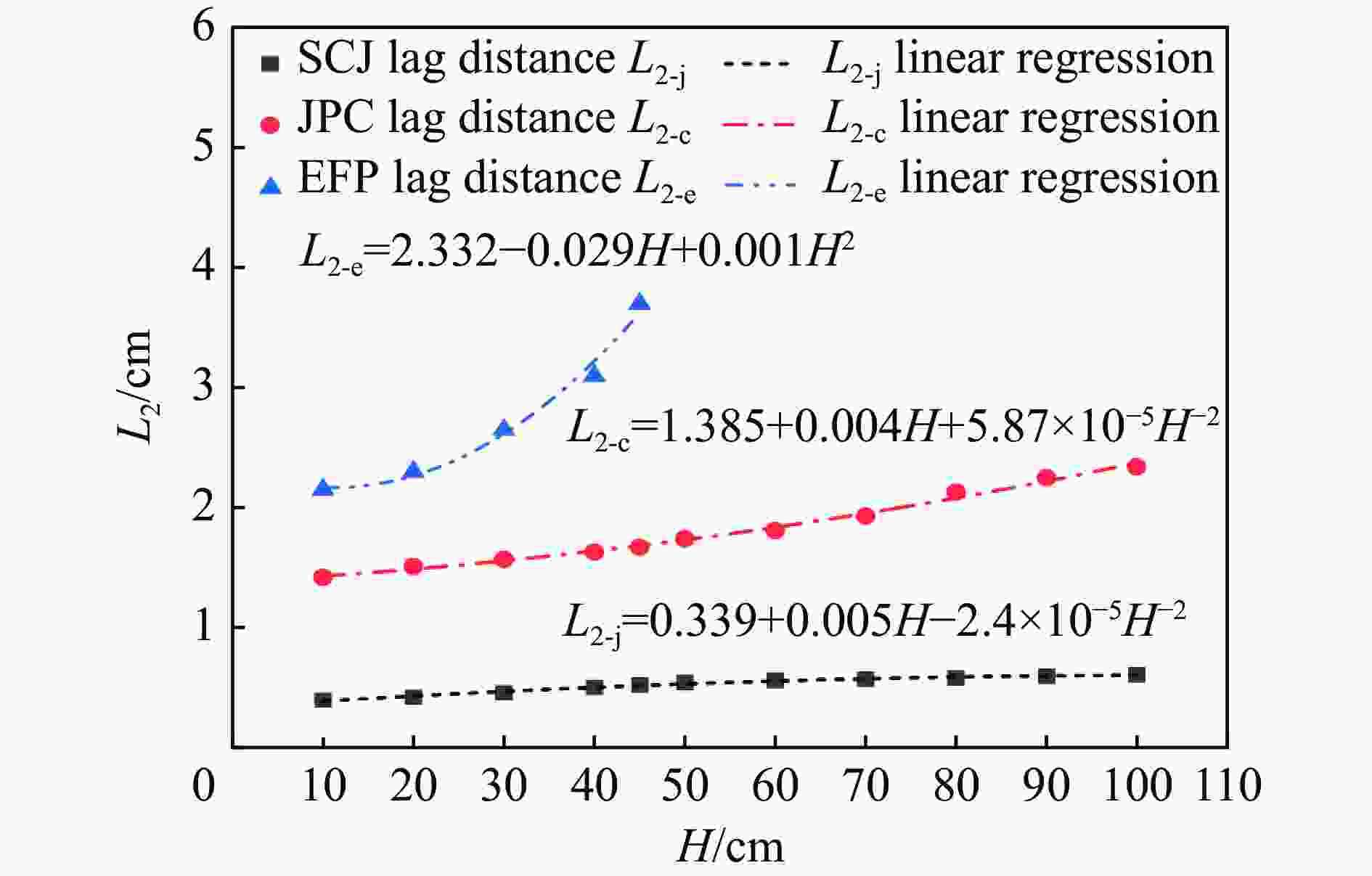

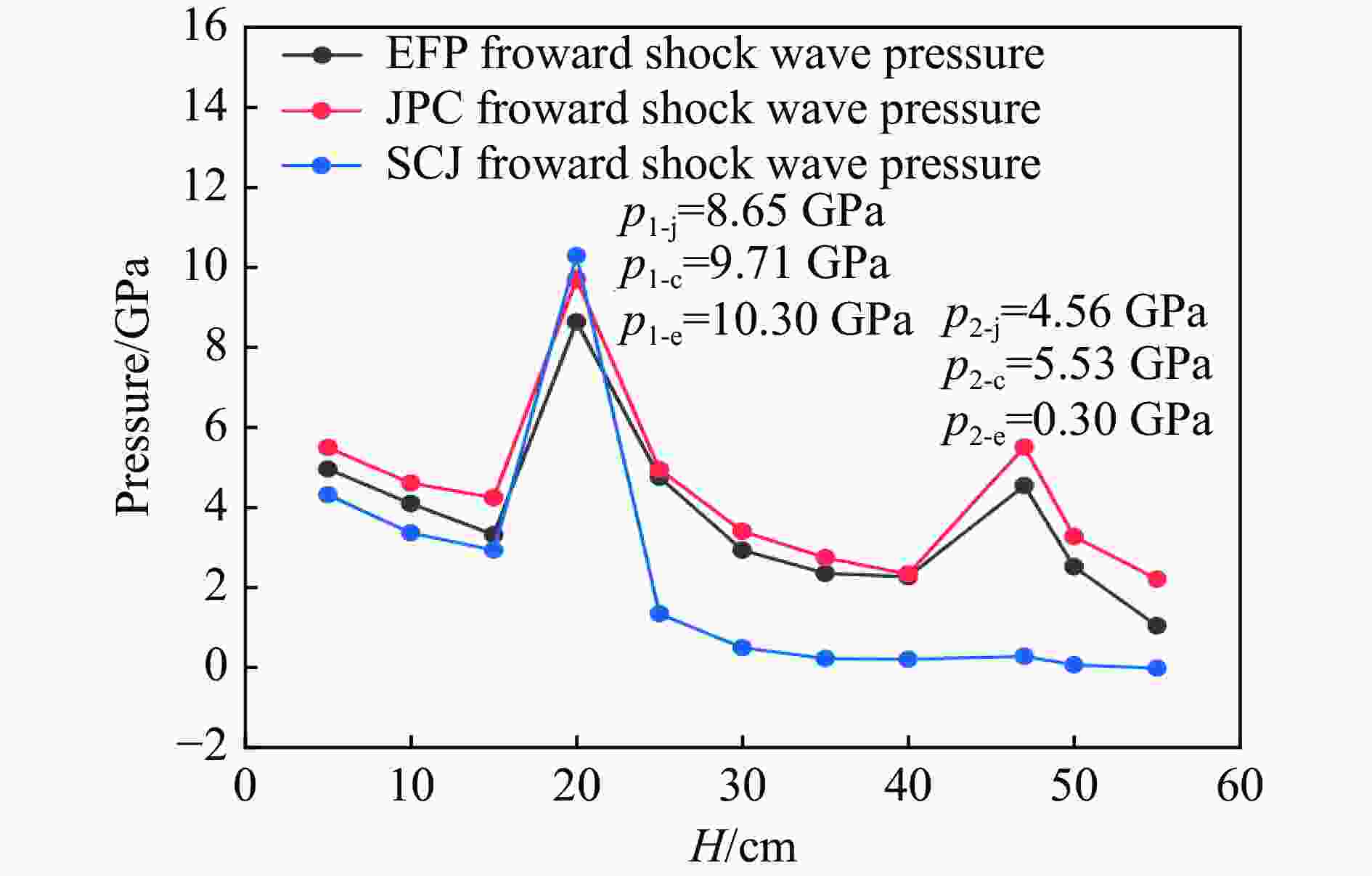

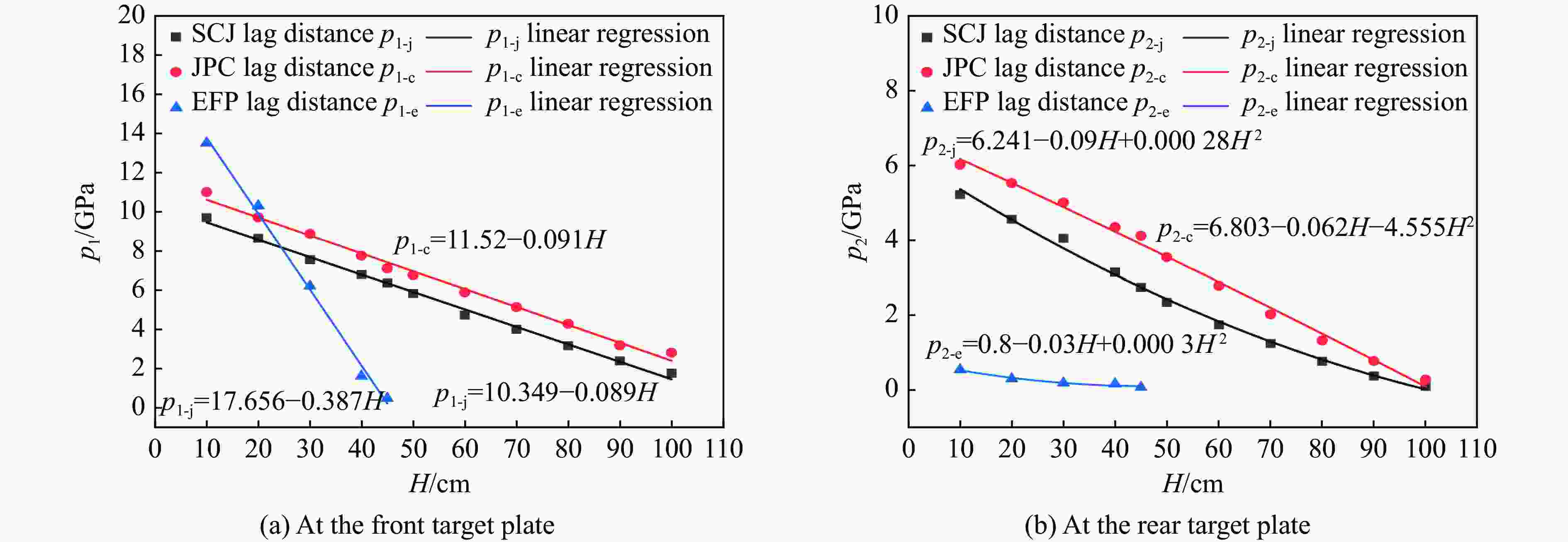

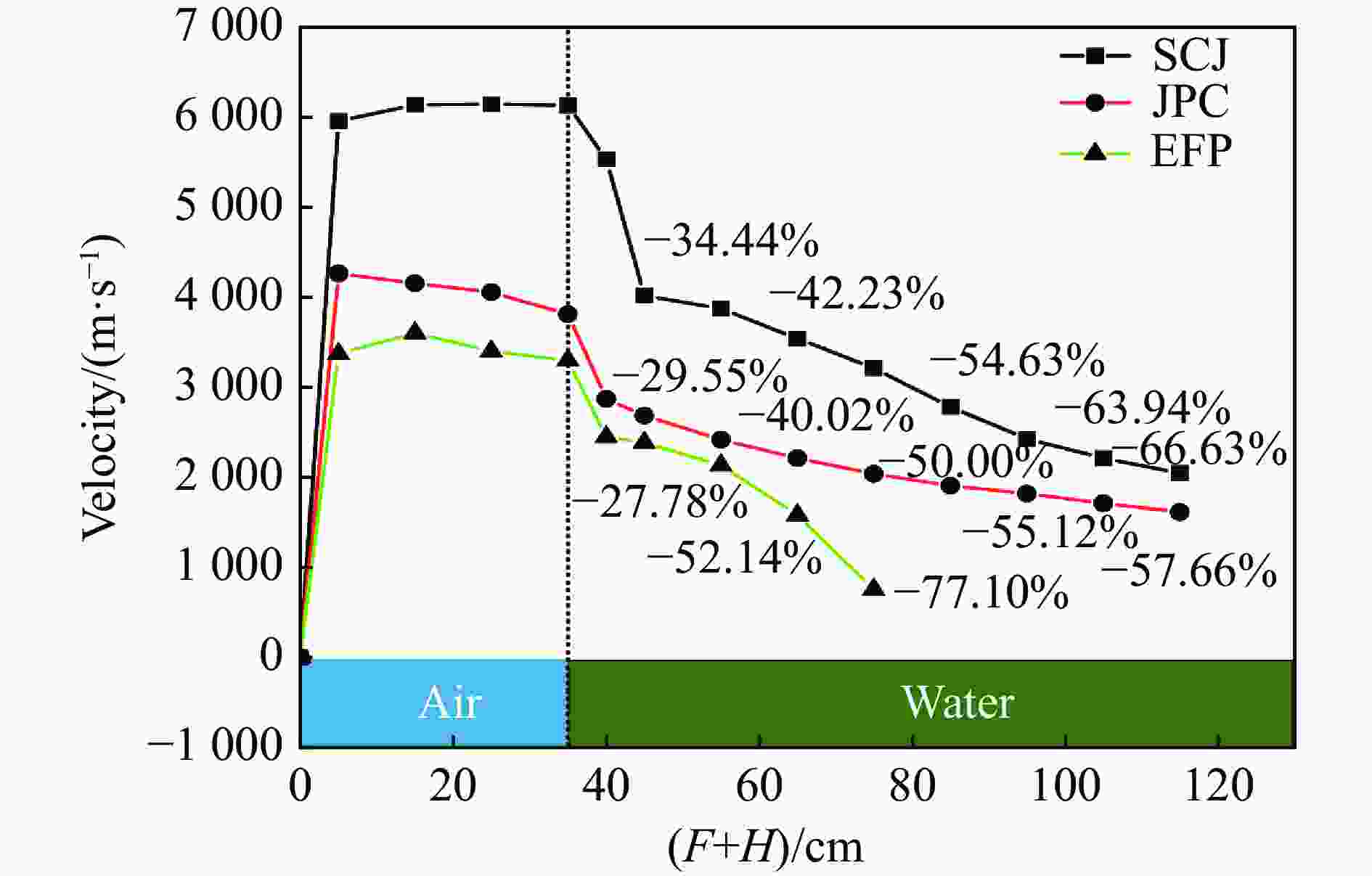

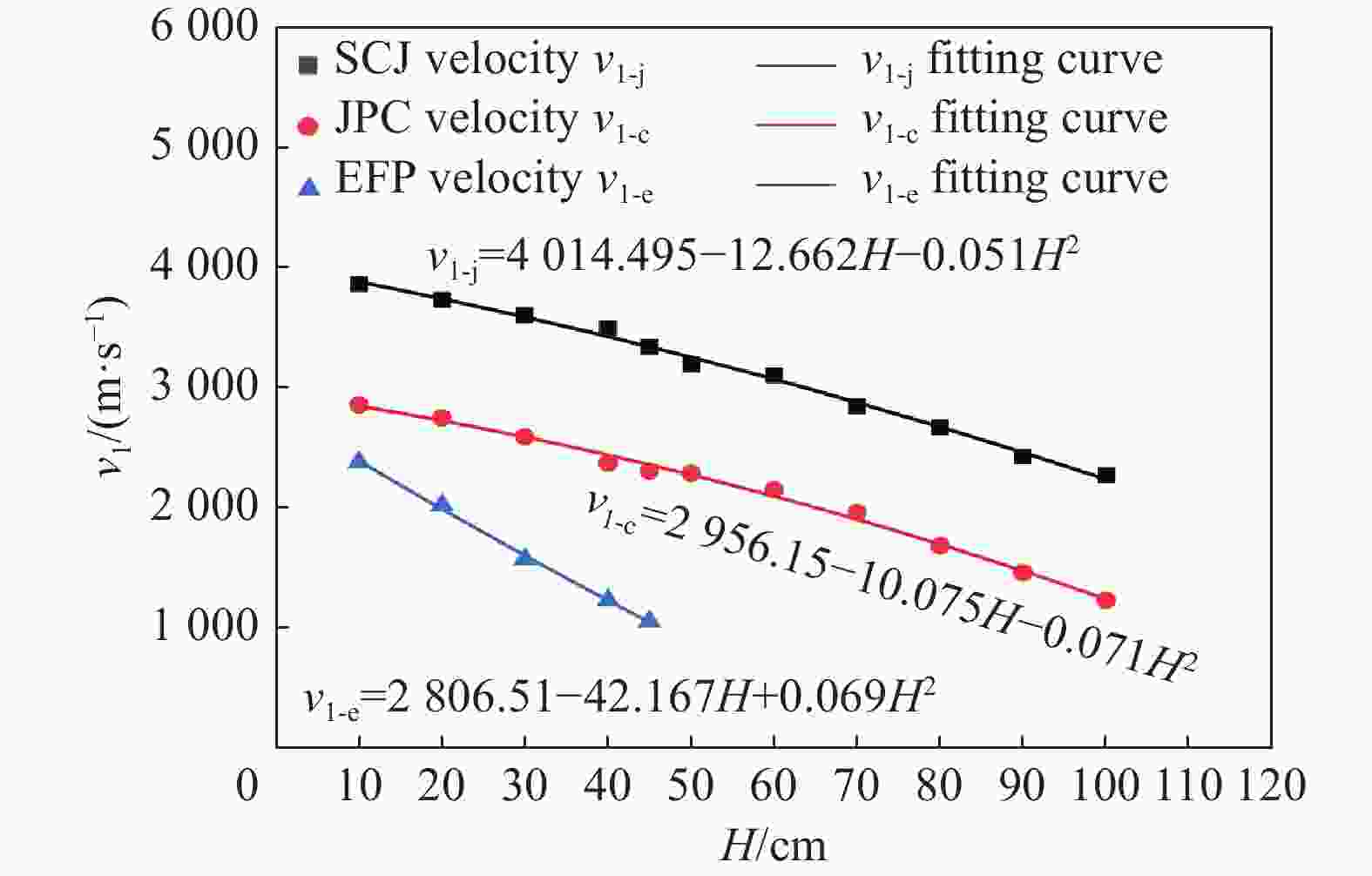

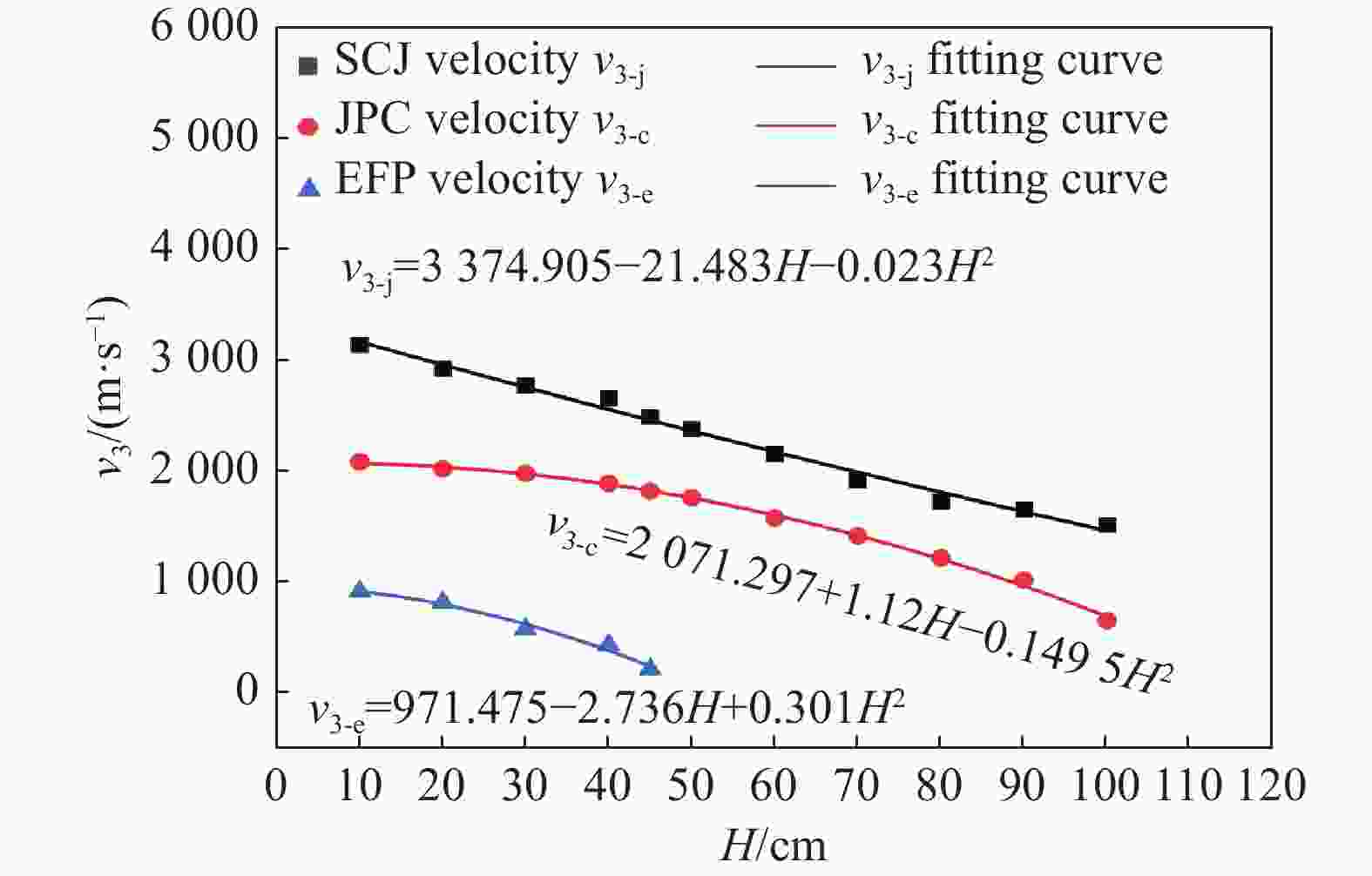

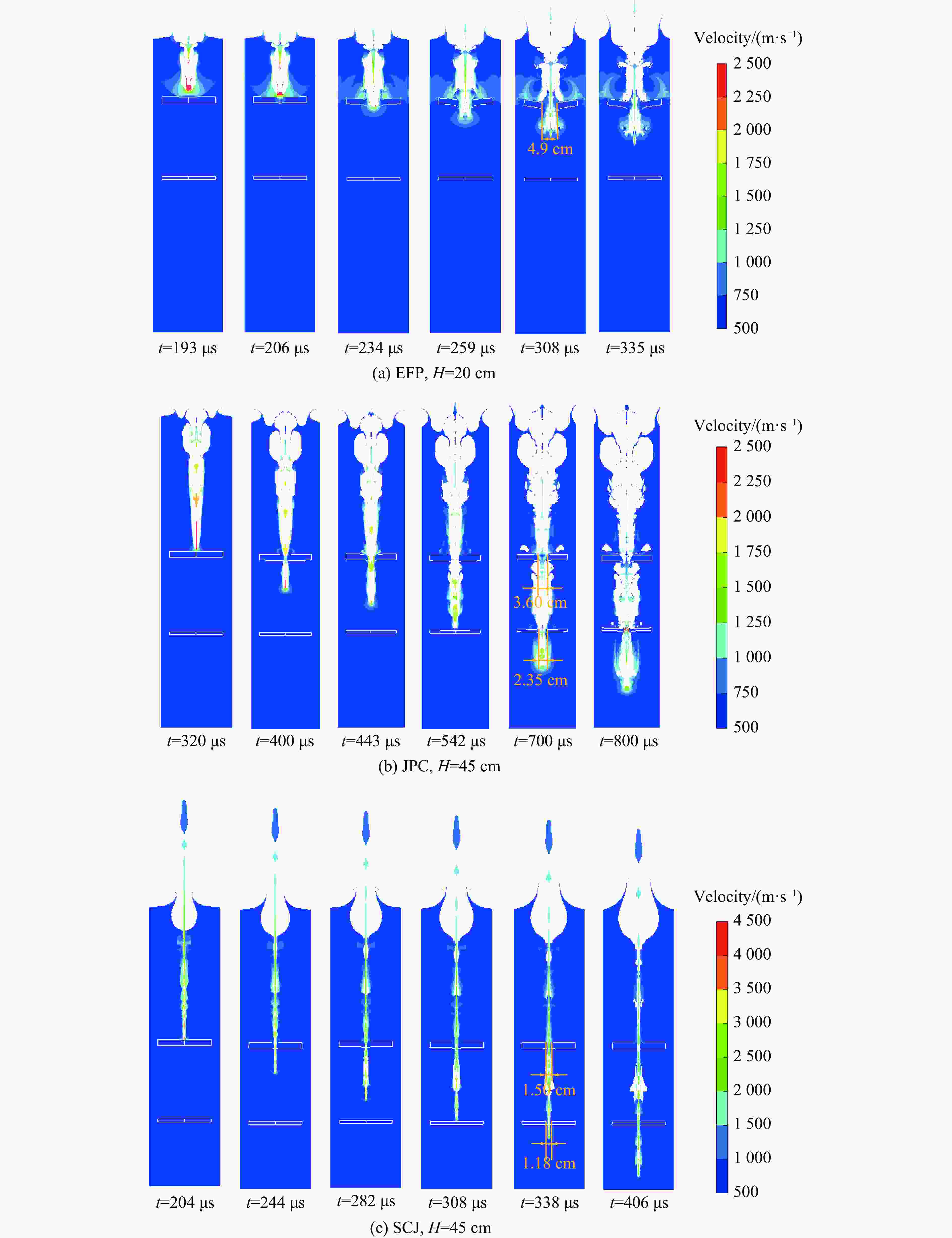

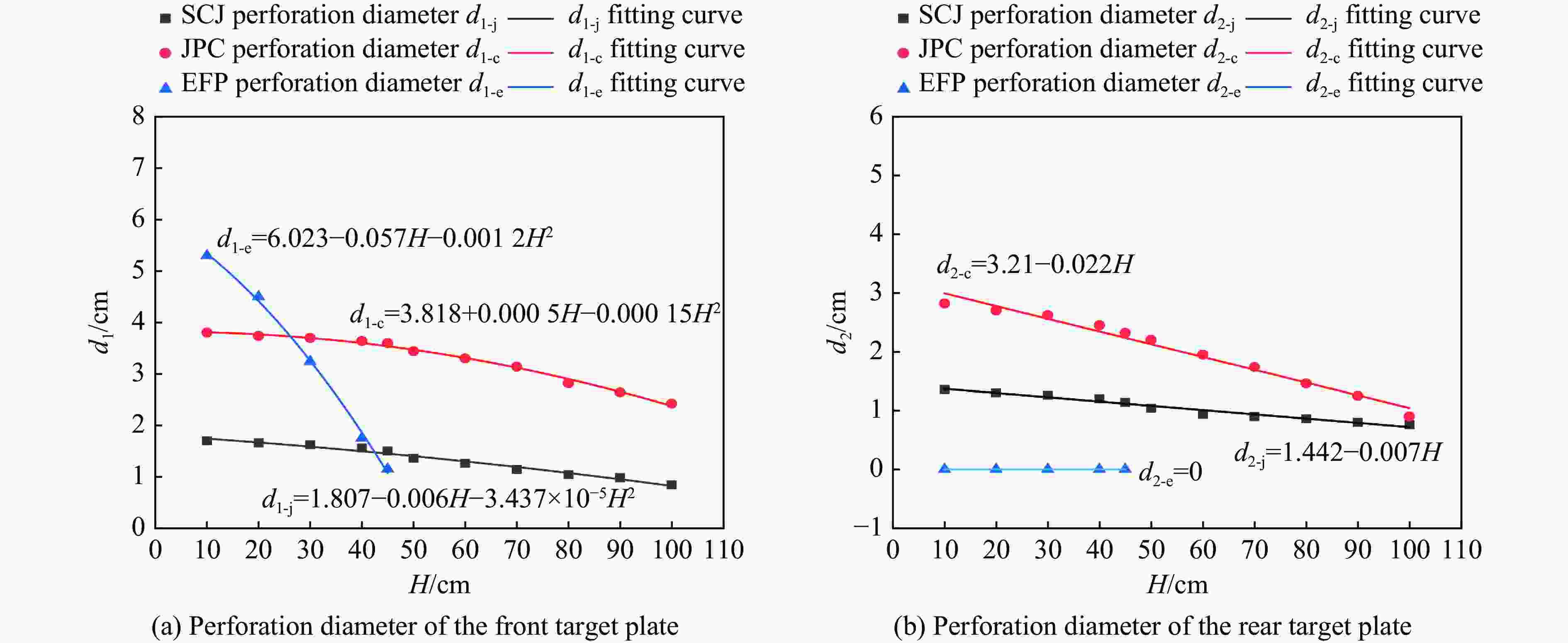

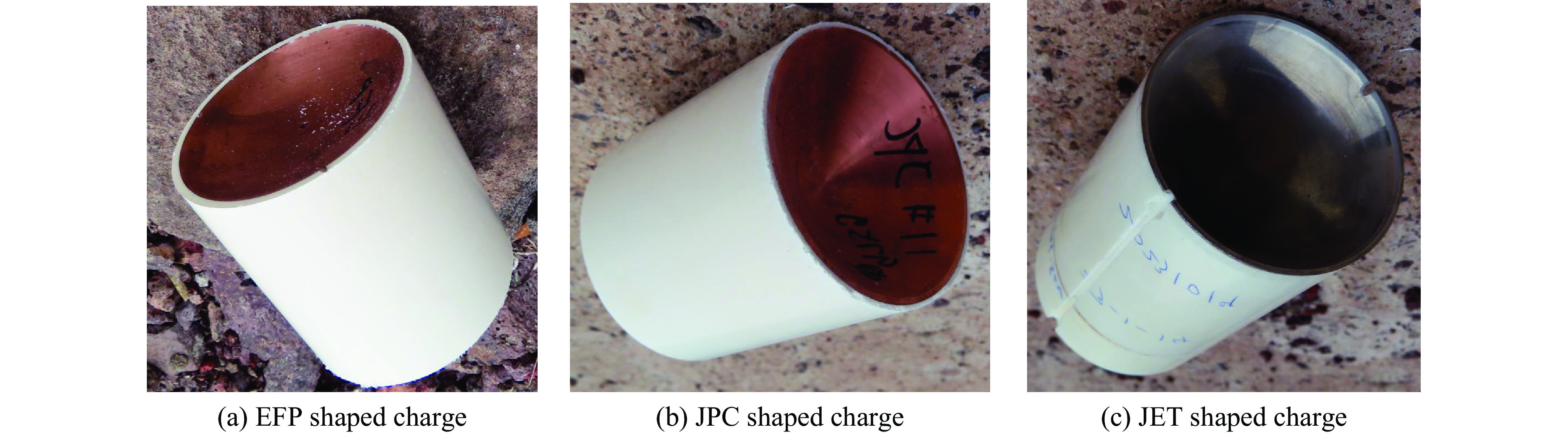

摘要: 为了选择适合水中大距离非接触性侵彻毁伤的聚能装药结构,针对爆炸成型弹丸(explosively formed projectile, EFP)、杆式射流(jetting projectile charge, JPC)、聚能射流(shaped charge jet, SCJ)3种典型聚能装药结构,开展了不同侵彻体入水前、着靶前、穿靶后的速度测试及对水中双层间隔靶的侵彻实验,建立了靶前水介质长度为0~100 cm时的水中侵彻数值计算模型,分析了靶前水介质长度对聚能装药水中毁伤元时序特性、水中前向冲击波压力峰值、水中侵彻速度及水中双层间隔靶侵彻性能的影响。结果表明:3种聚能装药侵彻水中间隔靶时,前向冲击波均先于侵彻体到达靶板。随着水介质长度的增大,前靶板处的前向冲击波压力峰值呈线性下降,后靶板处的前向冲击波压力峰值呈非线性下降;EFP、JPC和SCJ速度呈非线性下降,其中SCJ靶前速度约是JPC靶前速度的2倍。在靶前水介质长度不大于25 cm时,EFP在前靶板上形成的最大穿孔直径达到了5 cm,是JPC穿孔直径的1.3倍,是SCJ穿孔直径的3倍;在靶前水介质长度不大于100 cm时,JPC和SCJ对双层间隔靶具有较好的侵彻效果,且JPC的侵彻性能要优于SCJ。Abstract: To select the shaped charge structure suitable for large-distance non-contact penetration damage in water, three typical shaped-charge structures, explosively formed projectile (EFP), jetting projectile charge (JPC), and shaped charge jet (SCJ), were selected. The velocity tests of different penetrators before entering water, before hitting the target, and after penetrating the target were carried out, and the penetration tests of double-layer spaced targets in water were conducted. Firstly, a comparative test of penetration of three types of shaped charges in the air was carried out to verify the rationality of the structure of shaped charges. The air explosion height of 35 cm was selected to meet the penetration requirements of the three shaped charges. At the same time, the velocity of the shaped charges before penetrating water was measured, which provides the basis for the underwater penetration test. Secondly, the penetration test of three types of shaped charges on an underwater double-layer spaced target was carried out when the air height was 35 cm, and the length of the water medium in front of the target was 20, 45, and 100 cm. The reflected pressures were measured by the wall pressure sensor and PVDF sensor. The velocities of the penetrator at the time of water entry, before the target, and after the target were measured by double-layer on-off net targets.The damage performance of three shaped charge structures on the double-layer spaced target plate was respectively obtained when the water medium in front of the target was at short range, medium range and long range.Based on the projectile-target structure used in the experiment, a two-dimensional finite element model of shaped charge penetrating a double-layer spaced target in water was established using ANSYS/LS-DYNA finite element software. The measured velocity values of the shaped charge penetrator before entering the water, before hitting the target, and after passing through the target were compared with the numerical simulation results to verify the accuracy of the model. The error rate is about 3%. Based on the verified finite element model, the time series characteristics of the underwater damage element of the shaped charge, the peak characteristics of the forward shock wave in the water, the variation law of the penetration velocity in the water, and the penetration performance of the shaped charge against the double-layer spaced target in the water were studied. The results show that the forward shock wave reaches the target plate before the penetrator. As the length of the water medium increases, the peak pressure of the forward shock wave at the front target plate decreases linearly, and the peak pressure of the forward shock wave at the rear target plate decreases nonlinearly. The velocities of EFP, JPC, and SCJ decrease nonlinearly with the increase of water medium, and the velocity in front of the SCJ target is about twice that of JPC. When the length of the water medium in front of the target is not more than 25 cm, the maximum perforation diameter formed by EFP on the front target plate reaches 5 cm, which is 1.3 times the perforation diameter of JPC and 3 times the perforation diameter of SCJ. When the length of the water medium in front of the target is not more than 100 cm, JPC and SCJ have better penetration effect on the double-layer spacer target, and the penetration performance of JPC is better than that of SCJ.

-

表 1 聚能装药侵彻体在不同介质中的侵彻速度

Table 1. Penetration velocity of shaped charge penetrator in different media

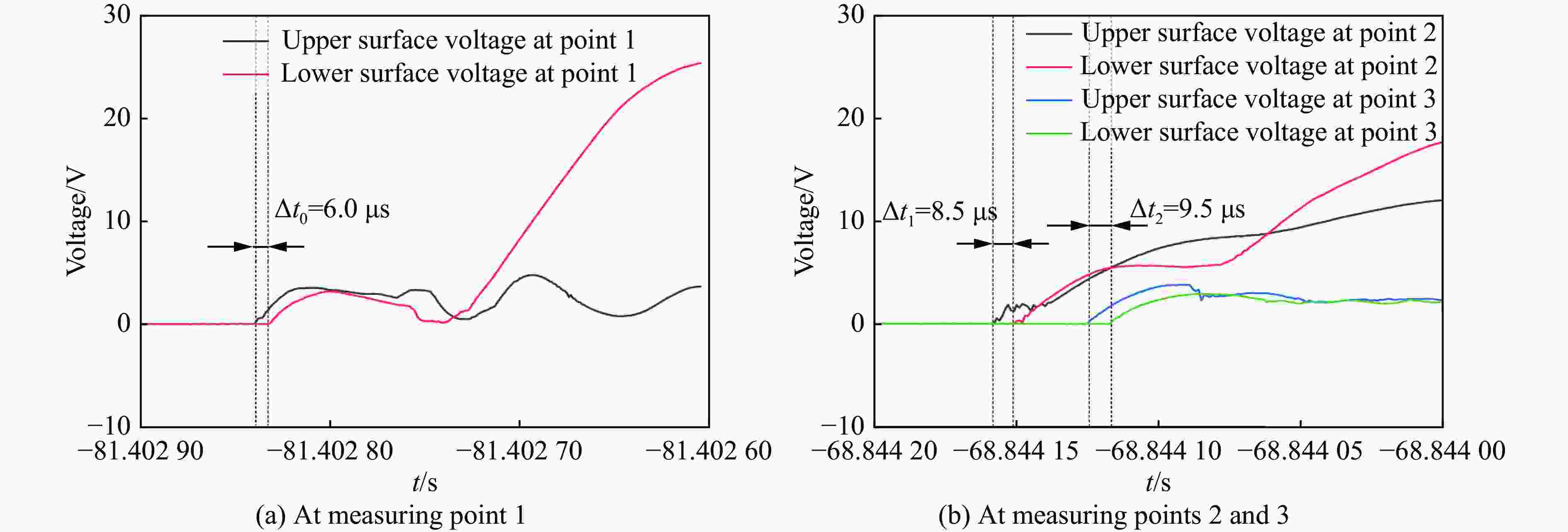

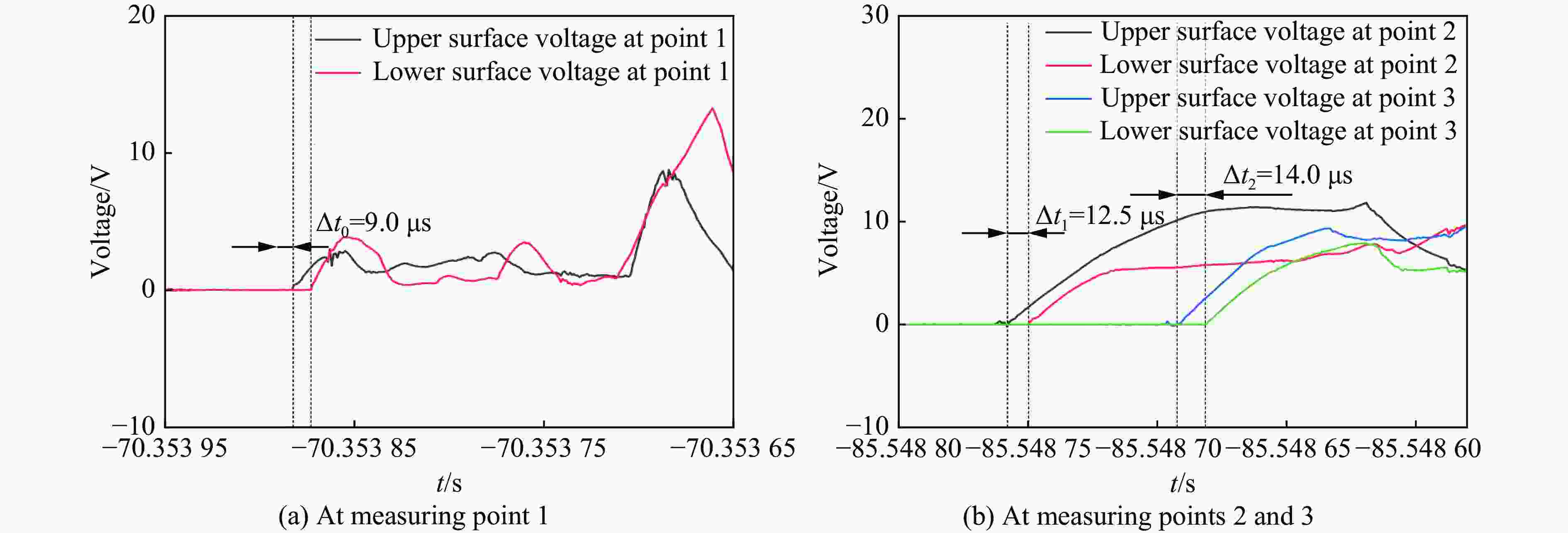

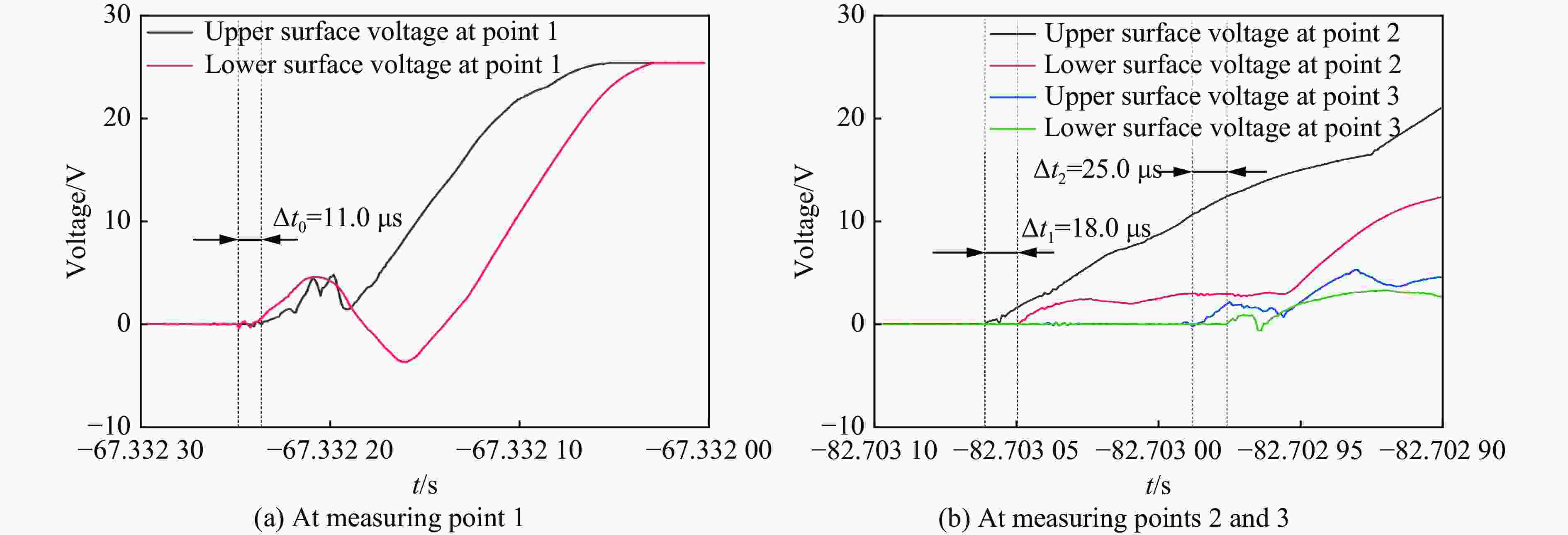

装药类型 F/cm 入水前(测点1) H/cm 着靶前(测点2) 穿靶后(测点3) η3/% Δt0/μs v0/(m·s−1) Δt1/μs v1/(m·s−1) η1/% Δt2/μs v2/(m·s−1) η2/% SCJ 35 6.0 5833 20 8.5 4118 29.41 9.5 3684 10.53 36.84 45 10.0 3500 40.00 11.0 3182 9.09 45.44 JPC 35 9.0 3889 20 12.5 2800 28.00 14.0 2500 10.71 35.71 45 15.0 2333 40.01 16.0 2187 6.26 43.76 EFP 35 11.0 3182 20 18.0 1944 38.89 25.0 1400 28.00 56.00 45 32.0 1094 65.63 59.0 593 45.79 81.36 表 2 3种聚能装药对水中双层靶的的侵彻效果

Table 2. Penetration effect of three kinds of shaped charge on double-layer target in water

装药类型 F/cm H/cm 前靶板 后靶板 入口尺寸/cm 出口尺寸/cm 穿靶效果 入口尺寸/cm 出口尺寸/cm 穿靶效果 EFP 35 20 $\varnothing $5.0 $\varnothing $5.2 穿透 − − − JPC 35 45 4.0×3.5 5.0×3.8 穿透 $\varnothing $2.3 $\varnothing $2.3 穿透 100 $\varnothing $2.3 $\varnothing $2.3 穿透 $\varnothing $1.0 $\varnothing $1.0 穿透 SCJ 35 45 3.6×1.6 3.2×1.5 穿透 $\varnothing $1.2 $\varnothing $1.2 穿透 100 $\varnothing $1.1 $\varnothing $1.1 穿透 $\varnothing $0.8 $\varnothing $0.8 穿透 材料 ρ/(g·cm−3) A/GPa B/GPa R1 R2 ω E0/GPa JH-2 1.7 56.4 6.801 4.1 1.3 0.36 10 材料 ρ/(kg·m−3) c/(m·s−1) S1 S2 S3 ω V0 空气 1.25 344 1.4 0 水 1.02×103 1647 2.56 1.986 1.23 0.5 1 材料 ρ/(g·cm−3) A/MPa B/MPa n C m Tm/K Tr/K 紫铜 8.96 90 292 0.31 0.025 1.09 1 356 293 45钢 7.80 507 320 0.28 0.064 1.06 1 795 300 D1 D2 D3 D4 D5 0.1 0.76 1.57 0.005 0.84 表 6 靶板毁伤效果数值模拟值与实验值对比

Table 6. Comparison of numerical simulation values and experimental measurements of damage effect of target plate

装药类型 H/cm d1 d2 数值模拟值/cm 实验平均值/cm 误差/% 数值模拟值/cm 实验平均值/cm 误差/% EFP 20 4.90 5.00 −2.00 JPC 45 3.60 3.65 −1.37 2.35 2.30 2.17 SCJ 45 1.50 1.55 −3.22 1.18 1.20 −1.67 -

[1] HUANG X, MAO J W, LI Q, et al. On the interaction between the underwater explosion and the double-layer structure with an orifice on the outer plate [J]. Ocean Engineering, 2024, 306: 118050. DOI: 10.1016/j.oceaneng.2024.118050. [2] XU L Y, TIAN Y, LIU X B, et al. Numerical investigation on jet penetration capacity of hypervelocity shaped charge in underwater explosion [J]. Ocean Engineering, 2023, 281: 114668. DOI: 10.1016/j.oceaneng.2023.[2]114668. [3] 姬祥, 明付仁, 张梁. 水下聚能金属射流载荷特性及毁伤效应研究 [J]. 舰船科学技术, 2024, 46(1): 15–20. DOI: 10.3404/j.issn.1672-7649.2024.01.003.JI X, MING F R, ZHANG L. Research on load characteristics and damage effect of underwater shaped metal jet [J]. Ship Science and Technology, 2024, 46(1): 15–20. DOI: 10.3404/j.issn.1672-7649.2024.01.003. [4] 梁争峰, 胡焕性. 爆炸成形弹丸技术现状与发展 [J]. 火炸药学报, 2004, 27(4): 21–25. DOI: 10.14077/j.issn.1007-7812.2004.04.006.LIANG Z F, HU H X. The Current situation and future development direction of explosively formed projectile technology [J]. Chinese Journal of Explosives and Propellants, 2004, 27(4): 21–25. DOI: 10.14077/j.issn.1007-7812.2004.04.006. [5] 徐斌, 王成, 徐文龙. 高速杆式射流形成的数值模拟与实验研究 [J]. 北京理工大学学报, 2018, 38(4): 331–337. DOI: 10.15918/j.tbit1001-0645.2018.04.001.XU B, WANG C, XU W L. Numerical simulation and experiment investigation on hypervelocity jetting projectile charge formation [J]. Transactions of Beijing Institute of Technology, 2018, 38(4): 331–337. DOI: 10.15918/j.tbit1001-0645.2018.04.001. [6] 王利侠, 谷鸿平, 丁刚, 等. 聚能射流对带壳浇注PBX装药的撞击响应 [J]. 含能材料, 2015, 23(11): 1067–1072. DOI: 10.11943/j.issn.1006-9941.2015.11.006.WANG L X, GU H P, DING G, et al. Reaction characteristics for shelled cast-cured PBX explosive impacted by shaped charge jet [J]. Chinese Journal of Energetic Materials, 2015, 23(11): 1067–1072. DOI: 10.11943/j.issn.1006-9941.2015.11.006. [7] 王雅君, 李伟兵, 王晓鸣, 等. EFP水中飞行特性及侵彻间隔靶的仿真与试验研究 [J]. 含能材料, 2017, 25(6): 459–465. DOI: 10.11943/j.issn.1006-9941.2017.06.003.WANG Y J, LI W B, WANG X M, et al. Numerical simulation and experimental study on flight characteristics and penetration against spaced targets of EFP in water [J]. Chinese Journal of Energetic Materials, 2017, 25(6): 459–465. DOI: 10.11943/j.issn.1006-9941.2017.06.003. [8] 张雪梅, 谢兴博, 顾文彬, 等. 球缺型EFP在不同介质中的成型形态及侵彻性能研究 [J]. 兵器装备工程学报, 2024, 45(10): 189–198. DOI: 10.11809/bqzbgcxb2024.10.024.ZHANG X M, XIE X B, GU W B, et al. Study on the forming morphology and penetration performance of spherical-defect EFP in different media [J]. Journal of Ordnance Equipment Engineering, 2024, 45(10): 189–198. DOI: 10.11809/bqzbgcxb2024.10.024. [9] 孙远翔, 胡皓亮, 张之凡. EFP水下成型影响因素的数值模拟 [J]. 高压物理学报, 2020, 34(6): 065104. DOI: 10.11858/gywlxb.20200557.SUN Y X, HU H L, ZHANG Z F. Simulation study on influential factors of EFP underwater forming [J]. Chinese Journal of High Pressure Physics, 2020, 34(6): 065104. DOI: 10.11858/gywlxb.20200557. [10] 王海福, 江增荣, 俞为民, 等. 杆式射流装药水下作用行为研究 [J]. 北京理工大学学报, 2006, 26(3): 189–192. DOI: 10.3969/j.issn.1001-0645.2006.03.001.WANG H F, JIANG Z R, YU W M, et al. Behavior of jetting penetrator charge operating underwater [J]. Transactions of Beijing Institute of Technology, 2006, 26(3): 189–192. DOI: 10.3969/j.issn.1001-0645.2006.03.001. [11] 蒋文灿, 程祥珍, 梁斌, 等. 一种组合药型罩聚能装药战斗部对含水复合结构毁伤的数值模拟及试验研究 [J]. 爆炸与冲击, 2022, 42(8): 083303. DOI: 10.11883/bzycj-2021-0389.JIANG W C, CHENG X Z, LIANG B, et al. Numerical simulation and experimental study on the damage of water partitioned structure by a shaped charge warhead with a combined charge liner [J]. Explosion and Shock Waves, 2022, 42(8): 083303. DOI: 10.11883/bzycj-2021-0389. [12] 张向荣, 黄风雷. 炸高对钨铜射流空气及水中侵彻的影响 [J]. 北京理工大学学报, 2011, 31(3): 262–264. DOI: 10.15918/j.tbit1001-0645.2011.03.003.ZHANG X R, HUANG F L. Effects of standoff on the penetration of WCu-pseudo-alloy shaped charges in the air and water [J]. Transactions of Beijing Institute of Technology, 2011, 31(3): 262–264. DOI: 10.15918/j.tbit1001-0645.2011.03.003. [13] 陈冬梅, 陈智刚, 侯秀成, 等. 三类聚能侵彻体鱼雷战斗部对目标毁伤数值模拟 [J]. 弹箭与制导学报, 2012, 32(2): 110–113. DOI: 10.15892/j.cnki.djzdxb.2012.02.047.CHEN D M, CHEN Z G, HOU X C, et al. The simulation on target damage of three shaped-charge penetrators torpedo warheads [J]. Journal of Projectiles, Rockets, Missiles and Guidance, 2012, 32(2): 110–113. DOI: 10.15892/j.cnki.djzdxb.2012.02.047. [14] 周迪锋, 唐娟, 赖建云. 水下聚能爆破技术研究 [J]. 四川兵工学报, 2013, 34(2): 45–47. DOI: 10.11809/scbgxb2013.02.014.ZHOU D F, TANG J, LAI J Y. Research of shaped underwater blasting technology [J]. Journal of Ordnance Equipment Engineering, 2013, 34(2): 45–47. DOI: 10.11809/scbgxb2013.02.014. [15] 李明星, 王志军, 伊建亚, 等. 不同聚能装药水下作用效果的对比分析 [J]. 兵器材料科学与工程, 2017, 40(5): 95–99. DOI: 10.14024/j.cnki.1004-244x.20170911.002.LI M X, WANG Z J, YI J Y, et al. Comparative analysis of underwater effect for different shaped charge [J]. Ordnance Material Science and Engineering, 2017, 40(5): 95–99. DOI: 10.14024/j.cnki.1004-244x.20170911.002. [16] 王长利, 马坤, 周刚, 等. 防雷舱结构在聚能装药水下爆炸作用下的毁伤研究 [J]. 爆炸与冲击, 2018, 38(5): 1145–1154. DOI: 10.11883/bzycj-2017-0119.WANG C L, MA K, ZHOU G, et al. Damage effect of cabin near shipboard under shaped charge exploding underwater [J]. Explosion and Shock Waves, 2018, 38(5): 1145–1154. DOI: 10.11883/bzycj-2017-0119. [17] 侯海量, 张成亮, 李茂, 等. 冲击波和高速破片联合作用下夹芯复合舱壁结构的毁伤特性 [J]. 爆炸与冲击, 2015, 35(1): 116–123. DOI: 10.11883/1001-1455(2015)01-0116-08.HOU H L, ZHANG C L, LI M, et al. Damage characteristics of sandwich bulkhead under the impact of shock and high-velocity fragments [J]. Explosion and Shock Waves, 2015, 35(1): 116–123. DOI: 10.11883/1001-1455(2015)01-0116-08. [18] 吴晗玲, 段卓平, 汪永庆. 杆式射流形成的数值模拟研究 [J]. 爆炸与冲击, 2006, 26(4): 328–332. DOI: 10.11883/1001-1455(2006)04-0328-05.WU H L, DUAN Z P, WANG Y Q. Simulation investigation of rod-like jets [J]. Explosion and Shock Waves, 2006, 26(4): 328–332. DOI: 10.11883/1001-1455(2006)04-0328-05. [19] 陈兴, 周兰伟, 李福明, 等. 杆式射流对充液防护结构的毁伤机理及影响因素的数值模拟 [J]. 高压物理学报, 2021, 35(2): 025202. DOI: 10.11858/gywlxb.20200626.CHEN X, ZHOU L W, LI F M, et al. Numerical simulation of the damage mechanism and influencing factors of rod jets on liquid-filled protective structures [J]. Chinese Journal of High Pressure Physics, 2021, 35(2): 025202. DOI: 10.11858/gywlxb.20200626. [20] 时党勇, 李裕春, 张胜民. 基于ANSYS/LS-DYNA 8.1进行显式动力分析 [M]. 北京: 清华大学出版社, 2005: 295–296. [21] 桂毓林, 于川, 刘仓理, 等. 带尾翼的翻转型爆炸成形弹丸的三维数值模拟 [J]. 爆炸与冲击, 2005, 25(4): 313–318. DOI: 10.11883/1001-1455(2005)04-0313-06.GUI Y L, YU C, LIU C L, et al. 3D simulation of over-turned explosively formed projectile (EFP) with star-shaped fins [J]. Explosion and Shock, 2005, 25(4): 313–318. DOI: 10.11883/1001-1455(2005)04-0313-06. [22] 陈刚, 陈小伟, 陈忠富, 等. A3钢钝头弹撞击45钢板破坏模式的数值分析 [J]. 爆炸与冲击, 2007, 27(5): 390–397. DOI: 10.11883/1001-1455(2007)05-0390-08.CHEN G, CHEN X W, CHEN Z F, et al. Simulations of A3 steel blunt projectiles impacting 45 steel plates [J]. Explosion and Shock Waves, 2007, 27(5): 390–397. DOI: 10.11883/1001-1455(2007)05-0390-08. -

下载:

下载: