Theoretical model of displacement response of clamped circular plate under multiple far-field blast loads

-

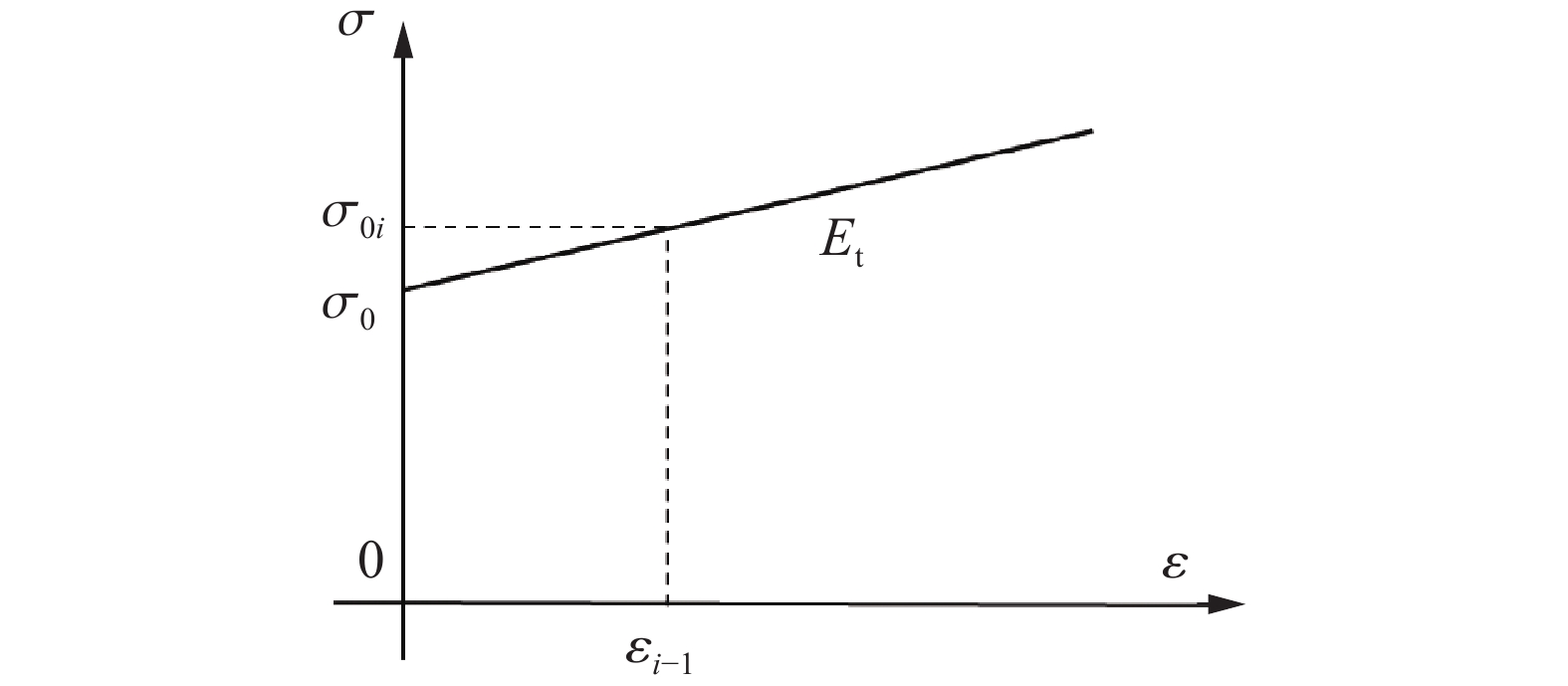

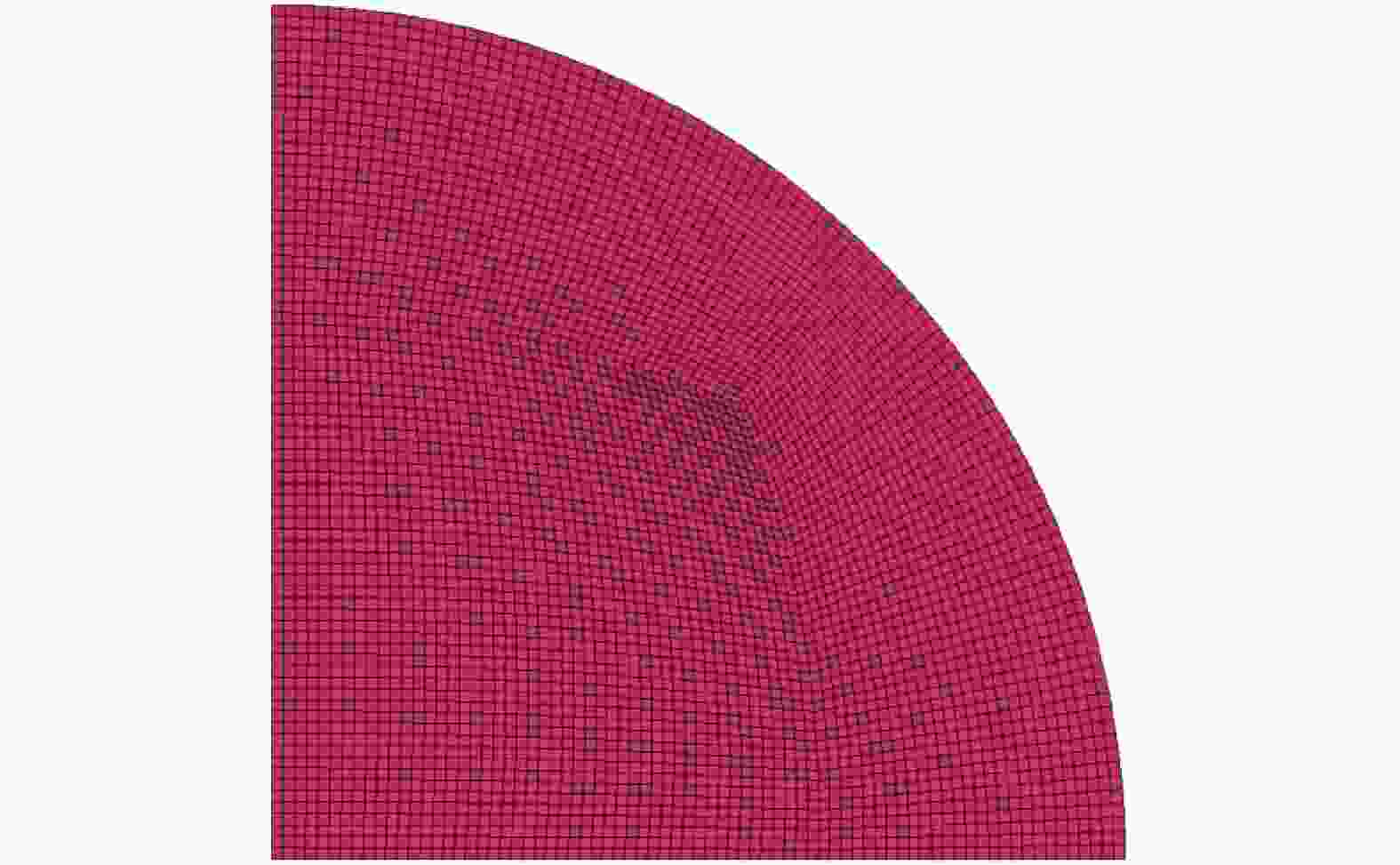

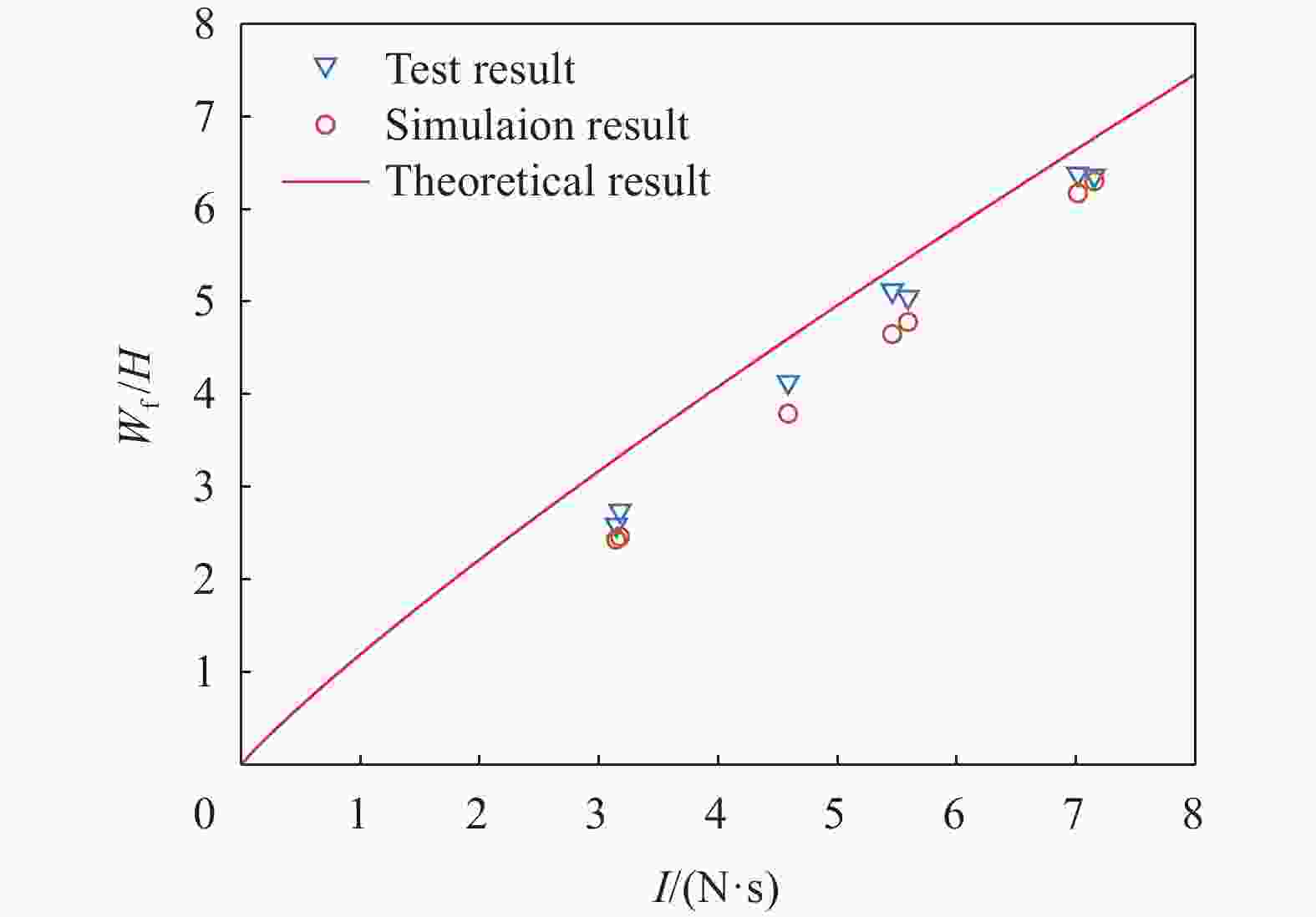

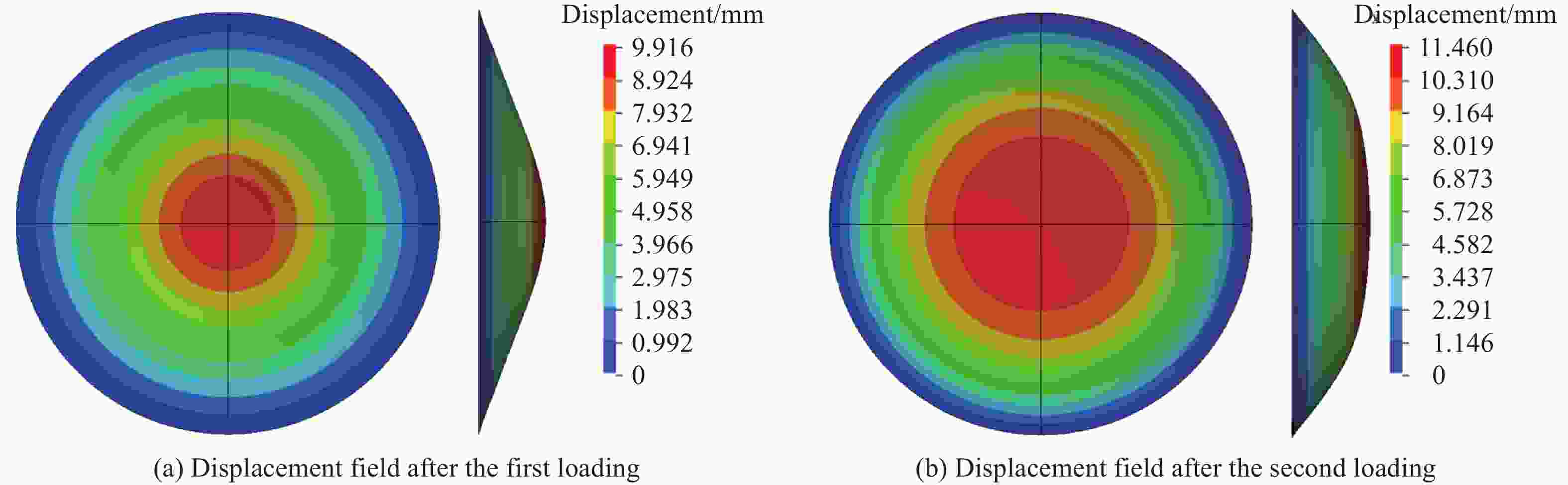

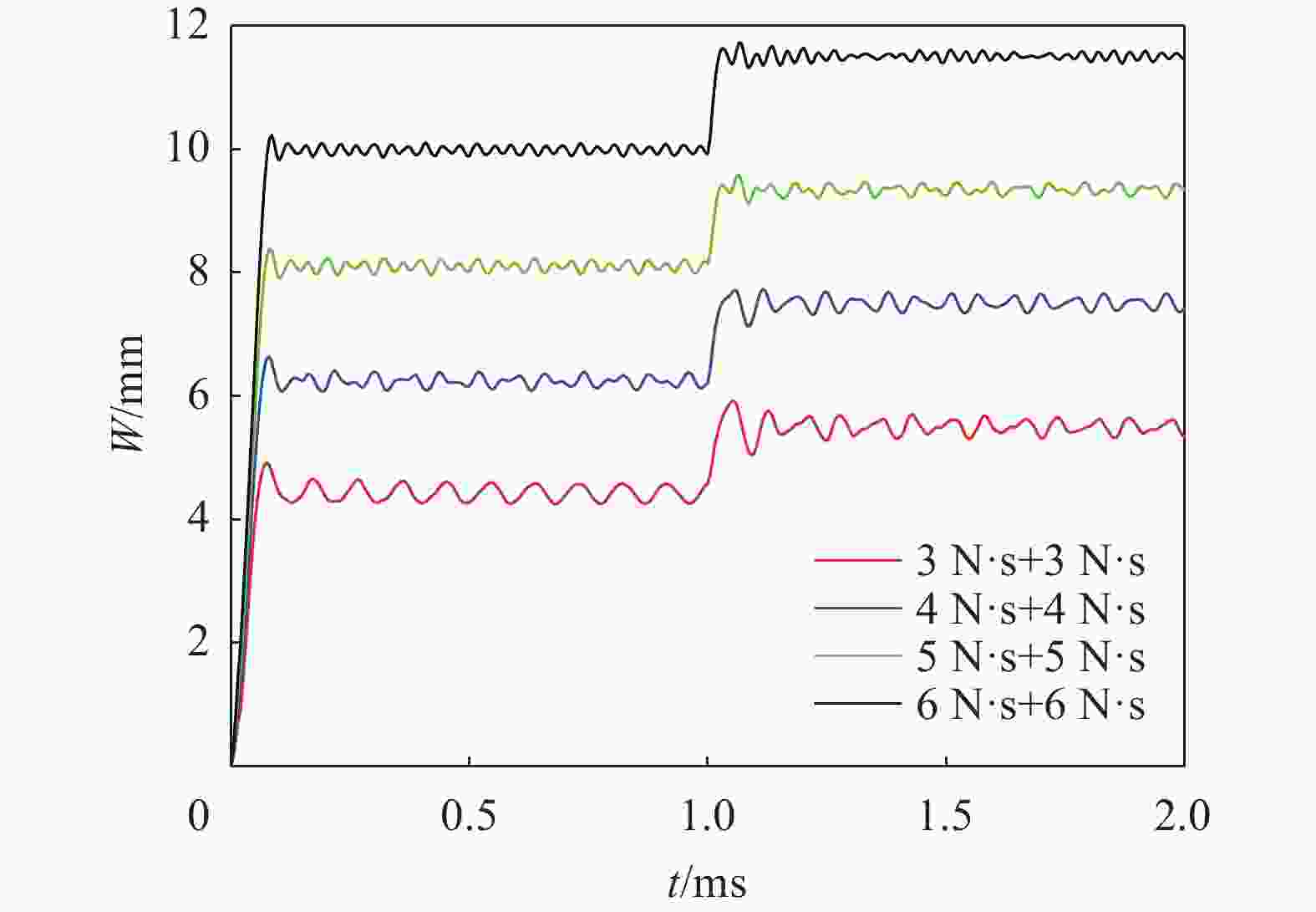

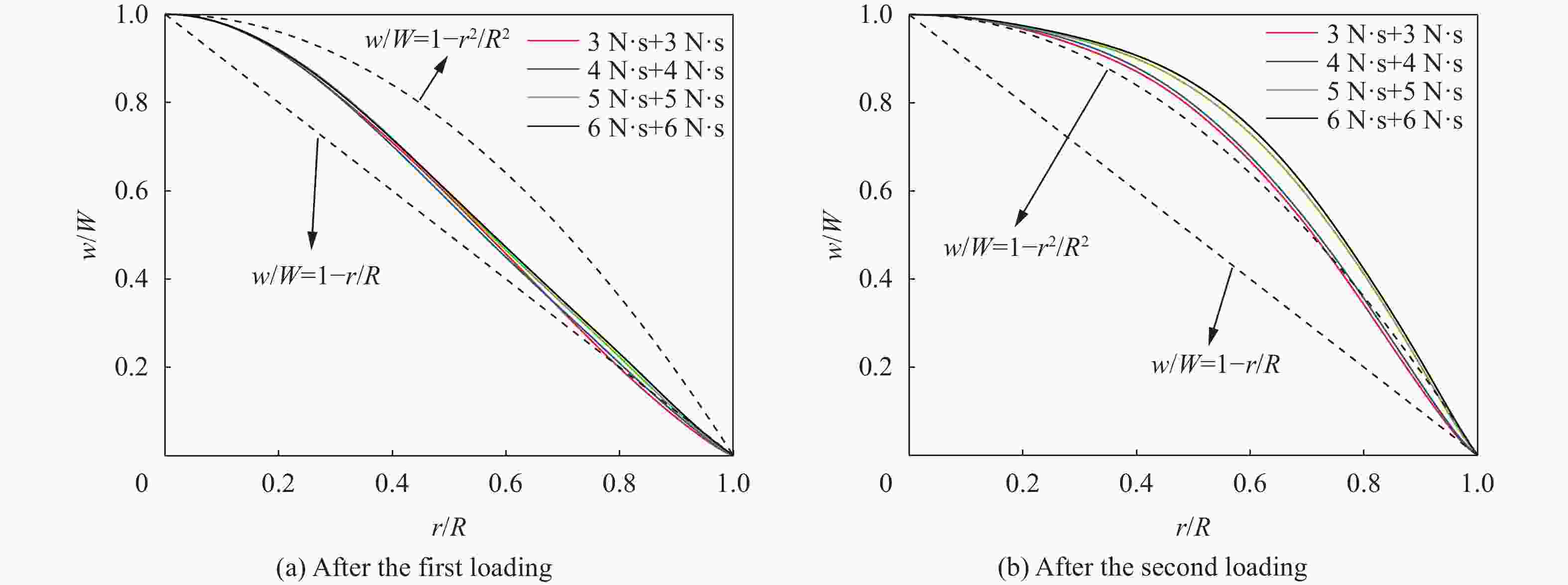

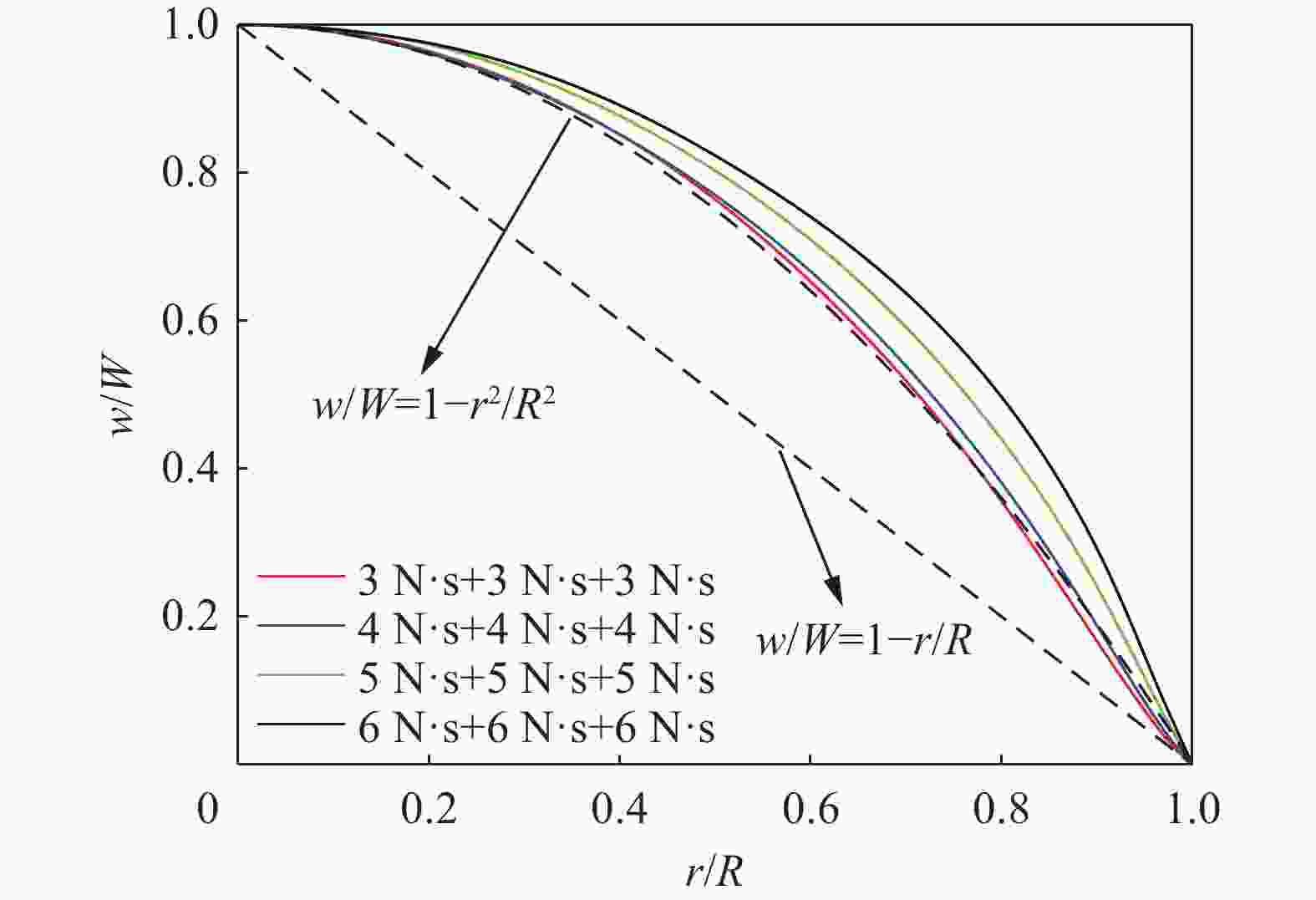

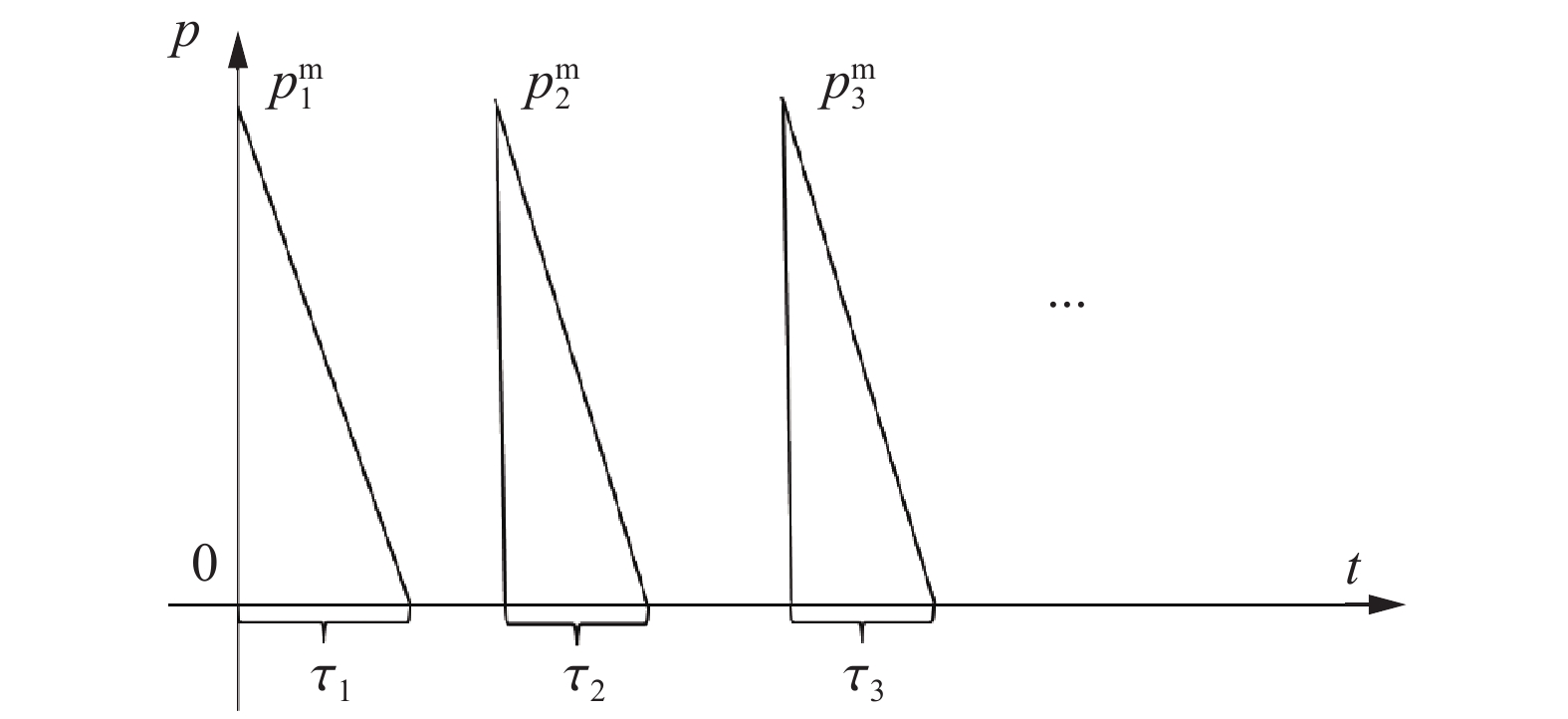

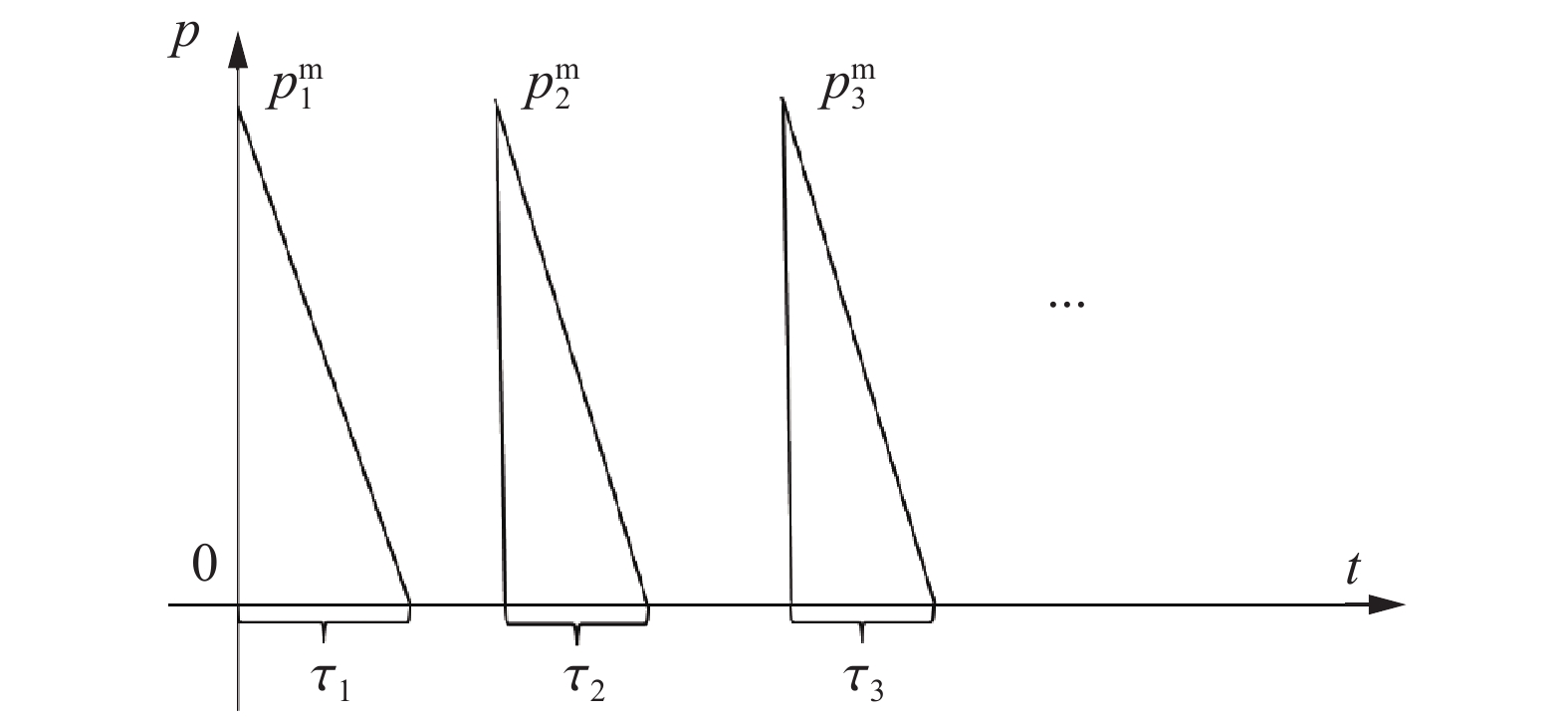

摘要: 本文针对固支圆板在多次远场空爆载荷下的位移响应问题,基于膜理论能量方程,提出一种理论建模方法:通过将多次空爆载荷简化为线性衰减脉冲序列,首次建立了考虑应变率强化效应与累积硬化效应的固支圆板位移响应理论模型。首次加载阶段采用线性位移场近似,后续加载阶段引入二次函数位移场假设,推导出多次爆炸下中点位移的递推公式。通过LS-Dyna二次、三次空爆数值模拟验证表明,理论解与模拟结果的误差分别为20%~30%和20%以下。理论模型表明,圆板中点位移可表征为末次爆炸单独位移与前期累积位移的加权平方根函数,且后期爆炸的位移增量随前期累积位移增大而减小。该模型为多次空爆毁伤评估提供了理论依据,揭示了累积毁伤的非线性增长特性,对优化爆炸打击策略具有指导意义。Abstract: Regarding the displacement response of clamped circular plates under multiple far-field blast loads, we proposes a novel theoretical modeling approach based on membrane theory energy equations, by simplifying multiple blast loads into linearly decaying pulse sequences, a theoretical displacement response model for clamped circular plates is established for the first time, considering both strain rate strengthening effects and cumulative hardening effects. The linear displacement field approximation is adopted for the initial loading phase, while a quadratic function displacement field assumption is introduced for subsequent loading phases, deriving recursive formulas for midpoint displacements under multiple blasts. Numerical validations were conducted using LS-DYNA for both double and triple blast scenarios. For double blast cases, theoretical predictions exhibited errors of 20%–30% compared to simulation results, while errors reduced to below 20% for triple blast conditions. The ASTM A415 steel circular plate model was used for the simulations, and the strain rate strengthening effect was described by the Cowper-Symonds model. Finite element models with quadrilateral shell elements demonstrated strong agreement with experimental data (errors <10%), confirming model reliability. The assumption of quadratic function displacement field for subsequent loading phases was verified by numerical displacement curves of the middle profiles of the plates. Further parametric analysis proved that the theoretical model is effective for different tangent modulus, which represents the strength of the strain strengthening effect. The model reveals that midpoint displacement can be characterized as a weighted square root function combining the final explosion’s individual displacement and prior cumulative displacement, with displacement increments from subsequent explosions decreasing as prior cumulative displacement increases. This study provides the first closed-form solution for multi-blast displacement prediction, addressing a critical gap in theoretical blast dynamics. This theoretical framework provides fundamental support for multiple blast damage assessments, unveils nonlinear cumulative damage growth characteristics, and offers guidance for optimizing explosive attack strategies.

-

表 1 圆板尺寸与材料参数[17]

Table 1. Size and material parameters of the circular plate

R/mm H/mm ρ/(kg·m−3) $ {\dot{\varepsilon }}_{0} $/s−1 n σ0/MPa Et/MPa 31.8 1.93 7800 40 5 223 10.8 表 2 实验与数值模拟结果对比

Table 2. Comparison of numerical and experimental results

序号 实验数据[16] 模拟数据 It/(N·s) Wf/H pm/MPa τ/ms Wf/mm Wf/H Wf/H误差 1 7.153 6.36 450.313 0.01 12.16 6.30 −0.94% 2 3.145 2.59 197.991 0.01 4.69 2.43 −6.18% 3 5.458 5.12 343.605 0.01 8.97 4.65 −9.18% 4 5.591 5.05 351.978 0.01 9.22 4.78 −5.35% 5 3.176 2.74 199.943 0.01 4.74 2.46 −10.22% 6 4.586 4.13 288.709 0.01 7.32 3.79 −8.23% 7 7.015 6.38 441.625 0.01 11.91 6.17 −3.29% 表 3 二次空爆载荷下圆板中点位移理论与模拟结果的比较

Table 3. Comparison between theoretical and numerical results of midpoint displacement of the circular plate under two blast loads

冲量/(N·s) $ W_{1}^{\mathrm{f}} $/mm $ W_{1}^{\mathrm{f}} $误差/% $ W_{2}^{\mathrm{f}} $/mm $ W_{2}^{\mathrm{f}} $误差/% 模拟 理论 模拟 理论 修正理论 理论 修正理论 3+3 4.43 6.12 38.15 5.49 8.65 7.65 57.56 39.34 3+4 4.43 6.12 38.15 6.37 9.97 8.50 56.51 33.44 3+5 4.43 6.12 38.15 7.72 11.36 9.43 47.15 22.15 3+6 4.43 6.12 38.15 9.25 12.77 10.40 38.05 12.43 4+3 6.24 7.88 26.12 6.95 9.97 9.11 43.45 31.08 4+4 6.24 7.88 26.12 7.50 11.14 9.84 48.40 31.20 4+5 6.24 7.88 26.12 8.30 12.39 10.65 49.28 28.31 4+6 6.24 7.88 26.12 9.43 13.70 11.52 45.28 22.16 5+3 8.10 9.57 18.02 8.62 11.36 10.61 31.67 23.09 5+4 8.10 9.57 18.02 8.94 12.39 11.24 38.59 25.73 5+5 8.10 9.57 18.02 9.34 13.53 11.95 44.75 27.94 5+6 8.10 9.57 18.02 10.11 14.74 12.73 45.70 25.91 6+3 9.99 11.22 12.11 10.47 12.77 12.10 21.87 15.57 6+4 9.99 11.22 12.11 10.74 13.70 12.66 27.47 17.88 6+5 9.99 11.22 12.11 11.09 14.74 13.30 32.82 19.93 6+6 9.99 11.22 12.11 11.50 15.85 14.00 37.74 21.74 表 4 三次空爆载荷下圆板中点位移理论与模拟结果的比较(Et=10.8 MPa)

Table 4. Comparison between theoretical and numerical results of midpoint displacement of the circular plate under three blast loads (Et=10.8 MPa)

冲量/(N·s) $ W_{1}^{\mathrm{f}} $/mm $ W_{1}^{\mathrm{f}} $误差/% $ W_{2}^{\mathrm{f}} $/mm $ W_{2}^{\mathrm{f}} $误差/% $ W_{3}^{\mathrm{f}} $/mm $ W_{3}^{\mathrm{f}} $误差/% 模拟 理论 模拟 理论 模拟 理论 3+3+3 4.43 6.12 38.15 5.49 7.65 39.34 6.76 8.92 31.95 4+4+4 6.24 7.87 26.12 7.50 9.84 31.20 9.42 11.48 21.87 5+5+5 8.10 9.56 18.02 9.34 11.95 27.94 11.79 13.94 18.24 6+6+6 9.99 11.20 12.11 11.50 14.00 21.74 15.17 16.33 7.65 4+5+6 6.24 7.87 26.12 8.30 10.65 28.31 11.84 13.57 14.61 4+6+5 6.24 7.87 26.12 9.43 11.52 22.16 12.37 13.57 9.70 5+4+6 8.10 9.56 18.02 8.94 11.24 25.73 12.00 14.03 16.92 5+6+4 8.10 9.56 18.02 10.11 12.73 25.91 11.81 14.03 18.80 6+4+5 9.99 11.20 12.11 10.74 12.66 17.88 12.07 14.55 20.55 6+5+4 9.99 11.20 12.11 11.09 13.30 19.93 12.20 14.55 19.26 表 5 三次空爆载荷下圆板中点位移理论与模拟结果的比较(Et=2 GPa)

Table 5. Comparison between theoretical and numerical results of midpoint displacement of the circular plate under three blast loads (Et=2 GPa)

冲量/(N·s) $ W_{1}^{\mathrm{f}} $/mm $ W_{1}^{\mathrm{f}} $误差/% $ W_{2}^{\mathrm{f}} $/mm $ W_{2}^{\mathrm{f}} $误差/% $ W_{3}^{\mathrm{f}} $/mm $ W_{3}^{\mathrm{f}} $误差/% 模拟 理论 模拟 理论 模拟 理论 3+3+3 4.18 5.70 36.36 5.33 7.14 33.96 5.78 8.27 43.08 4+4+4 5.85 7.04 20.34 6.68 8.87 32.78 8.36 10.25 22.61 5+5+5 7.45 8.18 9.80 8.46 10.37 22.58 10.10 11.98 18.61 6+6+6 9.02 9.16 1.55 10.08 11.70 16.07 12.36 13.52 9.39 4+5+6 5.85 7.04 20.34 7.51 9.62 28.10 10.78 12.00 11.32 4+6+5 5.85 7.04 20.34 8.50 10.41 22.47 10.59 12.02 13.50 5+4+6 7.45 8.18 9.80 7.95 9.72 22.26 10.27 12.07 17.53 5+6+4 7.45 8.18 9.80 9.10 11.08 21.76 10.33 12.09 17.04 6+4+5 9.02 9.16 1.55 9.37 10.49 11.95 10.51 12.08 14.94 6+5+4 9.02 9.16 1.55 9.70 11.07 14.12 10.35 12.08 16.71 -

[1] JONES N. Structural impact [M]. 2nd ed. New York: Cambridge University Press, 2012. [2] HENCHIE T F, YUEN S C K, NURICK G N, et al. The response of circular plates to repeated uniform blast loads: an experimental and numerical study [J]. International Journal of Impact Engineering, 2014, 74: 36–45. DOI: 10.1016/j.ijimpeng.2014.02.021. [3] 周游, 纪冲, 王雷元, 等. 重复爆炸载荷作用下薄壁方管动力响应研究 [J]. 兵工学报, 2019, 40(9): 1871–1880. DOI: 10.3969/j.issn.1000-1093.2019.09.012.ZHOU Y, JI Y, WANG L Y, et al. Research on the dynamic response of thin-walled square tube under repeated blast loads [J]. Acta Armamentarii, 2019, 40(9): 1871–1880. DOI: 10.3969/j.issn.1000-1093.2019.09.012. [4] 张斐, 张春辉, 张磊, 等. 多次水下爆炸作用下钢板动态响应数值模拟 [J]. 中国舰船研究, 2019, 14(6): 122–129. DOI: 10.19693/j.issn.1673-3185.01431.ZHANG F, ZHANG C H, ZHANG L, et al. Numerical simulation of dynamic response of steel plate subjected to multiple underwater explosions [J]. Chinese Journal of Ship Research, 2019, 14(6): 122–129. DOI: 10.19693/j.issn.1673-3185.01431. [5] 张斐, 张春辉, 张磊, 等. 多次水下爆炸作用下钢板与焊接钢板冲击损伤特性 [J]. 振动与冲击, 2020, 39(7): 196–201. DOI: 10.13465/j.cnki.jvs.2020.07.027.ZHANG F, ZHANG C H, ZHANG L, et al. Impact damage of steel plate and welding steel plate under multiple Underwater Explosions [J]. Journal of Vibration and Shock, 2020, 39(7): 196–201. DOI: 10.13465/j.cnki.jvs.2020.07.027. [6] 李旭东, 尹建平, 杜志鹏, 等. 多次水下爆炸钢制圆板应变与挠度增长规律分析 [J]. 振动与冲击, 2020, 39(5): 131–136. DOI: 10.13465/j.cnki.jvs.2020.05.017.LI X D, YIN J P, DU Z P, et al. Growth law analysis for strain and deflection of steel circular plates subjected to multiple underwater explosions [J]. Journal of Vibration and Shock, 2020, 39(5): 131–136. DOI: 10.13465/j.cnki.jvs.2020.05.017. [7] ZIYA-SHAMAMI M, BABAEI H, MOSTOFI T M, et al. Structural response of monolithic and multi-layered circular metallic plates under repeated uniformly distributed impulsive loading: an experimental study [J]. Thin-Walled Structures, 2020, 157: 107024. DOI: 10.1016/j.tws.2020.107024. [8] 李锡锋. 多次内爆加载下舰船舱室结构毁伤效应研究 [D]. 太原: 中北大学, 2021. DOI: 10.27470/d.cnki.ghbgc.2021.001010.LI X F. Research on damage effect of ship cabin structure under multiple implosion [D]. Taiyuan: North University of China, 2021. DOI: 10.27470/d.cnki.ghbgc.2021.001010. [9] NASIRI S, SADEGH-YAZDI M, MOUSAVI S M, et al. Repeated underwater explosive forming: experimental investigation and numerical modeling based on coupled Eulerian–Lagrangian approach [J]. Thin-Walled Structures, 2022, 172: 108860. DOI: 10.1016/j.tws.2021.108860. [10] 唐正鹏, 李翔宇, 郑监. 多次水下爆炸中船体梁的累积毁伤效应 [J]. 高压物理学报, 2022, 36(2): 025102. DOI: 10.11858/gywlxb.20210809.TANG Z P, LI X Y, ZHENG J. Cumulative damage effect of hull girder subjected to multiple underwater explosions [J]. Chinese Journal of High Pressure Physics, 2022, 36(2): 025102. DOI: 10.11858/gywlxb.20210809. [11] 唐正鹏, 李翔宇. 多次水下爆炸对船体梁累积毁伤试验研究 [J]. 水下无人系统学报, 2022, 30(3): 364–370,377. DOI: 10.11993/j.issn.2096-3920.2022.03.012.TANG Z P, LI X Y. Experiments on cumulative damage to hull girders subjected to multiple underwater explosions [J]. Journal of Unmanned Undersea Systems, 2022, 30(3): 364–370,377. DOI: 10.11993/j.issn.2096-3920.2022.03.012. [12] TIAN W J, ZHAI H B, LIU Y S, et al. A response prediction method for clamped circular plates subjected to repeated blast loading [J]. International Journal of Impact Engineering, 2023, 180: 104684. DOI: 10.1016/j.ijimpeng.2023.104684. [13] 黄鑫华, 李应刚, 张永峰, 等. 多次水下爆炸下背空加筋板损伤累积特性研究 [J]. 舰船科学技术, 2023, 45(19): 9–16. DOI: 10.3404/j.issn.1672-7649.2023.19.002.HUANG X H, LI Y G, ZHANG Y F, et al. Research on damage accumulation characteristic of air-backed stiffened plate subjected to multiple underwater explosions [J]. Ship Science and Technology, 2023, 45(19): 9–16. DOI: 10.3404/j.issn.1672-7649.2023.19.002. [14] 张文超. 多发武器水下爆炸作用下结构毁伤特性及冲击环境研究 [D]. 哈尔滨: 哈尔滨工程大学, 2022. DOI: 10.27060/d.cnki.ghbcu.2022.001456.ZHANG W C. Research on structural damage characteristics and impact environment of multiple weapons exploded underwater [D]. Harbin: Harbin Engineering University, 2022. DOI: 10.27060/d.cnki.ghbcu.2022.001456. [15] LI X Y, LIANG M Z, TIAN Z D, et al. Dynamic response and cumulative damage mechanism of simplified hull girders under repeated underwater explosions [J]. Thin-Walled Structures, 2024, 196: 111554. DOI: 10.1016/j.tws.2023.111554. [16] BODNER S R, SYMONDS P S. Experiments on viscoplastic response of circular plates to impulsive loading [J]. Journal of the Mechanics and Physics of Solids, 1979, 27(2): 91–113. DOI: 10.1016/0022-5096(79)90013-9. [17] WEI Q Y, WANG Z, SHI D Y, et al. Method based on the membrane theory for equivalence between arbitrarily shaped pressure pulse applied on circular plate and rectangular pressure pulse [J]. International Journal of Impact Engineering, 2023, 179: 104658. DOI: 10.1016/j.ijimpeng.2023.104658. -

下载:

下载: