Energy absorption characteristics and crashworthiness designs for typical metal aircraft fuselage substructure

-

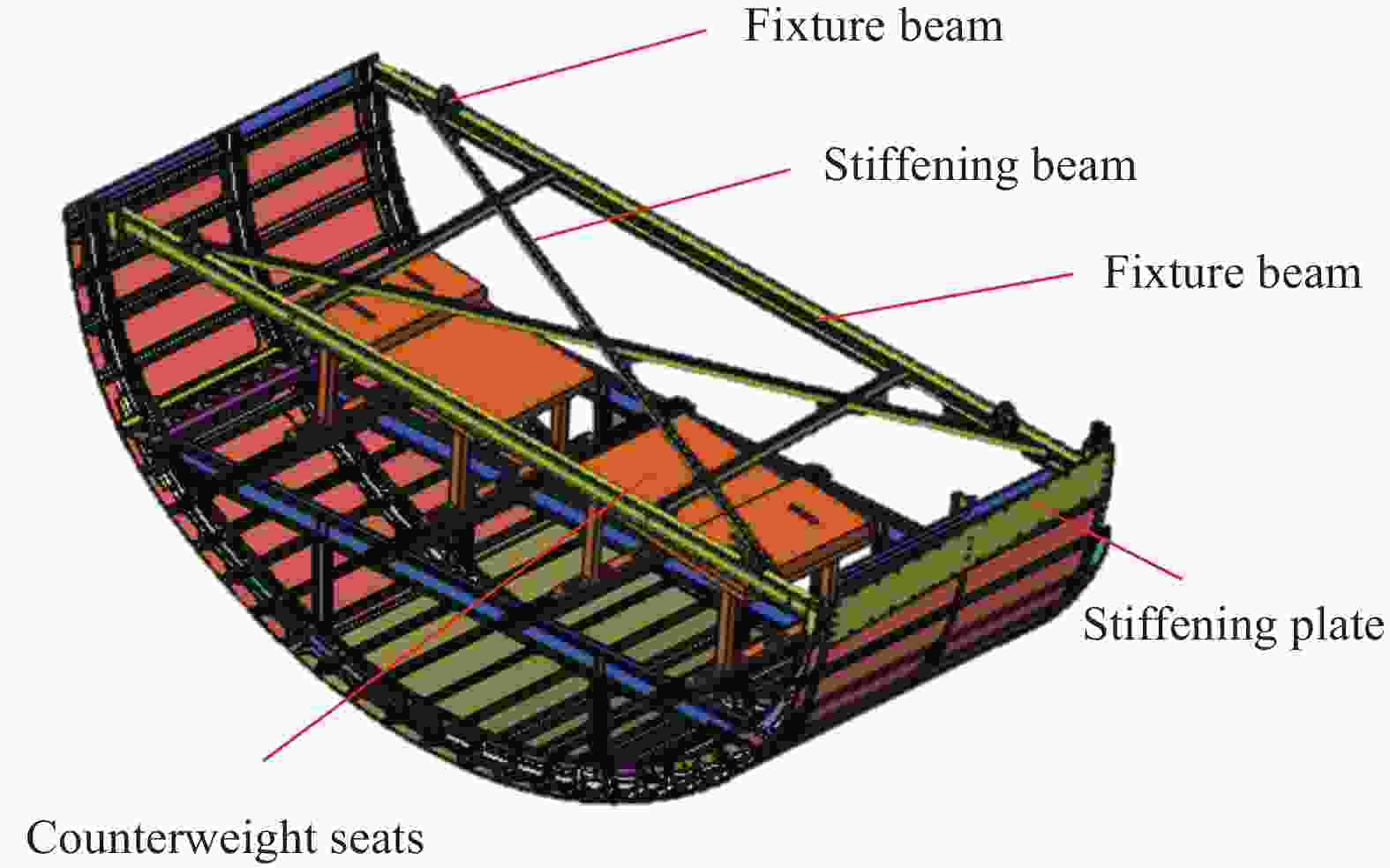

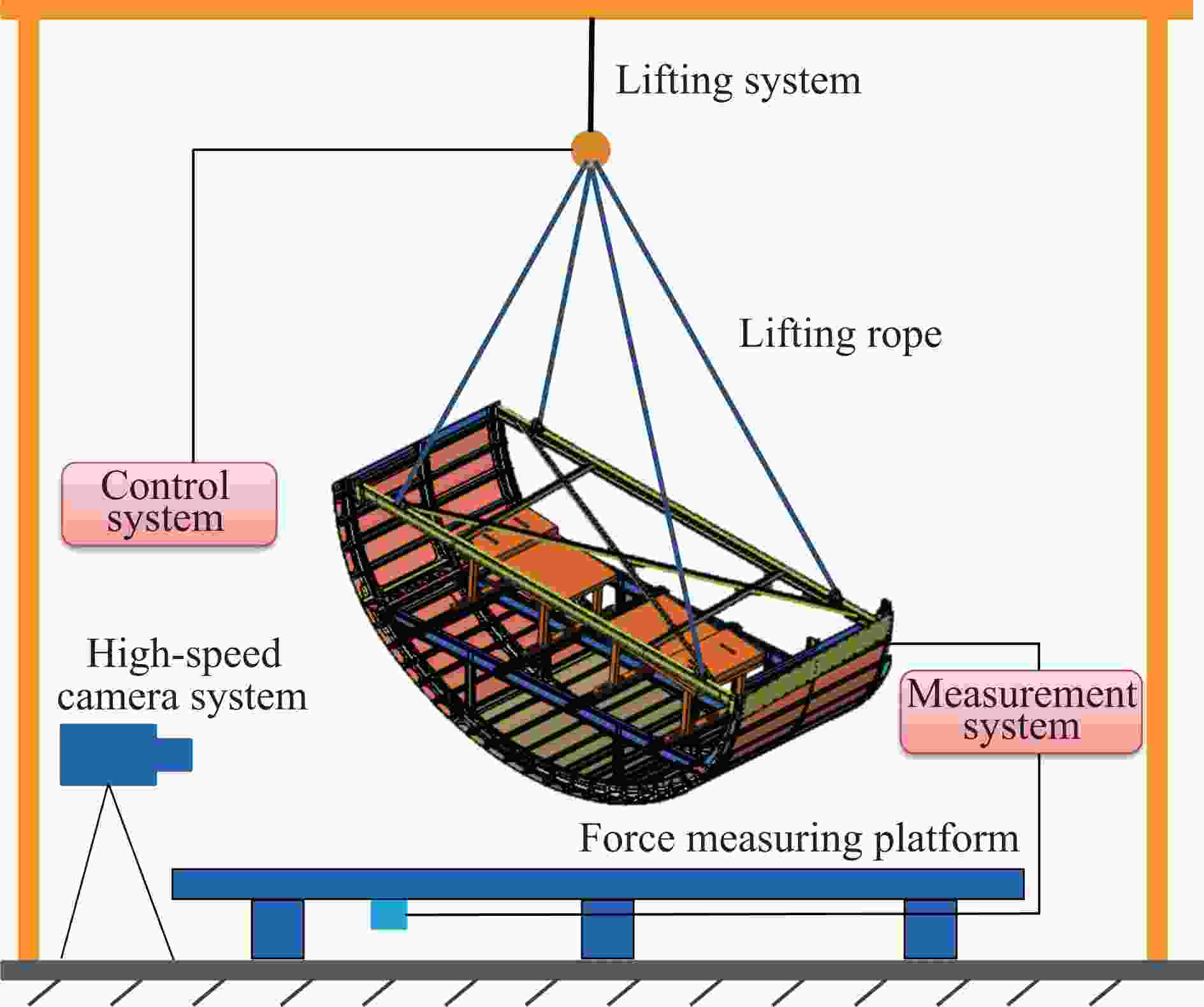

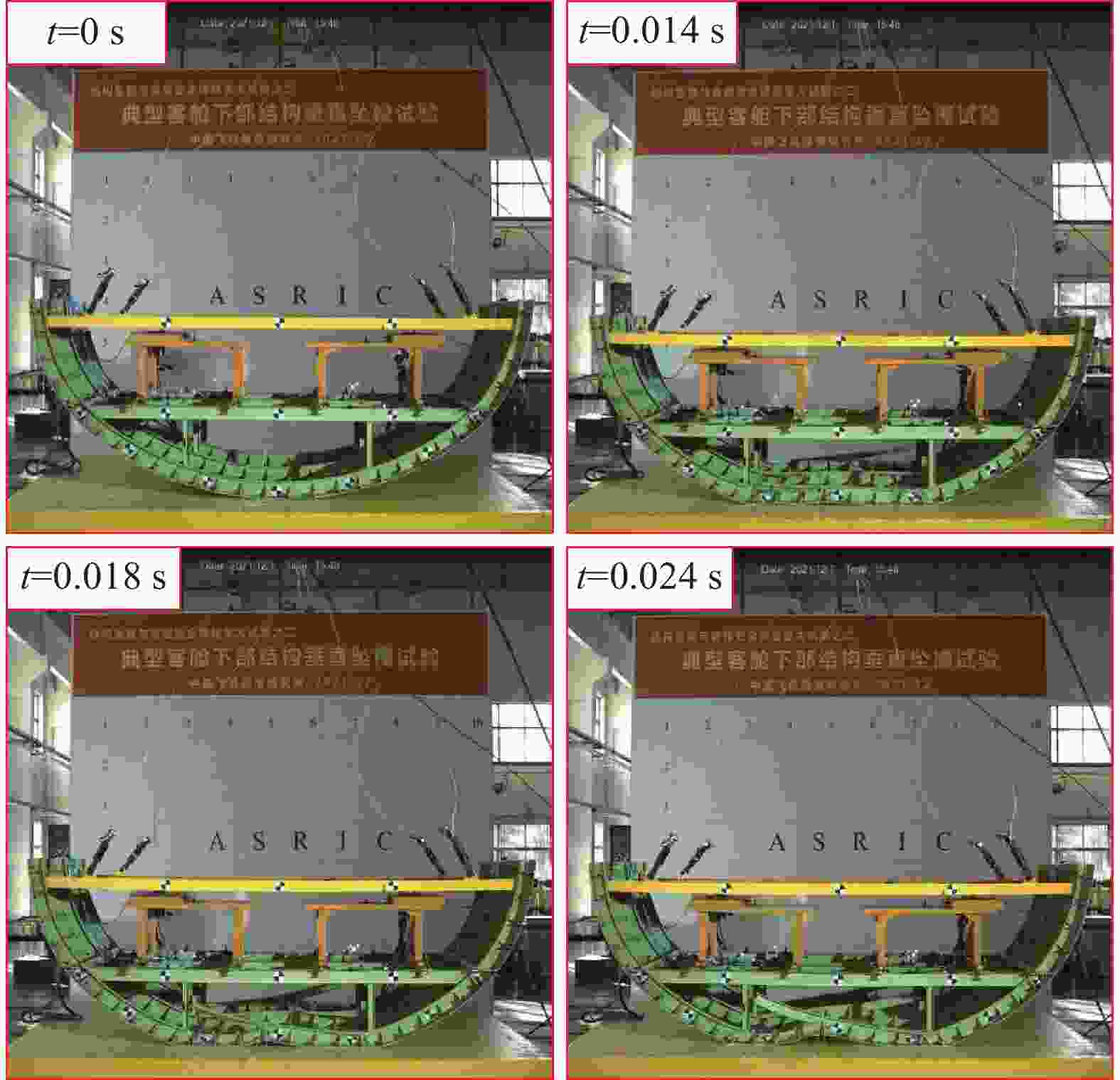

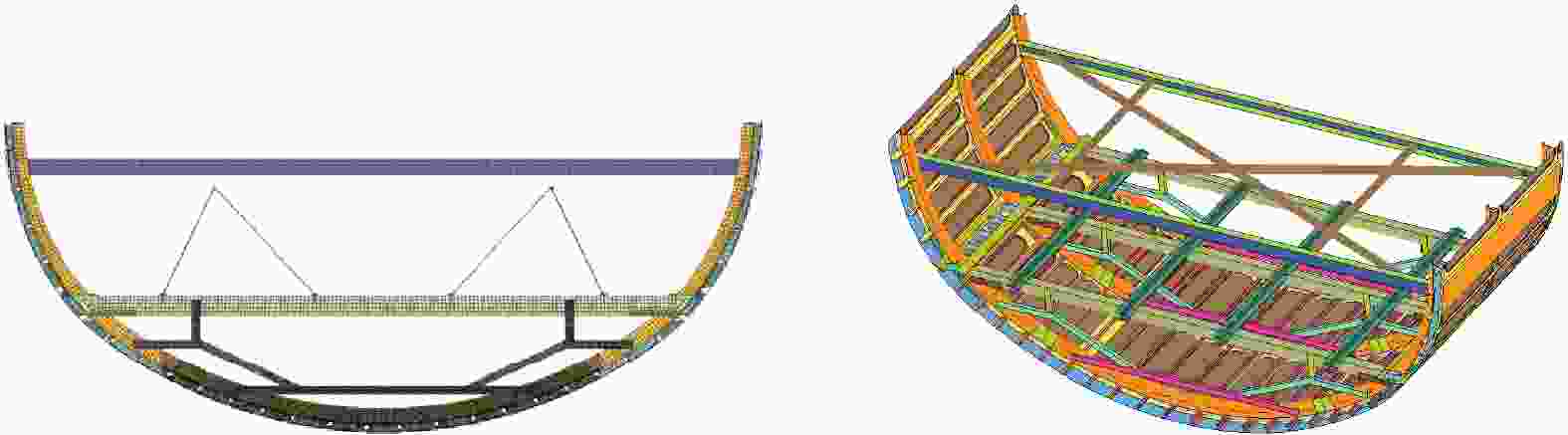

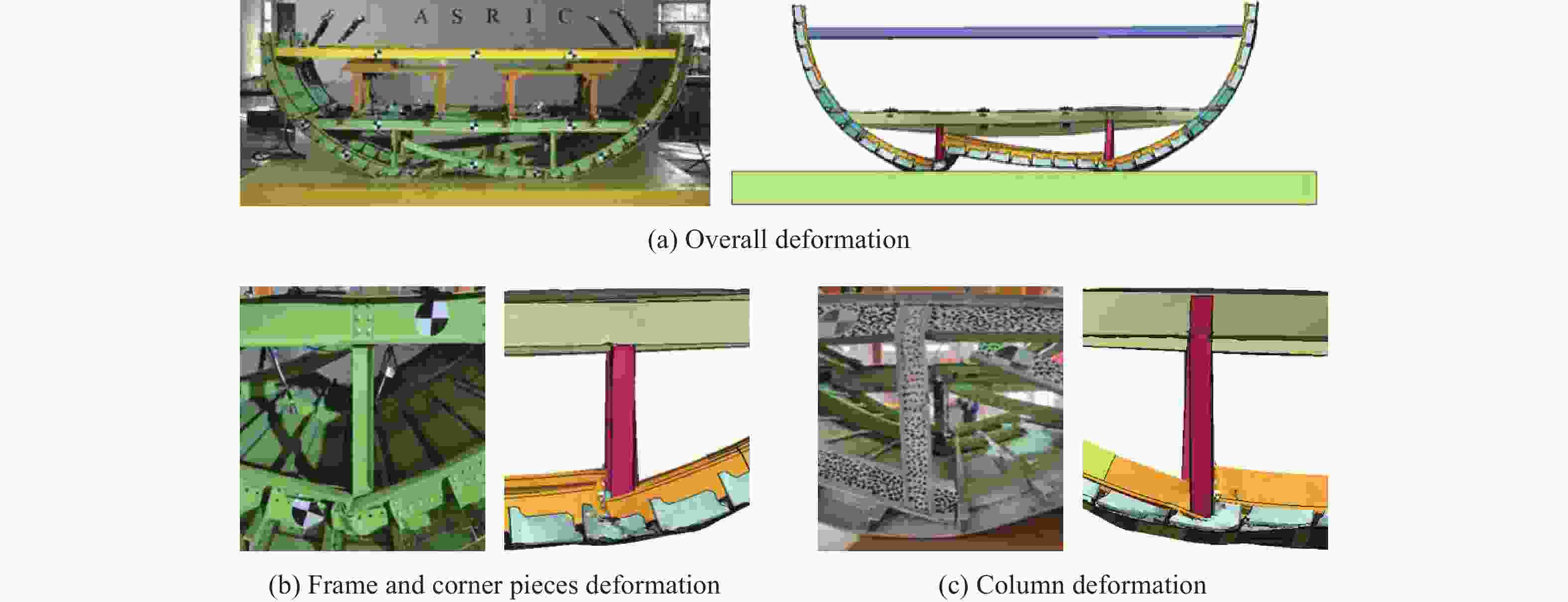

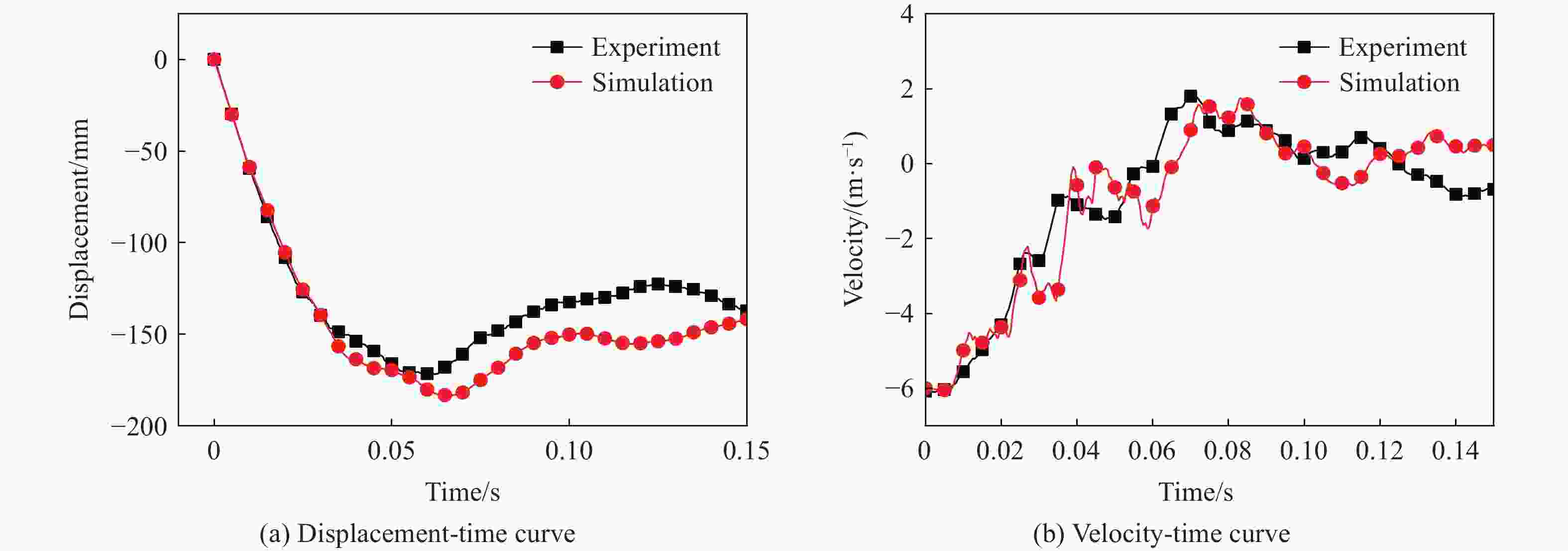

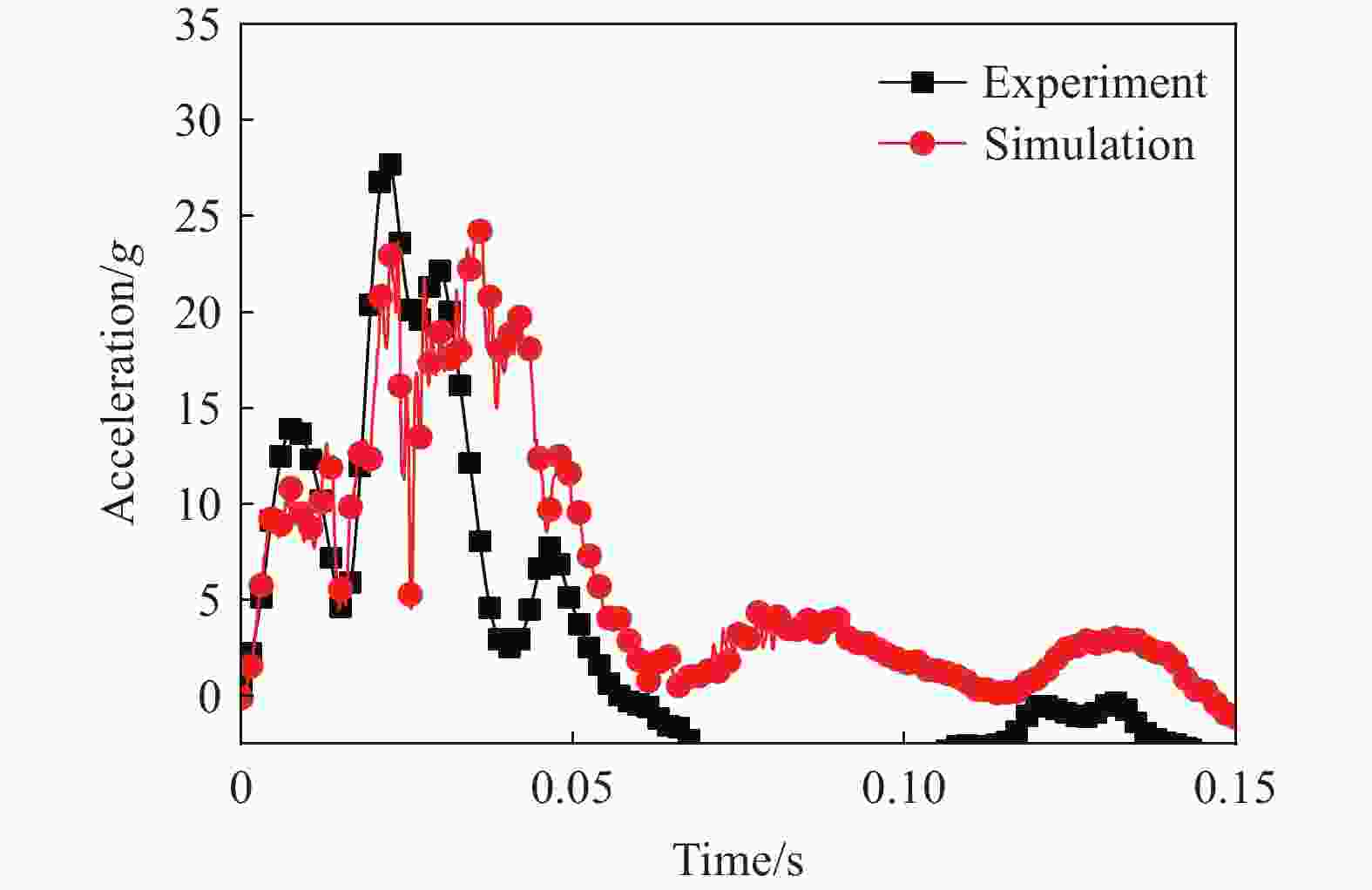

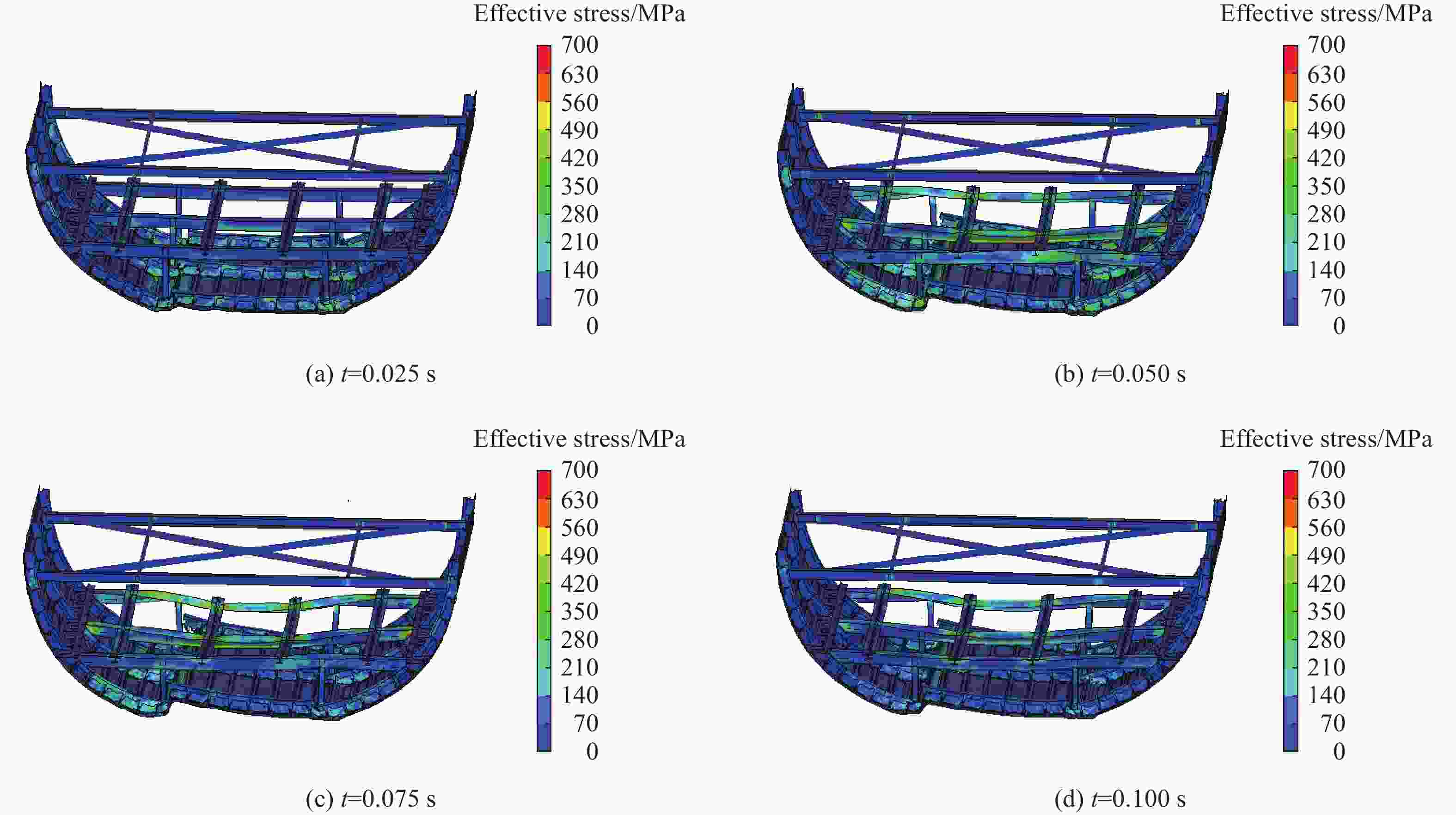

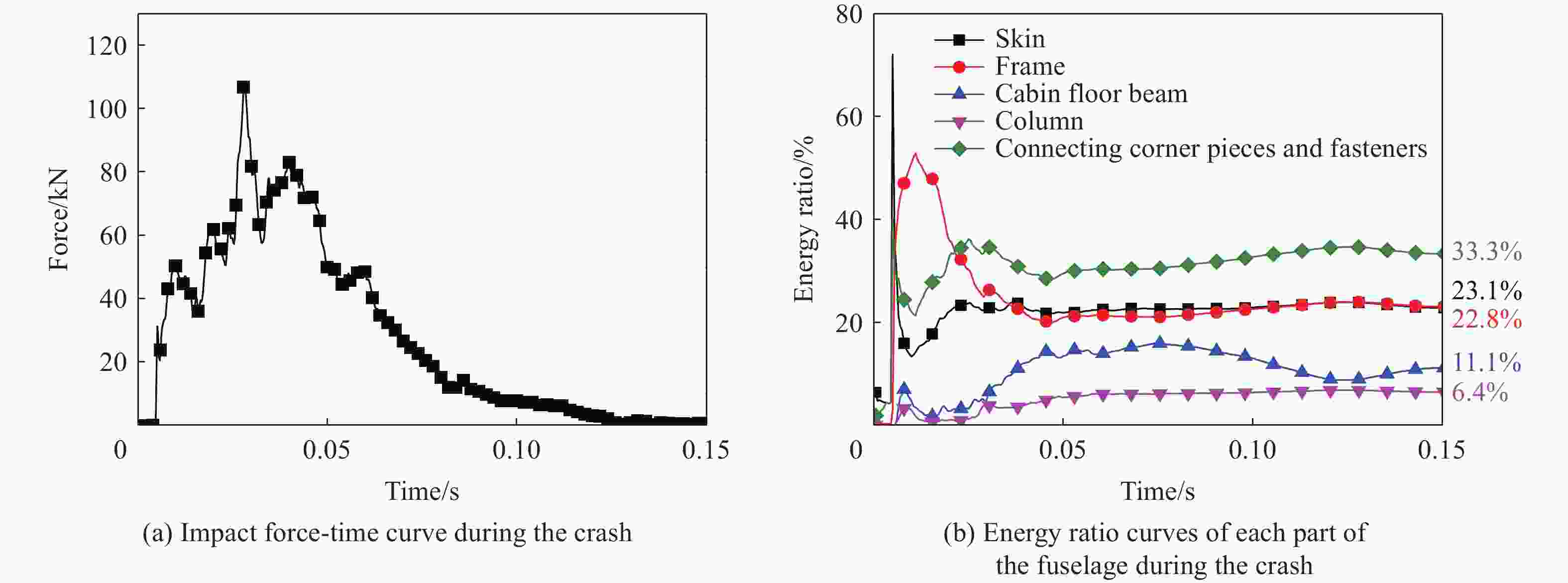

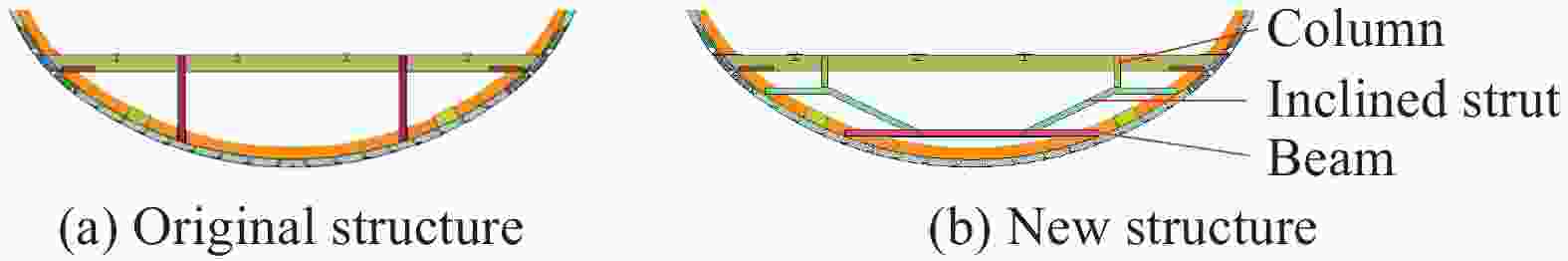

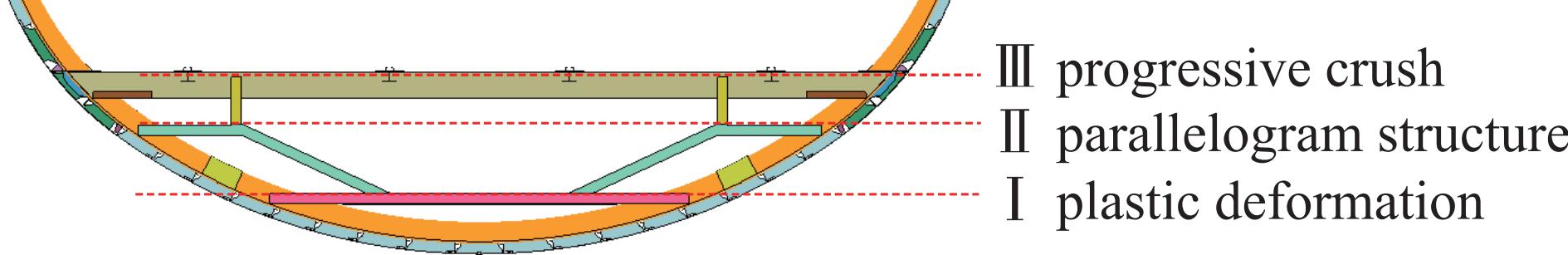

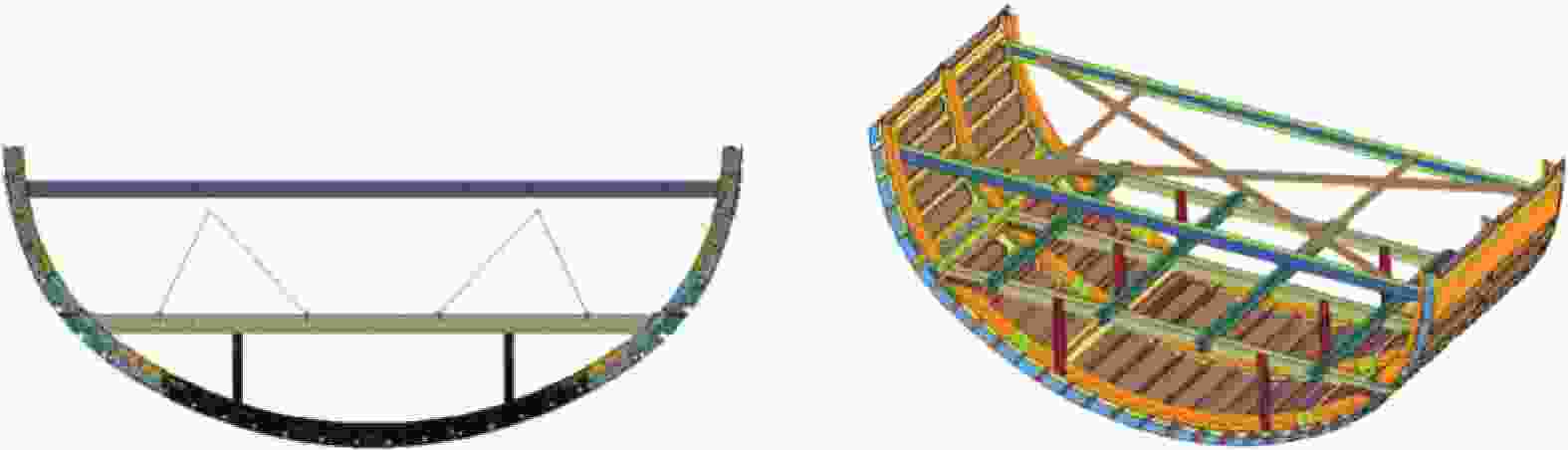

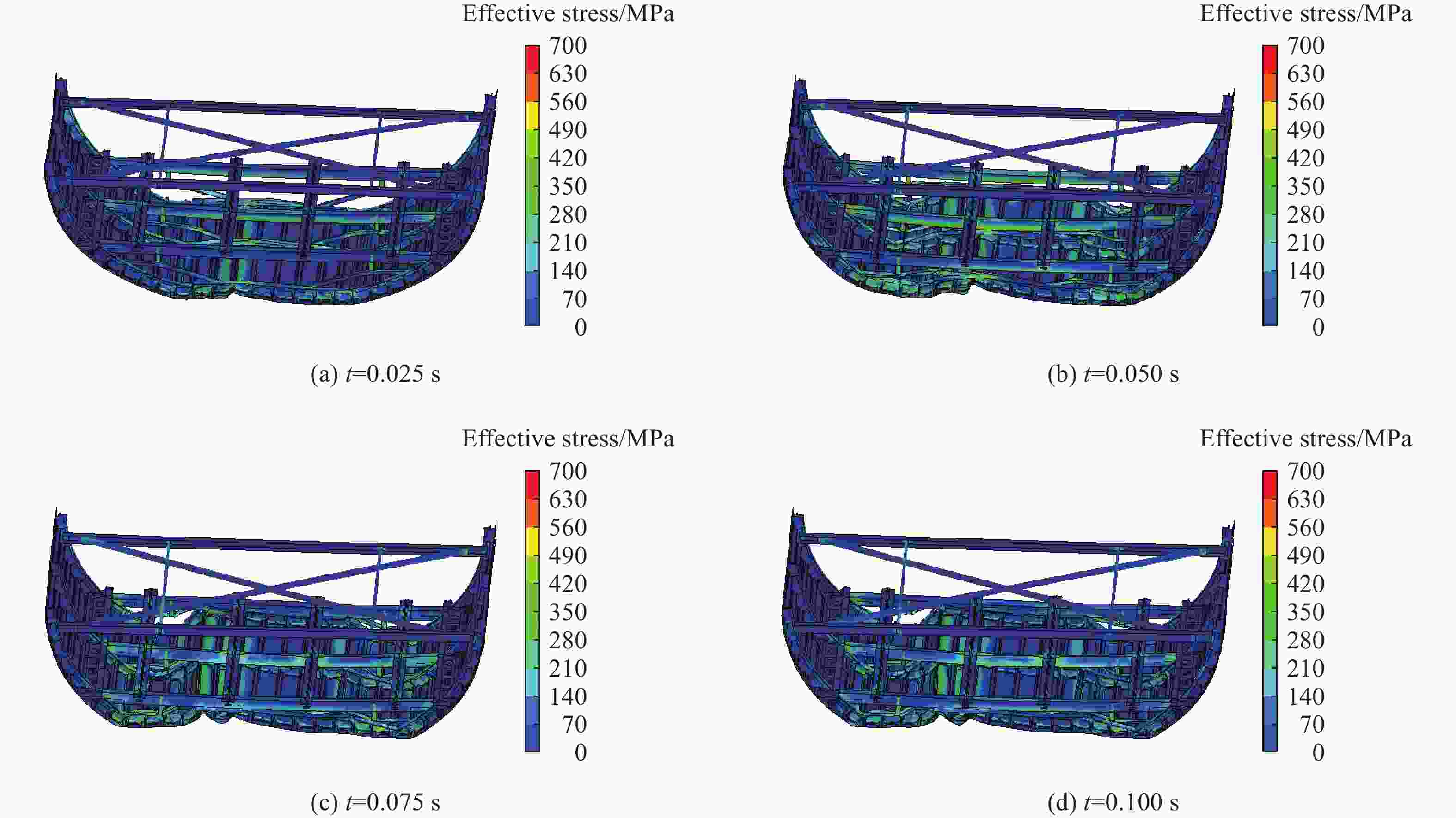

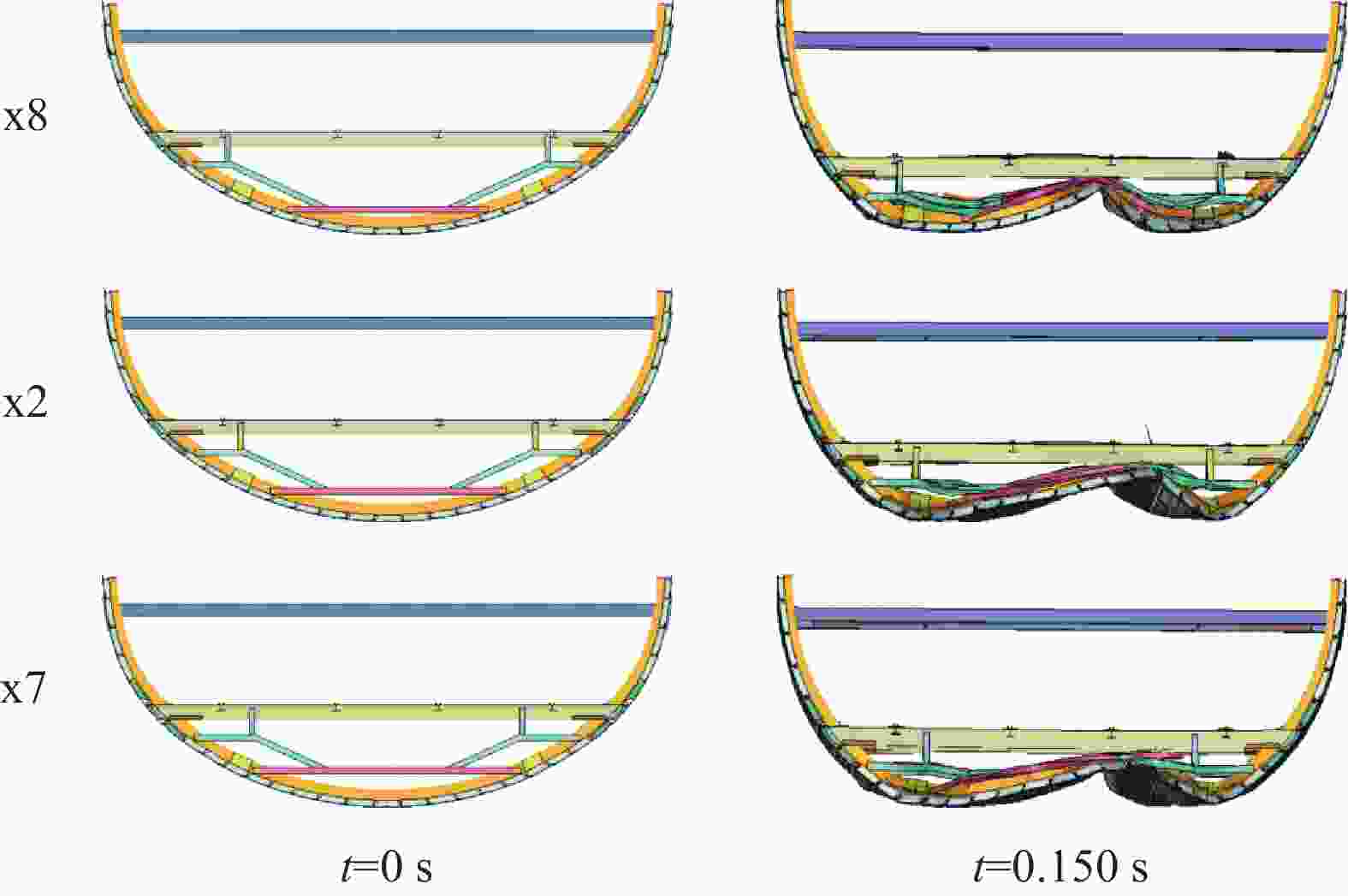

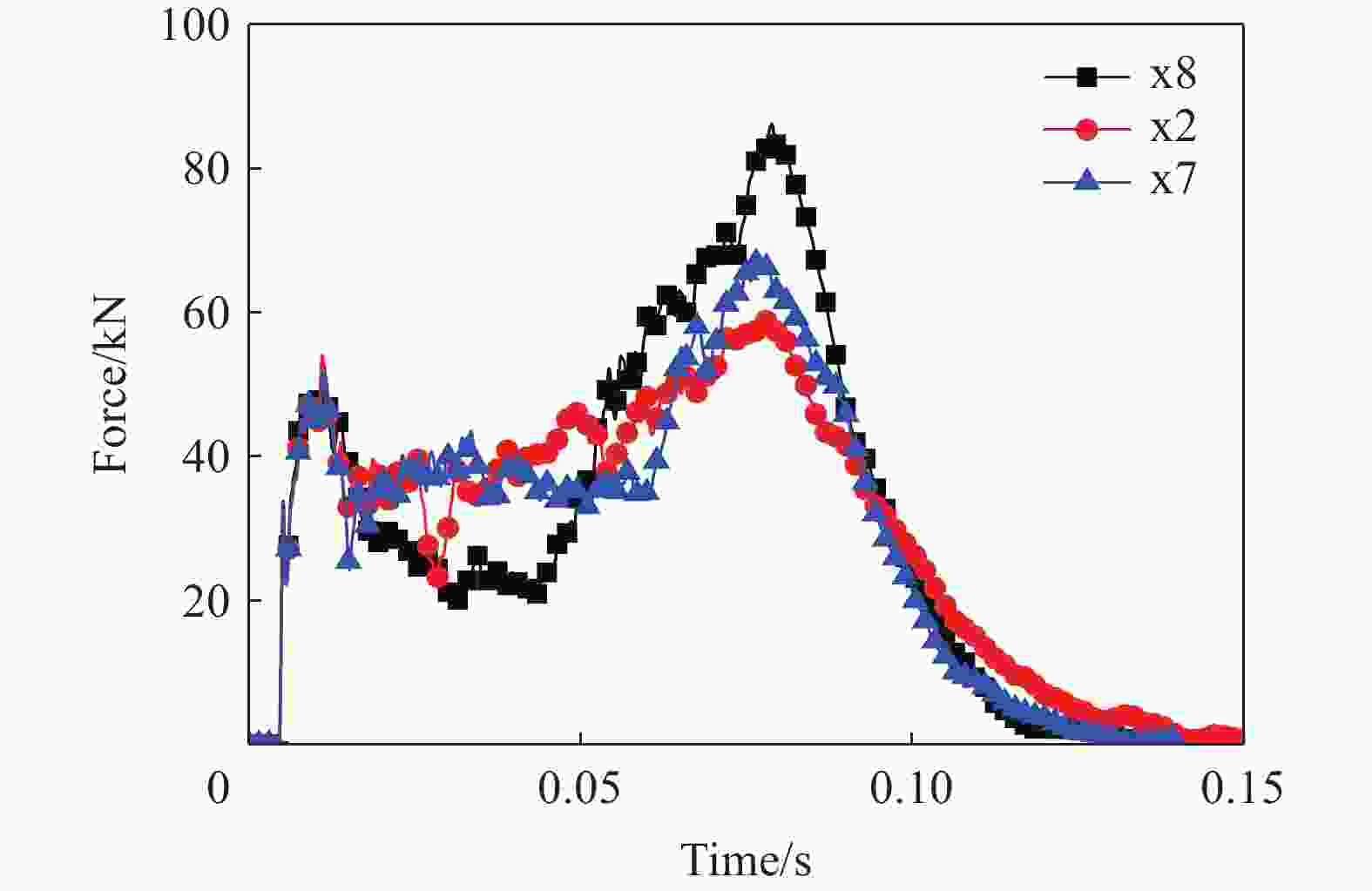

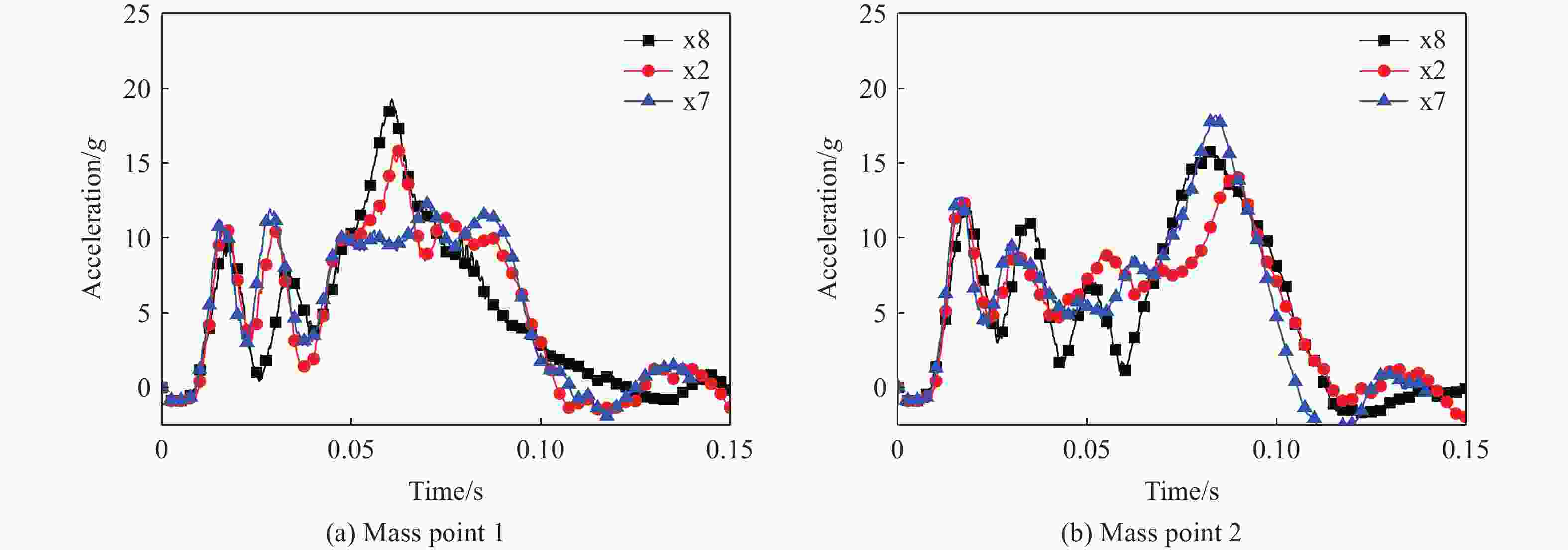

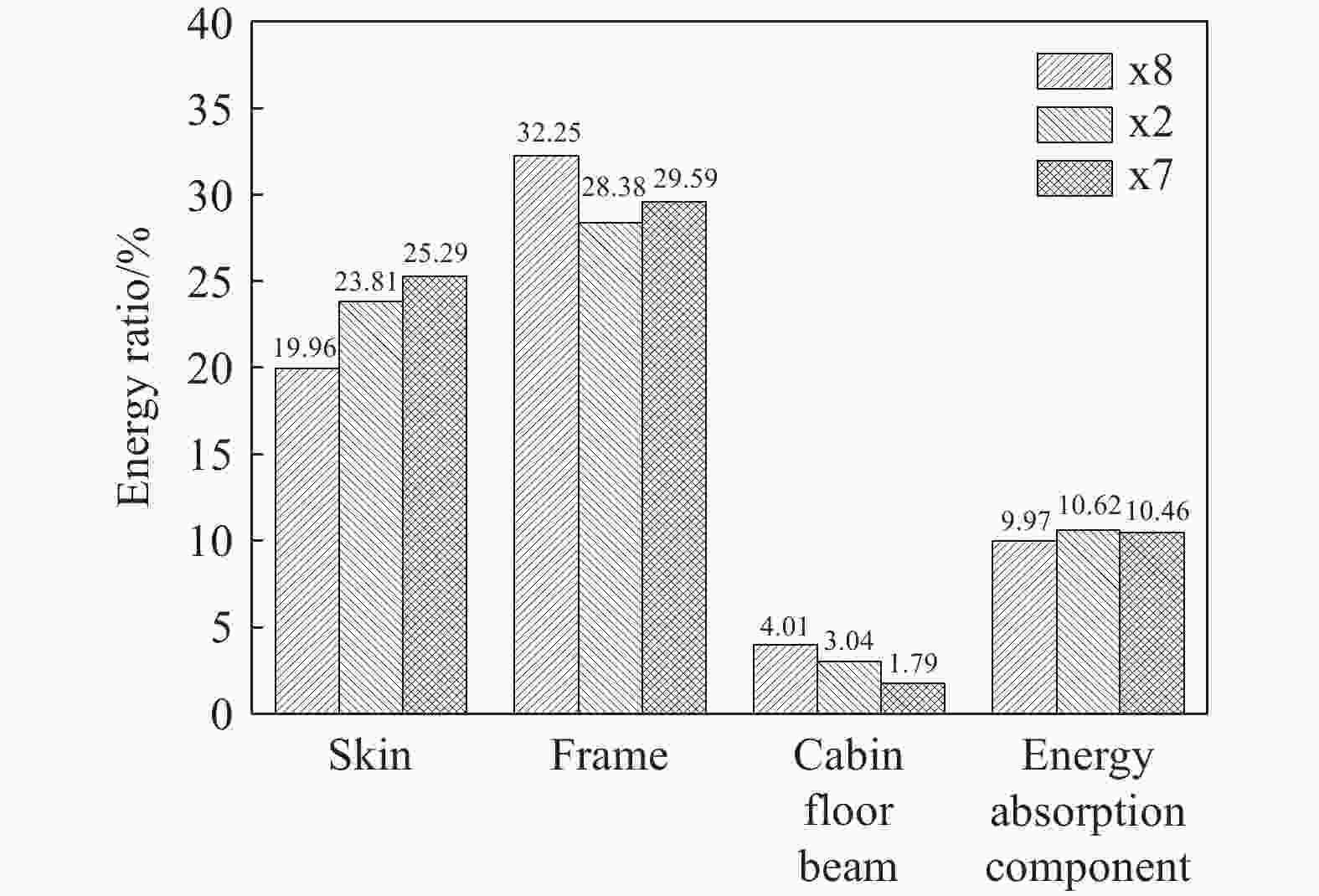

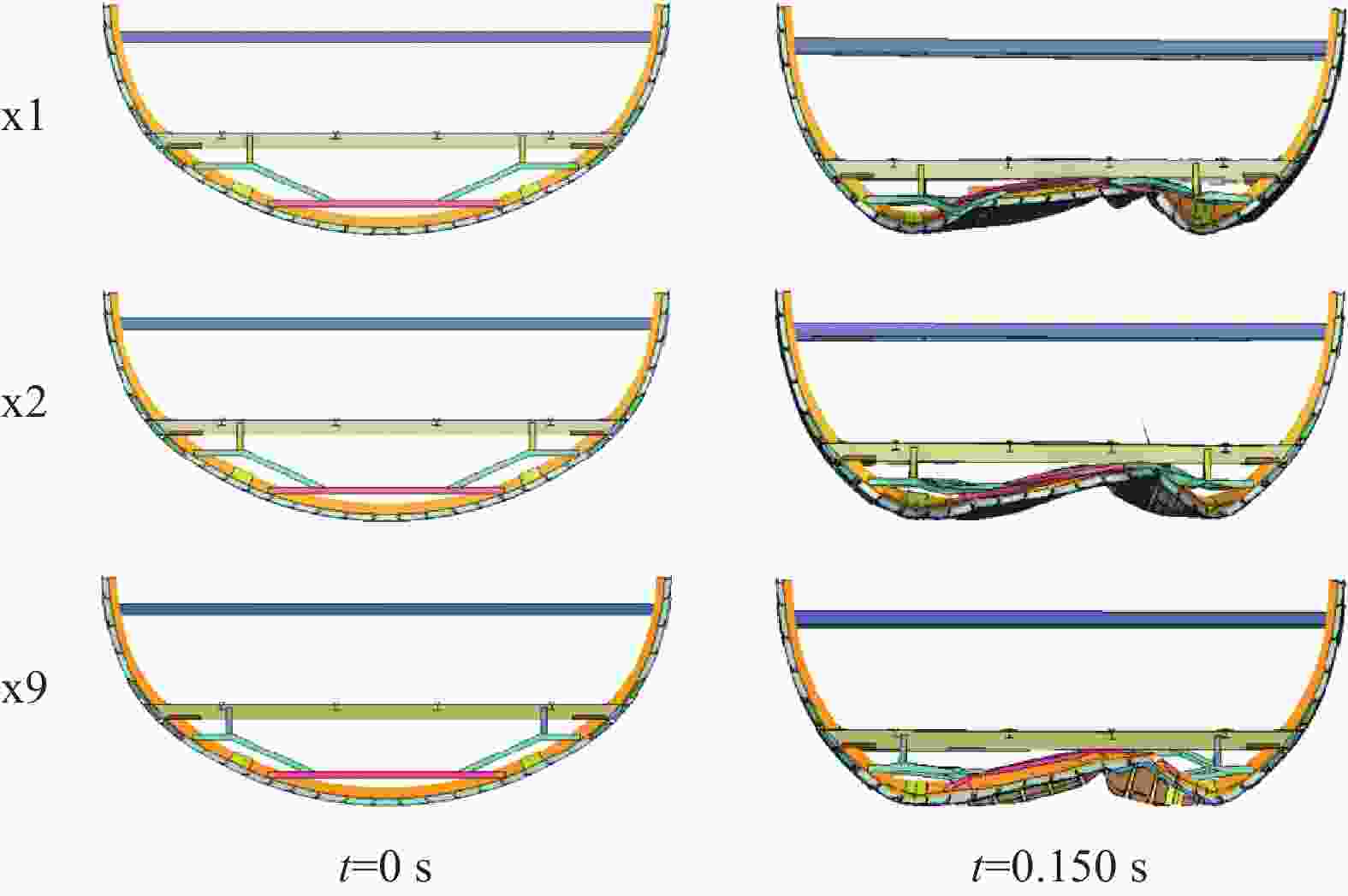

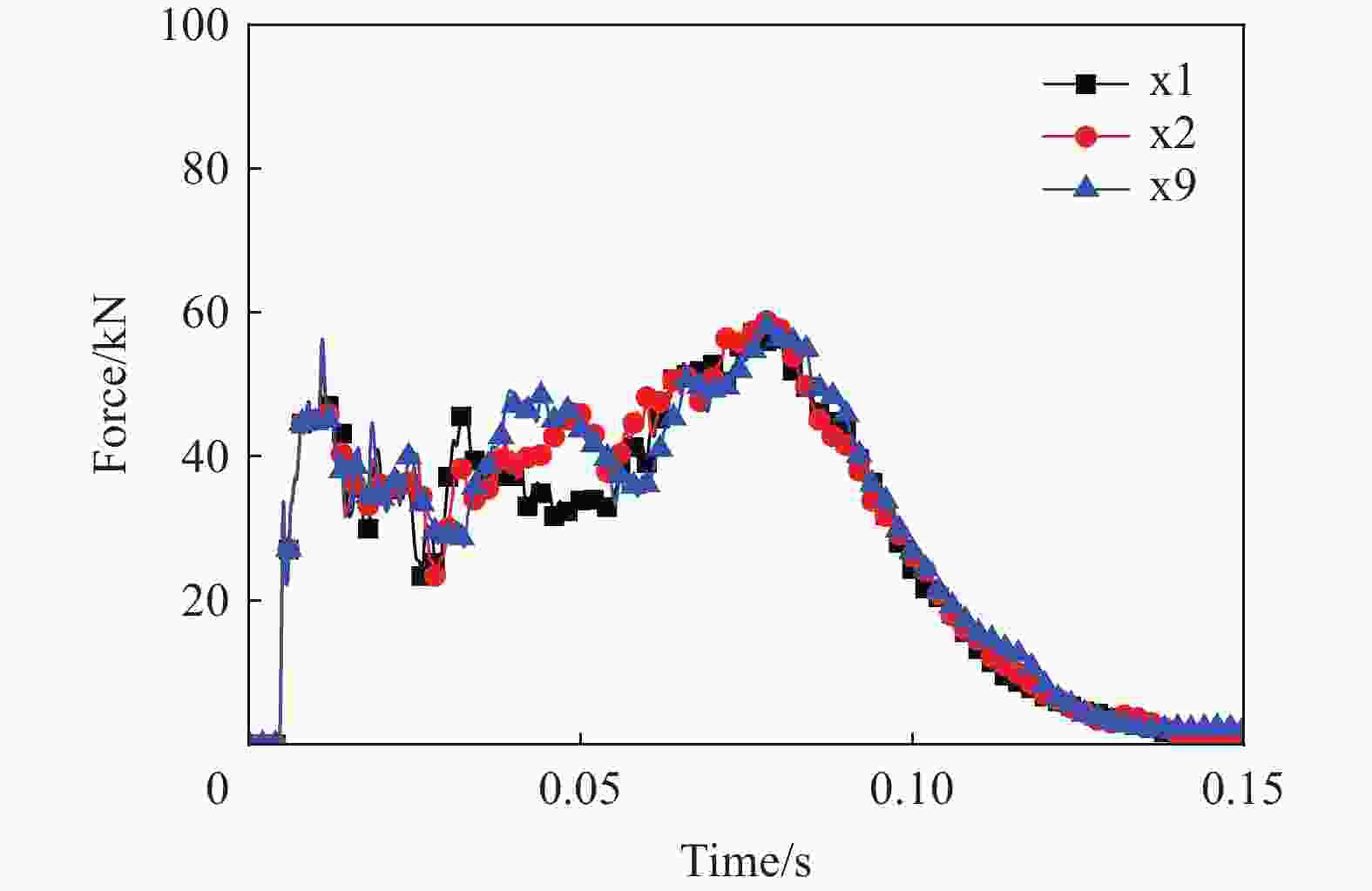

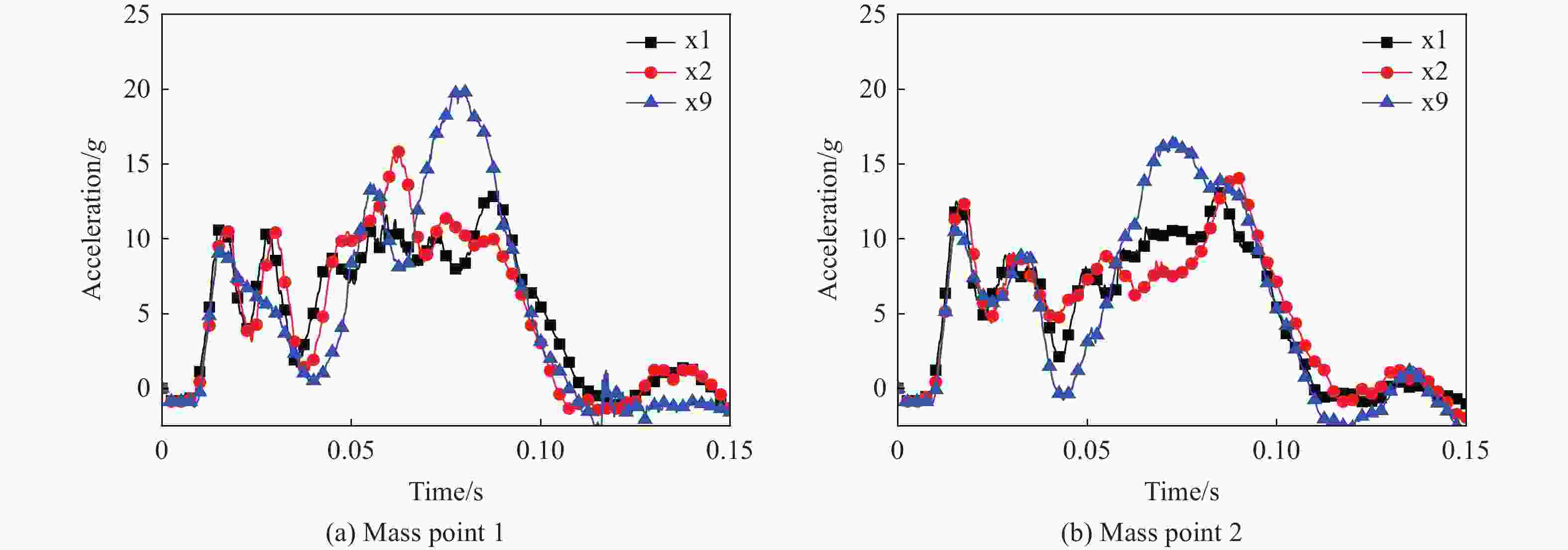

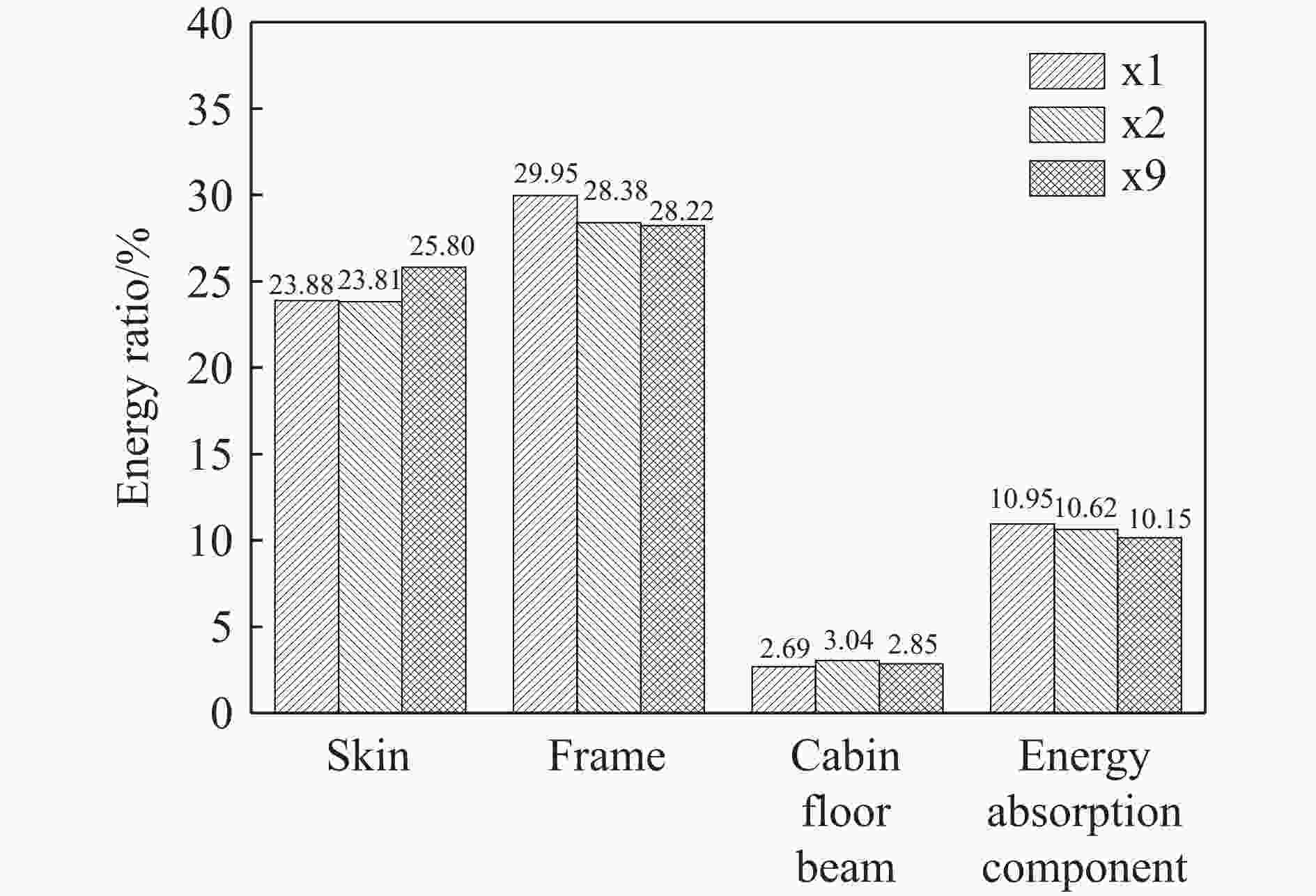

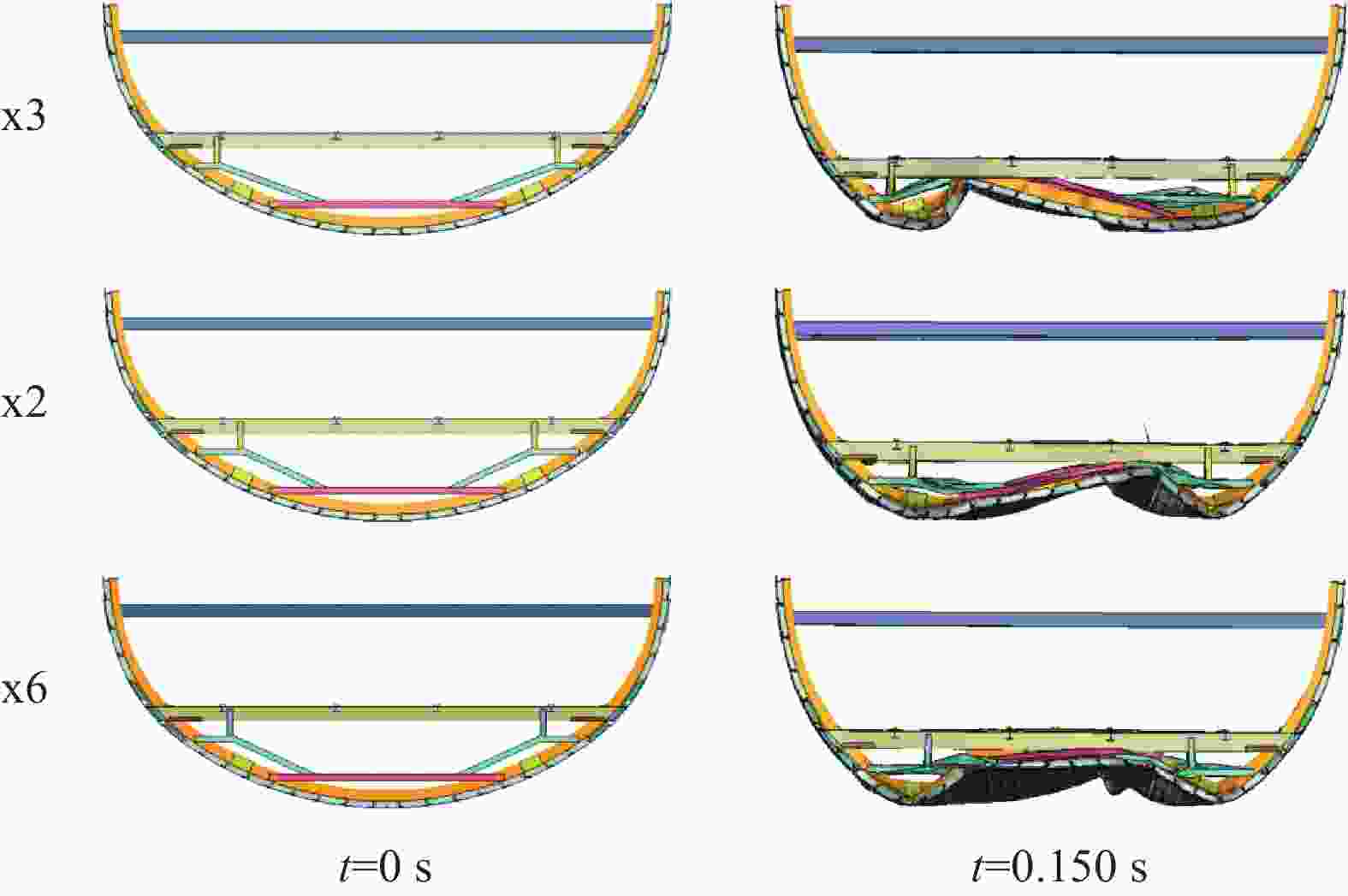

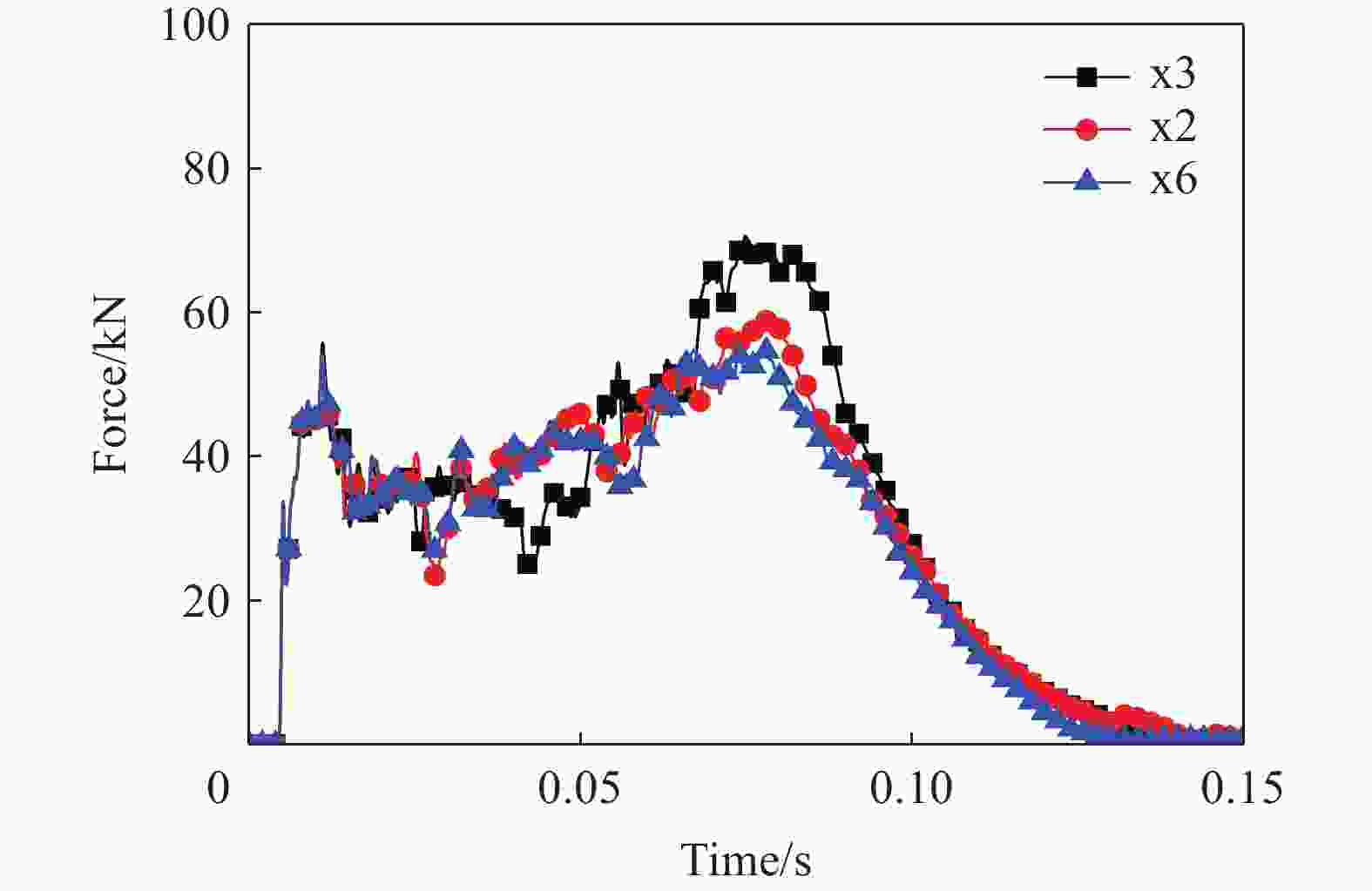

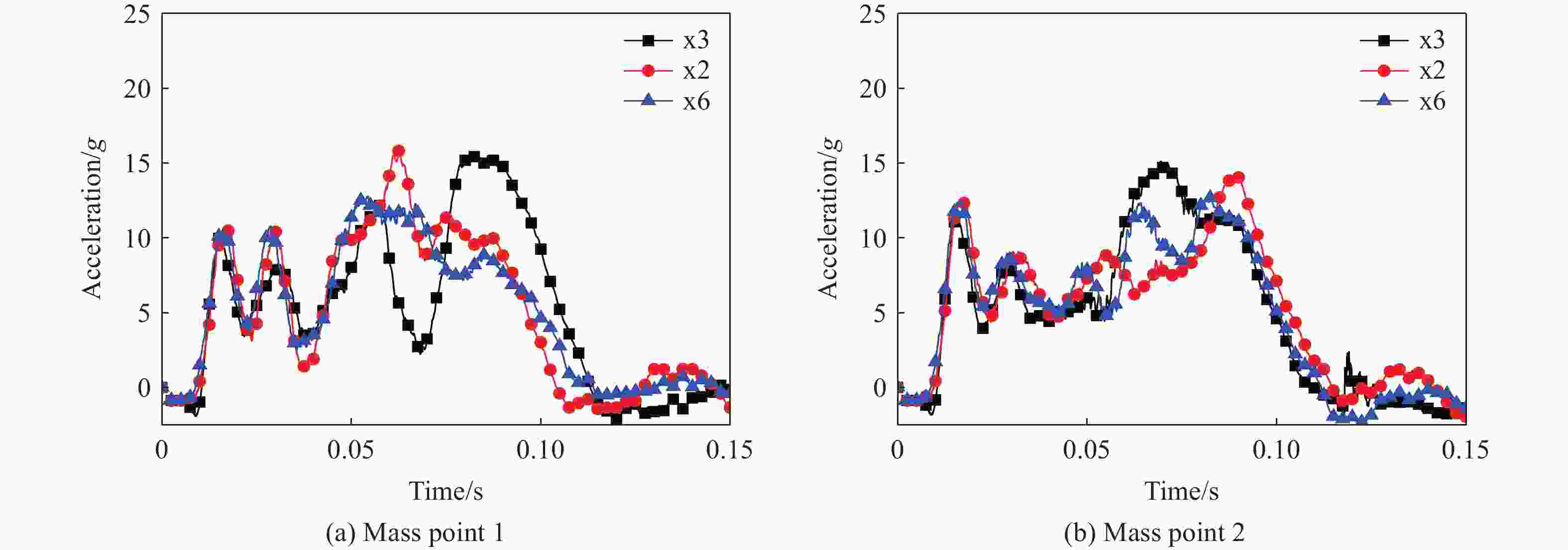

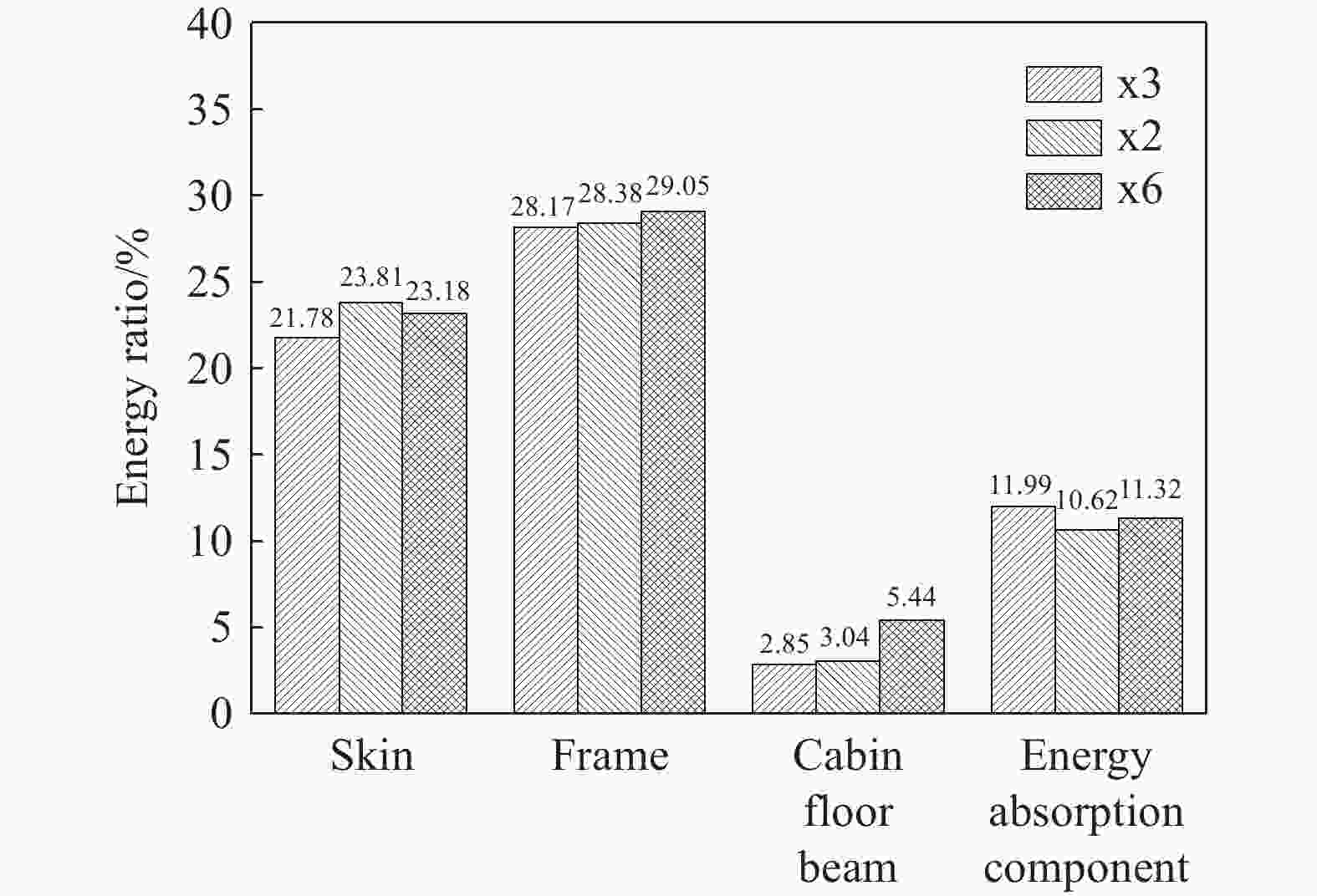

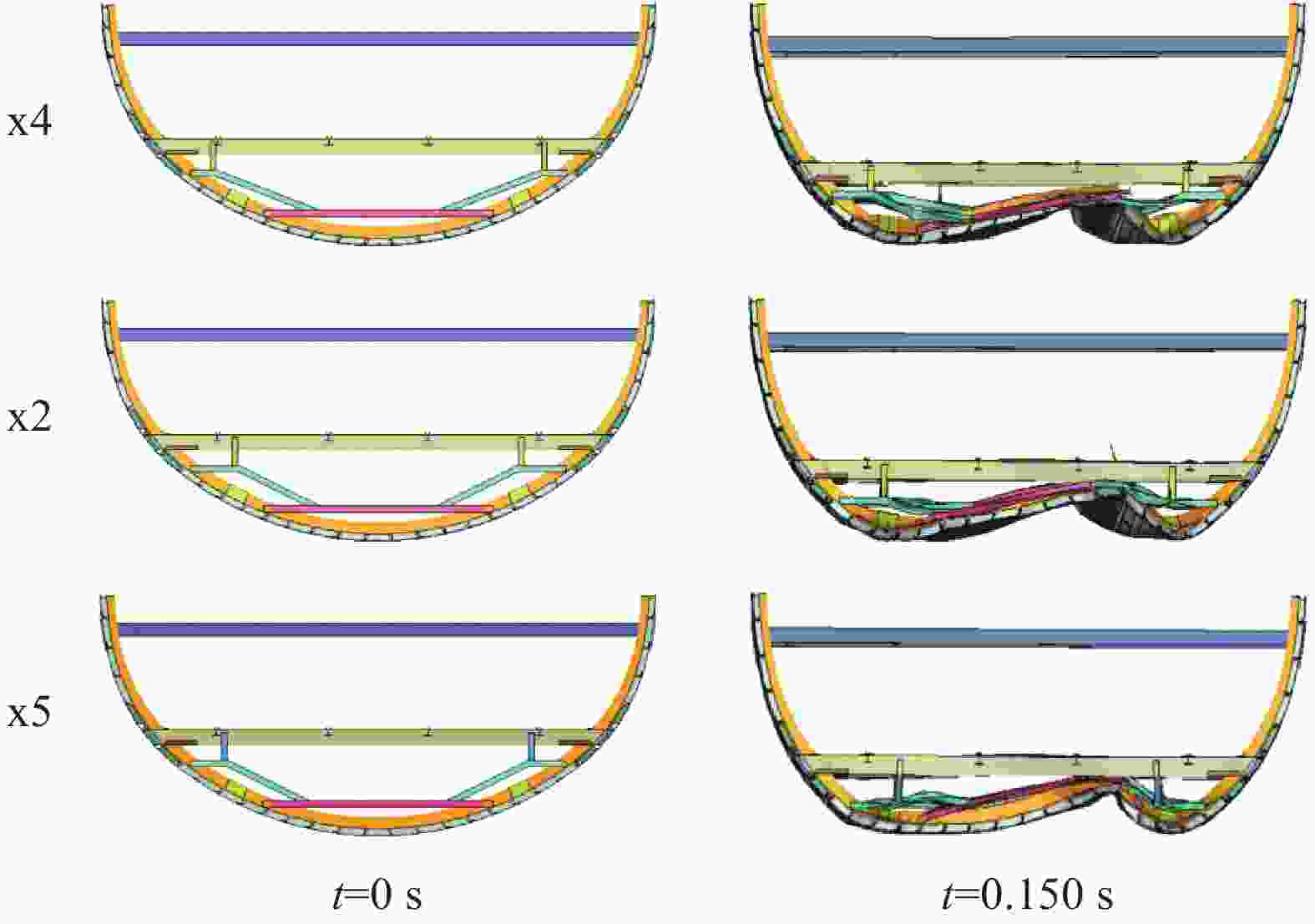

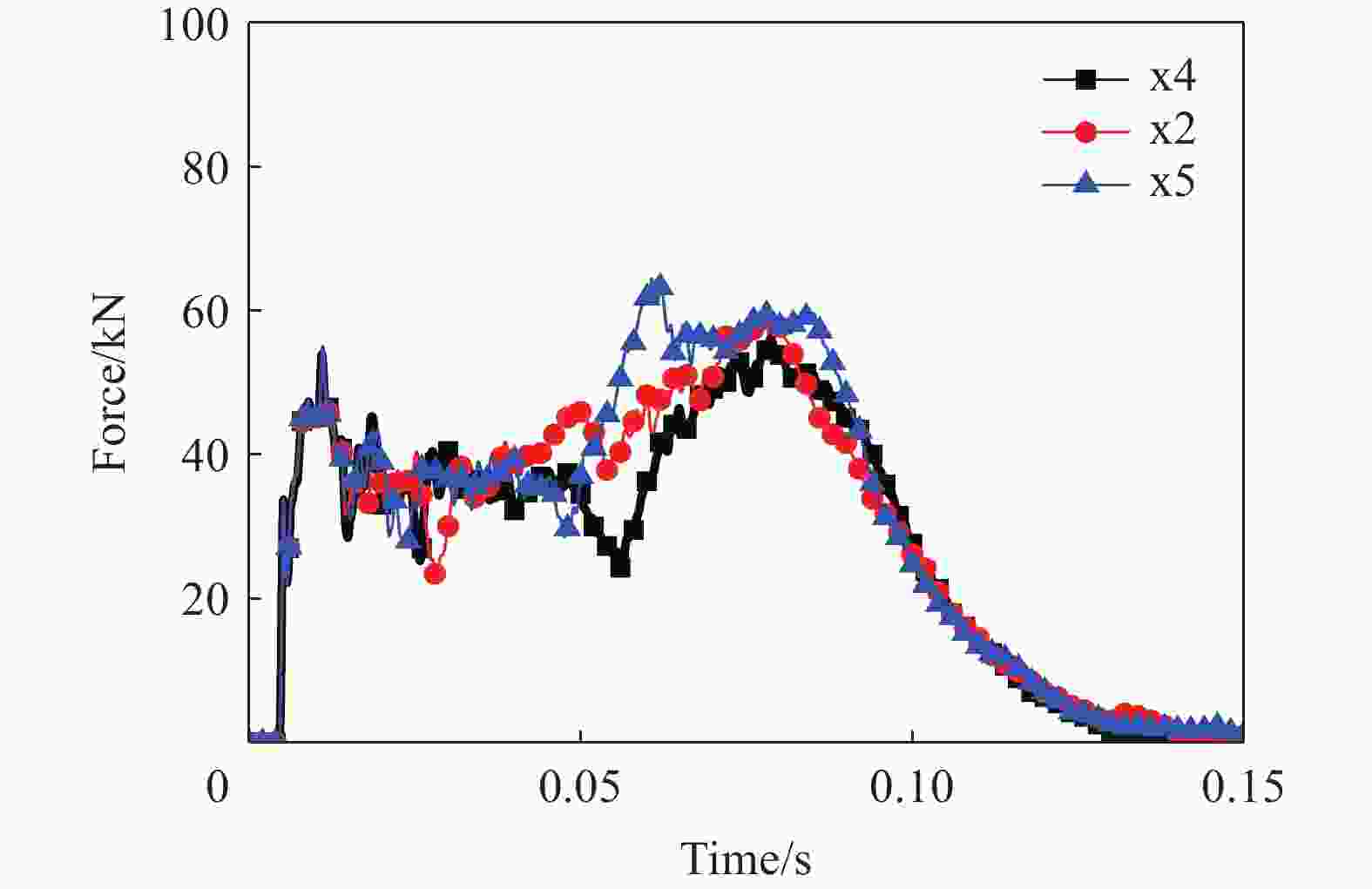

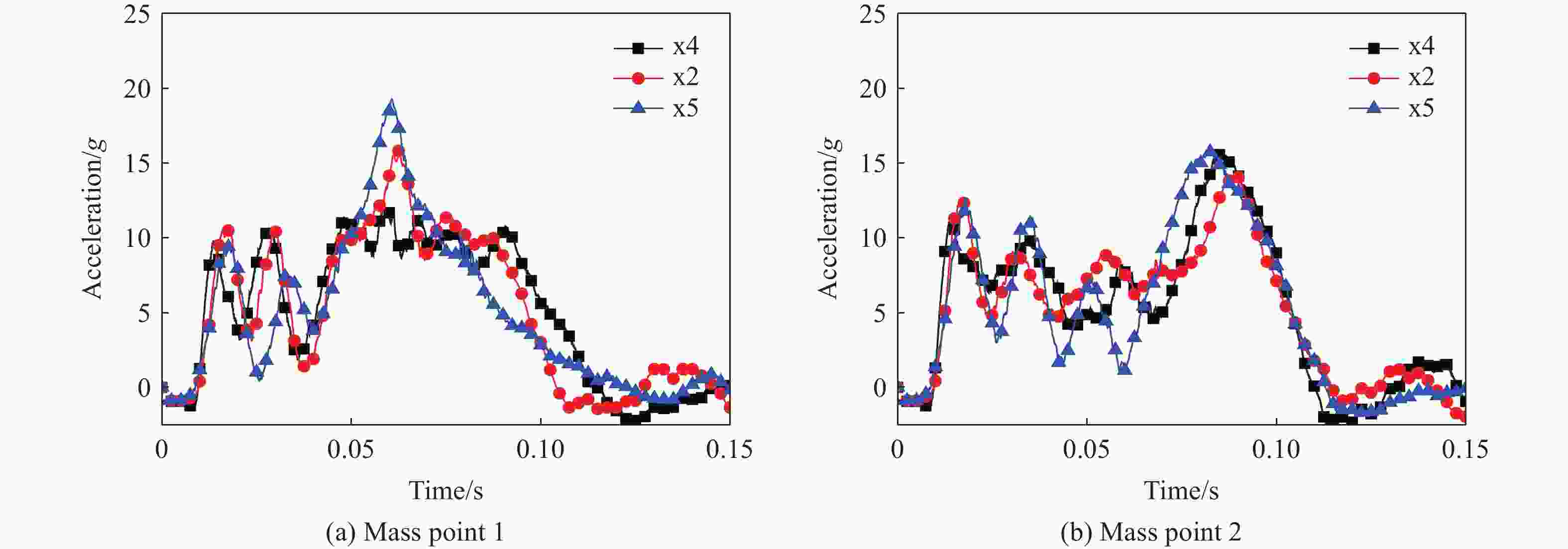

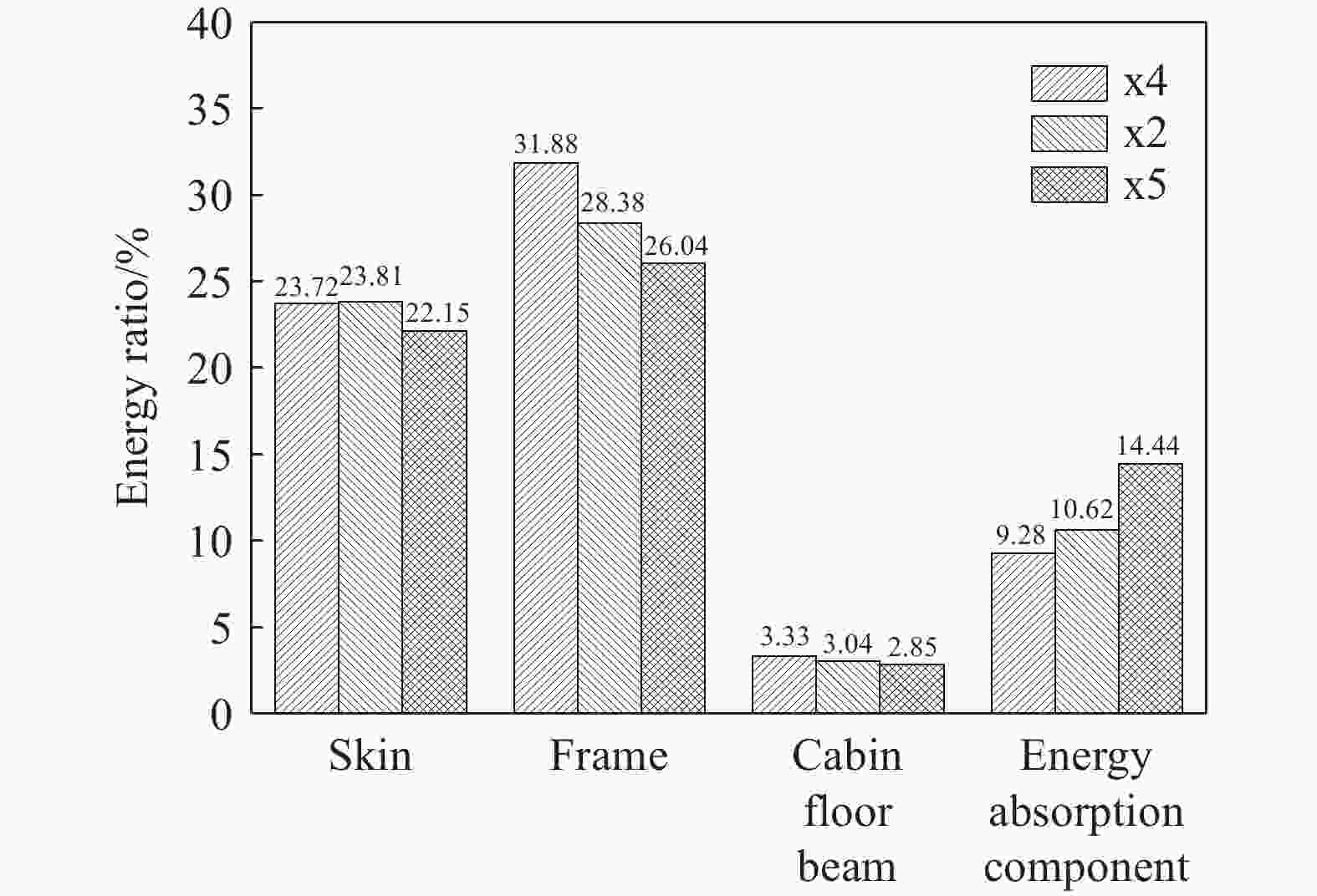

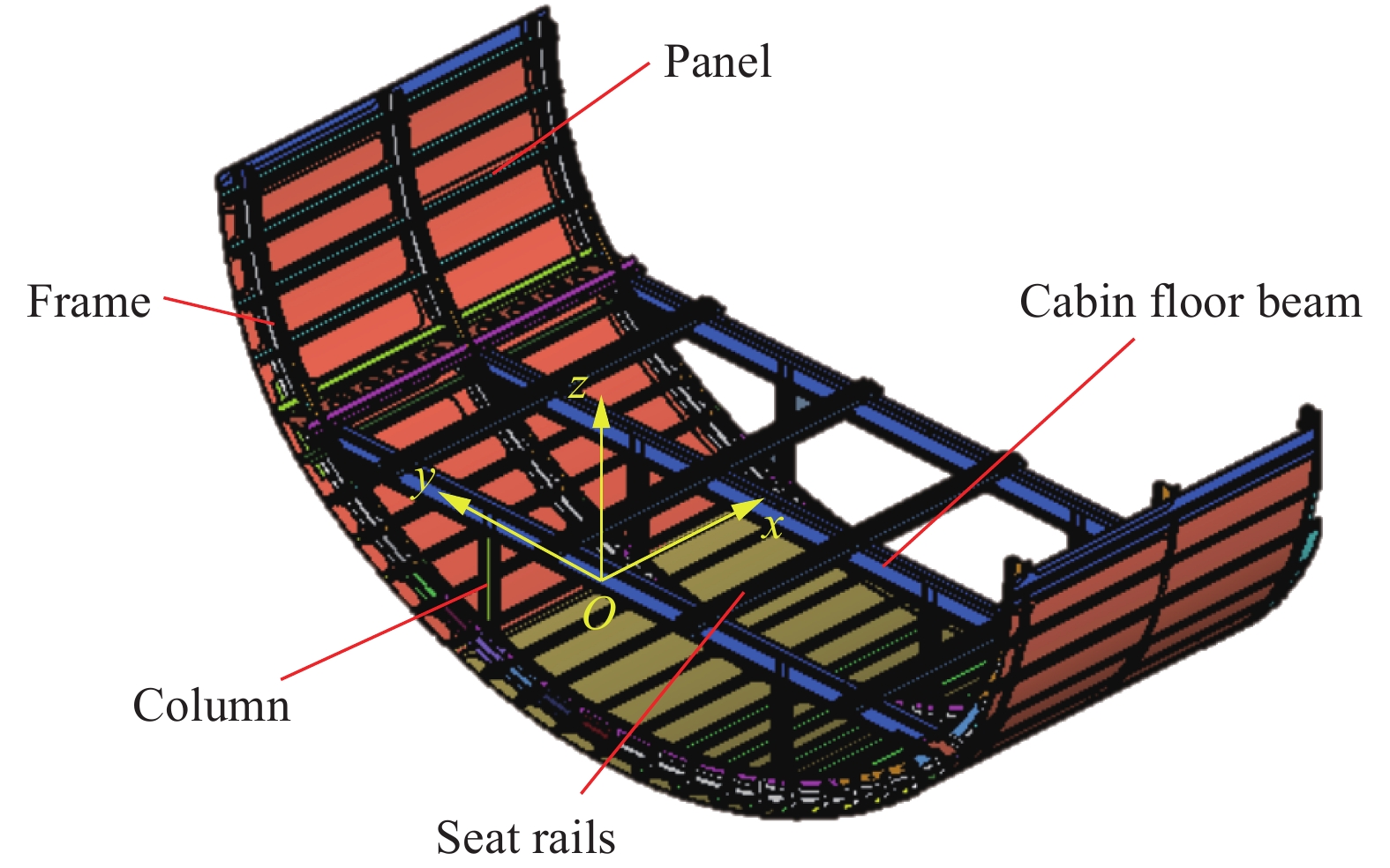

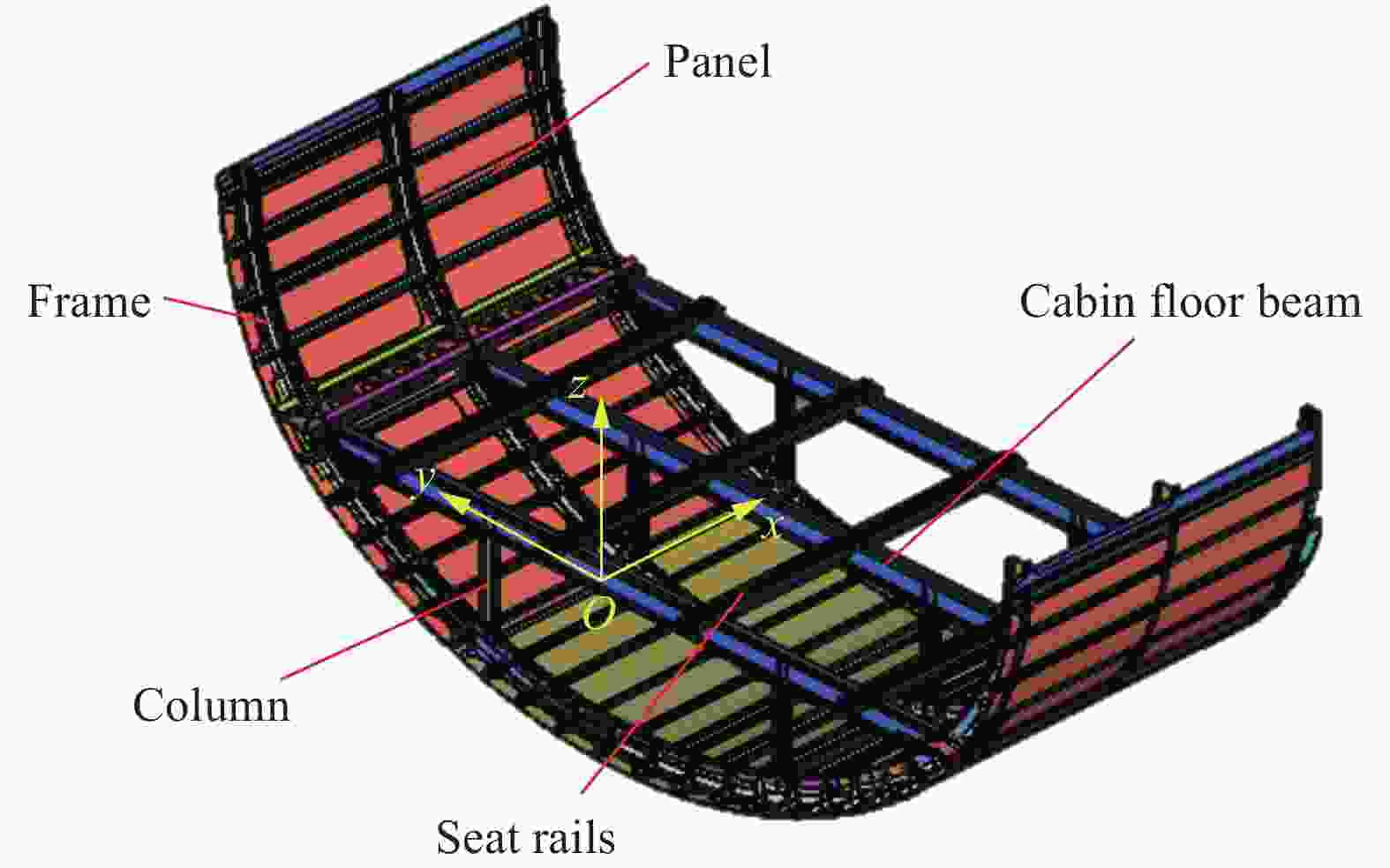

摘要: 为研究飞机机身下部结构的坠撞吸能特性并进行吸能设计,以典型民机金属机身的下部结构为对象,首先开展了典型机身下部结构的坠撞实验,基于实验和仿真结果,对机身下部结构的吸能特性进行了评估;在此基础上,开展了机身下部结构的坠撞吸能设计,并采用仿真手段研究了新型机身下部结构的布局参数对结构坠撞响应的影响。结果表明:在坠撞过程中,原构型机身下部结构的立柱均在连接处附近弯折并断裂,而立柱的其他区域几乎未发生塑性变形;在机身结构总质量基本不变的情况下,与原构型相比,新型机身下部结构变形更加充分,可显著降低飞机坠撞前期的载荷和加速度峰值,机身框和下部吸能结构的吸能占比明显增大;相较于原构型,优化后的新型机身结构的平均过载下降了30.8%,客舱地板上2个质量点的平均加速度分别下降了25.0%和37.6%。Abstract: To investigate the crashworthiness and energy absorption characteristics of aircraft fuselage substructures and to conduct structural crashworthiness design, this study focuses on a typical metal aircraft fuselage as the research object. A drop test of a typical fuselage substructure was performed, and the energy absorption characteristics were evaluated based on both experimental and simulation analysis results. Subsequently, an energy absorption design for the fuselage substructure was developed. The influence of structural layout parameters on the crash response of the new fuselage substructure was examined through simulation analysis. Comparisons were made regarding structural deformation, impact force-time curves, acceleration responses, and energy absorption for fuselage substructures with different layout parameters. The results indicate that during the crash process of the original structure, the primary energy absorption modes include plastic deformation and fracture in the column, frame, and beam connection areas, bending deformation of cabin floor beams, and failure of connectors. Since all columns bend and break near the connection areas, the other parts of the columns are almost entirely free of plastic deformation, resulting in limited energy absorption by the columns. The new substructure proposed in this study features a novel configuration that fully leverages the advantages of metal plastic deformation. Compared to the original configuration, the new substructure exhibits more uniform deformation while maintaining the same total mass of the fuselage structure. It significantly reduces the peak load and acceleration at the early stage of the crash. The proportion of energy absorption by the frame and energy-absorbing components has increased markedly. After optimization, the average overload of the new fuselage substructure is reduced by 30.8% compared to the original configuration. The average acceleration of the two mass points on the cabin floor of the new fuselage substructure is reduced by 25.0% and 37.6%, respectively, compared to the original configuration. These findings provide valuable insights and references for the crashworthiness design of aircraft fuselage substructures.

-

材料 部位 密度/(kg·m−3) 弹性模量/GPa 泊松比 屈服应力/MPa 硬化模量/MPa 失效应变 7075 框、角片 2 796 70 0.33 418 680 0.056 7050 角片 2 830 72 0.33 441 950 0.050 7150 长桁、横梁、滑轨、立柱 2 823 76 0.33 690 400 0.060 2524 蒙皮 2 768 72 0.35 328 920 0.150 表 2 新型机身下部吸能结构的材料参数

Table 2. Material parameters of the new fuselage energy absorbing substructure

材料 部位 密度/(kg·m−3) 弹性模量/GPa 泊松比 屈服应力/MPa 硬化模量/MPa 失效应变 2024 横梁、斜撑、立柱 2760 71 0.33 369 850 0.15 表 3 布局参数

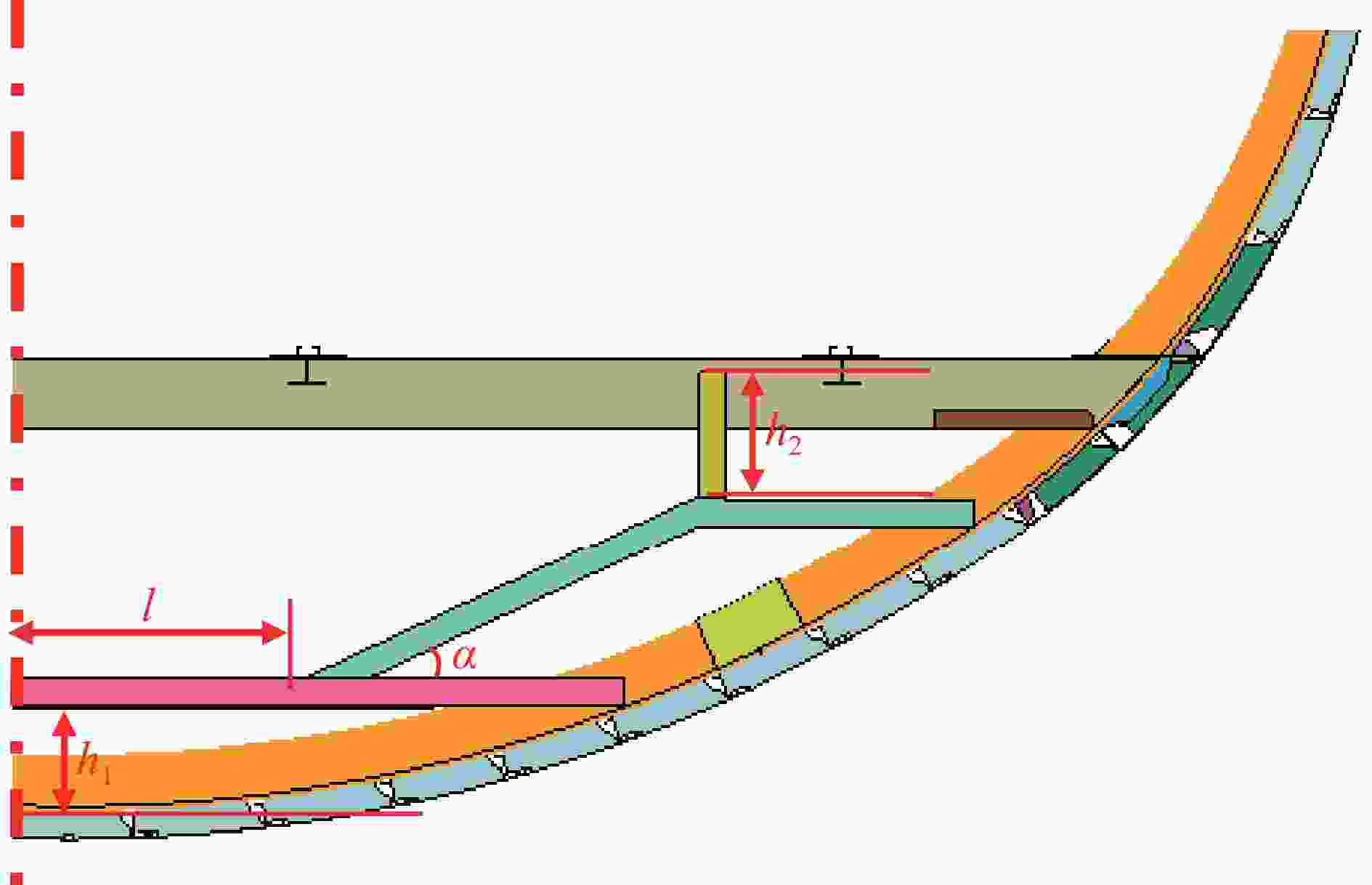

Table 3. Layout parameters

编号 h1/mm l/mm α/(˚) h2/mm x1 50 250 25 135 x2 50 300 25 135 x3 50 300 20 135 x4 50 300 25 100 x5 50 300 25 170 x6 50 300 30 135 x7 80 300 25 135 x8 20 300 25 135 x9 50 350 25 135 表 4 不同布局参数下机身结构的平均加速度

Table 4. Average acceleration of fuselage structure with different layout parameters

编号 质量/kg $ \bar a $/g $ {\bar a_1} $/g $ {\bar a_2} $/g 原构型 452.275 12.27 9.60 10.94 x1 452.350 8.79 6.99 7.10 x2 452.300 9.15 7.56 6.65 x3 452.307 9.55 6.64 7.36 x4 452.323 8.49 7.20 6.83 x5 452.316 9.49 7.60 6.59 x6 452.329 8.88 7.20 7.13 x7 452.364 9.11 7.43 7.15 x8 452.249 9.34 7.60 6.48 x9 452.181 9.14 7.98 7.50 表 5 不同布局参数下机身结构的吸能占比

Table 5. Energy absorption ratio of the fuselage structure with different layout parameters

编号 蒙皮/% 机身框/% 客舱地板横梁/% 下部吸能结构/% 原构型 23.13 23.33 10.50 6.54 x1 23.90 30.01 2.54 10.89 x2 23.94 28.21 3.00 10.59 x3 22.04 28.18 2.64 11.93 x4 23.85 31.90 3.33 9.26 x5 22.46 26.21 2.18 14.46 x6 23.37 28.80 5.40 11.21 x7 25.28 29.59 1.79 10.46 x8 19.90 32.12 3.94 9.84 x9 25.73 28.08 3.09 10.05 -

[1] 刘小川, 郭军, 孙侠生, 等. 民机机身段和舱内设施坠撞试验及结构适坠性评估 [J]. 航空学报, 2013, 34(9): 2130–2140. DOI: 10.7527/S1000-6893.2013.0182.LIU X C, GUO J, SUN X S, et al. Drop test and structure crashworthiness evaluation of civil airplane fuselage section with cabin interiors [J]. Acta Aeronautica et Astronautica Sinica, 2013, 34(9): 2130–2140. DOI: 10.7527/S1000-6893.2013.0182. [2] 刘小川, 白春玉, 惠旭龙, 等. 民机机身结构耐撞性研究的进展与挑战 [J]. 固体力学学报, 2020, 41(4): 293–323. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2020.035.LIU X C, BAI C Y, XI X L, et al. Progress and challenge of research on crashworthiness of civil airplane fuselage structures [J]. Chinese Journal of Solid Mechanics, 2020, 41(4): 293–323. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2020.035. [3] 中国民用航空局. 中国民用航空规章: 第25部运输类飞机适航标准 CCAR-25-R4 [S]. 北京: 中国民用航空局, 2011.Civil Aviation Administration of China. China civil aviation regulations: part 25-transport aircraft airworthiness standards CCAR-25-R4 [S]. Beijing: CAAC, 2011. [4] LIU X C, GUO J, BAI C Y, et al. Drop test and crash simulation of a civil airplane fuselage section [J]. Chinese Journal of Aeronautics, 2015, 28(2): 447–456. DOI: 10.1016/j.cja.2015.01.007. [5] 张欣玥, 惠旭龙, 刘小川, 等. 典型金属民机机身结构坠撞特性试验 [J]. 航空学报, 2022, 43(6): 526234. DOI: 10.7527/S1000-6893.2022.26234.ZHANG X Y, XI X L, LIU X C, et al. Experimental study on crash characteristics of typical metal civil aircraft fuselage structure [J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(6): 526234. DOI: 10.7527/S1000-6893.2022.26234. [6] 刘小川, 惠旭龙, 张欣玥, 等. 典型民用飞机全机坠撞实验研究 [J]. 航空学报, 2024, 45(5): 529664. DOI: 10.7527/S1000-6893.2023.29664.LIU X C, XI X L, ZHANG X Y, et al. Full-scale crash experimental study of typical civil aircraft [J]. Acta Aeronautica et Astronautica Sinica, 2024, 45(5): 529664. DOI: 10.7527/S1000-6893.2023.29664. [7] 冯振宇, 程坤, 赵一帆, 等. 运输类飞机典型货舱地板下部结构冲击吸能特性 [J]. 航空学报, 2019, 40(9): 222907. DOI: 10.7527/S1000-6893.2019.22907.FENG Z Y, CHENG K, ZHAO Y F, et al. Energy-absorbing characteristics of a typical sub-cargo fuselage section of a transport category aircraft [J]. Acta Aeronautica et Astronautica Sinica, 2019, 40(9): 222907. DOI: 10.7527/S1000-6893.2019.22907. [8] 牟浩蕾, 谢威威, 解江, 等. 坠撞环境下乘员伤害分析及飞机适坠性评估 [J]. 航空学报, 2024, 45(3): 228786. DOI: 10.7527/S1000-6893.2023.28786.MOU H L, XIE W W, XIE J, et al. Occupant injury analysis and aircraft crashworthiness evaluation under crash scenarios [J]. Acta Aeronautica et Astronautica Sinica, 2024, 45(3): 228786. DOI: 10.7527/S1000-6893.2023.28786. [9] 彭亮. 基于乘员生存性的机身结构适坠性设计与评价方法研究 [D]. 西安: 西北工业大学, 2018. DOI: 10.27406/d.cnki.gxbgu.2018.000284.PENG L. Research on design and evaluation method of airframe structural crashworthiness based on occupants survivability [D]. Xi’an: Northwestern Polytechnical University, 2018. DOI: 10.27406/d.cnki.gxbgu.2018.000284. [10] DEEPAK S. Crashworthy design and analysis of aircraft structures [D]. Philadelphia: Drexel University, 2013. [11] JACKSON K E. Finite element simulations of two vertical drop tests of F-28 fuselage sections [M]. Virginia: National Aeronautics and Space Administration, 2018. [12] FASANELLA E L, JACKSON K E. Crash simulation of a vertical drop test of a B737 fuselage section with auxiliary fuel tank: 23681-0001 [R]. Hampton: US Army Research Laboratory, Vehicle Technology Directorate, NASA Langley Research Center, 2002. [13] JACKSON K E, FASANELLA E L. Crash simulation of vertical drop tests of two Boeing 737 fuselage sections [R]. Washington: Office of Aviation Research, 2002. [14] 冯振宇, 张晓敏, 牟浩蕾, 等. 不同冲击条件对机身结构适坠性的影响 [J]. 机械科学与技术, 2013, 32(3): 353–357. DOI: 10.13433/j.cnki.1003-8728.2013.03.023.FENG Z Y, ZHANG X M, MOU H L, et al. Influences of different impact conditions on aircraft fuselage crashworthiness [J]. Mechanical Science and Technology for Aerospace Engineering, 2013, 32(3): 353–357. DOI: 10.13433/j.cnki.1003-8728.2013.03.023. [15] 邹田春, 牟浩蕾, 任健, 等. 滚转角度对民机机身结构耐撞性能的影响 [J]. 机械强度, 2014, 36(1): 139–143. DOI: 10.16579/j.issn.1001.9669.2014.01.022.ZOU T C, MOU H L, REN J, et al. Effects of roll angles on civil aircraft fuselage crashworthiness [J]. Journal of Mechanical Strength, 2014, 36(1): 139–143. DOI: 10.16579/j.issn.1001.9669.2014.01.022. [16] RICCIO A, RAIMONDO A, DI CAPRIO F, et al. Experimental and numerical investigation on the crashworthiness of a composite fuselage sub-floor support system [J]. Composites Part B: Engineering, 2018, 150: 93–103. DOI: 10.1016/j.compositesb.2018.05.044. [17] RICCIO A, SAPUTO S, SELLITTO A, et al. On the crashworthiness behaviour of a composite fuselage sub-floor component [J]. Composite Structures, 2020, 234: 111662. DOI: 10.1016/j.compstruct.2019.111662. [18] PAZ J, DÍAZ J, ROMERA L, et al. Optimisation of thin-walled hybrid vertical struts for crashworthy aircraft designs [J]. Structural and Multidisciplinary Optimization, 2020, 61(1): 141–158. DOI: 10.1007/s00158-019-02350-3. [19] FERABOLI P. Development of a corrugated test specimen for composite materials energy absorption [J]. Journal of Composite Materials, 2008, 42(3): 229–256. DOI: 10.1177/0021998307086202. [20] SCHATROW P, WAIMER M. Crash concept for composite transport aircraft using mainly tensile and compressive absorption mechanisms [J]. CEAS Aeronautical Journal, 2016, 7(3): 471–482. DOI: 10.1007/s13272-016-0203-6. [21] WAIMER M, KOHLGRÜBER D, KECK R, et al. Contribution to an improved crash design for a composite transport aircraft fuselage: development of a kinematics model and an experimental component test setup [J]. CEAS Aeronautical Journal, 2013, 4(3): 265–275. DOI: 10.1007/s13272-013-0070-3. [22] WAIMER M, KOHLGRÜBER D, HACHENBERG D, et al. Experimental study of CFRP components subjected to dynamic crash loads [J]. Composite Structures, 2013, 105: 288–299. DOI: 10.1016/j.compstruct.2013.05.030. [23] DELSART D, PORTEMONT G, WAIMER M. Crash testing of a CFRP commercial aircraft sub-cargo fuselage section [J]. Procedia Structural Integrity, 2016, 2: 2198–2205. DOI: 10.1016/j.prostr.2016.06.275. [24] HEIMBS S, STROBL F, MIDDENDORF P, et al. Composite crash absorber for aircraft fuselage applications [J]. WIT Transactions on the Built Environment, 2010, 113(12): 3–14. DOI: 10.2495/SU100011. [25] REN Y R, XIANG J W, MENG S H, et al. Crashworthiness of civil aircraft subject to soft soil and concrete impact surface [J]. Procedia Engineering, 2014, 80: 193–201. DOI: 10.1016/j.proeng.2014.09.074. [26] JIANG H Y, REN Y R, GAO B H, et al. Design of novel plug-type triggers for composite square tubes: enhancement of energy-absorption capacity and inducing failure mechanisms [J]. International Journal of Mechanical Sciences, 2017, 131/132: 113–136. DOI: 10.1016/j.ijmecsci.2017.06.050. [27] 谭丽辉, 徐涛, 崔晓梅, 等. 带有圆弧形凹槽金属薄壁圆管抗撞性优化设计 [J]. 爆炸与冲击, 2014, 34(5): 547–553. DOI: 10.11883/1001-1455(2014)05-0547-07.TAN L H, XU T, CUI X M, et al. Design optimization for crashworthiness of metal thin-walled cylinders with circular arc indentations [J]. Explosion and Shock Waves, 2014, 34(5): 547–553. DOI: 10.11883/1001-1455(2014)05-0547-07. [28] 张欣玥, 惠旭龙, 葛宇静, 等. 中低速压缩加载下不同截面构型复合材料薄壁结构吸能特性及失效分析 [J]. 爆炸与冲击, 2022, 42(6): 063102. DOI: 10.11883/bzycj-2021-0347.ZHANG X Y, XI X L, GE Y J, et al. Energy absorption characteristics and failure analysis of composite thin-walled structures with different cross-sectional configurations under medium- and low-speed compression loading [J]. Explosion and Shock Waves, 2022, 42(6): 063102. DOI: 10.11883/bzycj-2021-0347. [29] JIANG H Y, REN Y R, GAO B H. Research on the progressive damage model and trigger geometry of composite waved beam to improve crashworthiness [J]. Thin-Walled Structures, 2017, 119: 531–543. DOI: 10.1016/j.tws.2017.07.004. [30] 汪洋, 吴志斌, 刘富. 复合材料货舱地板立柱压溃响应试验 [J]. 复合材料学报, 2020, 37(9): 2200–2206. DOI: 10.13801/j.cnki.fhclxb.20200111.001.WANG Y, WU Z B, LIU F. Crush experiment of composite cargo floor stanchions [J]. Acta Materiae Compositae Sinica, 2020, 37(9): 2200–2206. DOI: 10.13801/j.cnki.fhclxb.20200111.001. [31] REN Y R, XIANG J W. Improvement of aircraft crashworthy performance using inversion failure strut system [J]. Aircraft Engineering and Aerospace Technology, 2017, 89(2): 330–337. DOI: 10.1108/AEAT-09-2015-0205. [32] REN Y R, ZHANG H Y, XIANG J W. A novel aircraft energy absorption strut system with corrugated composite plate to improve crashworthiness [J]. International Journal of Crashworthiness, 2018, 23(1): 1–10. DOI: 10.1080/13588265.2017.1301082. [33] 《飞机设计手册》总编委会. 飞机设计手册 第3册 材料 [M]. 北京: 航空工业出版社, 1997: 186–260.General Editorial Board of Aircraft Design Manual. Aircraft design manual volume 3: materials [M]. Beijing: Aviation Industry Press, 1997: 186–260. -

下载:

下载: