Crash tests and simulation analysis for civil aircraft equipped with an auxiliary fuel tank

-

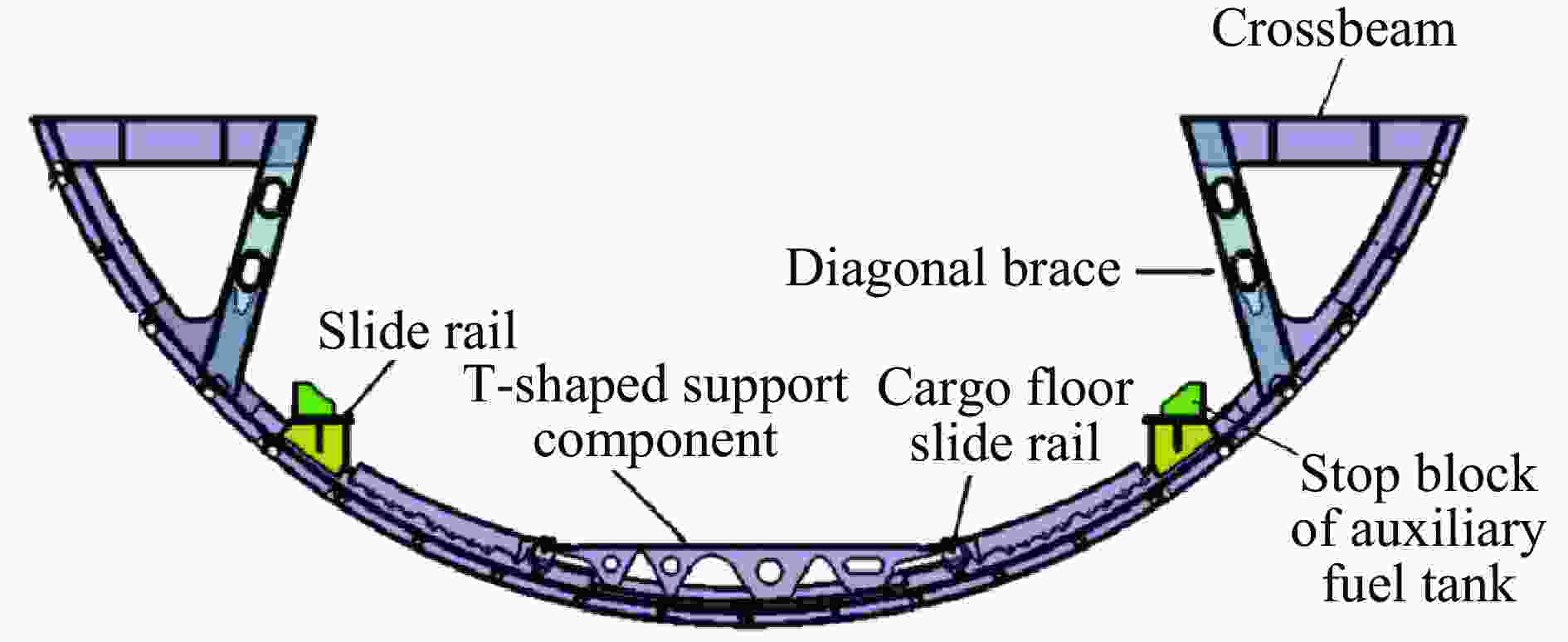

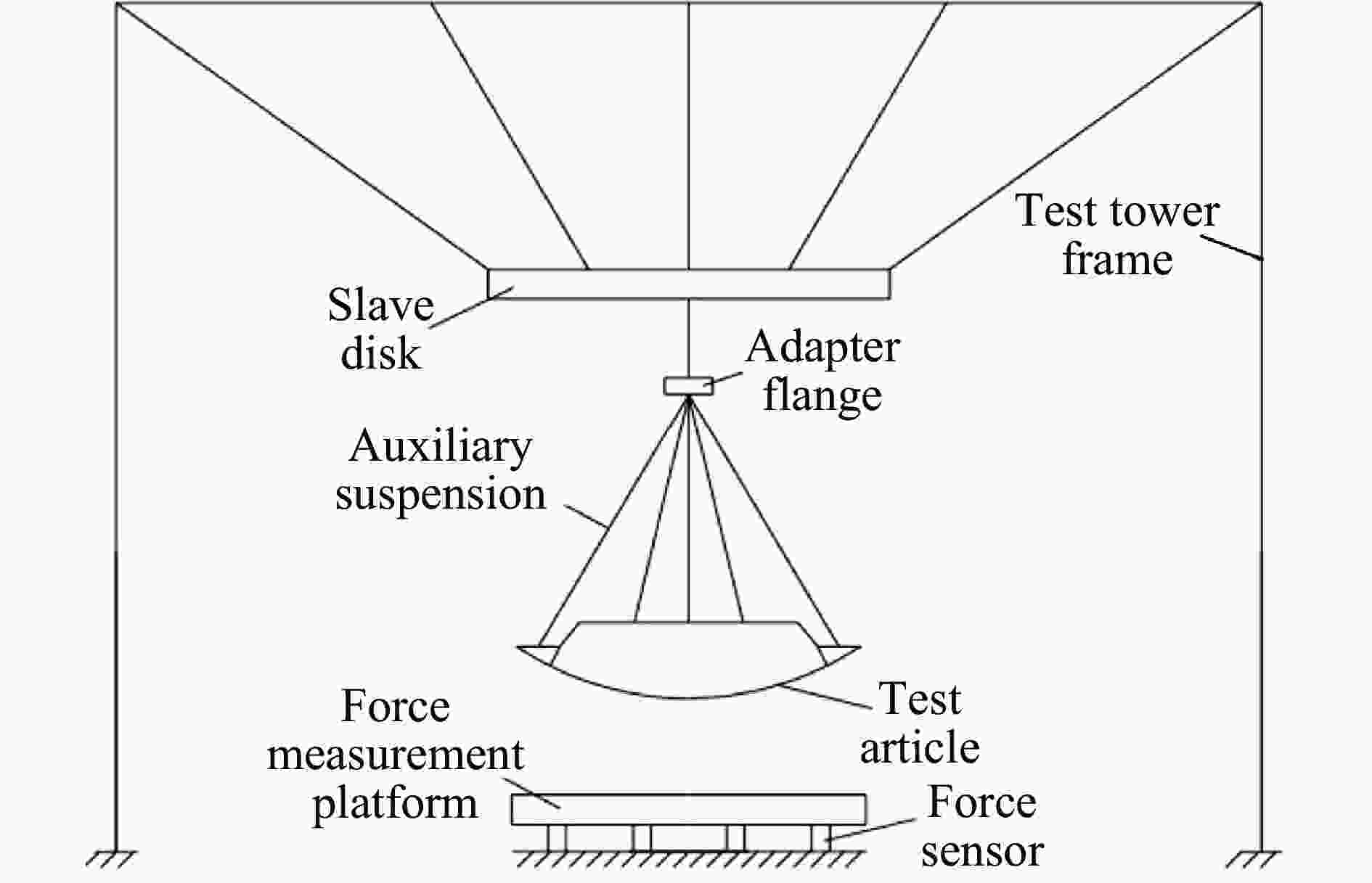

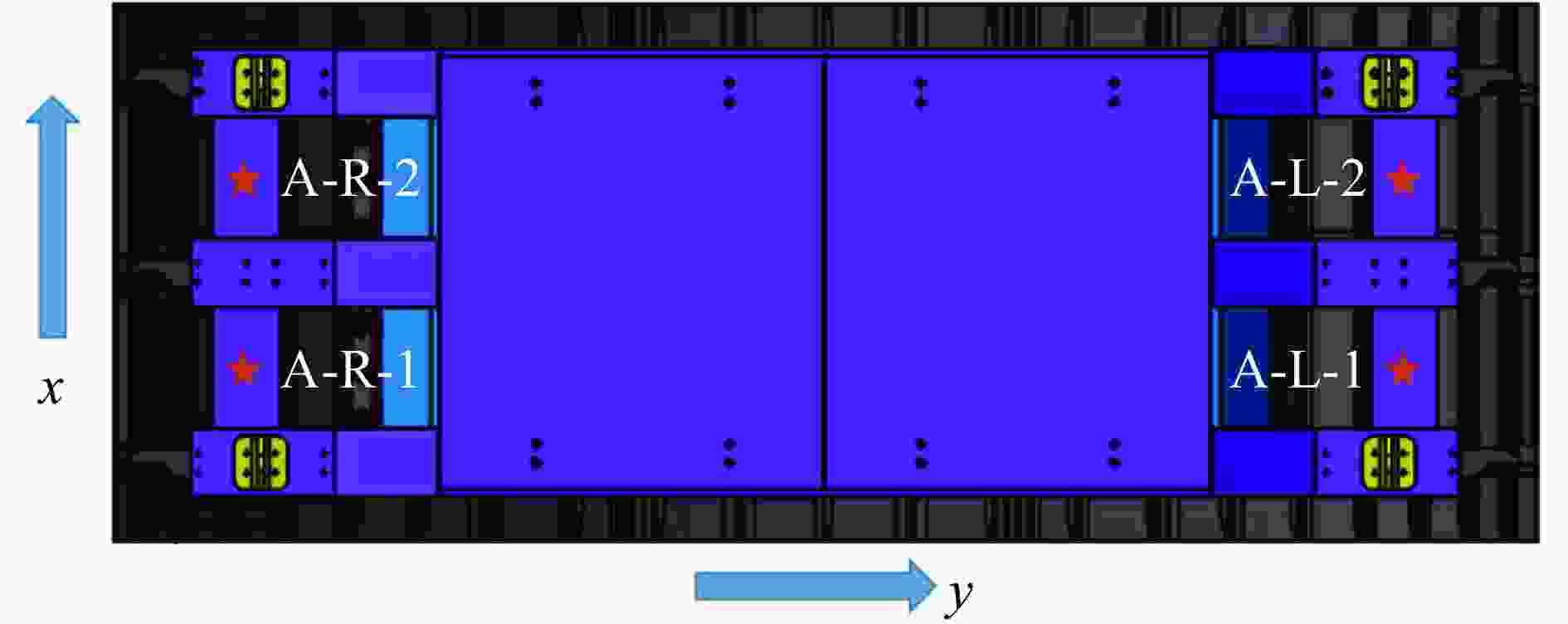

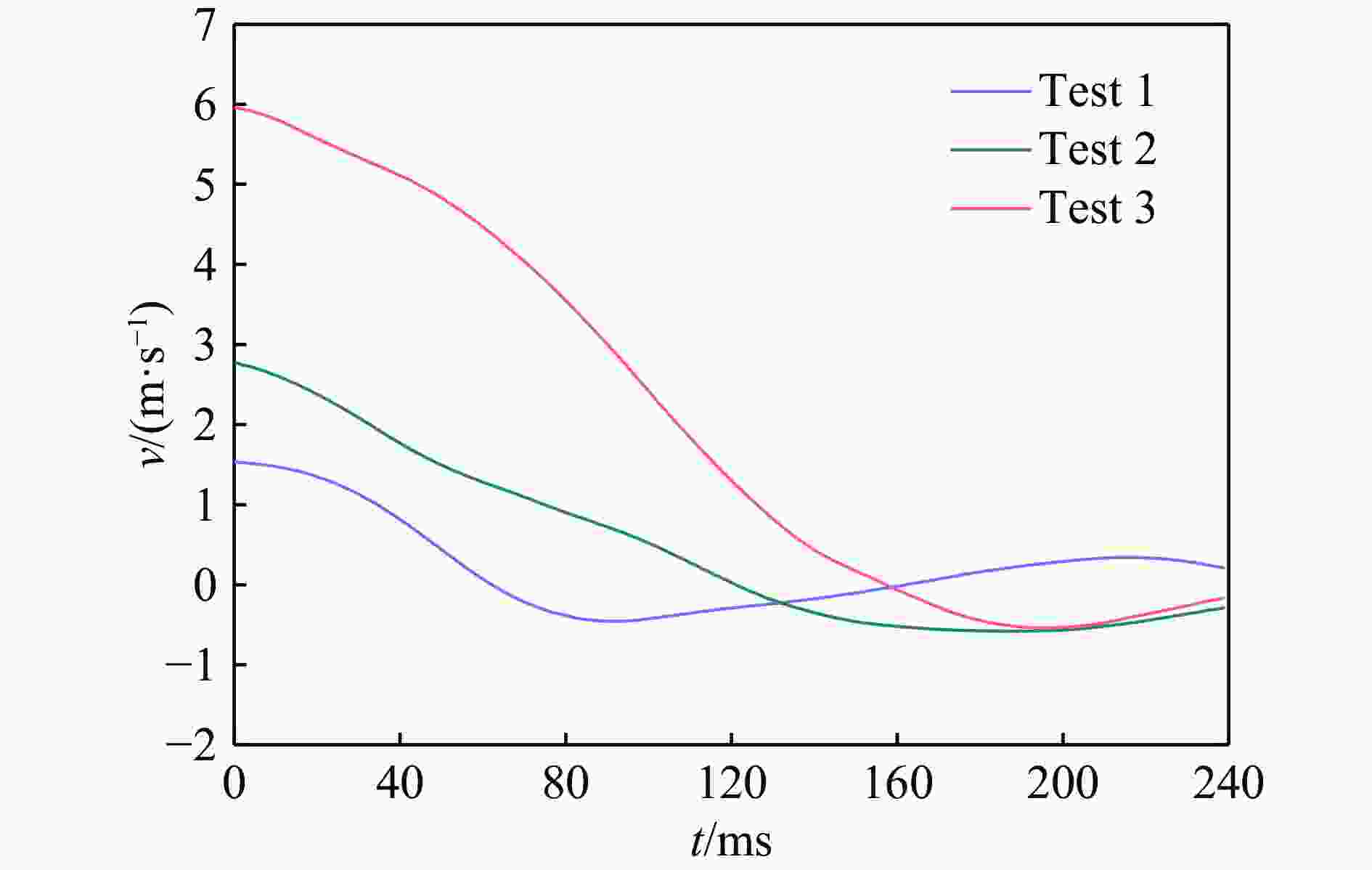

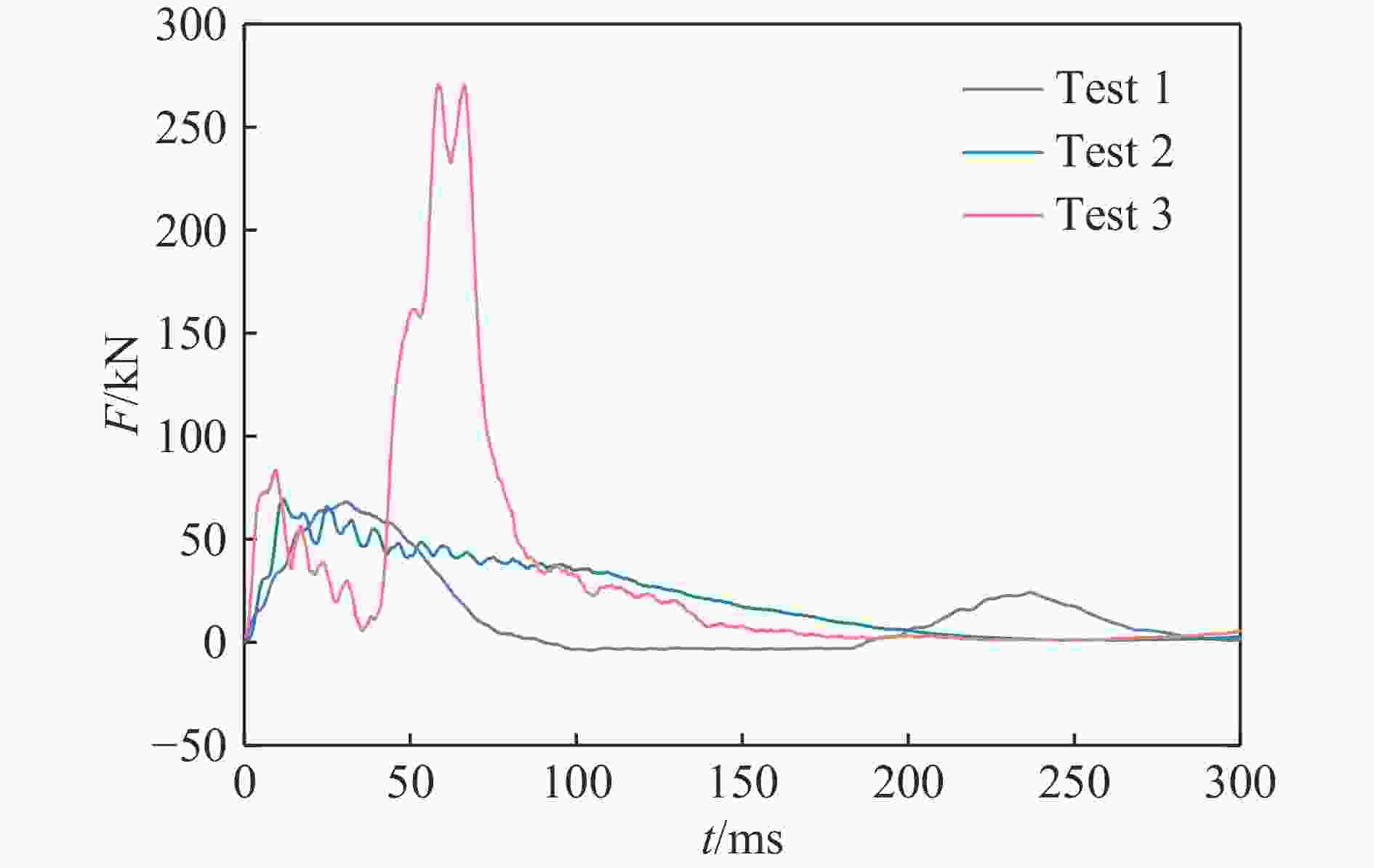

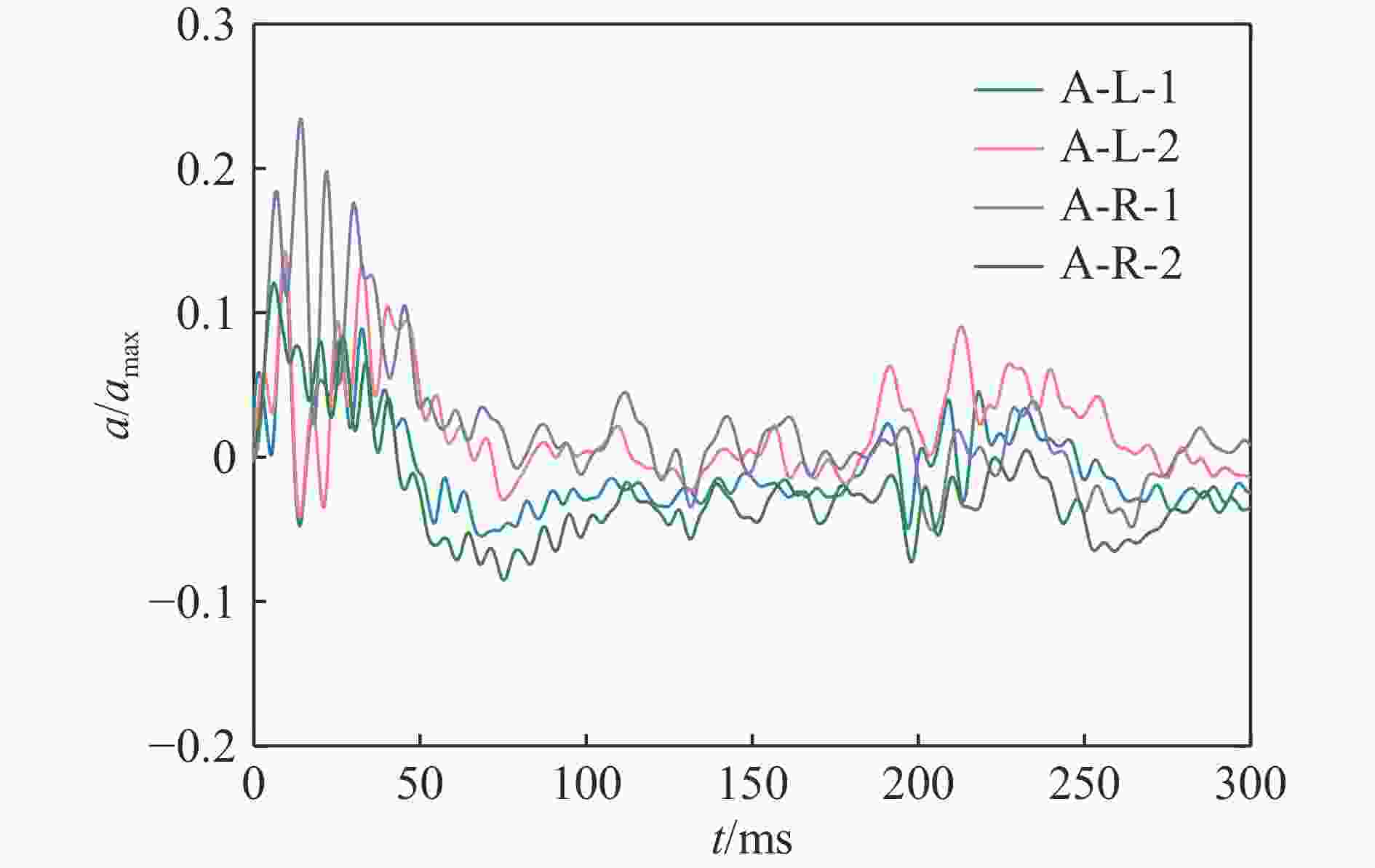

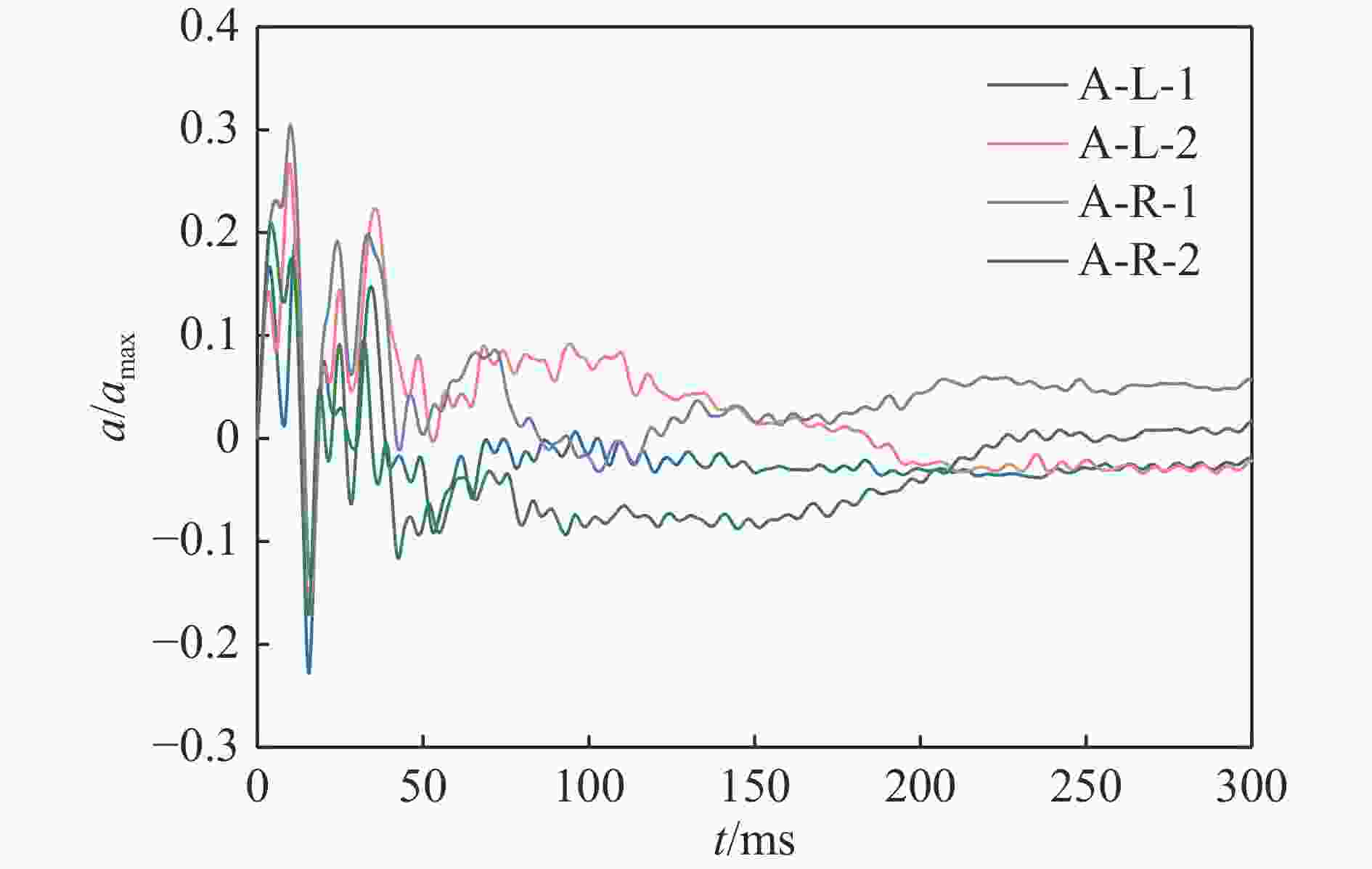

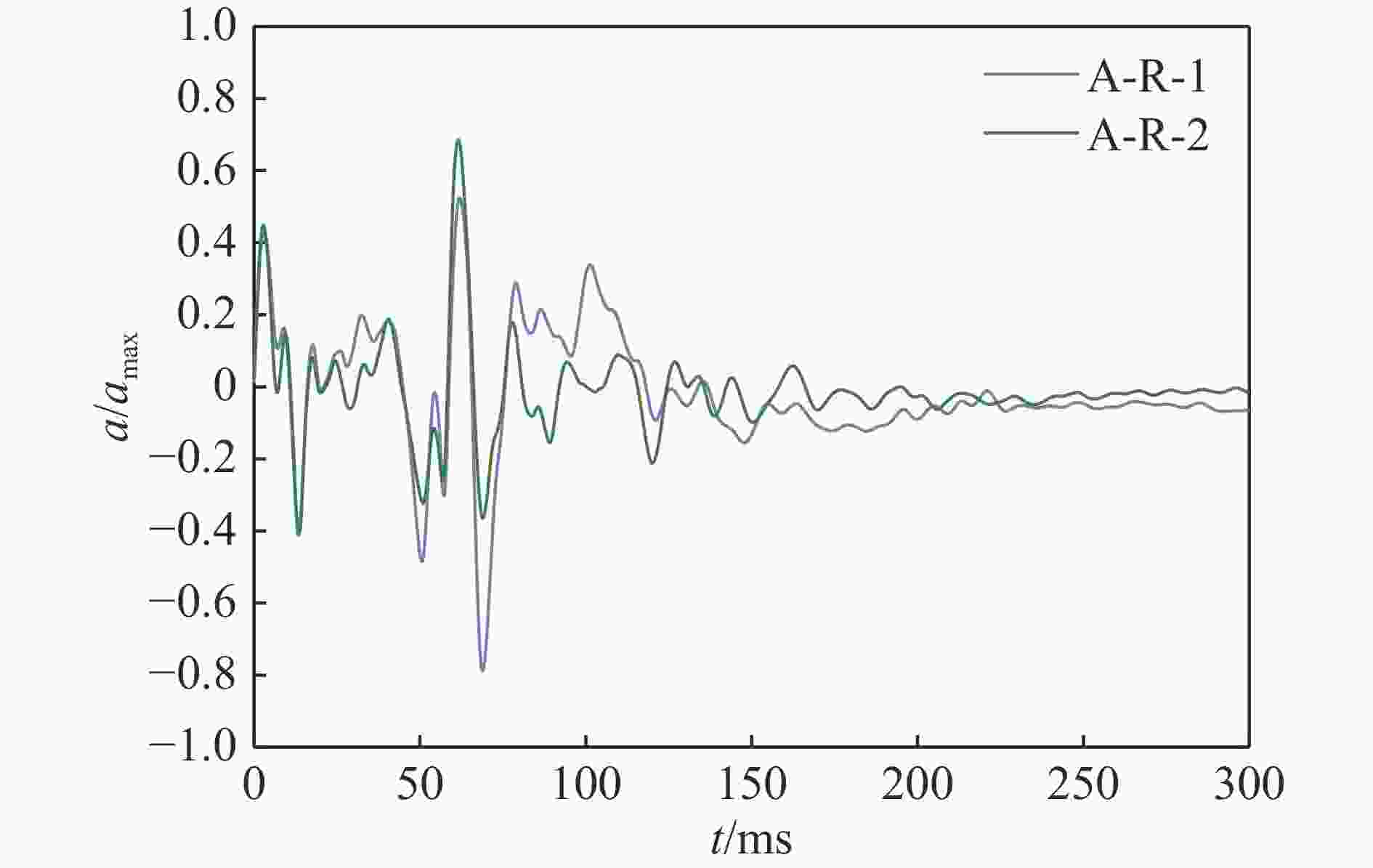

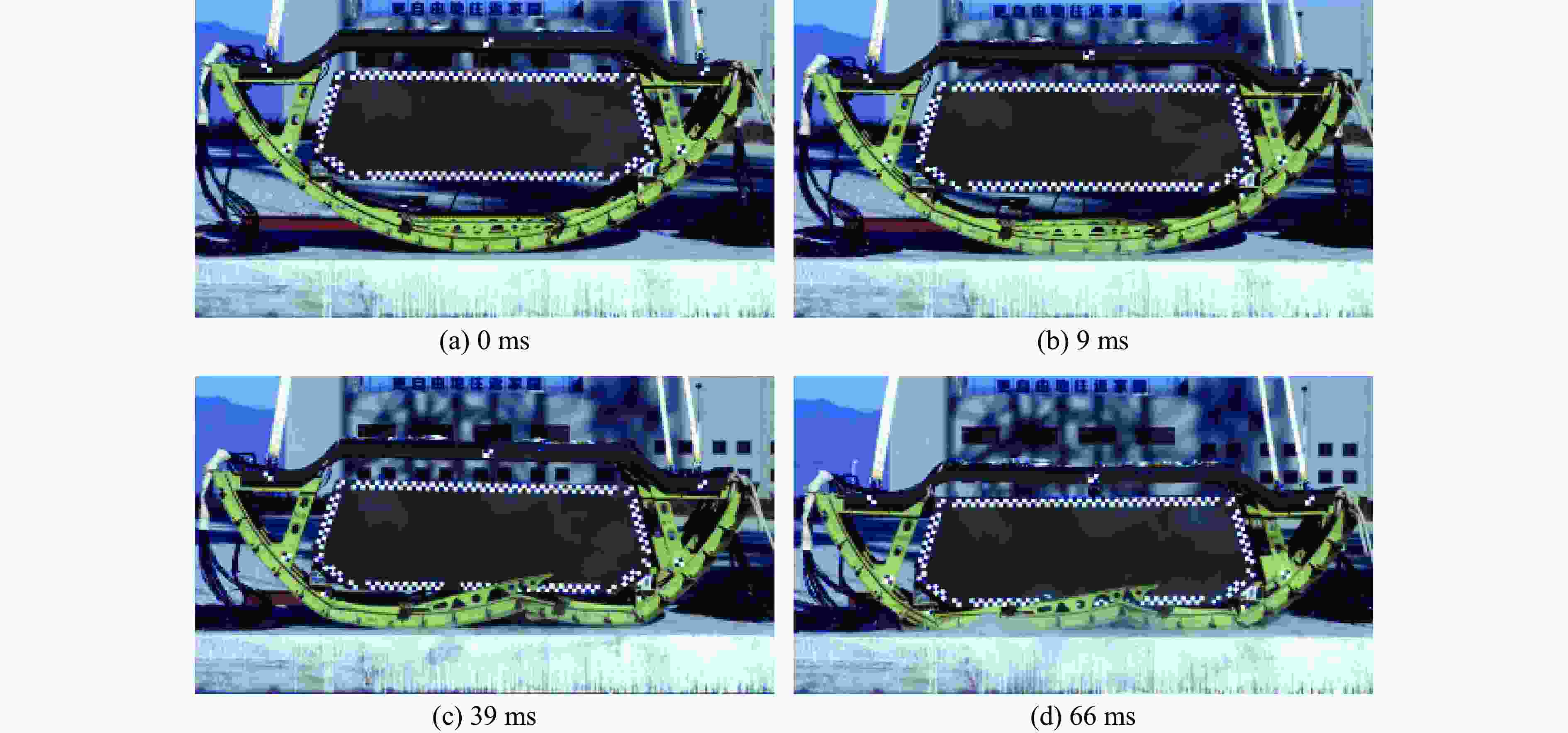

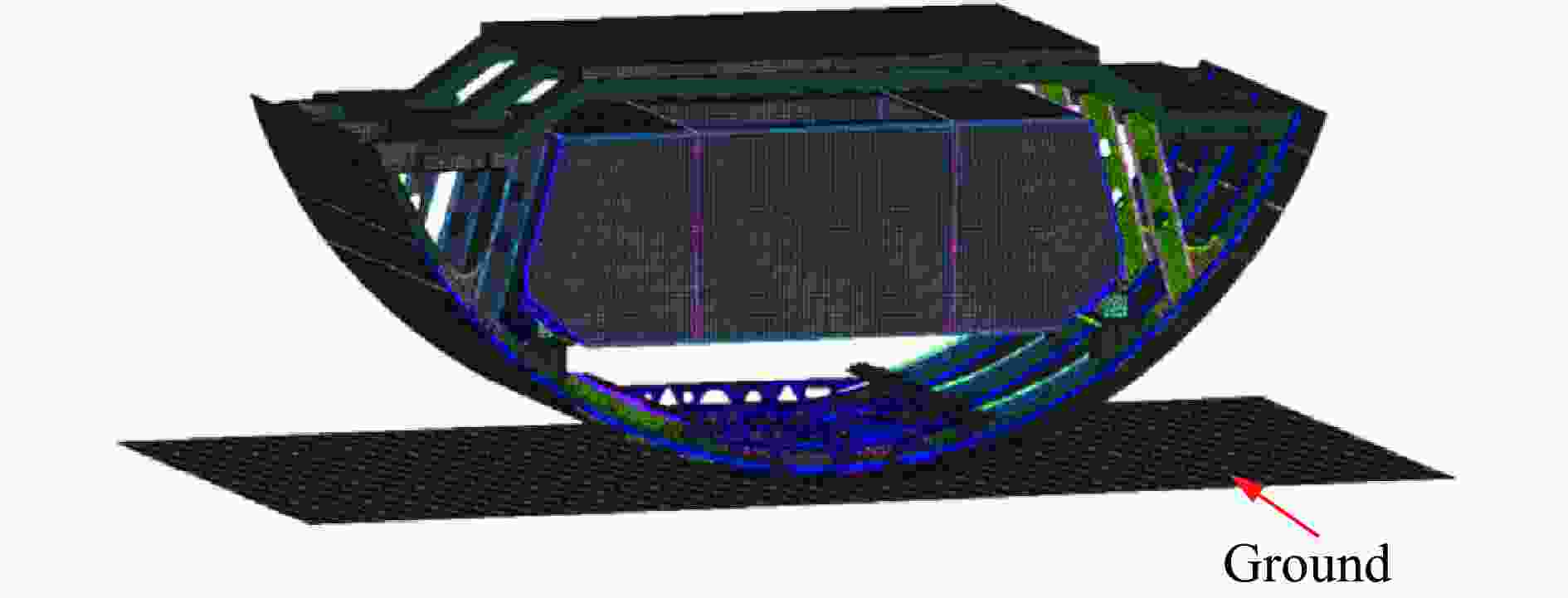

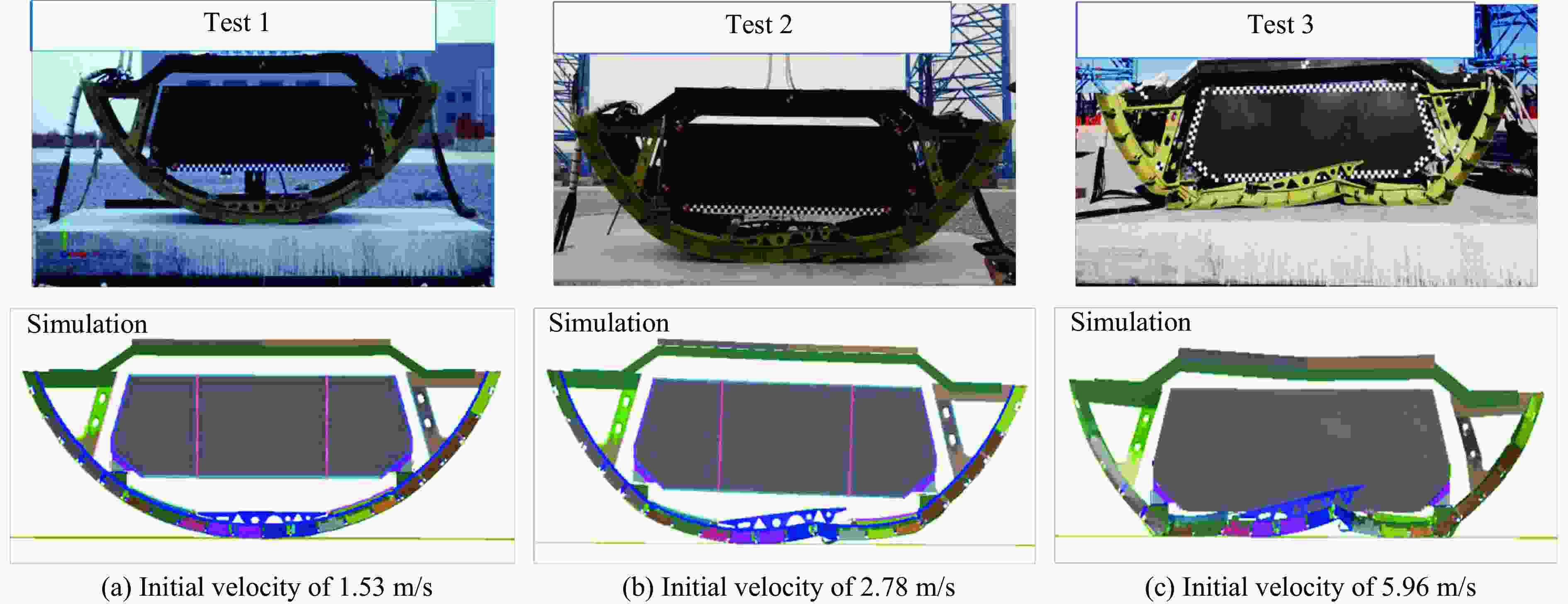

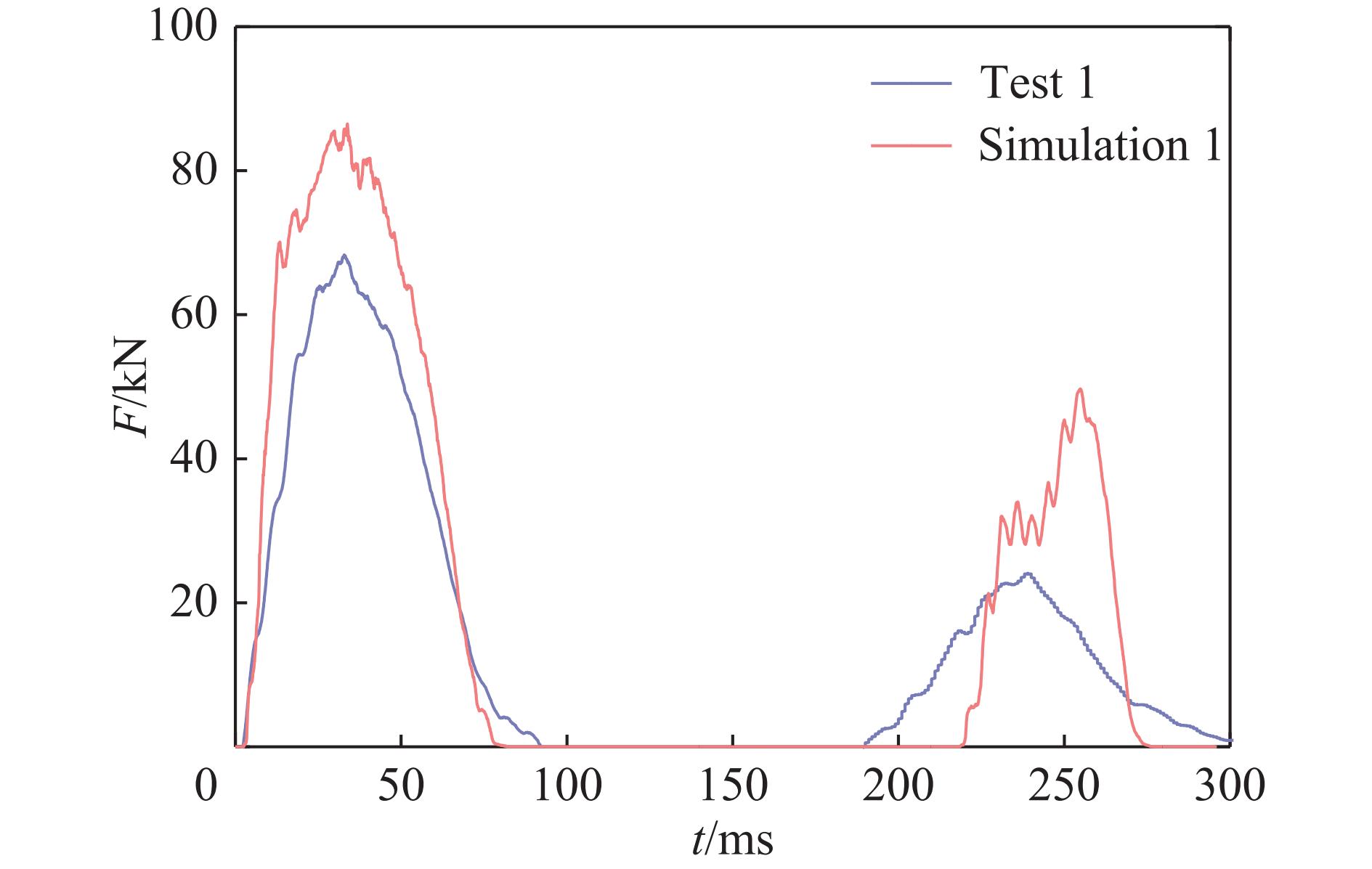

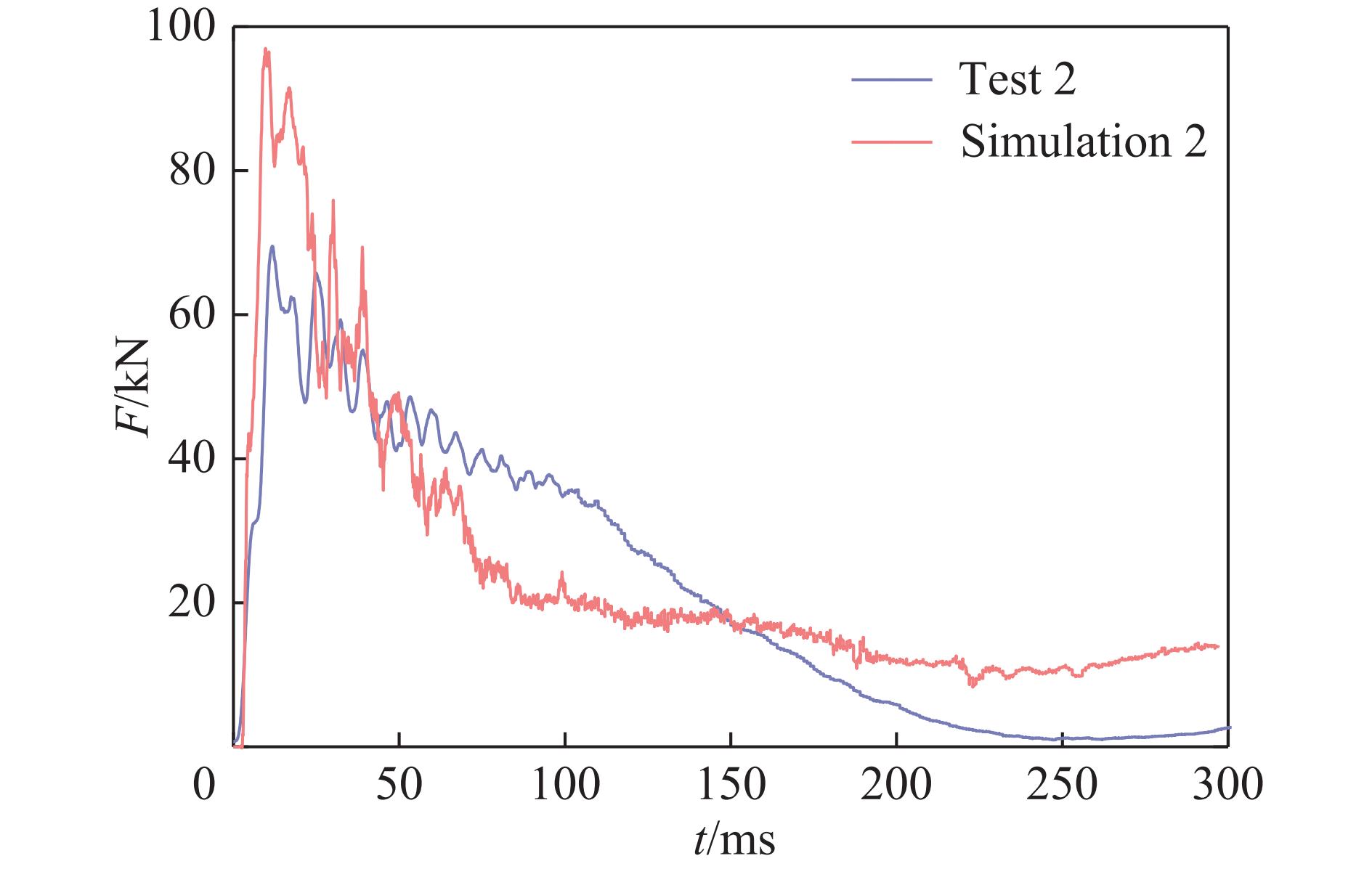

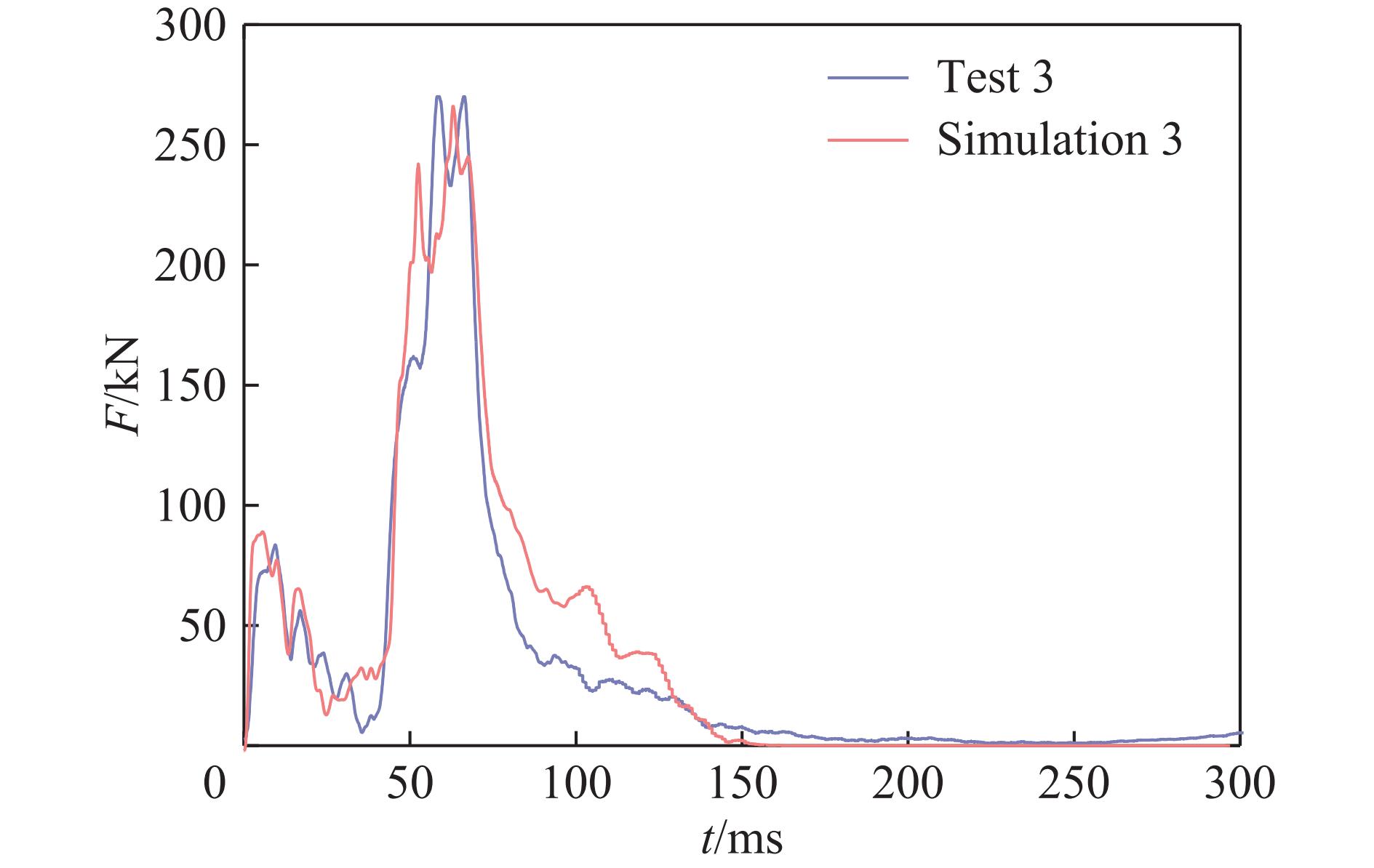

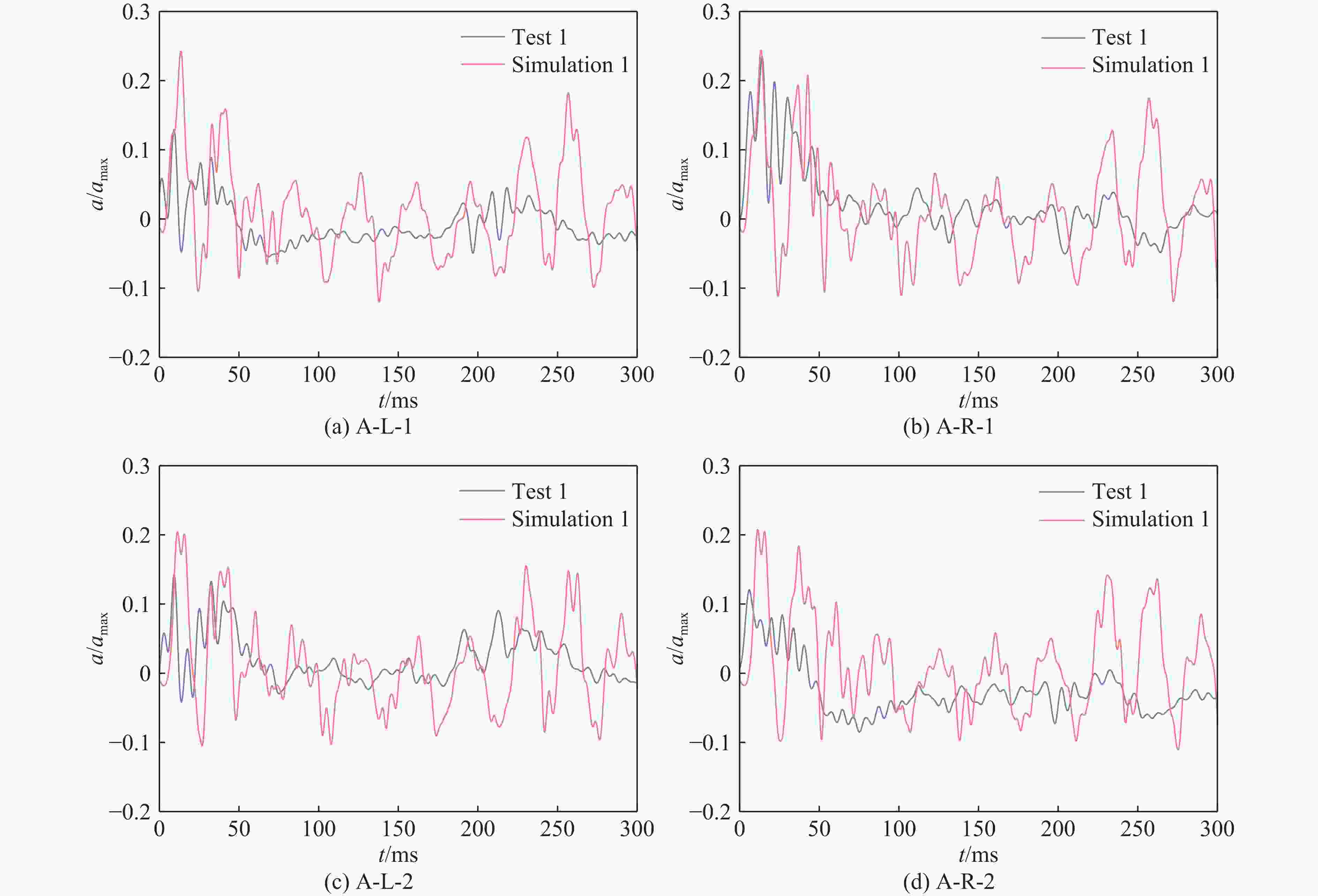

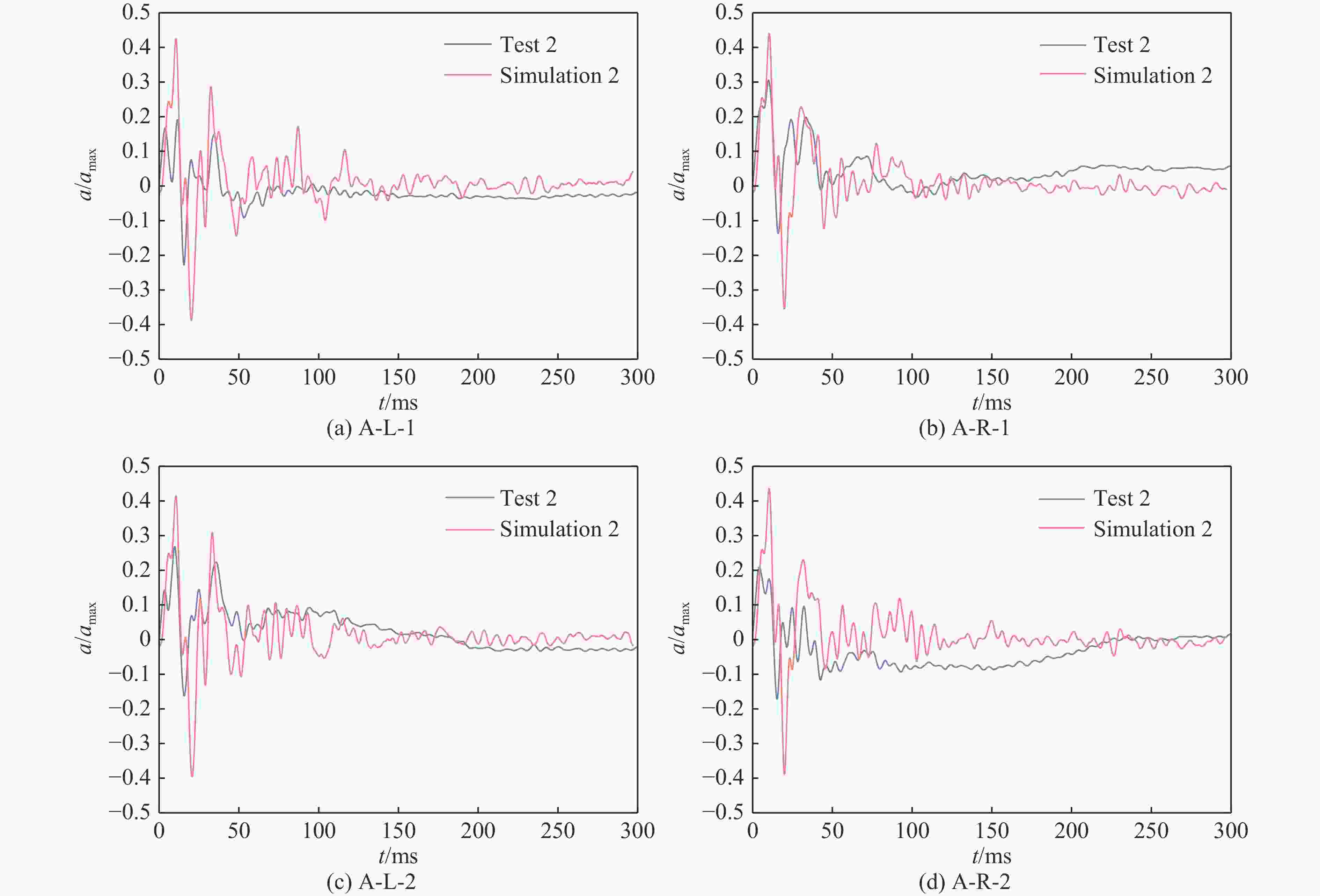

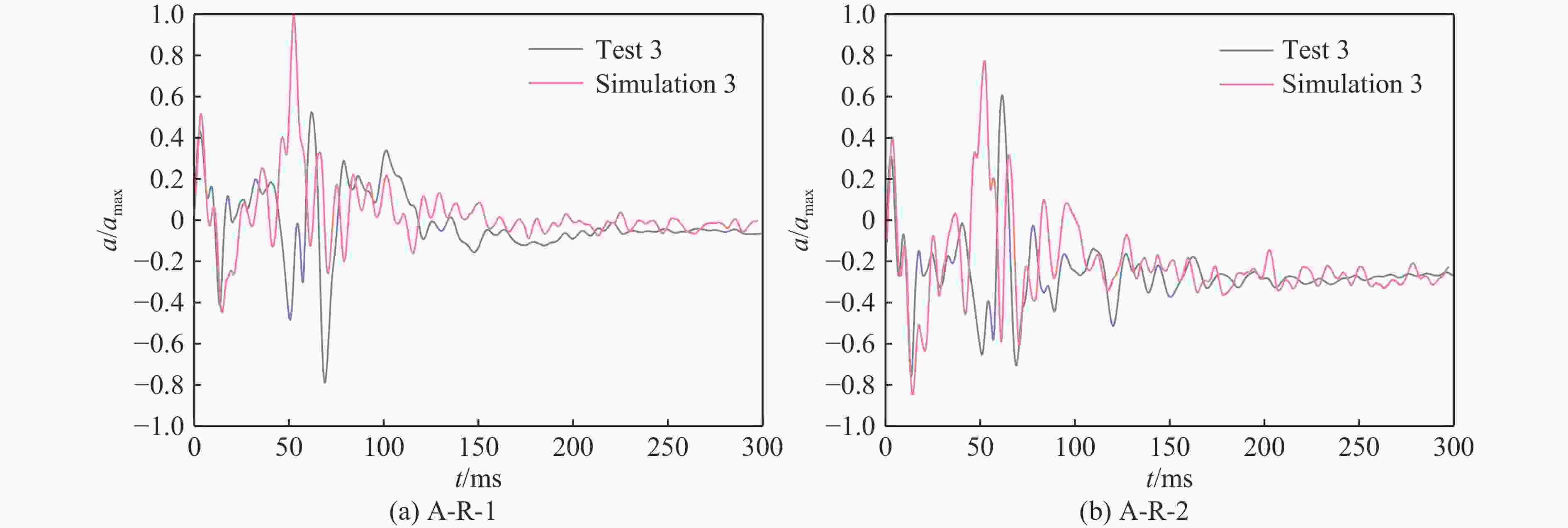

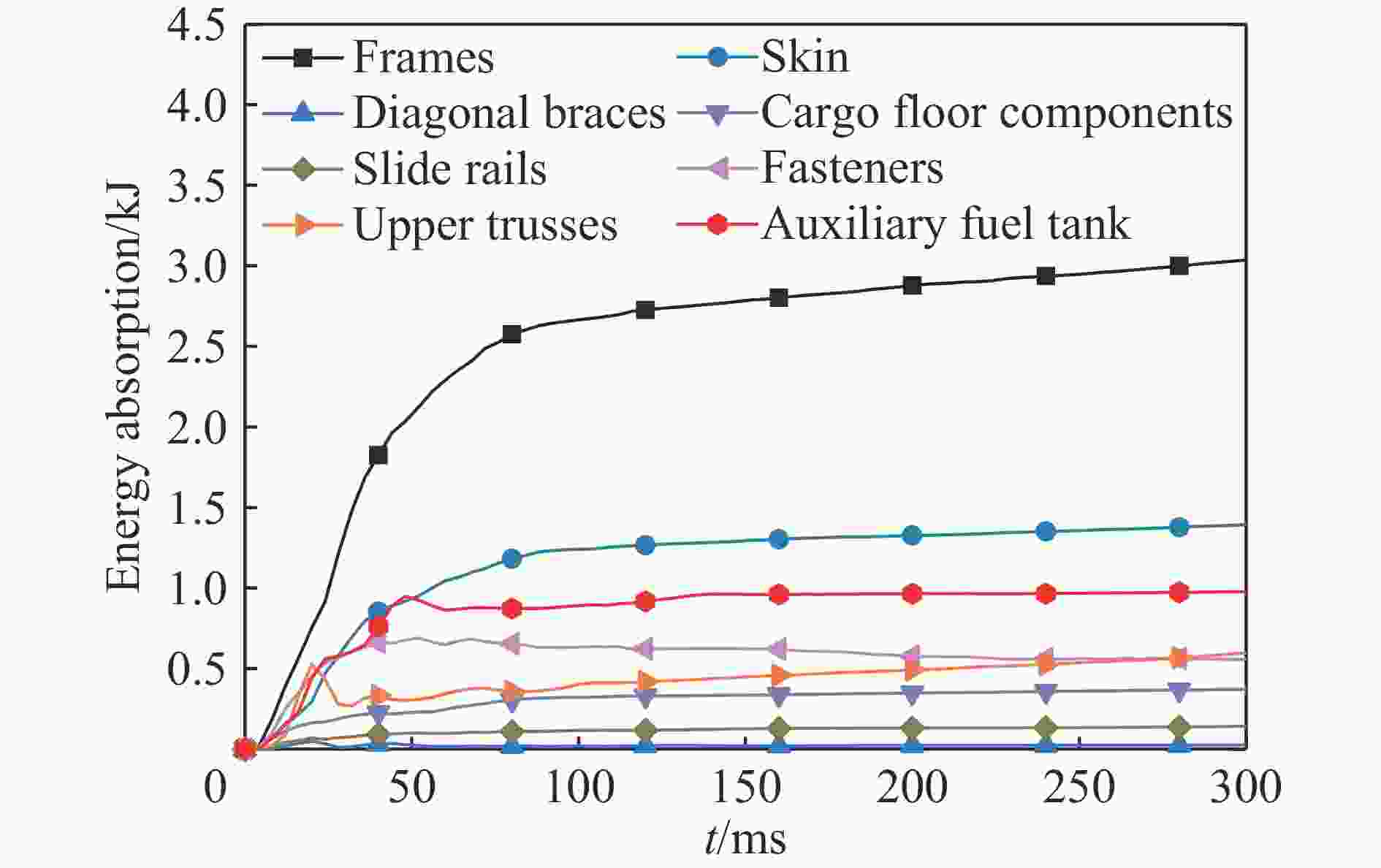

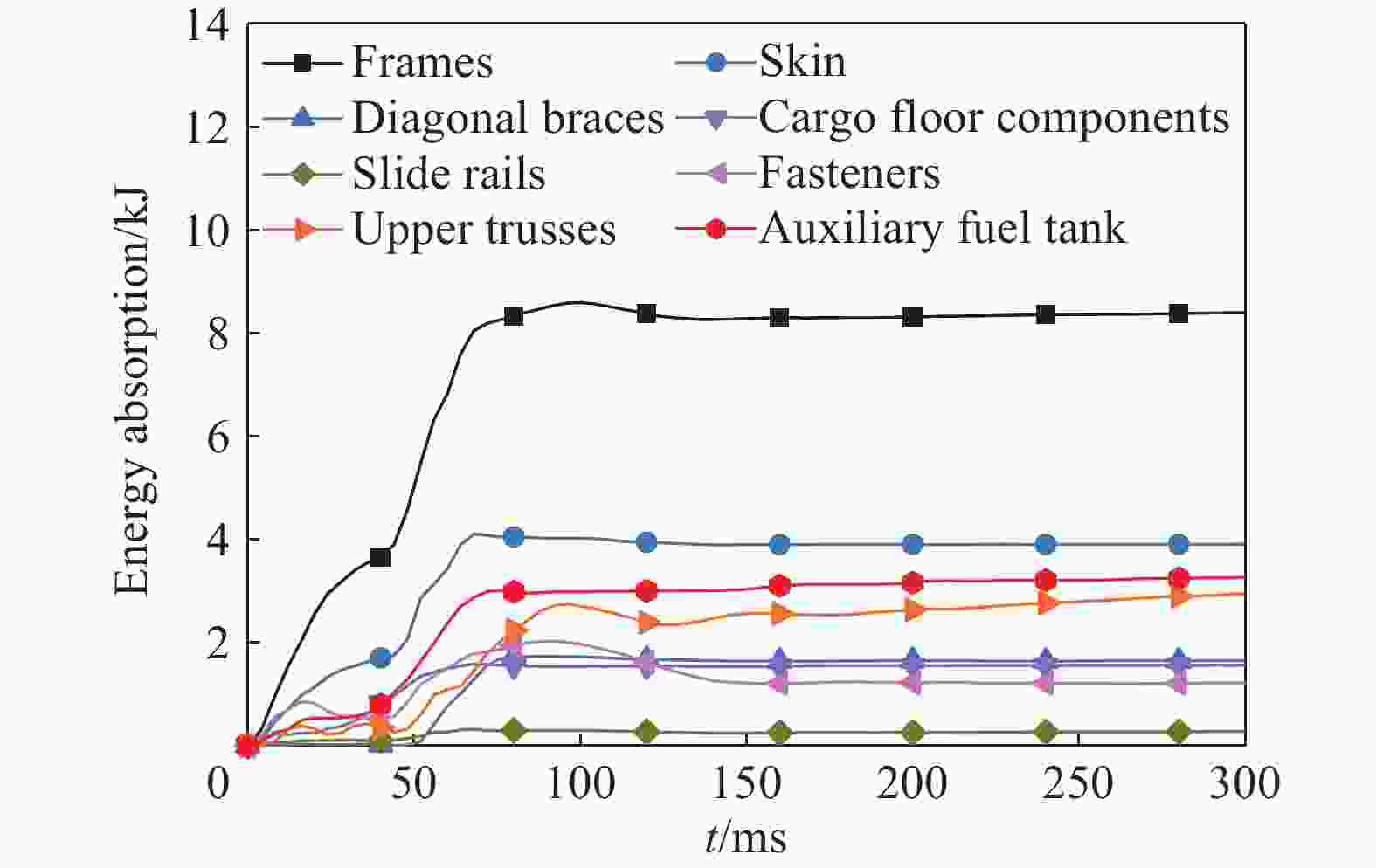

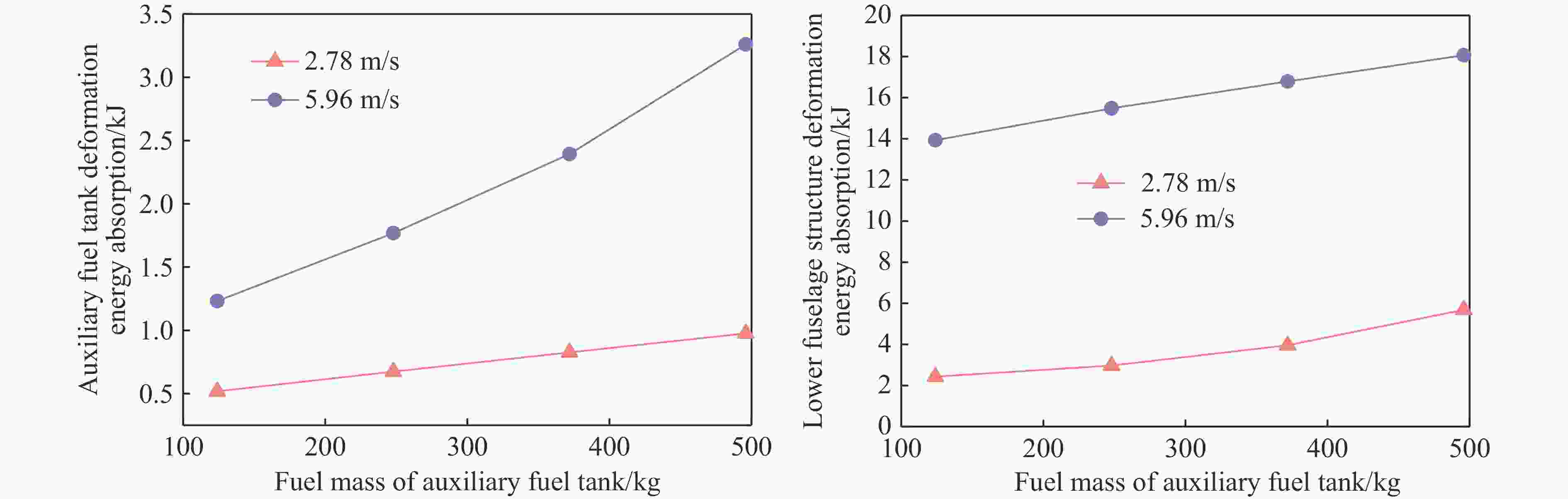

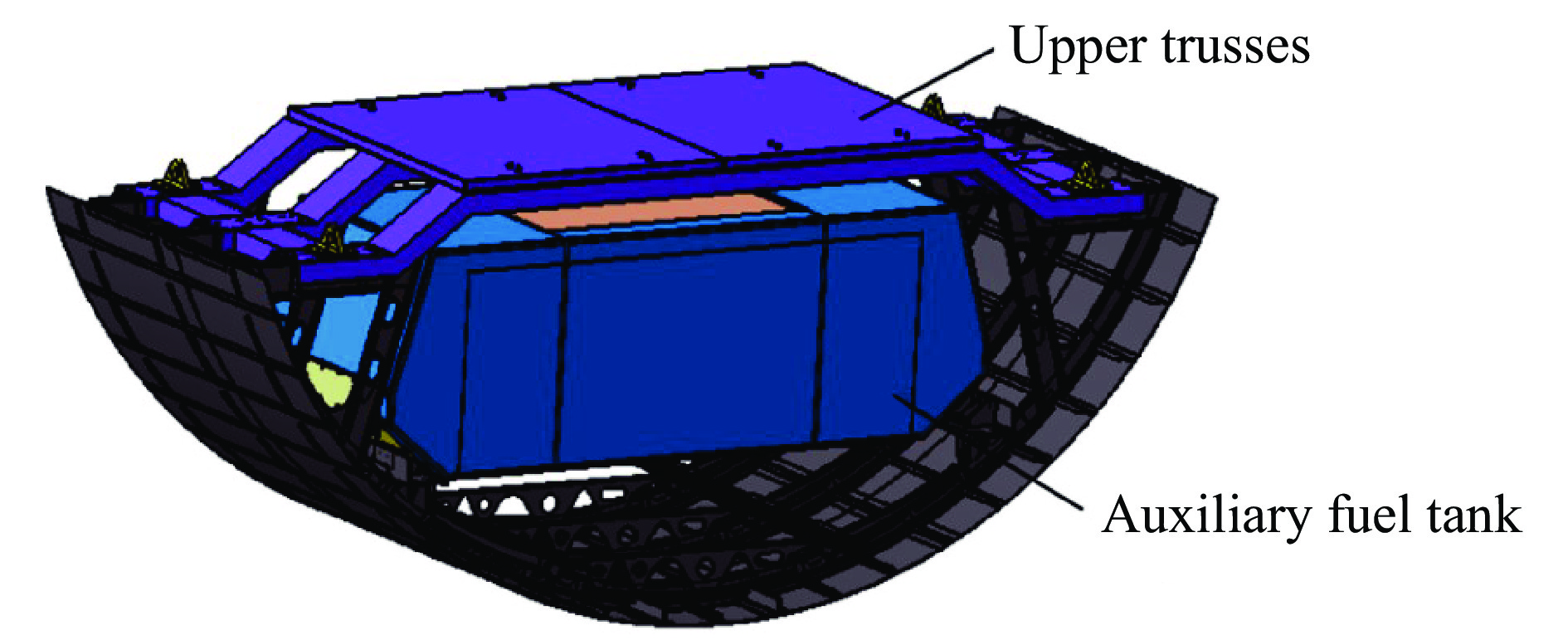

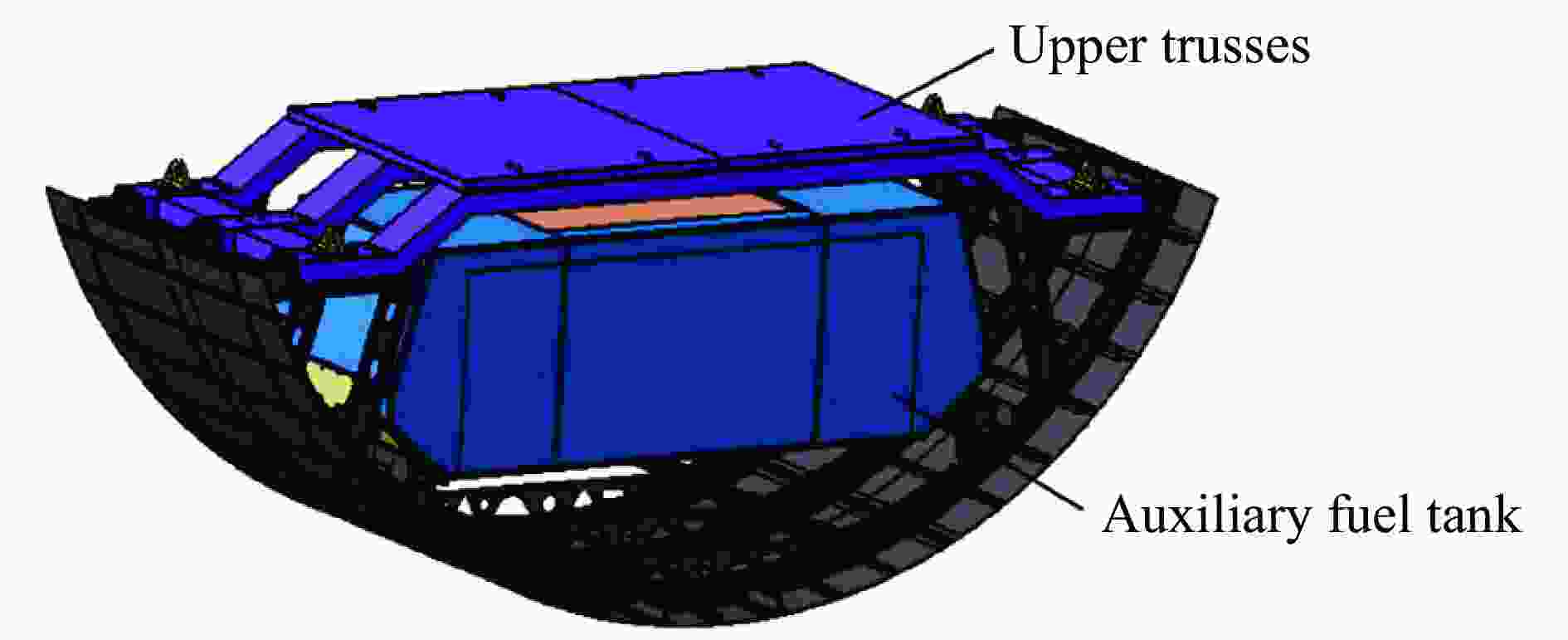

摘要: 针对典型民用飞机机身下部结构加装辅助燃油箱,开展了冲击速度为1.53、2.78和5.96 m/s的垂直坠撞试验,研究了辅助燃油箱对机身下部结构的触地冲击响应、结构变形和破坏模式的影响。对比仿真与试验结果,验证了加装辅助燃油箱的机身下部结构有限元模型的有效性,通过仿真分析了垂直坠撞过程中的结构吸能形式。结果表明:在冲击速度为1.53 m/s的工况下,机身下部结构以弹性变形为主,仅有轻微的塑性变形;在冲击速度为2.78 m/s的工况下,机身框、蒙皮及货舱地板T形支撑件以弯曲变形为主,整体结构压缩程度较小,货舱地板T形支撑件与左侧地板滑轨连接失效后翘起,未触及油箱;在冲击速度为5.96 m/s的工况下,机身下部结构压缩变形严重,左侧斜支撑受压发生断裂,辅助燃油箱下沉至货舱地板。仿真的坠撞触地撞击力和典型位置加速度变化趋势与试验结果吻合较好,能有效模拟坠撞过程中结构的变形和破坏情况。仿真结果表明,在加装辅助燃油箱的机身下部结构的坠撞试验中,机身框是主要的变形吸能部件,蒙皮和辅助燃油箱是次要的变形吸能结构;随着辅助燃油箱装油质量的增加,仿真得到的辅助燃油箱和机身下部结构组件的吸收冲击能量增加,破坏更严重。Abstract: A study was conducted to investigate the crash impact response of the lower fuselage structure of a typical civil aircraft with an auxiliary fuel tank installed. The results of vertical crash tests conducted at impact velocities of 1.53, 2.78 and 5.96 m/s were obtained. These results include the influence of installing auxiliary fuel tanks on the impact response and the structural deformation and damage of the lower fuselage structure. The validity of the corresponding finite element model was verified through a correlation analysis between the simulation and test results. The impact energy absorption form during the vertical crash process was analyzed through simulation results. The results show that the structure mainly deforms elastically with only slight plastic deformation under the impact condition of 1.53 m/s. Under the impact condition of 2.78 m/s, the fuselage frames, skin, and T-shaped support components of the cargo floor are mainly deformed by bending, and the total structures were slightly compressed. The T-shaped support components connected to the left cargo floor slide rails extended upward and did not touch the fuel tank. Under the impact condition of 5.96 m/s, the lower fuselage structures were seriously compressed and the left diagonal brace was fractured under pressure. The auxiliary fuel tank sank to the cargo floor. The simulation analysis can effectively model the deformation and damage of the structure during the vertical crash process at different impact velocities. The impact force on the ground and the trend of acceleration at typical locations obtained by analysis are in good agreement with the test results. The analysis results show that the fuselage frame is the main deformation and energy absorption component in the crash of the lower fuselage structure equipped with auxiliary fuel tanks. The skin and auxiliary fuel tank are the secondary structures that participate in deformation and energy absorption. As the auxiliary fuel tank is filled with more fuel, the simulation results show that the energy absorption capacity of the auxiliary fuel tank and the lower fuselage structure components increases, i.e., the degree of damage becomes more serious. The research results can provide support for the anti-crash design, analysis, and verification of the fuselage structure of civil aircraft with auxiliary fuel tanks installed.

-

Key words:

- civil aircraft /

- auxiliary fuel tank /

- lower fuselage structure /

- crash test /

- impact response /

- deformation mode

-

表 1 机身结构及辅助燃油箱的材料参数

Table 1. Material parameters of fuselage structure and auxiliary fuel tank

材料牌号 密度/(kg·m−3) 弹性模量/GPa 泊松比 屈服强度MPa 硬化模量/MPa 失效应变 2524-T3 2768 71 0.35 310 759 0.15 7075-T62 2796 71 0.33 427 744 0.09 7050-T7451 2823 71 0.33 434 826 0.09 7050-T76511 2823 71 0.33 469 978 0.07 15-5PH-固溶-H1025 7833 197 0.27 1000 600 0.12 表 2 不同装油量工况下各组件的吸能分析

Table 2. Energy absorption of each component in the case of different oil capacities

装油量/kg 冲击速度/(m·s−1) 吸能/J 吸能占比/% 机身下部结构组件 上部桁架 辅助燃油箱 机身下部结构组件 上部桁架 辅助燃油箱 124 2.78 2432 616 518 68.2 17.3 14.5 248 2970 507 674 71.5 12.2 16.3 372 3956 527 826 74.5 9.9 15.6 496(试验) 5684 596 976 78.3 8.2 13.5 124 5.96 13929 2062 1231 80.9 12.0 7.1 248 15483 2329 1768 79.1 11.9 9.0 372 16789 2649 2393 76.9 12.1 11.0 496(试验) 18067 2647 3260 74.5 12.1 13.4 -

[1] GUIDA M, MARULO F, ABRATE S. Advances in crash dynamics for aircraft safety [J]. Progress in Aerospace Sciences, 2018, 98: 106–123. DOI: 10.1016/j.paerosci.2018.03.008. [2] 刘小川, 白春玉, 惠旭龙, 等. 民机机身结构耐撞性研究的进展与挑战 [J]. 固体力学学报, 2020, 41(4): 293–323. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2020.035.LIU X C, BAI C Y, XI X L, et al. Progress and challenge of research on crashworthiness of civil airplane fuselage structures [J]. Chinese Journal of Solid Mechanics, 2020, 41(4): 293–323. DOI: 10.19636/j.cnki.cjsm42-1250/o3.2020.035. [3] 刘小川. 民用飞机坠撞事故研究及启示 [M]. 北京: 航空工业出版社, 2022: 153–183.LIU X C. Research and enlightenment on civil aircraft crash accident [M]. Beijing: Aviation Industry Press, 2022: 153–183. [4] FASANELLA E L, WIDMAYER E, ROBINSON M P. Structural analysis of the controlled impact demonstration of a jet transport airplane [J]. Journal of Aircraft, 1987, 24(4): 274–280. DOI: 10.2514/3.45437. [5] FASANELLA E L, JACKSON K E, JONES Y T, et al. Crash simulation of a Boeing 737 fuselage section vertical drop test [C]//Proceedings of the Third KRASH User’s Conference. 2001. [6] FASANELLA E L, JACKSON K E. Crash simulation of a vertical drop test of a B737 fuselage section with auxiliary fuel tank: 23681-0001 [R]. USA: U. S. Army Research Laboratory, Vehicle Technology Center, Langley Research Center, 2002. [7] JACKSON K E, FASANELLA E L. Crash simulation of a vertical drop test of a B737 fuselage section with overhead bins and luggage [R]. USA: NASA Langley Technical Report Server, 2001: 22–25. [8] HASHEMI S M R, WALTON A C. A systematic approach to aircraft crashworthiness and impact surface material models [J]. Proceedings of the Institution of Mechanical Engineers, Part G: Journal of Aerospace Engineering, 2000, 214(5): 265–280. DOI: 10.1243/0954410001532051. [9] KUMAKURA I, MINEGISHI M, IWASAKI K, et al. Summary of vertical drop tests of YS-11 transport fuselage sections: 2003-01-3027 [R]. Montreal: SAE World Aviation Congress, 2003. [10] KUMAKURA I, MINEGISHI M, IWASAKI K, et al. Vertical drop test of a transport fuselage section[C]//SAE Technical Paper Series. Warrendale: SAE International 2002: 1–10. [11] 朱晓东, 朱广荣. 民机典型机身舱段结构坠撞有限元数值仿真研究 [J]. 振动工程学报, 2008, 21(S1): 28–30.ZHU X D, ZHU G R. Crashworthiness simulation of civil aircraft fuselage section [J]. Journal of Vibration Engineering, 2008, 21(S1): 28–30. [12] 汪洋, 吴志斌, 刘富. 复合材料货舱地板立柱压溃响应试验 [J]. 复合材料学报, 2020, 37(9): 2200–2206. DOI: 10.13801/j.cnki.fhclxb.20200111.001.WANG Y, WU Z B, LIU F. Crush experiment of composite cargo floor stanchions [J]. Acta Materiae Compositae Sinica, 2020, 37(9): 2200–2206. DOI: 10.13801/j.cnki.fhclxb.20200111.001. [13] 施萌, 汪洋, 吴志斌, 等. 民机货舱下部复合材料结构抗坠撞吸能特性试验研究 [J]. 复合材料科学与工程, 2021(9): 83–88. DOI: 10.19936/j.cnki.2096-8000.20210928.013.SHI M, WANG Y, WU Z B, et al. Study on the anti-crash energy absorption characteristic of composite structure in the sub-cargo structure [J]. Composites Science and Engineering, 2021(9): 83–88. DOI: 10.19936/j.cnki.2096-8000.20210928.013. [14] 任毅如, 向锦武, 罗漳平, 等. 客舱地板斜撑杆对民机典型机身段耐撞性能的影响 [J]. 航空学报, 2010, 31(2): 271–276.REN Y R, XIANG J W, LUO Z P, et al. Effect of Cabin-floor oblique strut on crashworthiness of typical civil aircraft fuselage section [J]. Acta Aeronautica et Astronautica Sinica, 2010, 31(2): 271–276. [15] 郑建强, 向锦武, 罗漳平, 等. 民机机身下部结构耐撞性优化设计 [J]. 航空学报, 2012, 33(4): 640–649. DOI: CNKI:11-1929/V.20111011.1411.006.ZHENG J Q, XIANG J W, LUO Z P, et al. Crashworthiness optimization of civil aircraft subfloor structure [J]. Acta Aeronautica et Astronautica Sinica, 2012, 33(4): 640–649. DOI: CNKI:11-1929/V.20111011.1411.006. [16] 刘小川, 郭军, 孙侠生, 等. 民机机身段和舱内设施坠撞试验及结构适坠性评估 [J]. 航空学报, 2013, 34(9): 2130–2140. DOI: 10.7527/S1000-6893.2013.0182.LIU X C, GUO J, SUN X S, et al. Drop test and structure crashworthiness evaluation of civil airplane fuselage section with cabin interiors [J]. Acta Aeronautica et Astronautica Sinica, 2013, 34(9): 2130–2140. DOI: 10.7527/S1000-6893.2013.0182. [17] 刘小川, 惠旭龙, 张欣玥, 等. 典型民用飞机全机坠撞实验研究 [J]. 航空学报, 2024, 45(5): 529664. DOI: 10.7527/S1000-6893.2023.29664.LIU X C, XI X L, ZHANG X Y, et al. Full-scale crash experimental study of typical civil aircraft [J]. Acta Aeronautica et Astronautica Sinica, 2024, 45(5): 529664. DOI: 10.7527/S1000-6893.2023.29664. [18] 张欣玥, 惠旭龙, 刘小川, 等. 典型金属民机机身结构坠撞特性试验 [J]. 航空学报, 2022, 43(6): 526234. DOI: 10.7527/S1000-6893.2022.26234.ZHANG X Y, XI X L, LIU X C, et al. Experimental study on crash characteristics of typical metal civil aircraft fuselage structure [J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(6): 526234. DOI: 10.7527/S1000-6893.2022.26234. [19] 解江, 牟浩蕾, 冯振宇, 等. 大飞机典型货舱下部结构冲击试验及数值模拟 [J]. 航空学报, 2022, 43(6): 525890. DOI: 10.7527/S1000-6893.2021.25890.XIE J, MOU H L, FENG Z Y, et al. Impact characteristics of typical sub-cargo structure of large aircraft: tests and numerical simulation [J]. Acta Aeronautica et Astronautica Sinica, 2022, 43(6): 525890. DOI: 10.7527/S1000-6893.2021.25890. [20] 牟浩蕾, 解江, 冯振宇, 等. 大型运输类飞机典型机身框段坠撞特性分析 [J]. 航空学报, 2023, 44(9): 227512. DOI: 10.7527/S1000-6893.2022.27512.MOU H L, XIE J, FENG Z Y, et al. Crashworthiness characteristics analysis of typical fuselage section of large transport aircraft [J]. Acta Aeronautica et Astronautica Sinica, 2023, 44(9): 227512. DOI: 10.7527/S1000-6893.2022.27512. [21] 何欢, 陈国平, 张家滨. 带油箱结构的机身框段坠撞仿真分析 [J]. 航空学报, 2008, 29(3): 627–633. DOI: 10.3321/j.issn:1000-6893.2008.03.015.HE H, CHEN G P, ZHANG J B. Crash simulation of fuselage section with fuel tank [J]. Acta Aeronautica et Astronautica Sinica, 2008, 29(3): 627–633. DOI: 10.3321/j.issn:1000-6893.2008.03.015. -

下载:

下载: