Study on the high-speed penetration resistance of honeycomb tube surface constrained concrete

-

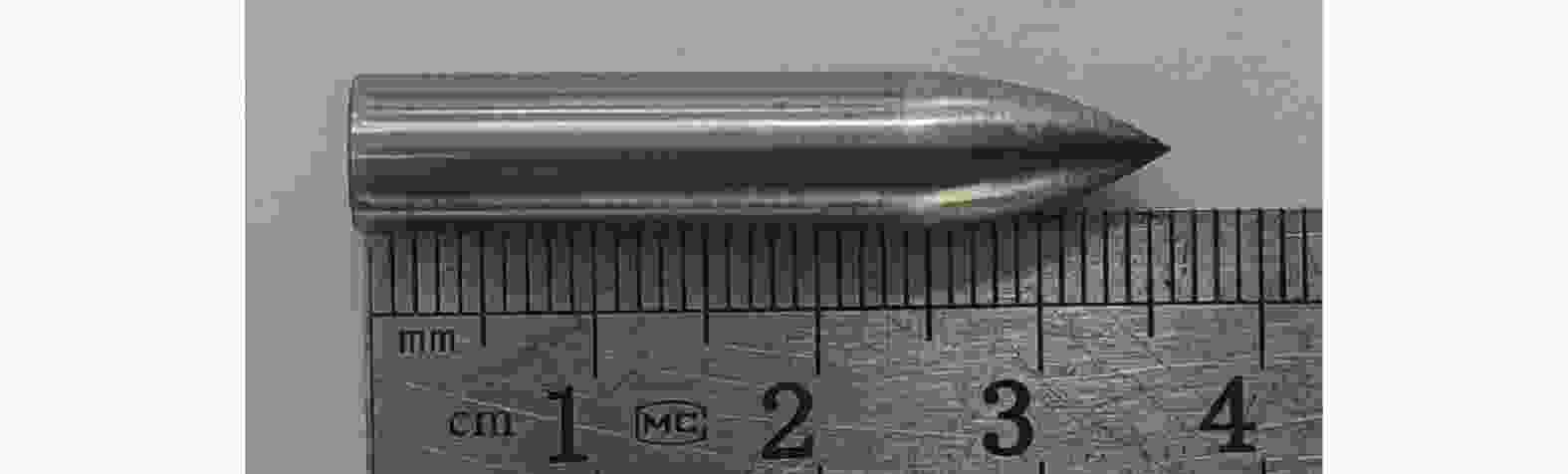

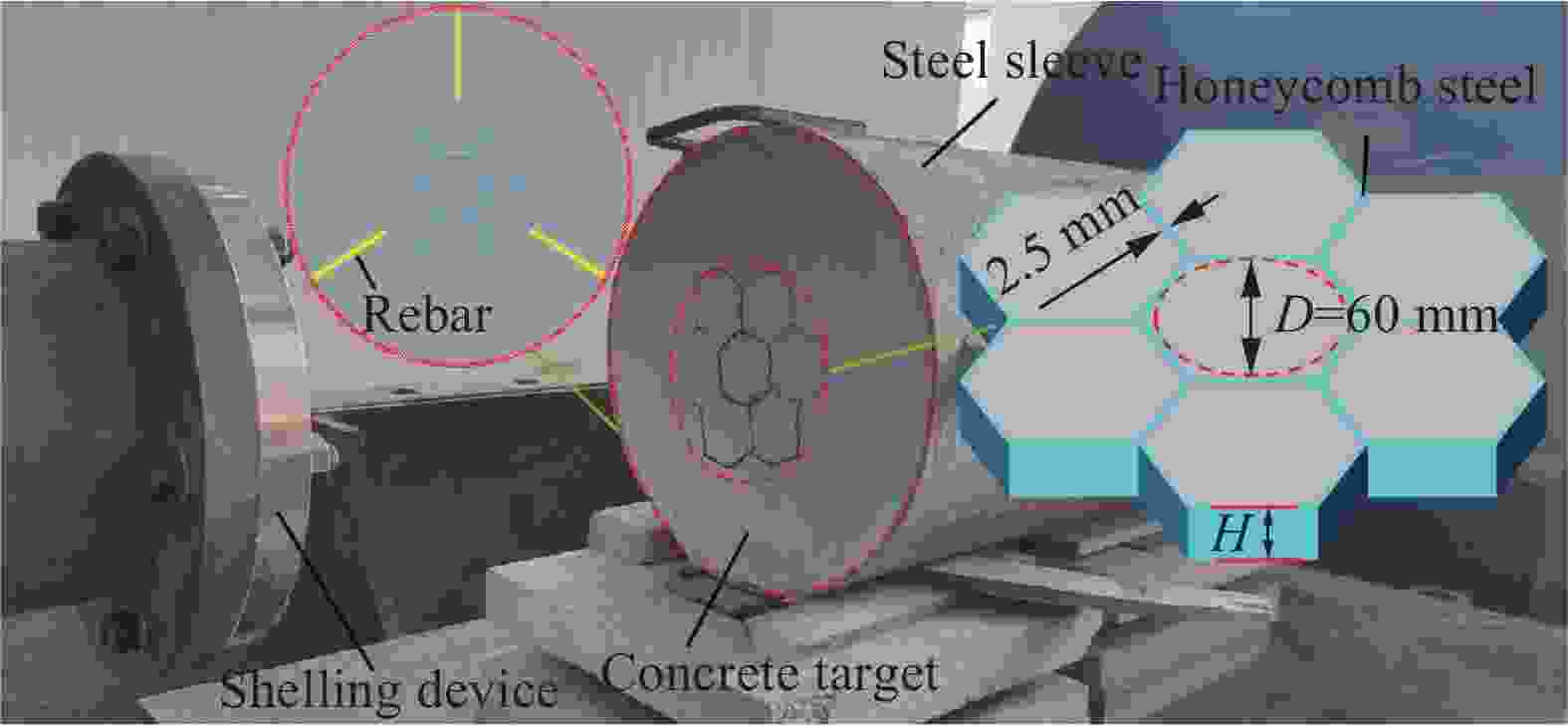

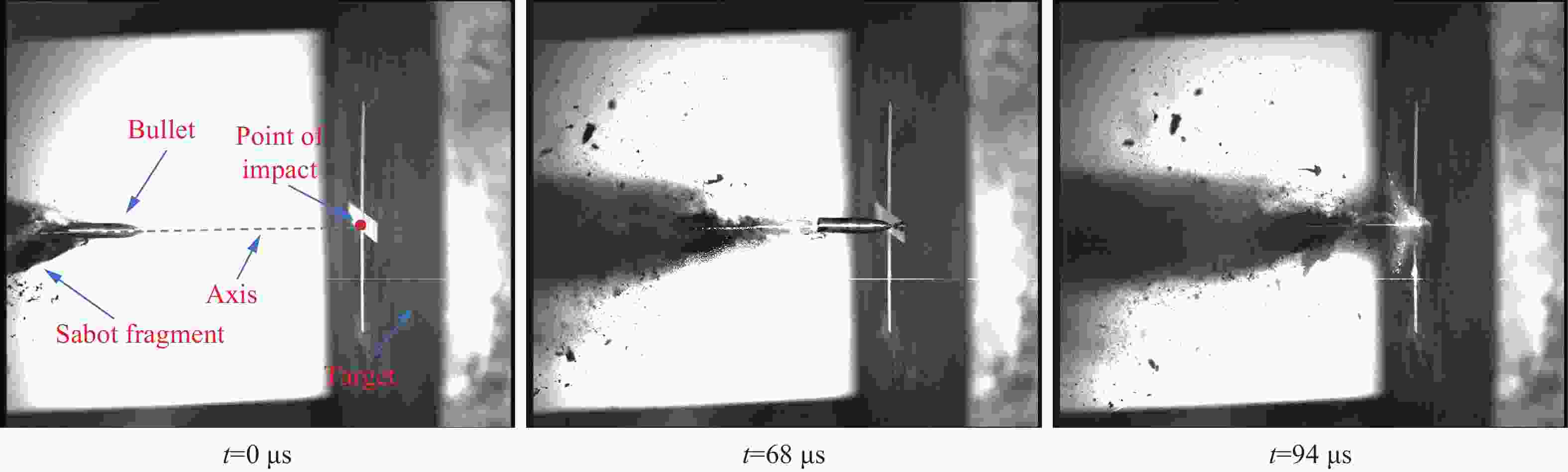

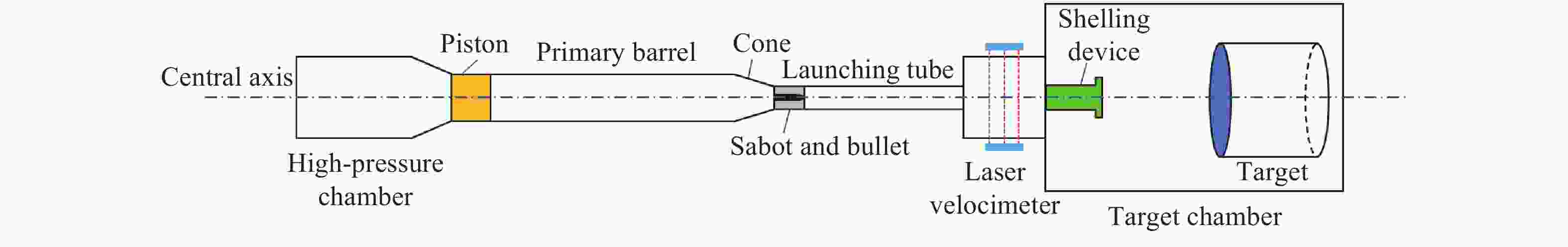

摘要: 为研究超高速侵彻下金属蜂窝管约束混凝土结构的抗侵彻性能,利用二级轻气炮开展了1 500 m/s附近弹体侵彻试验,使用物质点法模拟侵彻过程并对靶体和弹体参数的合理性进行验证,并利用该方法研究了蜂窝管壁厚、高度、直径和材料等参数对靶体抗侵彻性能的影响规律。数值计算结果表明:物质点法可以准确模拟高速侵彻过程,模拟结果与试验结果的相对误差小于10%。通过正交分析得到影响侵深的因素的显著程度由强到弱依次为蜂窝管特征管深、特征内径、特征壁厚、材料;影响开坑半径的因素的显著程度由强到弱依次为蜂窝管特征壁厚、特征管深、材料、特征内径。对于本文所采用的弹体,根据优化结果分析得到了综合因素最优的组合。Abstract: To investigate the penetration resistance of metal honeycomb tube-confined concrete structures under hypervelocity impact, penetration experiments were conducted using a two-stage light gas gun with projectile velocities near

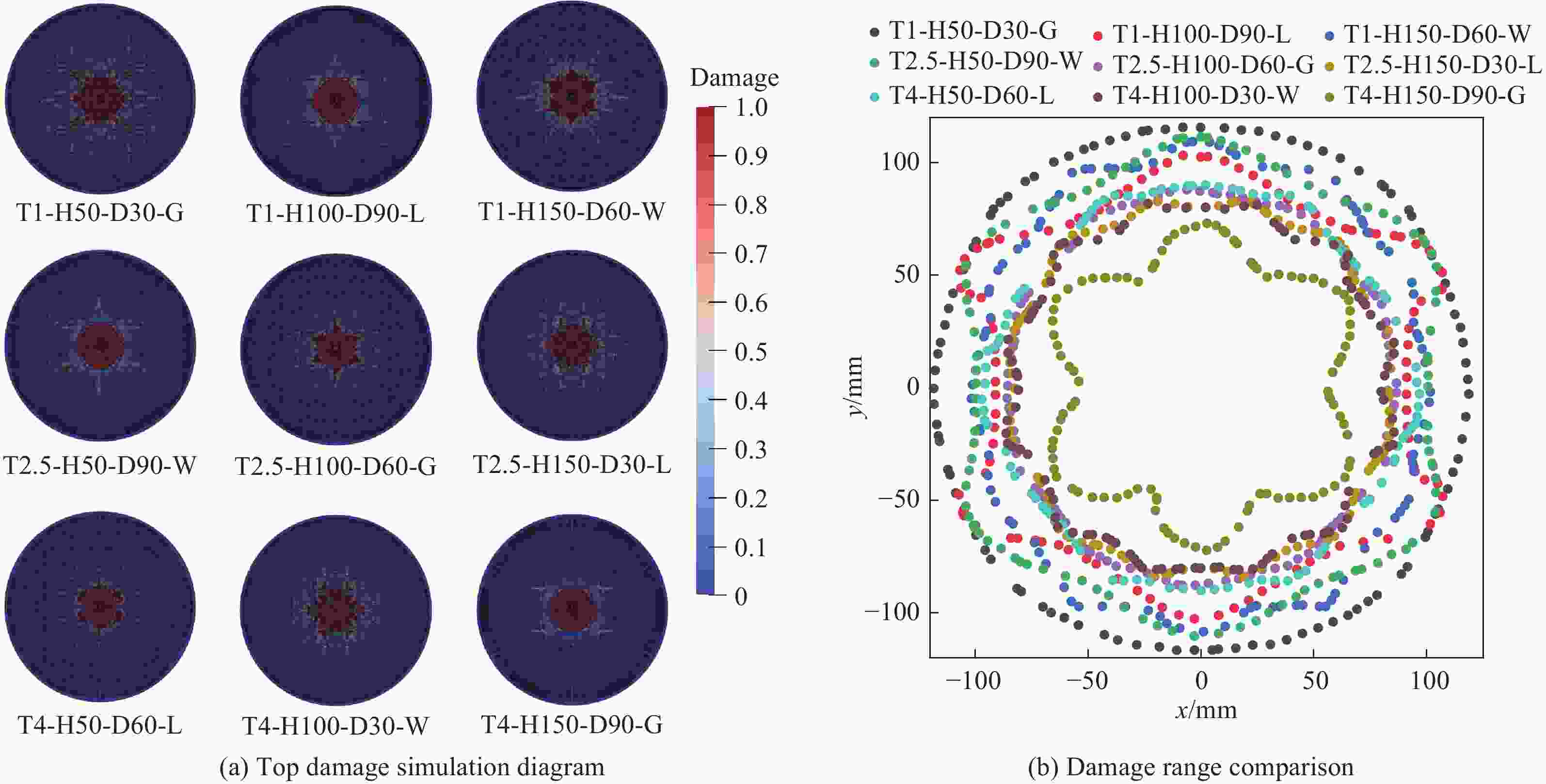

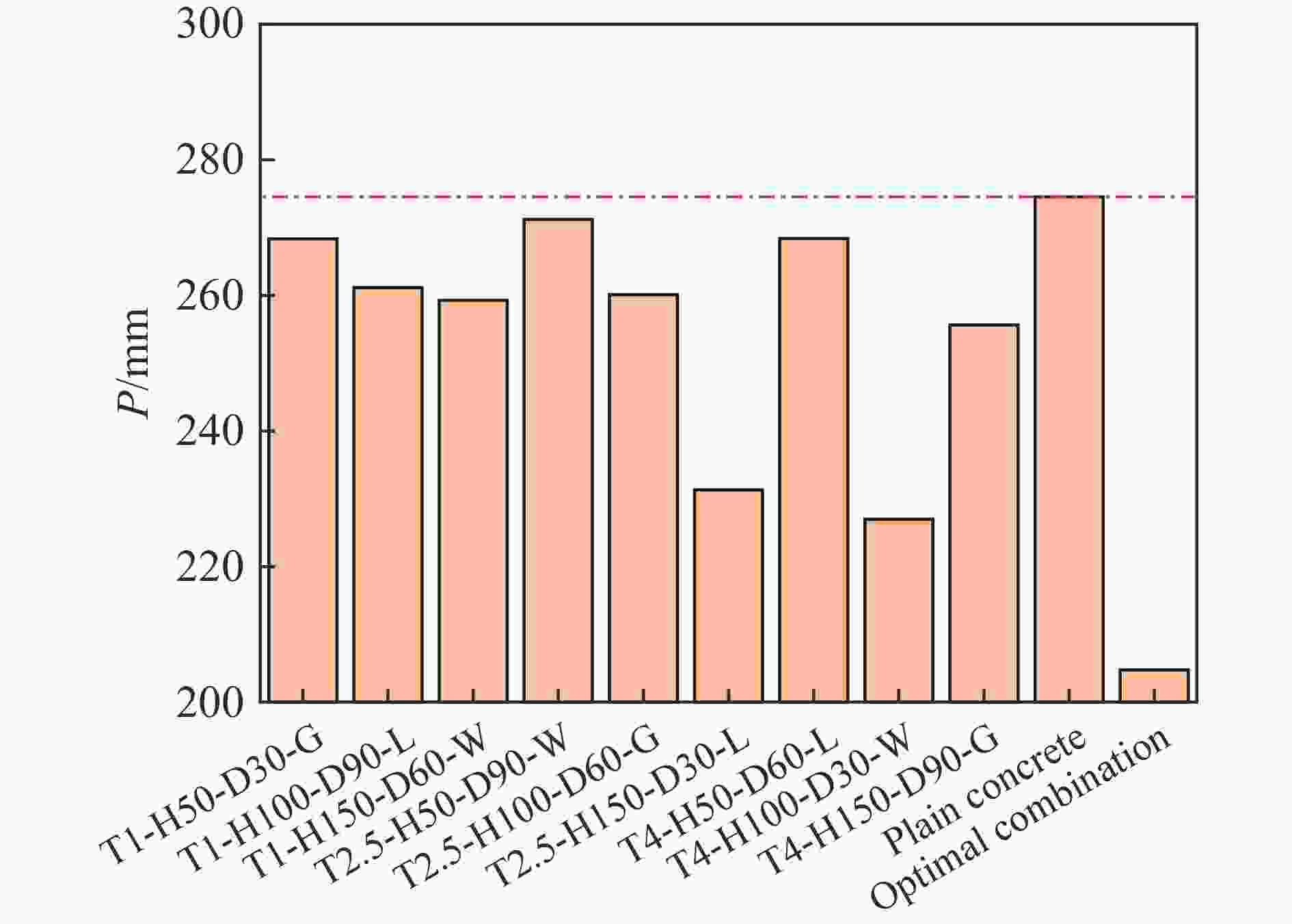

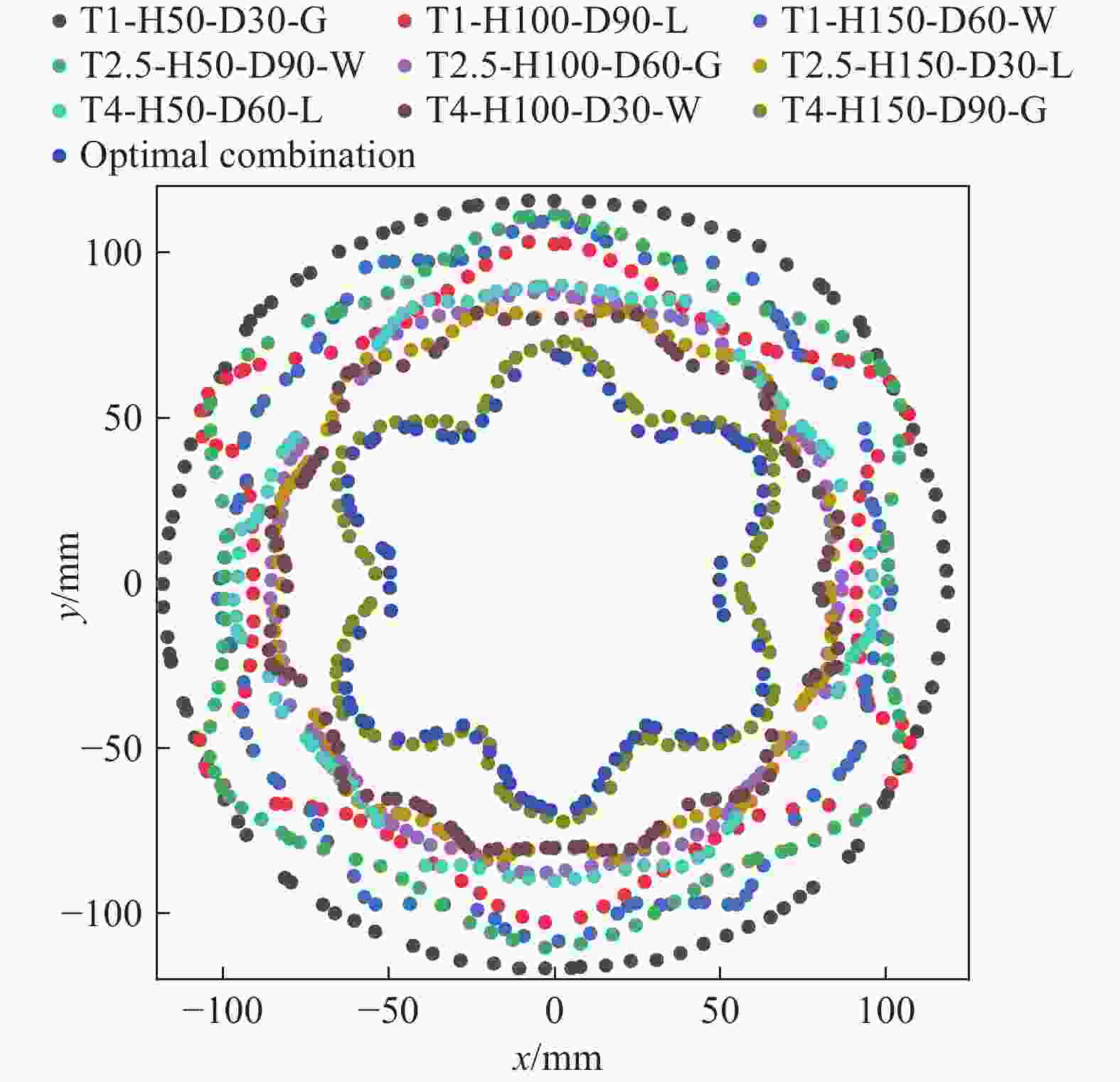

1500 m/s. The material point method (MPM) was employed to simulate the penetration process and validate the parameters of target and projectile. This method was further used to analyze the effects of honeycomb tube parameters, including wall thickness, height, diameter, and material, on the penetration resistance of the target structure. Numerical simulations showed that MPM can accurately simulate high-velocity penetration processes, with simulation results deviating from experimental data by less than 10%. Through orthogonal analysis, the factors influencing penetration depth were ranked in descending order as follows: characteristic tube depth, characteristic inner diameter, characteristic wall thickness, and material. For the cratering effect, the primary influencing factors were identified as characteristic wall thickness, characteristic tube depth, material, and characteristic inner diameter. For the projectiles tested in this study, optimization results indicated that a combination of4 mm wall thickness,150 mm height,30 mm incircle diameter, and tungsten alloy demonstrated the best penetration resistance, reducing penetration depth by 25.1% compared to plain concrete. A combination of4 mm wall thickness,150 mm height,90 mm incircle diameter, and aluminum exhibited superior resistance to the cratering effect, decreasing crater radius by 28.7% compared to plain concrete. Multi-objective optimization analysis determined the optimal overall configuration to be:4 mm wall thickness,150 mm height,30 mm mm incircle diameter, and aluminum. -

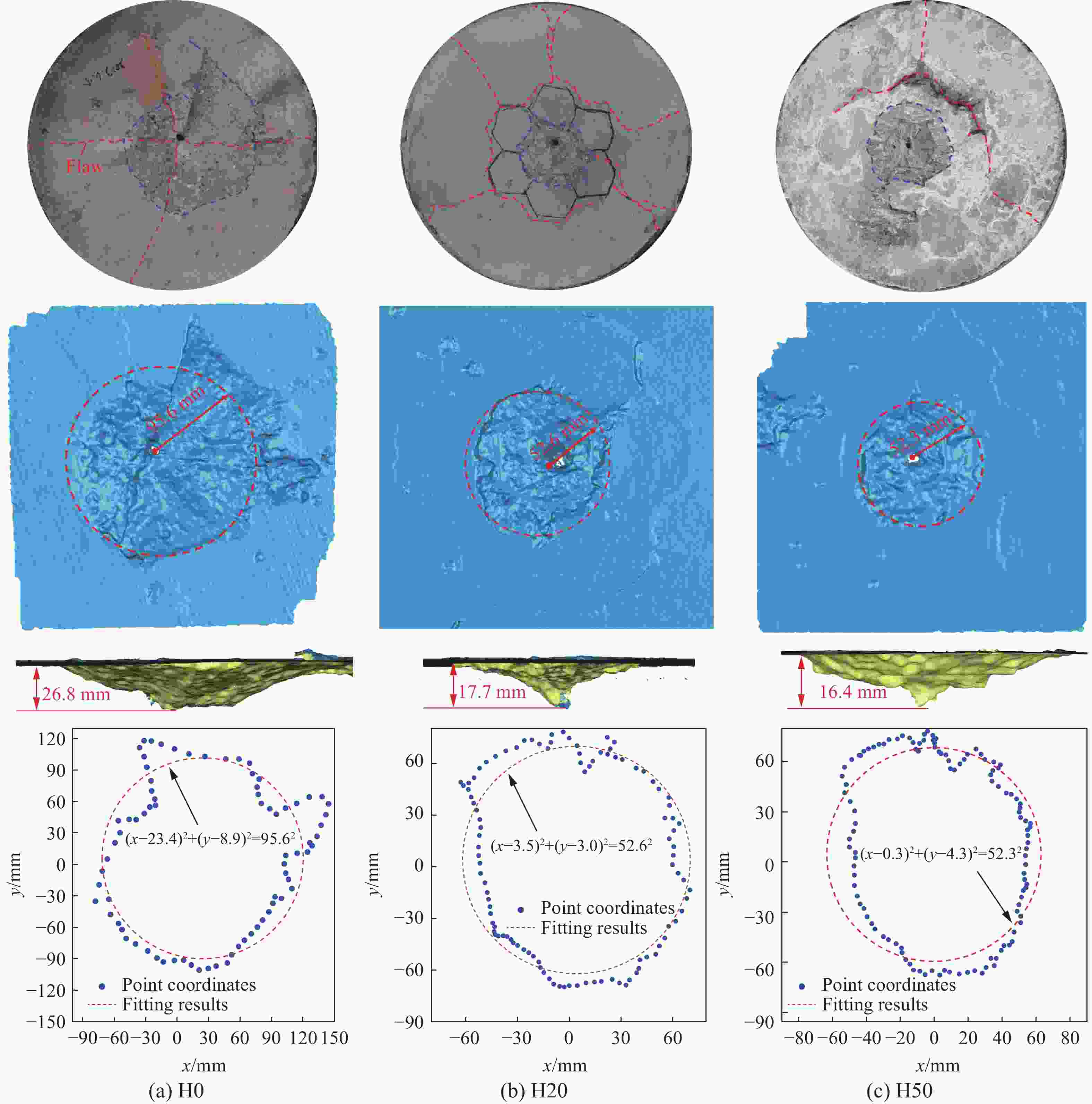

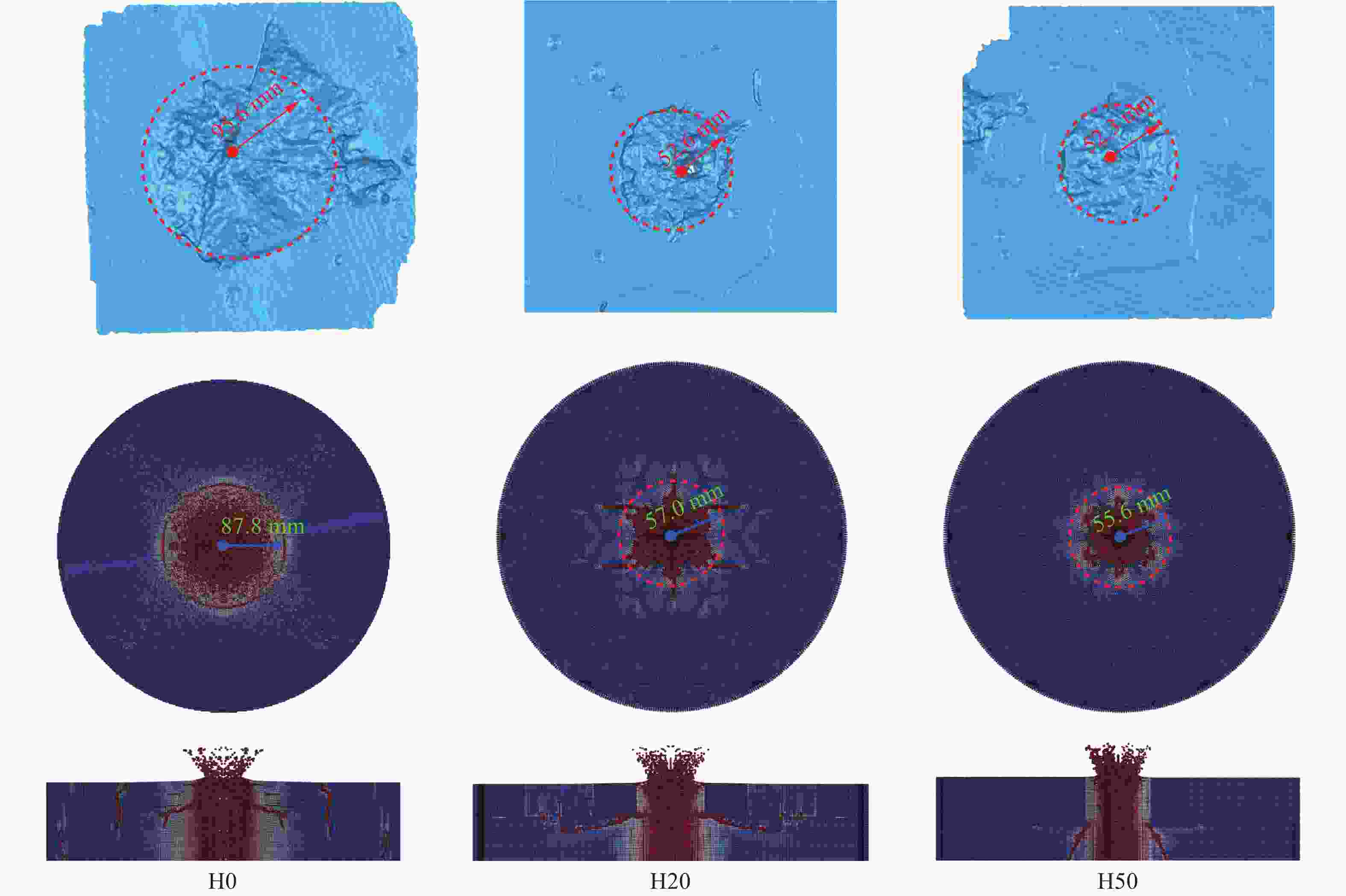

表 1 不同工况条件下开坑半径和开坑深度

Table 1. Pit radii and depths under different working conditions

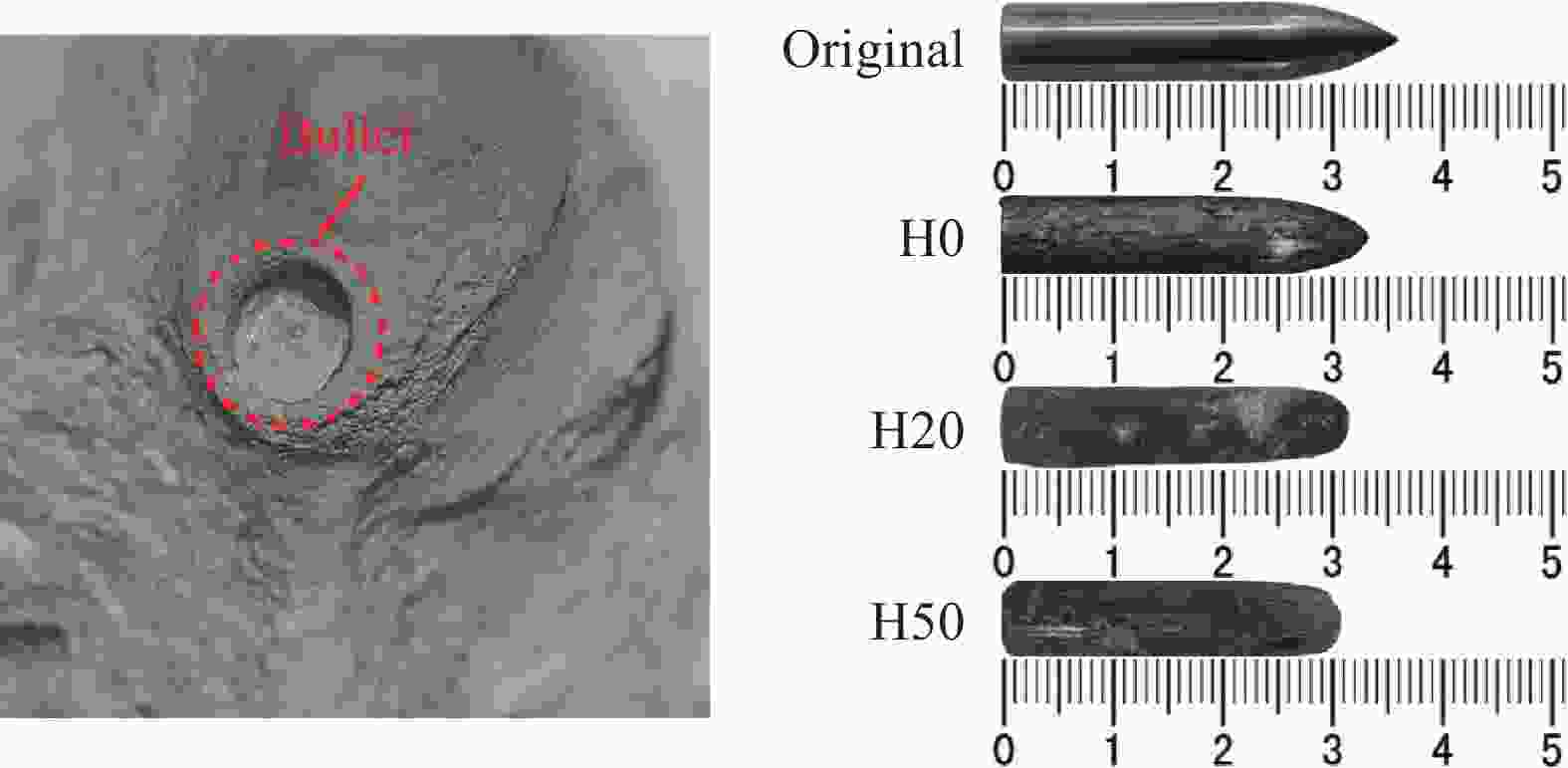

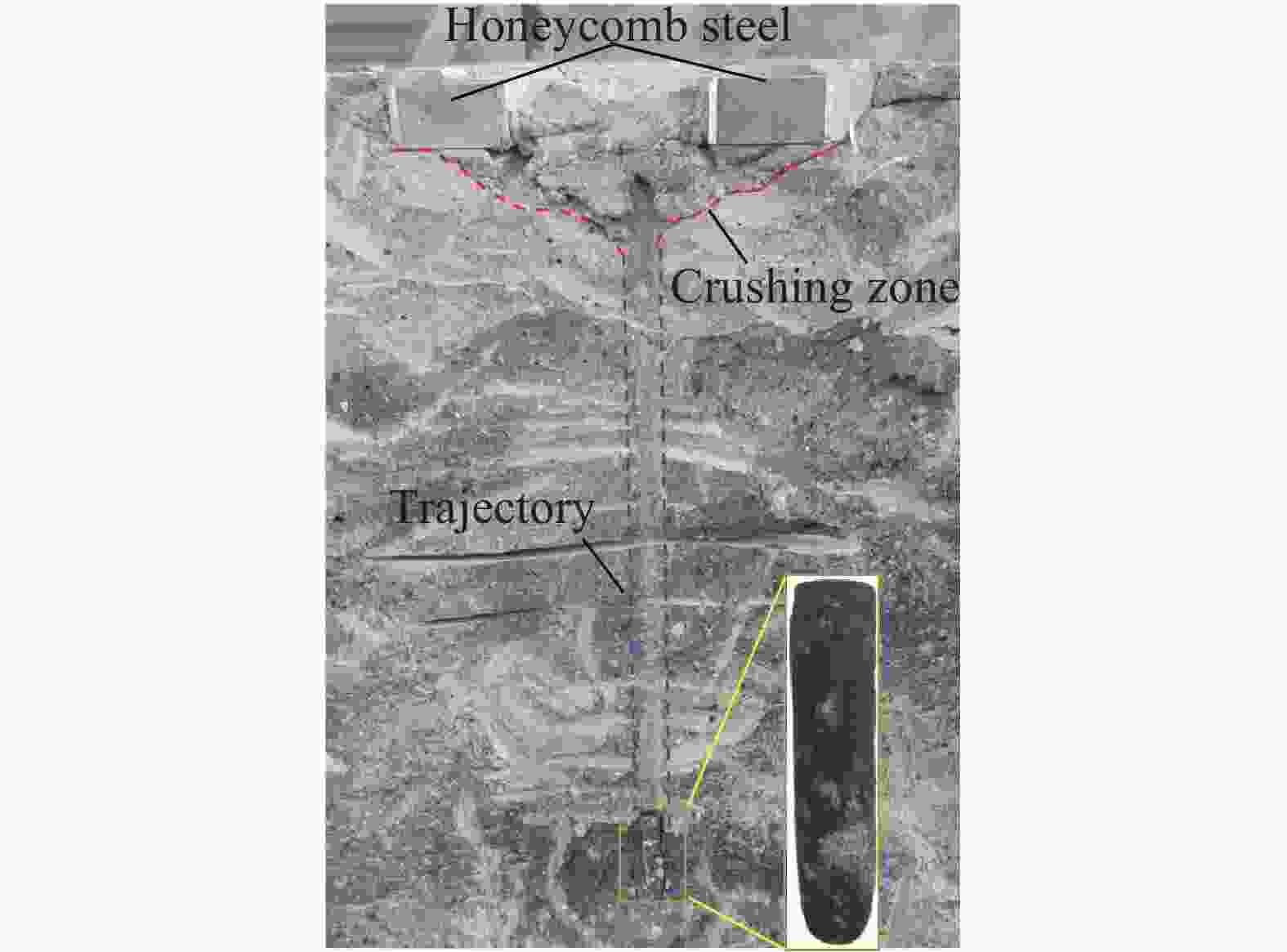

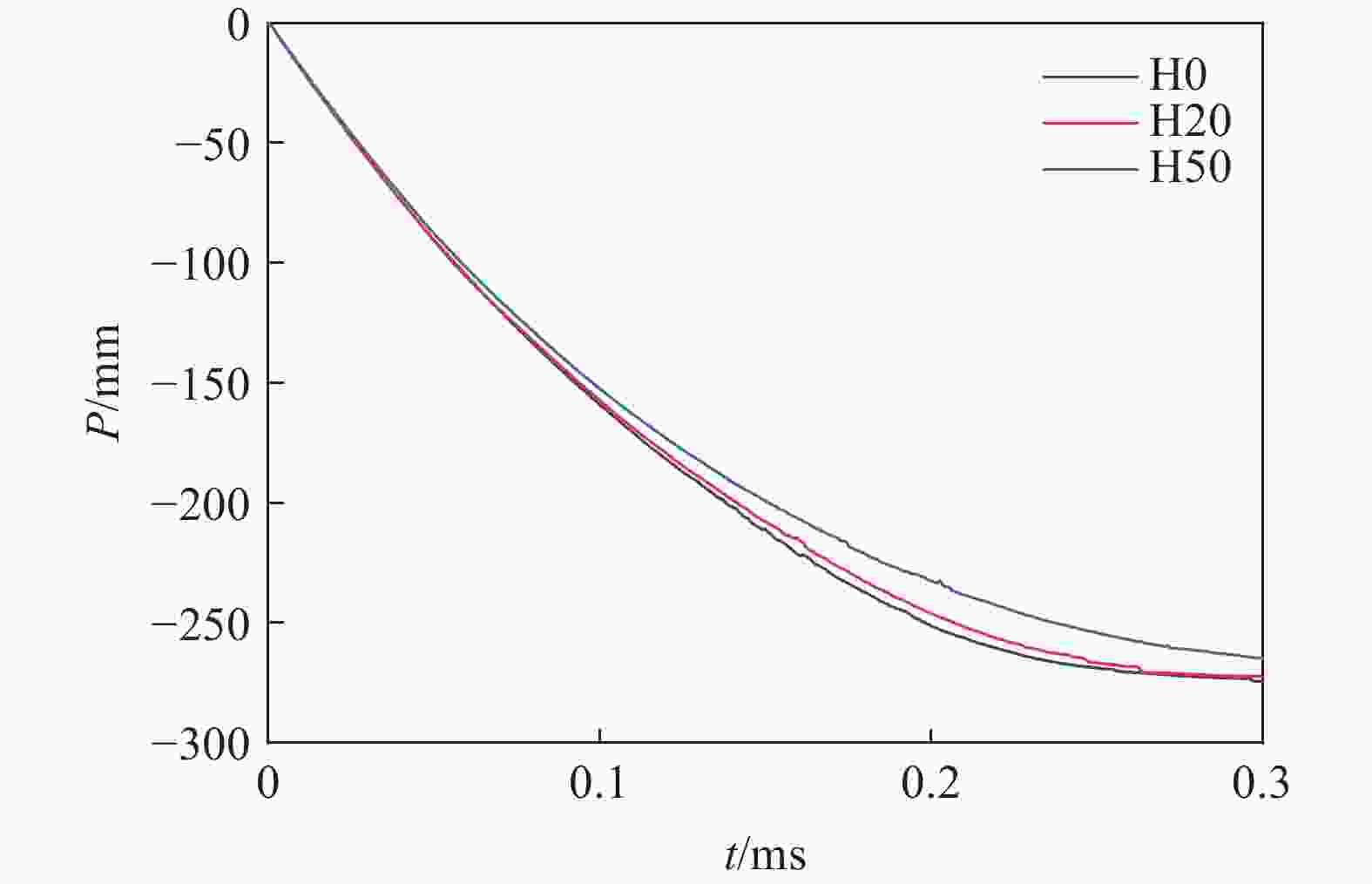

靶体 开坑半径/mm 开坑深度/mm H0 95.6 26.8 H20 52.6 17.7 H50 52.3 16.4 表 2 试验后弹体参数、侵彻深度对比

Table 2. Comparison of projectile parameters and penetration depths after test

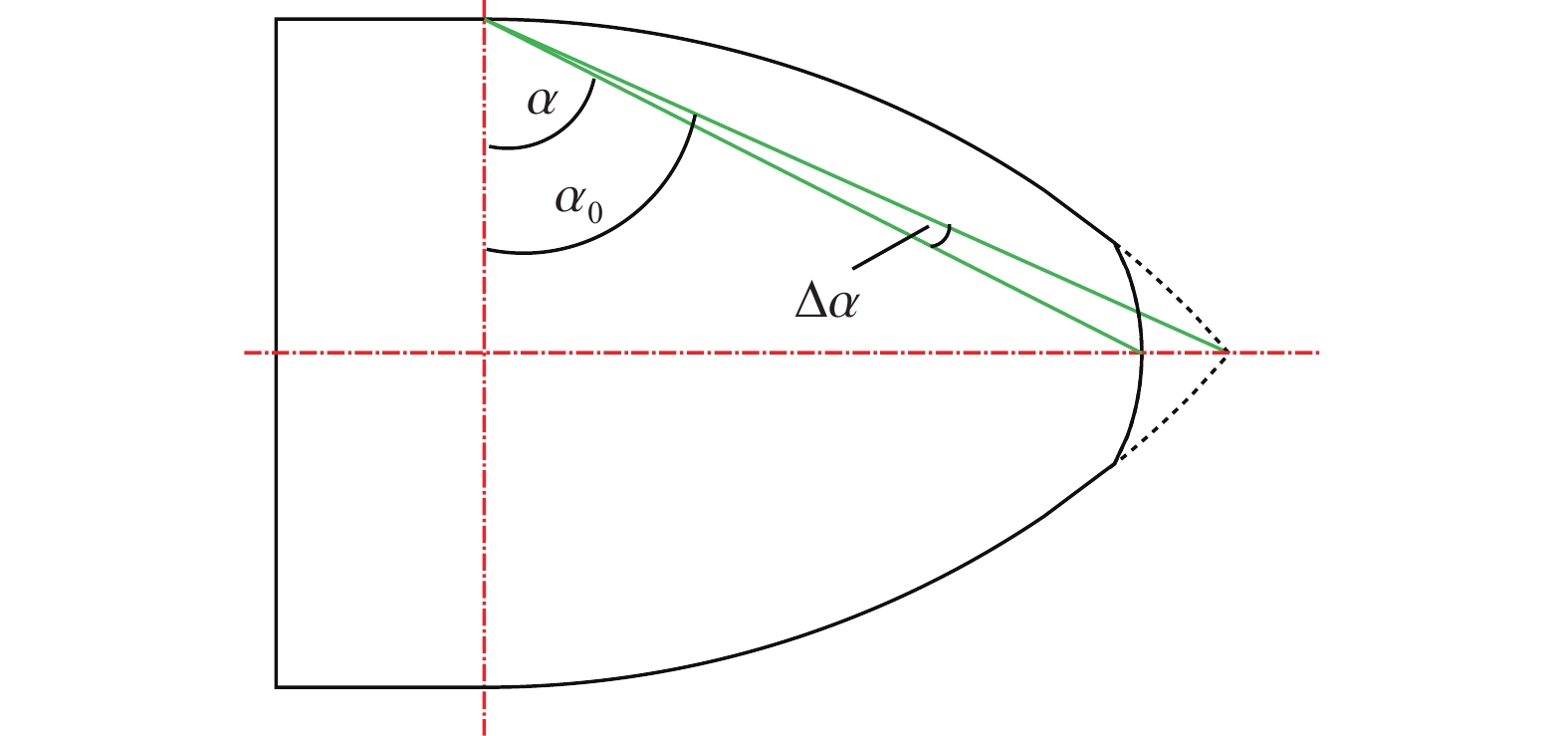

试验工况 v/(m·s−1) l/mm $\dfrac{{\Delta l}}{l} \times 100{\text{%}} $ m/g $\dfrac{{\Delta m}}{m} \times 100{\text{%}} $ $ \alpha $/(°) $\dfrac{{\Delta \alpha }}{{{\alpha _0}}} \times 100{\text{%}} $ P/mm P1500/mm H0 1469.8 33.2 7.8 8.7 7.4 68.5 6.4 285 291.0 H20 1533.5 31.5 12.5 8.6 8.5 64.2 12.3 294 287.6 H50 1456.7 30.4 15.6 8.4 10.6 60.6 17.2 267 275.0 注:l为弹体长度;m为弹体质量;α为弹头特征角度;α0为弹头初始特征角度;P为实际侵彻深度;P1500为 1500 m/s速度下侵彻深度。表 3 侵彻结束弹体损伤对比

Table 3. Comparison of projectile damage aafter penetration between simulation and test

靶体 数值模拟 试验回收 H0

H20

H50

表 4 正交模拟设计

Table 4. Orthogonal simulation design

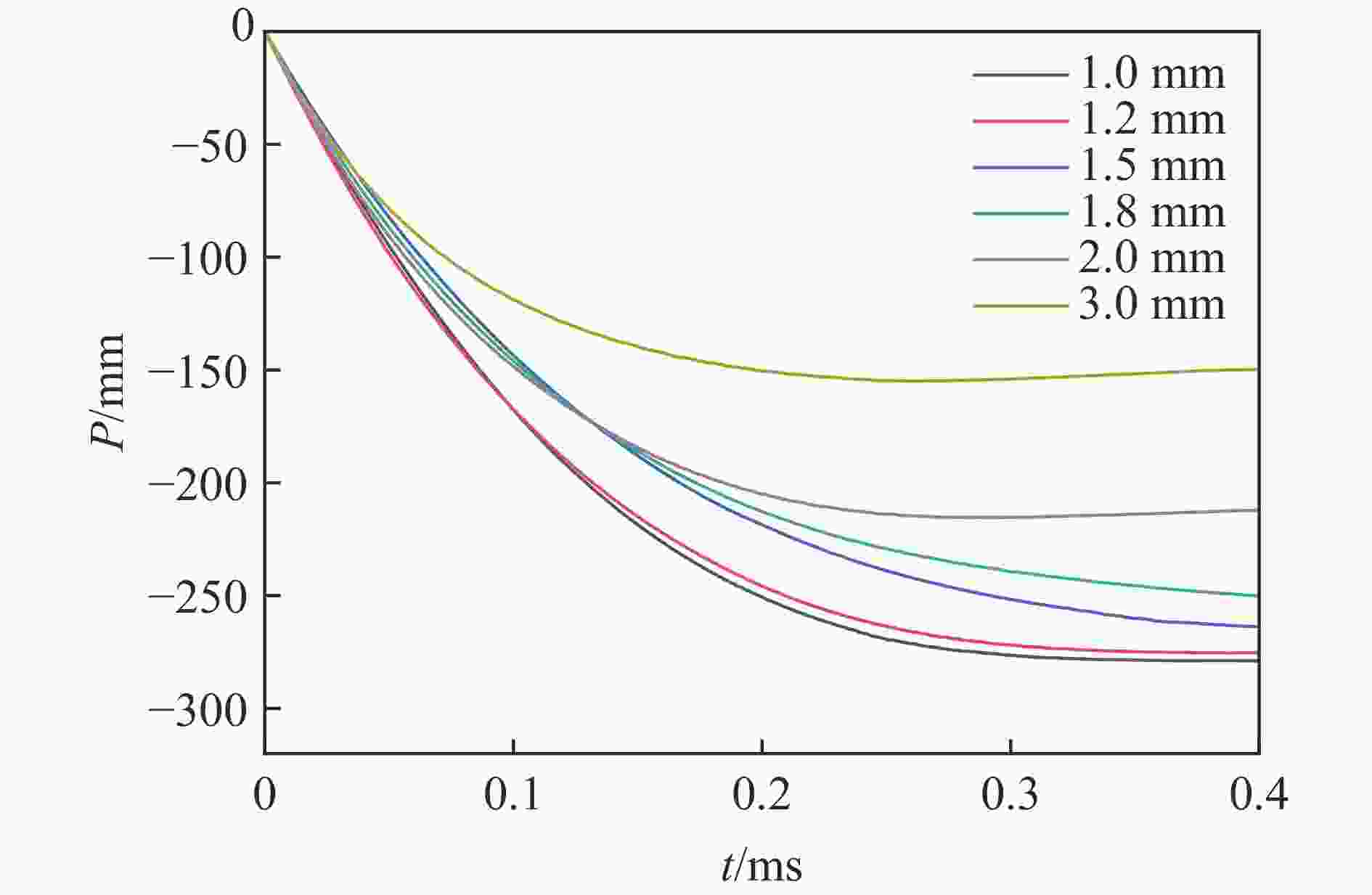

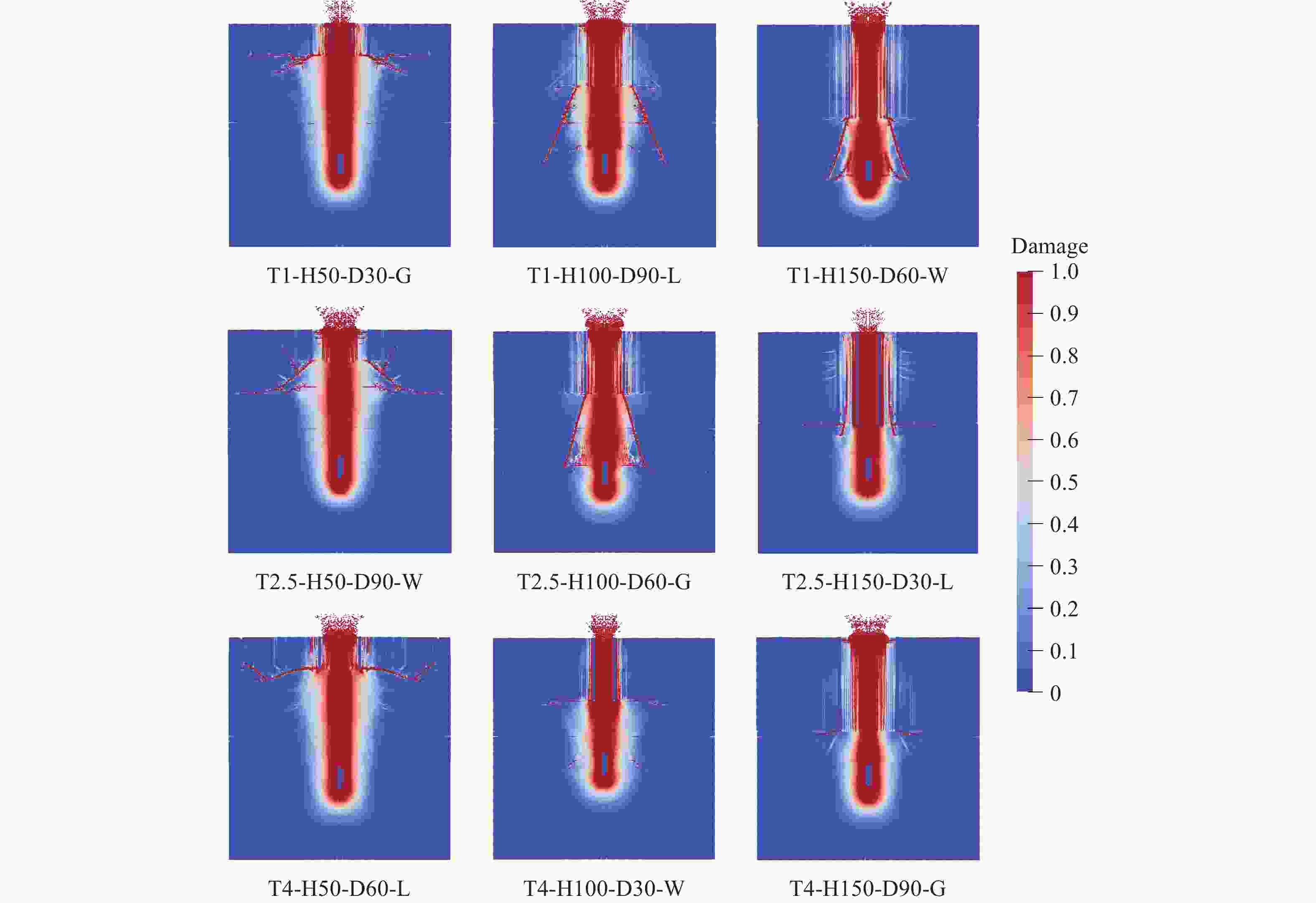

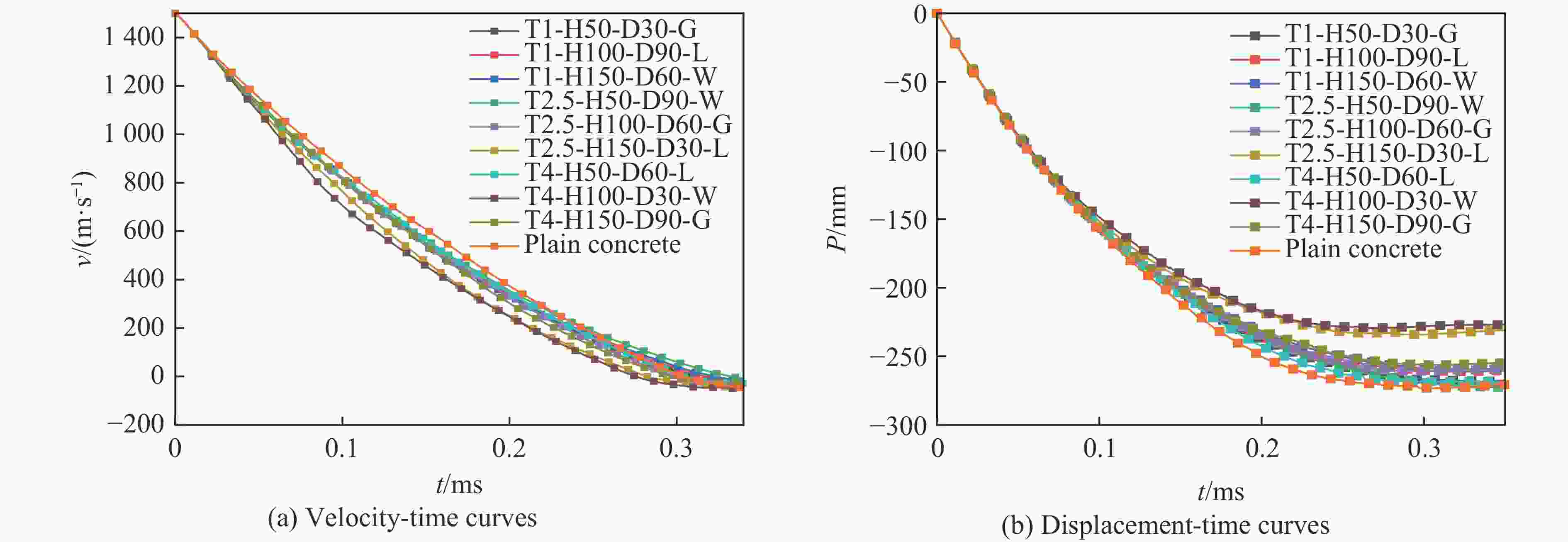

方案 T/mm H/mm D/mm 材料 1 1.0 50 30 钢 2 1.0 100 90 铝 3 1.0 150 60 钨 4 2.5 50 90 钨 5 2.5 100 60 钢 6 2.5 150 30 铝 7 4.0 50 60 铝 8 4.0 100 30 钨 9 4.0 150 90 钢 表 5 不同组合侵深结果极差分析

Table 5. Range analysis of penetration results under different simulation conditions

模拟工况 T/mm H/mm D/mm 材料 P/mm T1-H50-D30-G 1.0 50 30 钢 268.34 T1-H100-D90-L 1.0 100 90 铝 261.17 T1-H150-D60-W 1.0 150 60 钨 259.29 T2.5-H50-D90-W 2.5 50 90 钨 271.20 T2.5-H100-D60-G 2.5 100 60 钢 260.13 T2.5-H150-D30-L 2.5 150 30 铝 231.33 T4-H50-D60-L 4.0 50 60 铝 268.41 T4-H100-D30-W 4.0 100 30 钨 227.01 T4-H150-D90-G 4.0 150 90 钢 255.66 侵深极差 12.6 20.6 20.5 8.9 表 6 开坑平均半径正交分析

Table 6. Orthogonal analysis of average radius of excavation

模拟工况 T/mm H/mm D/mm 材料 R/mm T1-H50-D30-G 1.0 50 30 钢 118.4 T1-H100-D90-L 1.0 100 90 铝 101.1 T1-H150-D60-W 1.0 150 60 钨 103.7 T2.5-H50-D90-W 2.5 50 90 钨 107.8 T2.5-H100-D60-G 2.5 100 60 钢 86.4 T2.5-H150-D30-L 2.5 150 30 铝 84.3 T4-H50-D60-L 4.0 50 60 铝 91.0 T4-H100-D30-W 4.0 100 30 钨 78.3 T4-H150-D90-G 4.0 150 90 钢 65.3 成坑半径极差 29.5 21.3 2.3 6.6 表 7 综合因素正交分析

Table 7. Orthogonal analysis of comprehensive factors

工况 T/mm H/mm D/mm 材料 j p r F T1-H50-D30-G 1.0 50 30 钢 0 0.94 1.00 0.65 T1-H100-D90-L 1.0 100 90 铝 9.62×10−6 0.77 0.67 0.48 T1-H150-D60-W 1.0 150 60 钨 0.20 0.73 0.72 0.55 T2.5-H50-D90-W 2.5 50 90 钨 0.11 1.00 0.80 0.64 T2.5-H100-D60-G 2.5 100 60 钢 2.18×10−3 0.75 0.40 0.38 T2.5-H150-D30-L 2.5 150 30 铝 0.02 0.10 0.36 0.16 T4-H50-D60-L 4.0 50 60 铝 3.03×10−3 0.94 0.48 0.47 T4-H100-D30-W 4.0 100 30 钨 1.00 0.00 0.24 0.41 T4-H150-D90-G 4.0 150 90 钢 4.35×10−3 0.65 0.00 0.22 综合得分极差 0.19 0.28 0.06 0.16 -

[1] 王明洋, 岳松林, 李海波, 等. 超高速弹撞击岩石的地冲击效应等效计算 [J]. 岩石力学与工程学报, 2018, 37(12): 2655–2663. DOI: 10.13722/j.cnki.jrme.2018.0473.WANG M Y, YUE S L, LI H B, et al. Equivalent calculation of ground impact effect of hypervelocity projectile on rock [J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(12): 2655–2663. DOI: 10.13722/j.cnki.jrme.2018.0473. [2] 韩林海. 钢管混凝土结构[M]. 北京: 科学出版社, 2000. [3] 刘培生. 多孔固体结构与性能[M]. 北京: 清华大学出版社, 2003. [4] 石少卿, 黄翔宇, 刘颖芳, 等. 多边形钢管混凝土短构件在防护工程中的应用 [J]. 混凝土, 2005(2): 95–98. DOI: 10.3969/j.issn.1002-3550.2005.02.027.SHI S Q, HUANG X Y, LIU Y F, et al. Application of polygonal concrete-filled steel tube short members in protective engineering [J]. Concrete, 2005(2): 95–98. DOI: 10.3969/j.issn.1002-3550.2005.02.027. [5] 程华, 黄宗明, 石少卿, 等. 应用仿生原理设计遮弹层及其抗侵彻数值模拟分析 [J]. 应用力学学报, 2005(4): 593–597, 679. DOI: 10.3969/j.issn.1000-4939.2005.04.019.CHENG H, HUANG Z M, SHI S Q, et al. Numerical simulation analysis of design of bullet shield layer and its anti-penetration using biomimetic principle [J]. Chinese Journal of Applied Mechanics, 2005(4): 593–597, 679. DOI: 10.3969/j.issn.1000-4939.2005.04.019. [6] 蒙朝美, 宋殿义, 蒋志刚, 等. 多边形钢管约束混凝土靶抗侵彻性能试验研究 [J]. 振动与冲击, 2018, 37(13): 14–19. DOI: 10.13465/j.cnki.jvs.2018.13.003.MENG C M, SONG D Y, JIANG Z G, et al. Experimental study on the anti-penetration performance of polygonal steel tube confined concrete target [J]. Journal of Vibration and Shock, 2018, 37(13): 14–19. DOI: 10.13465/j.cnki.jvs.2018.13.003. [7] 宋殿义, 谭清华, 蒙朝美, 等. 格栅钢管约束混凝土靶抗多发打击性能试验研究 [J]. 防护工程, 2020, 42(3): 11–18. DOI: 10.3969/j.issn.1674-1854.2020.03.002.SONG D Y, TAN Q H, MENG C M, et al. Experimental study on the resistance to multiple impacts of grating steel tube confined concrete target [J]. Protective Engineering, 2020, 42(3): 11–18. DOI: 10.3969/j.issn.1674-1854.2020.03.002. [8] 宋殿义, 谭清华, 申志强, 等. 蜂窝钢管约束混凝土靶抗多发打击试验研究 [J]. 振动与冲击, 2021, 40(10): 133–139, 158. DOI: 10.13465/j.cnki.jvs.2021.10.017.SONG D Y, TAN Q H, SHEN Z Q, et al. Experimental investigation on cellular steel-tube-confined concrete tar-gets under multi-hit of projectiles [J]. Journal of Vibration and Shock, 2021, 40(10): 133–139, 158. DOI: 10.13465/j.cnki.jvs.2021.10.017. [9] 赵宏远, 武海军, 董恒, 等. 蜂窝钢管混凝土抗侵彻性能实验研究 [J]. 爆炸与冲击, 2023, 43(5): 053101. DOI: 10.11883/bzycj-2022-0050.ZHAO H Y, WU H J, DONG H, et al. Experimental study on the anti-penetration performance of honeycomb steel tube concrete [J]. Explosion and Shock Waves, 2023, 43(5): 053101. DOI: 10.11883/bzycj-2022-0050. [10] 李季, 储召军, 孙建虎, 等. 钢管钢纤维高强混凝土遮弹层抗侵彻数值模拟 [J]. 后勤工程学院学报, 2016, 32(2): 27–31. DOI: 10.3969/j.issn.1672-7843.2016.02.005.LI J, CHU Z J, SUN J H, et al. Numerical simulation of the anti-penetration performance of steel tube steel fiber high-strength concrete armor layer [J]. Journal of Logistics Engineering College, 2016, 32(2): 27–31. DOI: 10.3969/j.issn.1672-7843.2016.02.005. [11] 李干, 宋春明, 邱艳宇, 等. 超高速弹对花岗岩侵彻深度逆减现象的理论与实验研究 [J]. 岩石力学与工程学报, 2018, 37(1): 60–66. DOI: 10.13722/j.cnki.jrme.2017.0584.LI G, SONG C M, QIU Y Y, et al. Theoretical and experimental study on the penetration depth reduction phenomenon of ultra-high-speed projectiles into granite [J]. Chinese Journal of Rock Mechanics and Engineering, 2018, 37(1): 60–66. DOI: 10.13722/j.cnki.jrme.2017.0584. [12] Measurement of projectile velocities: NATO STANAG 4114 [S]. Brussels: NATO, 1977. [13] FORRESTAL M J, ALTMAN B S, CARGILE J D, et al. An empirical equation for penetration depth of ogive-nose projectiles into concrete targets [J]. International Journal of Impact Engineering, 1994, 15(4): 395–405. DOI: 10.1016/0734-743X(94)80024-4. [14] 邓云飞, 崔亚男, 慕忠成, 等. 卵形头弹体对素混凝土高速侵彻的实验研究 [J]. 应用力学学报, 2019, 36(5): 1144–1151, 1262. DOI: 10.11776/cjam.36.05.D050.DENG Y F, CUI Y N, Mu Z C, et al. Experimental study on high-speed penetration of ogive-nose projectiles into plain concrete [J]. Chinese Journal of Applied Mechanics, 2019, 36(5): 1144–1151, 1262. DOI: 10.11776/cjam.36.05.D050. [15] MA S, ZHANG X, QIU X M. Comparison study of MPM and SPH in modeling hy-pervelocity impact problems. International Journal of Impact Engineering, 2009, 36: 272–282. DOI: 10.1016/j.ijimpeng.2008.07.001. [16] 倪锐晨, 孙梓贤, 李家盛, 等. 结构爆炸毁伤的浸没多介质有限体积物质点法 [J]. 力学学报, 2022, 54(12): 3269–3282. DOI: 10.6052/0459-1879-22-446.NI R C, SUN Z X, LI J S, et al. An immersed multi-material finite volume-material point method for structural blast damage [J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(12): 3269–3282. DOI: 10.6052/0459-1879-22-446. [17] 谢桂兰, 左立来, 宋慕清, 等. 基于物质点法弹丸侵彻靶板的仿真与结构优化 [J]. 弹道学报, 2023, 35(2): 46–52. DOI: 10.12115/j.issn.1004-499X(2023)02-006.XIE G L, ZUO L L, SONG M Q, et al. Simulation and structural optimization of projectile penetration of target plates based on the material point method [J]. Journal of Ballistics, 2023, 35(2): 46–52. DOI: 10.12115/j.issn.1004-499X(2023)02-006. [18] 谢桂兰, 侯昆, 龚曙光, 等. 基于物质点法Ti/Al3Ti层状复合材料抗斜侵彻性能研究 [J]. 兵器装备工程学报, 2023, 44(4): 194–199. DOI: 10.11809/bqzbgcxb2023.04.027.XIE G L, HOU K, GONG S G, et al. Research on oblique penetration resistance of Ti/Al3Ti laminate composites based on the material point method [J]. Journal of Ordnance Equipment Engineering, 2023, 44(4): 194–199. DOI: 10.11809/bqzbgcxb2023.04.027. [19] ZHANG X, MA S, HUANG X, et al. Contact algorithms for the material point method in impact and penetration simulation [J]. International Journal for Numerical Methods in Engineering, 2011, 85(4): 498–517. [20] 王宇新, 李晓杰, 杨国俊, 等. 304L/Q235B大面积金属板爆炸焊接物质点法模拟分析 [J]. 爆炸与冲击, 2022, 42(3): 035301. DOI: 10.11883/bzycj-2021-0198.WANG Y X, LI X J, YANG G J, et al. Simulation analysis of 304L/Q235B large-area metal plate explosive we-lding substance point method [J]. Explosion and Shock Waves, 2022, 42(3): 035301. DOI: 10.11883/bzycj-2021-0198. [21] HU W Q, CHEN Z. Model-based simulation of the synergistic effects of blast and fragmentation on a concrete wall using the MPM [J]. Interational Journal of lmpact Engineering, 2006, 32(12): 2066–2096. DOI: 10.1016/j.ijimpeng.2005.05.004. [22] 张雄, 廉艳平, 杨鹏飞, 等. 冲击爆炸问题的三维物质点法数值仿真 [J]. 计算机辅助工程, 2011, 20(4): 29–37. DOI: 10.3969/j.issn.1006-0871.2011.04.007.ZHANG X, LIAN Y P, YANG P F, et al. 3D simulation based on material point method for impact and explosion problems [J]. Computer Aided Engineering, 2011, 20(4): 29–37. DOI: 10.3969/j.issn.1006-0871.2011.04.007. [23] 李磊, 张先锋, 吴雪, 等. 不同硬度30CrMnSiNi2A钢的动态本构与损伤参数 [J]. 高压物理学报, 2017, 31(3): 239–248. DOI: 10.11858/gywlxb.2017.03.005.LI L, ZHANG X F, WU X, et al. Dynamic constitutive and damage parameters of 30CrMnSiNi2A steel with different hardness [J]. Chinese Journal of High Pressure Physics, 2017, 31(3): 239–248. DOI: 10.11858/gywlxb.2017.03.005. [24] HOLMQUIST T J, JOHNSON G R. A computational constitutive model for concrete subjected to larger strains, high strain rates and high pressure [C]//The 14th International Symposium Ballistics. USA: American Defense Preparedness Association, 1995: 591–600. [25] ROHR I, NAHME H, THOMA K, et al. Material characterisation and constitutive modelling of a tungsten-sintered alloy for awide range of strain rates [J]. International Journal of Impact Engineering, 2008, 35(8): 811–819. DOI: 10.1016/j.ijimpeng.2007.12.006. [26] 杜明燃, 陈宇航, 陆少锋, 等. 基于正交试验法的气泡帷幕削波特性研究 [J]. 高压物理学报, 2023, 37(6): 195–205. DOI: 10.11858/gywlxb.20230684.DU M R, CHEN Y H, LU S F, et al. Study on the wave-cutting characteristics of bubble curtain based on orthogonal test method [J]. Chinese Journal of High Pressure Physics, 2023, 37(6): 195–205. DOI: 10.11858/gywlxb.20230684. [27] 辛春亮, 朱星宇, 薛再清, 等. 有限元分析常用材料参数手册[M]. 2版. 北京: 机械工业出版社, 2022. -

下载:

下载: