A review of equivalent loading test techniques for simulating explosion load

-

摘要: 随着全球恐怖主义和工业事故的增加,对基础设施在爆炸冲击下的安全性研究变得尤为迫切。试验作为探究材料和结构在爆炸冲击下动力响应和损伤特性的关键手段,它能安全、高效、准确地模拟爆炸冲击加载技术成为了该领域的研究热点与挑战。综述了模拟远场爆炸荷载的等效加载试验技术的研究进展,包括炸药驱动激波管、高压气体驱动激波管、落锤冲击试验机和液压驱动模拟器等。这些技术在模拟爆炸冲击波方面各有优势和局限,但都致力于提供一个安全、可控的实验环境,以复现爆炸产生的高速气流和冲击波。通过对比分析,揭示了各种技术在模拟爆炸载荷的准确性、适用性和操作便利性等,并讨论了它们在实际应用中的潜力和挑战。最后,介绍了一种基于液气相变膨胀的新型模拟爆炸加载试验技术并展望了后续研究方向。Abstract: Against the backdrop of rising global terrorism and industrial accidents, research on infrastructure safety under blast impact has become critically urgent. As a pivotal approach for investigating dynamic responses and damage characteristics of materials and structures subjected to explosive loading, the equivalent blast-loading techniques, which show safe, efficient, and accurate, have emerged as both a research frontier and challenge. This review synthesizes advancements in equivalent blast-loading techniques for far-field explosion simulation, encompassing explosive-driven shock tubes, high-pressure gas-driven shock tubes, drop-weight impact testing machines, and hydraulically-actuated simulators. While each technique exhibits distinct advantages and limitations in simulating blast shockwaves, all strive to establish controlled and secure experimental environments that reproduce high-velocity air flow fields and pressure waves generated by explosions. Through comparative assessment, their performance in load replication fidelity, applicability, and operational efficiency are elucidated, alongside discussions on implementation challenges and potential. Finally, a novel blast simulation technique leveraging liquid-gas phase-transition-driven expansion is introduced and the follow-up research directions are prospected.

-

Key words:

- equivalent loading /

- shock tube /

- blast simulator /

- structural response /

- damage assessment

-

表 1 激波管模拟爆炸加载试验装置

Table 1. Shock tube-based simulated explosion loading experimental setup

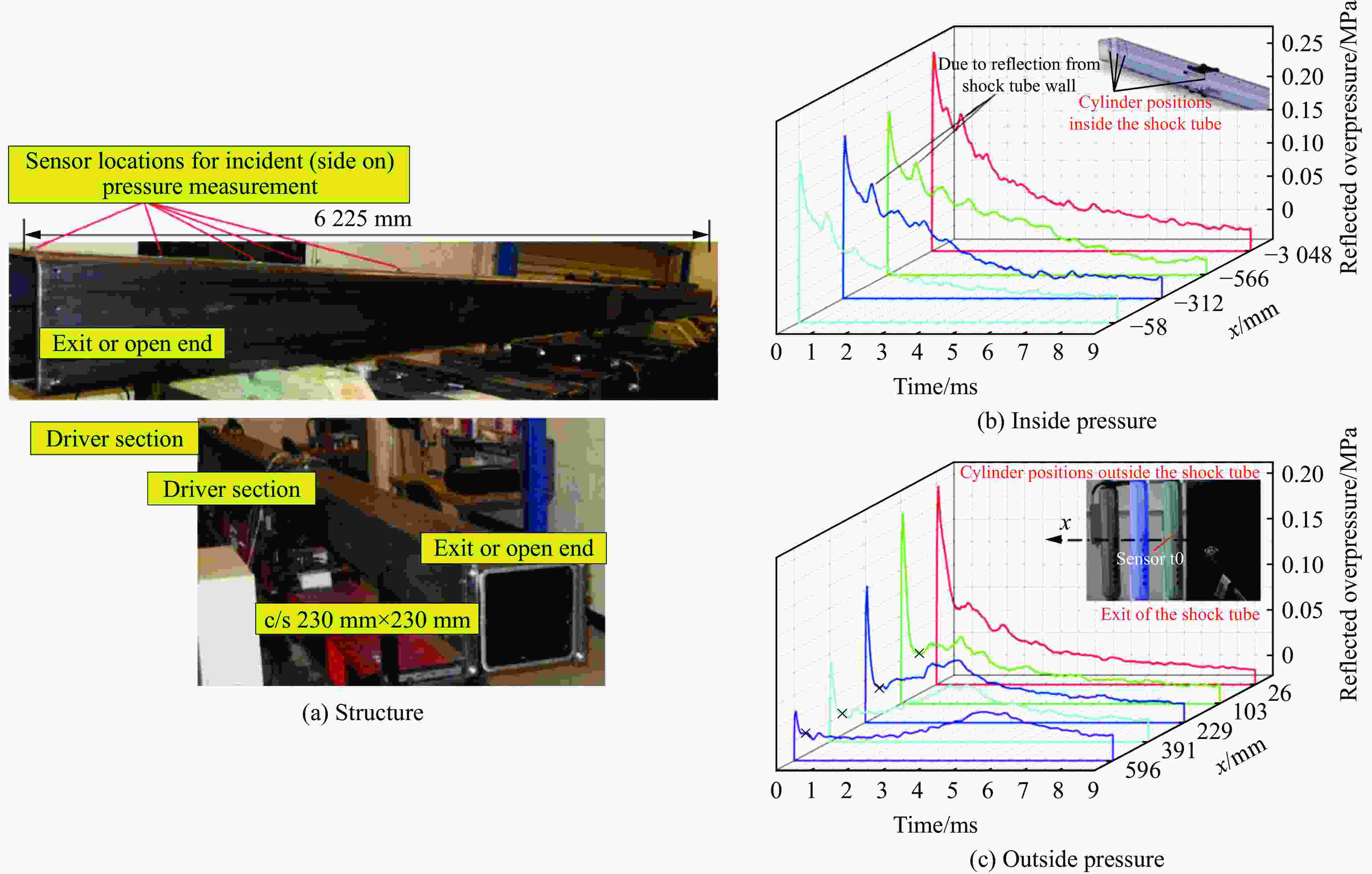

激波管 机构 尺寸 驱动方式 目的 EDST[30, 51] 比利时布鲁塞尔大学材料与结构力学系 内径168.2 mm,长1 200 mm,

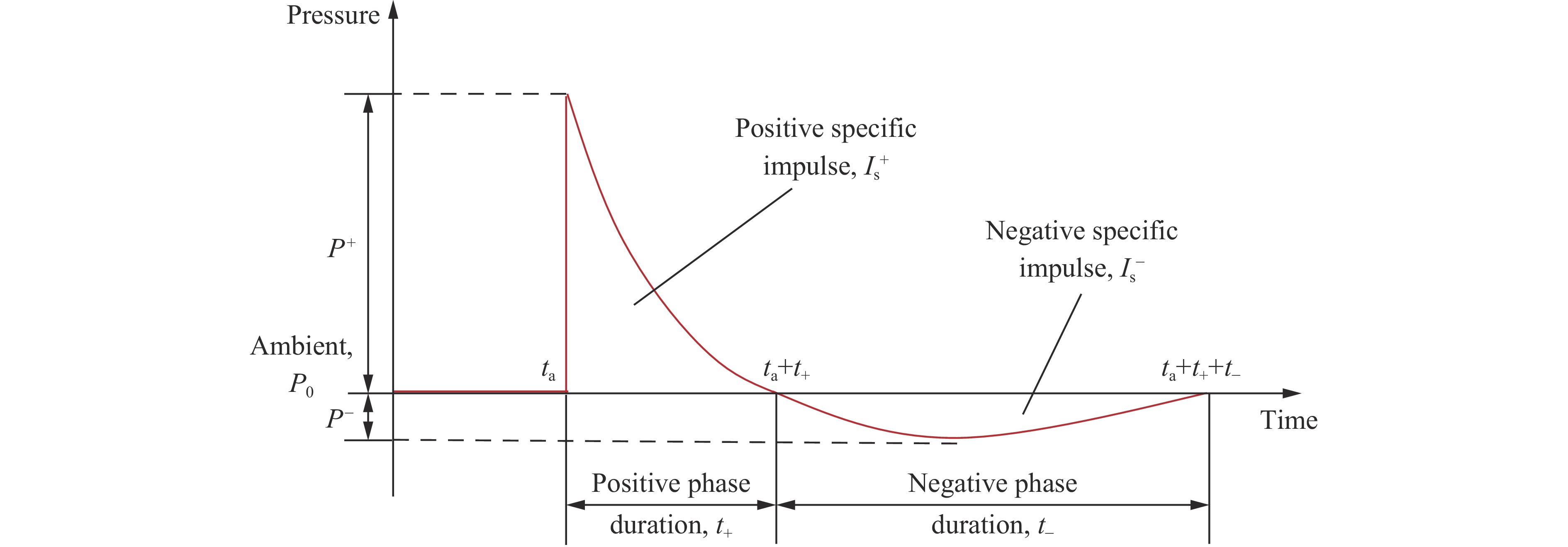

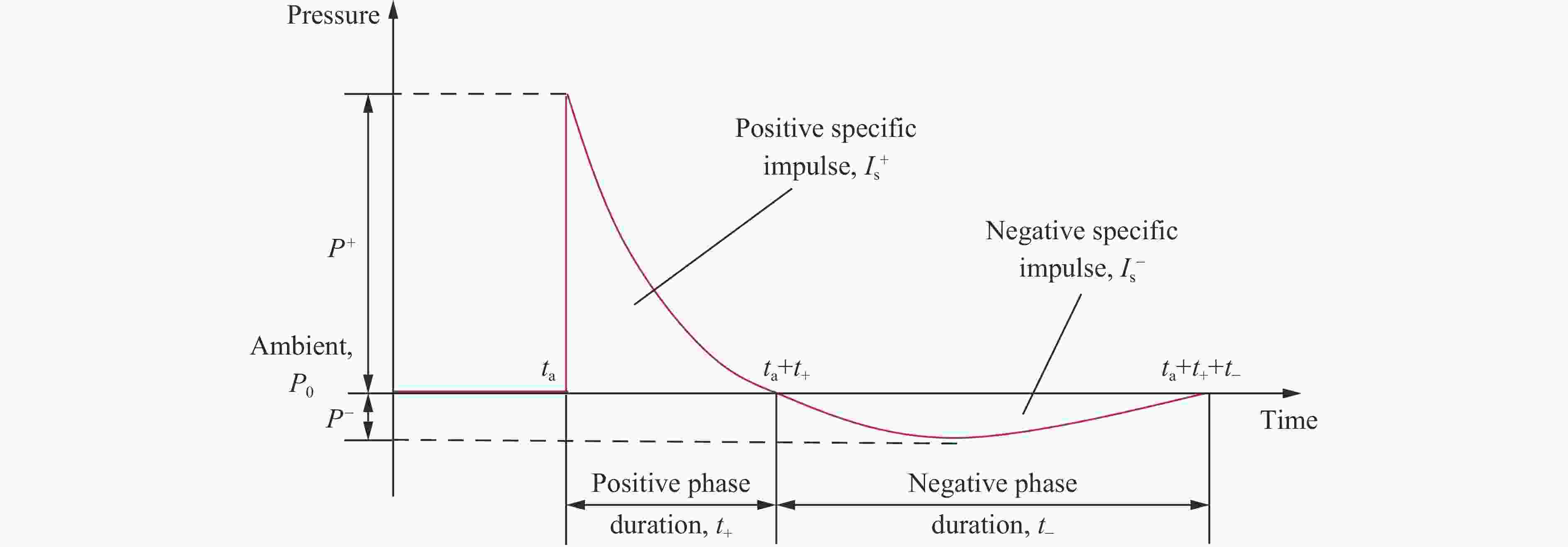

圆柱形激波管C4炸药驱动,

无隔膜研究材料在极端条件下的性能 炸药驱动激

波管 [48, 91]中国强脉冲辐射环境模拟与效应国家重点实验室 总长9.5 m,驱动段长1.5 m内径0.14 m,圆柱形激波管 TNT炸药驱动,

无隔膜探究炸药驱动激波管内的冲击超压环境 锥形激波管[56-58] 美国陆军研究实验室 长193.04 cm,圆锥角17°,起始直径10.16 cm,锥形激波管 C4炸药驱动,

无隔膜研究空气爆炸对防护材料相互作用和人员的影响 2 m激波管[66-67] 加拿大渥太华大学结构工程实验室 驱动段0.305~5.185 m可调,扩张段为从0.597 m圆形扩张到2.032 m的方形截面 压缩空气驱动,

铝膜片分隔用于测试结构部件在爆炸荷载下的响应 0.23 m方形激

波管[68]美国内布拉斯加大学

林肯分校驱动截面0.23 m×0.23 m,总长6.2 m 氮气驱动,

单隔膜爆炸荷载引起的脑部

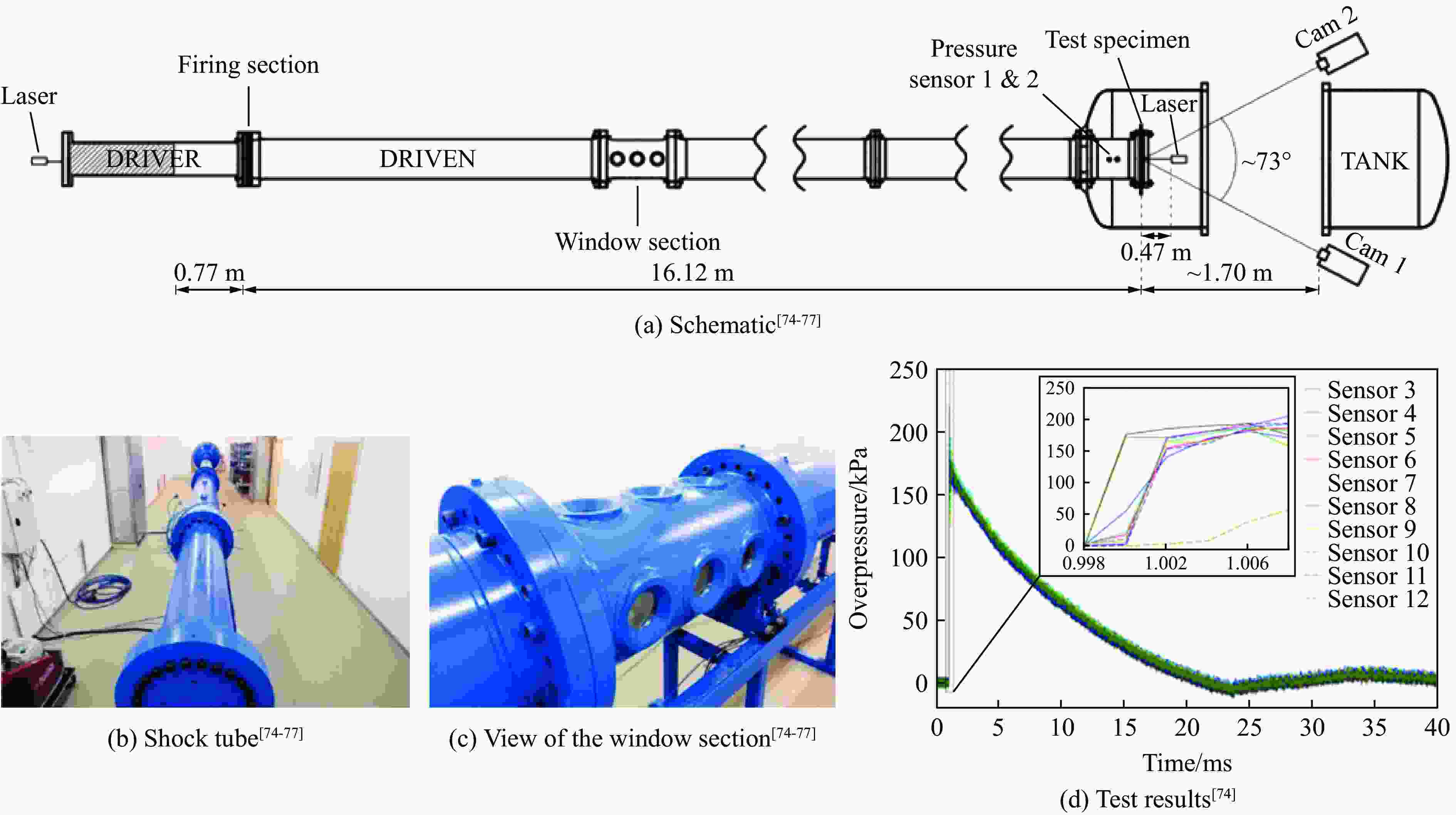

损伤的影响SIMLab激波管(SSTF)[74-77] 挪威科技大学 圆柱形驱动段,出口方形截面0.3 m,总长18.355 m 压缩气体驱动,

Melinex片隔膜研究复合材料和结构在水下爆炸载荷作用下的响应 BST-Ⅰ大型生物

激波管[82-83]陆军军医大学 总长39 m,试验段直径1 m 压缩空气驱动,

双夹模结构研究爆炸冲击波对生物造成的原发性损伤 3马赫激波管 [85] 中国科学技术大学空天飞行高温气动全国重点实验室 驱动段总长13.16 m, 高压气体驱动,

聚酯薄膜强激波诱导的Richtmyer-Meshkov不稳定性 Blast-STAR[86-87] 德国弗劳恩霍夫高速

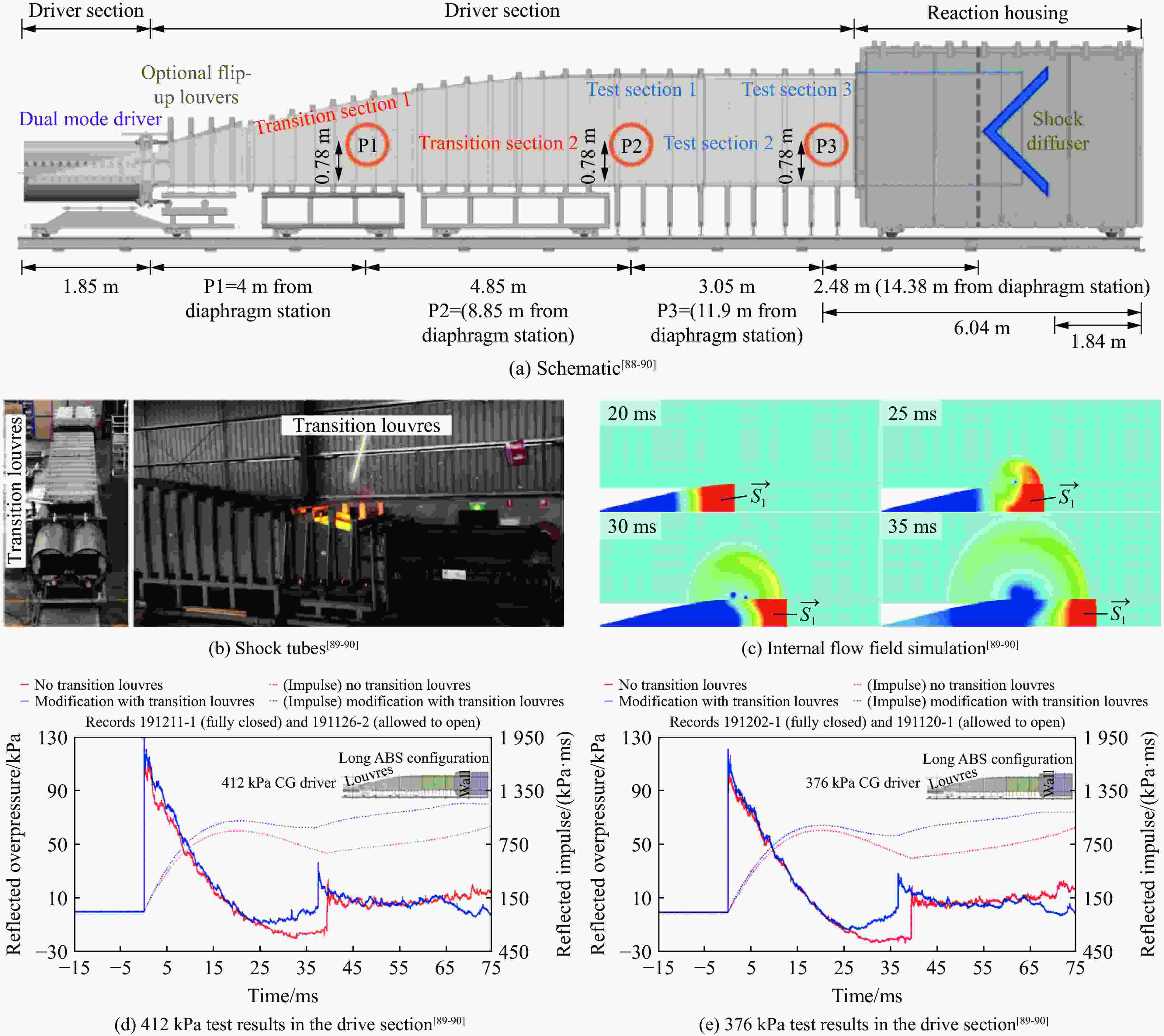

动力研究所总长22 m,测试段为3 m×3 m的方形截面 高压气体驱动,铝隔膜 分析部件对爆炸荷载的抵抗力,指导建筑设计 NFPBS ABS[88-90] 澳大利亚卧龙岗大学 出口方形界面1.5 m×2.0 m,总长19.79 m 高压气体或氧乙炔爆炸驱动,Valmex隔膜 提供各种爆炸波加载状态,

探究军用和民用设施的

爆炸毁伤特性表 2 比较各种模拟爆炸试验方法

Table 2. Compare various simulated explosion test methods

试验方法 优点 缺点 适用范围 炸药驱动激波管 模拟精度高,能够较好地复现爆炸

冲击波的压力历程冲击波脉管较短,安全性要求高,

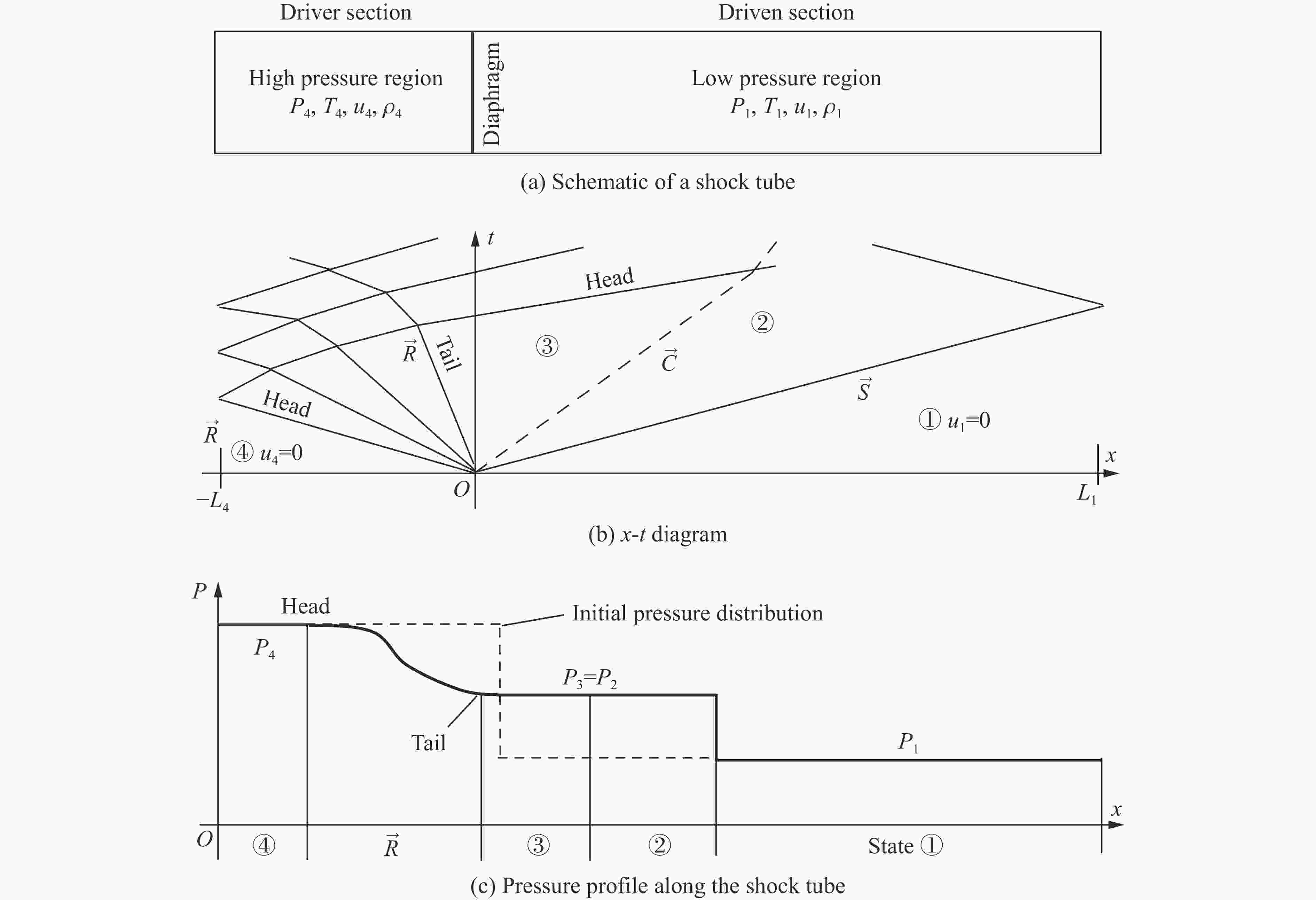

成本高,污染环境高强度爆炸模拟,研究材料在极端

条件下的性能高压气体驱动激波管 安全性高,成本较低,操作简便 技术难度大,能量输出和脉冲持续

时间调节范围有限中等规模爆炸模拟,大量重复性模拟

爆炸试验落锤冲击试验机 操作简便,成本相对较低,重复性好 难模拟爆炸产生的复杂多维载荷,

对于大尺度结构的模拟能力有限结构部件的冲击响应测试,如桥梁、建筑结构等在局部冲击下的性能评估 液压驱动模拟器 能够精确控制加载的时间和强度,

适用于模拟复杂载荷条件设备成本高,技术难度大,产生的载荷

上升时间较长,衰减时间较短脉冲毁伤占主要原因,对爆炸波精度

要求不高环境 -

[1] 张飞燕, 张念思, 韩颖, 等. 近10年我国民爆物品爆炸事故统计及预测 [J]. 爆破, 2022, 39(4): 192–200. DOI: 10.3963/j.issn.1001-487X.2022.04.028.ZHANG F Y, ZHANG N S, HAN Y, et al. Statistics and prediction of civil explosive articles explosion accidents in China in recent decade [J]. Blasting, 2022, 39(4): 192–200. DOI: 10.3963/j.issn.1001-487X.2022.04.028. [2] 常笑康, 罗本永, 陈长海, 等. 近距空爆载荷作用下高韧钢的抗爆性能及影响因素研究 [J]. 高压物理学报, 2024, 38(5): 054103. DOI: 10.11858/gywlxb.20240732.CHANG X K, LUO B Y, CHEN C H, et al. Study on the blast-resistant performance and influence factors of high-toughness steel subjected to close-range air-blasts [J]. Chinese Journal of High Pressure Physics, 2024, 38(5): 054103. DOI: 10.11858/gywlxb.20240732. [3] 赵春风, 张利, 李晓杰. 近场爆炸下波纹双钢板混凝土组合墙板的损伤破坏及抗爆性能 [J]. 高压物理学报, 2024, 38(1): 014102. DOI: 10.11858/gywlxb.20230727.ZHAO C F, ZHANG L, LI X J. Damage failure and anti-blast performance of concrete-Infilled double steel corrugated-plate wall under near field explosion [J]. Chinese Journal of High Pressure Physics, 2024, 38(1): 014102. DOI: 10.11858/gywlxb.20230727. [4] 毛致远, 段超伟, 宋浦, 等. 基于有效冲量的水下爆炸冲击波对平板结构的毁伤准则 [J]. 高压物理学报, 2023, 37(2): 025103. DOI: 10.11858/gywlxb.20220625.MAO Z Y, DUAN C W, SONG P, et al. Criterion of plate structure damage caused by underwater explosion shock wave based on effective impulse [J]. Chinese Journal of High Pressure Physics, 2023, 37(2): 025103. DOI: 10.11858/gywlxb.20220625. [5] UFC. Structures to resist the effects of accidental explosions: UFC 3-340-02 [S]. Washington, DC, USA: UFC, 2008. [6] Canadian Standards Association. S850-12 Design and assessment of buildings subjected to blast loads [S]. Toronto, Ontario, Canada: Canadian Standards Association, 2012. [7] American Society of Civil Engineers. ASCE/SEI 59-11 Blast protection of buildings [S]. Reston, Virginia, USA: American Society of Civil Engineers, 2011. [8] 黄家蓉, 王幸, 周松柏. 飞行器地面模拟试验中电磁脉冲干扰分析与解决措施 [J]. 防护工程, 2017, 39(1): 29–33.HUANG J R, WANG X, ZHOU S B. Electromagnetic pulse interference analysis and solving method in the aircraft ground simulation test [J]. Protective Engineering, 2017, 39(1): 29–33. [9] BAKER W E. Explosions in air [M]. Austin: University of Texas Press, 1973: 55–136. [10] DEWEY J M. Measurement of the physical properties of blast waves [M]//IGRA O, SEILER F. Experimental Methods of Shock Wave Research. Cham: Springer, 2016: 53–86. [11] 孙远翔, 田俊宏. 近场水下爆炸载荷及舰船结构动态响应研究综述 [J]. 舰船科学技术, 2019, 41(6): 1–8. DOI: 10.3404/j.issn.1672-7649.2019.06.001.SUN Y X, TIAN J H. Review of near-field underwater explosion load and ship structure dynamic response [J]. Ship Science and Technology, 2019, 41(6): 1–8. DOI: 10.3404/j.issn.1672-7649.2019.06.001. [12] HE Z H, DU Z P, ZHANG L, et al. Damage mechanisms of full-scale ship under near-field underwater explosion [J]. Thin-Walled Structures, 2023, 189: 110872. DOI: 10.1016/j.tws.2023.110872. [13] ISMAIL A, EZZELDIN M, El-DAKHAKHNI W, et al. Blast load simulation using conical shock tube systems [J]. International Journal of Protective Structures, 2020, 11(2): 135–158. DOI: 10.1177/2041419619858098. [14] RIGBY S E, TYAS A, BENNETT T, et al. The negative phase of the blast load [J]. International Journal of Protective Structures, 2014, 5(1): 1–19. DOI: 10.1260/2041-4196.5.1.1. [15] FRIEDLANDER F G. The diffraction of sound pulses I. Diffraction by a semi-infinite plane [J]. Proceedings of the Royal Society A: Mathematical, Physical and Engineering Sciences, 1946, 186(1006): 322–344. DOI: 10.1098/rspa.1946.0046. [16] 程祥, 杨明, 郭亚丽, 等. 修正的Friedlander方程指数衰减因子 [J]. 爆炸与冲击, 2009, 29(4): 425–428. DOI: 10.11883/1001-1455(2009)04-0425-04.CHENG X, YANG M, GUO Y L, et al. Analysis on an exponential attenuation factor in the modified Friedlander equation by overpressure tests [J]. Explosion and Shock Waves, 2009, 29(4): 425–428. DOI: 10.11883/1001-1455(2009)04-0425-04. [17] RUSHCHITSKY J J, YURCHUK V M. Distortion of a nonlinear elastic solitary plane wave with Friedlander profile [J]. International Applied Mechanics, 2022, 58(4): 389–397. DOI: 10.1007/s10778-022-01164-z. [18] DEWEY J M. The shape of the blast wave: studies of the Friedlander equation [C]//International Symposium on Military Aspects of Blast and Shock (MABS 21). Jerusalem, 2010: 1-9. [19] 杨科之, 刘盛. 空气冲击波传播和衰减研究进展 [J]. 防护工程, 2020, 42(3): 1–10. DOI: 10.3969/j.issn.1674-1854.2020.03.001.YANG K Z, LIU S. Progress of research on propagation and attenuation of air blast [J]. Protective Engineering, 2020, 42(3): 1–10. DOI: 10.3969/j.issn.1674-1854.2020.03.001. [20] STEWART M G. Simplified calculation of air blast variability and reliability-based design load factors for spherical air burst and hemispherical surface burst explosions [J]. International Journal of Protective Structures, 2022, 13(2): 144–160. DOI: 10.1177/20414196211043537. [21] SI D D, PAN Z F, ZHANG H P. Probabilistic assessment and expression of load factor design model for explosive blast loading [J]. Reliability Engineering & System Safety, 2024, 242: 109802. DOI: 10.1016/j.ress.2023.109802. [22] IOANNOU O, RIGOUTSOS G, VAMVATSIKOS D, et al. A baseline approach for probabilistic blast risk analysis of building cladding under external explosions [J]. Structural Safety, 2024, 109: 102472. DOI: 10.1016/j.strusafe.2024.102472. [23] BOGOSIAN D, FERRITTO J, SHI Y. Measuring uncertainty and conservatism in simplified blast models [C]// 30th Explosives Safety Seminar, Atlanta, Georgia, 2002. [24] XIAO W F, ANDRAE M, GEBBEKEN N. Air blast TNT equivalence concept for blast-resistant design [J]. International Journal of Mechanical Sciences, 2020, 185: 105871. DOI: 10.1016/j.ijmecsci.2020.105871. [25] RATCLIFF A, RIGBY S, CLARKE S, et al. A review of blast loading in the urban environment [J]. Applied Sciences, 2023, 13(9): 5349. DOI: 10.3390/ app13095349. DOI: 10.3390/app13095349. [26] SHIN J, WHITTAKER A S, CORMIE D. Incident and normally reflected overpressure and impulse for detonations of spherical high explosives in free air [J]. Journal of Structural Engineering, 2015, 141(12): 04015057. DOI: 10.1061/(ASCE)ST.1943-541X.0001305. [27] 王雅, 张宏, 陈翔. 大当量TNT空中爆炸超压的模拟与修正 [J]. 力学研究, 2019, 8(4): 229–237. DOI: 10.12677/IJM.2019.84026.WANG Y, ZHANG H, CHEN X. Simulation and correction of large equivalent TNT air explosion overpressure [J]. International Journal of Mechanics Research, 2019, 8(4): 229–237. DOI: 10.12677/IJM.2019.84026. [28] PENG W W, PAN M L, LENG C J, et al. Blast loading prediction in a typical urban environment based on Bayesian deep learning [J]. Engineering Applications of Computational Fluid Mechanics, 2025, 19(1): 2445765. DOI: 10.1080/19942060.2024.2445765. [29] DENNIS A A, RIGBY S E. The direction-encoded neural network: a machine learning approach to rapidly predict blast loading in obstructed environments [J]. International Journal of Protective Structures, 2024, 15(3): 455–483. DOI: 10.1177/ 20414196231177364. DOI: 10.1177/20414196231177364. [30] LOUAR M A, BELKASSEM B, OUSJI H, et al. Explosive driven shock tube loading of aluminium plates: experimental study [J]. International Journal of Impact Engineering, 2015, 86: 111–123. DOI: 10.1016/j.ijimpeng.2015.07.013. [31] 张云峰, 陈博, 魏欣, 等. 空气自由场爆炸冲击波数值建模及应用 [J]. 爆炸与冲击, 2023, 43(11): 114202. DOI: 10.11883/bzycj-2023-0004.ZHANG Y F, CHEN B, WEI X, et al. Numerical modeling and application of shock wave of free-field air explosion [J]. Explosion and Shock Waves, 2023, 43(11): 114202. DOI: 10.11883/bzycj-2023-0004. [32] BREWER T R, CRAWFORD J E, MORRILL K B, et al. Design, analysis, and testing of a blast- resistant building façade [J]. International Journal of Computational Methods and Experimental Measurements, 2016, 4(3): 191–200. DOI: 10.2495/CMEM-V4-N3-191-200. [33] JACQUES E. Blast retrofit of reinforced concrete walls and slabs [D]. Ottawa: University of Ottawa, 2011: 40–122. [34] 张坤玉, 陈德, 吴昊. 高压气体驱动激波管的数值模拟与参数影响分析 [J]. 高压物理学报, 2023, 37(3): 033301. DOI: 10.11858/gywlxb.20220704.ZHANG K Y, CHEN D, WU H. Numerical simulation and parametric analysis of high-pressure gas-driven shock tube [J]. Chinese Journal of High Pressure Physics, 2023, 37(3): 033301. DOI: 10.11858/gywlxb.20220704. [35] PAYNE T, WILLIAMS A, WORFOLK T, et al. Large-scale explosive arena trials – is your target being loaded correctly? [J]. Explosives Engineering, 2016: 10–16. [36] 马亮亮, 吴昊. 爆炸作用下预应力RC梁桥的损伤评估 [J]. 工程力学, 2025, 42(11): 159–172. DOI: 10.6052/j.issn.1000-4750.2023.05.0378.MA L L, WU H. Damage assessment of prestressed RC girderbridge under explosion [J]. Engineering Mechanics, 2025, 42(11): 159–172. DOI: 10.6052/j.issn.1000-4750.2023.05.0378. [37] RITCHIE C B, PACKER J A, SEICA M V, et al. Rectangular hollow sections subject to blast loading [J]. Journal of Structural Engineering, 2017, 143(12): 04017167. DOI: 10.1061/(ASCE)ST.1943-541X.0001922. [38] YAO S J, CHEN F P, WANG Y J, et al. Experimental and numerical investigation on the dynamic response and damage of large-scale multi-box structure under internal blast loading [J]. Thin-Walled Structures, 2023, 183: 110430. DOI: 10.1016/j.tws.2022.110430. [39] 周岳兰, 裴鲁, 龙仁荣, 等. 激波管内压力脉冲演化特性及模拟空爆冲击波的方法研究 [J]. 兵工学报, 2023, 44(12): 3815–3825. DOI: 10.12382/bgxb.2023.0284.ZHOU Y L, PEI L, LONG R R, et al. Study on the evolution characteristics of pressure pulse in shock tube and a method of simulating air explosion shock wave [J]. Acta Armamentarii, 2023, 44(12): 3815–3825. DOI: 10.12382/bgxb.2023.0284. [40] KOCHAVI E, GRUNTMAN S, BEN-DOR G, et al. Design and construction of an in-laboratory novel blast wave simulator [J]. Experimental Mechanics, 2020, 60(8): 1149–1159. DOI: 10.1007/s11340-020-00650-0. [41] DAVY H. VII. Some researches on flame [J]. Philosophical Transactions of the Royal Society of London, 1817, 107: 45–76. DOI: 10.1098/rstl.1817.0008. [42] VIEILLE M. Étude sur le role des discontinuités dans les phénomènes de propagation [J]. Journal of Physics: Theories and Applications, 1900, 9(1): 621–644. DOI: 10.1051/JPHYSTAP:019000090062100. [43] VIELLE P. Sur les discontinuités produites par la détente brusque de gaz comprimés [J]. Comptes Rendus de lÁ cadémie des Sciences, 1889, 129: 1228. [44] IGRA O, SEILER F. Experimental methods of shock wave research [M]. Cham: Springer, 2016: 3–52. DOI: 10.1007/978-3-319-23745-9. [45] 汤文辉. 冲击波物理教程 [M]. 长沙: 国防科技大学出版社, 2016: 195–202. [46] COURANT R, FRIEDRICHS K O. Supersonic flow and shock waves [M]. New York: Springer, 1999: 83–99. [47] ANDERSON J D JR. Modern compressible flow: with historical perspective [M]. New York: McGraw-Hill, 1990. [48] 殷文骏, 童念雪, 程帅, 等. 爆炸驱动激波管冲击波压力参数研究 [J]. 现代应用物理, 2024, 15(2): 021003. DOI: 10.12061/j.issn.2905-6223.2024.021003.YIN W J, TONG N X, CHENG S, et al. Shock wave pressure parameters of blast-driven shock tube [J]. Modern Applied Physics, 2024, 15(2): 021003. DOI: 10.12061/j.issn.2905-6223.2024.021003. [49] SCHIMIZZE B, SON S F, GOEL R, et al. An experimental and numerical study of blast induced shock wave mitigation in sandwich structures [J]. Applied Acoustics, 2013, 74(1): 1–9. DOI: 10.1016/j.apacoust.2012.05.011. [50] 胡洋, 杨雨欣, 吴秋遐. 基于激波管系统对瓦斯爆炸的研究 [J]. 华北科技学院学报, 2022, 19(4): 89–93. DOI: 10.19956/j.cnki.ncist.2022.04.015.HU Y, YANG Y X, WU Q X. Study on gas explosion based on shock tube system [J]. Journal of North China Institute of Science and Technology, 2022, 19(4): 89–93. DOI: 10.19956/j.cnki.ncist.2022.04.015. [51] LOUAR M A, BELKASSEM B, OUSJI H, et al. Estimation of the strain rate hardening of aluminium using an inverse method and blast loading [J]. Journal of Dynamic Behavior of Materials, 2017, 3(3): 347–361. DOI: 10.1007/s40870-017-0101-y. [52] SPRANGHERS K, VASILAKOS I, LECOMPTE D, et al. Full-field deformation measurements of aluminum plates under free air blast loading [J]. Experimental Mechanics, 2012, 52(9): 1371–1384. DOI: 10.1007/s11340-012-9593-5. [53] SPRANGHERS K, VASILAKOS I, LECOMPTE D, et al. Identification of the plastic behavior of aluminum plates under free air explosions using inverse methods and full-field measurements [J]. International Journal of Solids and Structures, 2014, 51(1): 210–226. DOI: 10.1016/j.ijsolstr.2013.09.027. [54] SPRANGHERS K, VASILAKOS I, LECOMPTE D, et al. Numerical simulation and experimental validation of the dynamic response of aluminum plates under free air explosions [J]. International Journal of Impact Engineering, 2013, 54: 83–95. DOI: 10.1016/j.ijimpeng.2012.10.014. [55] ZALESAK J F, POCHÉE L B. The shock test facility: an explosive-driven, water-filled conical shock tube [C]//Proceedings of a Conference Sponsored by the Department of Defense, the National Aeronautics and Space Administration, and the Department of Energy. Virginia Beach, 1989: 73–76. [56] STEWART J B, PECORA C. Explosively driven air blast in a conical shock tube [J]. Review of Scientific Instruments, 2015, 86(3): 035108. DOI: 10.1063/1.4914898. [57] STEWART J B. Influence of explosively driven shock tube configuration on the mid-field blast environment [J]. AIP Conference Proceedings, 2018, 1979(1): 160026. DOI: 10.1063/1.5045025. [58] STEWART J B. Approximating a free-field blast environment in the test section of an explosively driven conical shock tube [J]. Shock Waves, 2019, 29(2): 355–360. DOI: 10.1007/S00193-018-0811-7. [59] 郑监, 卢芳云, 陈荣. 柱形装药条件下锥形水中爆炸激波管内的冲击波特性 [J]. 爆炸与冲击, 2021, 41(10): 103201. DOI: 10.11883/bzycj-2020-0316.ZHENG J, LU F Y, CHEN R. Shock wave characteristics in a conical water explosion shock tube under cylindrical charge condition [J]. Explosion and Shock Waves, 2021, 41(10): 103201. DOI: 10.11883/bzycj-2020-0316. [60] 张军, 黄含军, 王军评, 等. 炸药驱动式爆炸管的载荷计算 [J]. 装备环境工程, 2021, 18(5): 21–27. DOI: 10.7643/issn.1672-9242.2021.05.004.ZHANG J, HUANG H J, WANG J P, et al. Simulation on the blast load inside the explosively drived shock tube [J]. Equipment Environmental Engineering, 2021, 18(5): 21–27. DOI: 10.7643/issn.1672-9242.2021.05.004. [61] GUO Q P, YANG S J, WANG Y C, et al. Prediction research for blasting peak particle velocity based on random GA-BP network group [J]. Arabian Journal of Geosciences, 2022, 15(15): 1351. DOI: 10.1007/s12517-022-10615-3. [62] 陈梓薇, 王仲琦, 曾令辉. 基于BP神经网络的爆炸用激波管峰值压力预测方法 [J]. 爆炸与冲击, 2024, 44(5): 054101. DOI: 10.11883/bzycj-2023-0187.CHEN Z W, WANG Z Q, ZENG L H. A method for predicting peak pressure in an explosion shock tube based on BP neural network [J]. Explosion and Shock Waves, 2024, 44(5): 054101. DOI: 10.11883/bzycj-2023-0187. [63] KANG Y, WANG J L, ZHANG S Z, et al. A review of the development of shock tubes for simulating blast waves [C]//2023 IEEE 16th International Conference on Electronic Measurement & Instruments (ICEMI). Harbin: IEEE, 2023: 416–425. DOI: 10.1109/ICEMI59194.2023.10269910. [64] SKOTAK M, ALAY E, CHANDRA N. On the accurate determination of shock wave time-pressure profile in the experimental models of blast-induced neurotrauma [J]. Frontiers in Neurology, 2018, 9: 52. DOI: 10.3389/fneur.2018.00052. [65] UY B, REMENNIKOV A, RITZEL D, et al. Development of the Australian National facility for physical blast simulation [C]//12th International Conference on Shock & Impact Loads on Structures. Singapore, 2017: 15–16. [66] LLOYD A, JACQUES E, SAATCIOGLU M, et al. Capabilities of a shock tube to simulate blast loading on structures [J]. Special Publication, 2011, 281: 1–20. DOI: 10.14359/51683611. [67] LLOYD A, SAATCIOGLU M, PALERMO D. New shock tube testing facilities for simulated blast loading of structural and non-structural components [C]//2nd International Workshop on Performance, Protection & Strengthening of Structures Under Extreme Loading. Hayama, 2009. [68] CHANDRA N, GANPULE S, KLEINSCHMIT N N, et al. Evolution of blast wave profiles in simulated air blasts: experiment and computational modeling [J]. Shock Waves, 2012, 22(5): 403–415. DOI: 10.1007/s00193-012-0399-2. [69] LEBLANC J, GARDNER N, SHUKLA A. Effect of polyurea coatings on the response of curved E-glass/vinyl ester composite panels to underwater explosive loading [J]. Composites Part B: Engineering, 2013, 44(1): 565–574. DOI: 10.1016/j.compositesb.2012.02.038. [70] LEBLANC J, SHUKLA A. The effects of polyurea coatings on the underwater explosive response of composite plates [M]//GOPALAKRISHNAN S, RAJAPAKSE Y. Blast Mitigation Strategies in Marine Composite and Sandwich Structures. Singapore: Springer, 2018: 53–72. DOI: 10.1007/978-981-10-7170-6_3. [71] LEBLANCD J M. Response of composite materials to dynamic and low temperature environments [D]. Rhode Island: University of Rhode Island, 2019: 52–58. DOI: 10.23860/thesis-leblanc-james-2019. [72] LEBLANC J, GAUCH E, JAVIER C, et al. The response of composite materials subjected to underwater explosive loading: experimental and computational studies [M]//LEE S W. Advances in Thick Section Composite and Sandwich Structures: an Anthology of ONR-Sponsored Research. Cham: Springer, 2020: 43–83. DOI: 10.1007/978-3-030-31065-3_2. [73] CHENNAMSETTY A R K, LEBLANC J, ABOTULA S, et al. Dynamic response of Hastelloy® X plates under oblique shocks: Experimental and numerical studies [J]. International Journal of Impact Engineering, 2015, 85: 97–109. DOI: 10.1016/j.ijimpeng.2015.06.016. [74] AUNE V, FAGERHOLT E, LANGSETH M, et al. A shock tube facility to generate blast loading on structures [J]. International Journal of Protective Structures, 2016, 7(3): 340–366. DOI: 10.1177/2041419616666236. [75] AUNE V, VALSAMOS G, CASADEI F, et al. On the dynamic response of blast-loaded steel plates with and without pre-formed holes [J]. International Journal of Impact Engineering, 2017, 108: 27–46. DOI: 10.1016/j.ijimpeng.2017.04.001. [76] AUNE V, VALSAMOS G, CASADEI F, et al. Numerical study on the structural response of blast-loaded thin aluminium and steel plates [J]. International Journal of Impact Engineering, 2017, 99: 131–144. DOI: 10.1016/j.ijimpeng.2016.08.010. [77] AUNE V, VALSAMOS G, CASADEI F, et al. Fluid-structure interaction effects during the dynamic response of clamped thin steel plates exposed to blast loading [J]. International Journal of Mechanical Sciences, 2021, 195: 106263. DOI: 10.1016/j.ijmecsci.2020.106263. [78] STOLZ A, FISCHER K, ROLLER C, et al. Dynamic bearing capacity of ductile concrete plates under blast loading [J]. International Journal of Impact Engineering, 2014, 69: 25–38. DOI: 10.1016/j.ijimpeng.2014.02.008. [79] ELVELI B S, IDDBERG M B, BØRVIK T, et al. On the strength–ductility trade-off in thin blast-loaded steel plates with and without initial defects—An experimental study [J]. Thin-Walled Structures, 2022, 171: 108787. DOI: 10.1016/j.tws.2021.108787. [80] ELVELI B S, BERSTAD T, BØRVIK T, et al. Performance of thin blast-loaded steel plates after ballistic impact from small-arms projectiles [J]. International Journal of Impact Engineering, 2023, 173: 104437. DOI: 10.1016/j.ijimpeng.2022.104437. [81] LI Y, JIANG X W, TANG Y, et al. Investigation on the dynamic response of steel plates with a pre-formed hole loaded by underwater shock wave [J]. Thin-Walled Structures, 2025, 210: 112926. DOI: 10.1016/j.tws.2025.112926. [82] 王正国, 孙立英, 杨志焕, 等. 系列生物激波管的研制与应用 [J]. 爆炸与冲击, 1993, 13(1): 77–83. DOI: 10.11883/1001-1455(1993)01-0077-7.WANG Z G, SUN L Y, YANG Z H, et al. The design production and application of a series of bio-shock tubes [J]. Explosion and Shock Waves, 1993, 13(1): 77–83. DOI: 10.11883/1001-1455(1993)01-0077-7. [83] 王峰, 杨志焕, 朱佩芳, 等. 高原冲击伤伤情特点的实验研究 [J]. 创伤外科杂志, 2008, 10(6): 549–551. DOI: 10.3969/j.issn.1009-4237.2008.06.026.WANG F, YANG Z H, ZHU P F, et al. Experimental study on characteristics of blast injury at high altitude [J]. Journal of Traumatic Surgery, 2008, 10(6): 549–551. DOI: 10.3969/j.issn.1009-4237.2008.06.026. [84] 袁丹凤, 杨傲, 麻超, 等. 冲击波强度与幼年大鼠肺冲击伤程度的量效关系 [J]. 中国医学物理学杂志, 2021, 38(6): 780–784. DOI: 10.3969/j.issn.1005-202X.2021.06.022.YUAN D F, YANG A, MA C, et al. Dose-effect relationship between shock wave intensity and blast lung injury in juvenile rats [J]. Chinese Journal of Medical Physics, 2021, 38(6): 780–784. DOI: 10.3969/j.issn.1005-202X.2021.06.022. [85] JIANG S S, CAI W, XIE J, et al. Realization of a shock-tube facility to study the Richtmyer–Meshkov instability driven by a strong shock wave [J]. Review of Scientific Instruments, 2024, 95(8): 085114. DOI: 10.1063/5.0217768. [86] BURRELL R P, AOUDE H, SAATCIOGLU M. Response of SFRC columns under blast loads [J]. Journal of Structural Engineering, 2015, 141(9): 04014209. DOI: 10.1061/(ASCE)ST.1943-541X.0001186. [87] STOLZ A, MILLON O, KLOMFASS A. Analysis of the resistance of structural components to explosive loading by shock-tube tests and SDOF models [J]. Chemical Engineering Transactions, 2016, 48: 151–156. DOI: 10.3303/CET1648026. [88] GAN E C J, REMENNIKOV A, RITZEL D, et al. Approximating a far-field blast environment in an advanced blast simulator for explosion resistance testing [J]. International Journal of Protective Structures, 2020, 11(4): 468–493. DOI: 10.1177/2041419620911133. [89] GAN E C J. Experimental and numerical investigation of shock wave propagation in an advanced blast simulator [D]. New South Wales: University of Wollongong, 2021: 89-179. [90] GAN E C J, REMENNIKOV A, RITZEL D. Blast waveform tailoring using controlled venting in blast simulators and shock tubes [J]. Defence Technology, 2024, 37: 14–26. DOI: 10.1016/j.dt.2023.11.026. [91] 程帅, 童念雪, 刘文祥, 等. 基于高压气体驱动的爆炸波模拟激波管冲击波衰减历程控制方法 [J]. 爆炸与冲击, 2024, 44(5): 052201. DOI: 10.11883/bzycj-2023-0094.CHENG S, TONG N X, LIU W X, et al. A control method for attenuation history of shock wave generated by blast simulation shock tube based on high pressure gas driving technic [J]. Explosion and Shock Waves, 2024, 44(5): 052201. DOI: 10.11883/bzycj-2023-0094. [92] BALAN G S, RAJ S A. A review on shock tubes with multitudinous applications [J]. International Journal of Impact Engineering, 2023, 172: 104406. DOI: 10.1016/j.ijimpeng.2022.104406. [93] ANDREOTTI R, COLOMBO M, GUARDONE A, et al. Performance of a shock tube facility for impact response of structures [J]. International Journal of Non-Linear Mechanics, 2015, 72: 53–66. DOI: 10.1016/j.ijnonlinmec.2015.02.010. [94] HOUAS L, BIAMINO L, MARIANI C, et al. The effects that changes in the diaphragm aperture have on the resulting shock tube flow [J]. Shock Waves, 2012, 22(4): 287–293. DOI: 10.1007/s00193-012-0372-0. [95] KIM I, PARK G. Experimental study of oxygen catalytic recombination on a smooth surface in a shock tube [J]. Applied Thermal Engineering, 2019, 156: 678–691. DOI: 10.1016/j.applthermaleng.2019.04.054. [96] KIM I, YANG Y, PARK G. Effect of titanium surface roughness on oxygen catalytic recombination in a shock tube [J]. Acta Astronautica, 2020, 166: 260–269. DOI: 10.1016/j.actaastro.2019.10.030. [97] HEITZER J. Dynamic interaction of a plate and an impactor [J]. Computers & Structures, 1996, 60(5): 837–848. DOI: 10.1016/0045-7949(95)00445-9. [98] KRAUTHAMMER T. Modern protective structures [M]. Boca Raton: CRC Press, 2008: 24–103. DOI: 10.1201/9781420015423. [99] JONES N. Structural impact [M]. Cambridge: Cambridge University Press, 2012: 377–424. DOI: 10.1017/CBO9780511820625. [100] 孙桂娟, 高伟亮, 刘瑞朝, 等. 爆炸近区荷载模拟试验技术研究进展 [J]. 防护工程, 2019, 41(4): 66–73.SUN G J, GAO W L, LIU R Z, et al. Research progress of simulation test technology of load in near-field of explosion [J]. Protective Engineering, 2019, 41(4): 66–73. [101] XIAN W, CHEN W S, HAO H, et al. Experimental and numerical studies on square steel-reinforced concrete-filled steel tubular (SRCFST) members subjected to lateral impact [J]. Thin-Walled Structures, 2021, 160: 107409. DOI: 10.1016/j.tws.2020.107409. [102] 王宇, 严鹏志, 范鹏贤. 岩土中爆炸冲击荷载的落锤模拟试验研究 [J]. 陆军工程大学学报, 2023, 2(6): 60–67. DOI: 10.12018/j.issn.2097-0730.20230525001.WANG Y, YAN P Z, FAN P X. Physical simulation of explosion impact load in geomaterials by drop hammers [J]. Journal of Army Engineering University of PLA, 2023, 2(6): 60–67. DOI: 10.12018/j.issn.2097-0730.20230525001. [103] 李腾飞, 钟冬望, 何理, 等. 基于落锤-弹簧碰撞系统的燃气爆炸载荷模拟加载方法研究 [J]. 力学与实践, 2024, 46(4): 796–802. DOI: 10.6052/1000-0879-23-461.LI T F, ZHONG D W, HE L, et al. Research on gas explosion load simulation loading method based on drop weight-spring collision system [J]. Mechanics in Engineering, 2024, 46(4): 796–802. DOI: 10.6052/1000-0879-23-461. [104] 程帅, 陈博, 刘文祥, 等. 基于落锤实验平台的爆炸载荷模拟装置原理性设计 [J]. 现代应用物理, 2016, 7(4): 041002. DOI: 10.3969/j.issn.2095-6223.2016.04.010.CHENG S, CHEN B, LIU W X, et al. Theoretical design of an explosive loading analogue device based on drop hammer test system [J]. Modern Applied Physics, 2016, 7(4): 041002. DOI: 10.3969/j.issn.2095-6223.2016.04.010. [105] 任佳, 刘小川, 杨建波, 等. 防雷座椅台架试验冲击波形模拟技术 [J]. 科学技术与工程, 2020, 20(33): 13673–13679. DOI: 10.3969/j.issn.1671-1815.2020.33.023.REN J, LIU X C, YANG J B, et al. Waveform simulation technology for drop test of the mine protected seat [J]. Science Technology and Engineering, 2020, 20(33): 13673–13679. DOI: 10.3969/j.issn.1671-1815.2020.33.023. [106] BOSCH K, HARRIS K, CLARK D, et al. Blast mitigation seat analysis-drop tower data review: SAE Technical Paper 2024-01-3496 [R]. Warren, Michigan, USA: SAE, 2014: 2. DOI: 10.4271/2024-01-3496. [107] CHENG M, DIONNE J P, MAKRIS A. On drop-tower test methodology for blast mitigation seat evaluation [J]. International Journal of Impact Engineering, 2010, 37(12): 1180–1187. DOI: 10.1016/j.ijimpeng.2010.08.002. [108] 傅耀宇, 牛善田, 闫际宇, 等. 模拟爆炸冲击载荷的防雷座椅跌落试验研究 [J]. 兵器装备工程学报, 2023, 44(6): 154–160. DOI: 10.11809/bqzbgcxb2023.06.021.FU Y Y, NIU S T, YAN J Y, et al. Drop tests of lightning protection seats in simulation of explosion impact load [J]. Journal of Ordnance Equipment Engineering, 2023, 44(6): 154–160. DOI: 10.11809/bqzbgcxb2023.06.021. [109] WOLFSONO J C. Blast damage mitigation of steel structures from near- contact charges [D]. San Diego: University of California, 2008: 30–75. [110] OESTERLE M G. Blast simulator wall tests: experimental methods and mitigation strategies for reinforced concrete and concrete masonry [D]. San Diego: University of California, 2009: 78–151. [111] STEWART L K. Experimental and computational methods for steel columns subjected to blast loading [J]. WIT Transactions on The Built Environment, 2012, 126: 157–168. DOI: 10.2495/SU120141. [112] STEWART L K, FREIDENBERG A, RODRIGUEZ-NIKL T, et al. Methodology and validation for blast and shock testing of structures using high-speed hydraulic actuators [J]. Engineering Structures, 2014, 70: 168–180. DOI: 10.1016/j.engstruct.2014.03.027. [113] STEWART L K. Computational modeling of steel columns subjected to experimentally simulated blasts [J]. International Journal of Computational Methods and Experimental Measurements, 2014, 2(3): 225–242. DOI: 10.2495/CMEM-V2-N3-235-242. [114] FREIDENBERG A, LEE C W, DURANT B, et al. Characterization of the Blast Simulator elastomer material using a pseudo-elastic rubber model [J]. International Journal of Impact Engineering, 2013, 60: 58–66. DOI: 10.1016/j.ijimpeng.2013.04.009. [115] FREIDENBERG A, AVIRAM A, STEWART L K, et al. Demonstration of tailored impact to achieve blast-like loading [J]. International Journal of Impact Engineering, 2014, 71: 97–105. DOI: 10.1016/j.ijimpeng.2014.04.006. [116] PERONI M, SOLOMOS G, CAVERZAN A, et al. Blast simulator project: first tests on reinforced concrete beams [R]. Luxembourg: Publications Office of the European Union, 2015. DOI: 10.2788/598353. [117] XIONG Z X, WANG W, YU G C, et al. Experimental and numerical study of non-explosive simulated blast loading on reinforced concrete slabs [J]. Materials, 2023, 16(12): 4410. DOI: 10.3390/ma16124410. [118] 姚术健, 王延靖, 陈奕恺, 等. 基于二氧化碳相变的模拟爆炸加载试验系统及方法: CN202411061136.3 [P]. 2024-10-22.YAO S J, WANG Y J, CHEN Y K, et al. Simulated explosion loading test system and method based on carbon dioxide phase change: CN202411061136.3 [P]. 2024-10-22. -

下载:

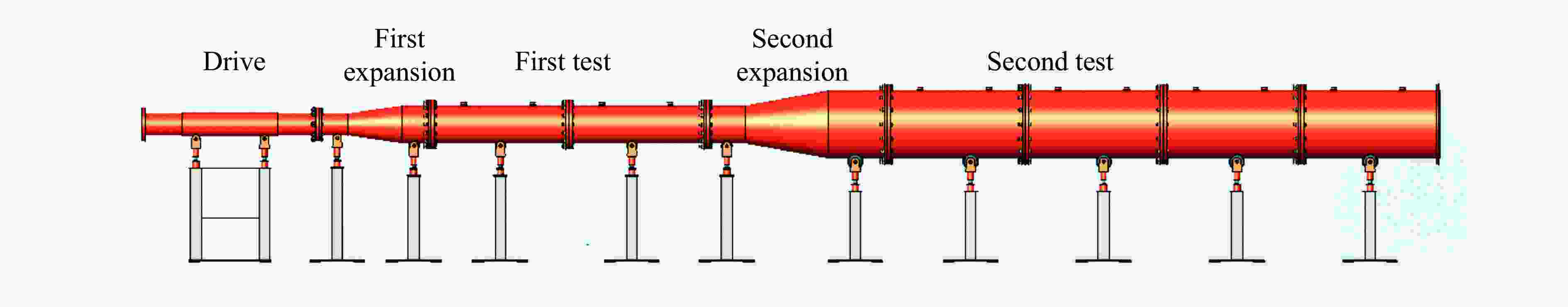

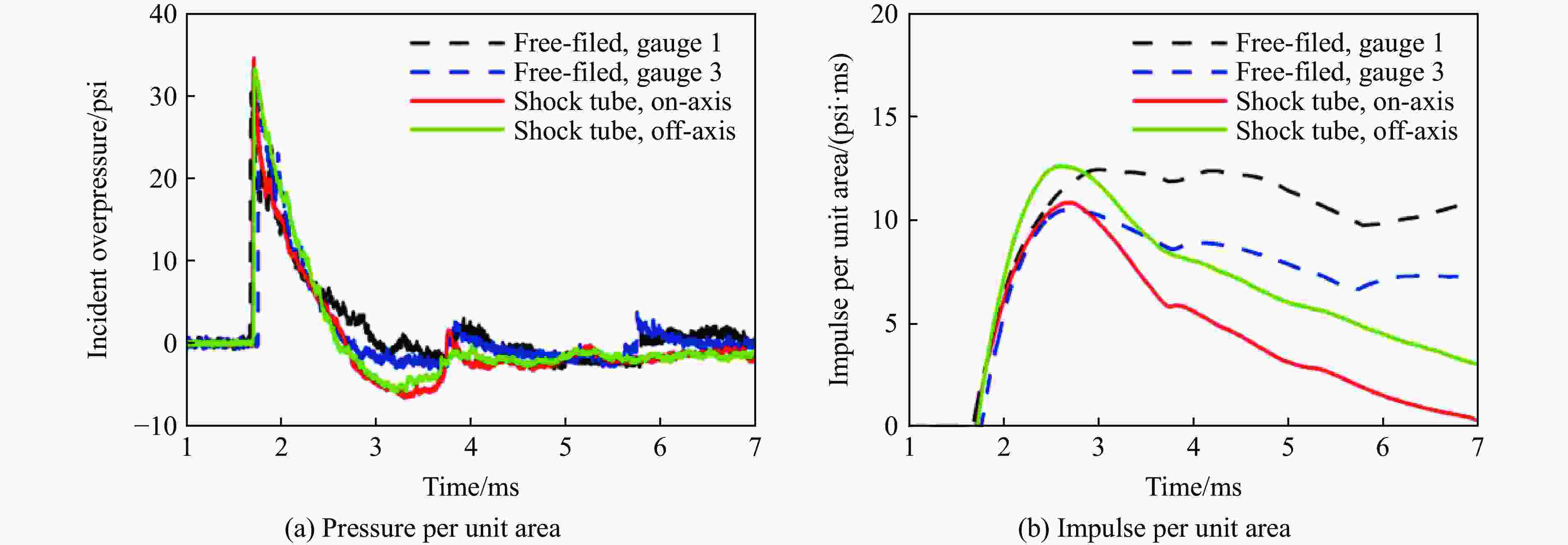

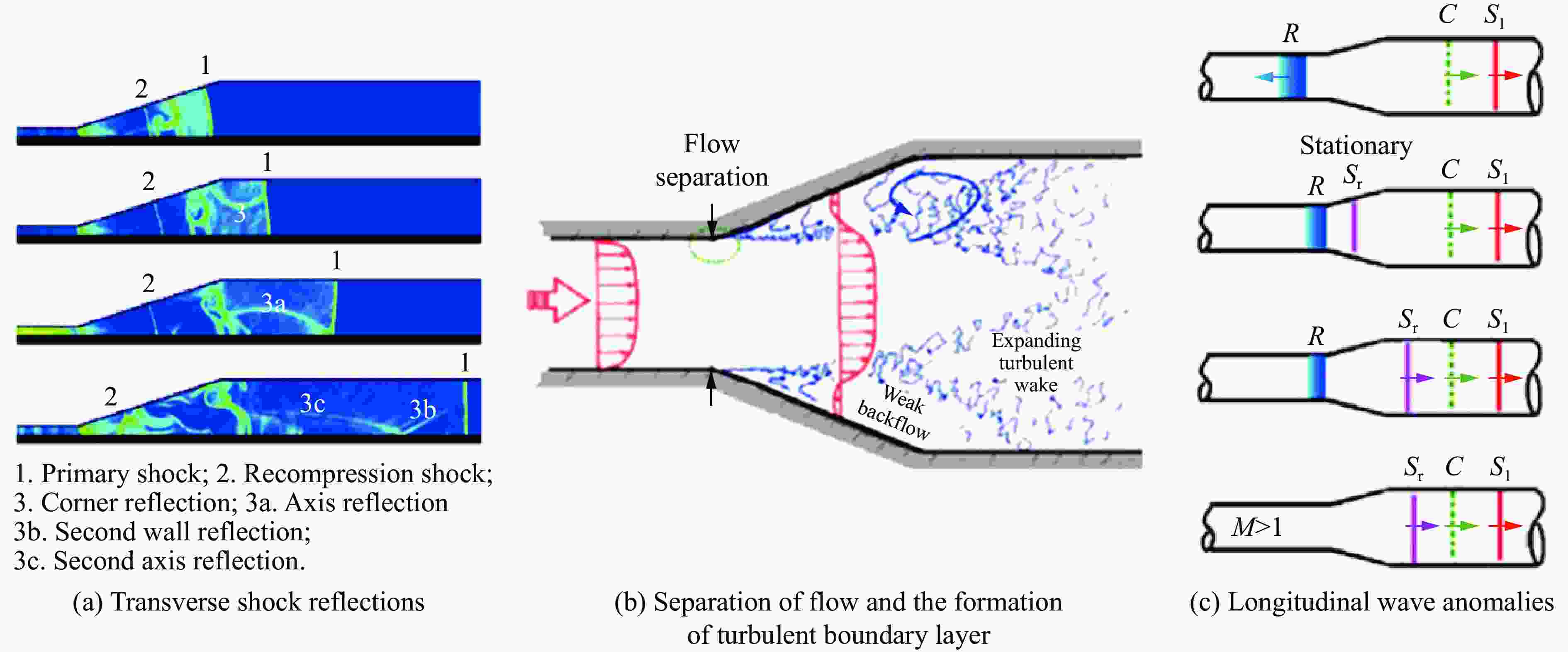

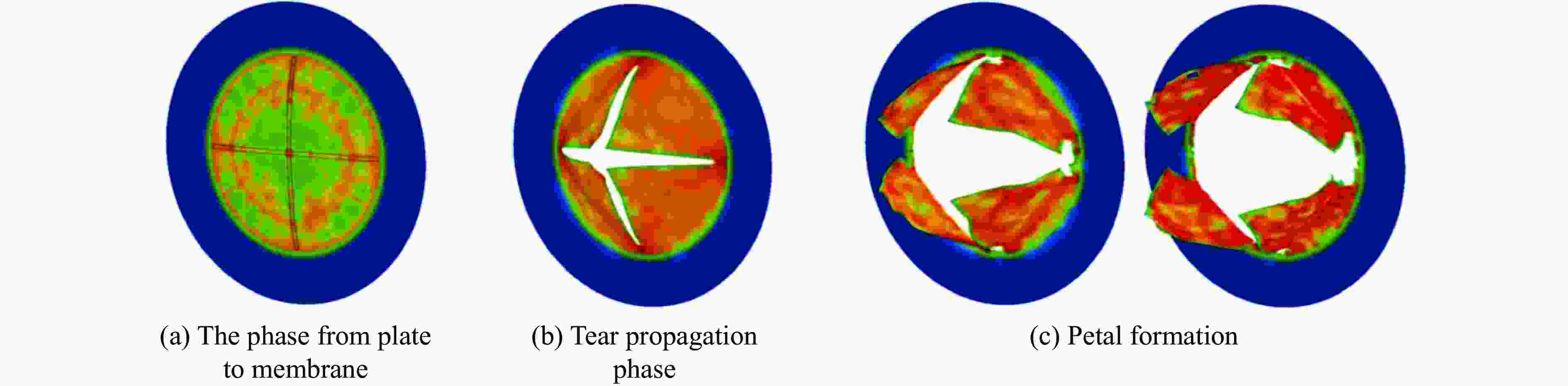

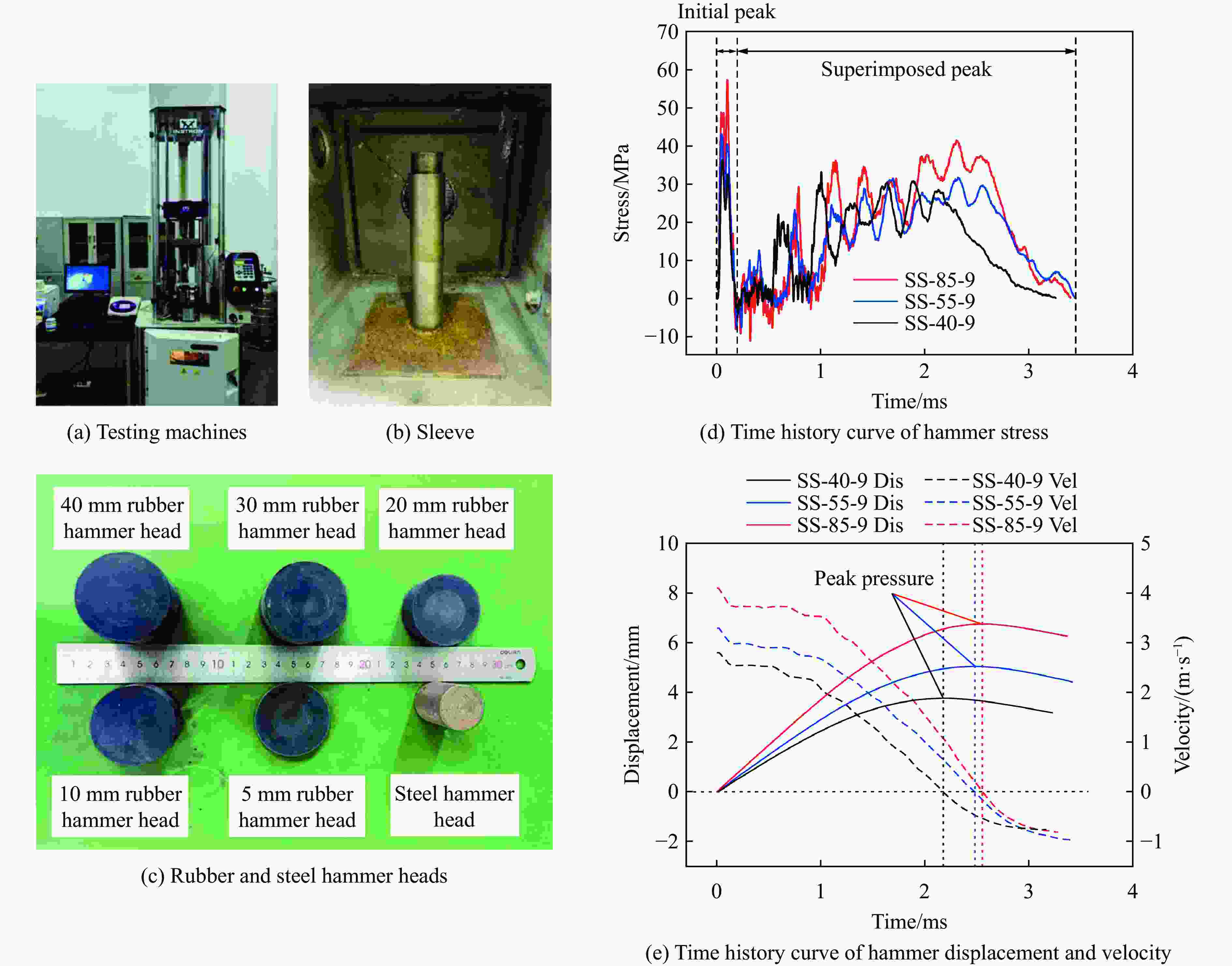

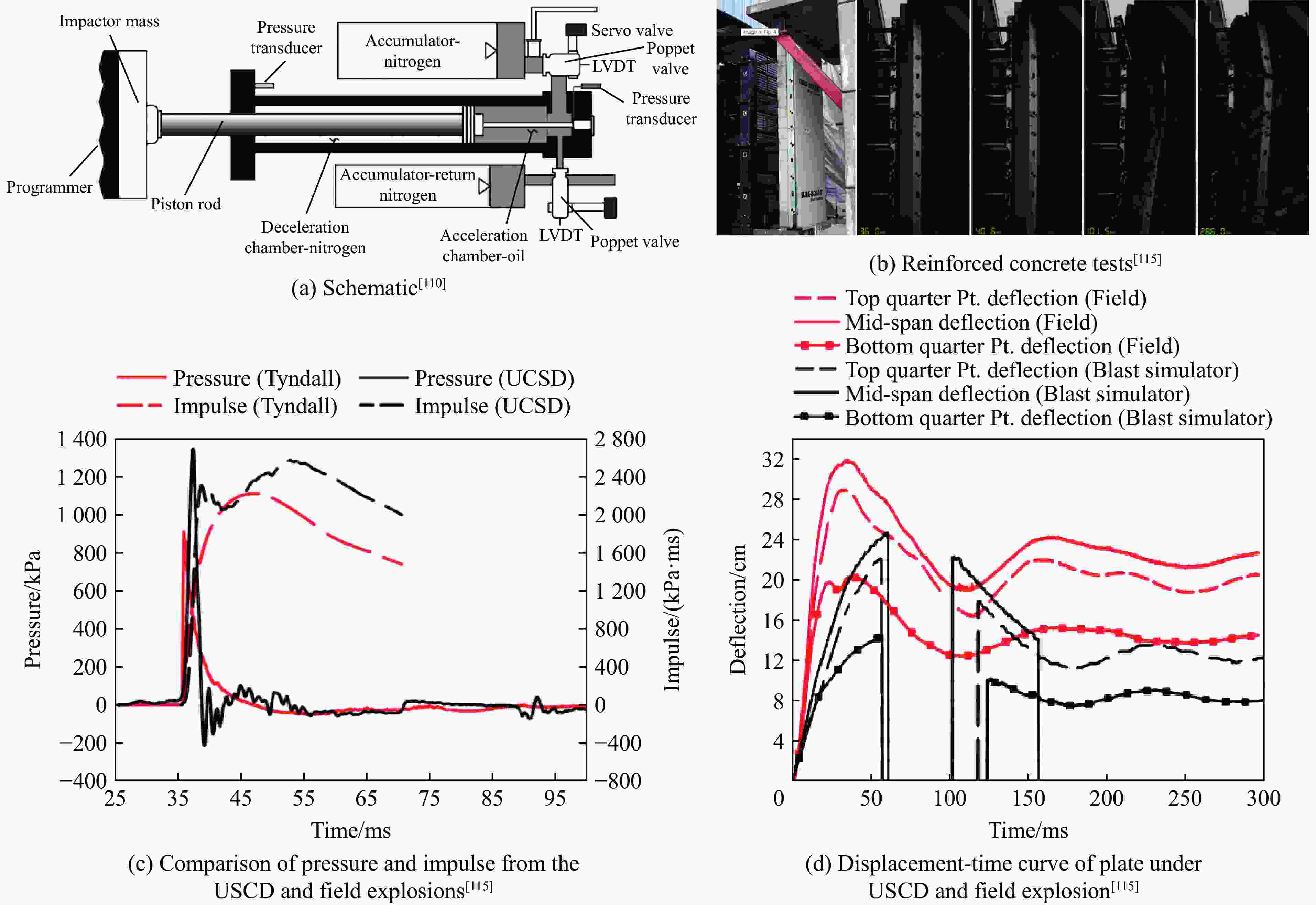

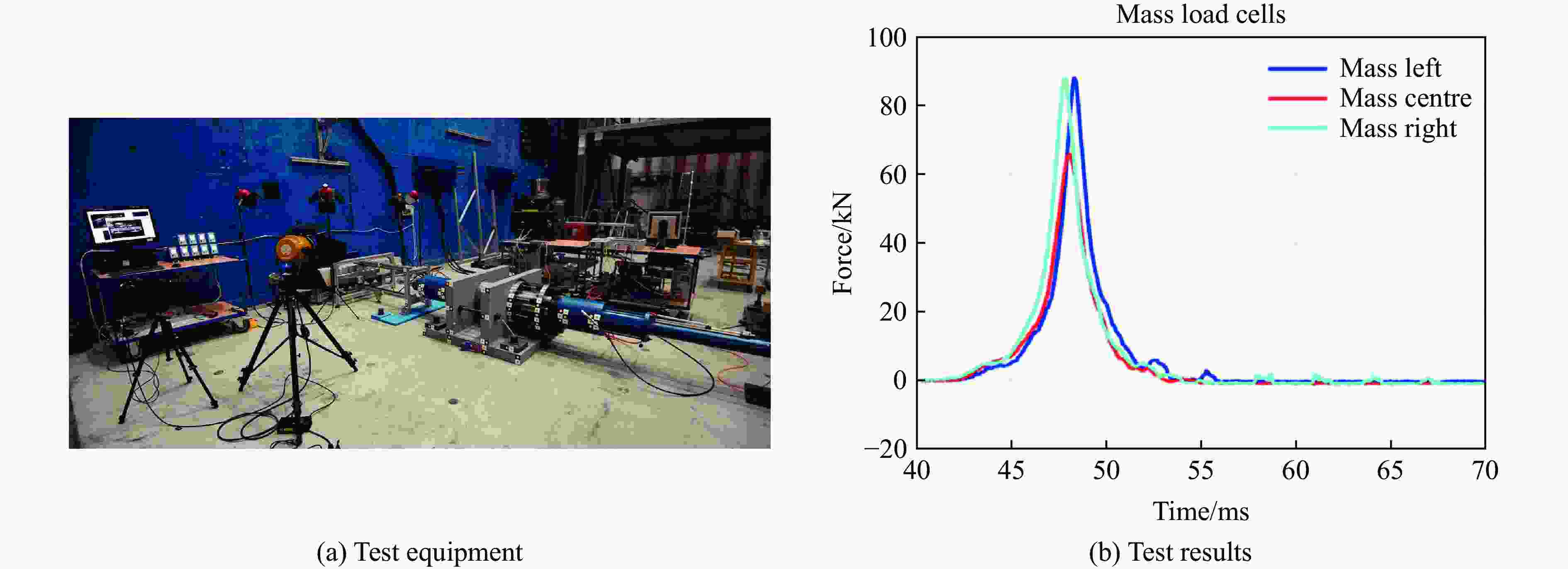

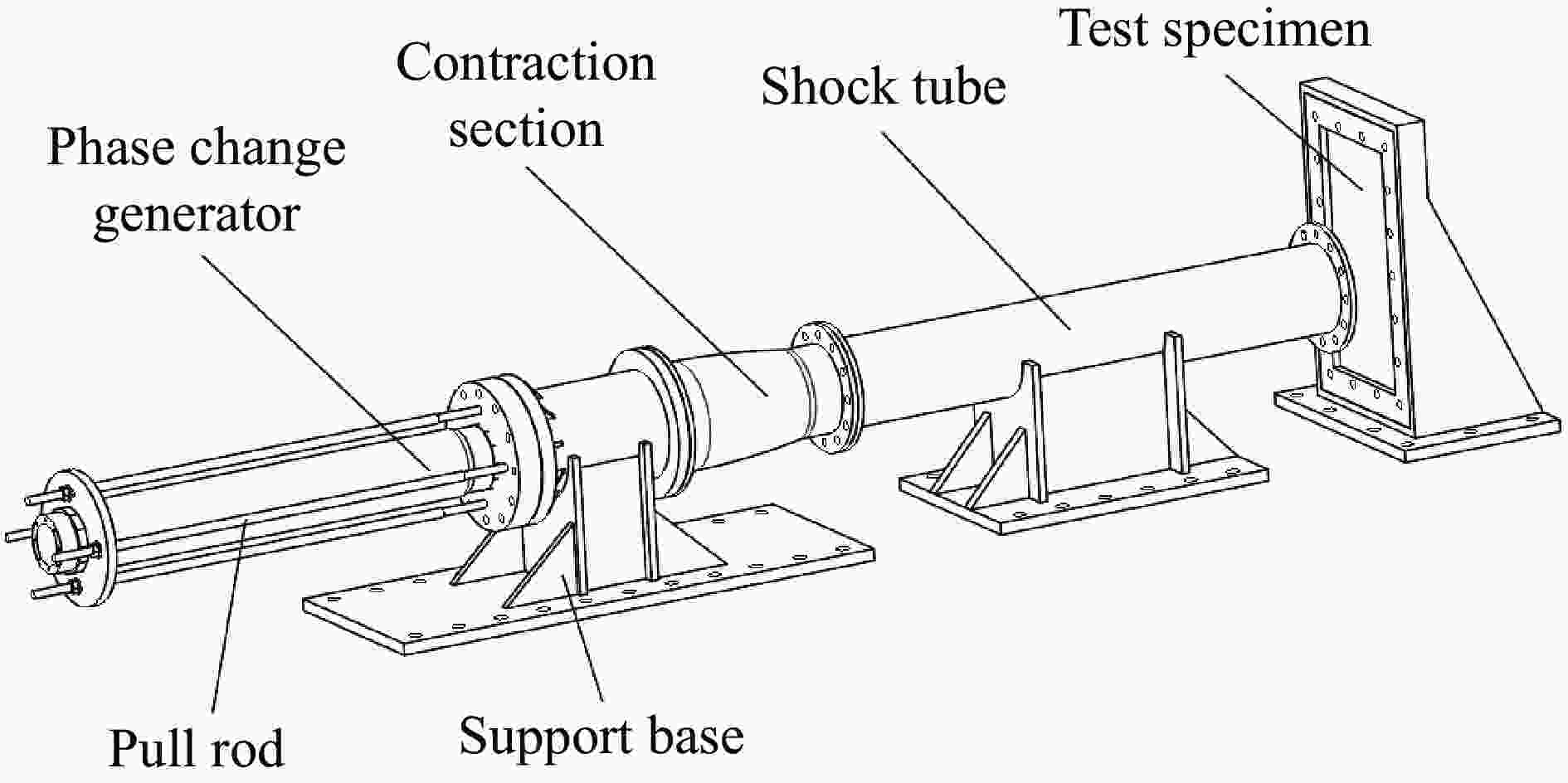

下载: